Technology for manufacturing in-mold label with raised touch feeling

A technology of in-mold labeling and manufacturing process, which is applied to instruments, identification devices, seals, etc., and can solve problems such as the inability to achieve three-dimensional raised effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings:

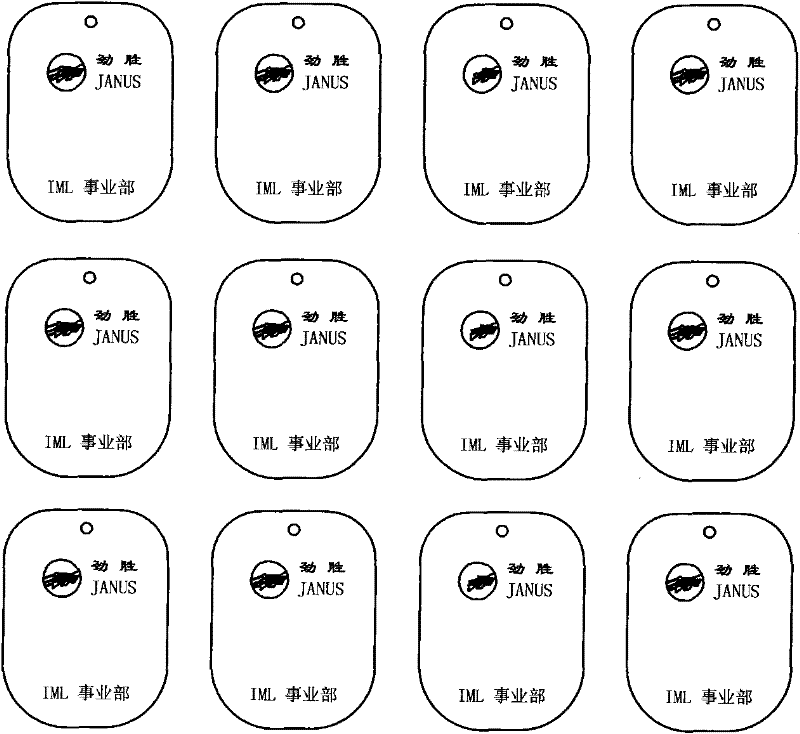

[0020] Such as figure 1 As shown, the full-page sheet consisting of three rows and four columns is printed with "image logo", "Jingsheng", English "JANUS", "IML" and "business department", and "image logo" is printed with mirror silver and blue "Jingsheng" and English "JANUS" are printed with UV oil, and other parts of the sheet are printed with pearlescent white, white ink, varnish, and adhesive.

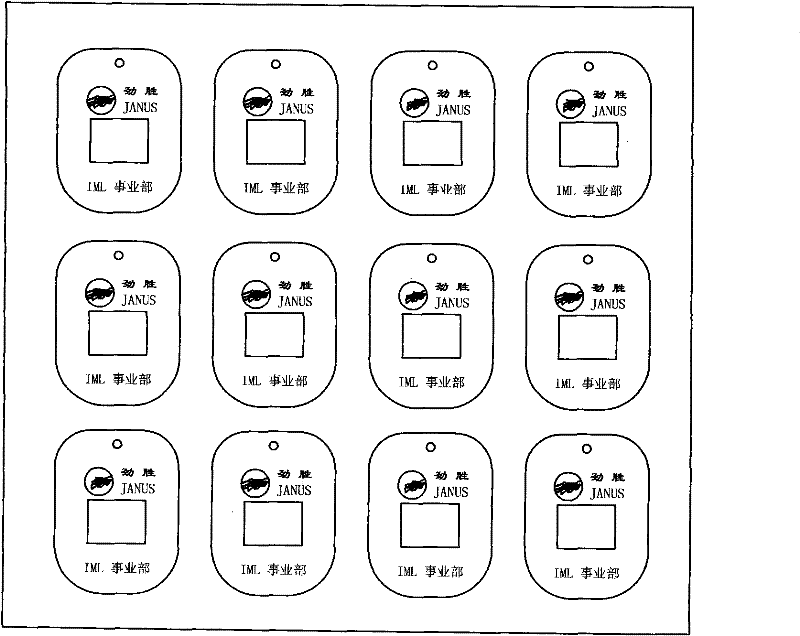

[0021] Such as figure 2 As shown, a protective film is attached to the printed full-page sheet.

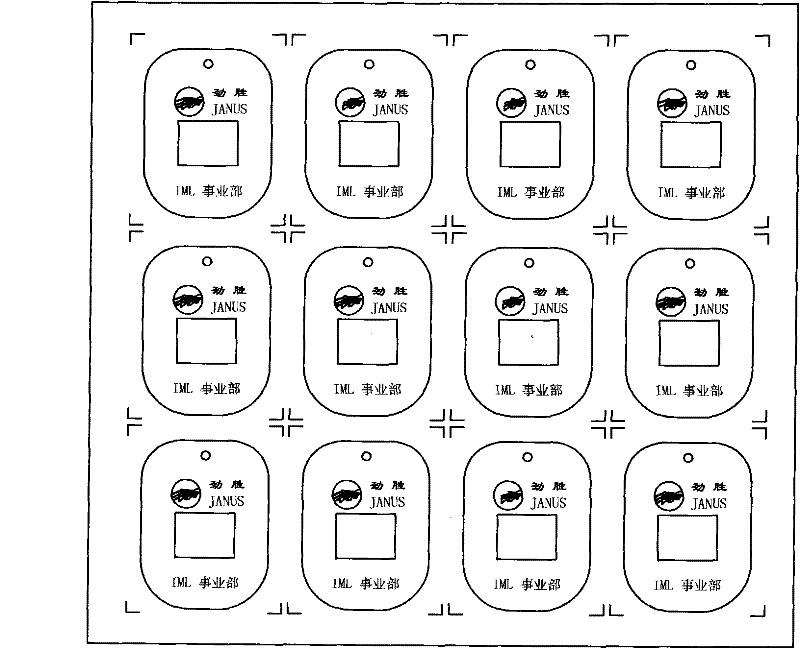

[0022] Such as image 3 As shown, positioning holes are punched on the full-page sheet with a protective film through a punching machine. Put the full-page sheet with fixed holes into the die, and punch out a single sheet.

[0023] The process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com