Driving device

A technology for driving devices and moving parts, applied in focusing devices, electromechanical devices, installation, etc., can solve problems such as the limitation of contact rod material selection, achieve the effect of avoiding alignment problems and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

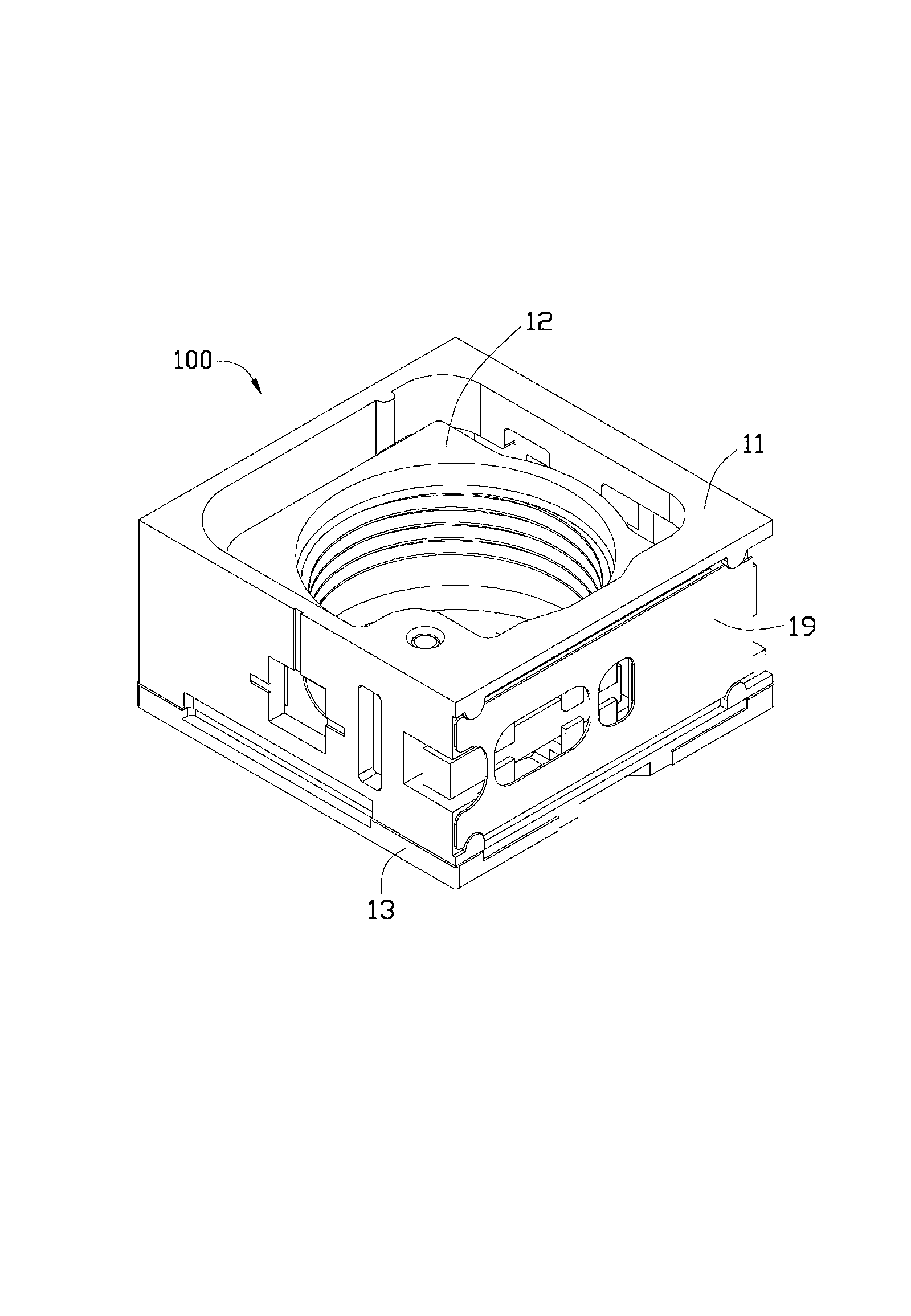

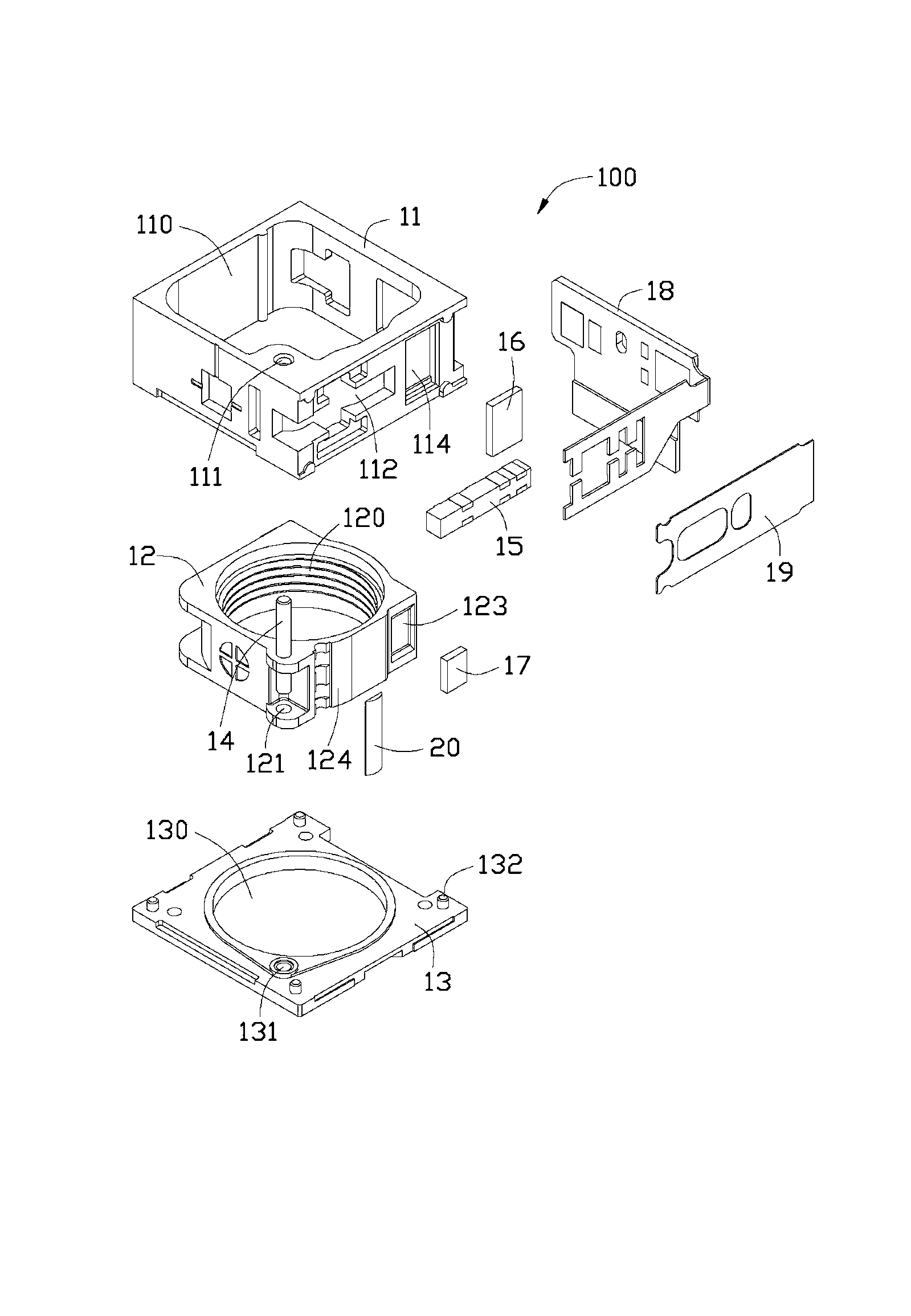

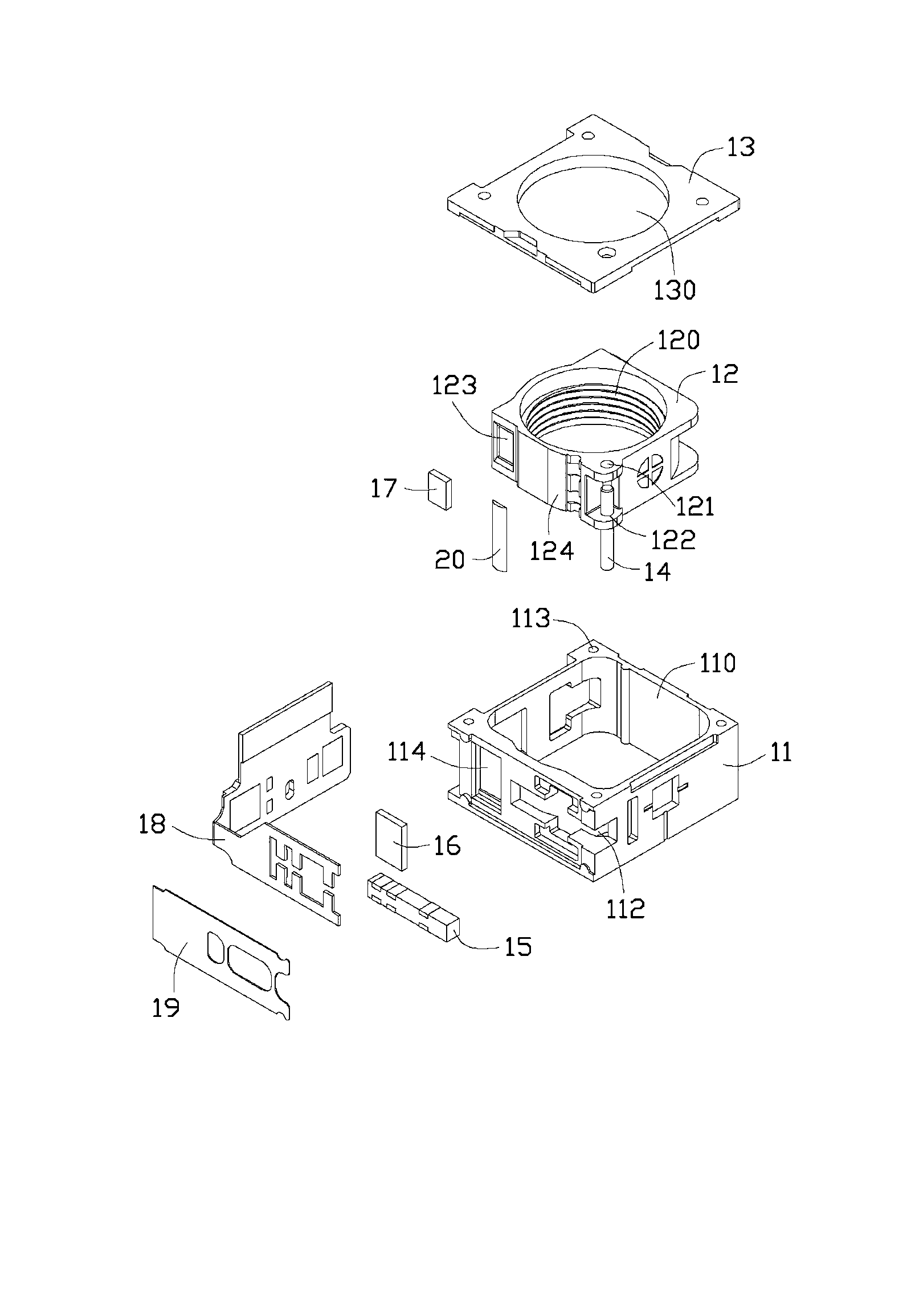

[0014] see figure 1 , figure 2 and image 3 As shown, the driving device 100 provided by the embodiment of the present invention is used to drive the movement of the lens module (not shown) to realize the focusing operation. A piezoelectric unit 15 , a magnet 16 , a magnetic sheet 17 , a circuit board 18 , a holder 19 and a contact rod 20 .

[0015] The circuit board 18 is used to provide electrical energy to the piezoelectric unit 15 to make it work. When the circuit board 18 provides voltage to the piezoelectric unit 15, the piezoelectric unit 15 has mechanical deformation, and voltages in different directions have mechanical deformations in different directions, and different Different magnitudes of voltage have different magnitudes of mechanical deformation. The circuit board 18 may be a general printed circuit board or a flexible circuit board (FPCB).

[0016] The fixing frame 11 has a square structure with a first receiving space 110 for receiving the movable elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com