Imaging interference photo etching method and system by rotating a mask and a resist silicon slice

A technology of imaging interference and resist, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, electrical components, etc., can solve the problems affecting the quality and fidelity of graphics, the difficulty of optical path and graphics alignment, and the reduction of exposure efficiency and other problems, to achieve the effect of improving laser utilization, shortening exposure time, and improving exposure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

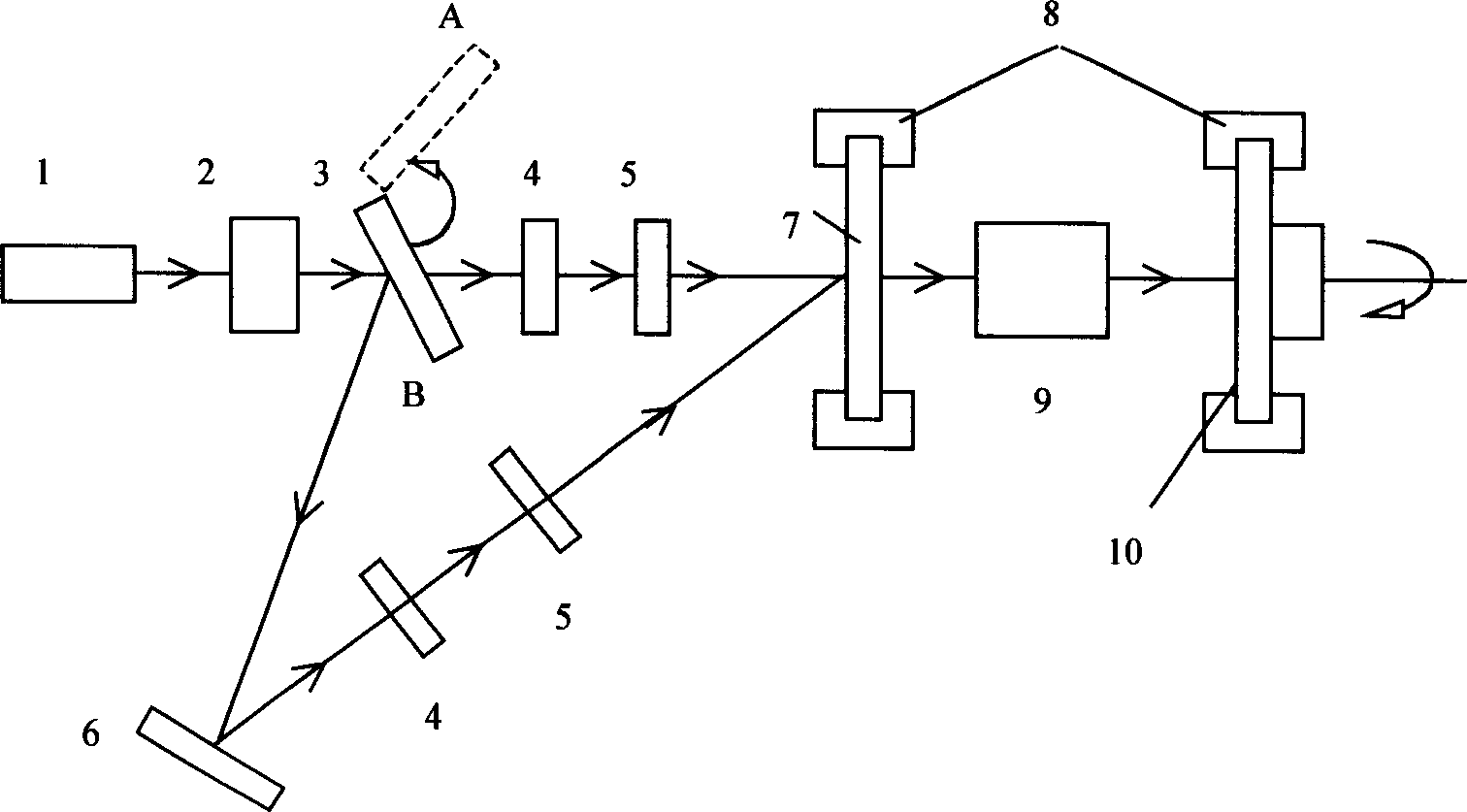

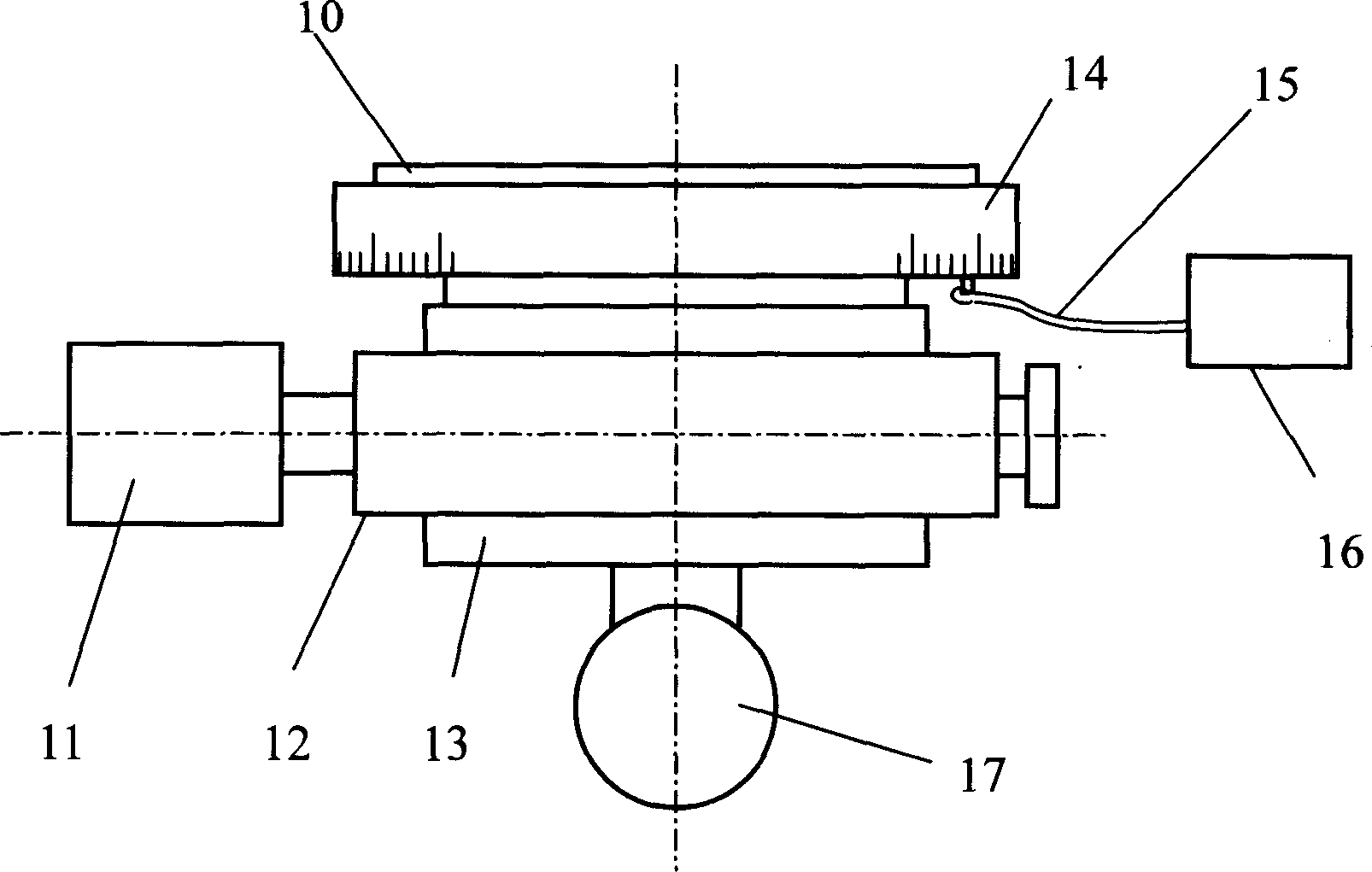

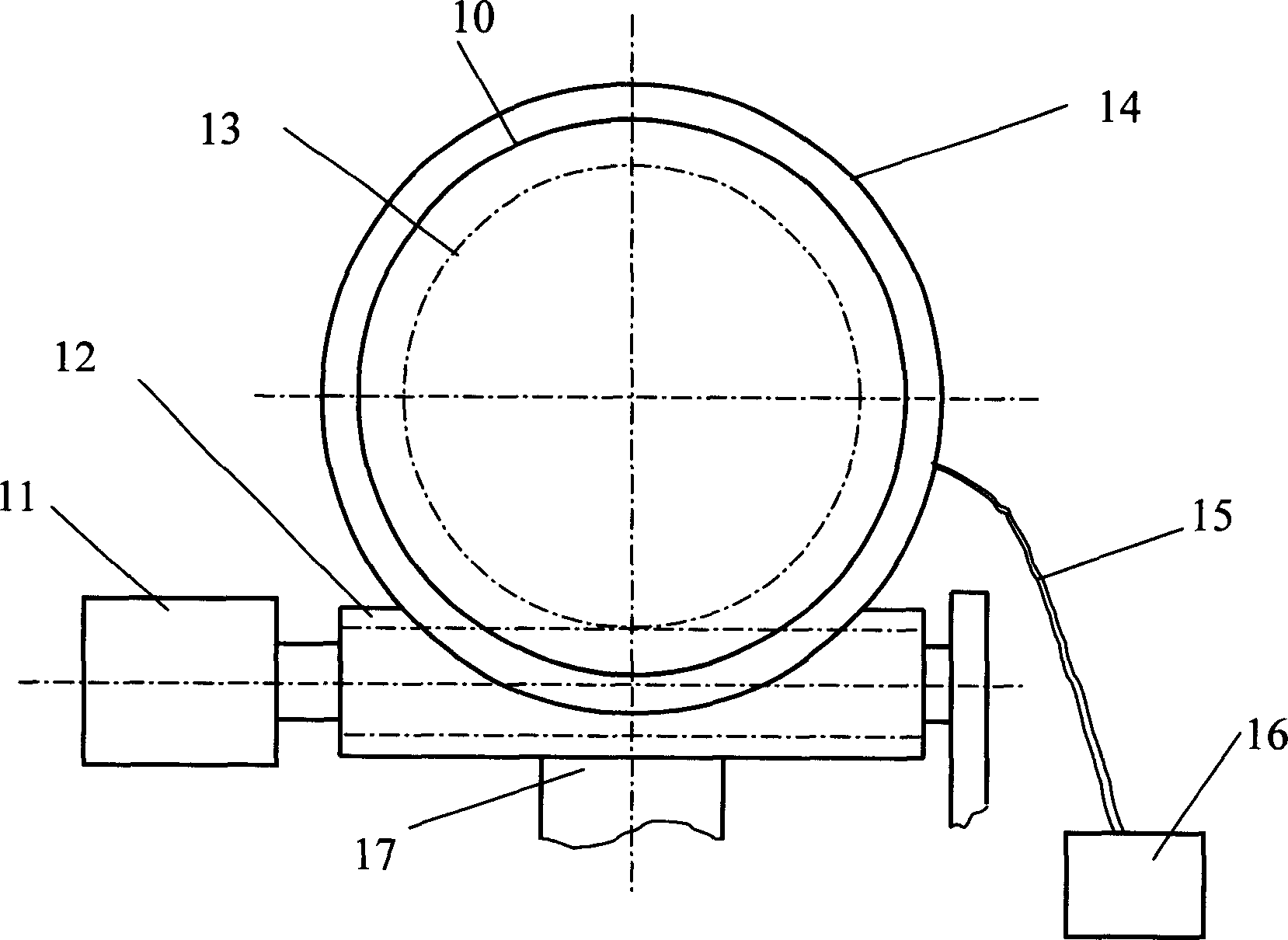

[0019] Such as figure 1 As shown, the embodiment system of the imaging interference lithography method of rotating mask and resist silicon wafer of the present invention includes a laser 1, a beam expander collimator 2, a rotatable total reflection mirror 3, a timing shutter 4, a variable density Neutral filter 5, total reflection mirror 6, mask 7, synchronous rotating mechanism 8, imaging optical system 9 and resist silicon wafer 10. When the rotatable total reflection mirror 3 is placed at the A position, the laser beam emitted by the laser 1 is expanded into a parallel beam through the beam expander collimator 2, and the parallel beam passes through the timing shutter 4 and the variable density neutral filter 5 perpendicularly The mask 7 is illuminated, and the imaging optical system 9 images the mask 7 on the resist silicon wafer 10 to expose the resist for the first time. Afterwards, the rotatable total reflection mirror 3 is transferred to the B position. At this time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com