A substrate edge protection device, lithography equipment and protection method

An edge protection and lithography equipment technology, applied in the field of substrate edge protection devices, can solve the problems of reduced reliability of silicon wafers, reduced production efficiency, reduced adsorption reliability, etc., and achieves improved exposure quality and yield, improved production efficiency, and improved adsorption Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

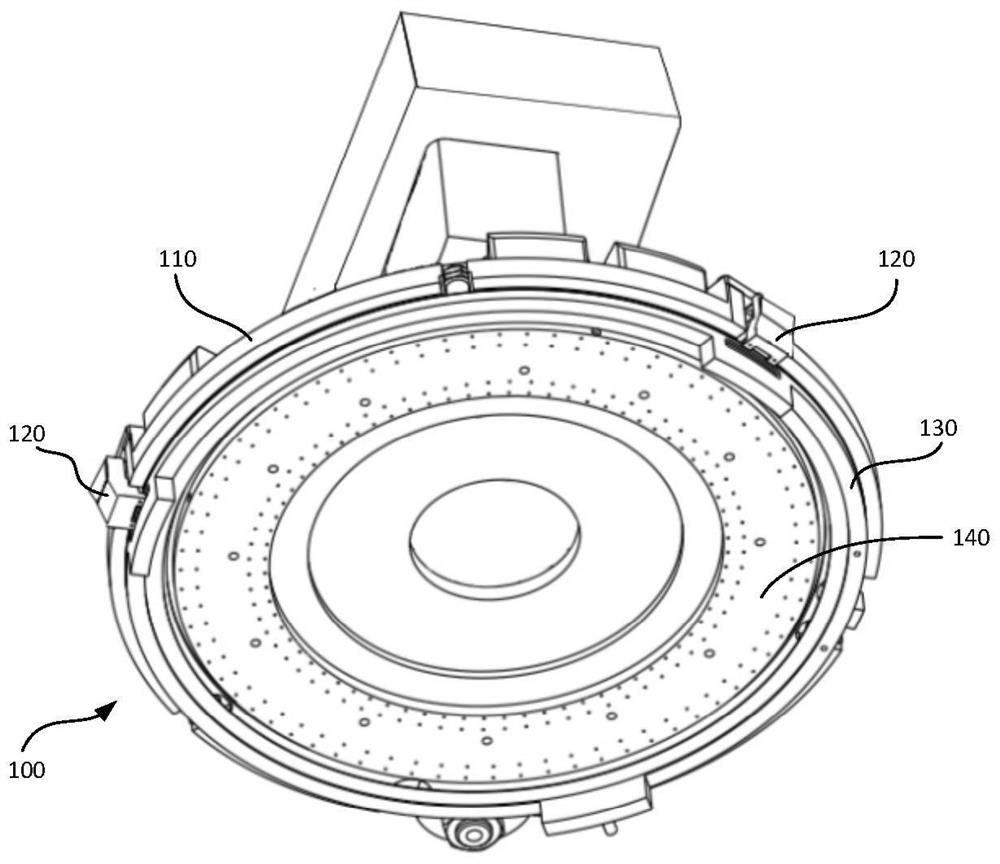

[0050] Embodiment 1 of the present invention provides a substrate edge protection device, figure 1 is a perspective view of the base edge protection device provided by Embodiment 1 of the present invention, figure 2 It is a structural schematic diagram of the warpage processing mechanism in the substrate edge protection device provided in Embodiment 1 of the present invention. Such as figure 1 As shown, the base edge protection device 100 includes a base 110, a grasping part 120 arranged on the working side edge of the base 110, and the grasping part 120 is used to grasp and place the base edge protection ring 130;

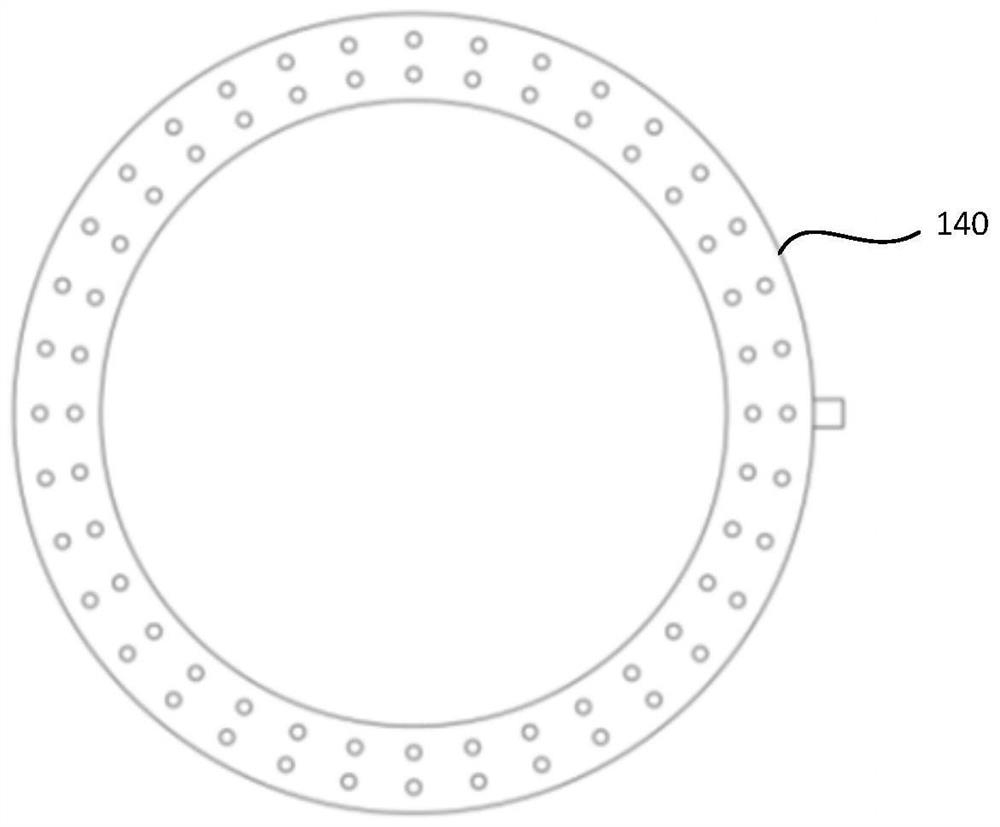

[0051] The warpage processing mechanism 140 arranged on the working side of the base 110, such as figure 2 As shown, the warpage processing mechanism 140 includes a plurality of air blowing holes formed on the working surface, and an air inlet communicating with the air blowing holes, and the warpage processing mechanism 140 is used to blow air through the air...

Embodiment 2

[0061] Embodiment 2 of the present invention provides a lithography equipment, which includes the substrate edge protection device 100 described in Embodiment 1, such as figure 1 As shown, the base edge protection device 100 includes a base 110, a grasping part 120 arranged on the edge of the working side of the base 110, the grasping part 120 is used to grasp and fix the base edge protection ring 130; Warp processing mechanism 140, warp processing mechanism 140 includes a plurality of blowing holes formed on the working surface, and an air inlet connected with the blowing holes, warping processing mechanism 140 is used to blow air through the blowing holes to level the substrate .

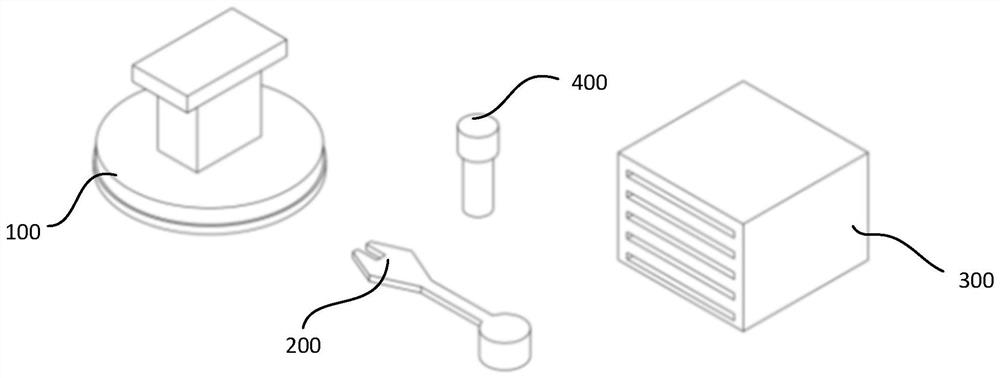

[0062] The lithography equipment also includes a workpiece table, the substrate edge protection device 100 is located directly above the workpiece table of the lithography equipment, and can move in the vertical direction; the working side of the substrate edge protection device 100 is facing the ...

Embodiment 3

[0072] Embodiment 3 of the present invention provides a protection method for a substrate edge protection device, Figure 5 It is a flow chart of a protection method of a substrate edge protection device provided in Embodiment 3 of the present invention. refer to figure 1 , the base edge protection device 100 includes a base 110, a grasping part 120 arranged on the edge of the working side of the base 110, the grasping part 120 is used to grasp and fix the base edge protection ring 130; Mechanism 140, the warpage processing mechanism 140 includes a plurality of blowing holes formed on the working surface, and an air inlet connected to the blowing holes, and the warpage processing mechanism is used to blow air through the blowing holes to level the substrate. The substrate edge protection device 100 is located in a lithography equipment, and the lithography equipment also includes a manipulator 200 and a workpiece table. Such as Figure 5 As shown, the method includes:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com