Double-table-board exposure machine and method for controlling opening and closing of door of double-table-board exposure machine

An exposure machine and a double-table technology are applied in the direction of photomechanical equipment, microlithography exposure equipment, and photoplate making process on patterned surfaces. It can solve problems such as insufficient door closing, high environmental requirements, and poor exposure. Precisely set the gate position, improve the exposure quality, and avoid the effect of poor exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

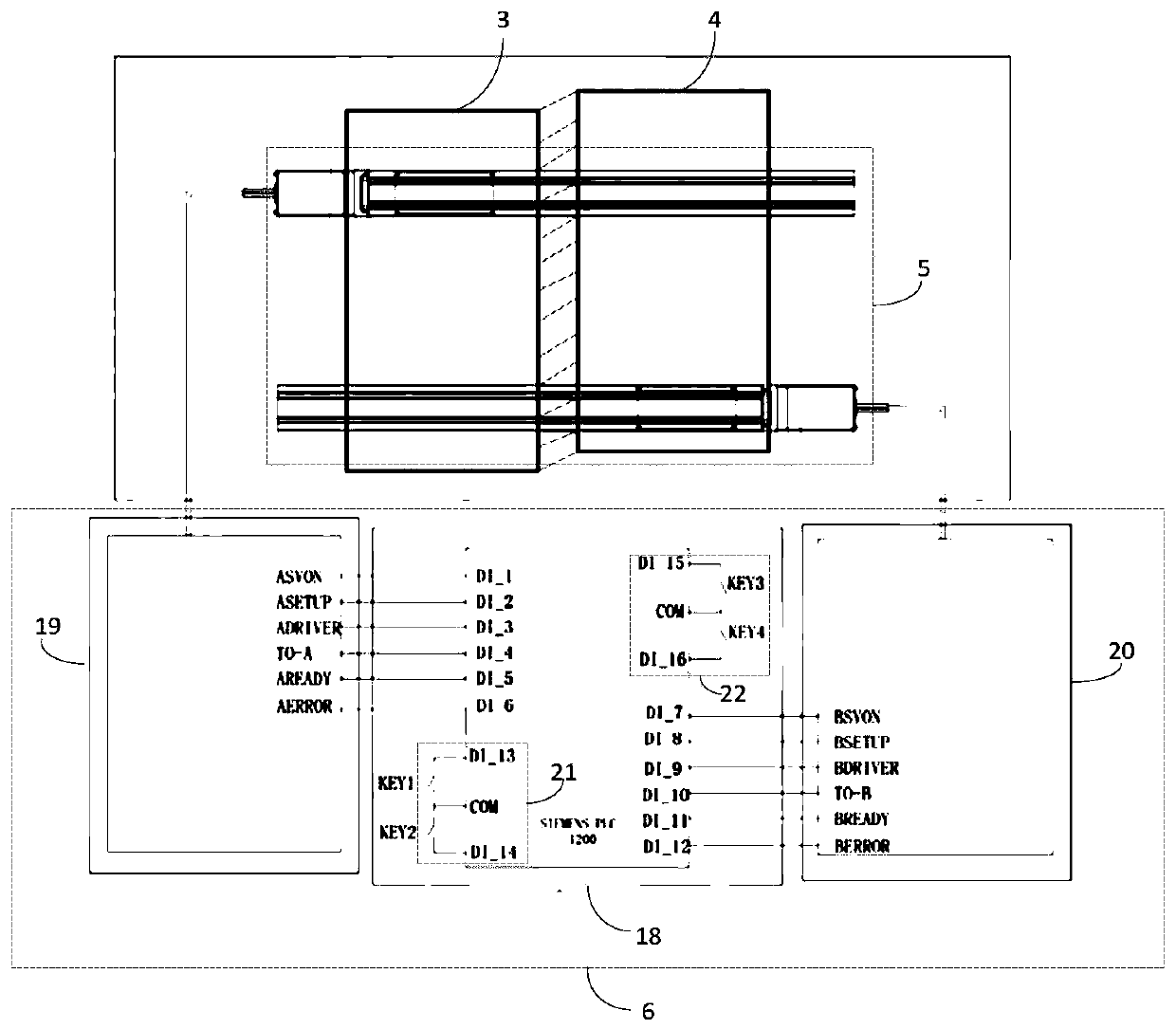

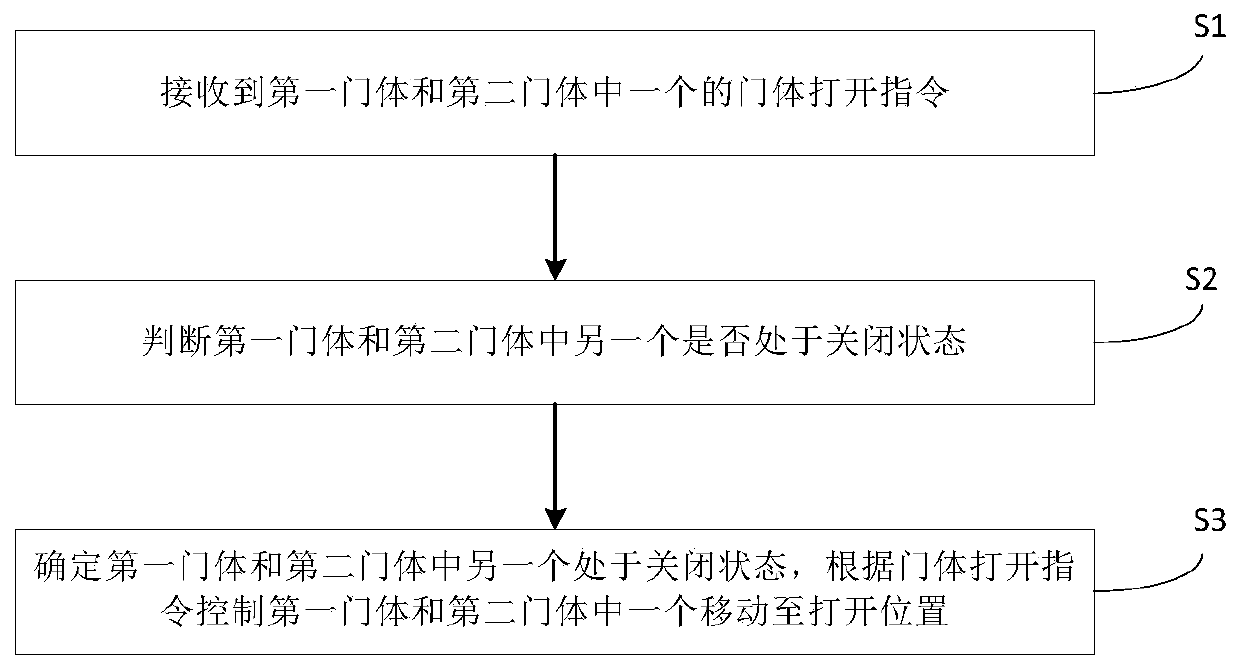

[0024] Embodiments of the present invention are described in detail below, and the embodiments described with reference to the drawings are exemplary, and embodiments of the present invention are described in detail below.

[0025] Refer below Figure 1-Figure 2 A dual-stage exposure machine according to an embodiment of the first aspect of the present invention will be described.

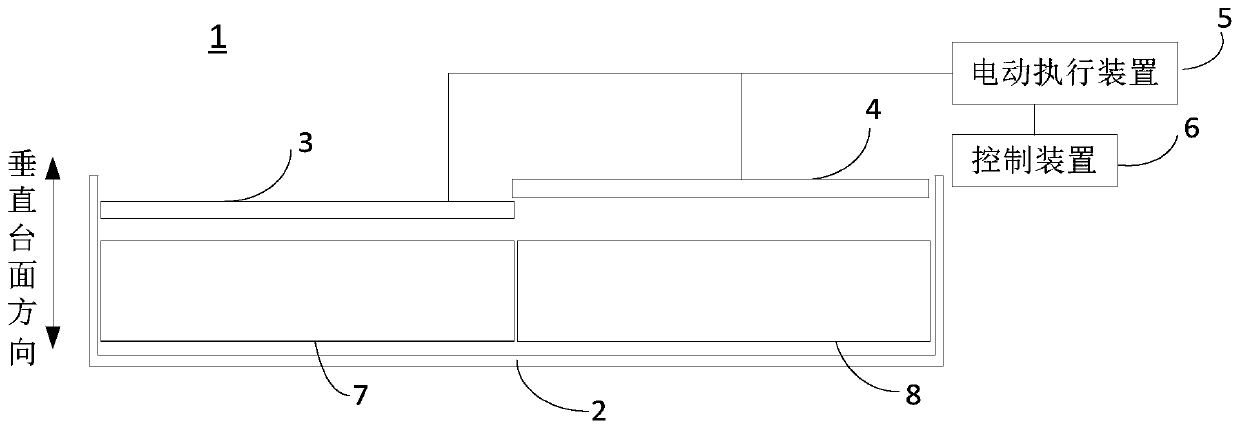

[0026] Such as figure 1 As shown, the double-stage exposure machine 1 of the embodiment of the present invention includes a machine body 2 , a first door body 3 , a second door body 4 , an electric actuator 5 and a control device 6 .

[0027] Wherein, an exposure chamber can be arranged on the body 2, and a first table 7 and a second table 8 are arranged in the exposure chamber, and PCB boards to be exposed can be placed on the table.

[0028] The first door body 3 is positioned on the first table top 7 and has a gap with the first table top 7, and the second door body 4 is positioned on the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com