Patents

Literature

89results about How to "Improve exposure quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

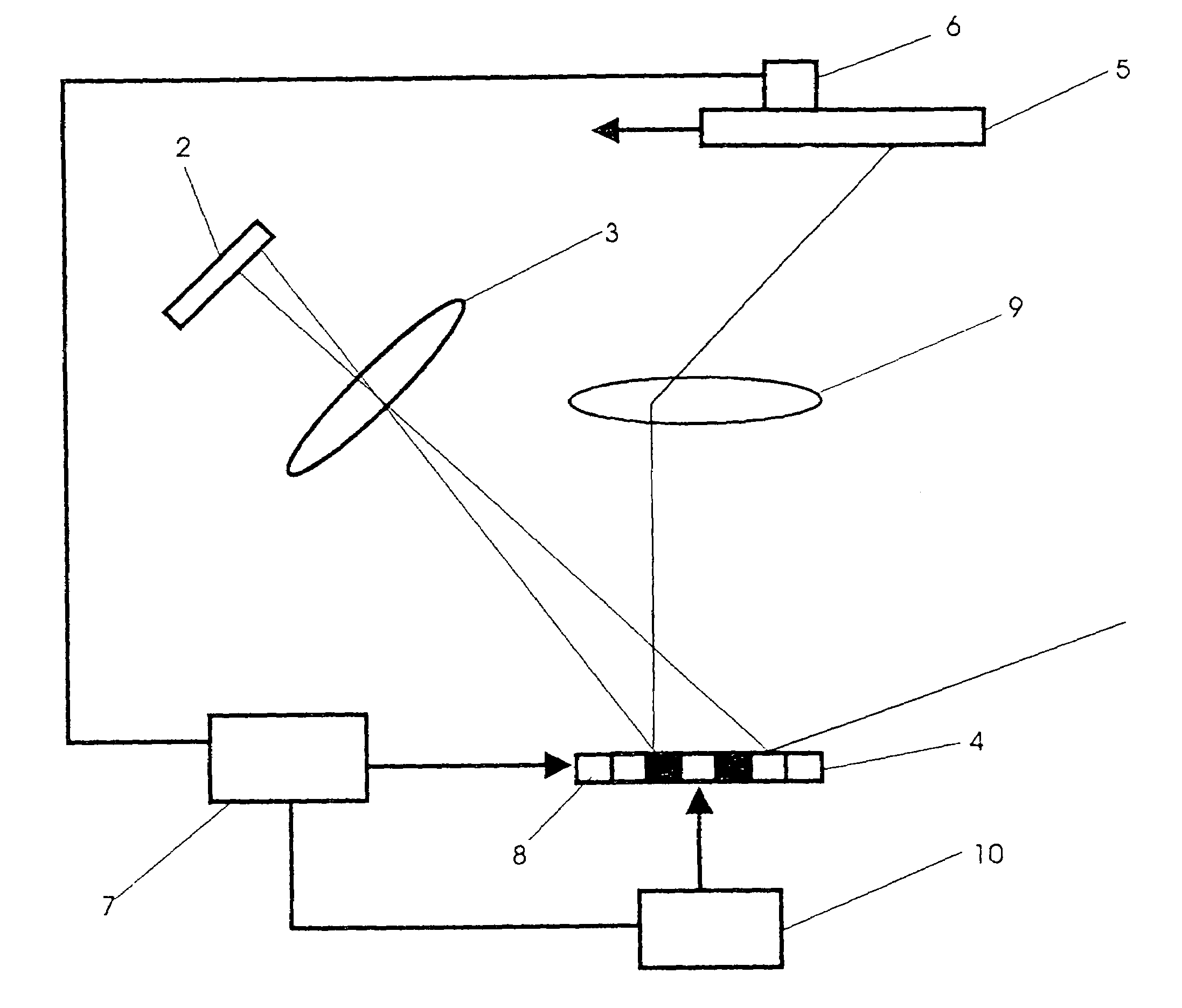

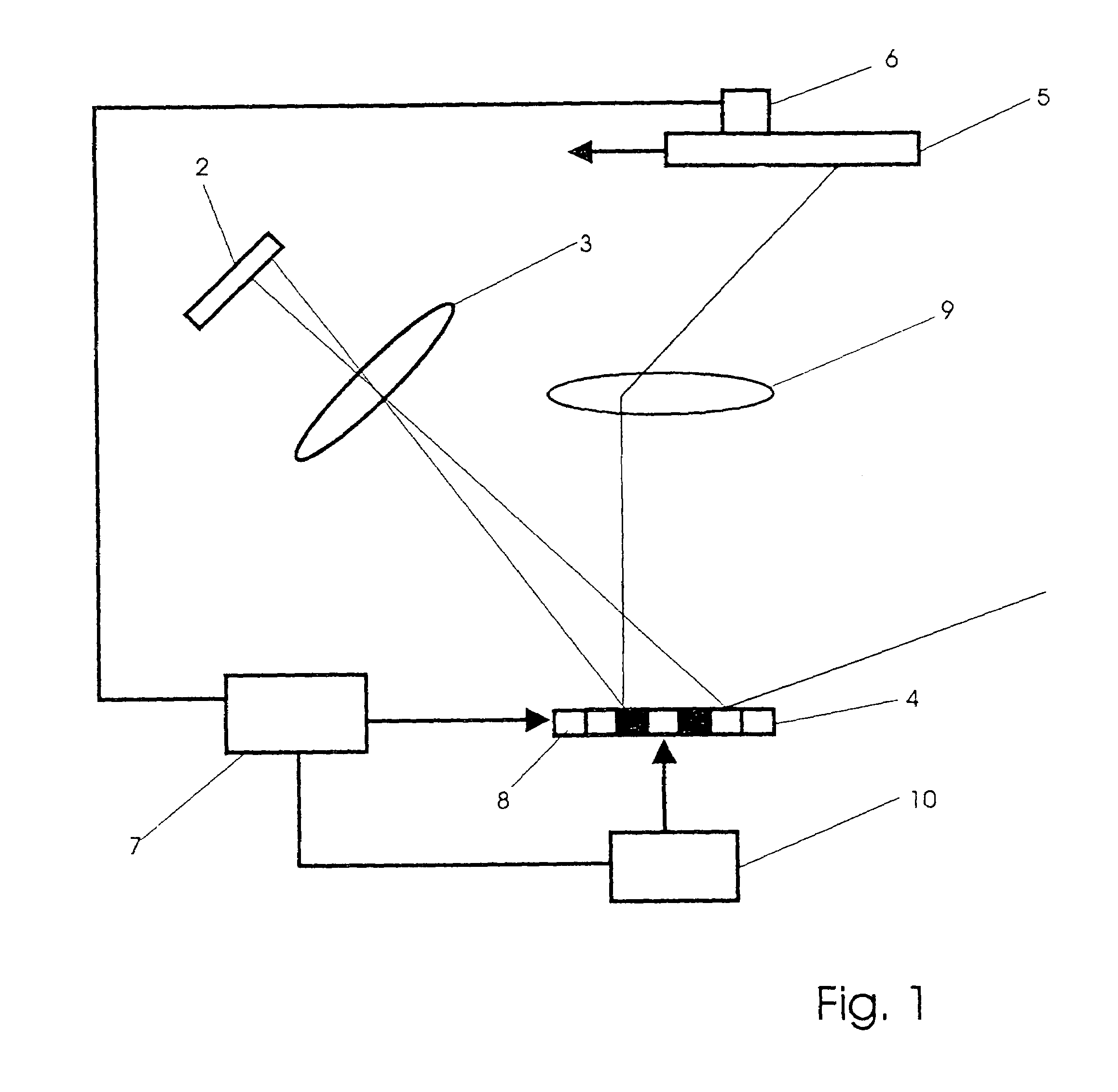

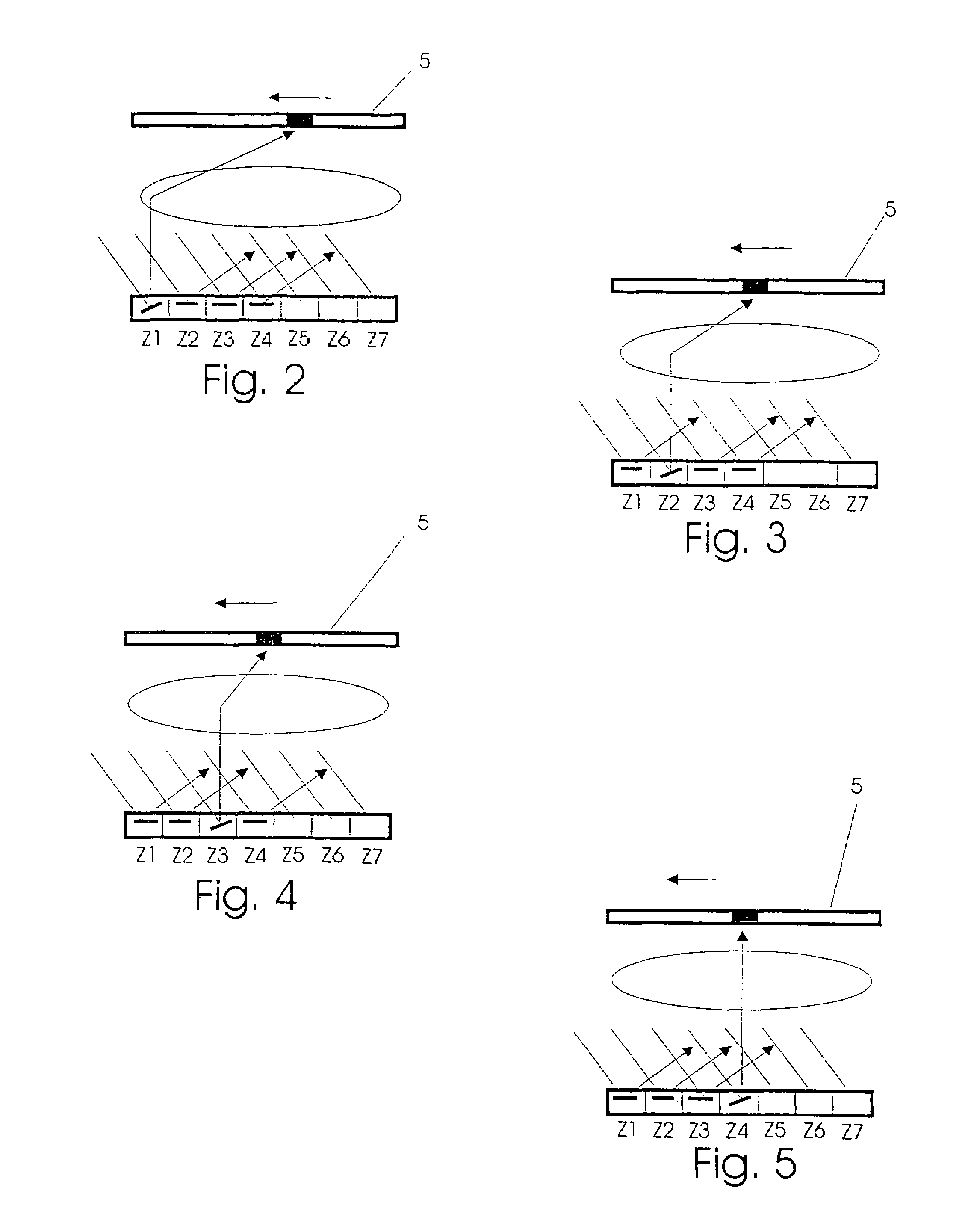

Device and method for compensating non-uniformities in imaging systems

InactiveUS6965364B1Improve exposure qualityQuality improvementVisual representatino by photographic printingCathode-ray tube indicatorsLight sourceLight sensitive

An illumination and modulation device is described, as well as a method for modulating the exposure intensity in the integrating digital screen imaging system (IDSI), comprising a light source, a light modulator, and various devices. The object of the invention is to present a device and a method with which the exposure quality can be optimized using simple means. The object on which the invention is based is attained by the fact that the device comprises at least one device for varying the number of cells of the light modulator used to expose the photosensitive material or by the fact that, in the method according to the invention, the number of cells of the light modulator used to expose the photosensitive material can be varied.

Owner:XEIKON PREPRESS NV

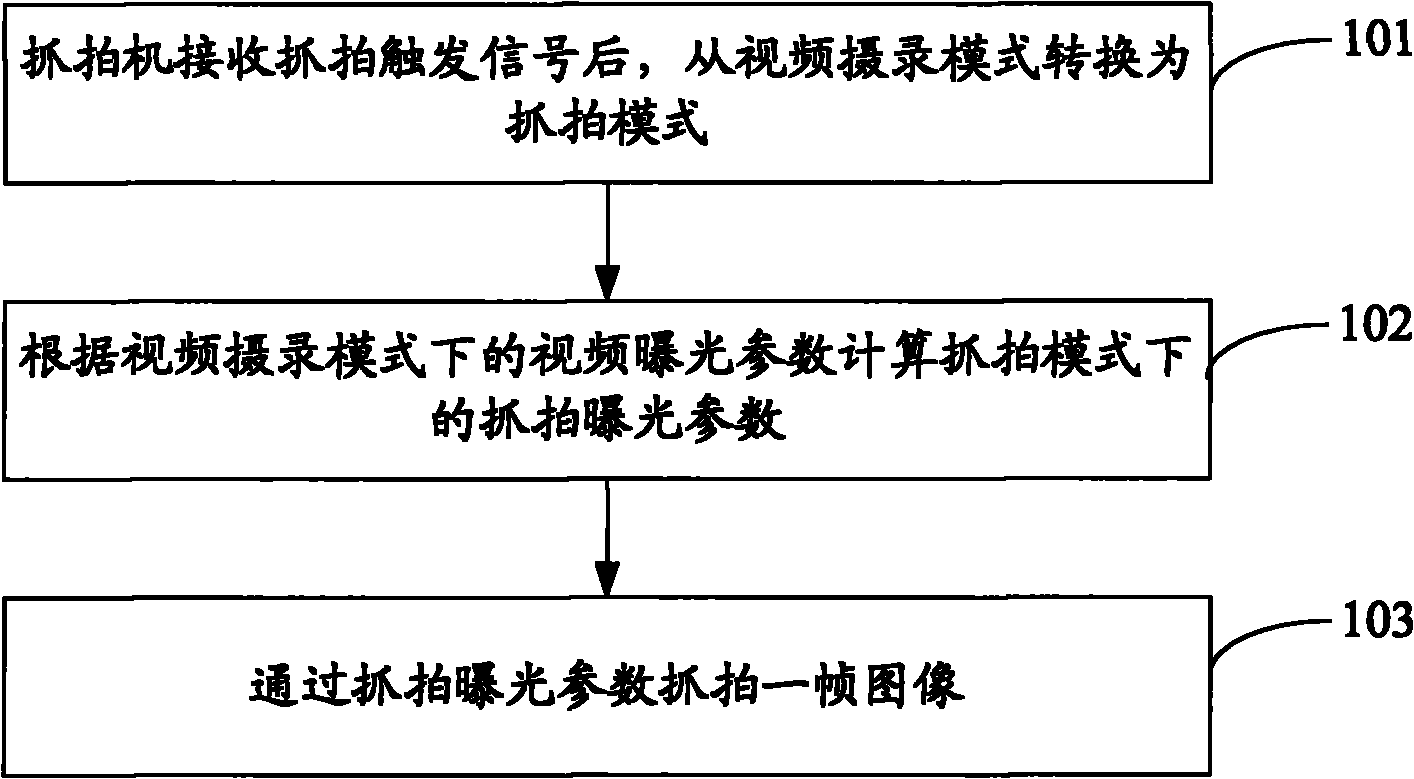

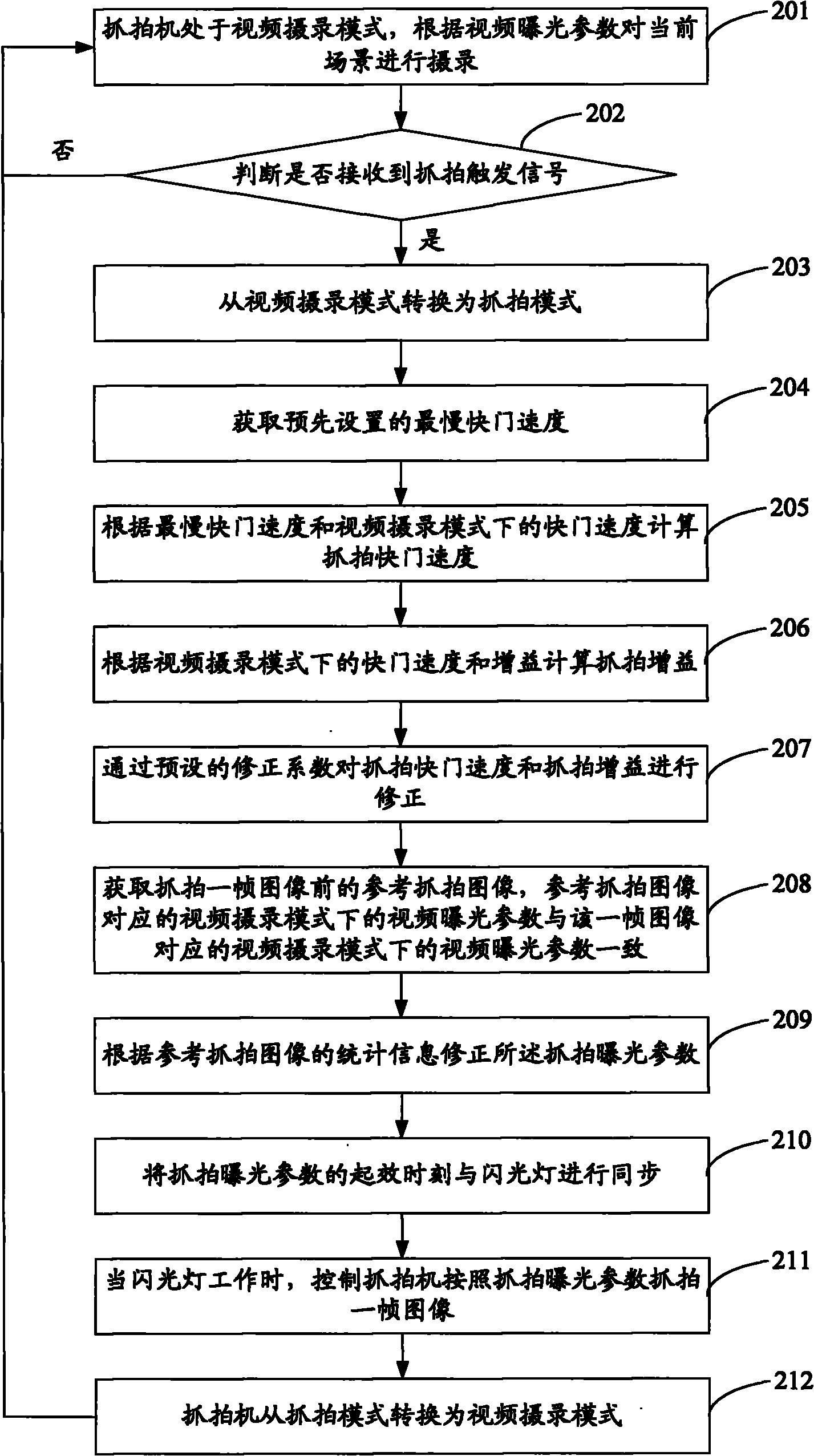

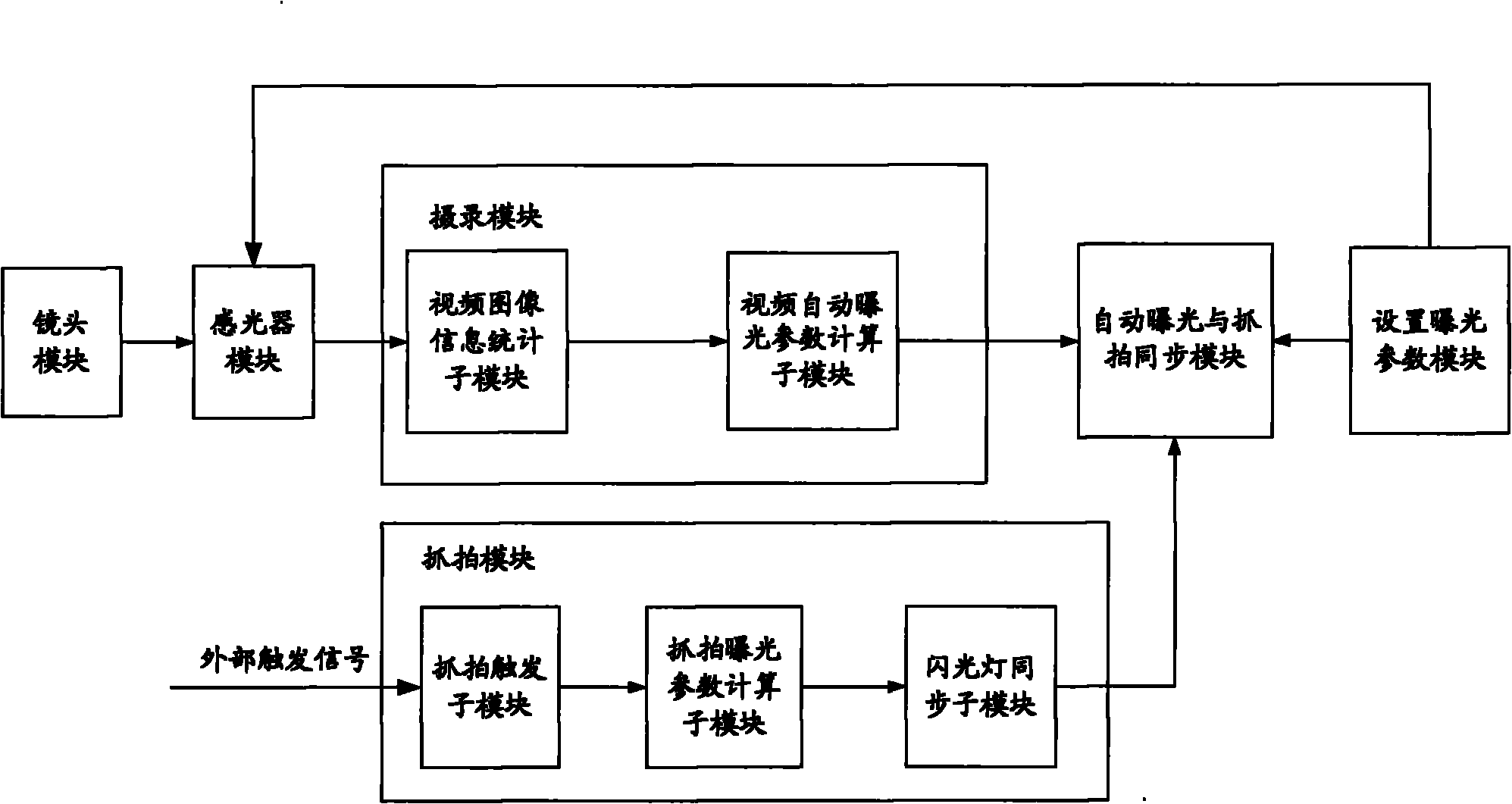

Exposure control method and device

ActiveCN101893804ADual function realizationReal-time recordingTelevision system detailsColor television detailsExposure controlVideo record

The embodiment of the invention discloses an exposure control method and device which are used in a candid camera with a video recording mode and a candid mode. The method comprises the following steps: after receiving a candid trigger signal, the candid camera converts the video recording mode to the candid mode; the candid exposure parameter in the candid mode is calculated according to a video exposure parameter in the video recording mode; and one frame of candid image is shot according to the candid exposure parameter. The candid camera in the embodiment of the invention has double functions of video recording and candid so that the candid exposure parameter of any moment can be calculated according to the video exposure parameter; as the video exposure parameter is characterized by changing according to the physical environment, the calculated candid exposure parameter can change to adapt to the environment and the exposure quality of the candid image can be increased; and when the candid function of the candid camera in the embodiment of the invention is not triggered, the candid camera can perform real-time recording of the video image, thus the double functions of the candid camera can be realized.

Owner:HANGZHOU HIKVISION DIGITAL TECH

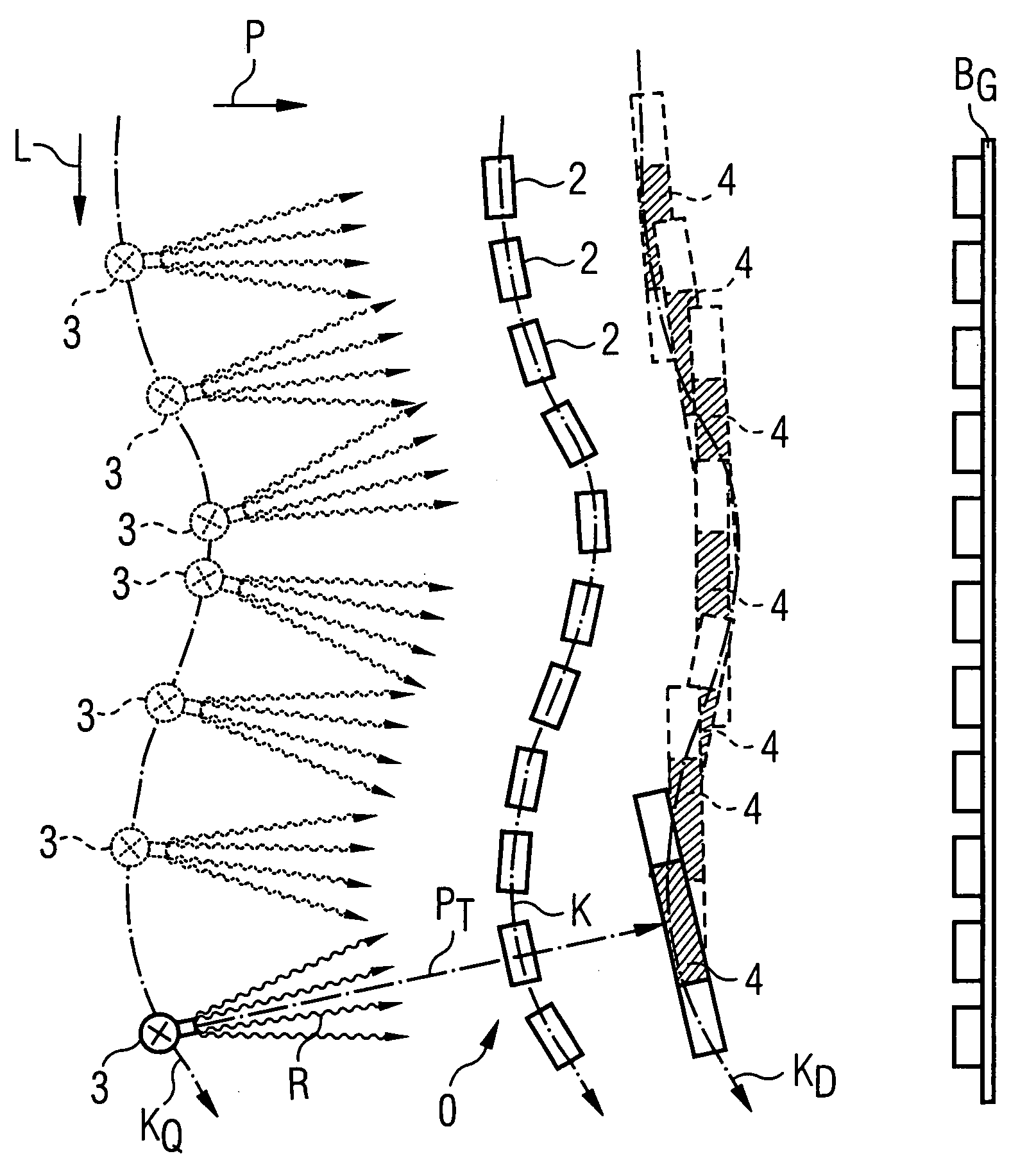

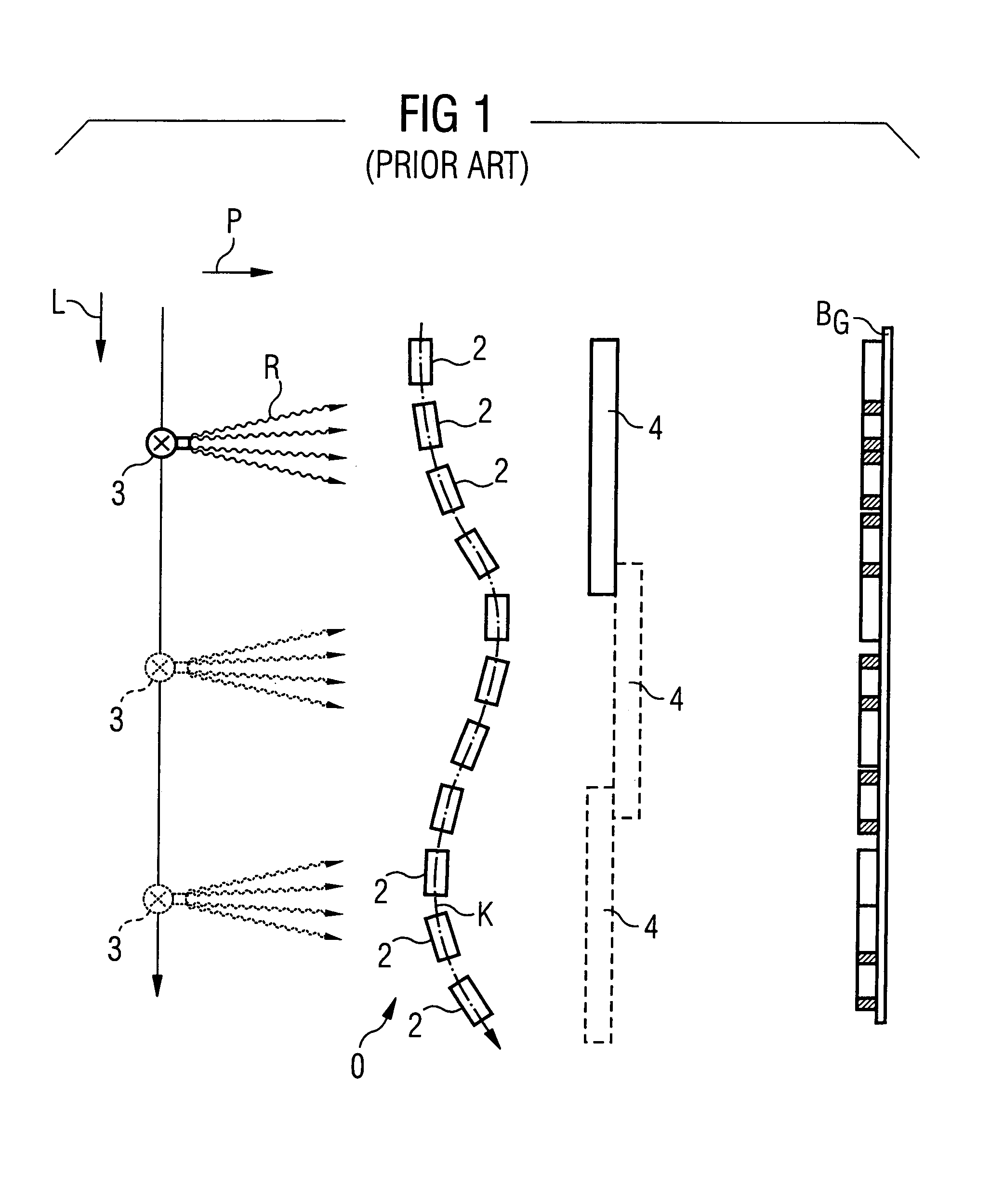

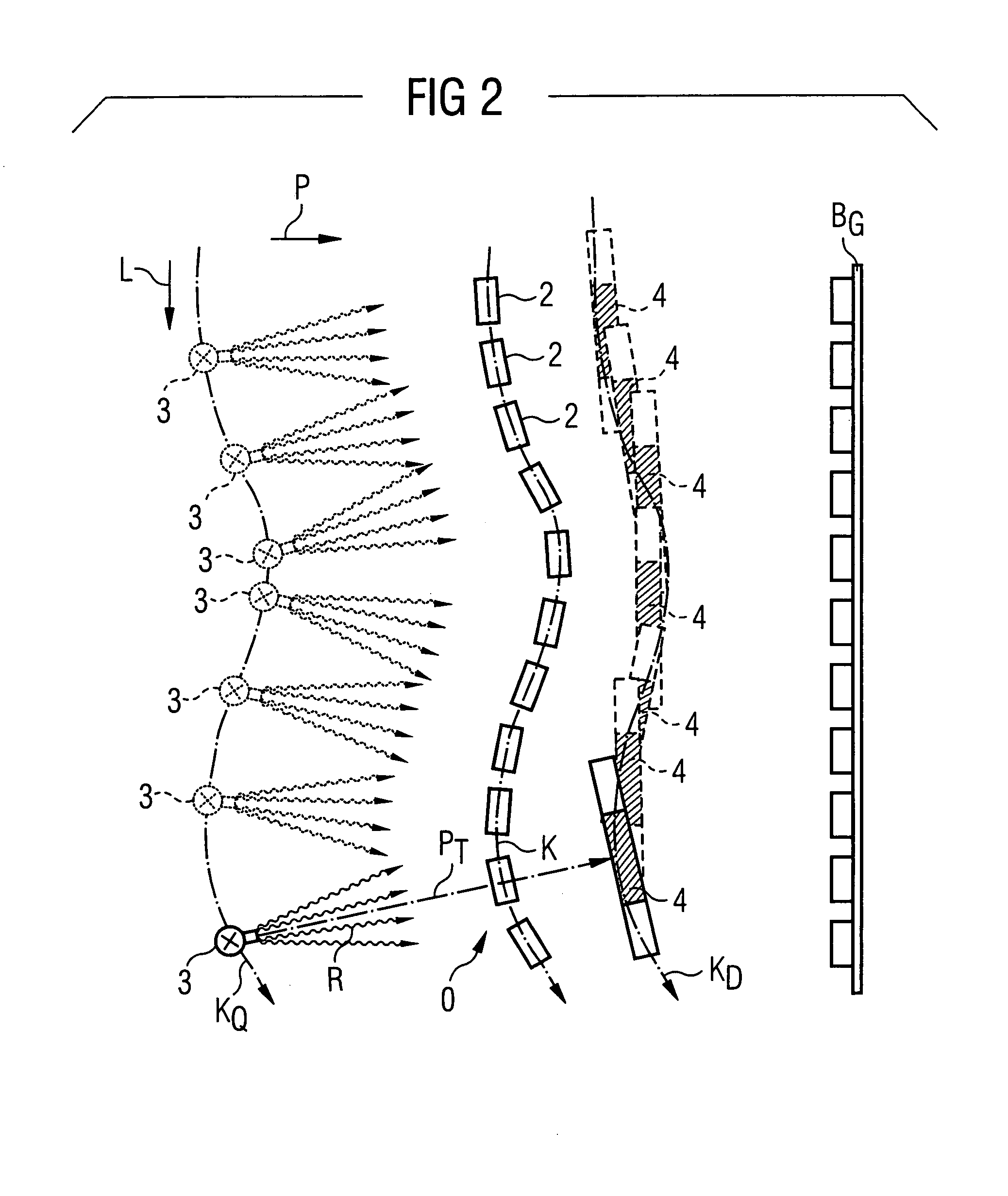

Method and system for generating an x-ray exposure

InactiveUS7073939B2Shadow formations caused thereby, can be reduced or even completely preventedImprove exposure qualityImage-conversion/image-amplification tubesX-ray apparatusSoft x rayX-ray

In a method and system for generating an x-ray exposure of an examination subject extending in a longitudinal direction and exhibiting, in a main projection direction, a geometry that is curved at least in sections, an x-ray source and an x-ray detector are respectively positioned and aligned appropriately with regard to one another and to the section to be acquired of the exposure subject in order to generate partial exposures along a curved course substantially adapted to the geometry of the exposure subject. The partial exposures of the sections subsequently are combined into an overall x-ray exposure of the exposure subject.

Owner:SIEMENS AG

Reticle cleaning method for a lithography tool and a reticle cleaning system thereof

InactiveUS20110180108A1Enhance qualityIncreased yieldSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEngineeringReticle

A reticle cleaning method for a lithography tool, wherein an inspection apparatus deployed in the lithography tool is used to perform the cleaning procedure on reticle in the EUV reticle pod, the reticle cleaning method comprising: transporting the EUV reticle pod to the upper chamber of the inspection apparatus; forming vacuum in the upper chamber of the inspection apparatus; transporting the inner box of the EUV reticle pod to the lower chamber of the inspection apparatus; forming vacuum in the lower chamber of the inspection apparatus; performing the cleaning process multiple times for gas filling and vacuum exhausting, wherein an inert gas is provided for the process of gas filling to be performed multiple times on the inner box to allow the particles in the inner box to be brought away by the flow field formed by the inert gas in the inner box; and transporting the inner box to a reticle library.

Owner:GUDENG PRECISION IND CO LTD

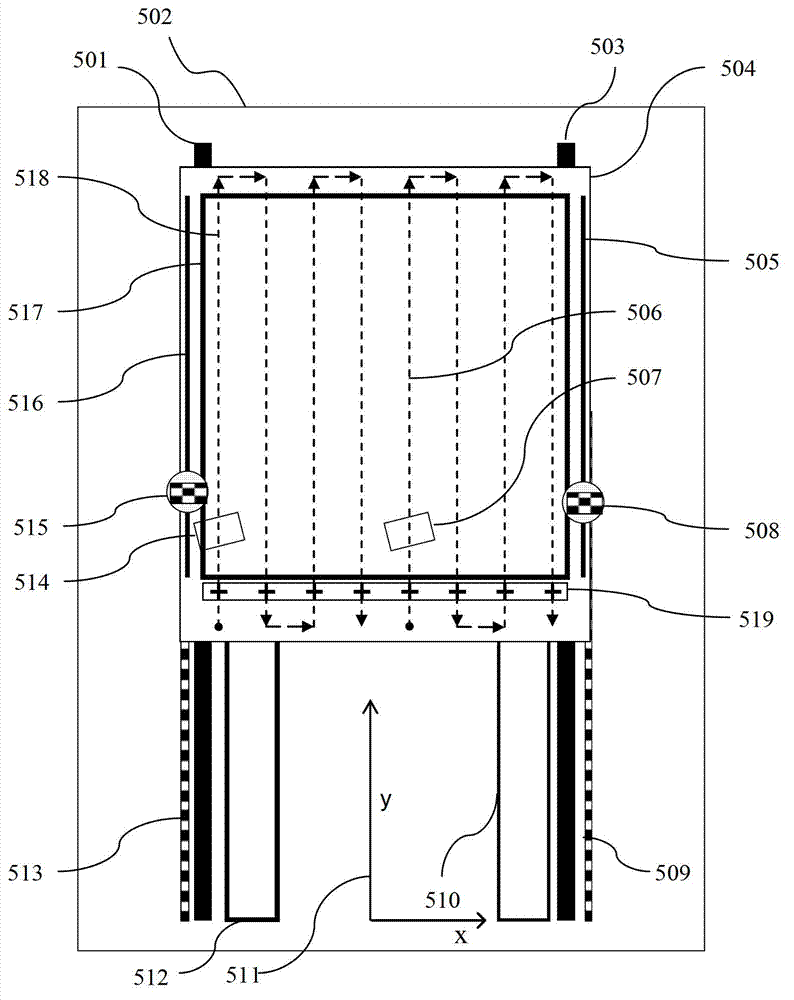

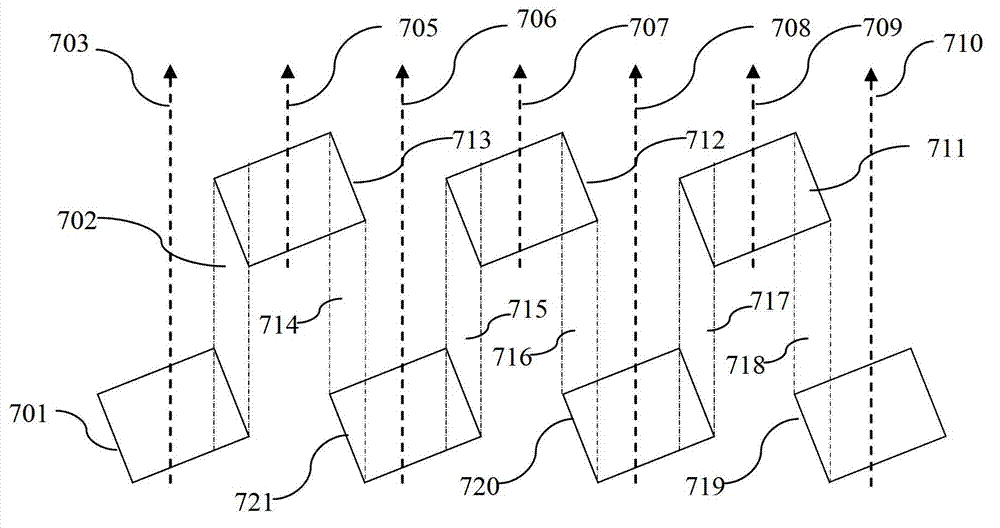

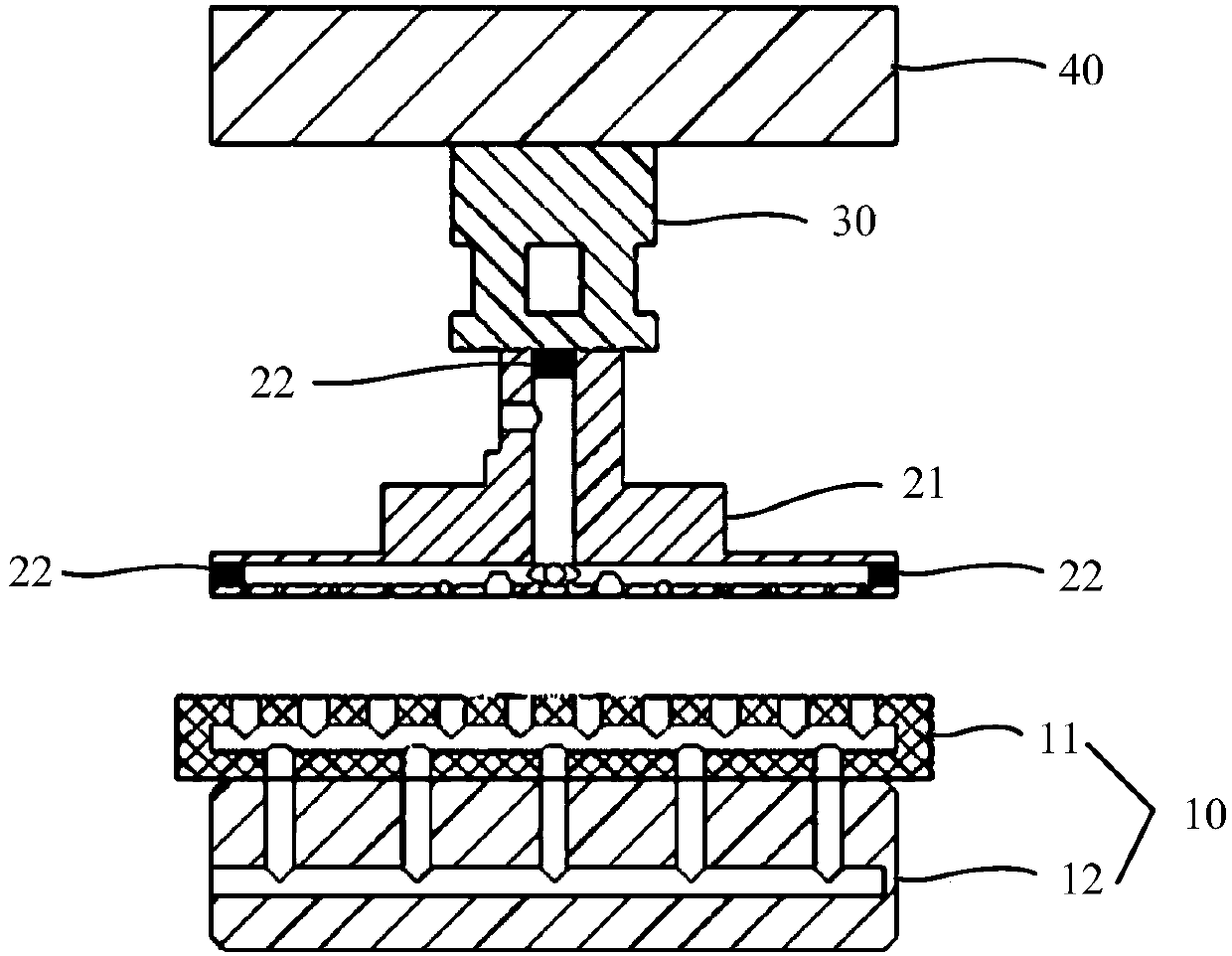

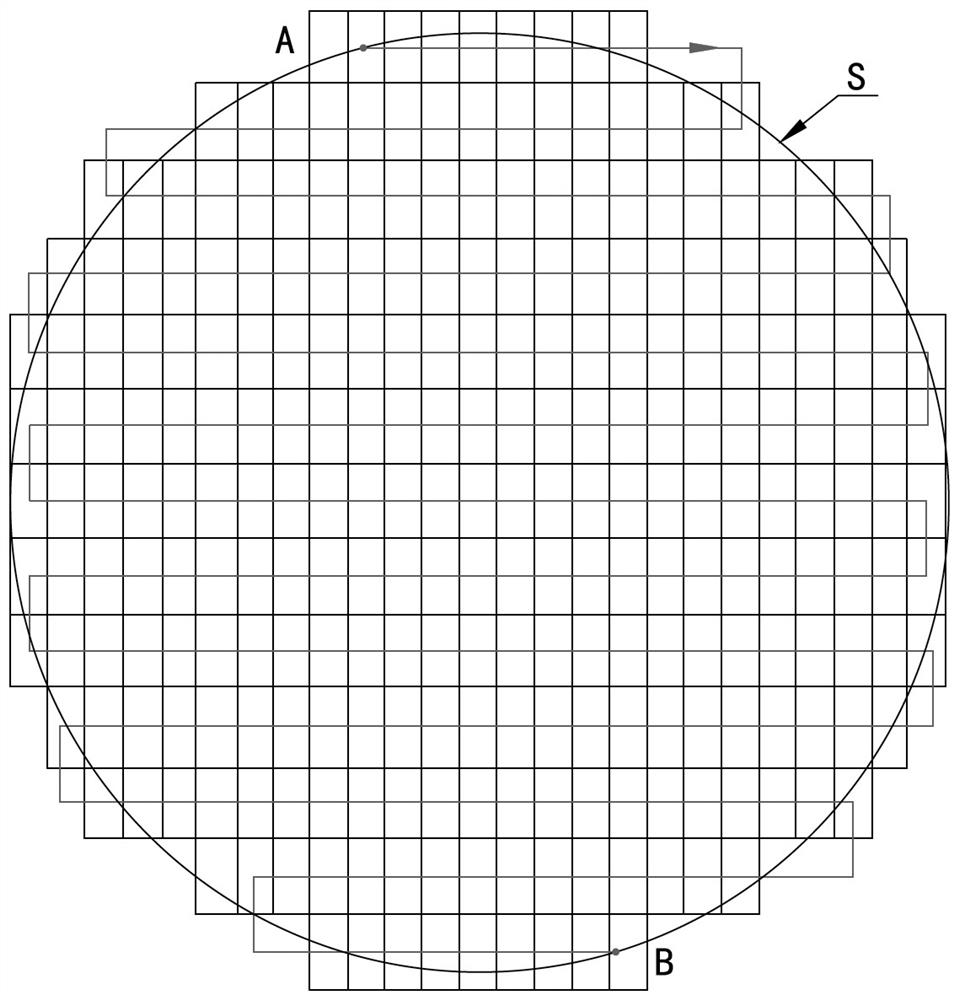

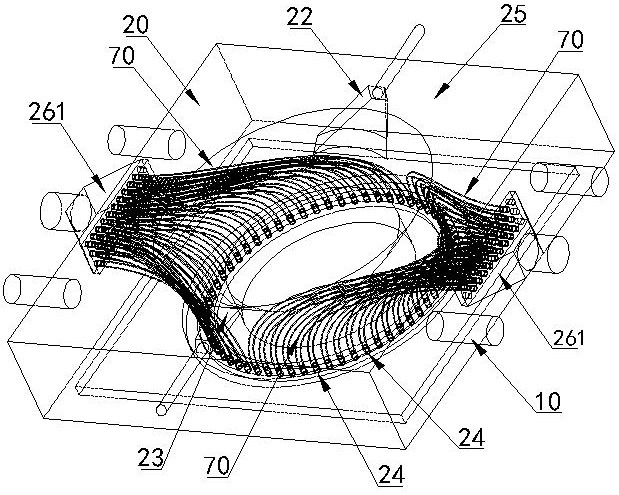

Ultra-large size flat panel display maskless photolithography system and method

ActiveCN103048885AReduce distanceReduce scan timePhotomechanical exposure apparatusMicrolithography exposure apparatusData processing systemProduction rate

A maskless exposure system that has multiple maskless optical engines arranged in an (NM) matrix that form and project a pattern onto a substrate. A first stage system is capable of driving the maskless optical engines in a first direction, a second stage system capable of holding and moving the substrate in a second direction perpendicular to the first direction. A control system that processes data and synchronizing movement of the first and second stage systems and a vision system that detects the positions of the second stage system to synchronize movements with the multiple optical engines.

Owner:ZHONGSHAN AISCENT TECH

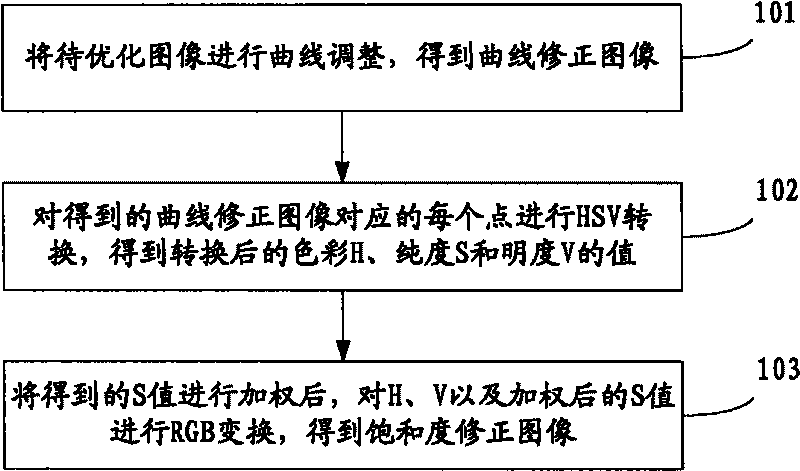

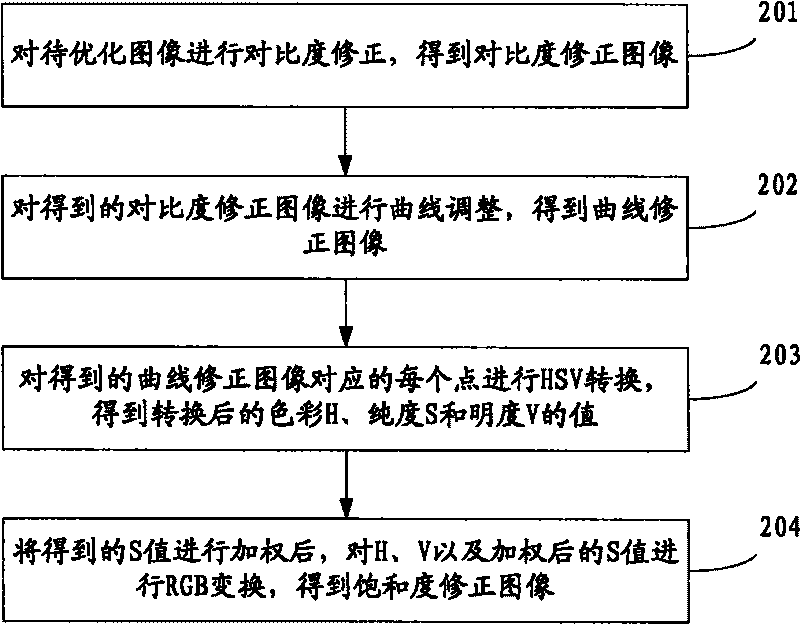

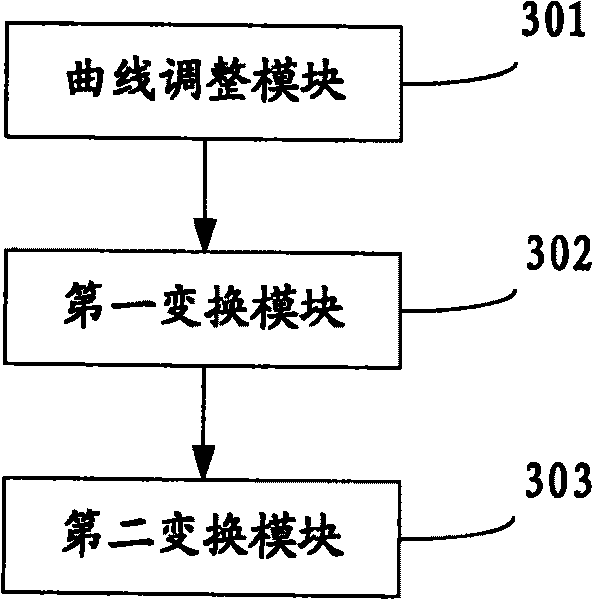

Method and device for optimizing and editing image

ActiveCN101742340ABright colorsImprove exposure qualityColor signal processing circuitsBrightness perceptionImaging processing

The invention discloses a method and a device for optimizing and editing an image, which belong to the technical field of image processing. The method comprises the following steps of: adjusting curves of an image to be optimized to obtain an image with modified curves, performing HSV conversion on each point corresponding to the image with modified curves to obtain a converted color value H, a converted purity value S and a converted brightness value V, weighing the obtained value of the S and then performing an RGB conversion to the color value H, the brightness value V and the weighed purity value S to acquire a saturation modified image. The device comprises a curve adjusting module, a first transformation module and a second transformation module. The method and the device for optimizing and editing the image make the color of the image brighter by adjusting the curves and modifying the saturation of the image to be optimized, do not break the tone of the image and have the effects of optimizing the display quality of the image.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

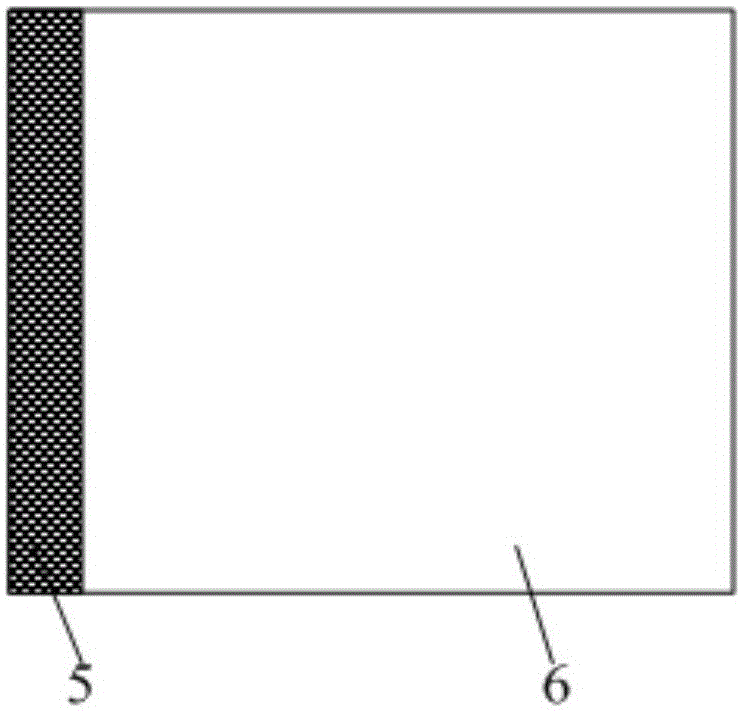

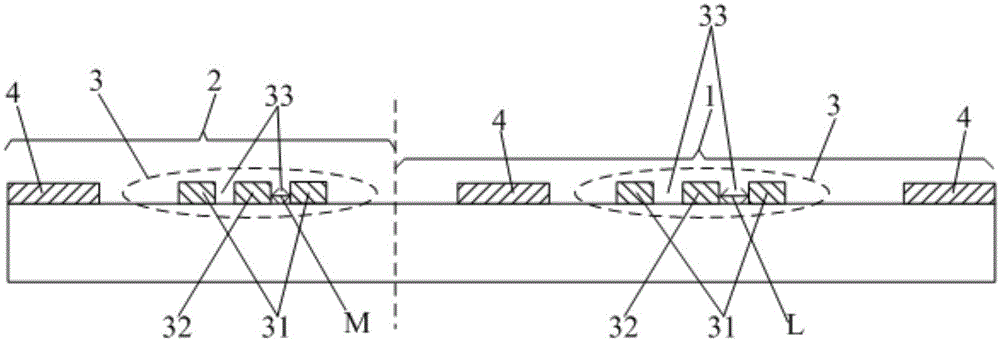

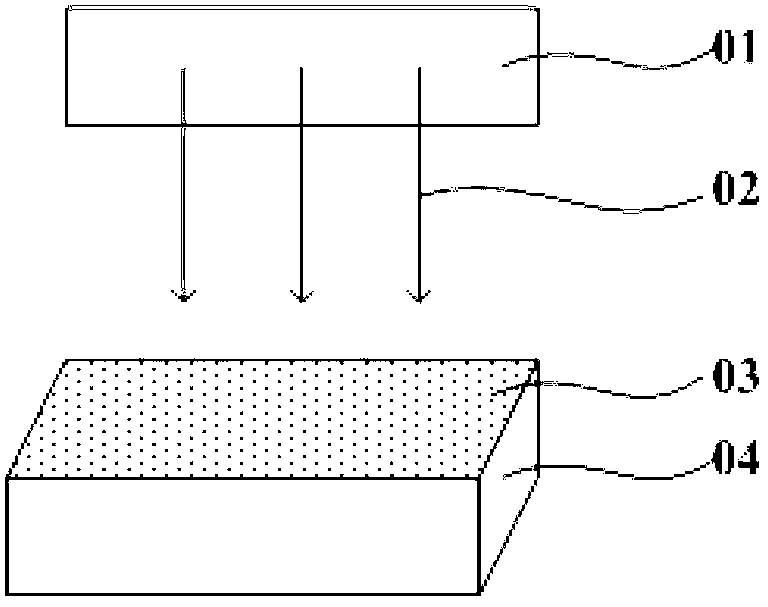

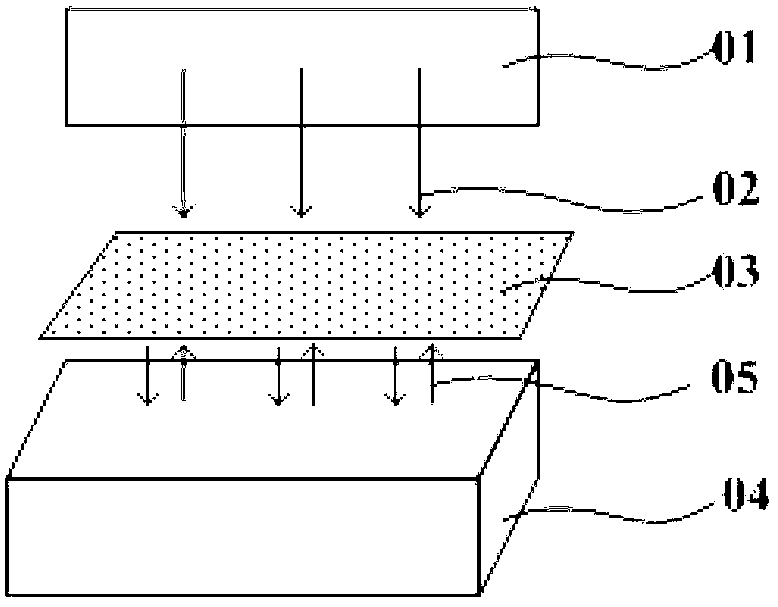

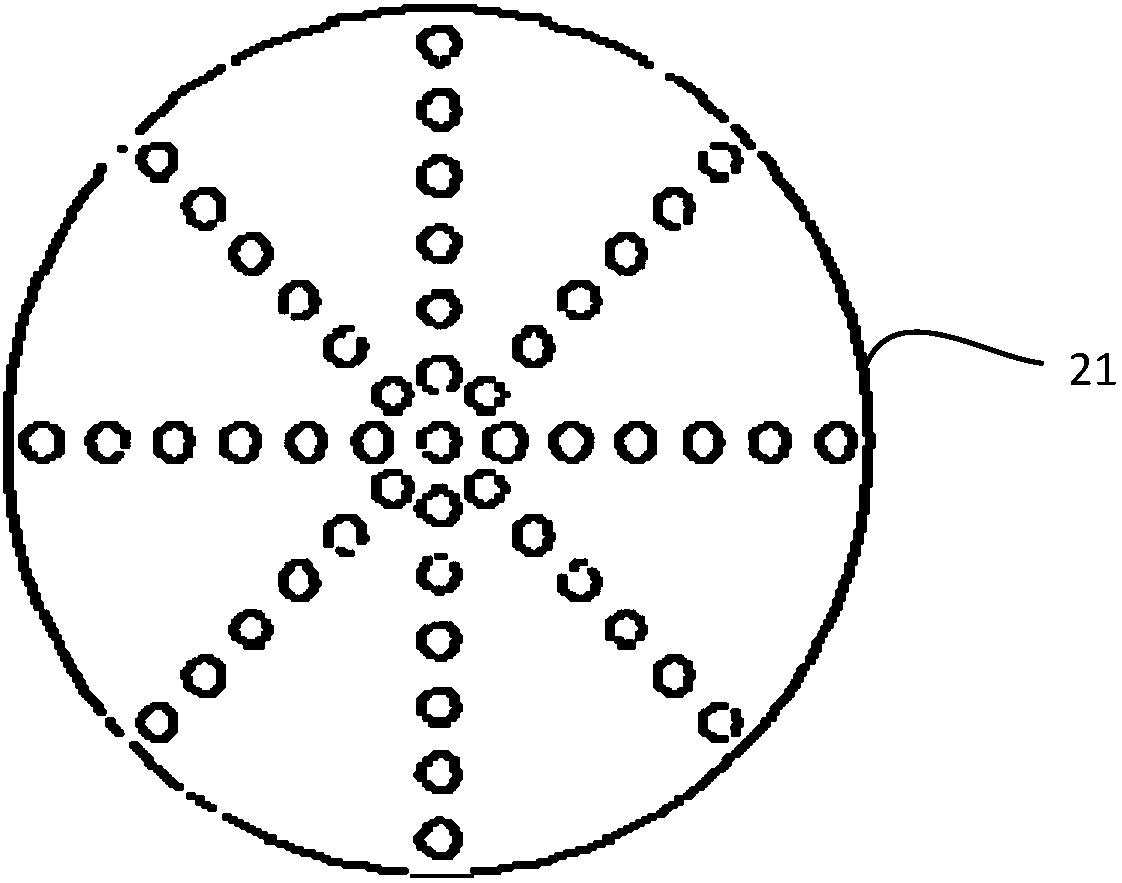

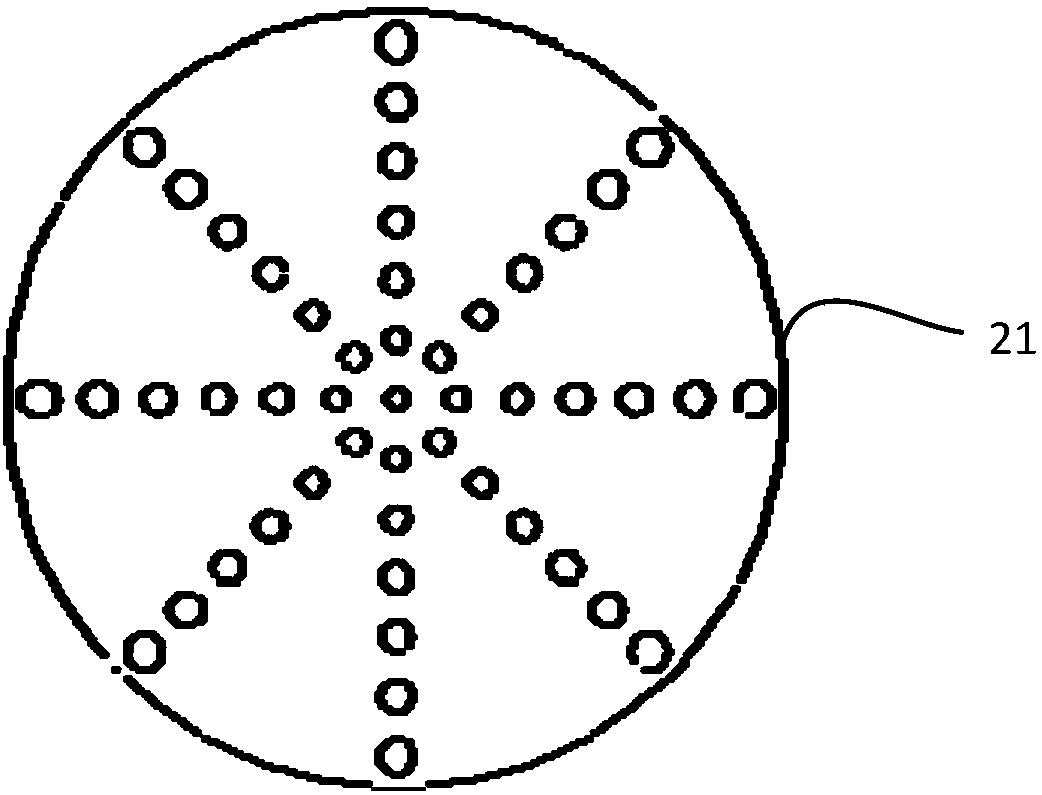

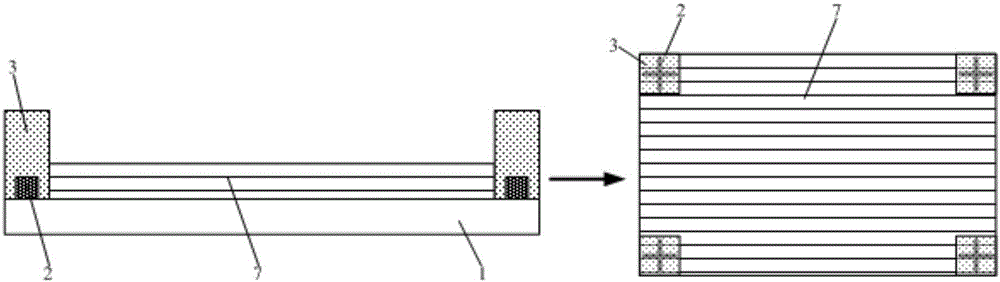

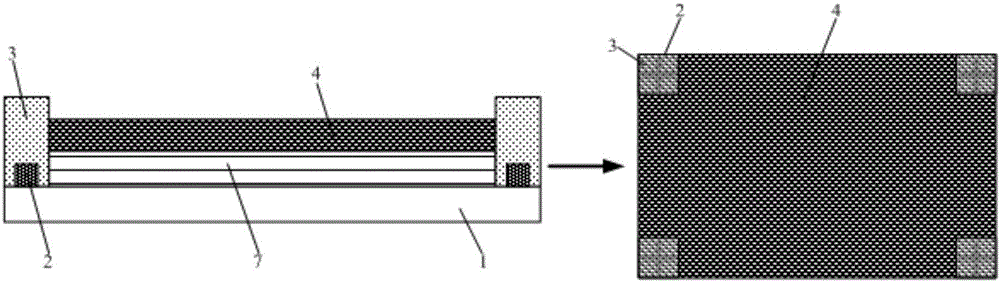

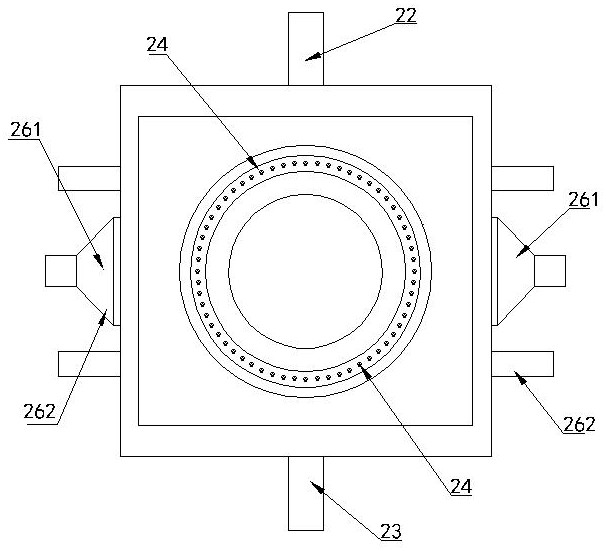

Mask plate, fabrication method thereof and exposure system

PendingCN105093807AGuaranteed to workConsistent thicknessSolid-state devicesPhotomechanical exposure apparatusComputational physicsPhotoresist

The invention provides a mask plate, a fabrication method thereof and an exposure system. The mask plate comprises a first region and a second region, wherein a plurality of patterning masks are arranged in both of the first region and the second region, and the distribution density of the plurality of patterning masks in the first region is smaller than the distribution density of the plurality of patterning masks in the second region; and each patterning mask comprises a first pattern, a second pattern and a slit between the two patterns, and the slit width in the first region is greater than the slit width in the second region. By the mask plate, the intensity of the exposure light ray penetrating through the slit in the second region is reduced relative to the intensity of the exposure light ray penetrating through the slit in the first region, thus, the thickness of a photoresist reserved on an active region film layer tends to consistency after transistors in a display region and a non-display region are exposed and developed through a source and a drain, an active region of the transistor in the non-display region after being subjected to an etching process is further ensured not to be broken, and finally, the transistor in the non-display region can be ensured to normally work.

Owner:BOE TECH GRP CO LTD +1

Exposure method and device

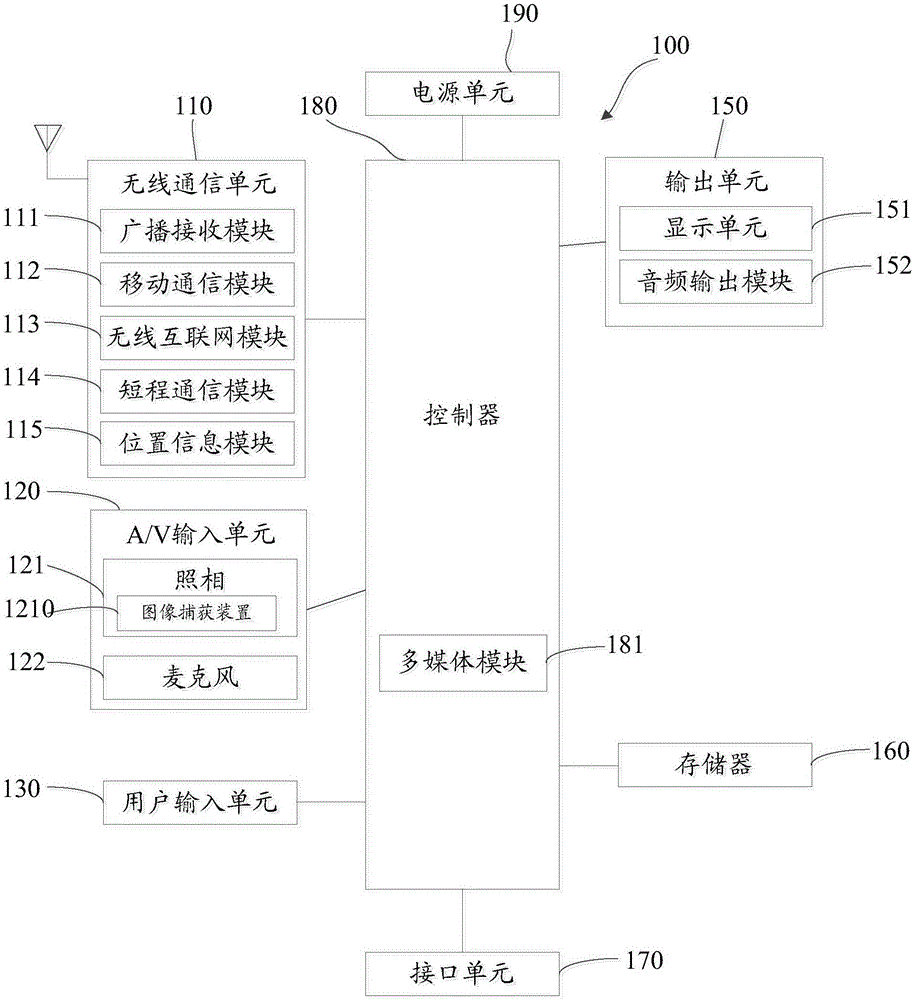

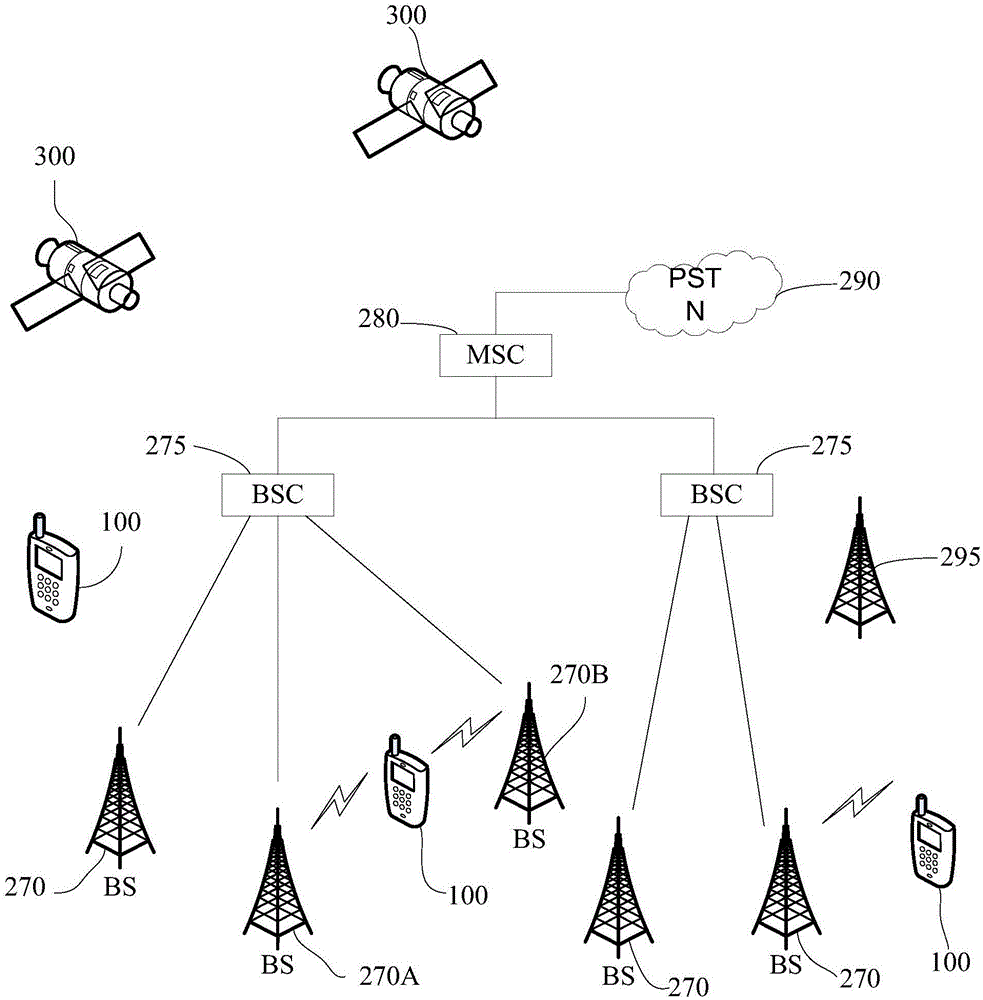

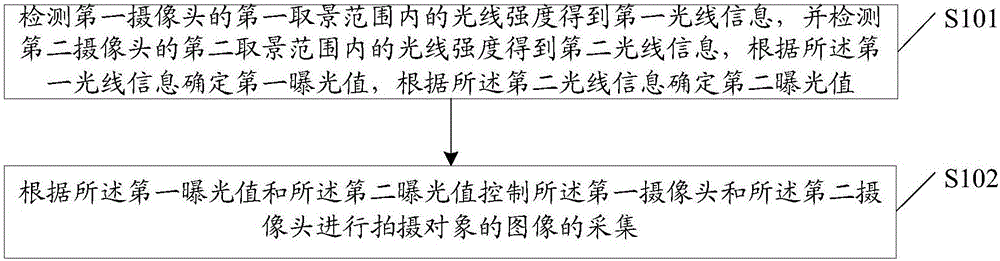

InactiveCN106375679AQuality improvementImprove exposure qualityTelevision system detailsColor television detailsExposure valueComputer science

The invention discloses an exposure method and device. The method comprises that the light intensity within a first viewing scope of a first camera is detected to obtain first light information, the light intensity within a second viewing scope of a second camera is detected to obtain second light information, and first and second exposure values are determined according to the first and second exposure information respectively; and the first and second cameras are controlled to collect images of a shooting object according to the first and second exposure values respectively.

Owner:NUBIA TECHNOLOGY CO LTD

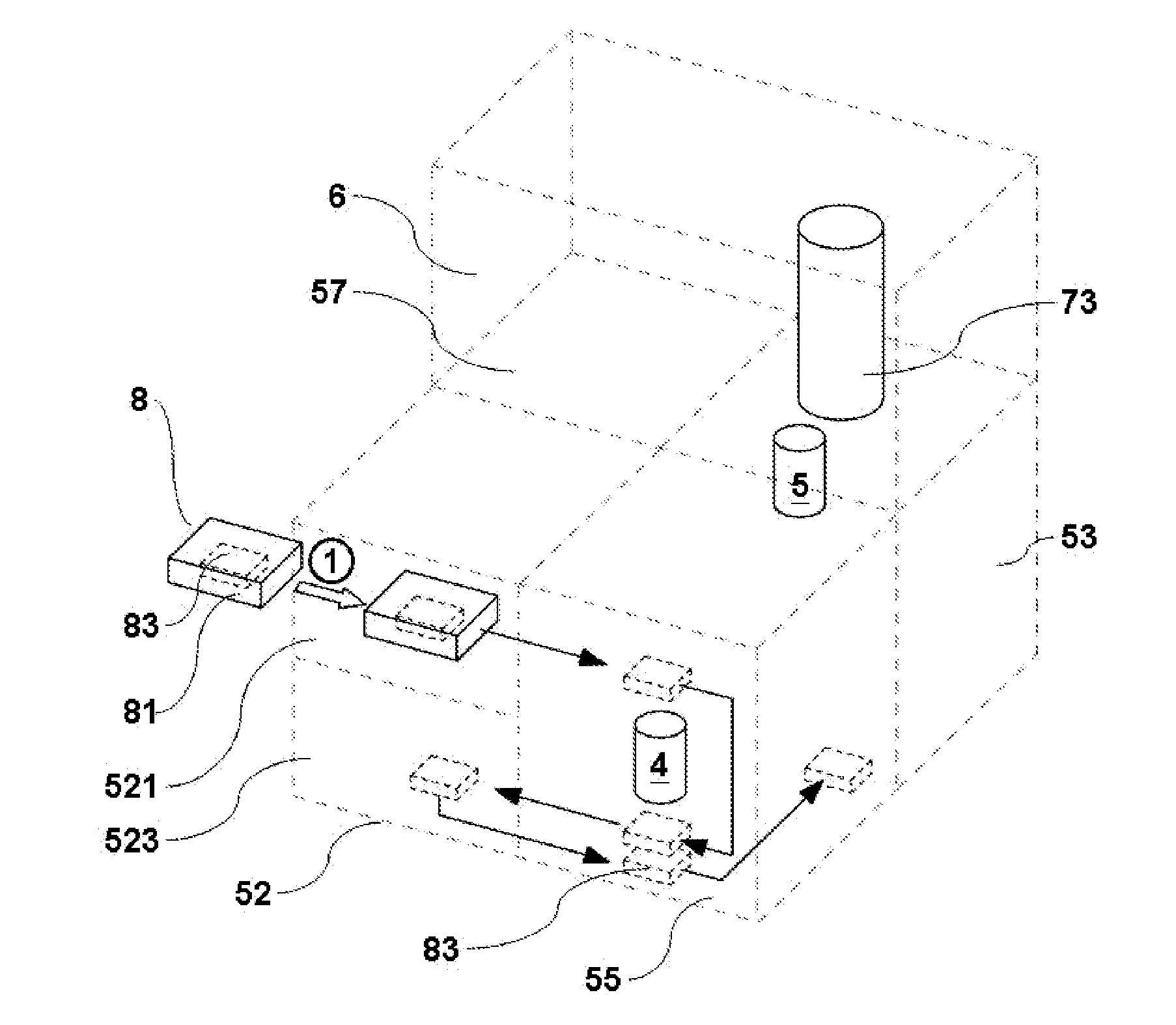

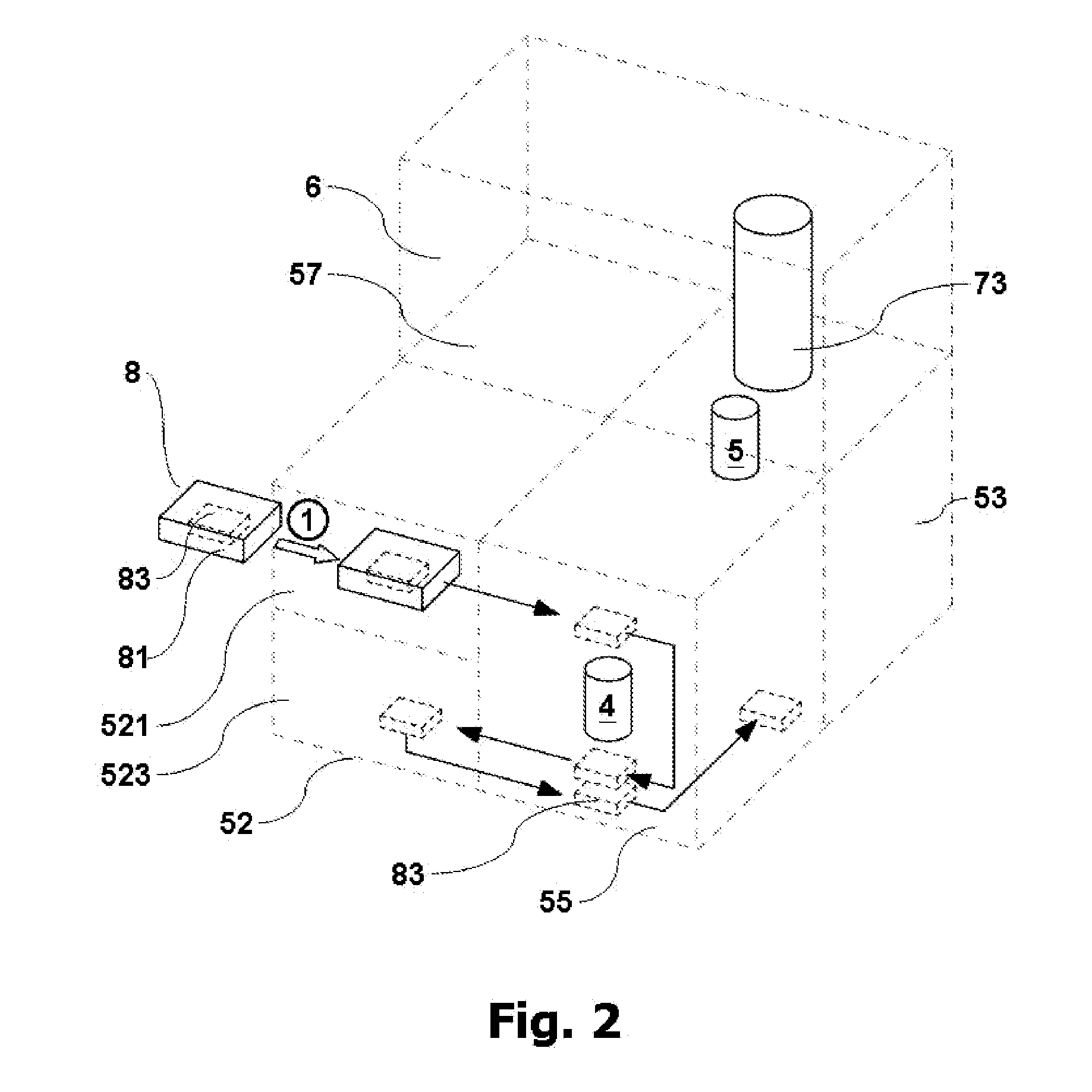

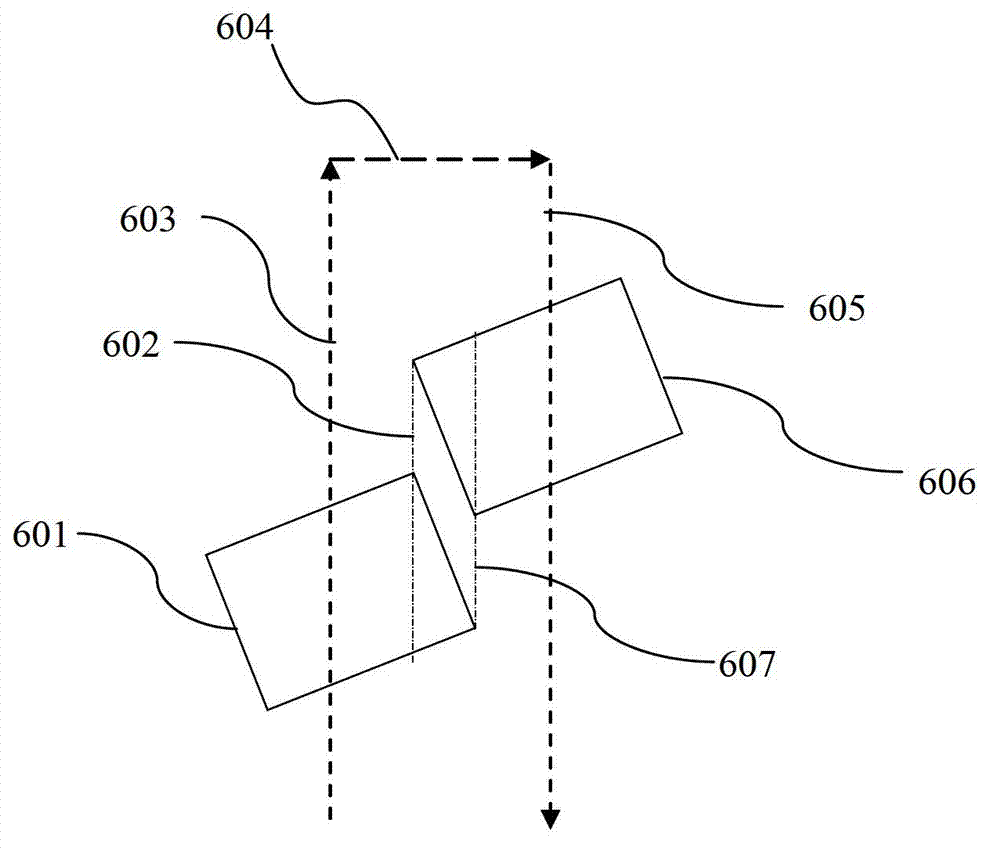

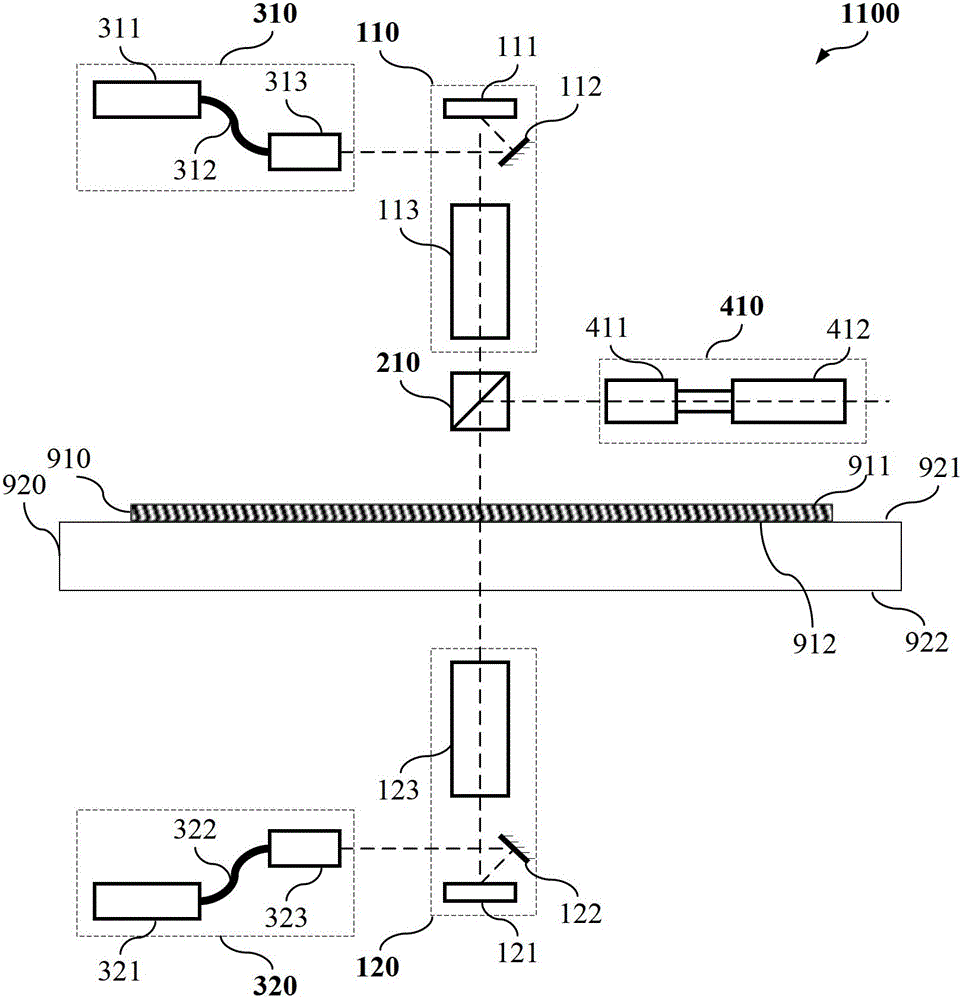

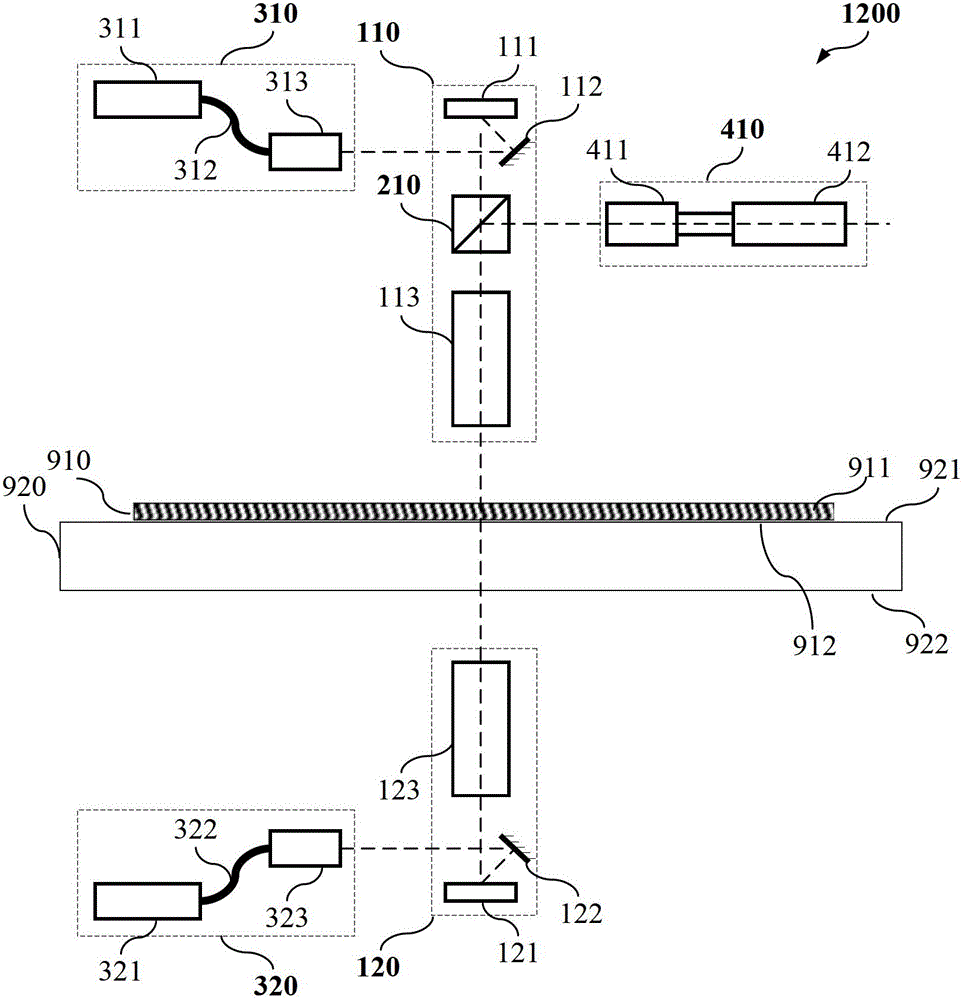

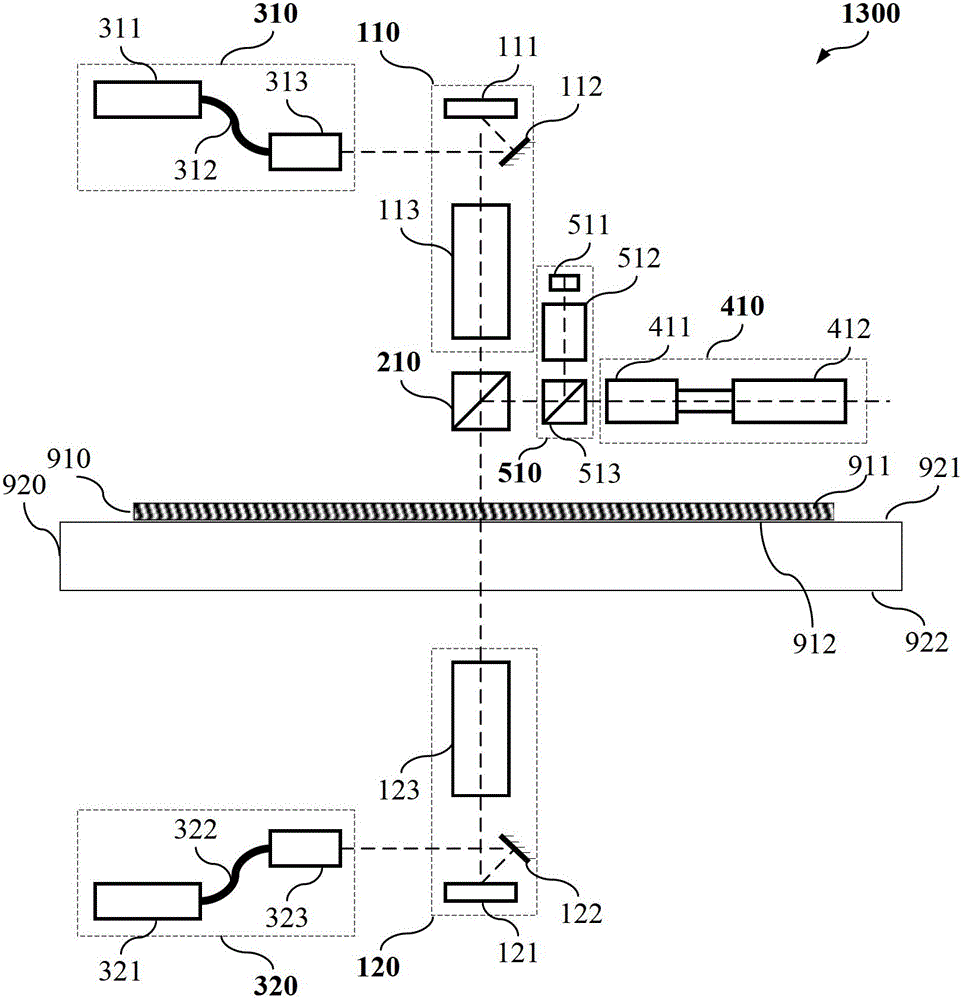

Exposure system, calibration system, optical engines, exposure method, and production method

ActiveCN102944978AImprove exposure qualityGuaranteed Calibration AccuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splittingOptical axis

The invention discloses an exposure system, a calibration system, optical engines, an exposure method, and a production method. The exposure system comprises a first optical engine, a second optical engine; an optical source system, which can be used to provide exposure light beams to the first optical engine and the second optical engine; a first beam splitting device, which is disposed on a first side, and can be used to split the light beams emitted by the first optical engine and the second optical engine; a first visual system, which is disposed on the first side, and can be used to receive the first light beam going through the first optical engine and reflected by the first light splitting device, and can be used to receive the second light beam going through the second light optical engine and reflected by the first light splitting device; and an optical axis, which can be used to calibrate the first optical engine, and the second optical engine. The exposure system, the calibration system, the optical engine, the exposure method, and the production method provided in the utility model can be used to calibrate the optical axis of each of the optical engines, therefore the exposure quality can be improved.

Owner:ZHONGSHAN AISCENT TECH

Exposure machine

InactiveCN103019041AAvoid spotImprove exposure qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringTriangular prism

The invention relates to the technical field of engineering exposure equipment, and discloses an exposure machine. The exposure machine comprises an object-carrying frame and a light source device, wherein a fixing element for fixing the exposed object is arranged at the inner side of the border of the object-carrying frame; and the light source device is located at one side of the plane on which the object-carrying frame is located, and the light-emitting direction is vertical to the plane on which the object-carrying frame is located. During exposure, the object-carrying frame cannot reflect the light ray which penetrates through the exposed object, thus avoiding the stops of an object-carrying stage. Additionally, the exposure machine adopts a vertical exposure mode, and can realize bidirectional exposure only by adding a triangular prism in the existing light source device, thus greatly increasing production efficiency.

Owner:BOE TECH GRP CO LTD +1

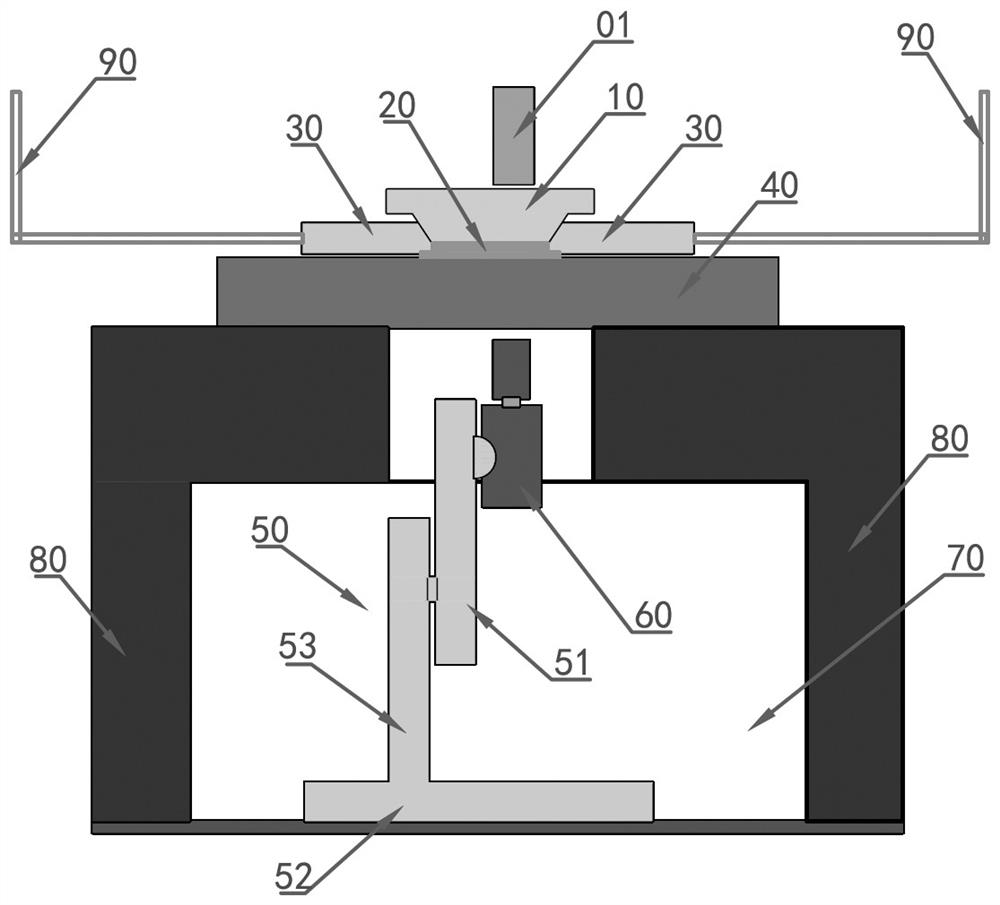

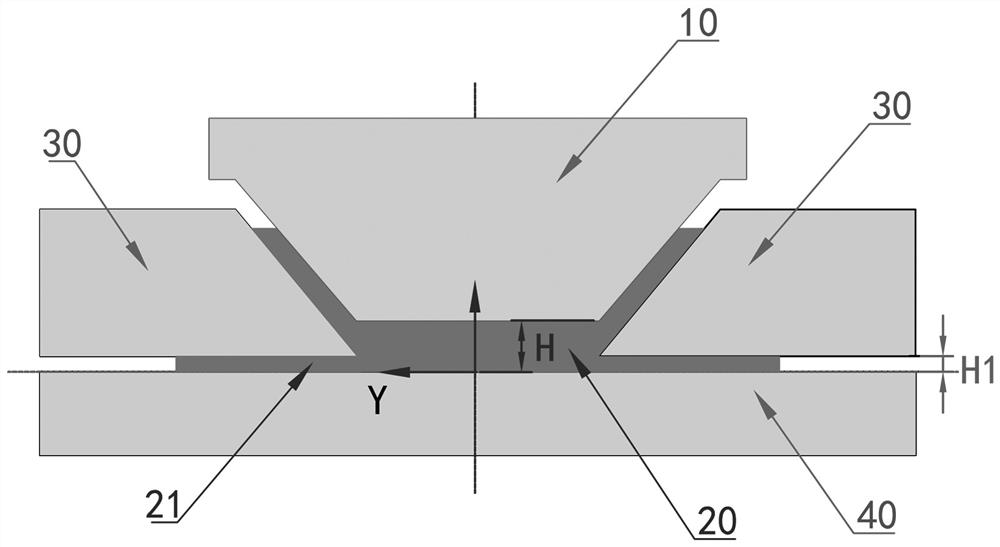

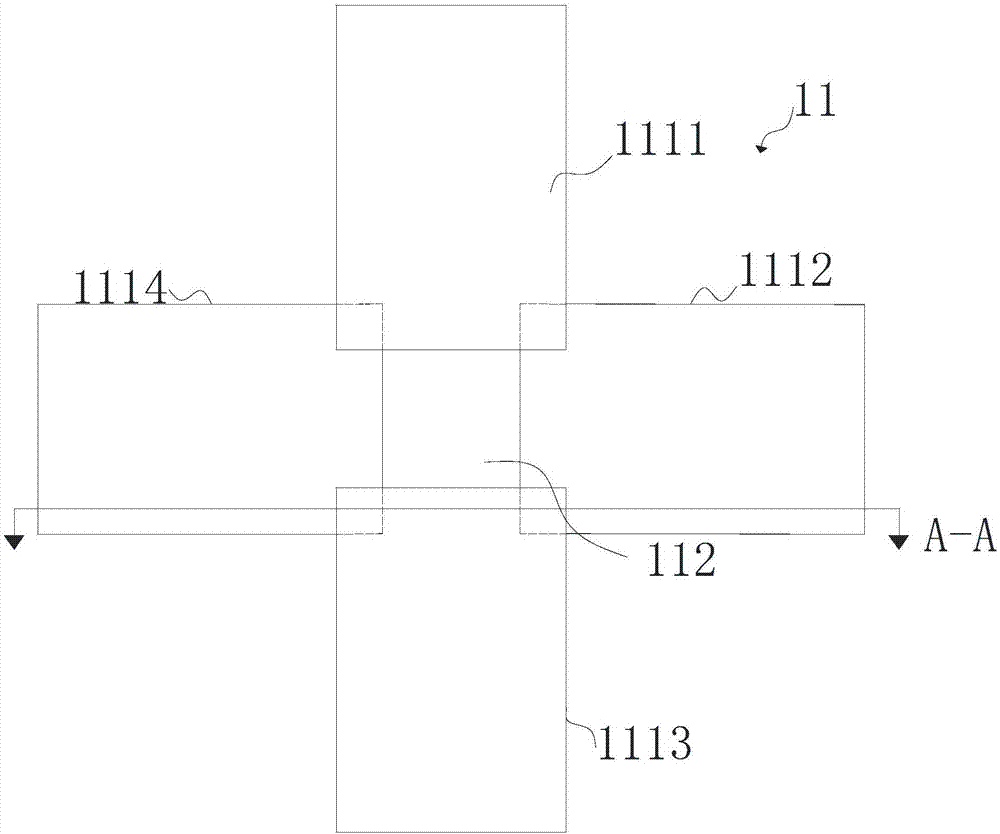

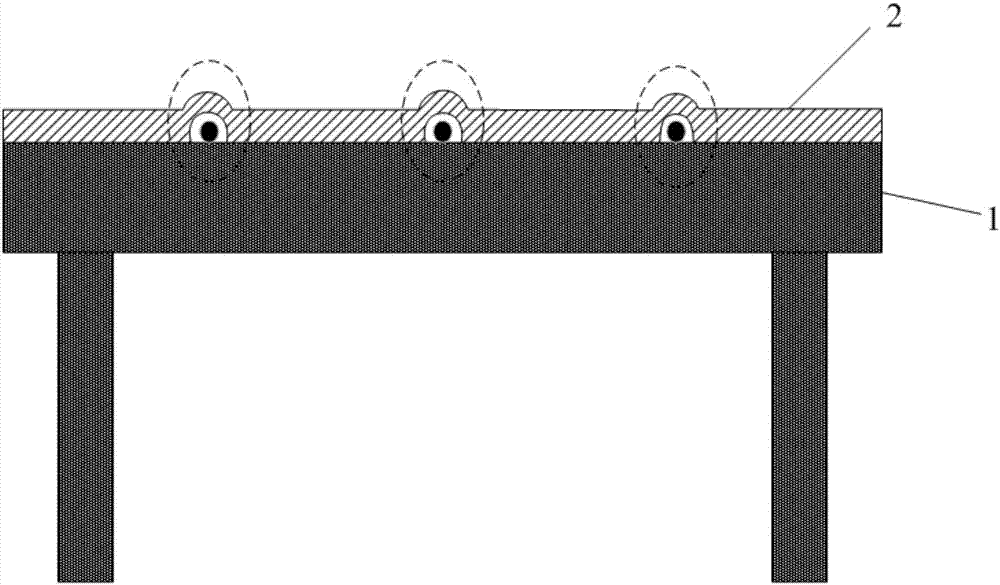

Sucker and method for eliminating wafer exposure defocus defects

ActiveCN104064508AReduce and eliminate warping locationsEliminate exposure out-of-focus defectsSemiconductor/solid-state device manufacturingSuction forceEngineering

The invention provides a sucker and method for eliminating wafer exposure defocus defects. The sucker is flat in upper surface and is used for supporting a wafer. The sucker comprises a plurality of vacuum suction holes and a plurality of thermoelectric couples, the vacuum suction holes are densely distributed in the upper surface of the sucker, all parts of the wafer are absorbed into the same plane by the vacuum suction holes, the thermoelectric couples are densely distributed at the bottom of the sucker, the thermoelectric couples and the vacuum suction holes are alternatively arranged, and the thermoelectric couples are used for heating the wafer. By means of the sucker and method, the thermoelectric couples densely distributed at the bottom of the sucker and the vacuum suction holes densely distributed in the upper surface of the sucker are arranged, the upper surface of the sucker is flat, stress in the wafer is slowly released in the heating process, vacuum suction force, acting on the wafer, of the vacuum suction holes enables the wafer to be attached to the flat upper surface of the sucker, buckling deformation defects of the wafer are accordingly reduced, the surface of the wafer is flattened, the defocus defects in the exposure process are further eliminated, and the exposure quality and the product yield are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

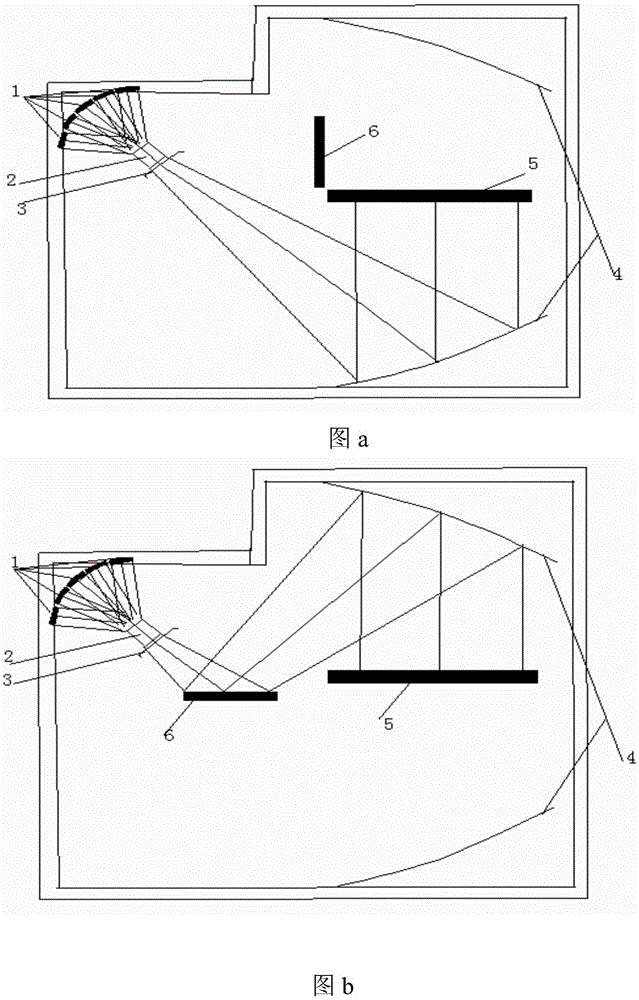

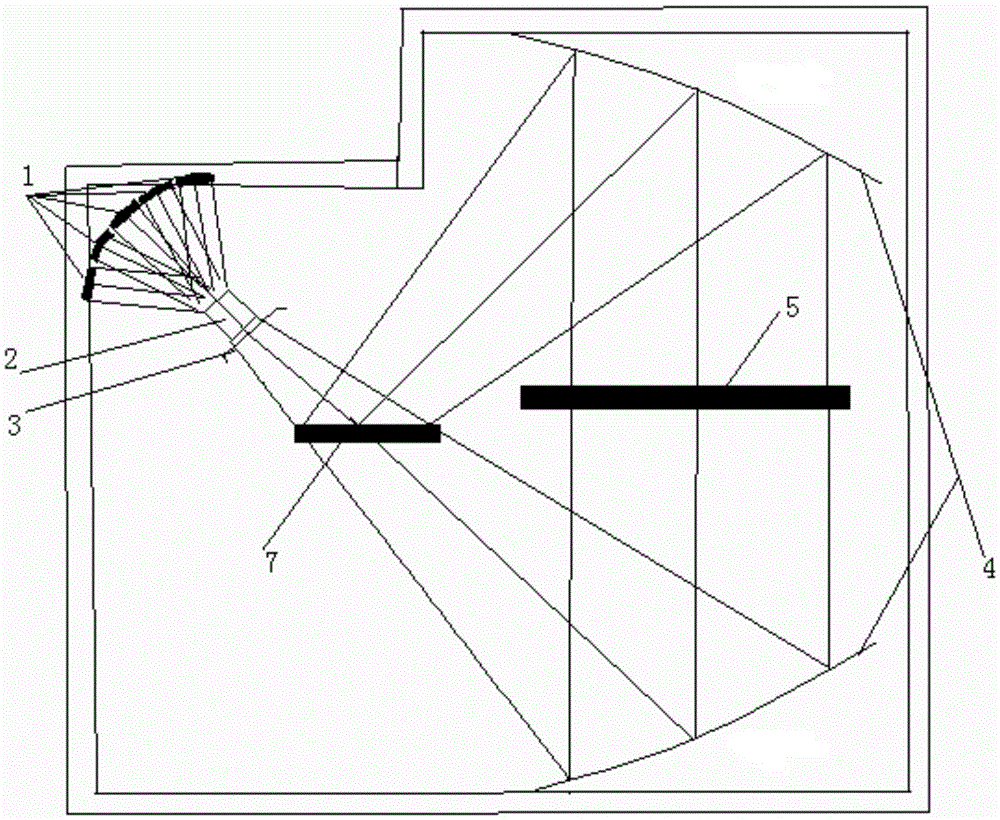

Ultraviolet light exposure system capable of emitting light in parallel and exposure machine

InactiveCN105589302AImprove parallelismImprove uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusUltraviolet lightsPrinted circuit board

The invention relates to the technical field of exposure treatment, and particularly discloses an ultraviolet light exposure system capable of emitting light in parallel. The system comprises a light source module, a condenser, a shutter, a curved mirror, an exposure table and other structures. A two-light-source assembly or a single-light-source assembly is adopted in the ultraviolet light exposure system capable of emitting light in parallel. The invention further provides an exposure machine with the ultraviolet light exposure system capable of emitting light in parallel. According to the ultraviolet light exposure system capable of emitting light in parallel, multiple UV-LED light sources are adopted and all irradiate the condenser, the light focus on the condenser, the UV-LED can emits continuous ultraviolet light, the heat dissipation performance is significantly improved, the parallel light is good in parallelism and high in uniformity, and ultraviolet light transmission is stable and is not affected by external factors, so that the uniformity of the ultraviolet light entering a printed circuit board is ensured, and the exposure quality is improved.

Owner:东莞王氏港建机械有限公司

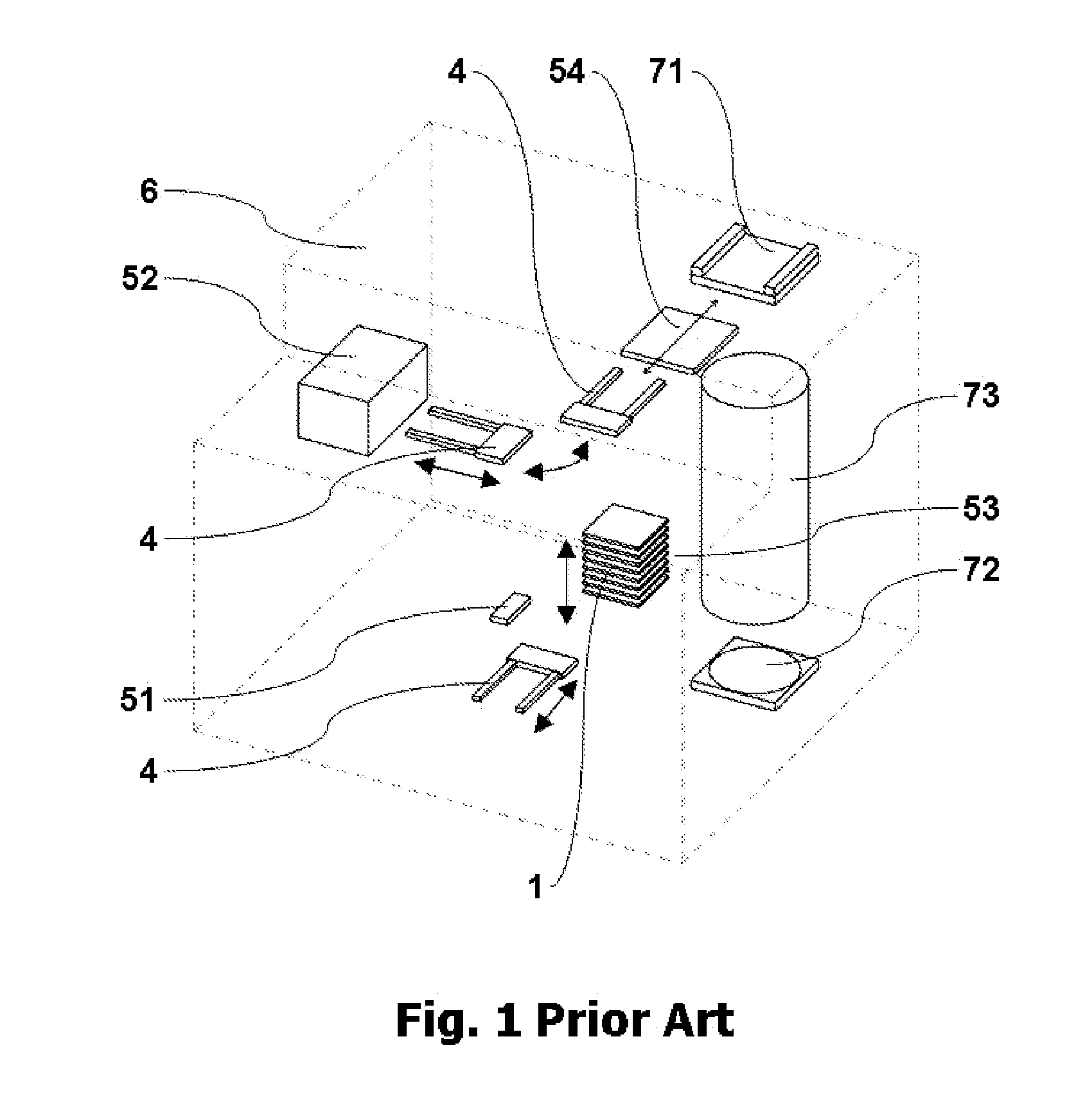

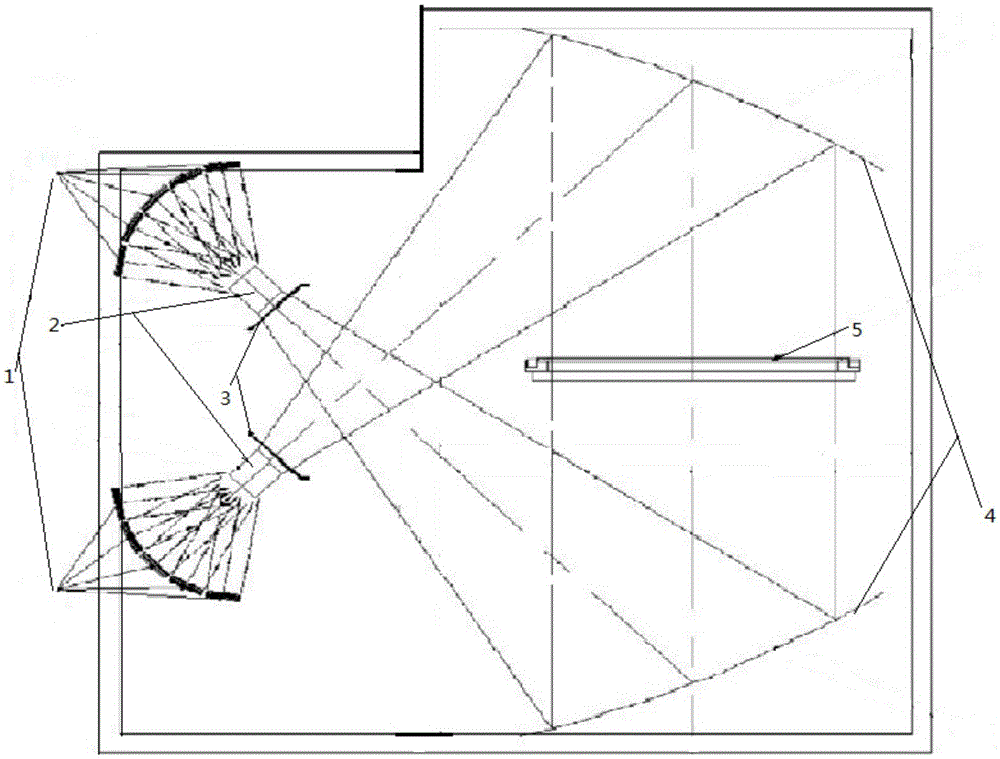

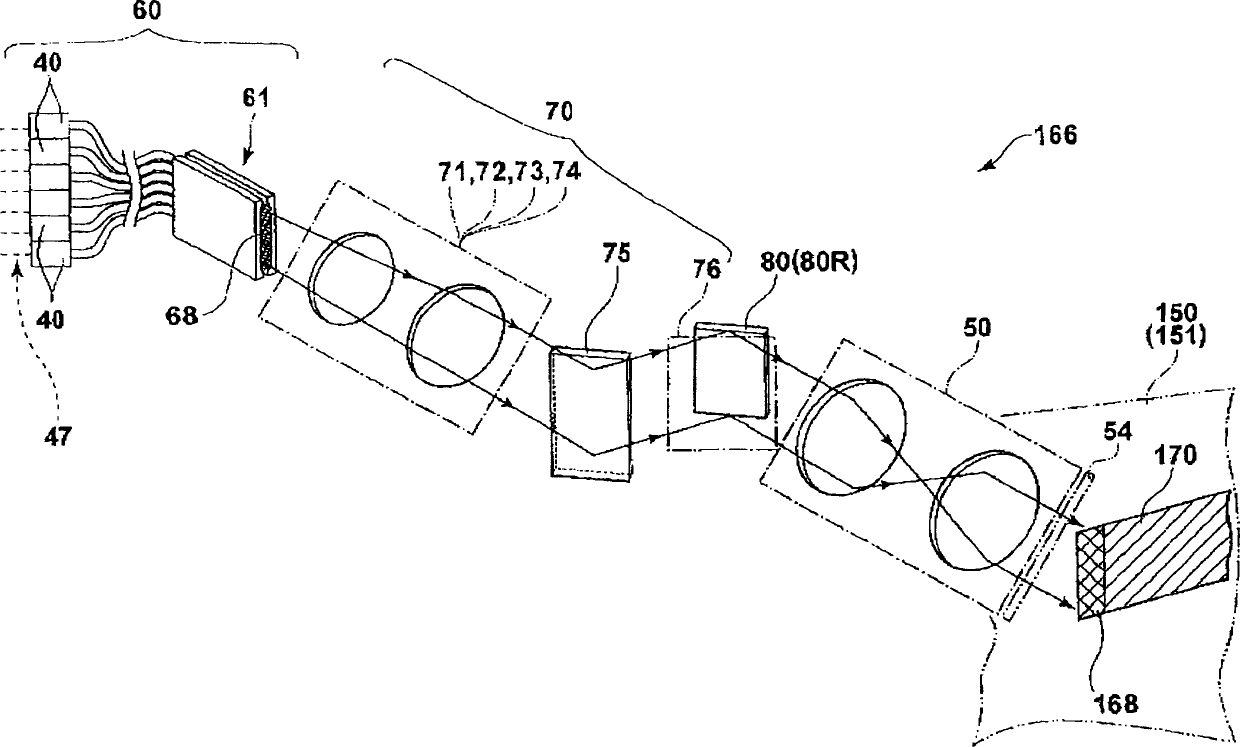

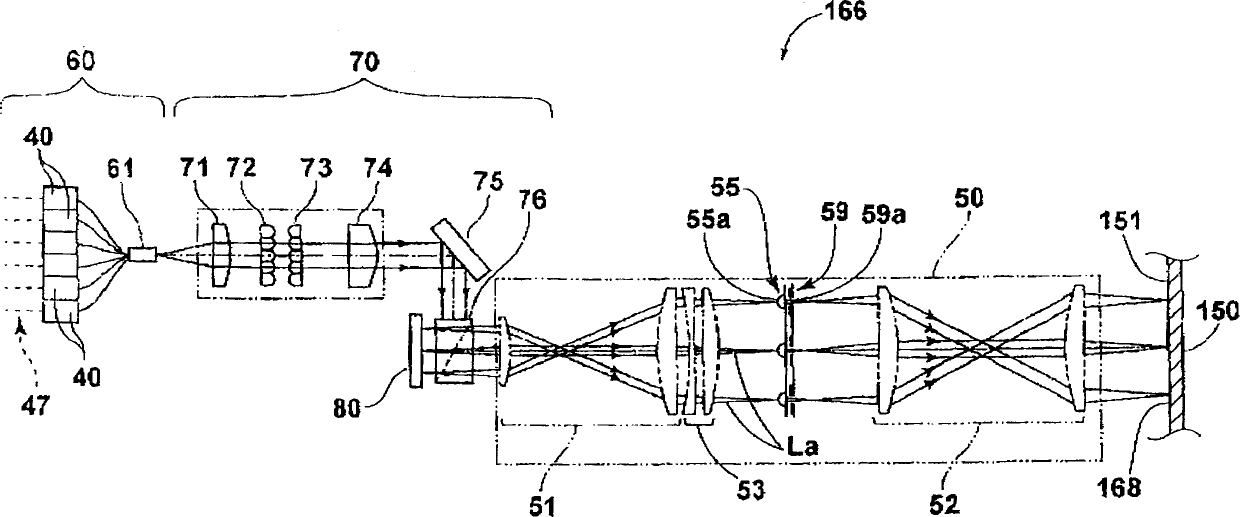

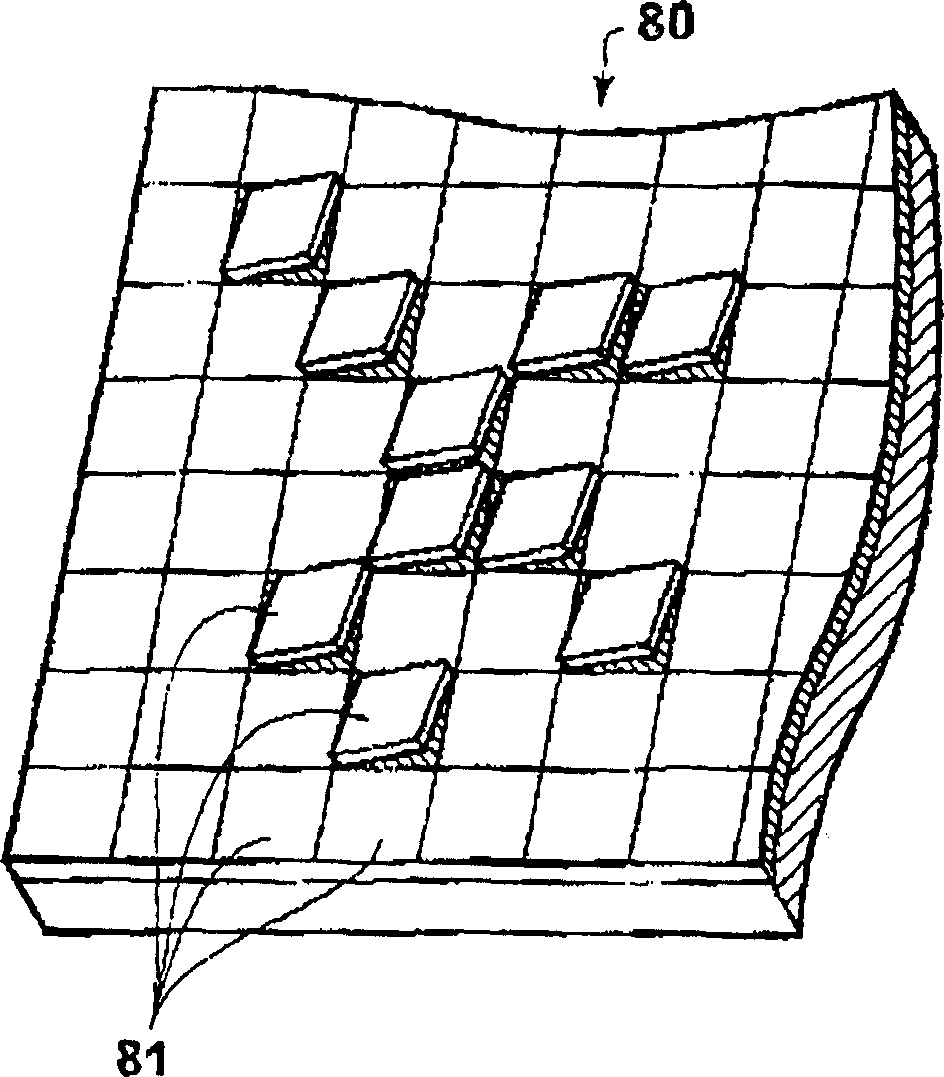

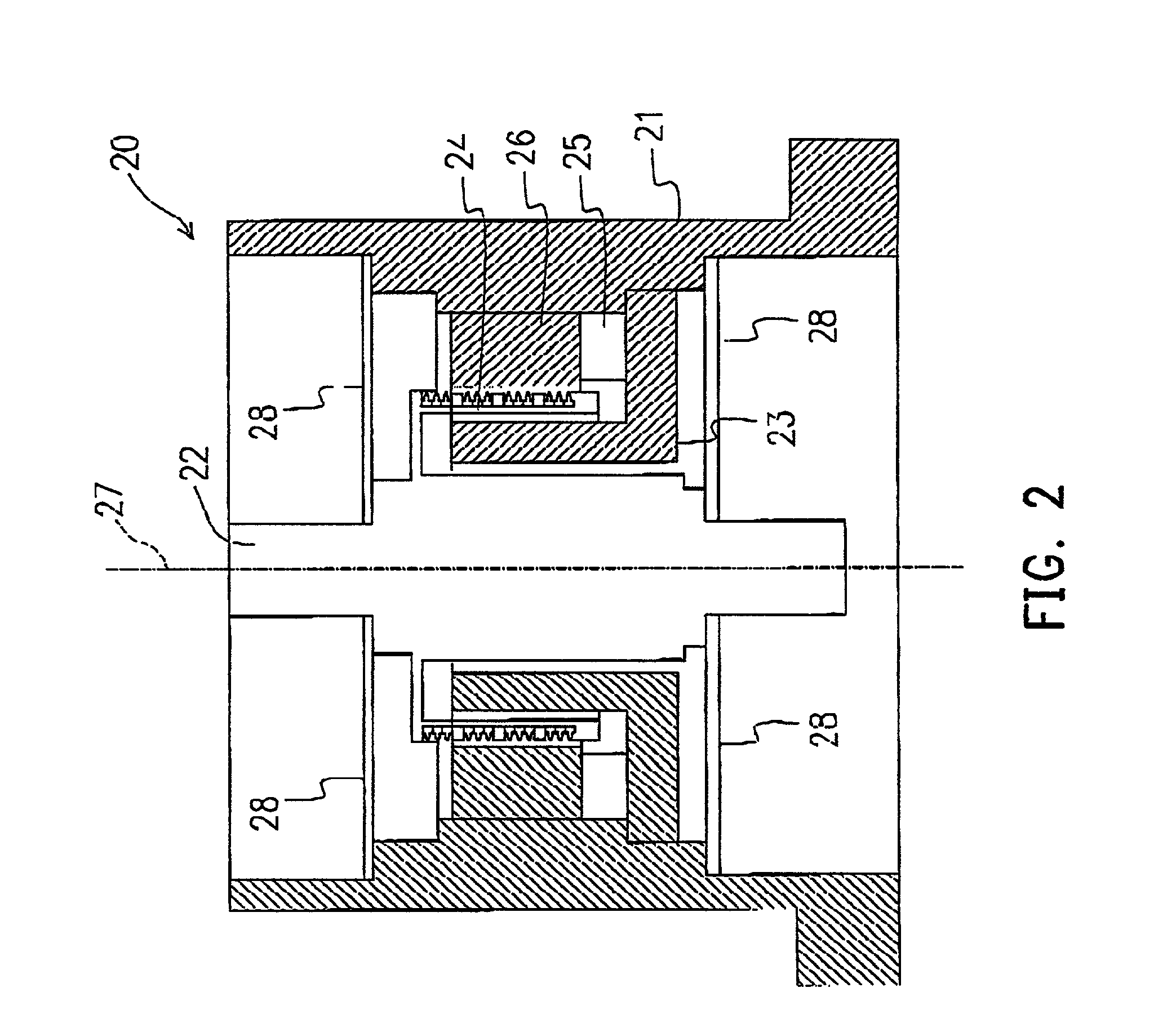

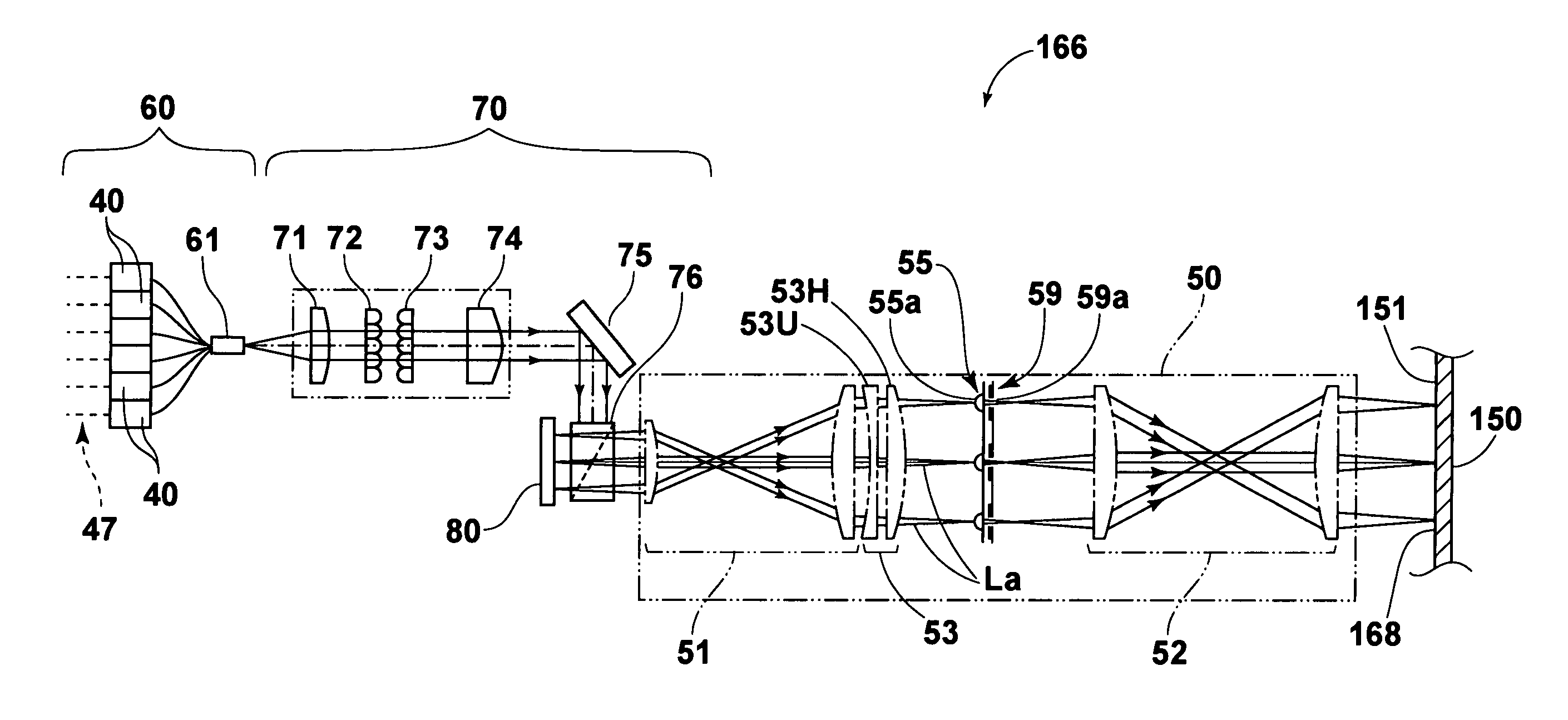

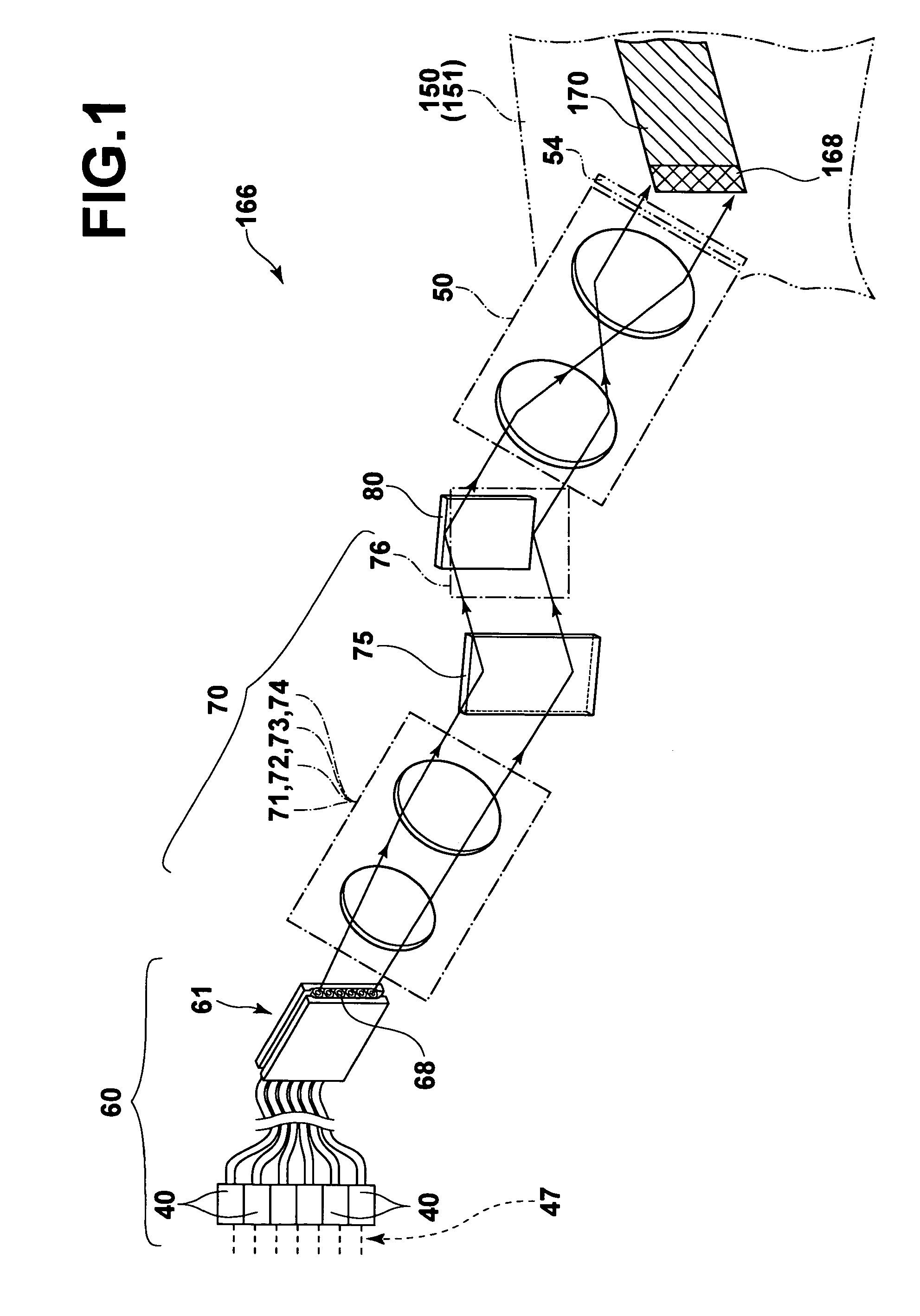

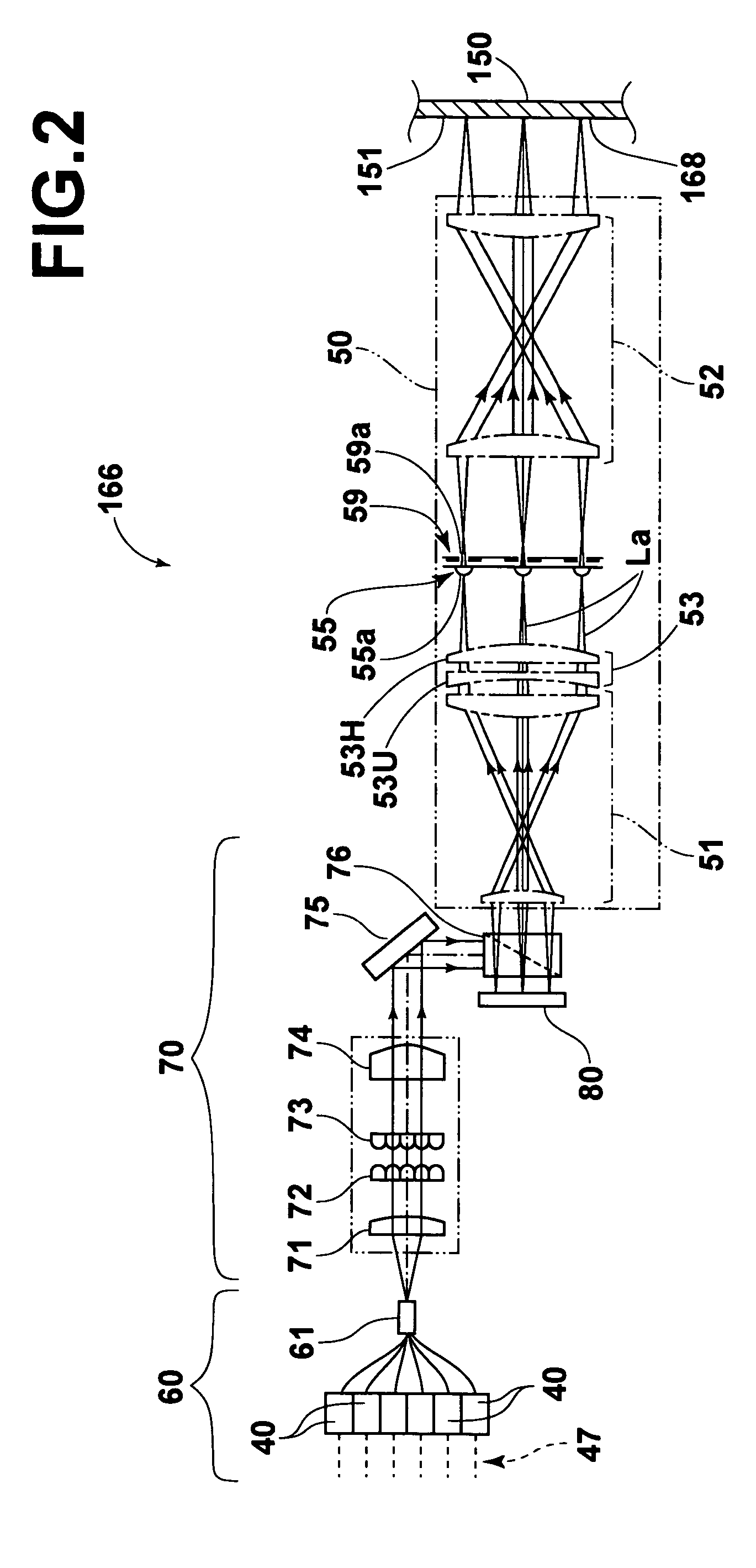

Projecting exposure apparatus

InactiveCN1550874AHigh extinction ratioImprove exposure qualitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage formationMagnification

To obtain a projection aligner in which the extinction ratio of a two-dimensional pattern projected onto a photosensitive material is enhanced. When a two-dimensional pattern of a light spatially modulation through a DMD 80 passes through an image side telecentric first image formation optical system 51 to form an image, magnification of the image is adjusted through a magnification adjusting optical system 53. Subsequently, an incident light emitted from a light source unit 60 and passed through a DMD irradiation optical system 70 is subjected to spatial light modulation through a DMD 80 and a two-dimensional pattern of a light spatially modulation through the DMD 80 is passed through the first image formation optical system 51, the magnification adjusting optical system 53, a microlens array 55, an aperture array 59 and a second image formation optical system 52 before being projected onto a photosensitive material 150 in order to expose the photosensitive material 150.

Owner:FUJIFILM CORP

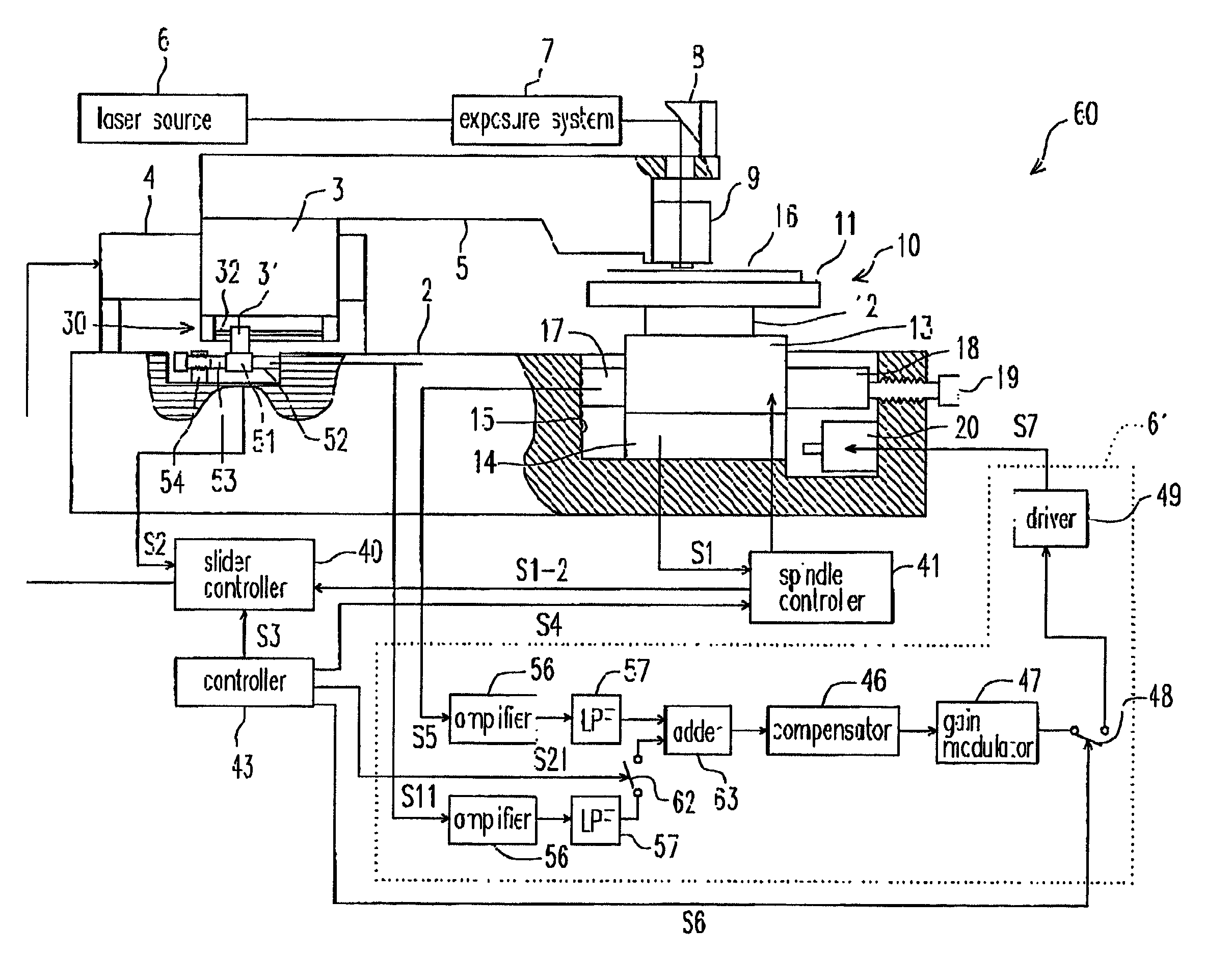

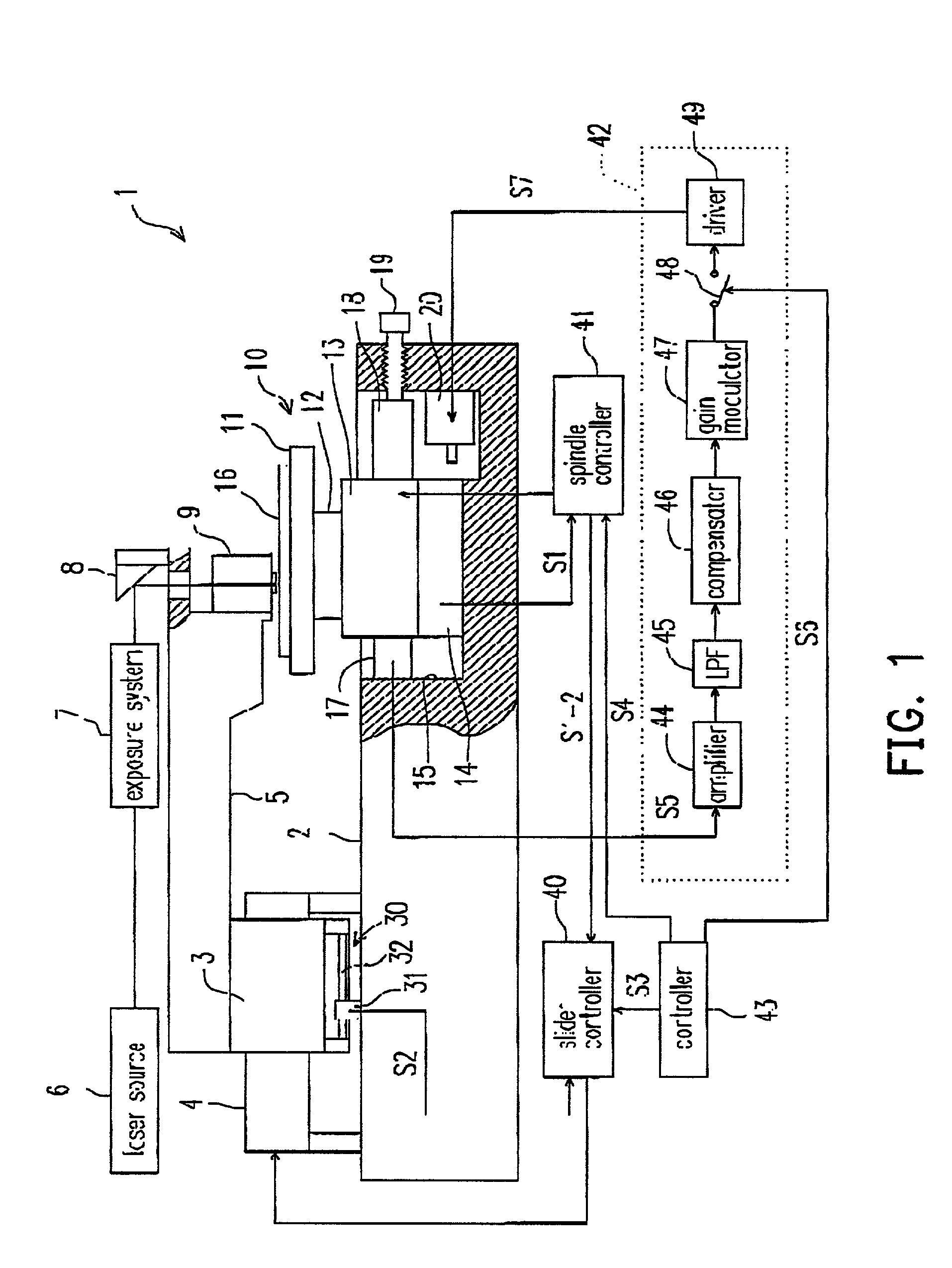

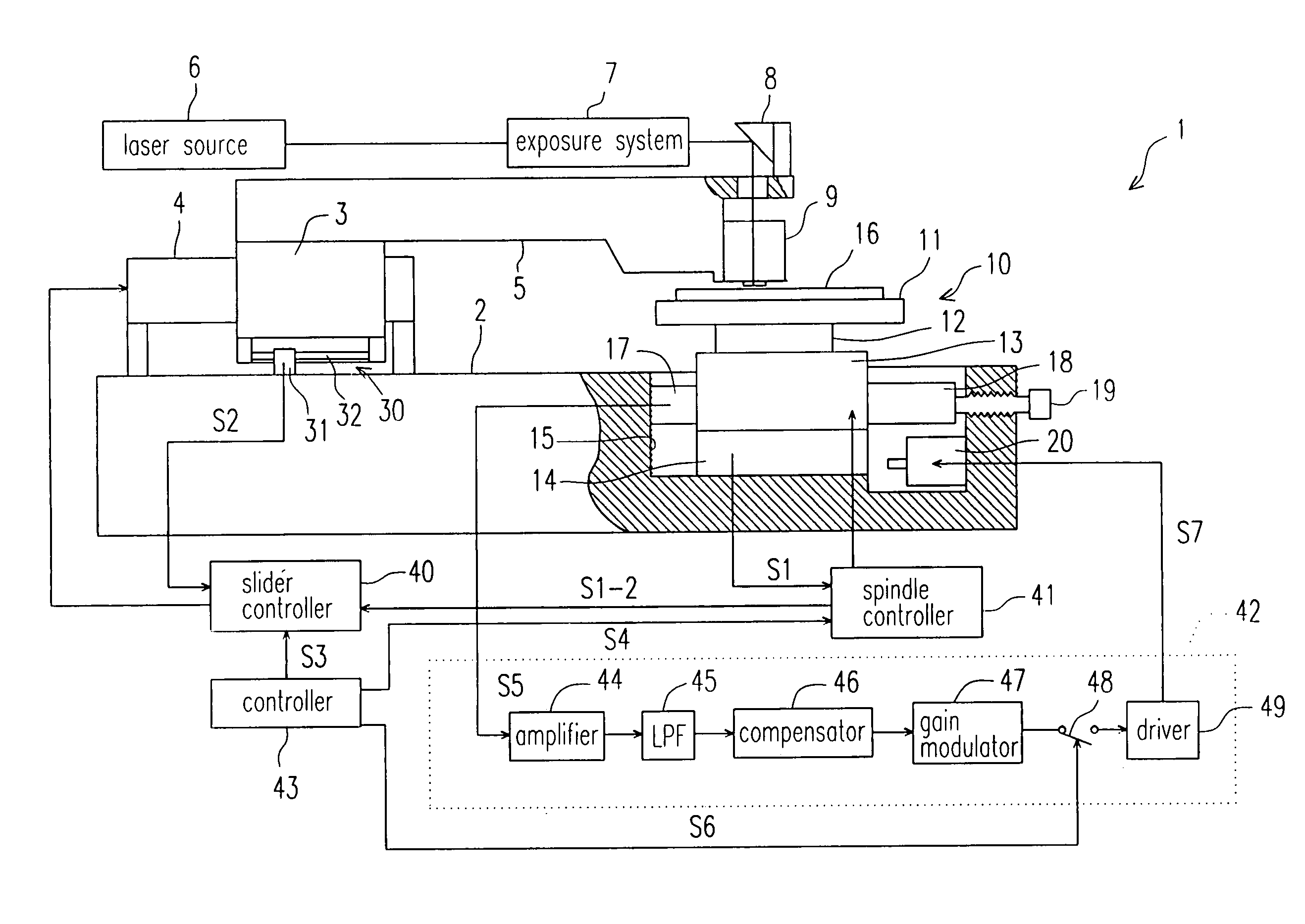

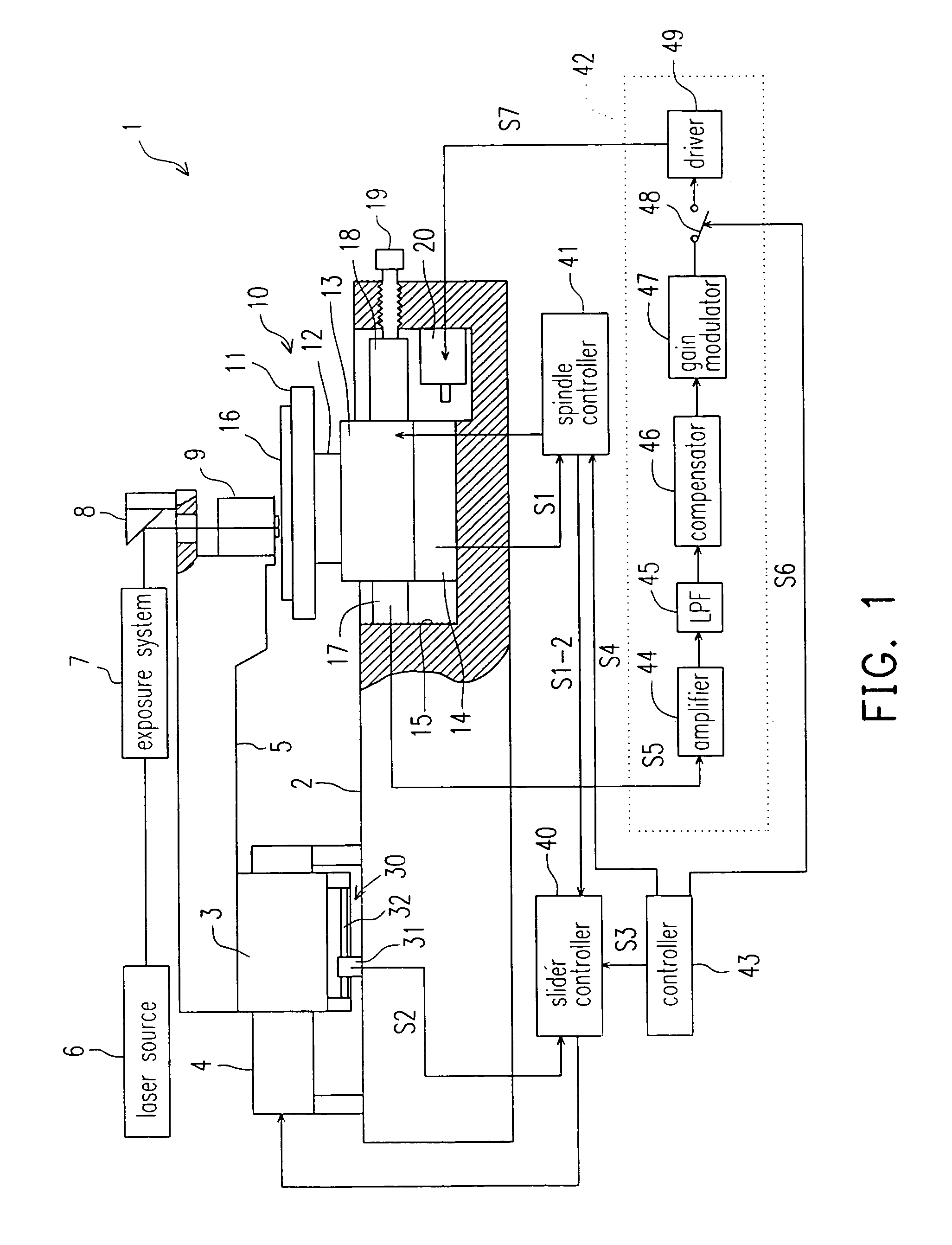

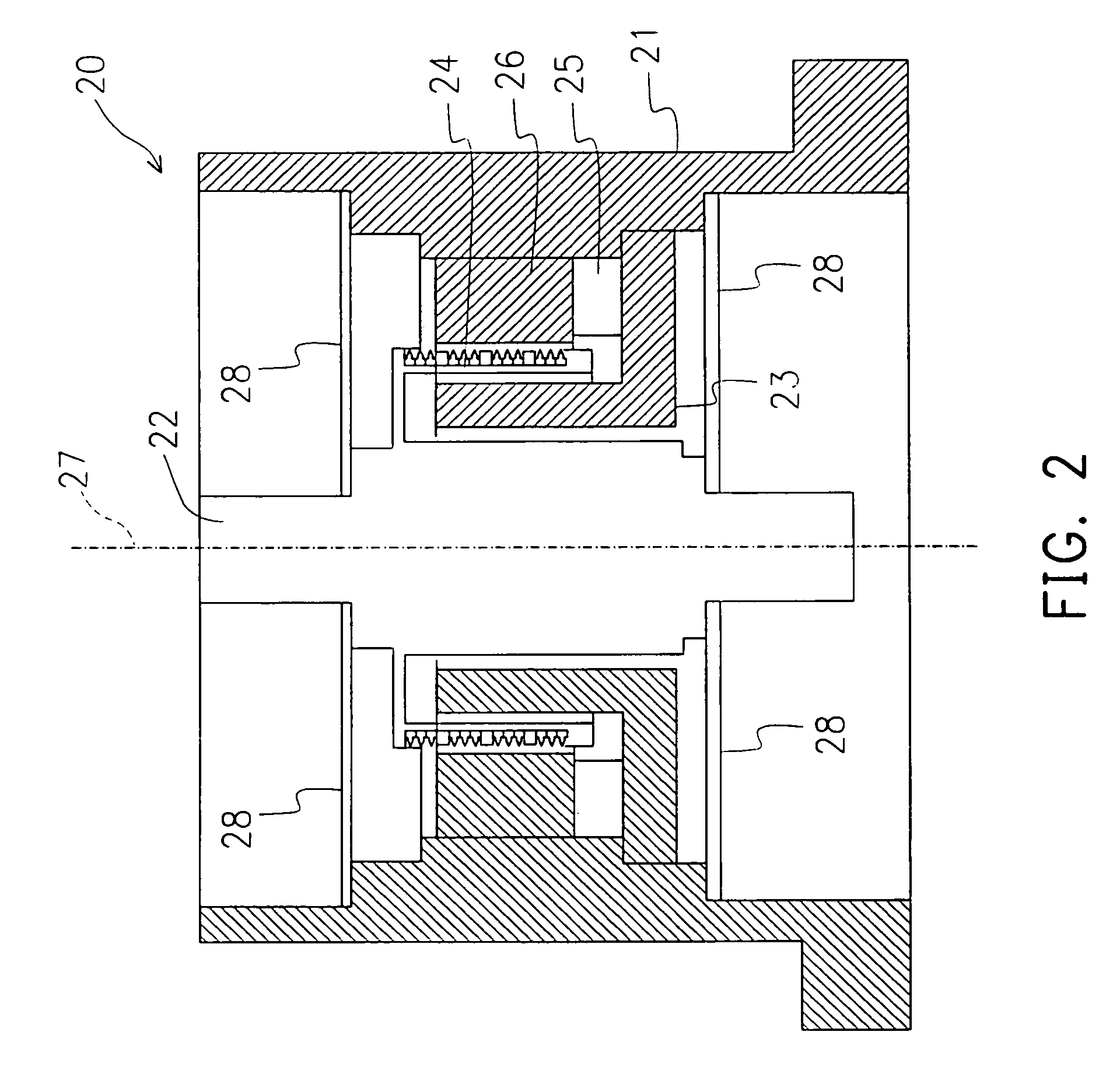

Exposure apparatus for optical disc

InactiveUS20020041549A1Suppress propagating componentImprove accuracyCombination recordingUndesired vibrations/sounds insulation/absorptionRotational vibrationEngineering

An exposure apparatus for an optical disc used for eliminating the vibrations in the propagating direction when a rotation mechanism rotates. The slider controller 40 and the spindle controller 41 of the exposure apparatus 1 are activated, and the then the optical disc begins to be rotated by an AC synchronized motor. Through a condensing device 9, laser beams emitted form the laser source 6 are irradiated on the optical disc for exposure. At this time, the optical disc is eccentrically chucked on the rotation mechanism, resulting a rotational vibration of the whole rotation mechanism. A measurer 17 is used for detecting a propagating component of the rotational vibration, and a vibrator controller 42 controls the vibrator 20 as the output of the measurer 17 approaches zero. Therefore, the vibration in the propagating direction of the base 2 is cancelled, and the propagation accuracy is increased and the exposure quality is enhanced.

Owner:RICOH KK

Substrate adsorption device, photoetching equipment and adsorption method

InactiveCN110119069AImprove exposure qualityImprove yieldSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusChemistryAdsorption method

The invention discloses a substrate adsorption device, photoetching equipment and an adsorption method, the adsorption device comprises an adsorption mechanism and a shaping mechanism arranged opposite to the adsorption mechanism, and a substrate accommodating space is formed between the adsorption mechanism and the shaping mechanism; the adsorption mechanism comprises a sucker, a plurality of suction holes are distributed in the surface of the sucker, and the sucker is used for adsorbing the substrate in the substrate accommodating space from the first side; the shaping mechanism is used foracting on the substrate in the substrate containing space from the second side opposite to the first side so as to be matched with the suction cup to level the substrate in the substrate containing space. According to the embodiment of the invention, the shaping mechanism opposite to the adsorption mechanism is arranged; the adsorption mechanism flattens the substrate through cooperation of the suction holes in the sucker, the adsorption substrate sheet, the shaping mechanism and the sucker, so that the substrate is completely adsorbed on the sucker, flattening and complete adsorption of the substrate with the large warping amount are achieved, the exposure quality and yield of the substrate are improved, and the production efficiency is improved.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

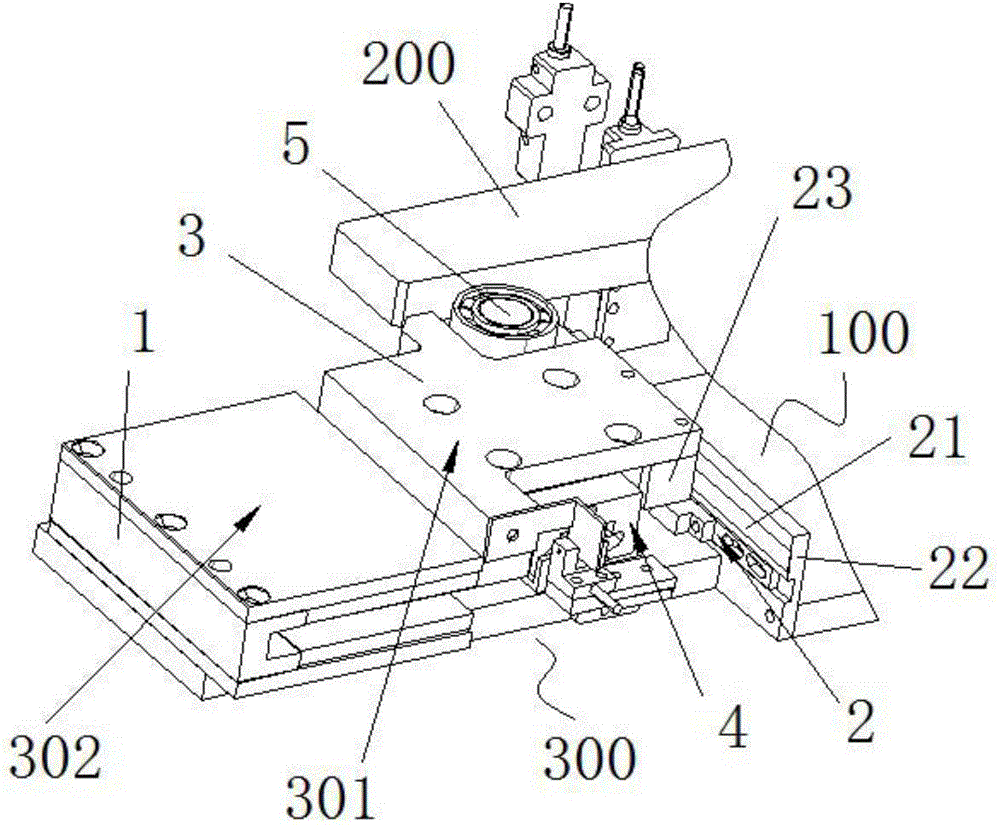

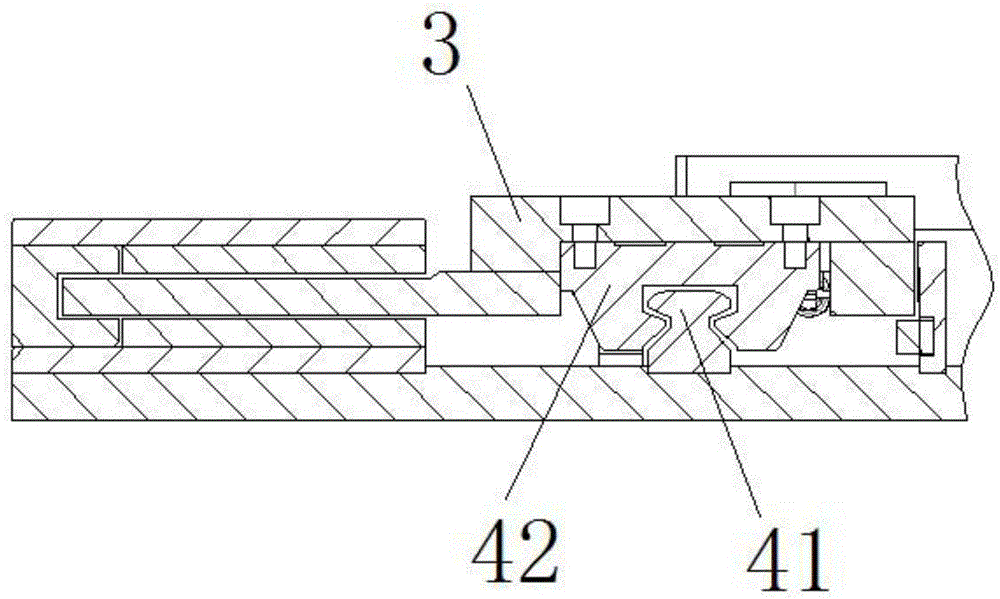

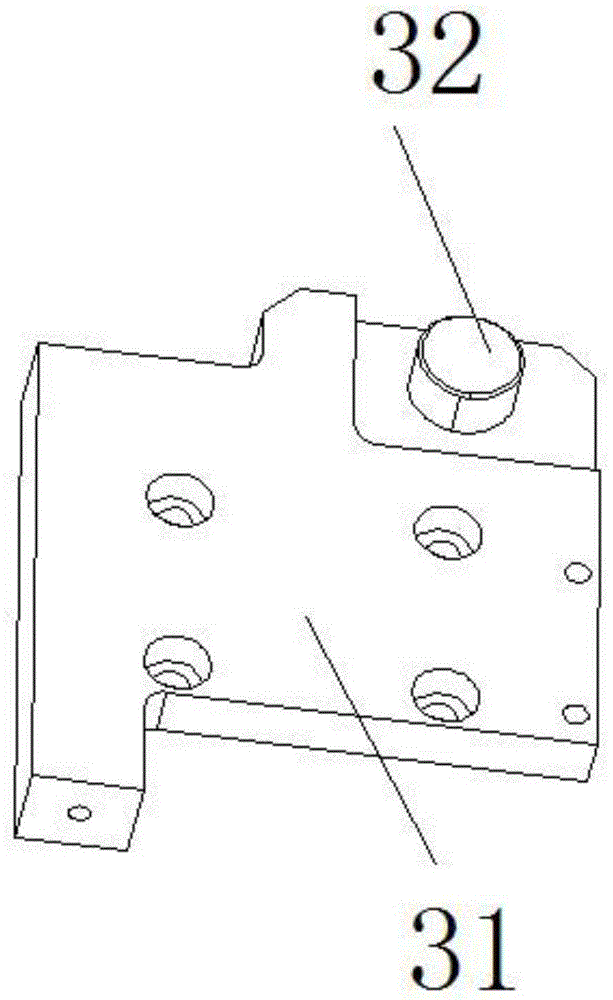

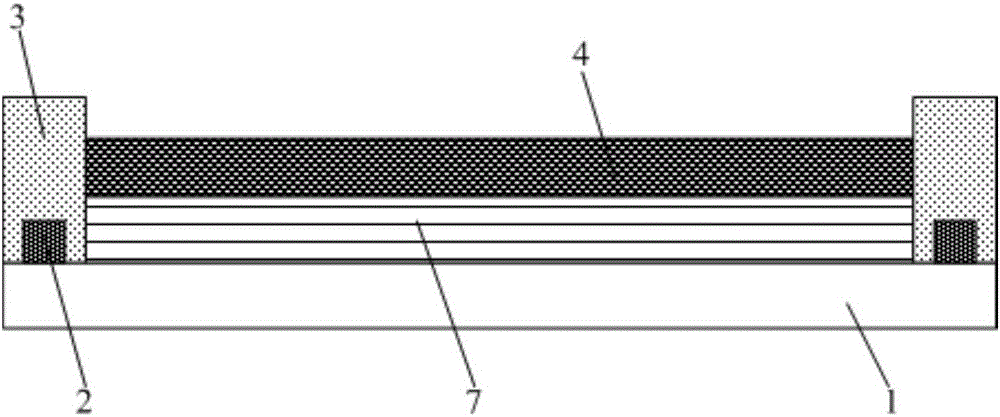

Alignment mechanism and exposure machine with same

ActiveCN104678721AGuaranteed accuracyGuaranteed stabilityPhotomechanical exposure apparatusMicrolithography exposure apparatusGratingControl system

The invention discloses an alignment mechanism. The alignment mechanism comprises a base assembly, an alignment bracket and an angle adjustment device, wherein the angle adjustment device is arranged on the base assembly and comprises a pushing device and a first driving device; the first driving device is used for driving the pushing device to horizontally move and comprises a linear motor assembly and a grating assembly; the grating assembly comprises a grating ruler, a mounting bracket and a grating ruler reading head; the grating ruler reading head is connected with the pushing device and is arranged parallel to the movement direction of the pushing device, the mounting bracket is connected with the base assembly, and the grating ruler is arranged on the mounting bracket. The invention further discloses an exposure machine. The exposure machine comprises an exposure machine main body, a light source device, a control system and the alignment mechanism, wherein the alignment mechanism is mounted on the exposure machine main body. The mounting position of the exposure machine is automatically regulated through the alignment mechanism; the alignment mechanism is simple in structure, good in stability and high in regulation precision.

Owner:浙江欧视电科技有限公司

Array substrate, method for manufacturing same and display device

ActiveCN106054482AImprove exposure qualityImprove performanceNon-linear opticsDisplay deviceComposition process

The invention provides an array substrate, a method for manufacturing the same and a display device. The method for manufacturing the array substrate includes forming alignment mark covering layers in certain regions of a corresponding substrate by the aid of picture composition processes; forming a black matrix film in regions outside alignment marks on the substrate; removing the alignment mark covering layers by means of exposure so as to expose the alignment marks; carrying out picture composition processes on the black matrix film to form patterns of black matrixes. The alignment marks are formed in the certain regions of the corresponding substrate. Exposure wavelengths of the alignment mark covering layers are different from exposure wavelengths of the black matrix film. The array substrate, the method and the display device have the advantages that interference of black matrix films with high optical density (the optical density is usually higher than or equal to 4.0) on alignment mark recognizing, grasping and positioning in exposure procedures can be prevented by the aid of the method, the alignment marks can be accurately aligned by the black matrix film during exposure, accordingly, the exposure precision of the black matrixes can be improved, and the exposure quality and the performance of the array substrate can be enhanced.

Owner:BOE TECH GRP CO LTD +1

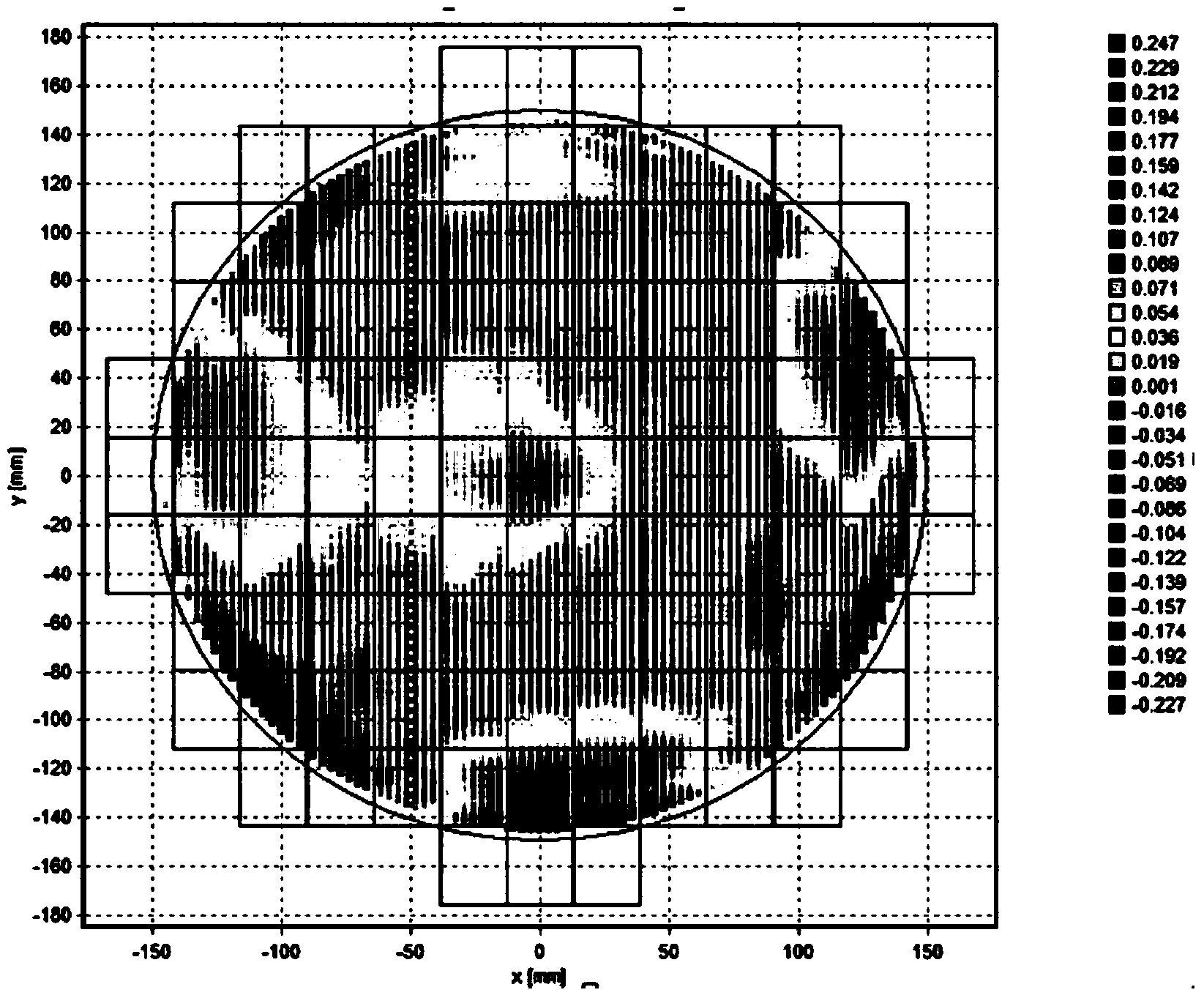

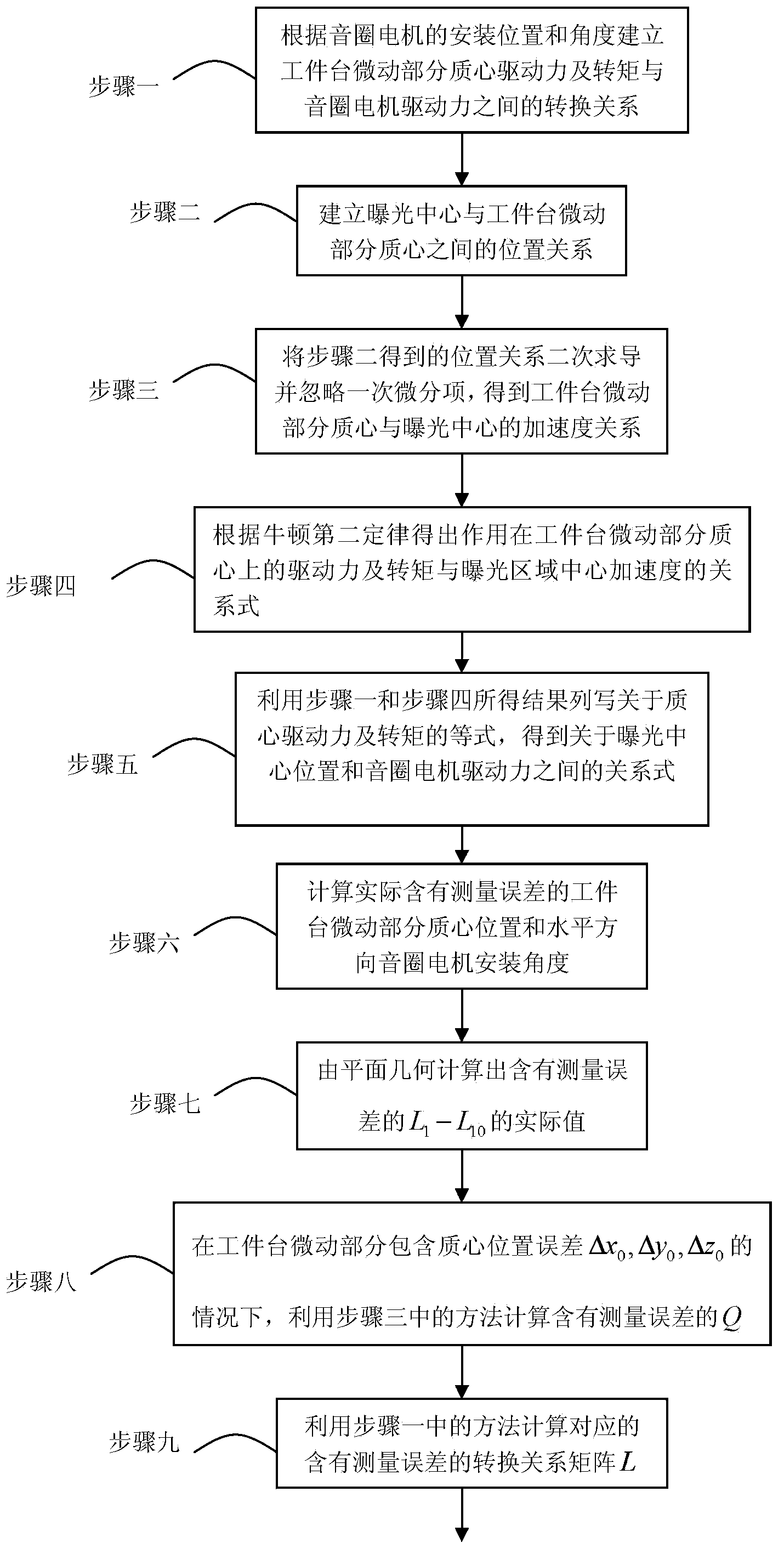

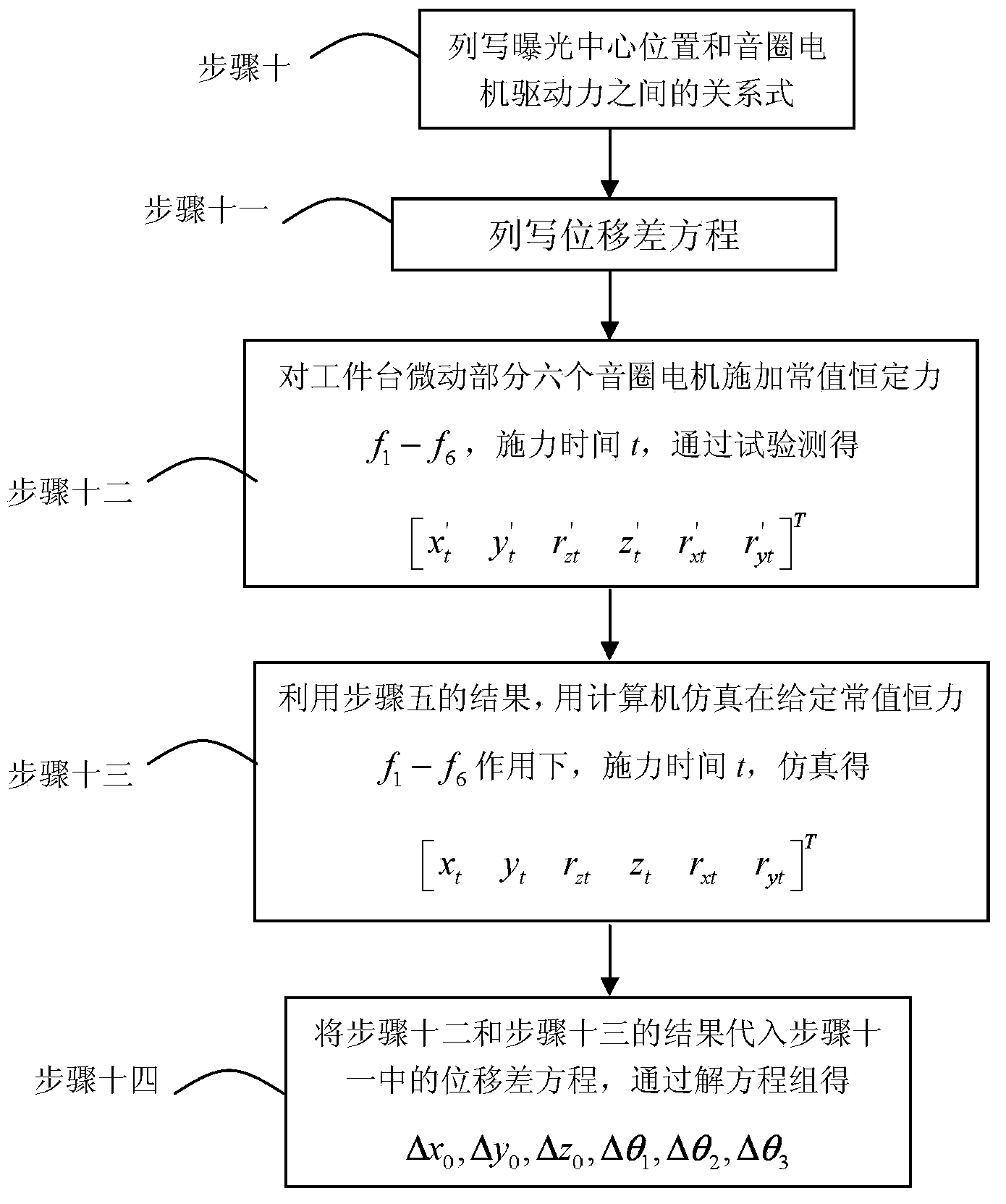

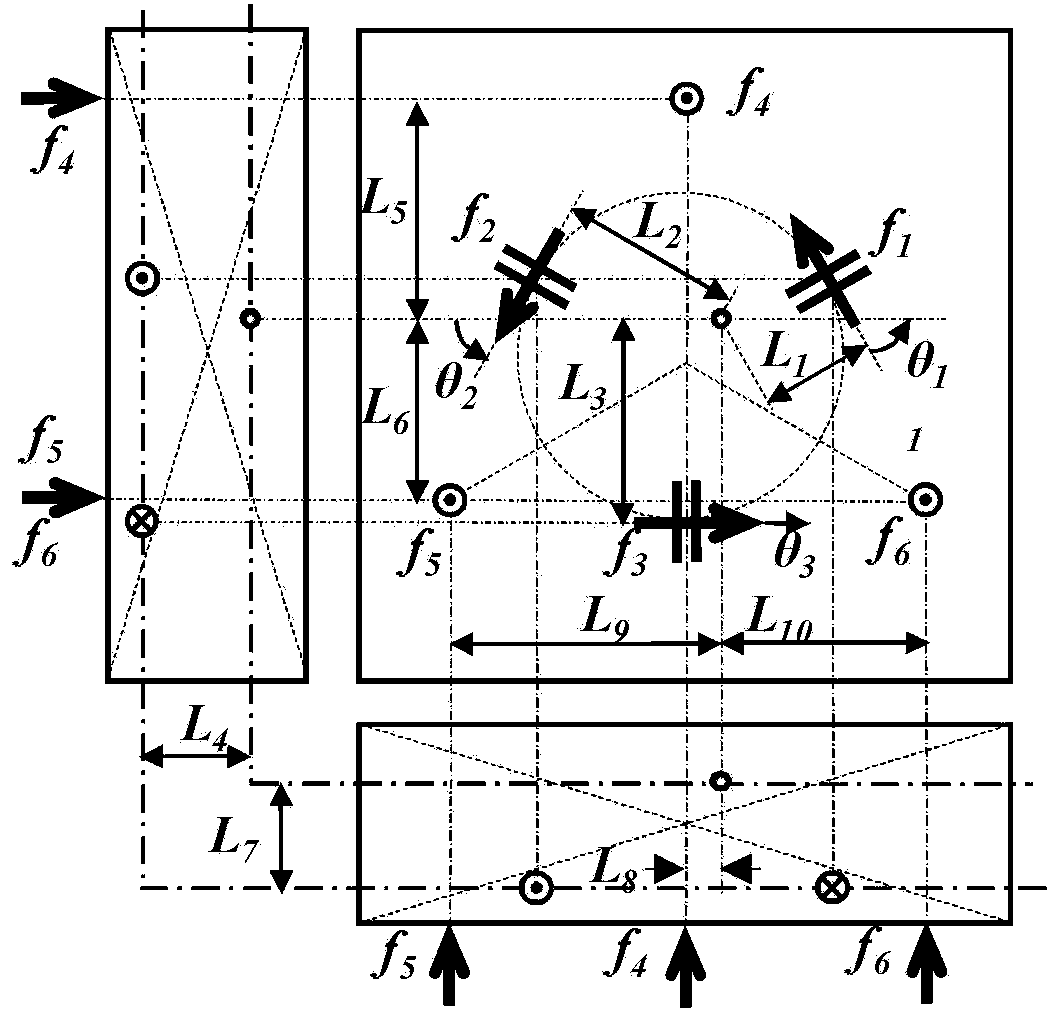

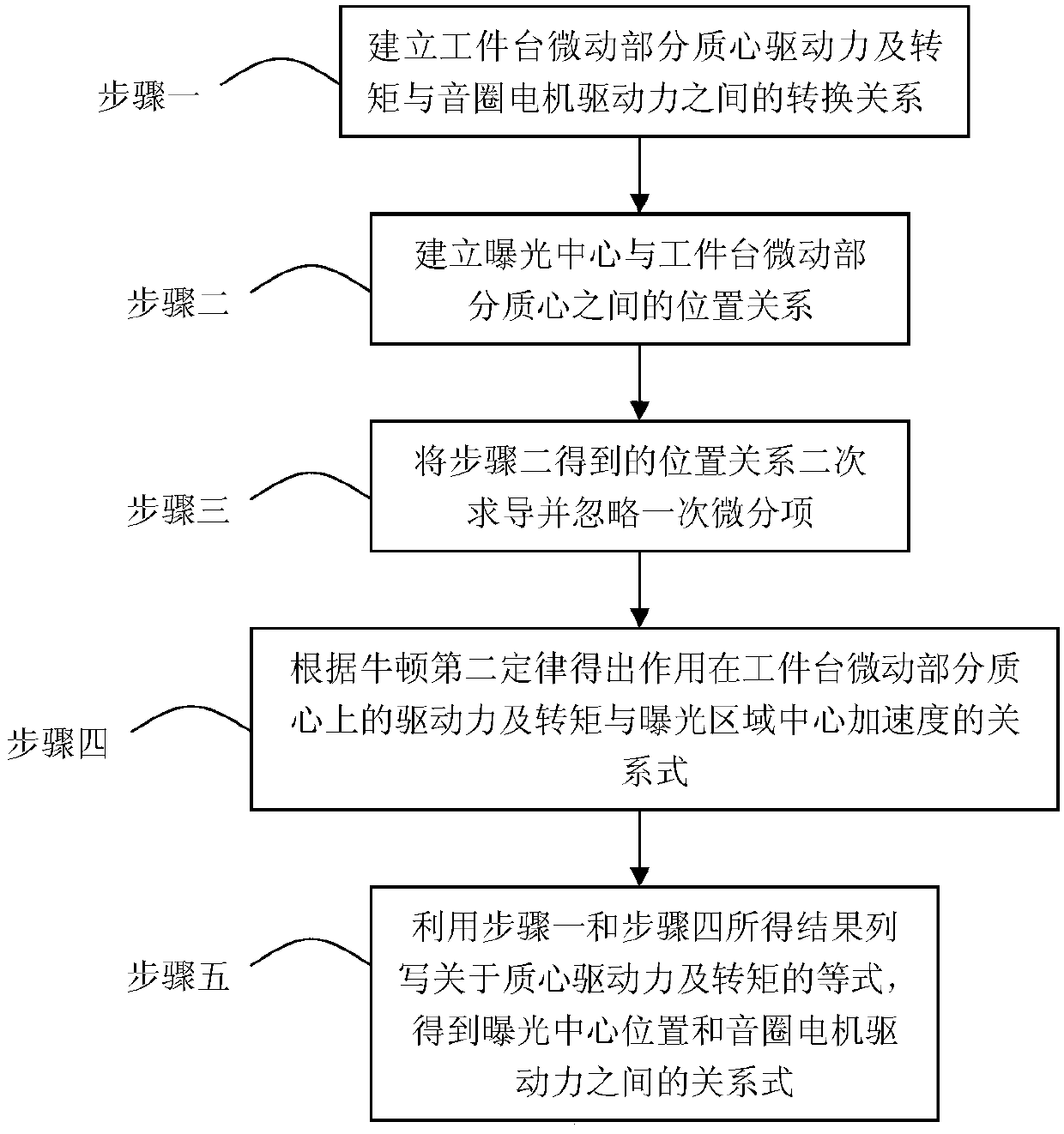

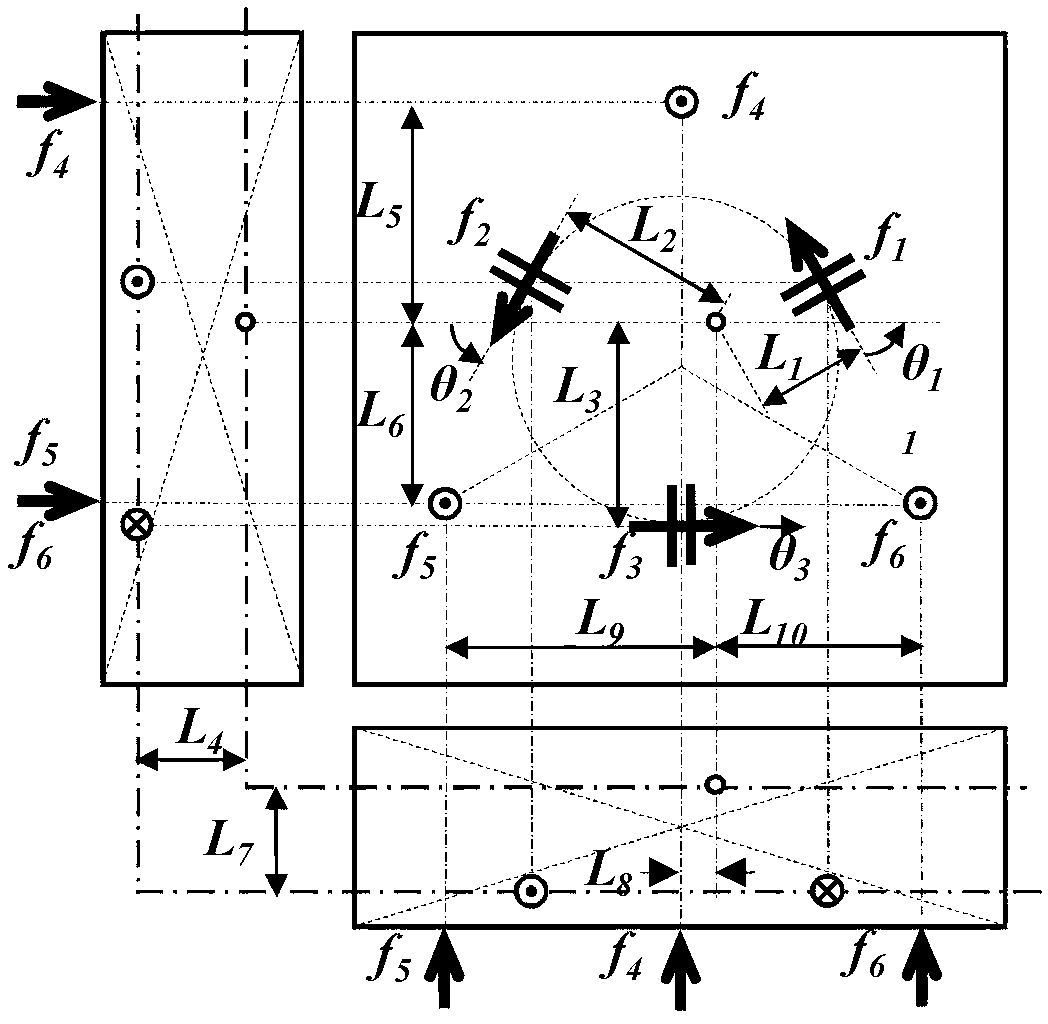

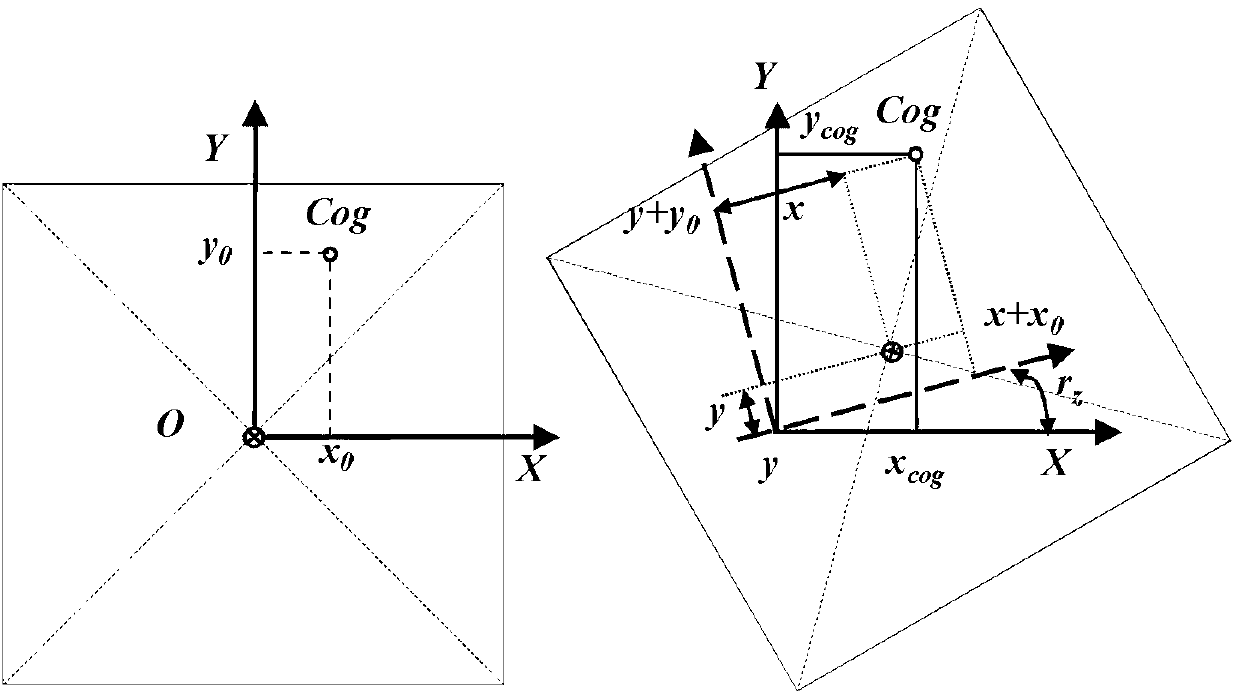

Method for workpiece platform micro moving part mechanical parameter estimation

ActiveCN103366063AImprove exposure qualityHigh movement precisionAerodynamics improvementSpecial data processing applicationsMotor driveSimulation

The invention mainly relates to a method for workpiece platform micro moving part mechanical parameter estimation, and aims to solve the problem that the installation angle and the centroid position of three horizontal voice coil motors of a photoetching machine workpiece platform micro moving part are hard to accurately measure through a traditional precision instrument. The method comprises the following steps: 1. establishing a transformational relation; 2. establishing a positional relation; 3. carrying out a quadratic derivation on the position relation; 4.obtaining a relational expression of the relative driving force and the torque with the exposure area center acceleration; 5. obtaining a relational expression of the exposure center position and the voice coil motor driving force; 6. setting the actual centroid position and installation angle; 7. obtaining an actual value of L1 to L10 through a plane geometry relation; 8. calculating the actual Q by utilizing the method in step 3; 9. calculating the actual L by utilizing the method in step 1; 10. establishing an error model; 11.listing a displacement difference equation; 12. measuring to obtain [ x't, y't, r'zt, z't, r'xt,r'yt] <T> through an experiment; 13. emulating to obtain [ xt, yt, rzt, zt, rxt,ryt] <T>; 14. solving the equation set to obtain delta x0, delta y0, delta z0, delta theta 1, delta theta 2 and delta theta 3. The invention belongs to the field of super-precision manufacturing.

Owner:HARBIN INST OF TECH

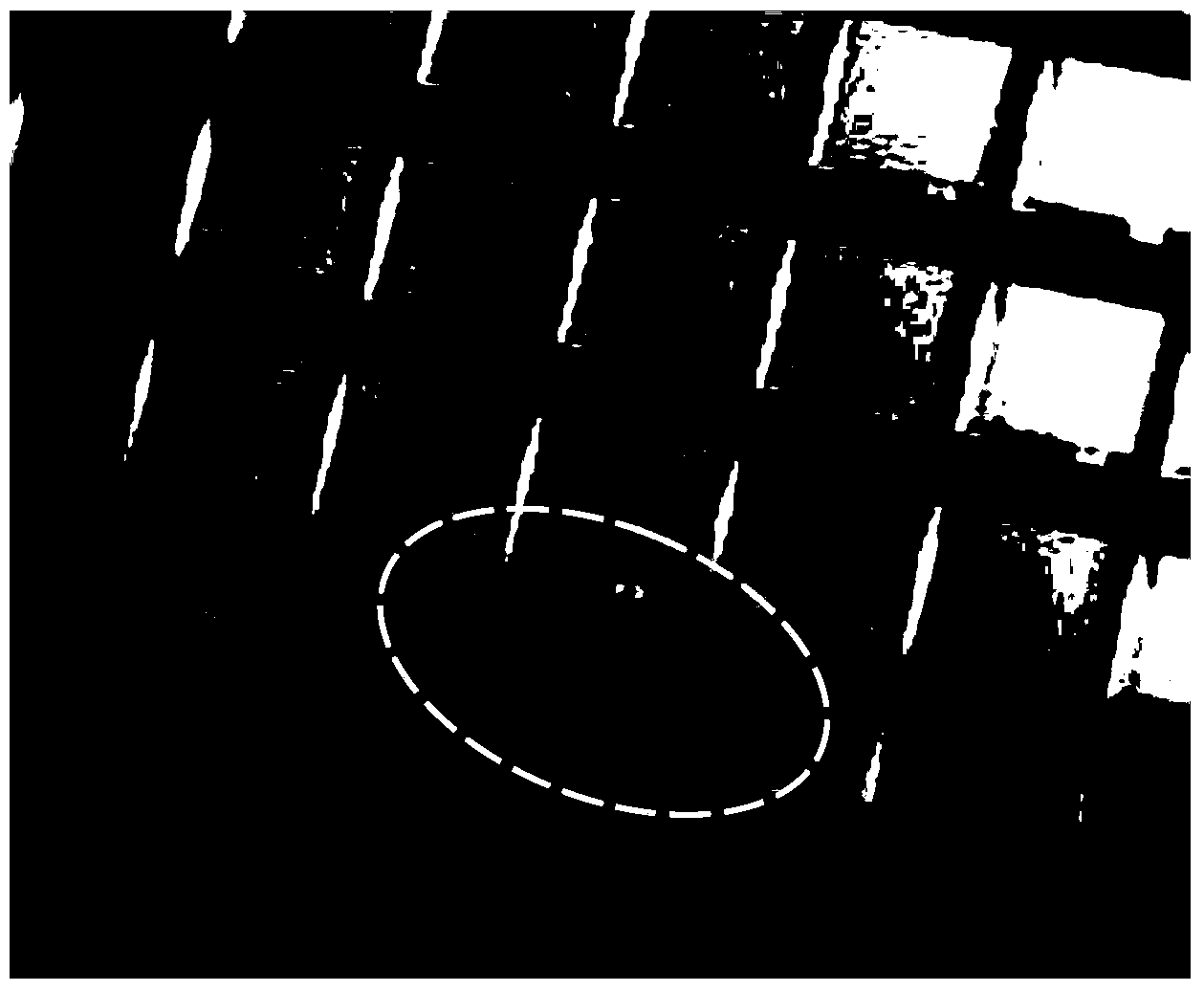

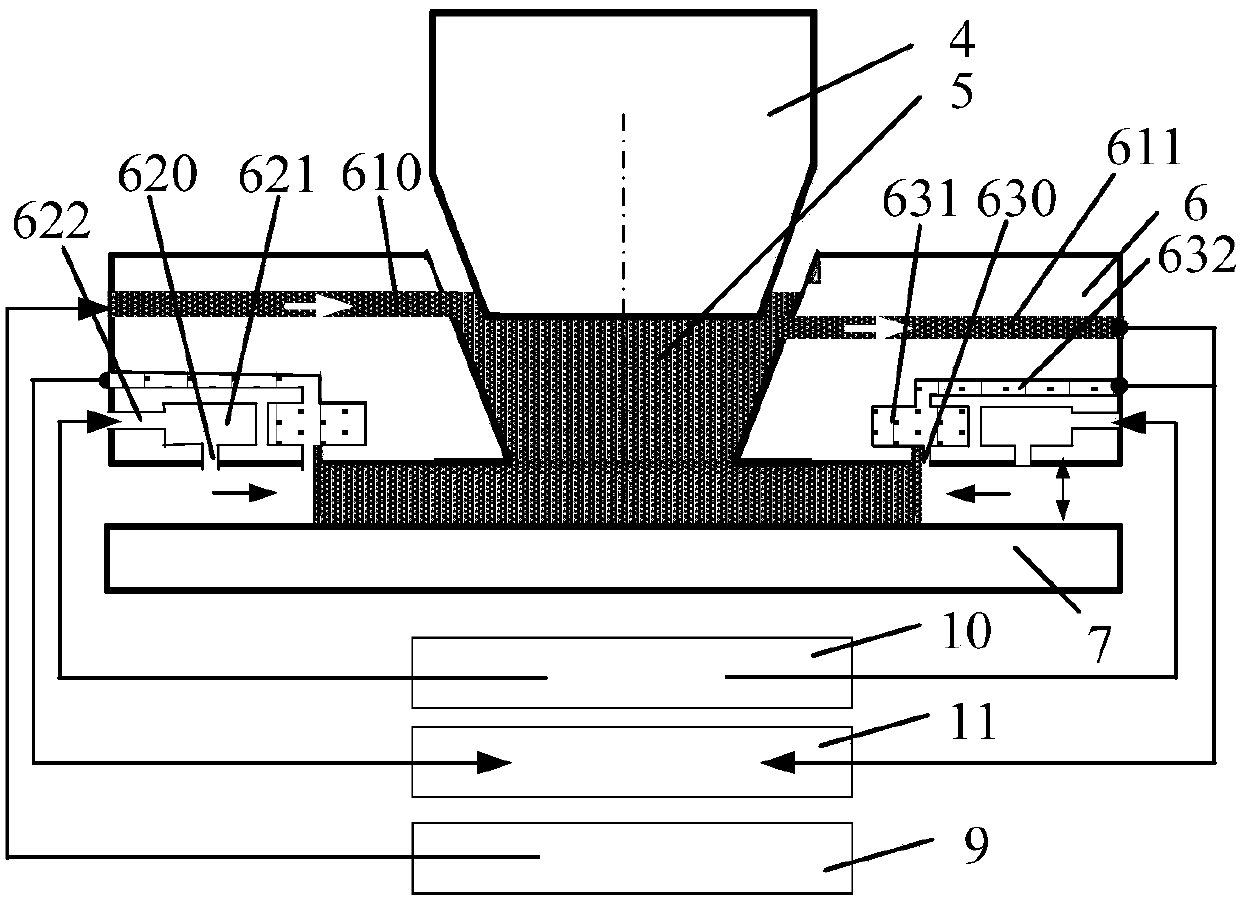

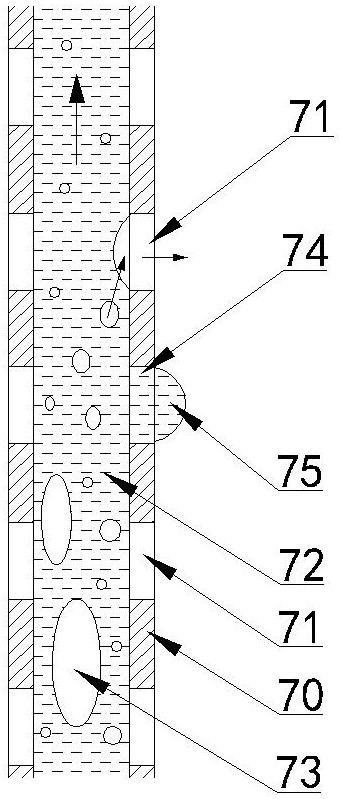

Tool and method for detecting tiny bubbles in immersion flow field of immersion lithography machine

PendingCN111830795AEfficiently obtainedReduce or avoid lossOptically investigating flaws/contaminationPhotomechanical exposure apparatusCamera lensEngineering

The invention discloses a tool and a method for detecting tiny bubbles in an immersion flow field of an immersion lithography machine, and the tool comprises an immersion flow field maintenance system, a photographing system, and a camera pose adjustment system, and the photographing system comprises a photographing camera, a camera lens, and a photographing light source. The camera pose adjustment system is used for adjusting motion adjustment of the shooting camera in the X-axis, Y-axis or Z-axis direction, and the Z-axis is used for realizing focusing and layered scanning motion of the shooting camera. The photographing light source is arranged above the simulation objective lens and used for providing a backlight source for bubble detection in the immersion flow field, the photographing camera and the camera lens are arranged below the simulation silicon wafer and located below the immersion flow field, and the photographing camera is arranged on the camera pose adjustment system.Image data processing is carried out on the shot images, and the bubble size and position on each image are detected. The global image of the whole flow field at the same moment is more effectively obtained, the phenomenon of bubble loss during detection is reduced or avoided, and the final photoetching exposure quality is improved.

Owner:ZHEJIANG CHEER TECH CO LTD

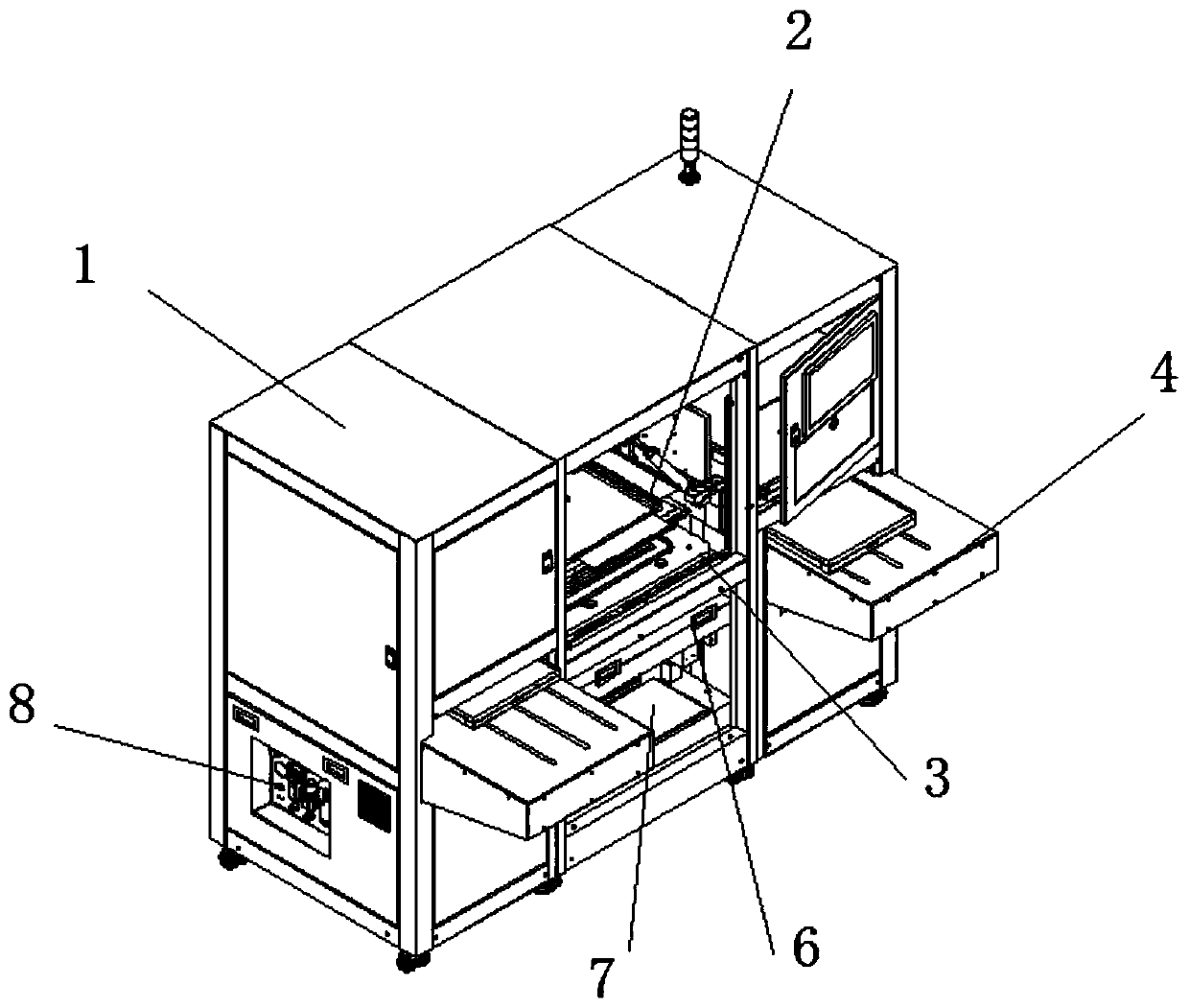

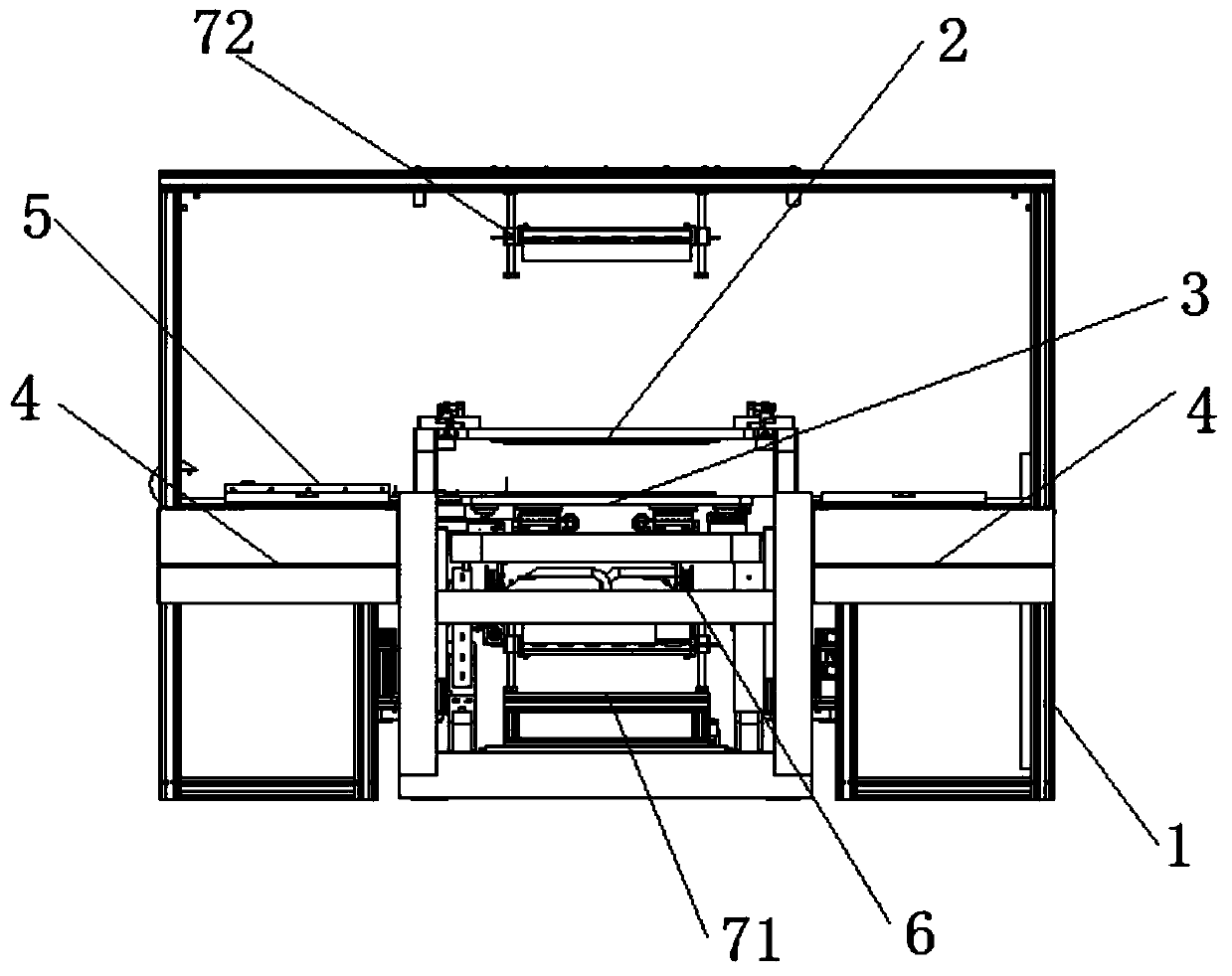

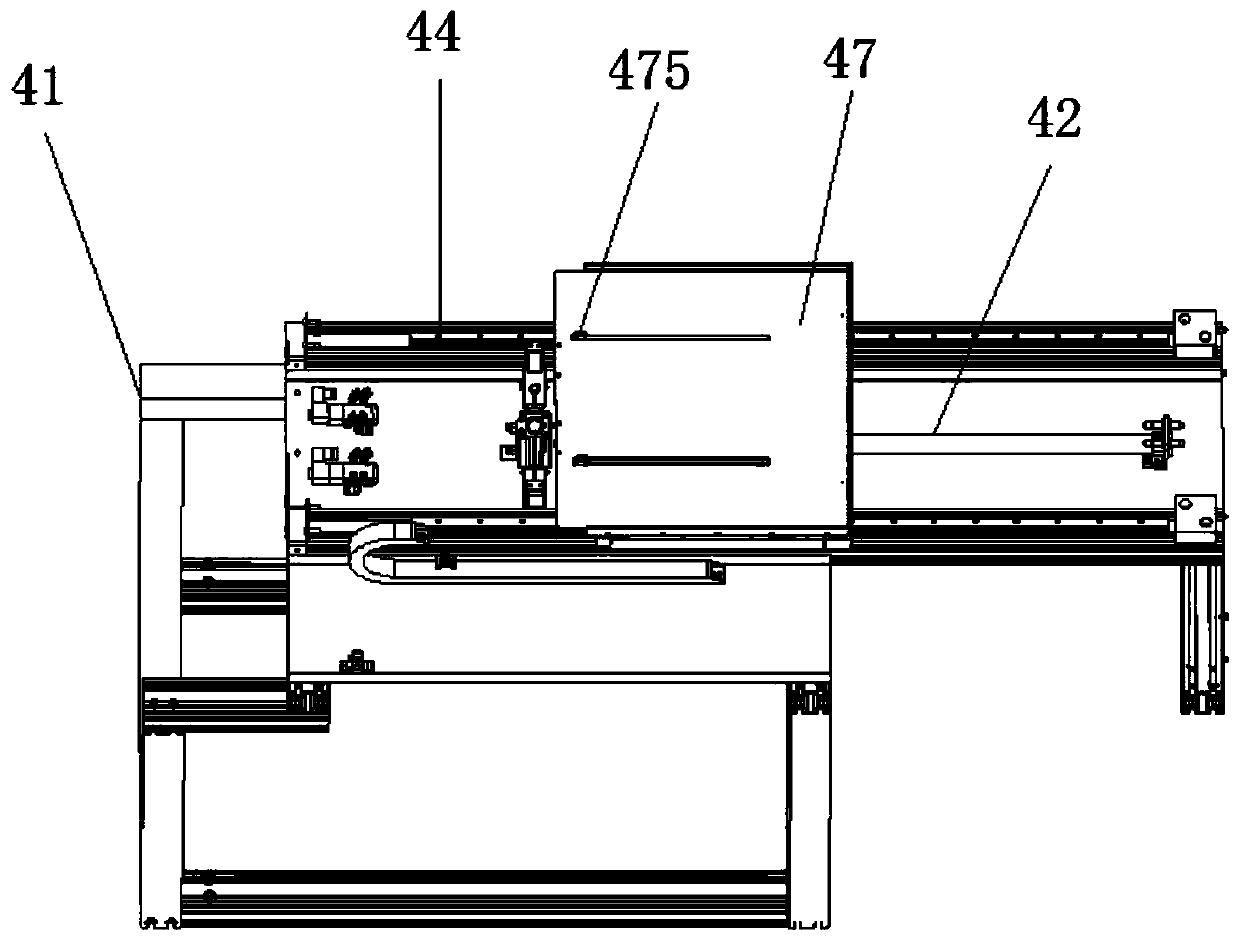

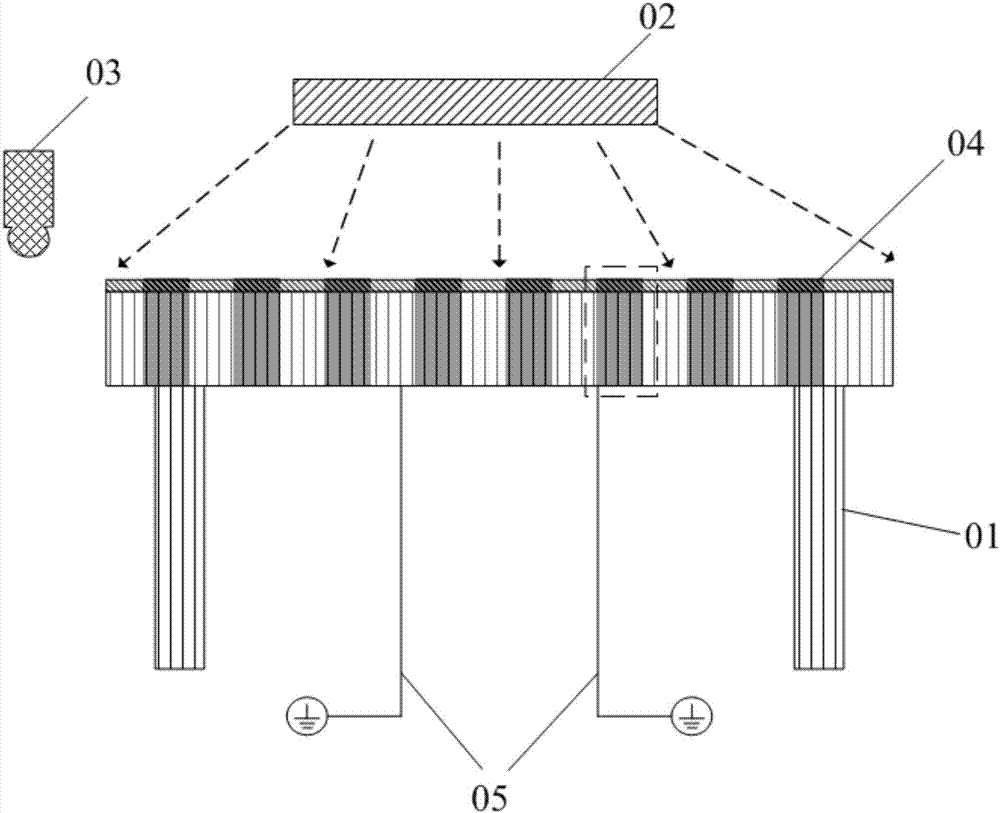

High-precision full-automatic double-side exposure machine

PendingCN110376853AAvoid misalignmentImprove exposure qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusControl systemComputer module

The invention relates to a high-precision full-automatic double-side exposure machine. The exposure machine comprises a support, an upper frame system, an alignment system, a charging and dischargingsystem, a manipulator system, a visual system, an exposure module, a constant temperature and humidity module and a control system; the support is used to support different modules and systems installed in the exposure machine; the upper frame system is positioned in the frame, and comprises an upper masking plate providing patterns for exposure of an upper surface of a product; the alignment system is provided with a lower masking plate providing patterns for exposure of a lower surface of the product, used to align the upper and lower masking plates accurately, and positioned under the upperframe system; and the charging and discharging system comprises a charging system and a discharging system, and is used to charge and discharge the product automatically. The upper and lower maskingplates are aligned via the alignment system and the visual system, pattern offset during exposure can be prevented, the exposure quality is improved, the alignment can realize adjustment in multiple directions and angles, and the alignment precision is high.

Owner:AMSKY TECHNOLOGY CO LTD

Exposure device

ActiveCN107065445AImprove Exposure AccuracyImprove exposure qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusOptoelectronicsDiffraction

The invention provides an exposure device. The exposure device comprises a baffle assembly and a lens assembly, wherein an exposure hole is formed in the baffle plate assembly, and the lens assembly is arranged between the baffle plate assembly and a substrate to be exposed and is used for converging a diffraction light ray generated by a side edge of the exposure hole onto a region to be exposed of the substrate to be exposed. By the exposure, relatively high exposure accuracy can be achieved, and the exposure quality of the substrate to be exposed is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Projecting exposure apparatus

InactiveUS6980366B2Increase exposureImprove exposure qualitySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage formationMagnification

A spatial light modulator has pixel sections for performing spatial light modulation of light. An image-side telecentric image forming optical system forms an image of a two-dimensional pattern of the light having been obtained from the spatial light modulation. A microlens array having microlenses arrayed in two-dimensional directions is located in the vicinity of a plane of image formation of the two-dimensional pattern, whose image is formed by the image forming optical system. A magnification adjusting optical system for adjusting a magnification of image formation at the time of the formation of the image of the two-dimensional pattern of the light with the image forming optical system is located between the image forming optical system and the microlens array.

Owner:FUJIFILM HLDG CORP +1

Six-freedom-degree decoupling modeling method of workpiece platform micro-motion part

ActiveCN103345197AGuaranteed motion accuracyImprove exposure qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusDegrees of freedomEngineering

The invention discloses a six-freedom-degree decoupling modeling method of a workpiece platform micro-motion part, and mainly relates to a six-freedom-degree decoupling modeling method of a photo-etching machine workpiece platform micro-motion part. The six-freedom-degree decoupling modeling method aims to solve the coupling problem of a vertical direction three-freedom-degree motion model of the photo-etching machine workpiece platform micro-motion part and a horizontal direction three-freedom-degree motion model of the photo-etching machine workpiece platform micro-motion part. The six-freedom-degree decoupling modeling method comprises the steps of 1 establishing the conversion relationships between centroid driving force of the workpiece platform micro-motion part and torque of the workpiece platform micro-motion part and driving force of a voice coil motor; 2 establishing the position relationship between an exposure center and the workpiece platform micro-motion part centroid; 3 conducting secondary derivation on the position relationship obtained in the step 2 and ignoring primary derivative items; 4 obtaining the relation between the driving force exerted on the workpiece platform micro-motion part centroid and the torque exerted on the workpiece platform micro-motion part centroid and the acceleration of the exposure area center according to the Newton second law; 5 listing equations about the centroid driving force and torque through the results obtained in the step 1and the step 4, and obtaining the relation between the exposure center position and the driving force of the voice coil motor. The invention belongs to the field of super precision manufacturing.

Owner:严格集团股份有限公司

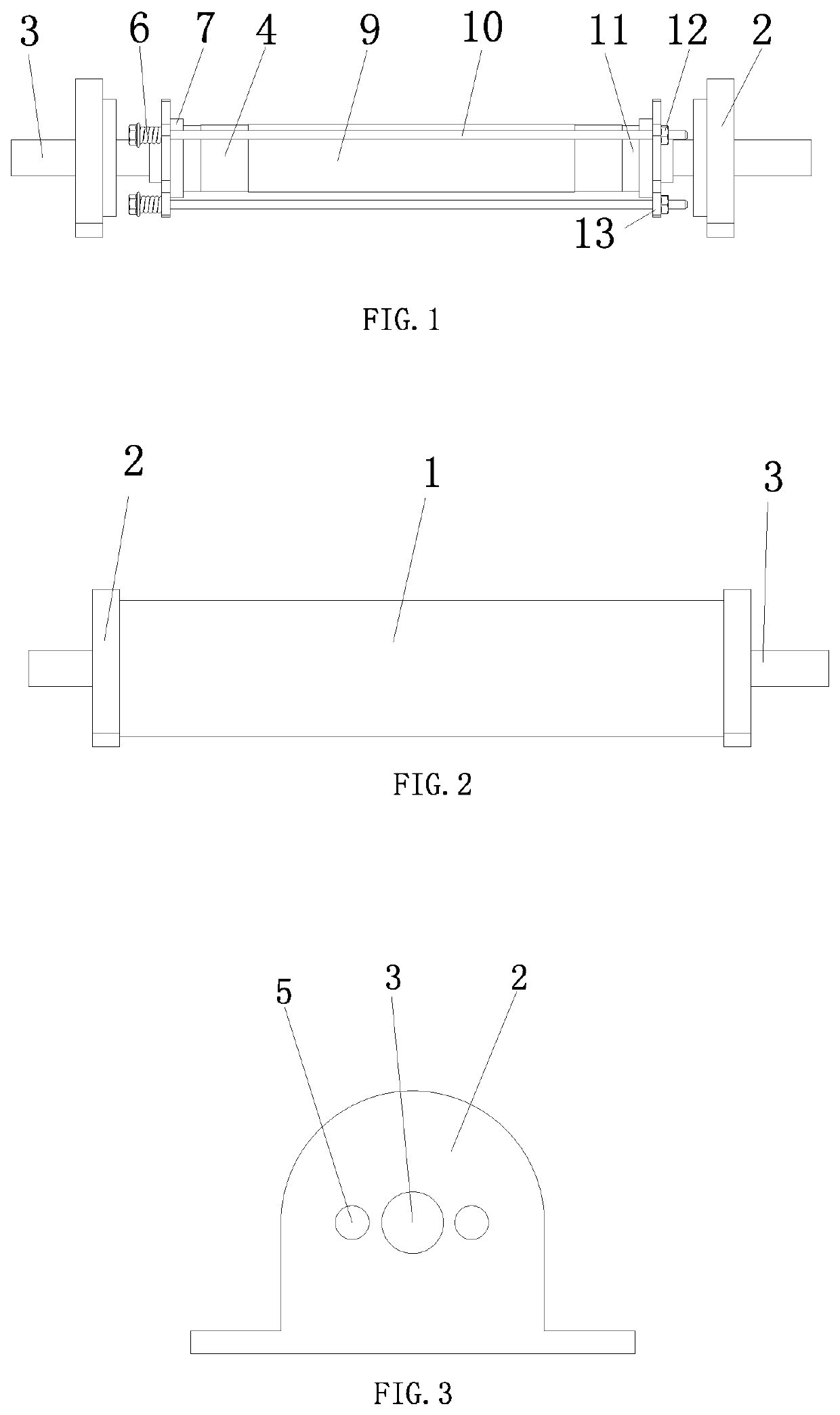

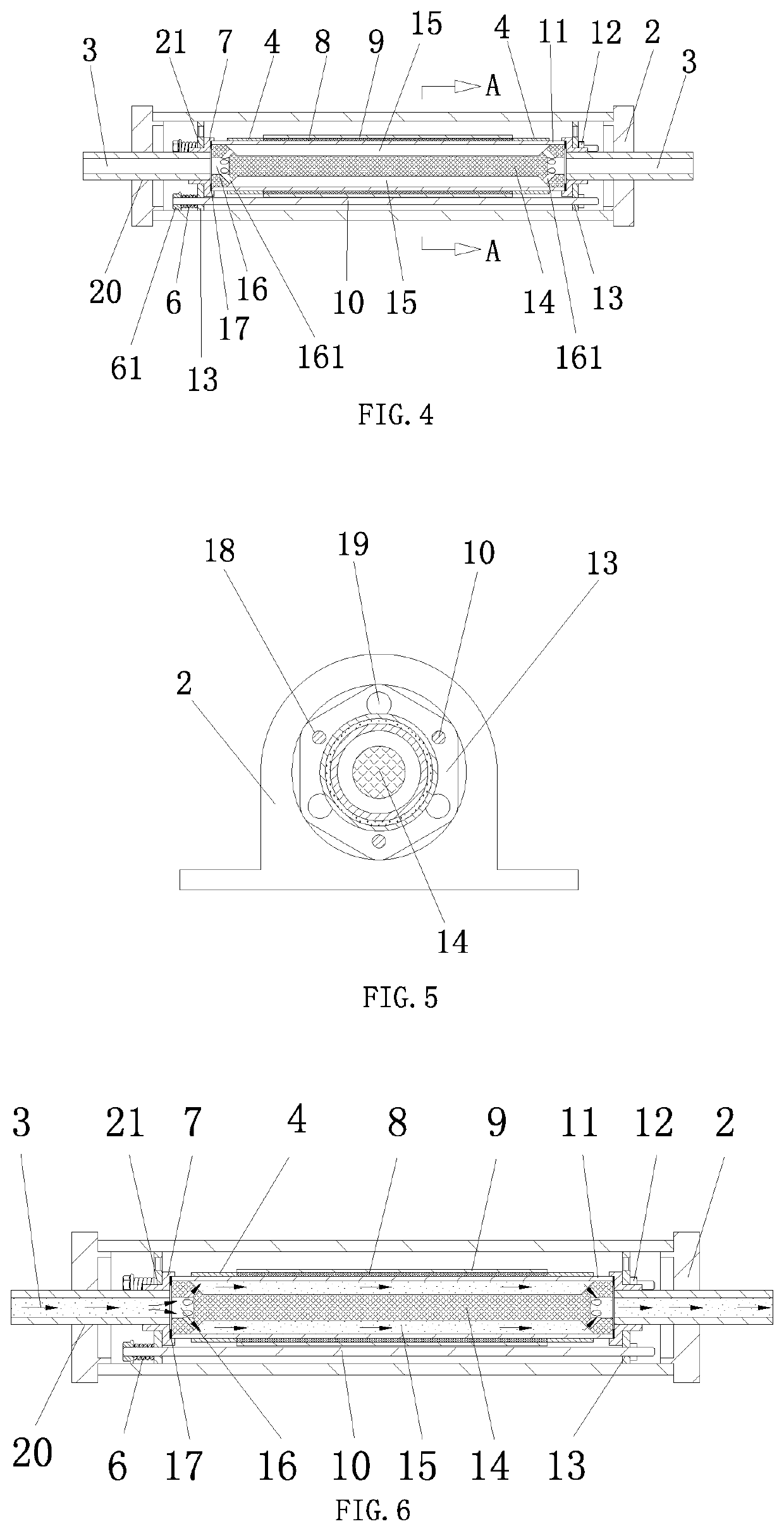

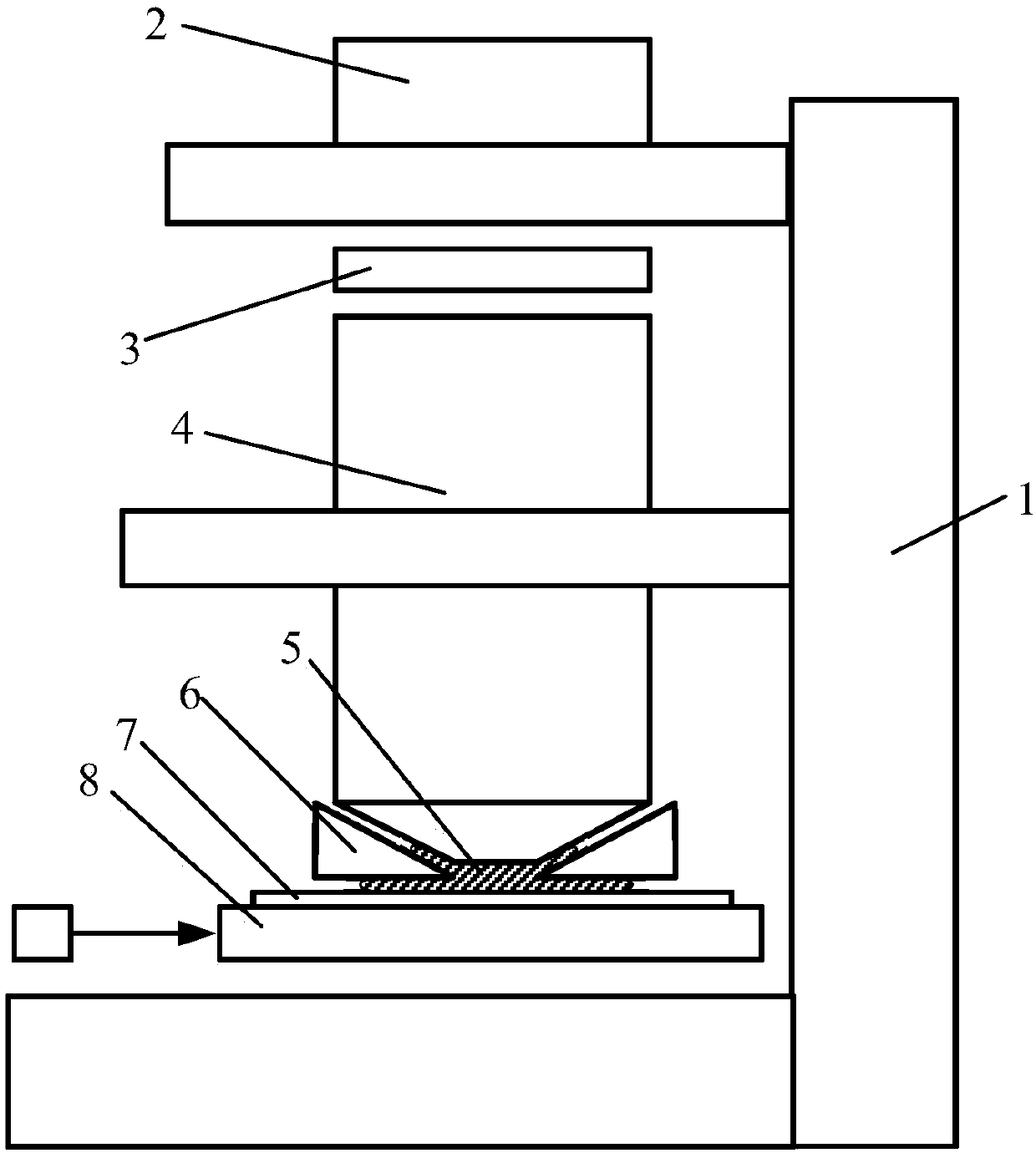

Film type liquid heater and uniform heating method thereof

PendingUS20220136733A1High precisionLong heating timeHeater elementsHeating element shapesHeating filmThin membrane

The present invention discloses a film type liquid heater and a uniform heating method thereof. End fixation plates are arranged at two ends of a barrel. A heating pipe is arranged in the barrel. Pipe ports run through the two end fixation plates, respectively. Connecting pipes are arranged in the pipe ports. Sealing connection components are arranged at inner ends of the two connecting pipes. A heating film layer is coated outside the heating pipe. Electrode layers are connected left and right sides of the heating film layer, and the electrode layers are connected to an external power supply. An insulating layer is coated outside the heating film layer. A flow splitting column is fixedly connected in the heating pipe. A heating chamber is formed between an inner side of the heating pipe and the flow splitting column. Flow splitting grooves are formed at left and right ends and on the inner side of the flow splitting column. Two outer ends of the flow splitting grooves are communicated with the connecting pipes, and the flow splitting grooves are communicated with the heating chamber. The heating film layer is electrified to generate heat. The heat is conducted inward to the heating pipe and the flow splitting column, and conducted outward to the barrel. Liquid flows into the heating chamber through the connecting pipes and the flow splitting grooves, so that the heating uniformity of the liquid flow flowing through the heating chamber is improved.

Owner:ZHEJIANG CHEER TECH CO LTD

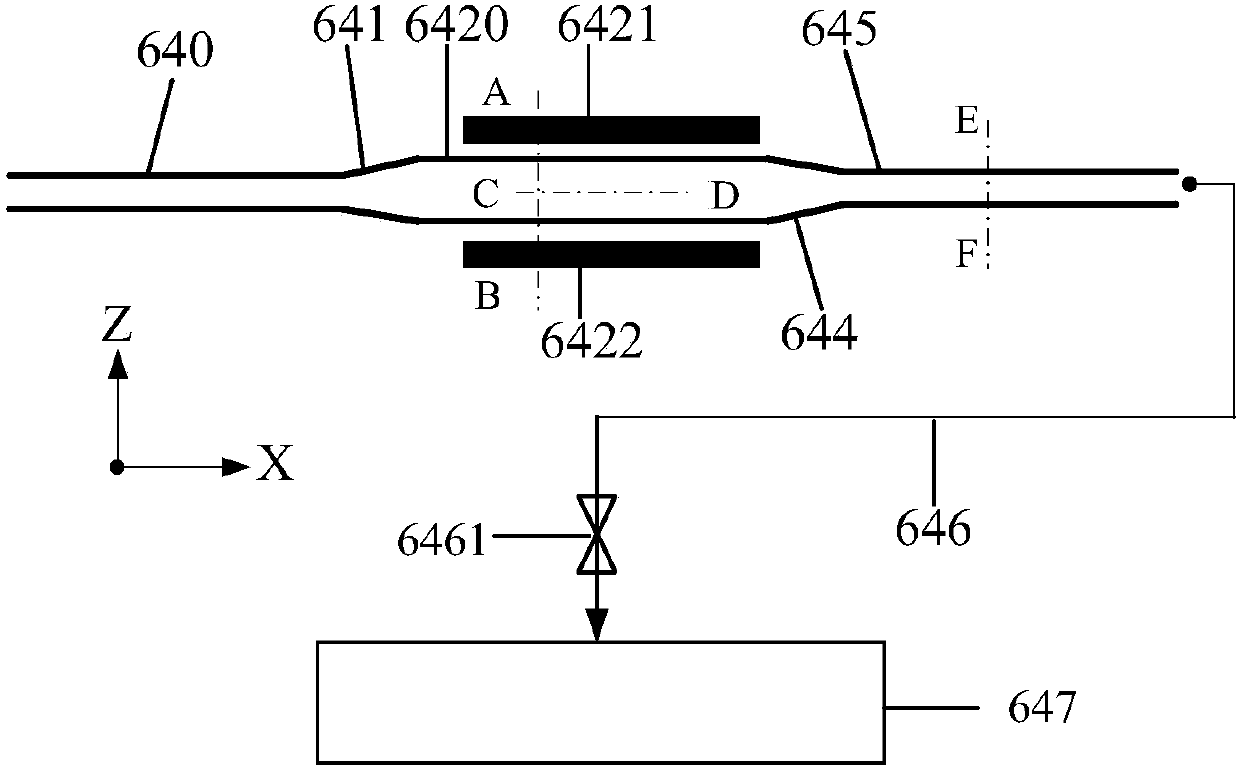

Fluid extracting-discharging apparatus and immersion type photoetching machine

ActiveCN107561865ASimple structureSmall footprintPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringPressure balance

The invention discloses a fluid extracting-discharging apparatus used for extracting and discharging a gas-liquid mixture from the edge of an immersion liquid flow field in an immersion head to gas-liquid recycling equipment; the fluid extracting-discharging apparatus comprises a first extracting-discharging pipe, an atomizing cavity and a second extracting-discharging pipe connected in sequence;the gas-liquid mixture enters the atomizing cavity to be atomized through the first extracting-discharging pipe; then the atomized mixture enters the gas-liquid recycling equipment through the secondextracting-discharging pipe; by virtue of the fluid extracting-discharging apparatus, the anisotropic gas-liquid two-phase flow which flows to the fluid extracting-discharging apparatus can be converted into isotropous ''atomized-shaped'' single-phase flow, so that pressure balance in each position of the fluid extracting-discharging apparatus can be maintained; the invention also discloses an immersion type photoetching machine provided with the fluid extracting-discharging apparatus; and the immersion type photoetching machine is stable in the immersion liquid flow field, good in flow fieldsealing effect, and capable of effectively preventing a gas-liquid two-phase ''water plugging'' phenomenon generated in the pipeline by the gas-liquid mixture in the extracting and discharging position of the immersion liquid flow field, and improving exposure quality.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

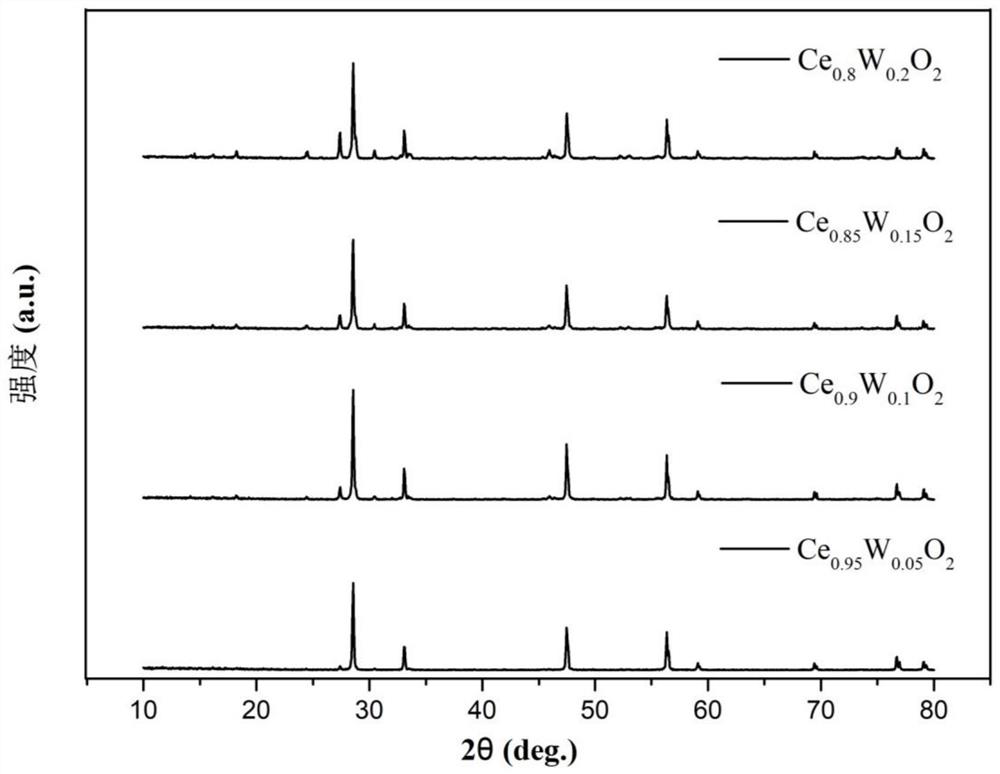

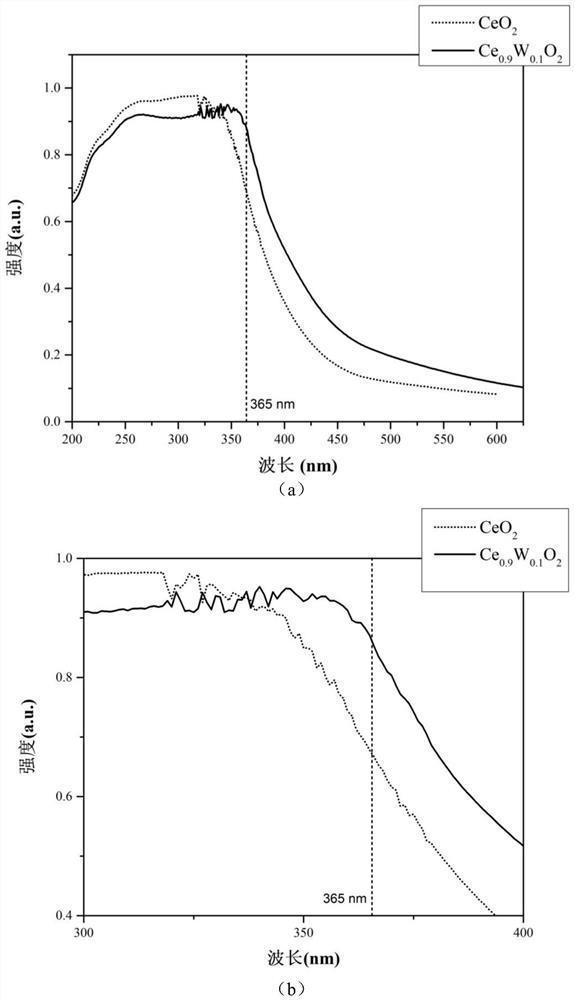

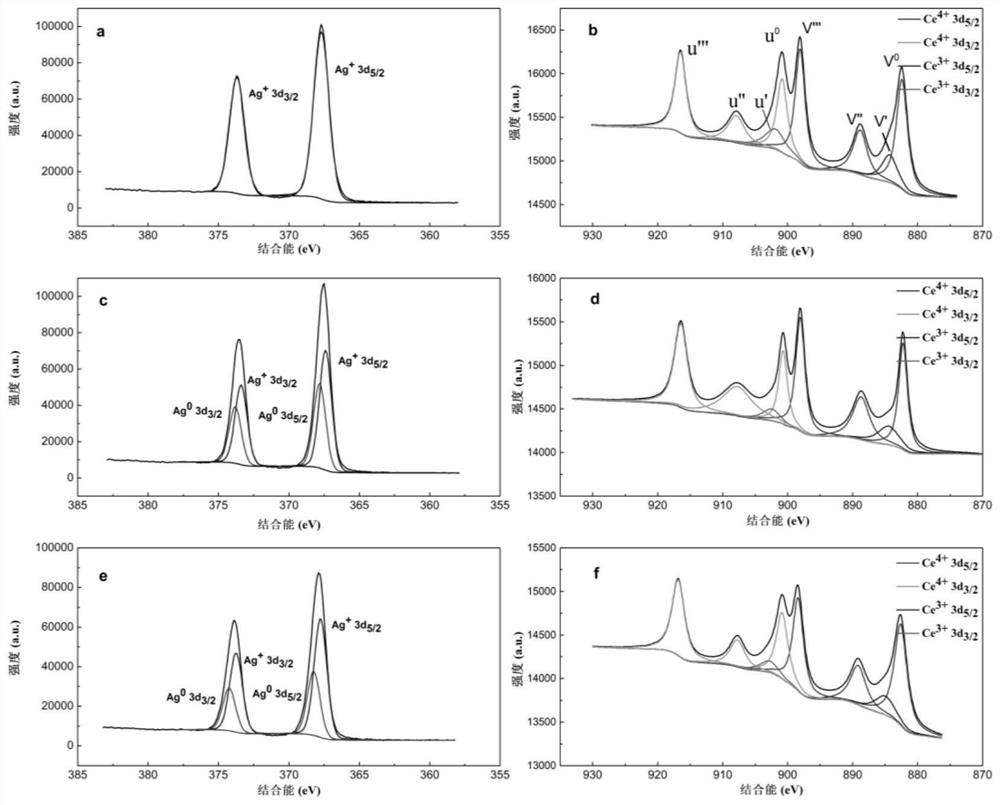

Cerium oxide-doped photosensitizer suitable for photosensitive microcrystalline glass as well as preparation method and application of cerium oxide-doped photosensitizer

ActiveCN114133928AImprove efficiencyImprove exposure qualityCerium oxides/hydroxidesRare earth metal compounds preparation/treatmentCerium nitrateAmmonium metatungstate

The invention discloses a doped cerium oxide photosensitizer suitable for photosensitive microcrystalline glass and a preparation method and application thereof, the doped cerium oxide photosensitizer is represented by a general formula Ce < 1-x > W < x > O < 2 >, and in the general formula, x is equal to 0.05-0.25. The catalyst is prepared by taking cerium nitrate, ammonium metatungstate hydrate and organic fuel as raw materials and adopting a sol-gel self-propagating combustion method. According to the cerium oxide doped photosensitizer provided by the invention, W ion doping is carried out on the existing photosensitizer CeO2, so that the light absorption performance of the photosensitizer CeO2 is improved, and the absorption peak of the photosensitizer CeO2 is moved, so that the absorption peak of the photosensitizer CeO2 is matched with the existing light source, and the nucleation efficiency and the exposure quality of photosensitive microcrystalline glass are improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Immersion liquid supply and recovery device with novel pumping and discharging assembly and immersion liquid pumping and discharging method

PendingCN111830796AGuaranteed drainage effectImproved vibration characteristicsPhotomechanical exposure apparatusMicrolithography exposure apparatusFluid phaseEngineering

The invention discloses an immersion liquid supply and recovery device with a novel pumping and discharging assembly and an immersion liquid pumping and discharging method. The device comprises a substrate, an immersion liquid supply channel, an immersion liquid recovery channel, a liquid-phase pumping and discharging channel, a gas-phase pumping and discharging channel, a pumping and dischargingcavity, a pumping and discharging opening and a selective pumping and discharging pipe. A plurality of pumping and discharging openings are formed in one side, opposite to the substrate, of the immersion liquid supply and recovery device. A pumping and discharging cavity is formed in the immersion liquid supply and recovery device, a plurality of selective pumping and discharging pipes are arranged in the pumping and discharging cavity, the pumping and discharging openings are communicated with the pumping and discharging cavity, one end of each selective pumping and discharging pipe is communicated with one pumping and discharging opening, the other end of each selective pumping and discharging pipe is communicated with the liquid-phase pumping and discharging channel, and the gas-phase pumping and discharging channel is connected with the pumping and discharging cavity. The negative pressure pulsation inhibition on the gas-liquid two-phase flow is improved, the vibration characteristic of the immersion liquid supply recovery device is improved, the pumping and discharging capability of a recovery port on immersion liquid is improved, and the exposure quality is improved.

Owner:ZHEJIANG CHEER TECH CO LTD

Exposure machine tool, exposure system and exposure method thereof

InactiveCN107219648AEasy to fixEasy to separatePhotomechanical exposure apparatusMicrolithography exposure apparatusMachine toolMetal

The invention discloses an exposure machine tool, an exposure system and an exposure method thereof. Under the effect of specific light rays emitted by a light source, light sensitive coating shifts between an insulating state and a conductive state, so that fixation and separation of a substrate to be exposed is facilitated; meanwhile, electrostatic charges are released to the light sensitive coating via an electrostatic generator, and the substrate to be exposed is fixed in an electrostatic adsorbing manner without generating a raised partition baffle wall; in addition, the metal tool surface of the exposure machine tool is grounded, so that the electrostatic charges can be exported from the light sensitive coating via the metal tool surface, so that the substrate to be exposed and the light sensitive coating are separated, and movement of the substrate to be exposed is facilitated; in a word, the exposure machine tool ensures generation of static electricity and adsorption to the substrate to be exposed, and also achieves elimination of the existing electrostatic charges, so that the substrate to be exposed is convenient to take out, stage mura caused by negative adsorption of gas is avoided, the substrate to be exposed is protected against damage, and exposure quality of the substrate to be exposed is effectively improved.

Owner:BOE TECH GRP CO LTD +1

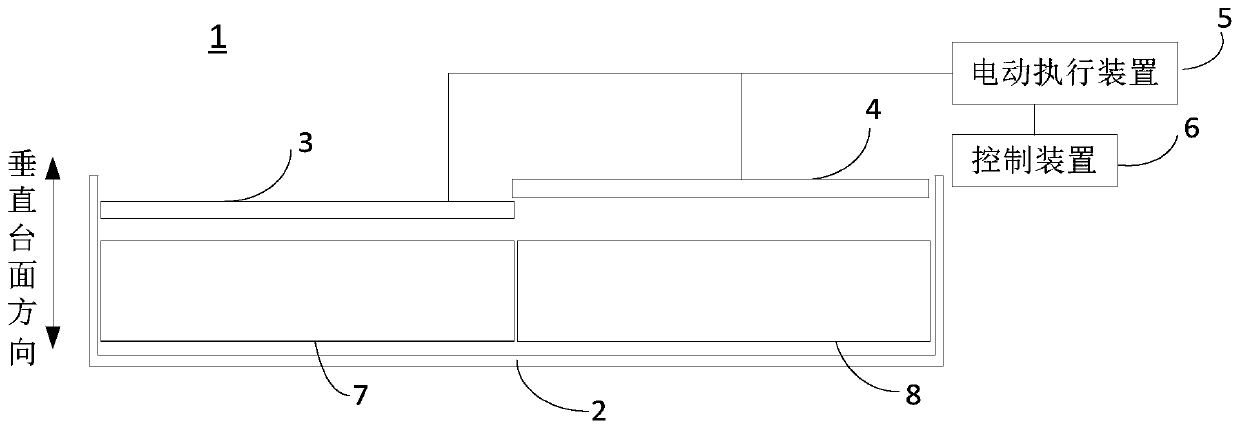

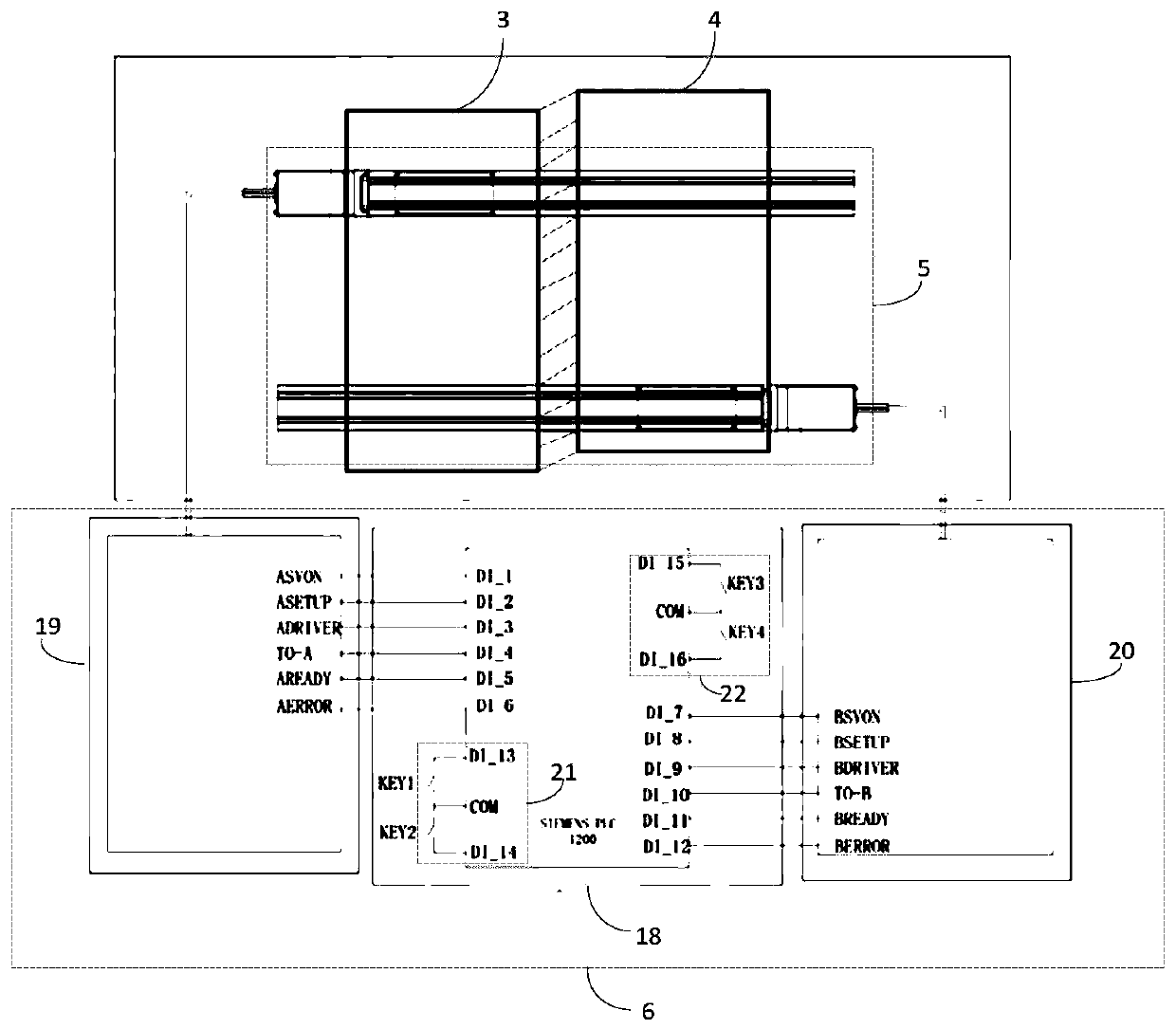

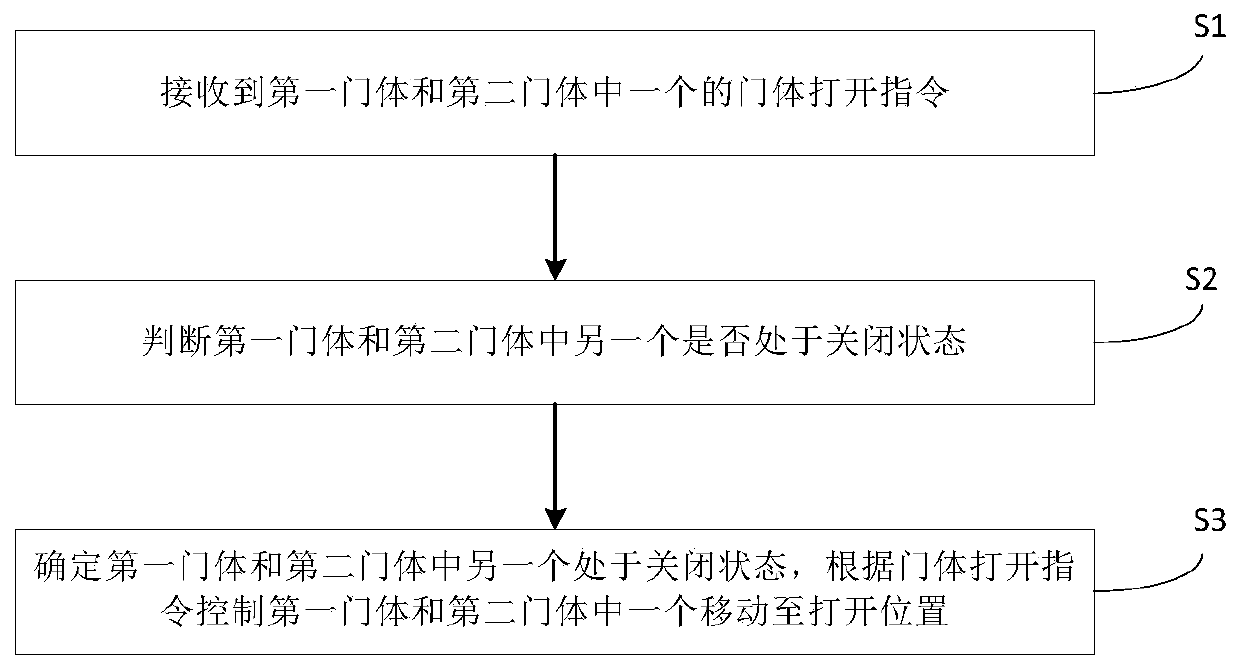

Double-table-board exposure machine and method for controlling opening and closing of door of double-table-board exposure machine

InactiveCN111308863AReduce widthPrevent fallingPhotomechanical exposure apparatusMicrolithography exposure apparatusMechanical engineeringElectrical and Electronics engineering

The invention provides a double-table-board exposure machine and a method for controlling the opening and closing of the double-table-board exposure machine, the double-table-board exposure machine comprises a machine body which comprises a first table board and a second table board, a first door body and a second door body, an electric executing device which is arranged on the machine body, is mechanically connected with the first door body and the second door body and is used for controlling the first door body to move in the direction parallel to the table board according to a first door body driving signal, and a control device which is electrically connected with the electric executing device and used for outputting the first door body driving signal or a second door body driving signal according to an operation instruction, wherein the first door body is located on the first table board, a gap is formed between the first door body and the first table board, the second door body is located on the second table board, a gap is formed between the second door body and the second table board, and the first door body and the second door body are staggered in the direction perpendicular to the table boards. According to the double-table-board exposure machine, external dust can be prevented from entering the table boards, and poor exposure is avoided.

Owner:HEFEI CHIP FOUND MICROELECTRONICS EQUIP CO LTD

Exposure apparatus for optical disc

InactiveUS7057992B2Suppress propagating componentImprove accuracyCombination recordingUndesired vibrations/sounds insulation/absorptionRotational vibrationEngineering

An exposure apparatus for an optical disc used for eliminating the vibrations in the propagating direction when a rotation mechanism rotates. The slider controller 40 and the spindle controller 41 of the exposure apparatus 1 are activated, and the then the optical disc begins to be rotated by an AC synchronized motor. Through a condensing device 9, laser beams emitted form the laser source 6 are irradiated on the optical disc for exposure. At this time, the optical disc is eccentrically chucked on the rotation mechanism, resulting a rotational vibration of the whole rotation mechanism. A measurer 17 is used for detecting a propagating component of the rotational vibration, and a vibrator controller 42 controls the vibrator 20 as the output of the measurer 17 approaches zero. Therefore, the vibration in the propagating direction of the base 2 is cancelled, and the propagation accuracy is increased and the exposure quality is enhanced.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com