Array substrate, method for manufacturing same and display device

An array substrate and black matrix technology, applied in the field of array substrate and its preparation method and display device, can solve the problems of array substrate film surface quality and abnormal function, pre-correction and adjustment, interference positioning, etc., to improve display quality and performance , Improving exposure quality and performance, improving the effect of preparation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

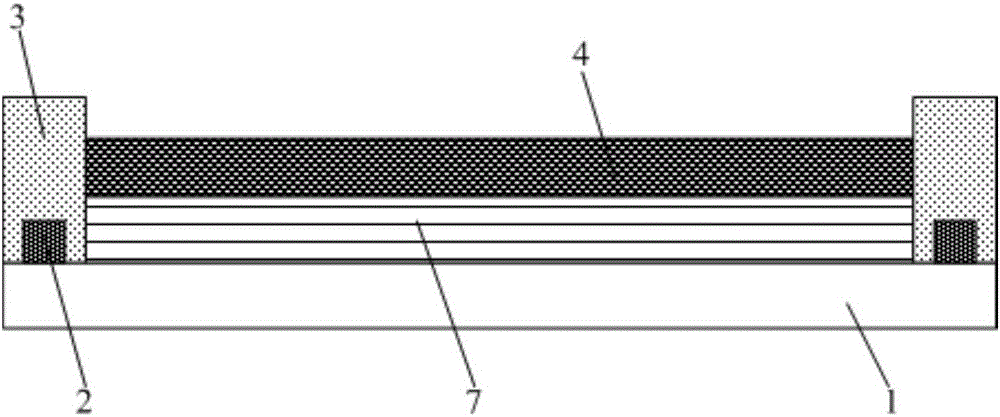

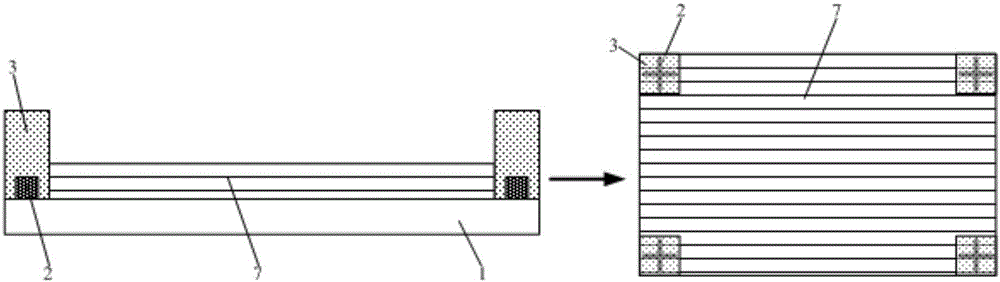

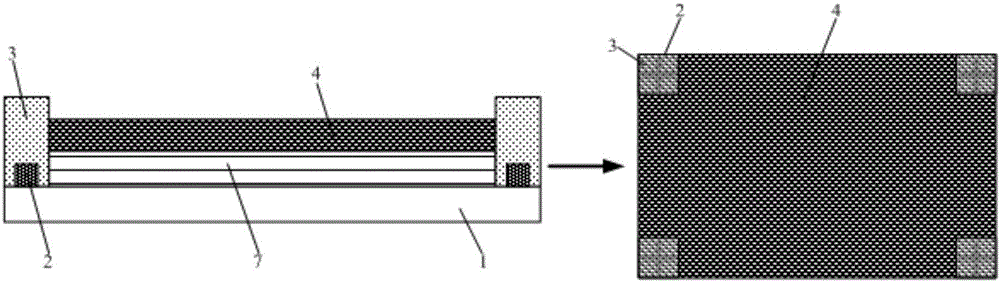

[0040] This embodiment provides a method for preparing an array substrate, such as Figure 1-Figure 7 As shown, it includes: step S1 : forming an alignment mark covering layer 3 on the region corresponding to the alignment mark 2 formed on the substrate 1 by using a patterning process. Step S2: forming a black matrix film 4 on the substrate 1 except for the alignment mark 2 . Step S3: removing the alignment mark covering layer 3 by exposure to expose the alignment mark 2 . Step S4: performing a patterning process on the black matrix film 4 to form a pattern 6 of the black matrix. Wherein, the exposure wavelength of the alignment mark covering layer 3 is different from the exposure wavelength of the black matrix film 4 .

[0041] In this preparation method, an alignment mark covering layer 3 and a black matrix film 4 are respectively formed on the area corresponding to the substrate 1 where the alignment mark 2 is formed and the area other than the alignment mark 2, and the a...

Embodiment 2

[0057] This embodiment provides a display device, including the array substrate in Embodiment 1.

[0058] By using the array substrate in Embodiment 1, the manufacturing quality of the display device can be improved, thereby improving the display quality and performance of the display device.

[0059] The display device provided by the present invention can be any product or component with a display function, such as a liquid crystal panel, a liquid crystal TV, a monitor, a mobile phone, a navigator, and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com