Cerium oxide-doped photosensitizer suitable for photosensitive microcrystalline glass as well as preparation method and application of cerium oxide-doped photosensitizer

A technology of glass-ceramics and cerium oxide, which is applied in chemical instruments and methods, preparation/treatment of cerium oxide/cerium hydroxide, rare earth metal compounds, etc., can solve the problems of low exposure efficiency and quality of photosensitive glass-ceramics, and achieve Improve nucleation efficiency and exposure quality, good application prospects, and short preparation process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

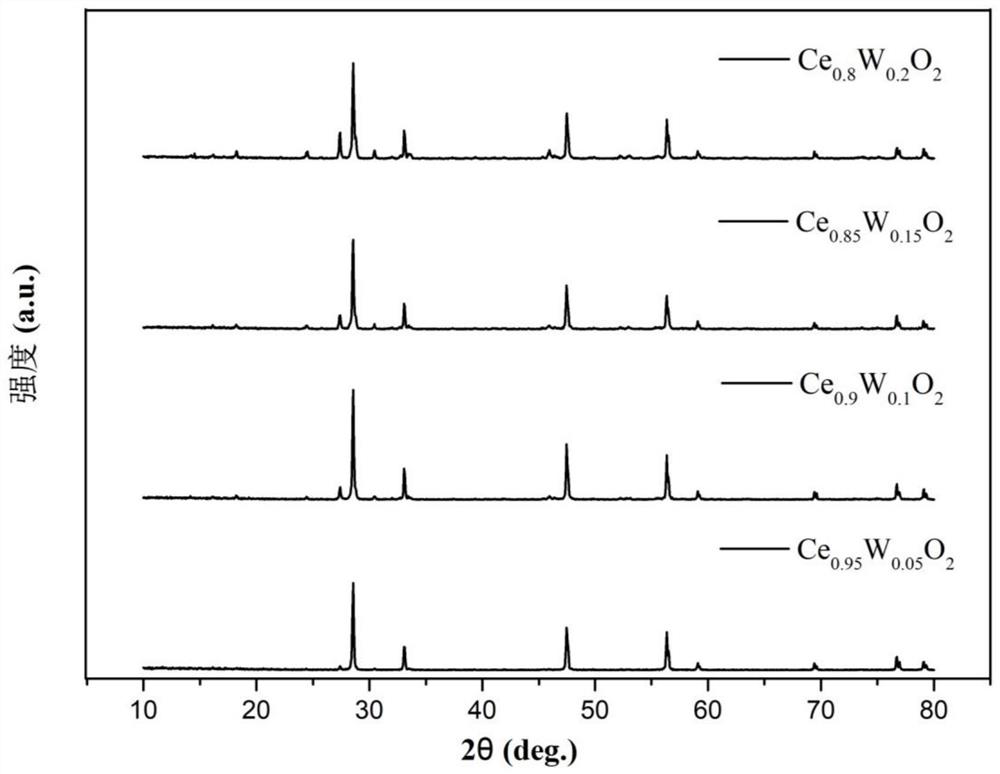

[0035] The present embodiment utilizes the citric acid-nitrate self-propagating combustion method to prepare the chemical formula Ce 0.95 W 0.05 o 2 (i.e. x=0.05) represents the doped cerium oxide photosensitizer applicable to photosensitive glass-ceramics, specifically comprising the following steps:

[0036] (1) Ingredients: with Ce(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O and citric acid are raw materials, according to the chemical formula Ce 0.95 W 0.05 o 2 The determined chemical formula is used to weigh the ingredients, and the molar ratio of metal ions to organic fuel is 1:1.5;

[0037] (2) Dissolution: 0.0285mol Ce(NO 3 ) 3 ·6H 2 O dissolved in deionized water, 0.000125mol (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O is dissolved in 15ml of nitric acid with a concentration of 14.4-15.2mol / L, and then the two solutions are mixed to form a mixed solution;

[0038] (3) Preparation of precursor solution: Add 0.045mol citric acid into the mixed solution a...

Embodiment 2

[0043] The present embodiment utilizes the citric acid-nitrate self-propagating combustion method to prepare the chemical formula Ce 0.9 W 0.1 o 2 The doped cerium oxide photosensitizer applicable to photosensitive glass-ceramics represented by (i.e. x=0.1) specifically comprises the following steps:

[0044] (1) Ingredients: with Ce(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O and citric acid are raw materials, according to the chemical formula Ce 0.9 W 0.1 o 2 The determined chemical formula is used to weigh the ingredients, and the molar ratio of metal ions to organic fuel is 1:1.5;

[0045] (2) Dissolution: 0.027mol Ce(NO 3 ) 3 ·6H 2 O dissolved in deionized water, 0.00025mol (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O is dissolved in 15ml of nitric acid with a concentration of 14.4-15.2mol / L, and then the two solutions are mixed to form a mixed solution;

[0046] (3) Preparation of precursor solution: Add 0.045mol citric acid into the mixed solution and st...

Embodiment 3

[0051] The present embodiment utilizes the citric acid-nitrate self-propagating combustion method to prepare the chemical formula Ce 0.85 W 0.15 o 2 (i.e. x=0.15) represents a doped cerium oxide photosensitizer suitable for photosensitive glass-ceramics, specifically comprising the following steps:

[0052] (1) Ingredients: with Ce(NO 3 ) 3 ·6H 2 O, (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O and citric acid are raw materials, according to the chemical formula Ce 0.85 W 0.15 o 2 The determined chemical formula is used to weigh the ingredients, and the molar ratio of metal ions to organic fuel is 1:1.5;

[0053] (2) Dissolution: 0.0255mol Ce(NO 3 ) 3 ·6H 2 O dissolved in deionized water, 0.000375mol (NH 4 ) 6 h 2 W 12 o 40 ·xH 2 O is dissolved in 15ml of nitric acid with a concentration of 14.4-15.2mol / L, and then the two solutions are mixed to form a mixed solution;

[0054] (3) Preparation of precursor solution: Add 0.045mol citric acid into the mixed solution and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com