Patents

Literature

36results about How to "The preparation process cycle is short" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

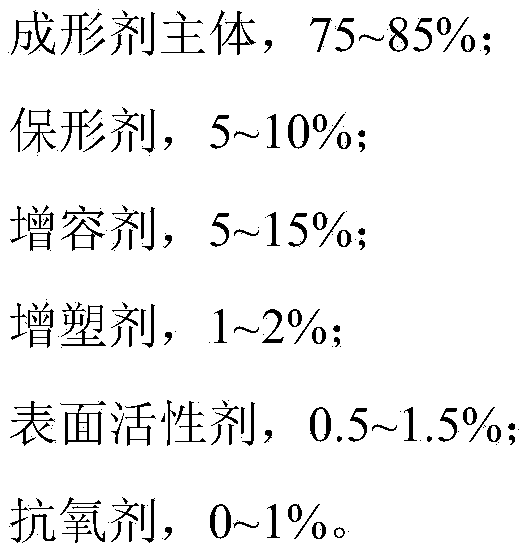

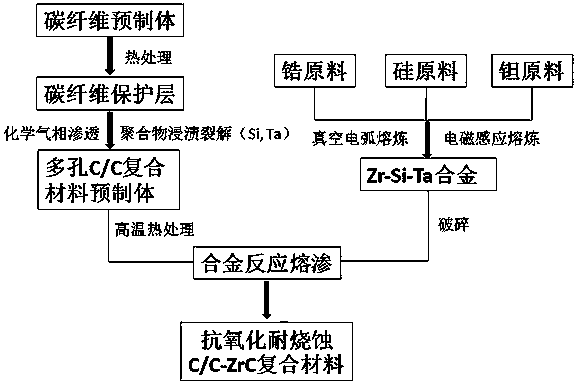

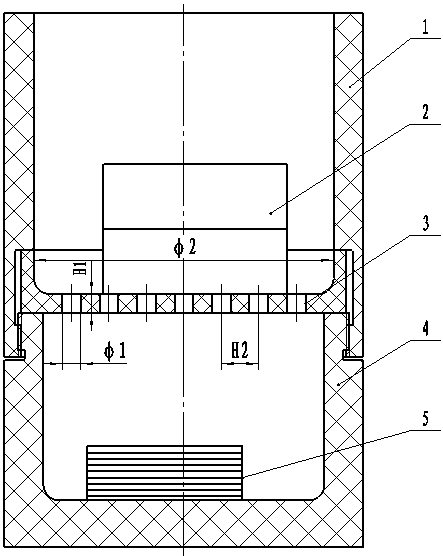

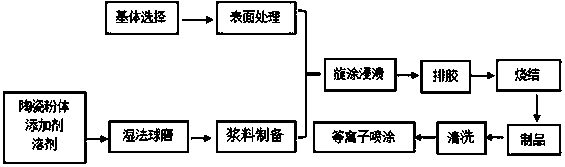

Preparation method of powder injection molded feeding material

ActiveCN104227003AThe preparation process cycle is shortSimple processCeramic shaping apparatusPre treatmentPower injection

The invention discloses a preparation method of a powder injection molded feeding material, which is applied to MIM (Metal Power Injection Molding) and CIM (Ceramic Power Injection Molding). The method comprises the following steps of S1, pre-treating, i.e. crushing an organic macromolecule polymer serving as a component of an adhesive into the powder with the same grain size as that of inorganic material powder to be mixed; S2, heating the inorganic material powder to the temperature at which the adhesive can be melted; S3, adding the adhesive into the pre-heated inorganic material powder to be mixed, so that the inorganic material powder and the adhesive are pre-felted into a block, wherein the adhesive comprises the organic macromolecule polymer which is treated in the step 1; S4, extruding the block to form particles, i.e. feeding the material treated in the step 3 into an extruder, and plasticizing, extruding and pelletizing the material to manufacture the powder injection molded feeding material. Due to the fact that the organic macromolecule polymer in the adhesive is crushed before mixing materials, after being added into the pre-heated inorganic material powder, the adhesive can be quickly melted and felted with the powder to form the block, the technical period is shortened, the energy consumption is reduced, and the low-melting point adhesive is prevented from being degraded and volatilized.

Owner:DONGGUAN HUAJING POWDER METALLURGY

Method for preparing high thermal conductivity graphite material

The invention relates to a method for preparing a high thermal conductivity graphite material. The method takes the 80-90 of natural scale graphite percentage by weight and the 10-20 of coal pitch percentage by weight as the raw materials, after the temperature of the natural scale graphite is raised to 120-150 DEG C and the coal pitch is fused into liquid, the natural scale graphite is added in for kneading for 0.5-2 h, after the kneading is finished, the mixed raw material is put in a die with temperature of 120-150 DEG C and then is molded by pressing under the pressure of 200-600 kg / cm<2> and the dwelling is carried out for 5-15 min, the demoulding is carried out after the die temperature is reduced to 60-90 DEG C, then the molded product is put in a graphitizing furnace for heating to 2300-2800 DEG C and constant temperature for 0.5-1 h at the highest temperature, and then the molded product is discharged from the furnace after being naturally cooled to 50-100 DEG C to obtain high thermal conductivity graphite material. The invention has the advantages of short period of the preparation process, low manufacturing cost and good thermal conductivity of the graphite material.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

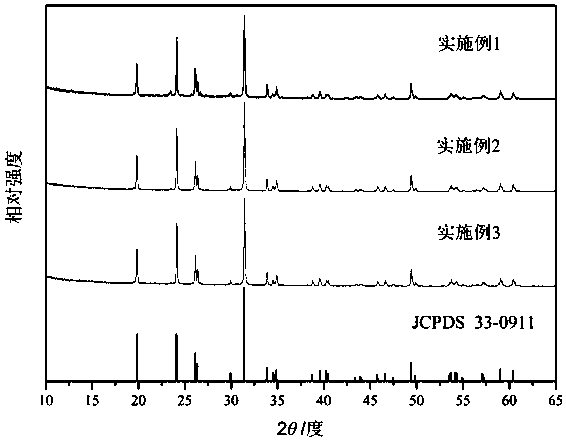

Wave-transparent silicon nitride radome material and preparation method thereof

The invention discloses a wave-transparent silicon nitride radome material and a preparation method thereof. The wave-transparent Si3N4 radome material uses low-density porous silicon nitride as a core layer, uses silicon nitride or boron nitride chopped fibers or crystal whiskers as a core layer reinforcement phase, and uses condense silicon nitride as a surface coating layer. Firstly, after being mixed with the silicon nitride or boron nitride chopped fibers for pelletizing, silicon powder is evenly mixed with pore forming agent by a certain ratio, and is molded to a blank with a certain shape; the pore forming agent is totally decomposed at the temperature of 200-300 DEG C to obtain a porous blank. Then, the nitriding treatment is implemented to obtain a chopped fiber-reinforced porous silicon nitride ceramic body; the drying is implemented after the ultrasonic cleaning. Finally, the chemical vapor deposition (CVD) is implemented for the porous silicon nitride ceramic body to prepare a condense silicon nitride coating layer. The wave-transparent silicon nitride radome material and the preparation method thereof have the following advantages: (1) the chopped fibers or crystal whiskers are inlaid in the porous silicon nitride core layer to act the reinforcement effect; (2) the condense silicon nitride is on the outer layer of the porous silicon nitride core layer to act the water and steam permeation preventing effect; (3) the preparation process has short period and low cost.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

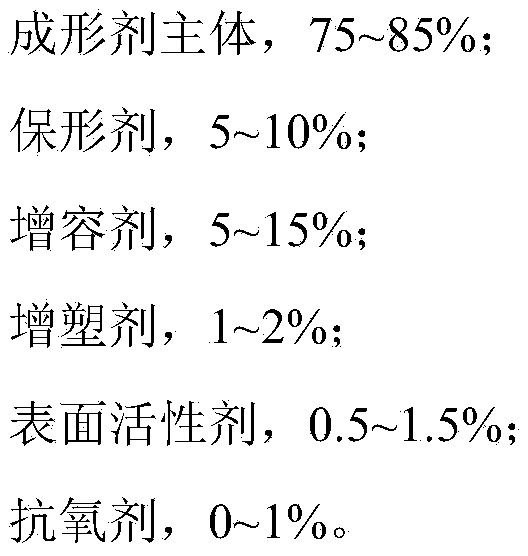

Method for preparing microencapsulation molybdenate

InactiveCN101544403AGood modification effectThe preparation process cycle is shortMolybdeum compoundsMicroballoon preparationDispersityPersulfate

The invention discloses a method for preparing microencapsulation molybdenate, which comprises the following steps: preparing a soluble molybdenate aqueous solution and a soluble metal salt aqueous solution respectively, adding the soluble metal salt aqueous solution into the soluble molybdenate aqueous solution at a temperature of between 20 and 80 DEG C, and controlling the pH to between 6 and 9 to react for 15 minutes to 1 hour; mixing melamine and a formaldehyde solution, and reacting for 30 minutes at a temperature of 85 DEG C with the pH value being equal to 9 to 9.5 to prepare a preformed polymer; adding soluble persulfate as an initiator and the preformed polymer into reactants in the third step successively, controlling the temperature to between 55 and 80 DEG C, and carrying out reaction for 2 to 4 hours; and performing suction filtration on the reaction solution, washing the reaction solution with water repeatedly, and drying the reaction solution to obtain the microencapsulation molybdenate without grinding. The method has short preparation process cycle and high yield, the decomposition temperature of cladding resin is more than 400 DEG C, and the dispersity of the cladding resin is good. Thus, the method is applicable to processing high polymer with relatively higher temperature requirement.

Owner:NANJING UNIV OF SCI & TECH

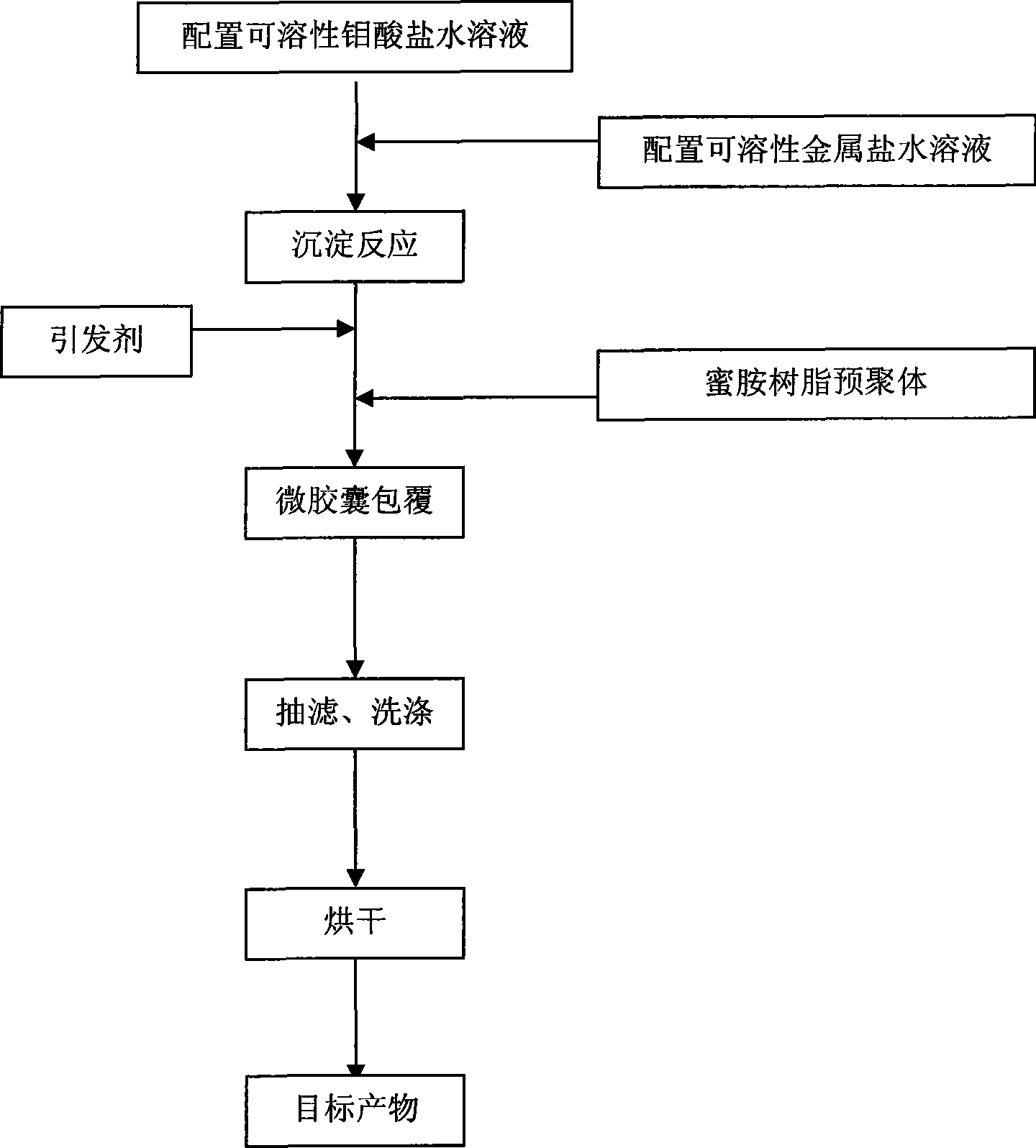

Preparation method of anti-oxidation and ablation-resistant C/C-ZrC carbon ceramic composite material

PendingCN108191447AImprove anti-oxidation and ablation resistanceControl contentFiberCeramic composite

The invention provides a preparation method of an anti-oxidation and ablation-resistant C / C-ZrC carbon ceramic composite material. The preparation method comprises the processing steps of preparationof a carbon fiber preform, heat treatment of the carbon fiber preform, preparation of a fiber protective layer, preparation of a porous C / C composite material preform, high temperature heat treatment,preparation of infiltration alloy and preparation of C / C-ZrC carbon ceramic composite material by reaction infiltration and the like. Compared with the prior art, the preparation method of the anti-oxidation and ablation-resistant C / C-ZrC carbon ceramic composite material can introduce a high-temperature silicon-containing compound and a high-temperature tantalum-containing compound into a C / C-ZrC composite matrix through one-step alloy reaction infiltration, and the two compounds conduct synergistic interaction during an oxidative ablation process. Oxidation and ablation resistance of an existing C / C-ZrC carbon ceramic composite material is effectively improved. The preparation process of the invention has short cycle period and high efficiency, and the prepared C / C-ZrC carbon ceramic composite material is low in cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

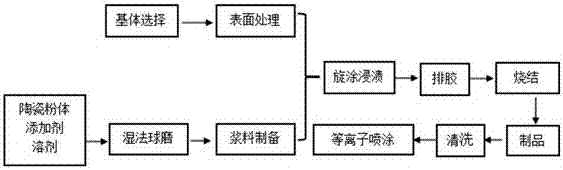

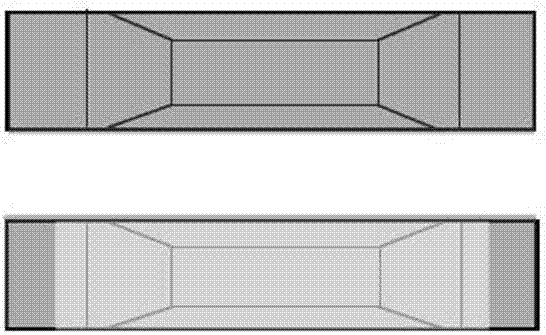

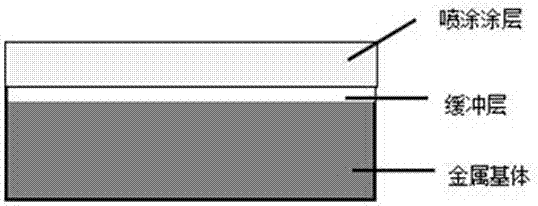

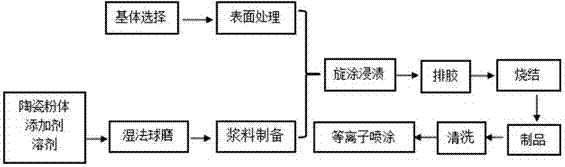

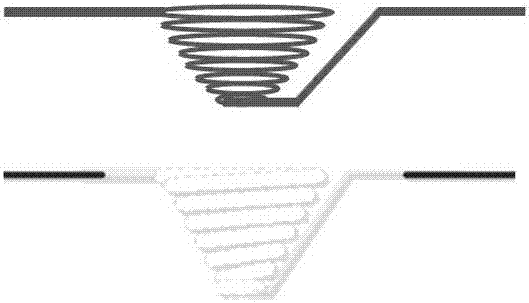

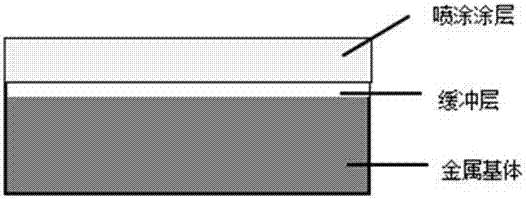

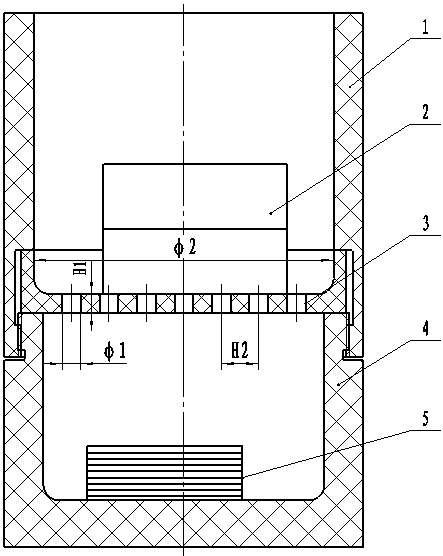

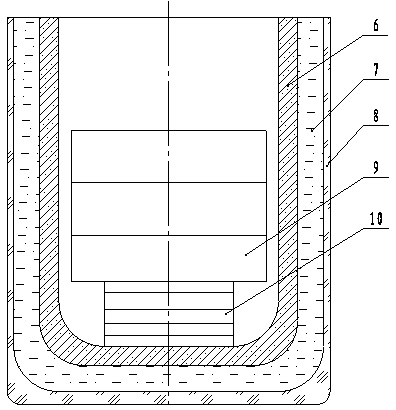

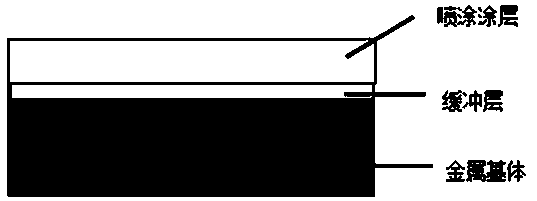

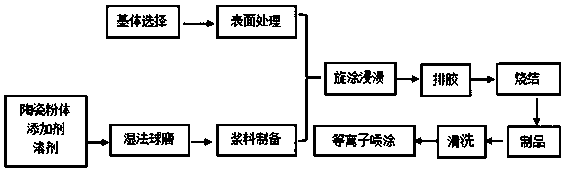

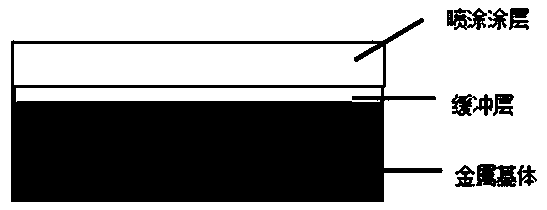

Internal-heated integrated evaporation boat with aluminum oxide porous structure buffering layer

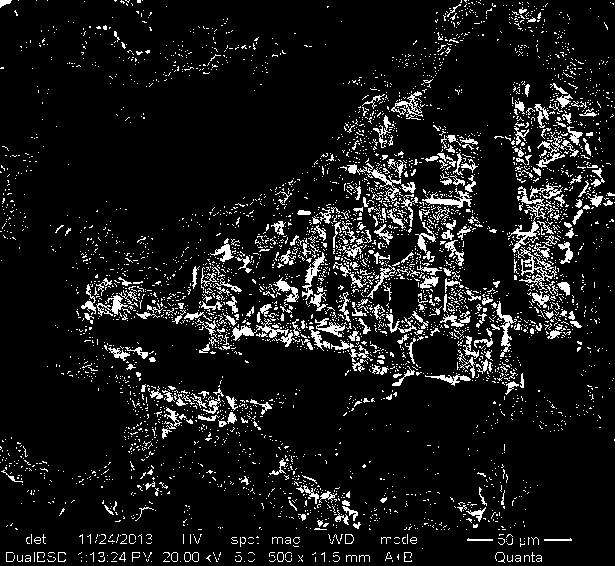

InactiveCN107326330ASolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

Method for preparing highly heat-conductive carbon/ceramic composite material

The invention discloses a preparing method of high-conductive coke / ceramic composite material, which comprises the following steps: allocating raw material with 50-65% natural scale graphite, 25-32% middle-phase tar, 2.5-5% Si powder, 5-15% Ti powder; blending these materials evenly; placing mixed raw material into ball grinder; introducing distilled water and polyvinyl alcohol to ball 1-3h; drying in the vacuum; removing solvent; heating to 2600-2800 Deg C at 200-600Deg C / h; pressurizing to 20-40Mpa under maximum high temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

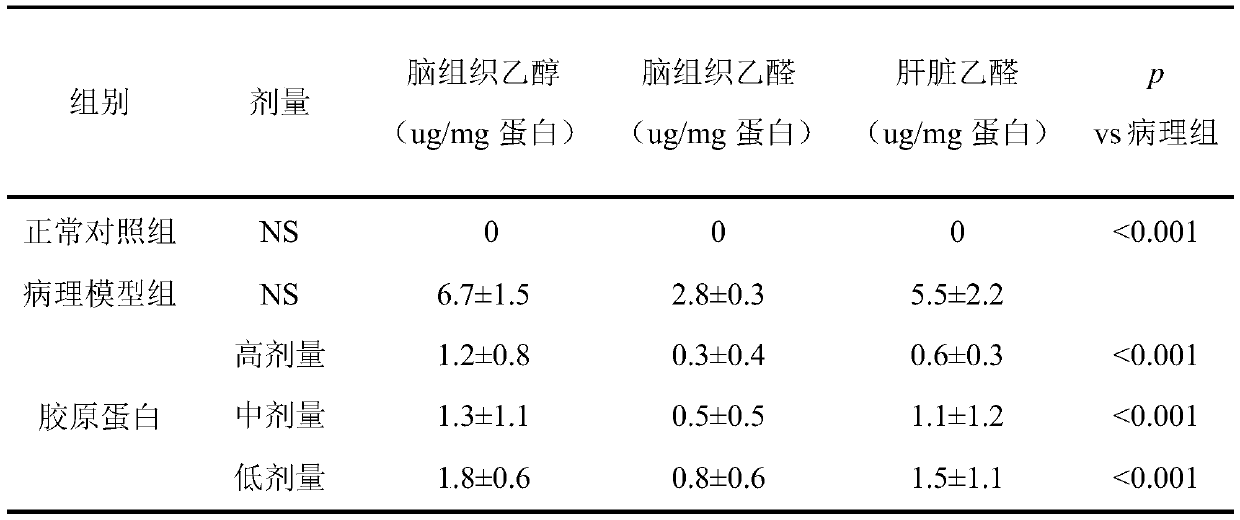

Medicine health-care usage of globefish I collagen extraction and preparing process thereof

InactiveCN100584343CBiologically activeLittle side effectsNervous disorderPeptide/protein ingredientsDiseaseHydrolysate

Owner:NANJING BESSON PHARMACY

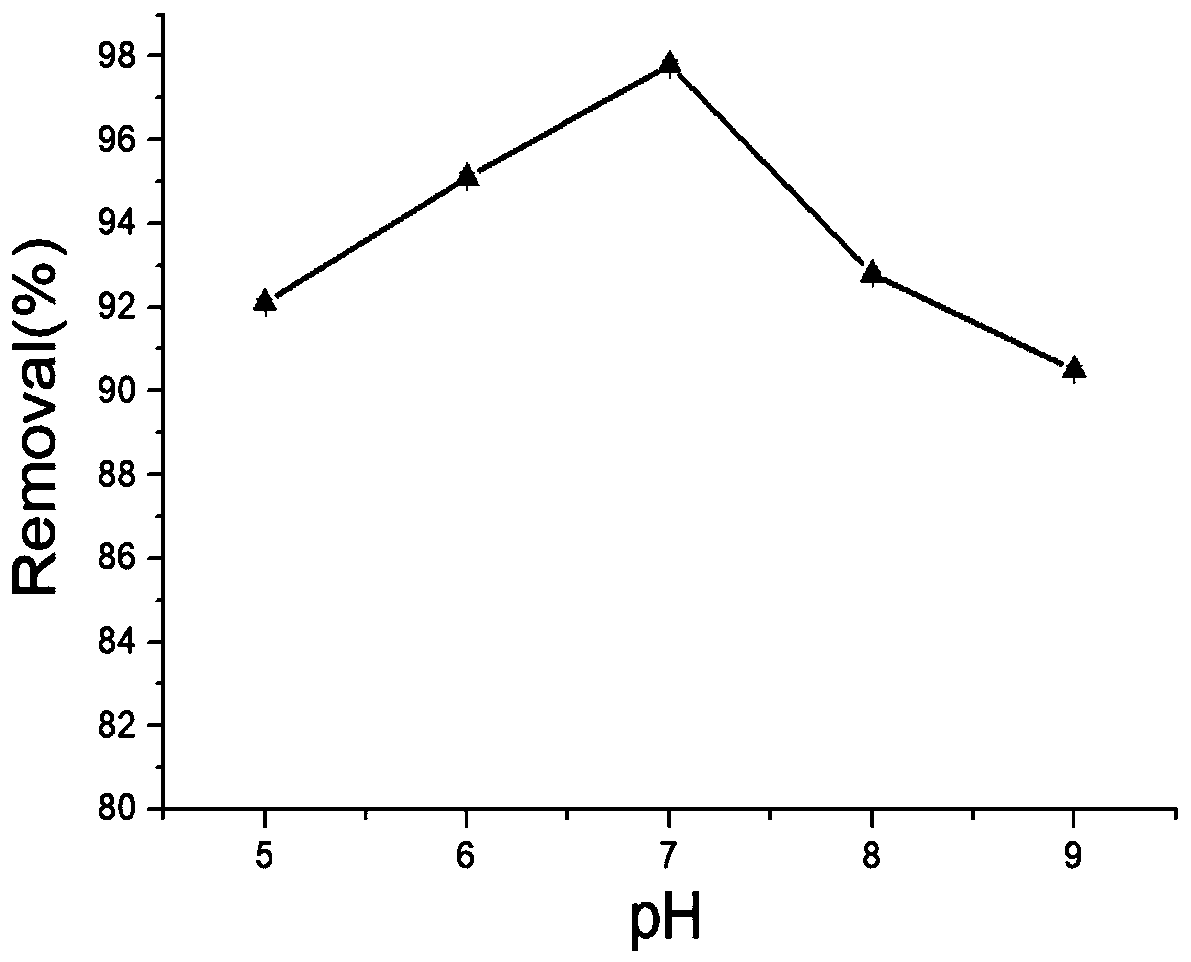

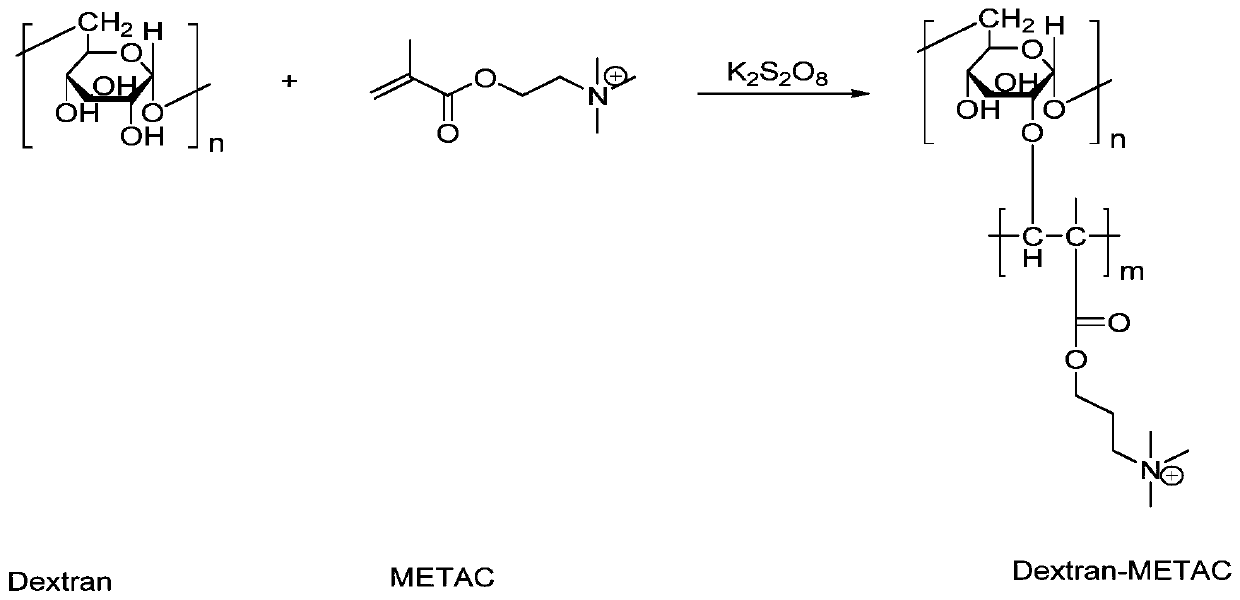

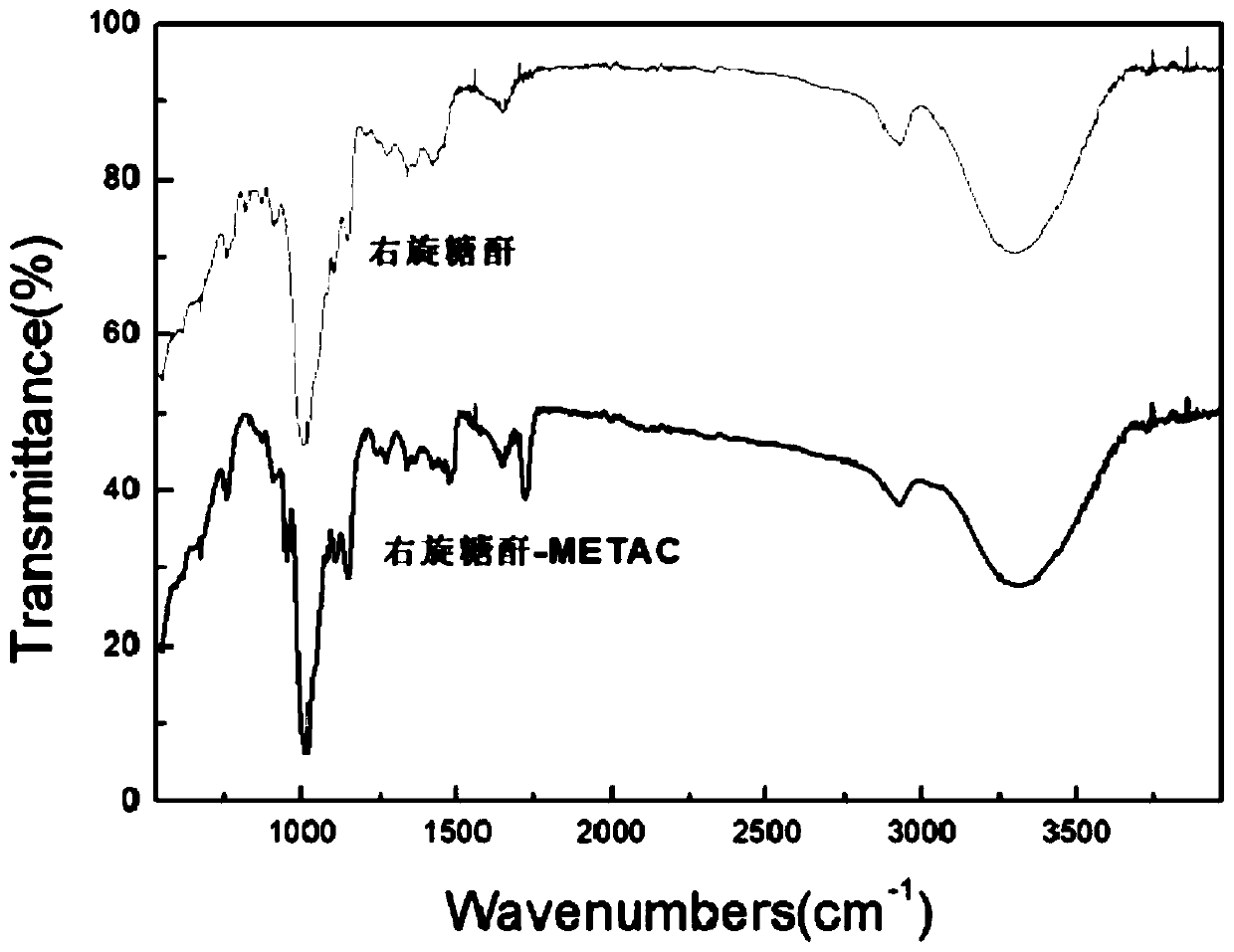

Cationic dextran-based polymer and preparation thereof, and applications as flocculant

InactiveCN110437378AIncrease production capacityPromote degradationWater/sewage treatment by flocculation/precipitationPotassium persulfateBiopolymer

The invention discloses a cationic dextran-based polymer preparation method, which comprises: adding potassium persulfate to a dextran solution under an oxygen-free condition, stirring for 15-20 min,adding METAC, carrying out a reaction for 2-4 h at a temperature of 65-75 DEG C, adding ethanol to obtain a precipitate, purifying, washing, and drying to obtain white dry solid particles, ie., the cationic dextran-based polymer, wherein a sucrose solution is subjected to an enzyme-catalyzed fermentation reaction with dextran sucrose to obtain the dextran solution. Compared with the commercially available organic flocculant, the flocculating agent of the invention is safe, non-toxic and pollution-free, does not contain environmentally harmful components, and achieves the industrial productionand application of environmentally-friendly bioflocculants; and based on the basic skeleton structure of the biopolymer, the grafted derivative can be regenerated, and has good biodegradability and good biocompatibility so as to meet the ecological concept of sustainable development.

Owner:安徽春霖环保科技有限公司

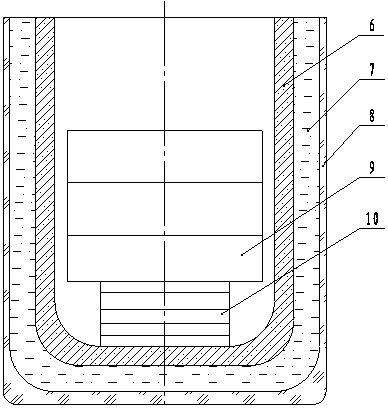

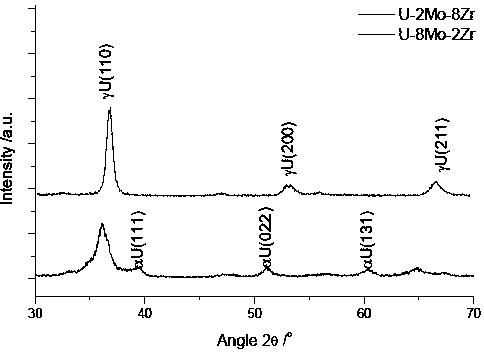

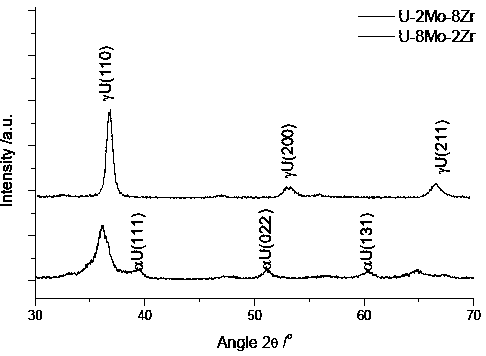

Preparing method for U-Mo-Zr alloy

The invention discloses a preparing method for a U-Mo-Zr alloy. The preparing method comprises the following steps of graphite crucible primary alloying, graphite sieve plate ingot leaking and ceramiccrucible secondary alloying. A primary ingot of a binary alloy is prepared through graphite crucible primary alloying firstly, then, a binary alloy ingot with few inclusions is obtained through ingotleaking in a graphite sieve plate, then, a tertiary alloy is prepared through ceramic crucible secondary alloying, and finally, the needed U-Mo-Zr alloy is obtained. In the preparing method, the graphite sieve plate is additionally arranged for conducting primary alloying, ceramic crucible secondary alloying and other optimization technology lines, technology parameters are reasonably controlled,and dissolving and diffusing of alloy elements are more sufficient. Meanwhile, the inclusions are further controlled through ingot leaking, ceramic crucible smelting is adopted for secondary alloying, the alloy purity is greatly improved, and the alloy uniformity is improved. In addition, the high-quality U-Mo-Zr alloy can be obtained by adopting three procedures, and the period of the preparingtechnology is short.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

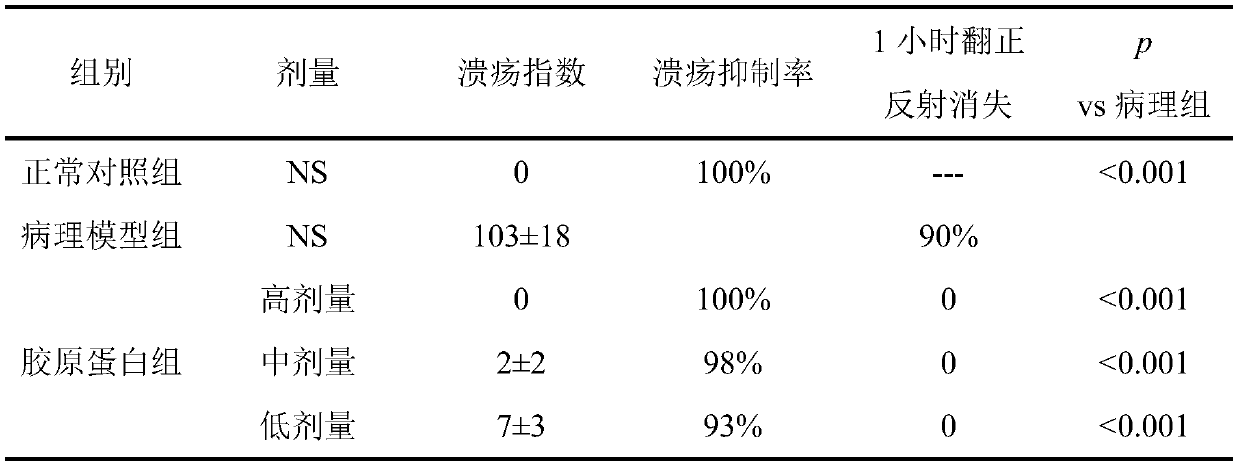

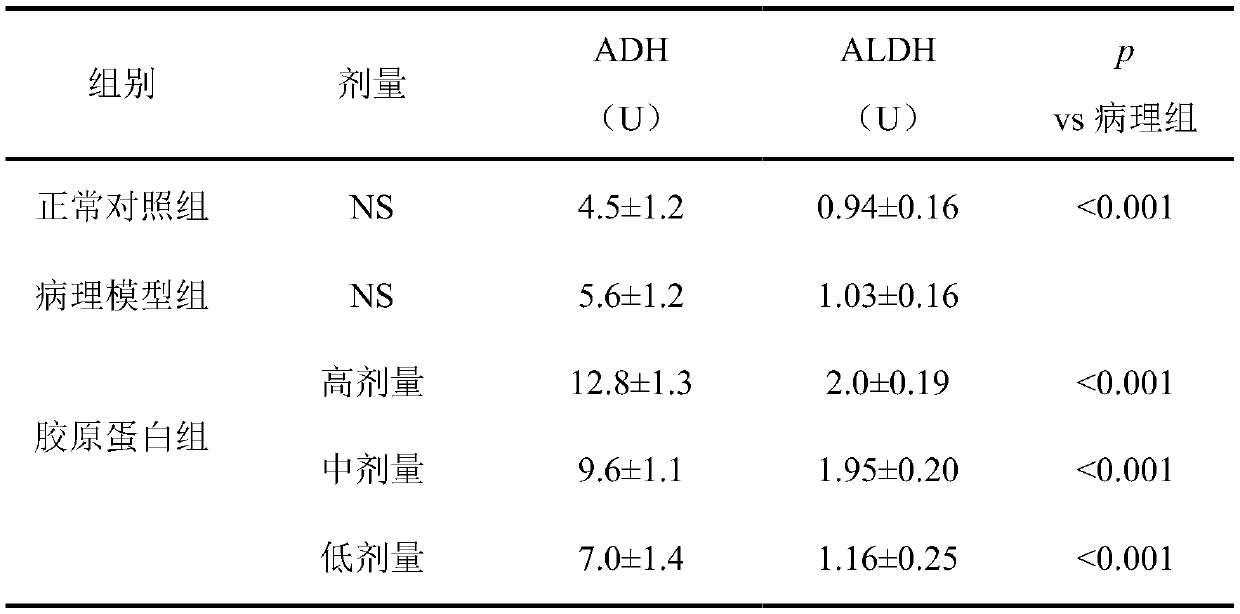

High-efficiency quick-acting long-acting hangover-alleviating agent

InactiveCN111214652AThe preparation process cycle is shortImprove pharmacological activityHydrolysed protein ingredientsDigestive systemPartial hydrolysisHydrolysate

The invention discloses a composition with a hangover alleviating effect. The composition comprises collagen and a partial hydrolysate thereof, wherein the collagen comprises denatured collagen. According to the invention, fish, cattle and pigs are used as raw materials, and collagen or denatured collagen thereof, a mixture of the collagen and the denatured collagen thereof and the partial hydrolysate of the collagen are prepared through extraction, concentration and partial hydrolysis; and experiments prove that the collagen or the denatured collagen thereof and the partial hydrolysate of thecollagen have an excellent hangover alleviating effect and can be used for preparing hangover alleviating agents.

Owner:南京顶顶生物科技有限公司

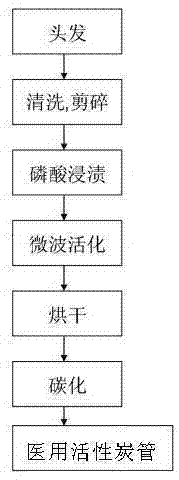

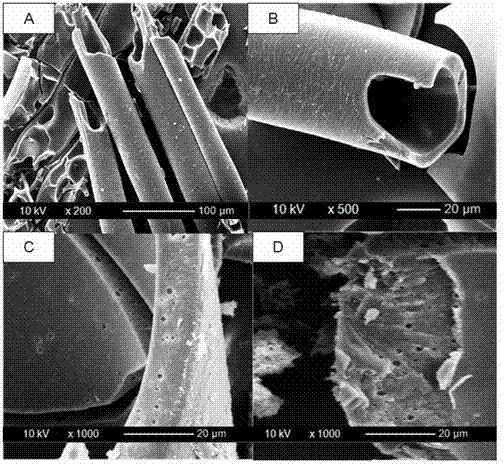

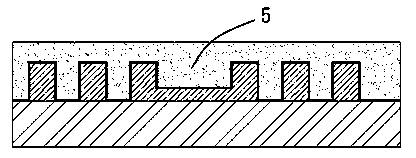

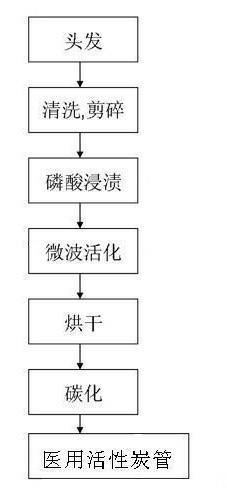

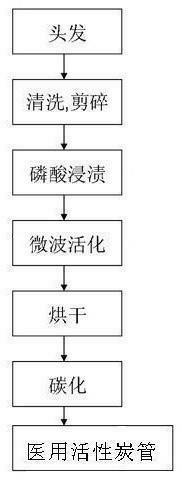

Method for preparing medical active carbon tube by utilizing hairs

InactiveCN102602931BUniform wall thicknessSimple preparation processCarbon compoundsMicrowaveCarbonization

Owner:WUHAN TEXTILE UNIV

Method for preparing high thermal conductivity graphite material

ActiveCN101538036BImprove thermal conductivityThe preparation process cycle is shortFree coolingGraphite

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

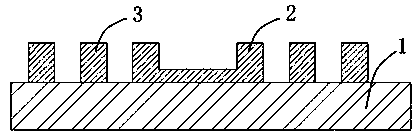

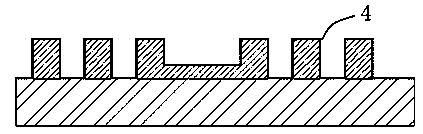

Sacrificial layer of micromechanical structure and manufacture method of micromechanical structure

ActiveCN104261346AEfficient removalLow costDecorative surface effectsChemical vapor deposition coatingMicrometerAlloy

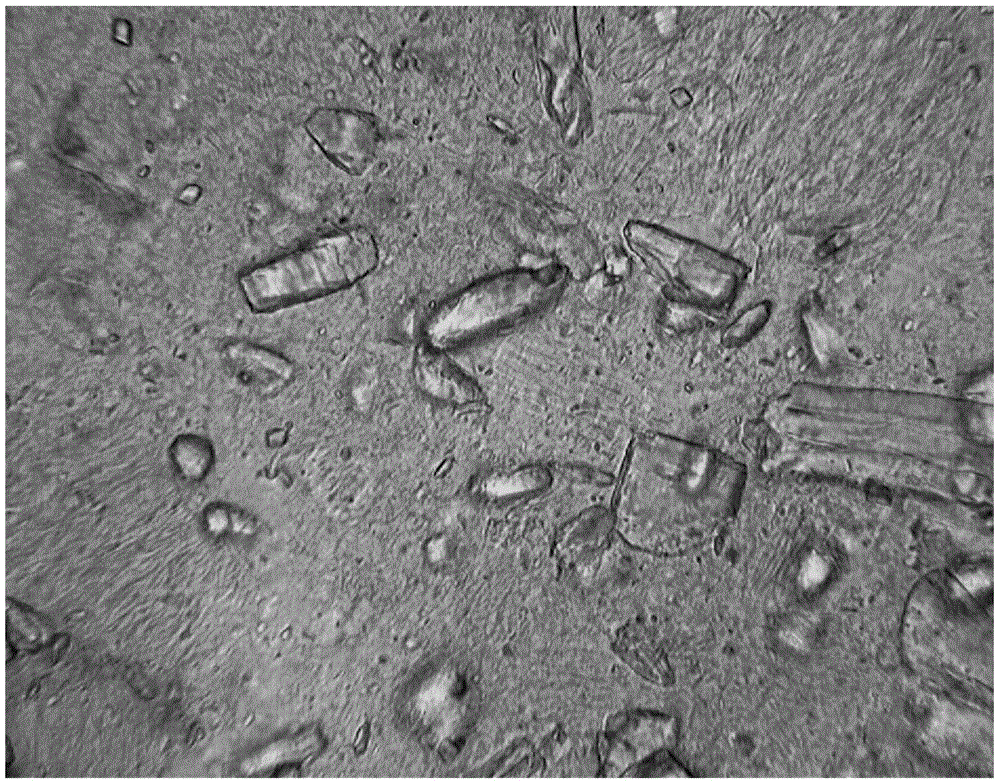

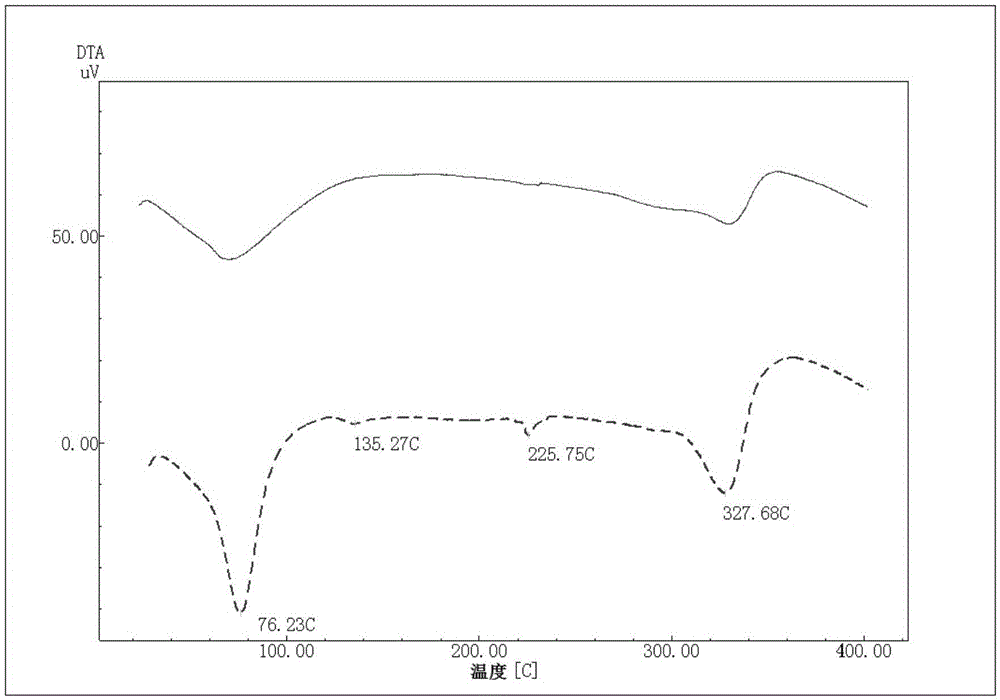

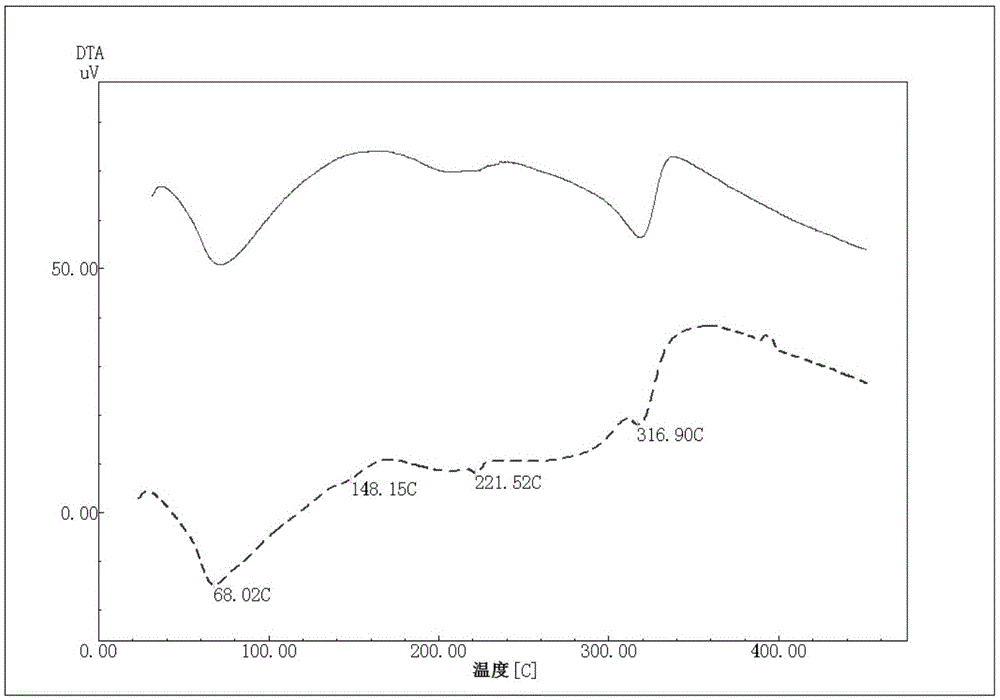

The invention provides a sacrificial layer of a micromechanical structure and a manufacture method of the micromechanical structure. Low-melting-point alloy is used for manufacturing the sacrificial layer of the micromechanical structure and refers to an alloy material with melting point of the alloy of below 300 DEG C; the sacrificial layer of the micromechanical structure can reach hundreds of micrometers, can be rapidly and effectively removed and can be compatible with organic matters; and the manufacture method of the micromechanical structure based on the sacrificial layer process can be operated simply, and the process period is 1 / 4 of that of the conventional thin film deposition method.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Method for preparing medical active carbon tube by utilizing hairs

InactiveCN102602931AUniform wall thicknessSimple preparation processCarbon compoundsMicrowaveCarbonization

The invention relates to a method for preparing a medical active carbon tube by utilizing hairs. The method comprises the following steps of: firstly cutting the hairs into small sections, then soaking the small sections of hairs into activating agent solution, then carrying out microwave activation, and finally carrying out high-temperature carbonization. The method has the beneficial effects that 1, the preparation process is simple, energy-saving and environment-friendly; 2, the prepared medical active carbon is stable, and the thickness of the tube wall is even, and the prepared medical active carbon is excellent medical active carbon; 3, the preparation process is short in period, and low in energy consumption, and the product yield is high; and 4, a new path for raw materials of the medical active carbon tube is opened up, and the method has important application prospect.

Owner:WUHAN TEXTILE UNIV

A kind of wave-transparent silicon nitride radome material and preparation method thereof

The invention discloses a wave-transparent silicon nitride radome material and a preparation method thereof. The wave-transparent Si3N4 radome material uses low-density porous silicon nitride as a core layer, uses silicon nitride or boron nitride chopped fibers or crystal whiskers as a core layer reinforcement phase, and uses condense silicon nitride as a surface coating layer. Firstly, after being mixed with the silicon nitride or boron nitride chopped fibers for pelletizing, silicon powder is evenly mixed with pore forming agent by a certain ratio, and is molded to a blank with a certain shape; the pore forming agent is totally decomposed at the temperature of 200-300 DEG C to obtain a porous blank. Then, the nitriding treatment is implemented to obtain a chopped fiber-reinforced porous silicon nitride ceramic body; the drying is implemented after the ultrasonic cleaning. Finally, the chemical vapor deposition (CVD) is implemented for the porous silicon nitride ceramic body to prepare a condense silicon nitride coating layer. The wave-transparent silicon nitride radome material and the preparation method thereof have the following advantages: (1) the chopped fibers or crystal whiskers are inlaid in the porous silicon nitride core layer to act the reinforcement effect; (2) the condense silicon nitride is on the outer layer of the porous silicon nitride core layer to act the water and steam permeation preventing effect; (3) the preparation process has short period and low cost.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

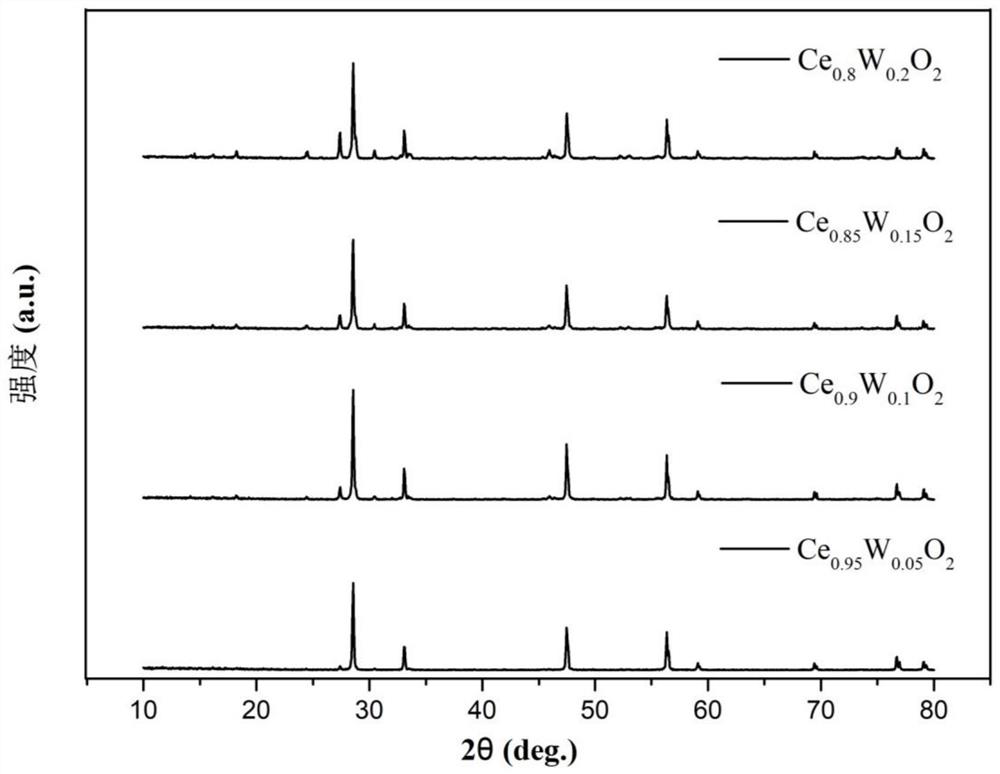

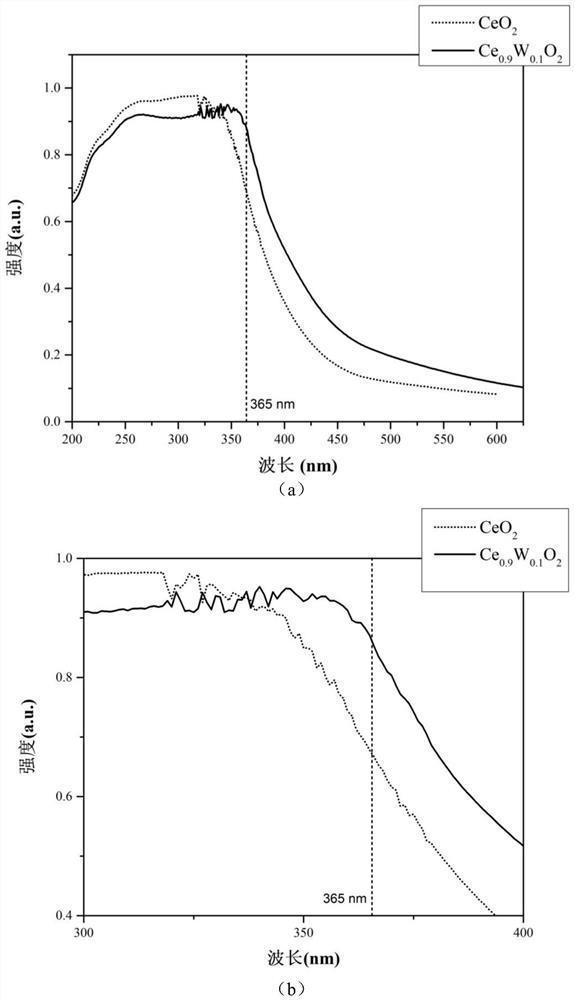

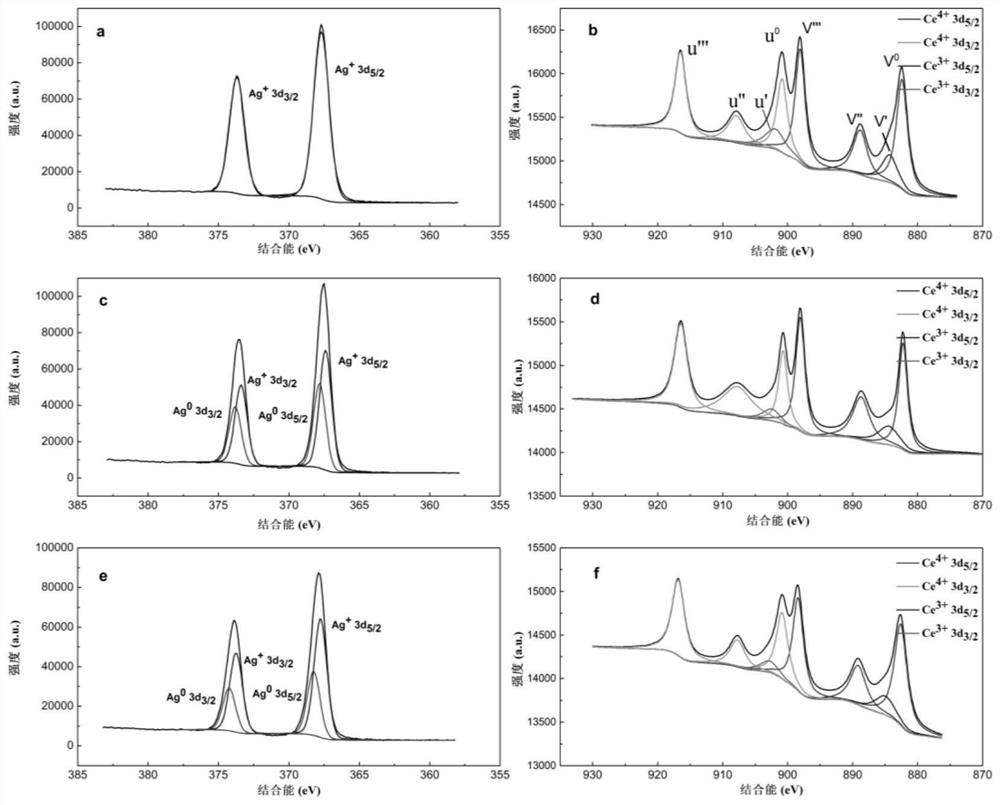

Cerium oxide-doped photosensitizer suitable for photosensitive microcrystalline glass as well as preparation method and application of cerium oxide-doped photosensitizer

ActiveCN114133928AImprove efficiencyImprove exposure qualityCerium oxides/hydroxidesRare earth metal compounds preparation/treatmentCerium nitrateAmmonium metatungstate

The invention discloses a doped cerium oxide photosensitizer suitable for photosensitive microcrystalline glass and a preparation method and application thereof, the doped cerium oxide photosensitizer is represented by a general formula Ce < 1-x > W < x > O < 2 >, and in the general formula, x is equal to 0.05-0.25. The catalyst is prepared by taking cerium nitrate, ammonium metatungstate hydrate and organic fuel as raw materials and adopting a sol-gel self-propagating combustion method. According to the cerium oxide doped photosensitizer provided by the invention, W ion doping is carried out on the existing photosensitizer CeO2, so that the light absorption performance of the photosensitizer CeO2 is improved, and the absorption peak of the photosensitizer CeO2 is moved, so that the absorption peak of the photosensitizer CeO2 is matched with the existing light source, and the nucleation efficiency and the exposure quality of photosensitive microcrystalline glass are improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Pickling processing method of whole cucumbers

The invention provides a pickling processing method of whole cucumbers. The method comprises the steps of 1 salted cucumber selecting; 2 prickling; 3 desalting and deairing; 4 selecting and cleaning; 5 flavoring and pickling, wherein desalted cucumbers and flavoring liquid are prepared according to the ratio of 3:1 and then pickled; 6 cold store refrigerating, circulating and analyzing; 7 packaging; 8 pasteurizing and drying. The pickling processing method has the advantages that the cucumbers are unique in flavor, spicy, crisp, adapted to the taste of most eaters of the brand regions, capable of being eaten once package bags are open, convenient to carry, short in preparation process cycle and suitable for batch production.

Owner:TIANJIN QIANDE FOOD

Cordyceps sinensis micro-powder containing cyclodextrin and preparation method and preparation of cordyceps sinensis micro-powder

InactiveCN105616451AImprove stabilityProlonged decomposition half-lifeDispersion deliveryPill deliverySolubilityCordyceps

The invention discloses cordyceps sinensis micro-powder containing cyclodextrin and a preparation method and a preparation of the cordyceps sinensis micro-powder. The cordyceps sinensis micro-powder is mainly prepared from cordyceps sinensis and cyclodextrin. The invention further discloses the preparation method of the cordyceps sinensis micro-powder, the preparation containing the cordyceps sinensis micro-powder and the preparation method of the preparation. Compared with the prior art, the prepared cordyceps sinensis micro-powder is capable of significantly promoting full release of cordyceps sinensis components, significantly improving the solubility of insoluble components and strengthening the stability of the components.

Owner:NANJING NORMAL UNIVERSITY +1

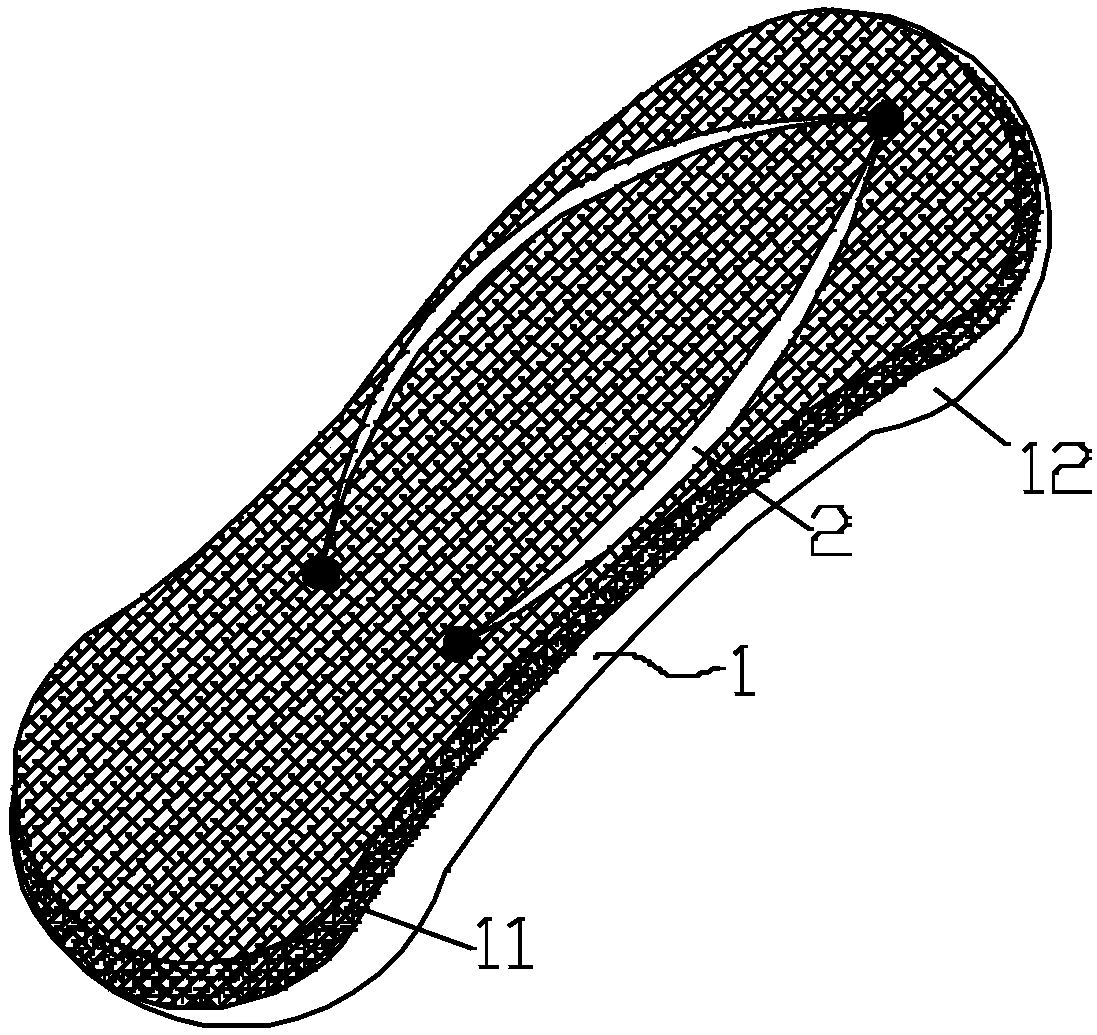

3D slipper printing method and slippers

InactiveCN107684188ADifficult to reproduceThe preparation process cycle is shortAdditive manufacturing apparatusSolesEngineering3d printer

The invention discloses a 3D slipper printing method and slippers. The 3D slipper printing method comprises the steps that shoe sole layers are tailored for use; foot pressure data is acquired to form3D printing drawings, the 3D printing drawings are transmitted to a 3D printer; the surfaces of the shoe sole layers are fused through high temperature of the 3D printer and are bonded with the bottom surfaces of upper-layer frames of shoe soles through melt blending in an adhesive-free mode, hollow-out upper-layer frame structures are printed on the shoe sole layers through the 3D printer layerby layer, and shoe sole making is completed; the made shoe soles are punched, shoe uppers are inserted, and slipper making is completed. Slipper soles are made by adopting a 3D printing technology, amaking process period of the method is short, the cost is low, the operation is simple, the soles of slippers are of the hollow-out upper-layer frame structures, the upper-layer frame structures and the shoe sole layers are combined together in the material bonding mode of melt blending, raw materials are saved, the firmness and air permeability of the shoe sole layers are improved, and bacteria are not likely to breed.

Owner:XIFENG 2D FUJIAN MATERIAL TECH CO LTD

Internal heating type integrated evaporation basket with aluminum oxide vesicular structure buffer layer

InactiveCN107245698AGuaranteed bonding strengthHigh bonding strengthMolten spray coatingVacuum evaporation coatingPorosityVacuum evaporation

The invention discloses an internal heating type integrated evaporation basket with an aluminum oxide vesicular structure buffer layer. Two layers of coatings are totally arranged on the surface of the evaporation basket, the inner layer is a Al2O3 buffer layer of a loose vesicular structure, the outer layer is a compact and low-porosity corrosion resistance Al2O3 coating, and a spinning impregnation technology is adopted for preparing a Al2O3 buffer layer with the thickness ranging from 0.15 mm to 0.5 mm on the surface of a base; and then a plasma spraying technology is adopted for preparing a Al2O3 corrosion resistance layer with the thickness ranging from 0.5 mm to 1 mm on the evaporation basket on the buffer layer in a spraying manner. According to the internal heating type integrated evaporation basket, a composite process is adopted for preparing the Al2O3 coating evaporation basket of different microstructures, the buffer layer of the vesicular structure can achieve the stress releasing effect on service, and the problem of base oxidation caused by follow-up spraying can be prevented; and the compact and low-porosity Al2O3 coating layer has the excellent corrosion resistance, and the internal heating type integrated evaporation basket can be permanently and widely applied to the technical field of metal thin film vacuum evaporation.

Owner:FUZHOU UNIV

A kind of preparation method of u-mo-zr alloy

The invention discloses a preparing method for a U-Mo-Zr alloy. The preparing method comprises the following steps of graphite crucible primary alloying, graphite sieve plate ingot leaking and ceramiccrucible secondary alloying. A primary ingot of a binary alloy is prepared through graphite crucible primary alloying firstly, then, a binary alloy ingot with few inclusions is obtained through ingotleaking in a graphite sieve plate, then, a tertiary alloy is prepared through ceramic crucible secondary alloying, and finally, the needed U-Mo-Zr alloy is obtained. In the preparing method, the graphite sieve plate is additionally arranged for conducting primary alloying, ceramic crucible secondary alloying and other optimization technology lines, technology parameters are reasonably controlled,and dissolving and diffusing of alloy elements are more sufficient. Meanwhile, the inclusions are further controlled through ingot leaking, ceramic crucible smelting is adopted for secondary alloying, the alloy purity is greatly improved, and the alloy uniformity is improved. In addition, the high-quality U-Mo-Zr alloy can be obtained by adopting three procedures, and the period of the preparingtechnology is short.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

A kind of method for preparing manganese molybdate telluride by self-propagating combustion of citrate gel

ActiveCN107720709BSimple preparation processLow costSelenium/tellurium compounds with other elementsChemical synthesisManganese

The invention relates to the technical field of chemical synthesis, in particular to a method for preparing manganese telluride molybdate by self-propagating combustion of citrate gel. The method comprises the following steps of: (1) dissolving citric acid in ammonia water to form a solution A; (2) dissolving raw materials of a Mn source, a Te source and a Mo source in nitric acid according to a stoichiometric ratio to form a solution B; (3) under the condition of magnetic stirring, mixing the solution A and the solution B to form gray milk; (4) dissolving the milk with ammonia water until themilk is clear, and adjusting the pH value of the solution to 7.5-8.5; (5) uniformly stirring the solution to obtain a Mn-Te-Mo sol; (6) drying the prepared Mn-Te-Mo sol to obtain a Mn-Te-Mo gel; and(7) heating the Mn-Te-Mo gel to realize self-burning of the gel after a few minutes to form loose manganese telluride molybdate powder. The method provided by the invention has the advantages of simple preparation process, continuous production, low price and low cost of equipment used for preparation, and short preparation process period.

Owner:YIBIN UNIV

Method for preparing highly heat-conductive carbon/ceramic composite material

The invention discloses a preparing method of high-conductive coke / ceramic composite material, which comprises the following steps: allocating raw material with 50-65% natural scale graphite, 25-32% middle-phase tar, 2.5-5% Si powder, 5-15% Ti powder; blending these materials evenly; placing mixed raw material into ball grinder; introducing distilled water and polyvinyl alcohol to ball 1-3h; drying in the vacuum; removing solvent; heating to 2600-2800 Deg C at 200-600Deg C / h; pressurizing to 20-40Mpa under maximum high temperature.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Process for producing ferro-molybdenum through electrothermal method

InactiveCN106906362AThe preparation process cycle is shortReduce the difficulty of operationPollutionHigh heat

The invention discloses a process for producing ferro-molybdenum through an electrothermal method. The process includes the following steps that A, molybdenite is roasted to obtain molybdenum oxide minerals; B, the molybdenum oxide minerals are smashed, ferric oxide powder and carbon powder are added into the smashed molybdenum oxide minerals for uniform mixing; C, a binder is added into mixed powder and then briquetting is performed; and D, a briquetted blank is put in a high-temperature electrothermal furnace to be smelted, and then the ferro-molybdenum can be obtained. By means of the process for producing the ferro-molybdenum through the electrothermal method, the molybdenite is roasted, powdered and uniformly mixed together with the ferric oxide powder and the carbon powder to obtain the mixture, the mixture is briquetted, smelting is performed through the high-temperature electrothermal furnace so as to obtain the ferro-molybdenum, equipment is simple, the period of the preparation process is short, the operation difficulty is low, the environment is protected, pollution is avoided, and the production and manufacturing cost is low.

Owner:SICHUAN DONGYU INFORMATION TECH

An internally heated integrated evaporation basket with a buffer layer of alumina porous structure

InactiveCN107245698BGuaranteed bonding strengthHigh bonding strengthMolten spray coatingVacuum evaporation coatingPorosityVacuum evaporation

The invention discloses an internal heating type integrated evaporation basket with an aluminum oxide vesicular structure buffer layer. Two layers of coatings are totally arranged on the surface of the evaporation basket, the inner layer is a Al2O3 buffer layer of a loose vesicular structure, the outer layer is a compact and low-porosity corrosion resistance Al2O3 coating, and a spinning impregnation technology is adopted for preparing a Al2O3 buffer layer with the thickness ranging from 0.15 mm to 0.5 mm on the surface of a base; and then a plasma spraying technology is adopted for preparing a Al2O3 corrosion resistance layer with the thickness ranging from 0.5 mm to 1 mm on the evaporation basket on the buffer layer in a spraying manner. According to the internal heating type integrated evaporation basket, a composite process is adopted for preparing the Al2O3 coating evaporation basket of different microstructures, the buffer layer of the vesicular structure can achieve the stress releasing effect on service, and the problem of base oxidation caused by follow-up spraying can be prevented; and the compact and low-porosity Al2O3 coating layer has the excellent corrosion resistance, and the internal heating type integrated evaporation basket can be permanently and widely applied to the technical field of metal thin film vacuum evaporation.

Owner:FUZHOU UNIV

An internal heating integrated evaporation boat with alumina porous structure buffer layer

InactiveCN107326330BSolve Oxidation ProblemsHigh bonding strengthVacuum evaporation coatingSputtering coatingPorosityStress relieving

The invention discloses an internal-heated integrated evaporation boat with an aluminum oxide porous structure buffering layer. Surface coatings of the evaporation boat totally comprise two layers. The inner layer is the Al2O3 buffering layer of a loose porous structure, and the outer layer is the compact low-porosity corrosion-resistantAl2O3 coating. Firstly, through a rotary-coating steeping technique, the Al2O3 buffering layer with the thickness being 0.1-0.3 mm is prepared on the surface of a matrix; and then through a plasma spraying technology, the Al2O3 corrosion-resistantlayer with the thickness being 0.5-1 mm is sprayed and prepared on the evaporation boat with the buffering layer. According to the composite technique, the evaporation boat with the Al2O3 coatings of different microstructures is prepared; in service, the buffering layer of the porous structure can achieve the stress relieving effect and can further prevent the problem of matrix oxidization caused by later spraying; and the compact low-porosity Al2O3 coating brings excellent corrosion resistance into play and can be widely applied to the technical field of vacuum evaporation metal thin films.

Owner:FUZHOU UNIV

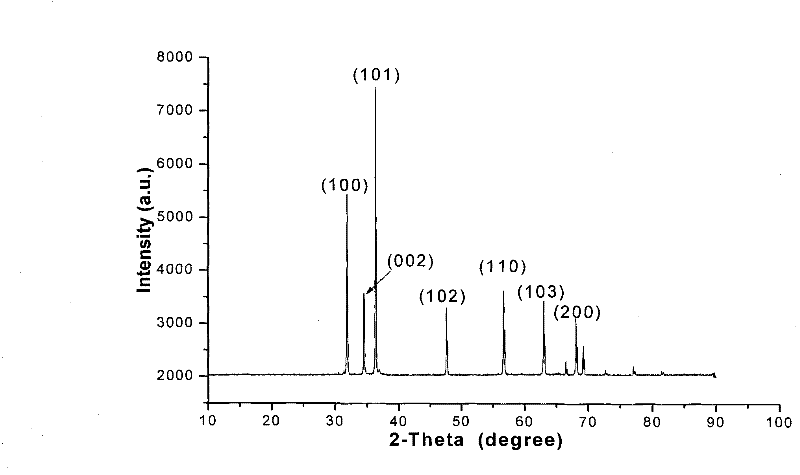

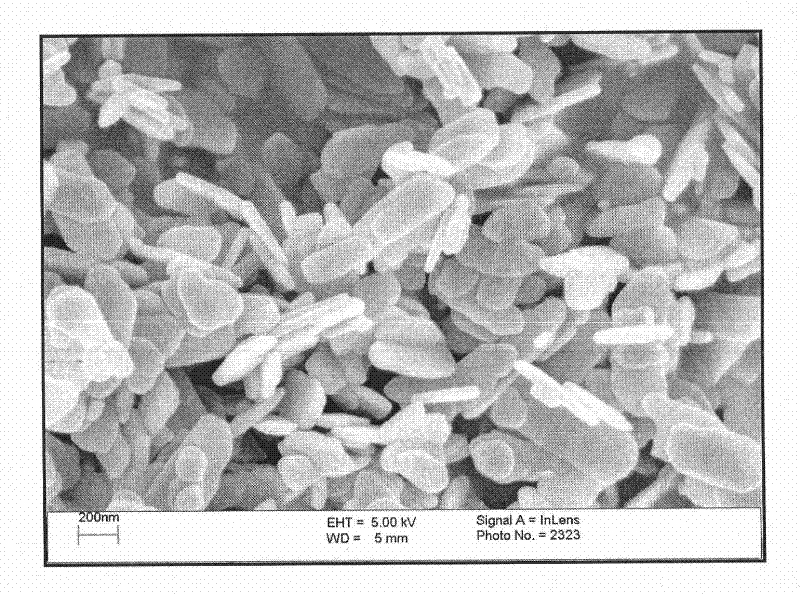

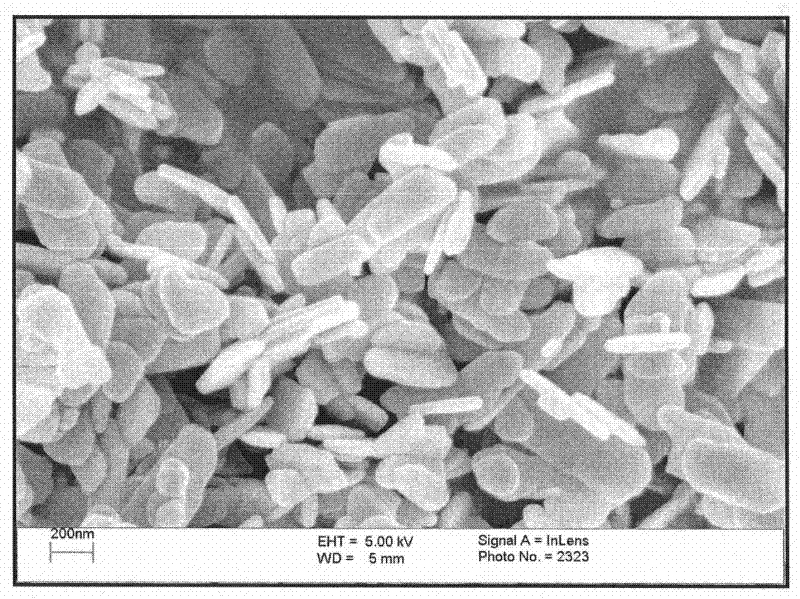

Preparation method of flaky nanometer zinc oxide powder

ActiveCN101767813BThe preparation process cycle is shortLow costNanostructure manufactureZinc oxides/hydroxidesRoom temperatureWater soluble

Owner:宁夏中色新材料有限公司

Preparation technology of phenylboronic acid reaction liquid

InactiveCN106117255ASimple processThe preparation process cycle is shortGroup 3/13 element organic compoundsPhenylboronic acidManufacturing technology

The invention discloses a preparation technology of phenylboronic acid reaction liquid, and relates to the technical field of chemical preparation. The preparation technology comprises the following steps of under the protection of nitrogen, enabling anhydrous tetrahydrofuran, iodobenzene and n-BuLi to be subjected to an interaction so as to prepare layered reaction liquid; then through triisopropyl borate, hydrochloric acid and MTBE, obtaining an organic matter; and finally performing extraction and separation on the organic matter so as to obtain phenylboronic acid crude products. The preparation technology is simple in technological process and short in period, mass production requirements can be met, besides, the preparation period is short, and the working efficiency is high.

Owner:XUCHANG HAOFENG CHEM TECH

Surface treatment method for phosphate green phosphor for illumination

InactiveCN102888216AImprove anti-aging propertiesImprove the problems of coagulation and poor coating performanceLuminescent compositionsPhosphorPhosphate

The invention discloses a surface treatment method for phosphate green phosphor for illumination. The method comprises the following steps of: metering rare-earth material, namely nitrate of which the stoichiometric ratio is 0.001 to 0.01 based on the weight of rare-earth phosphate phosphor, and adding the rare-earth material, namely nitrate into deionized water; stirring, and slowly adding phosphate phosphor powder into a solution; continuously stirring, and keeping constant temperature of between 30 and 35 DEG C; adding an alkaline aqueous solution KOH or ammonia water into the reaction solution; diluting until the concentration is about 1 percent; continuously stirring for over 4 hours; standing and settling; discharging water; washing for 3 to 5 times; dehydrating, firing at the temperature of between 150 and 200 DEG C for 1 to 2 hours; and sieving by using a 100-mesh nylon or stainless steel sieve to obtain phosphor of which the surface is coated with a film. By the method, the using performance of the rare-earth phosphate phosphor can be improved obviously, so that the effects of improving the quality of the formed film and short-wave ultraviolet resistance capacity can be achieved.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com