Method for preparing medical active carbon tube by utilizing hairs

A technology for activated carbon and hair, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low product yield, long process cycle, large energy consumption, etc., and achieve high product yield and simple preparation process. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

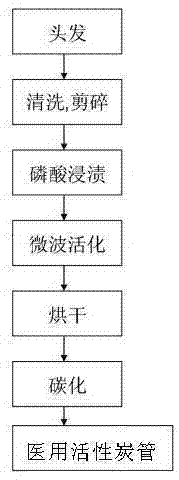

[0029] see figure 1 , a kind of method utilizing hair to prepare medical active carbon tube, concrete steps are:

[0030] Wash the hair several times with water to remove the impurities attached to the hair, at 105±5 o C dried and cut into small pieces with a length less than 5mm; then place this small piece of hair material in a phosphoric acid solution with a mass concentration of 30%, at 55 ± 5 o Soak for 24 hours at C, then activate with a microwave power of 300W for 5 minutes, then rinse the activated hair with deionized water and dry it at 105±5 o C drying; finally the above-mentioned treated hair is placed in a tubular reactor for high-temperature carbonization treatment, and the high-temperature carbonization treatment process is: the tubular reactor is heated at a rate of 10 o C / min heating up to 270 o After C, keep it warm for 30 minutes, and finally cool to room temperature and take it out. The finished product is the medical activated carbon tube.

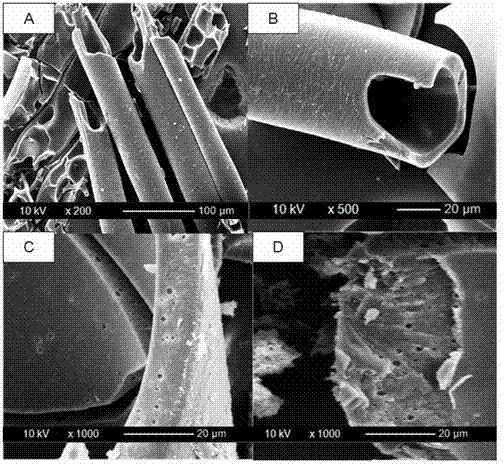

[0031] fi...

Embodiment 2

[0033] A method for preparing medical activated carbon tubes from hair, the specific steps are:

[0034] Wash the hair several times with water to remove the impurities attached to the hair, at 105±5 o C dried and cut into small pieces with a length less than 5mm; then place this small piece of hair material in a phosphoric acid solution with a mass concentration of 30%, at 55 ± 5 o Soak at C for 24 hours, then use a microwave activation treatment with a power of 450W for 5 minutes, then rinse the microwave-activated hair with deionized water and dry it at 105±5 o C drying; the above-mentioned dried hair is placed in a tubular reactor for high-temperature carbonization treatment, and the heating rate of carbonization treatment is 10 o C / min, when the temperature reaches 250 o C, keep it warm for 30 min, and finally take it out after it is cooled to room temperature to obtain the medical activated carbon tube.

[0035] figure 2 Middle B is the scanning electron microscop...

Embodiment 3

[0037] A method for preparing medical activated carbon tubes from hair, the specific steps are:

[0038] Wash the hair several times with water to remove the impurities attached to the hair, at 105±5 o C dried and cut into small pieces with a length less than 5mm; this small piece of hair material is placed in a phosphoric acid solution with a mass concentration of 30%, at 55 ± 5 oC Soak it under water for 24 hours, then use a microwave activation treatment with a power of 600W for 5 minutes, then rinse the microwave-activated hair with deionized water and dry it at 105±5 oC is dried, and then the above-mentioned dried hair is placed in a tubular reactor to carry out high-temperature carbonization treatment, and the heating rate of high-temperature carbonization treatment is 10 o C / min, when reaching the set temperature 230 o C, keep warm for 30 min, and take it out from the tubular reactor after it is cooled to room temperature, and the taken out is the medical activated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com