Preparation method for on-line pulling and extruding glass steel tube with multilayer annular weaving structure

A technology of annular weaving and fiberglass steel pipe, applied in the direction of household appliances, tubular items, other household appliances, etc., can solve the problems of insufficient extension of reinforcing fibers, loss of fiber prestressing effect, and fiber and fiber are not integrated, and achieve consistent strength, High production efficiency and uniform weaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

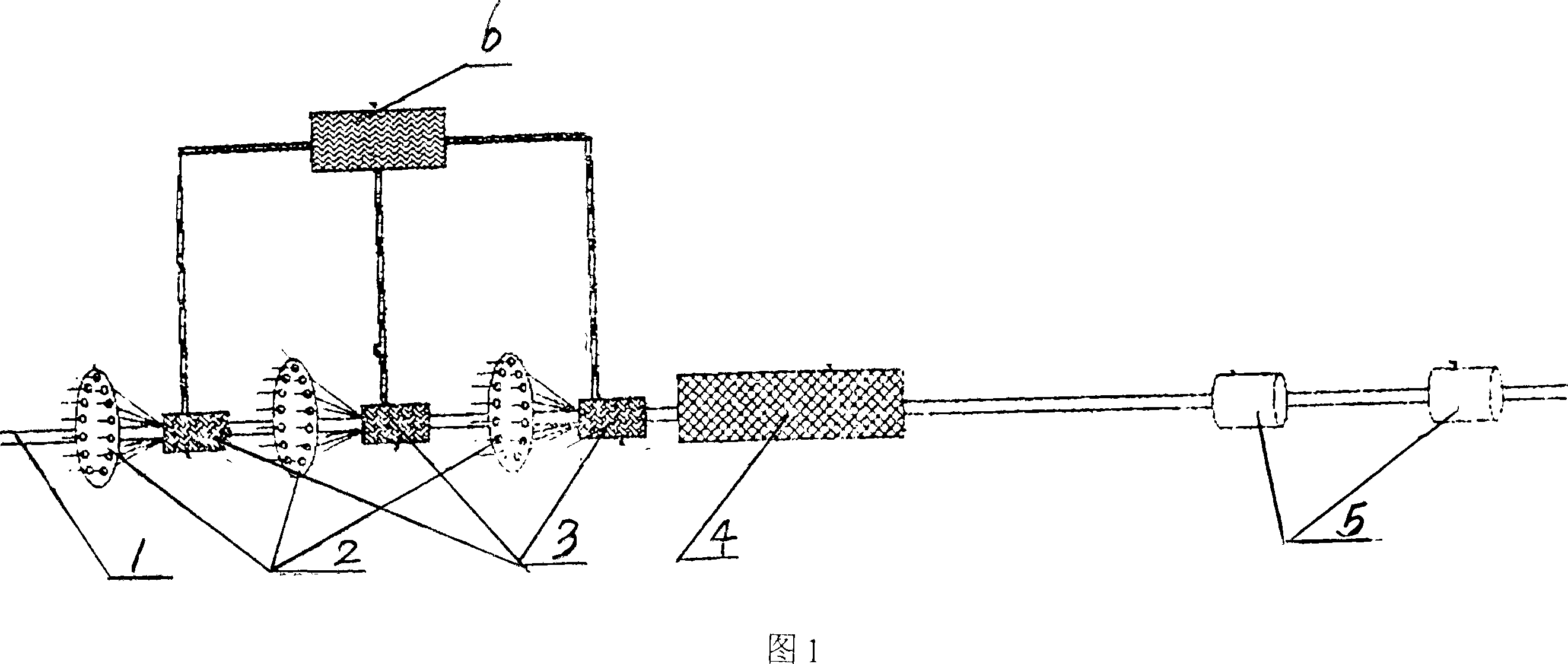

[0023] As can be seen from Fig. 1: the present invention adopts three two-dimensional horizontal braiding machines 1 controlled by computers to weave three-layer fiber annular braided layer composite glass steel pipes, and resin impregnation tanks 3 are arranged behind each braiding machine, and the first row Behind the three dipping tanks is the pultrusion mold 4; the core mold 1 is a uniform straight circular tube core mold with equal ends, the core mold is a mobile core mold that moves with the fiber annular braiding layer, and the core mold passes through the braiding machine , impregnation tank, and pultrusion die 4 move with the horizontal movement of the fibers drawn by the traction machine 5. It can also be seen from Figure 1 that a storage tank 6 is installed above the dipping tank, and the storage tank passes through the pipeline and the three dipping tanks. connected.

[0024] The operation process of the present invention is as follows: after the first braiding mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com