Method for preparing microencapsulation molybdenate

A technology of microencapsulation and molybdate, which is applied in the field of preparation of surface treatment of nanomaterials, can solve the problems of long cycle and achieve high yield, good modification effect and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

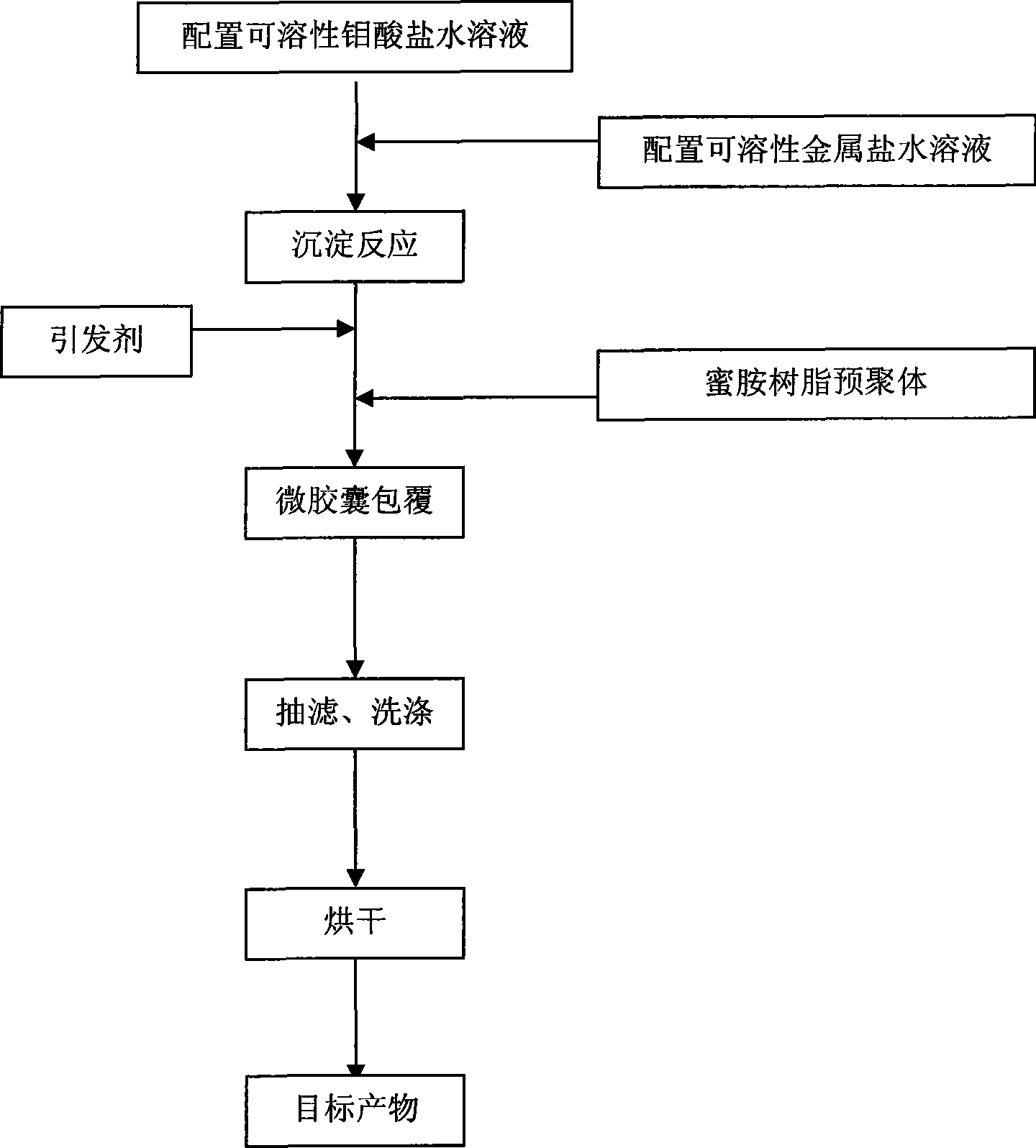

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Utilize the present invention to prepare microencapsulated calcium molybdate.

[0017] The first step: configure 1M sodium molybdate aqueous solution and 1M calcium chloride aqueous solution respectively;

[0018] Step 2: Add 50ml of 1M calcium chloride aqueous solution dropwise to 50ml of 1M sodium molybdate aqueous solution at 20°C, keep the pH at 6, and react for 15 minutes;

[0019] Step 3: Mix 2 g of melamine and 3.9 formaldehyde solution, react at pH=9-9.5, 85°C for 30 minutes, and prepare a prepolymer;

[0020] Step 4: Add 0.1 g of potassium persulfate and the above-mentioned prepolymer to the reaction product of the third step, adjust the pH value to 5.5, control the temperature at 55°C, and react for 2 hours;

[0021] Step 5: Suction filter the above reaction solution, and wash with water for 3 times;

[0022] Step 6: After washing, dry at 60°C to obtain microencapsulated calcium molybdate without grinding.

Embodiment 2

[0023] Embodiment 2: Utilize the present invention to prepare microencapsulated calcium molybdate.

[0024] The first step: configure 1M sodium molybdate aqueous solution and 1M calcium chloride aqueous solution respectively;

[0025] Step 2: Add 0.3g OP-10 to 50ml of 1M sodium molybdate aqueous solution and stir evenly;

[0026] Step 3: Slowly pour 50ml of 1M calcium chloride aqueous solution into the mixture in the second step at 60°C, keep the pH at 9, and react for 15 minutes;

[0027] Step 4: Mix 2 g of melamine and 3.9 formaldehyde solution, and react for 30 minutes at pH=9-9.5, 85°C to prepare a prepolymer;

[0028] Step 5: Add 0.1 g of potassium persulfate and the above-mentioned prepolymer to the reaction product of the third step successively, adjust the pH value to 5.5, control the temperature at 55°C, and react for 2 hours;

[0029] Step 6: Suction filter the above reaction solution, and wash with water for 3 times;

[0030] Step 7: After washing, dry at 60°C to...

Embodiment 3

[0032] Embodiment 3: Utilize the present invention to prepare microencapsulated calcium molybdate.

[0033] The first step: configure 3M sodium molybdate aqueous solution and 3M calcium chloride aqueous solution respectively;

[0034] The second step: add 0.3g polyethylene glycol 400 to 50ml of 3M sodium molybdate aqueous solution, and stir evenly;

[0035] Step 3: Slowly pour 50ml of 3M calcium chloride aqueous solution into the mixture in the second step at 60°C, keep the pH at 6, and react for 15 minutes;

[0036] Step 4: Mix 3 g of melamine and 6.0 g of formaldehyde solution, react at pH=9-9.5, 85°C for 30 minutes, and prepare a prepolymer;

[0037] Step 5: Add 0.2 g of sodium persulfate and the above-mentioned prepolymer to the reaction product of the third step successively, adjust the pH value to 5, control the temperature at 60°C, and react for 2 hours;

[0038] Step 6: Suction filter the above reaction solution, and wash with water for 3 times;

[0039] Step 7: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com