Sacrificial layer of micromechanical structure and manufacture method of micromechanical structure

A technology of micro-mechanical structure and manufacturing method, which is applied in the direction of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of high cost, difficulty in forming sacrificial layer materials, long process cycle, etc., and achieve low cost and production Short process cycle, fast and effective removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0037] A method for fabricating a sacrificial layer of a micromechanical structure, which uses a low-melting-point alloy as a material to make the sacrificial layer; the low-melting-point alloy refers to an alloy material with an alloy melting point below 300 degrees Celsius. This method not only solves the problem of filling and removing the sacrificial layer with a thickness exceeding 500 microns. Due to the low melting point alloy, the thermal stress in the process is small, the realization process is simple, and the cost is low. At the same time, it is compatible with organic materials in the structure.

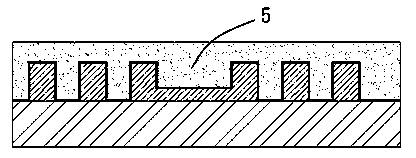

[0038] Such as image 3 with Figure 4 As shown, in this specific embodiment, the manufacturing method steps of the low melting point alloy sacrificial layer are:

[0039] 1. Coat the metal mixture material that forms a low melting point alloy on the base structure; uniformly coat the low melting point metal mixture on the base structure by printing or manual methods; ...

specific Embodiment 2

[0047] A method for manufacturing a micromechanical structure, the specific method steps are:

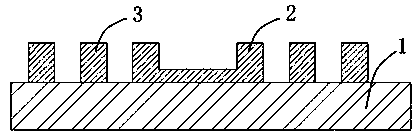

[0048] 1. If figure 1 As shown, the base structure of the micro-mechanical structure is made, including the substrate and the effective structure; before the micro-mechanical structure is made of a suspension or the final closed structure layer, the auxiliary materials used in the micro-structure processing are removed to expose the base structure that needs to be filled with a low-melting point alloy, including Effective structure and auxiliary structure.

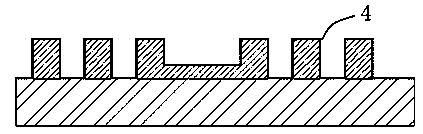

[0049] 2. If image 3 As shown, a metal mixture material forming a low-melting point alloy is coated on the base structure;

[0050] 3. If Figure 4 As shown, the metal mixture material is heated and alloyed to form a low melting point alloy filling; the low melting point metal mixture is evenly coated in the structure, and then heated and alloyed to form a relatively smooth low melting point alloy filling. After cooling, cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com