Preparing method for U-Mo-Zr alloy

A technology of alloy and alloy ingot, which is applied in the field of U-Mo-Zr alloy preparation, can solve the problems of material loss and impurity increase, and long process cycle, so as to improve alloy uniformity, high alloy purity, and increase melting temperature and the effect of smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

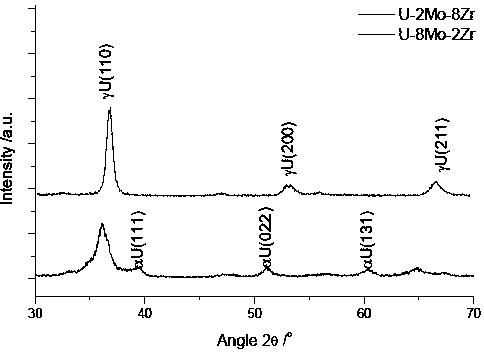

[0054] Example 1 Preparation of U-8Mo-2Zr alloy

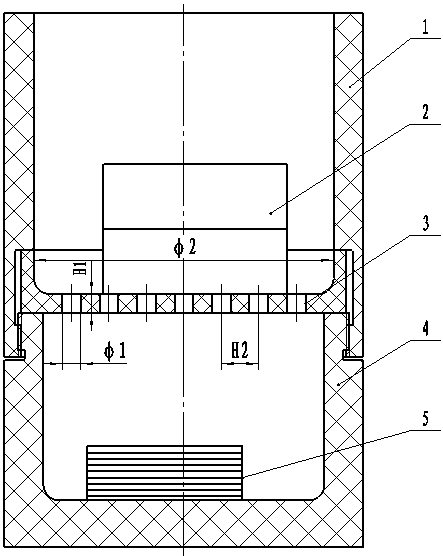

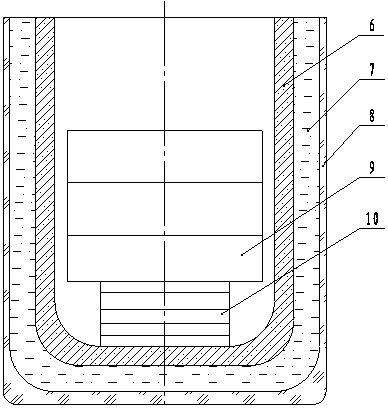

[0055] (1) U-8Mo alloy is prepared by one-time alloying with graphite crucible

[0056] The inner surface of the graphite crucible and the outer surface of the graphite sieve plate and the mesh holes are all plasma sprayed with calcium zirconate coating. Such as figure 1 As shown, the proportion of molybdenum raw material is adjusted to 8.3wt.%, and the molybdenum wire is placed under the graphite sieve plate, and the uranium ingot is placed on the graphite sieve plate. The sieve diameter of the graphite sieve plate is 5mm, and the center line of adjacent sieve holes The distance between them is 10mm, the sieve holes are evenly distributed, and the thickness of the sieve plate is 8mm. After the raw materials are placed, vacuum the furnace to 5*10 -2 After Pa, power is supplied, after the material is completely melted, the temperature is kept at 1500°C for 30min, and the temperature is reduced to 1200°C at a rate of 10°C / min, then t...

Embodiment 2

[0061] Example 2 Preparation of U-2Mo-8Zr alloy

[0062] (1) U-2Mo alloy is prepared by one-time alloying with graphite crucible

[0063] The inner surface of the graphite crucible and the outer surface of the graphite sieve plate and the mesh holes are all plasma sprayed with calcium zirconate coating. Such as figure 1 As shown, the proportion of molybdenum raw material is adjusted to 2.2wt.%, the molybdenum wire is placed under the graphite sieve plate, and the uranium ingot is placed on the graphite sieve plate. The sieve diameter of the graphite sieve plate is 5mm, and the center line of the adjacent sieve holes The distance between them is 10mm, the sieve holes are evenly distributed, and the thickness of the sieve plate is 8mm. After the raw materials are placed, vacuum the furnace to 5*10 -2 After Pa, the power is supplied, after the material is completely melted, the temperature is kept at 1450°C for 25min, the temperature is reduced to 1200°C at a rate of 12°C / min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com