3D slipper printing method and slippers

A 3D printing and 3D printer technology, applied in the field of 3D printing slippers, methods and slippers, can solve the problems of peculiar smell in the sole of the adhesive, long production cycle of slippers and short service life, etc. The effect of multiplying bacteria and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

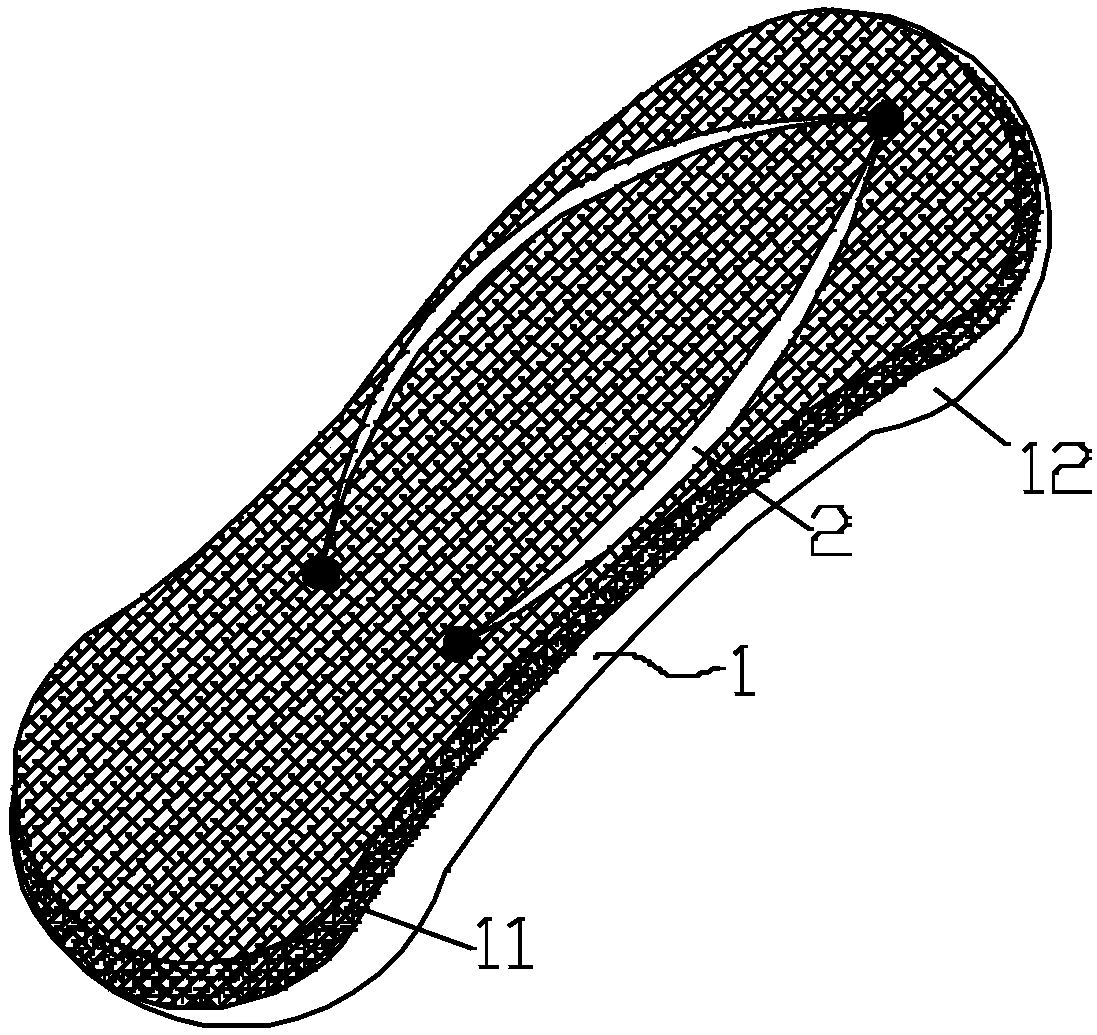

[0019] The invention discloses a method for 3D printing slippers, which includes:

[0020] Cut out the bottom layer of the sole for later use;

[0021] Collect foot pressure data, specifically, according to the actual wearer's foot pressure data, form 3D printing drawings, and send the 3D printing drawings to the 3D printer, thereby changing the traditional large-scale shoemaking method and realizing the tailoring of shoes Customized to meet the different needs of different groups of people for shoes, so that they have a better foot experience and improve their foot health;

[0022] The upper skeleton material of the sole is sintered at 130-180°C, and then supplied to the 3D printer nozzle. The 3D printer will select the sintered upper skeleton material according to the 3D printing drawing, and heat the upper skeleton material to 130-300°C through the 3D printer nozzle. ℃, and then directly print out the upper skeleton structure with different densities layer by layer on the ...

Embodiment 2

[0026] The difference from Example 1 is that in this example, the bottom layer is EVA, the upper frame is thermal Nylon, and the upper is polyurethane.

[0027] In practical applications, the bottom layer can also be at least one of PU, PVC or TPR; the upper skeleton is made of rubber, PP, PS, PMMA, PVC, Nylon, PC, PU, PTFE, PET, PETE or TPU. at least one of; the upper is cloth or rattan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com