Patents

Literature

126results about How to "Avoid spot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

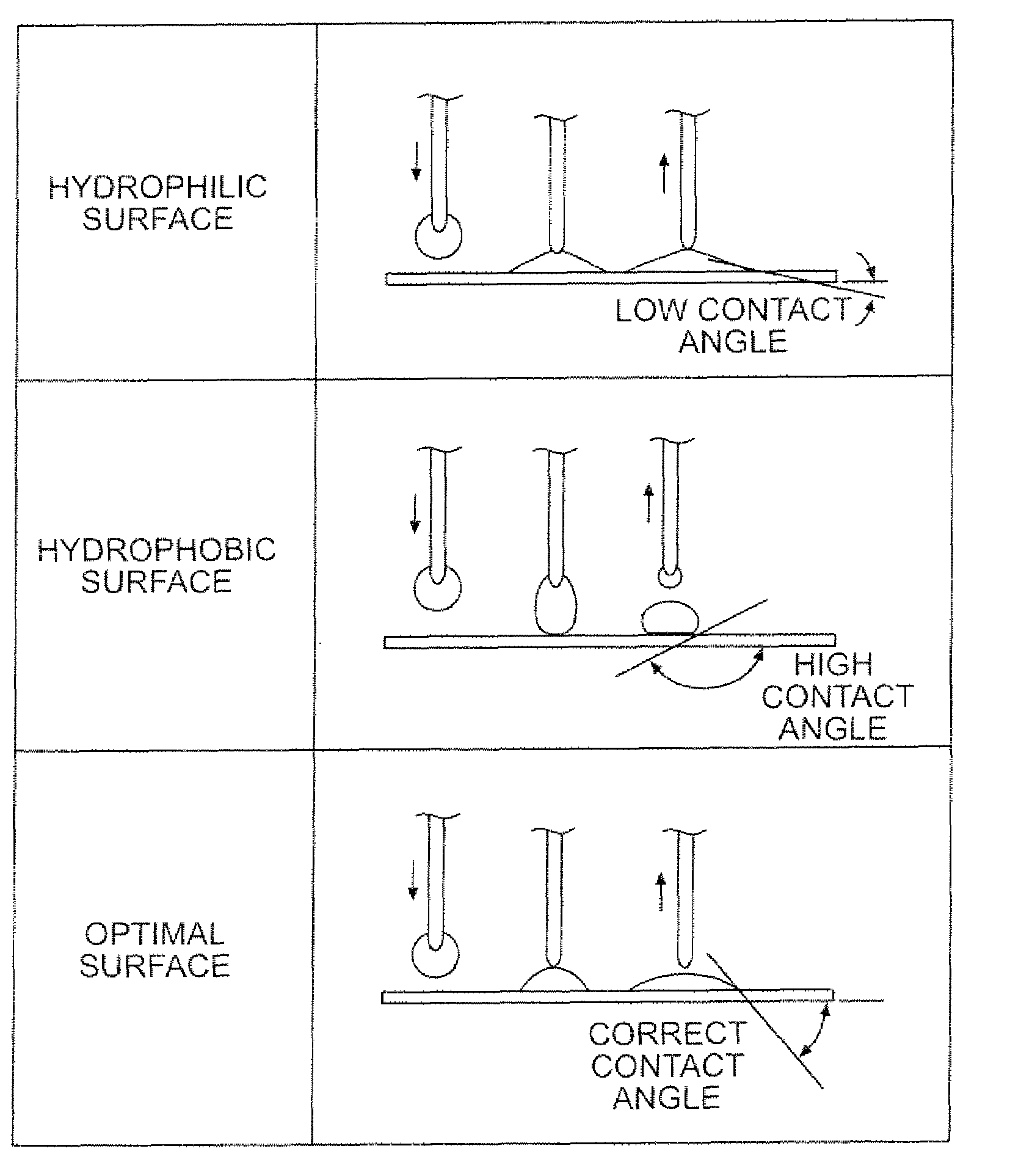

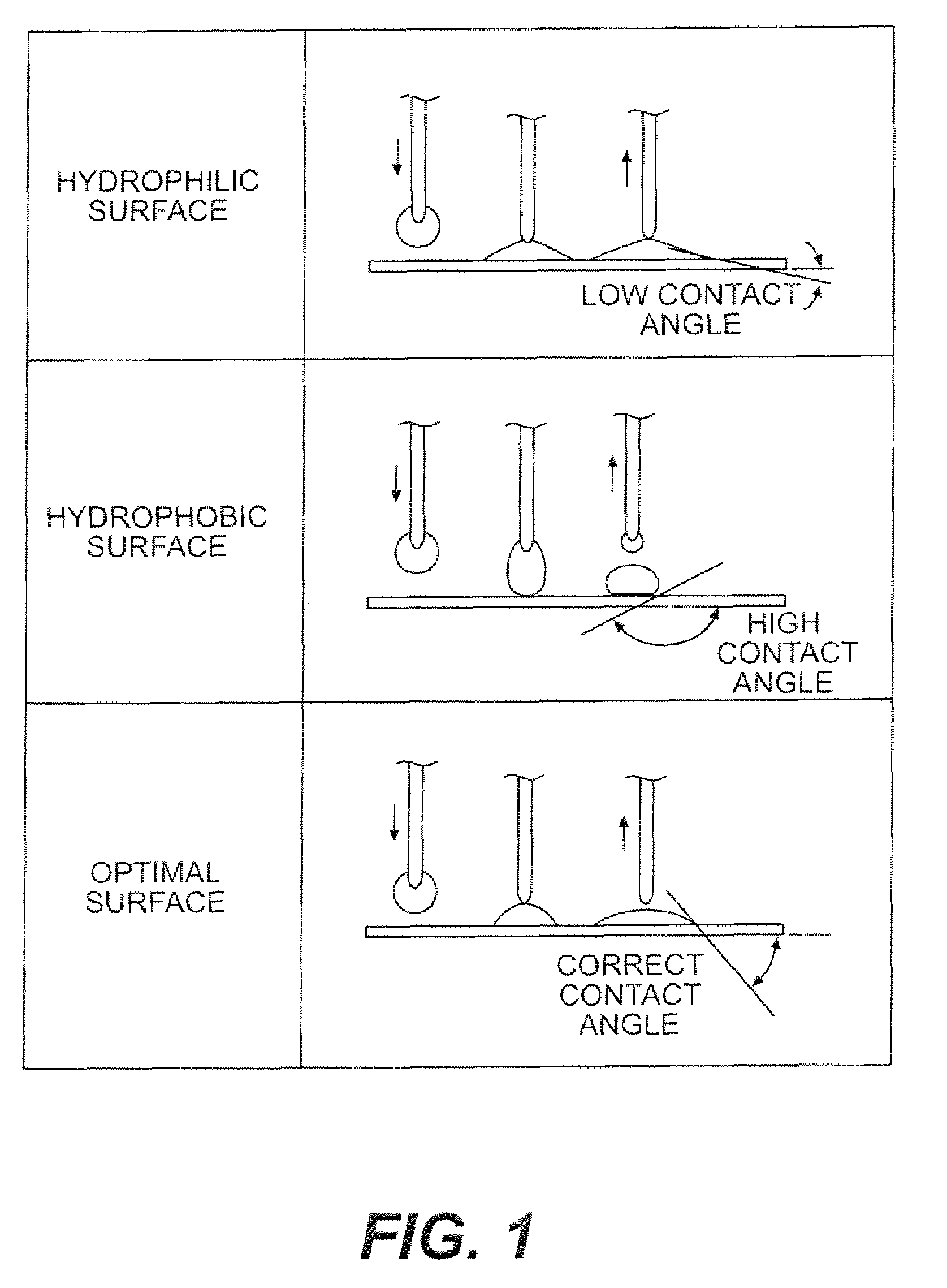

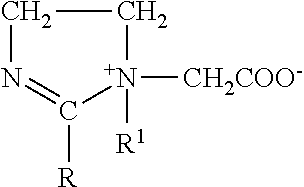

Methods of post chemical mechanical polishing and wafer cleaning using amidoxime compositions

InactiveUS20090133716A1Reducing and eliminating corrosion problemSignificant to useOrganic detergent compounding agentsNon-surface-active detergent compositionsDielectric surfaceCompound (substance)

The invention relates to a method for the removal of residues and contaminants from metal or dielectric surfaces and to a method for chemical mechanical polishing of a copper or aluminum surface. The methods of the invention include using an aqueous amidoxime complex agent. Optionally, the pH of the solution can be adjusted with an acid or base. The method includes applying the above composition to the copper or aluminum surface and polishing the surface in the presence of the composition.

Owner:EKC TECH

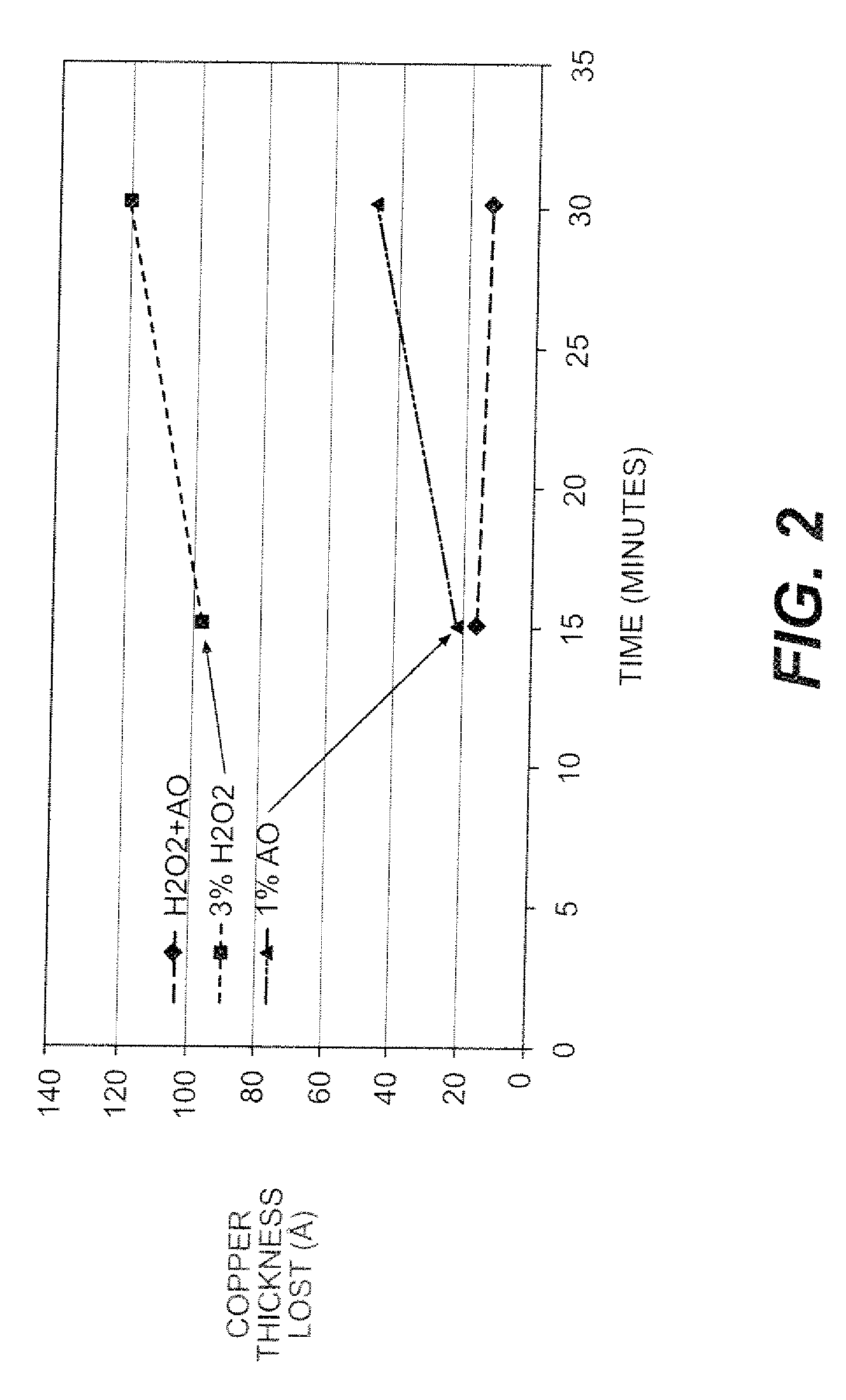

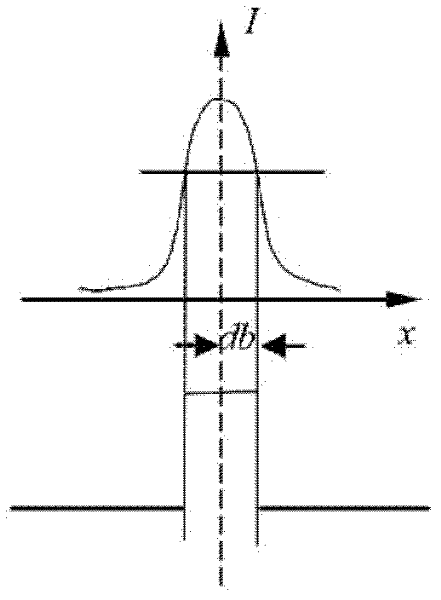

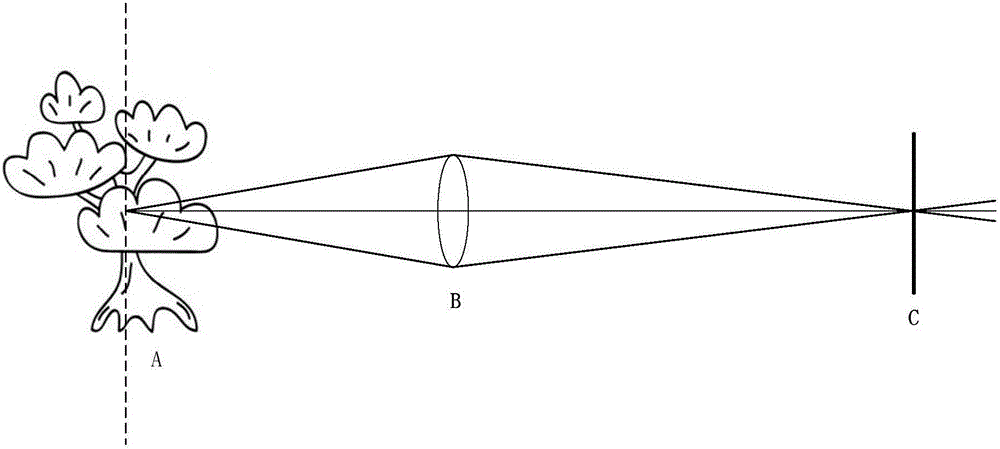

Method for acquiring laser meat image by double-laser triangle method

ActiveCN102353684AReduce reflectionReduced scattering effectOptically investigating flaws/contaminationUsing optical meansMultiple frameCcd camera

The invention discloses a method for acquiring a laser meat image by a double-laser triangle method. The method comprises the following steps of: 1) establishing a view field; 2) storing a gradient different between a laser meat curve and a laser plane reference curve which serves as meat thickness information to be a laser image meat thickness curve, and combining multi-frame laser meat thickness curves into a laser image according to an acquisition sequence; 3) unifying two laser images acquired by a left charge coupled device (CCD) camera and a right CCD camera to be under the same coordinate; and 4)splicing the laser images acquired at left and right angles under the unified coordinate into the same laser image to form a complete meat laser image.

Owner:NANJING FORESTRY UNIV

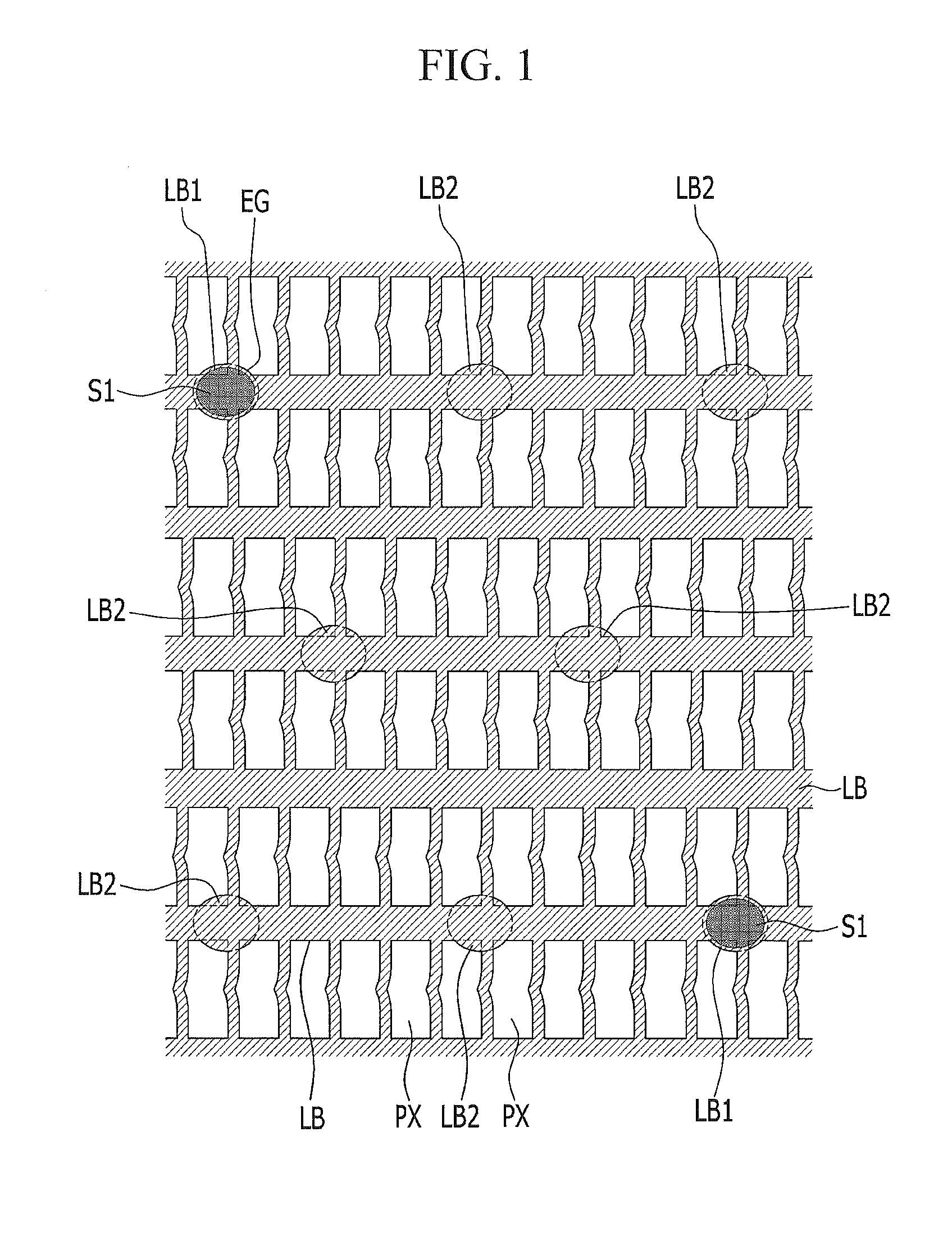

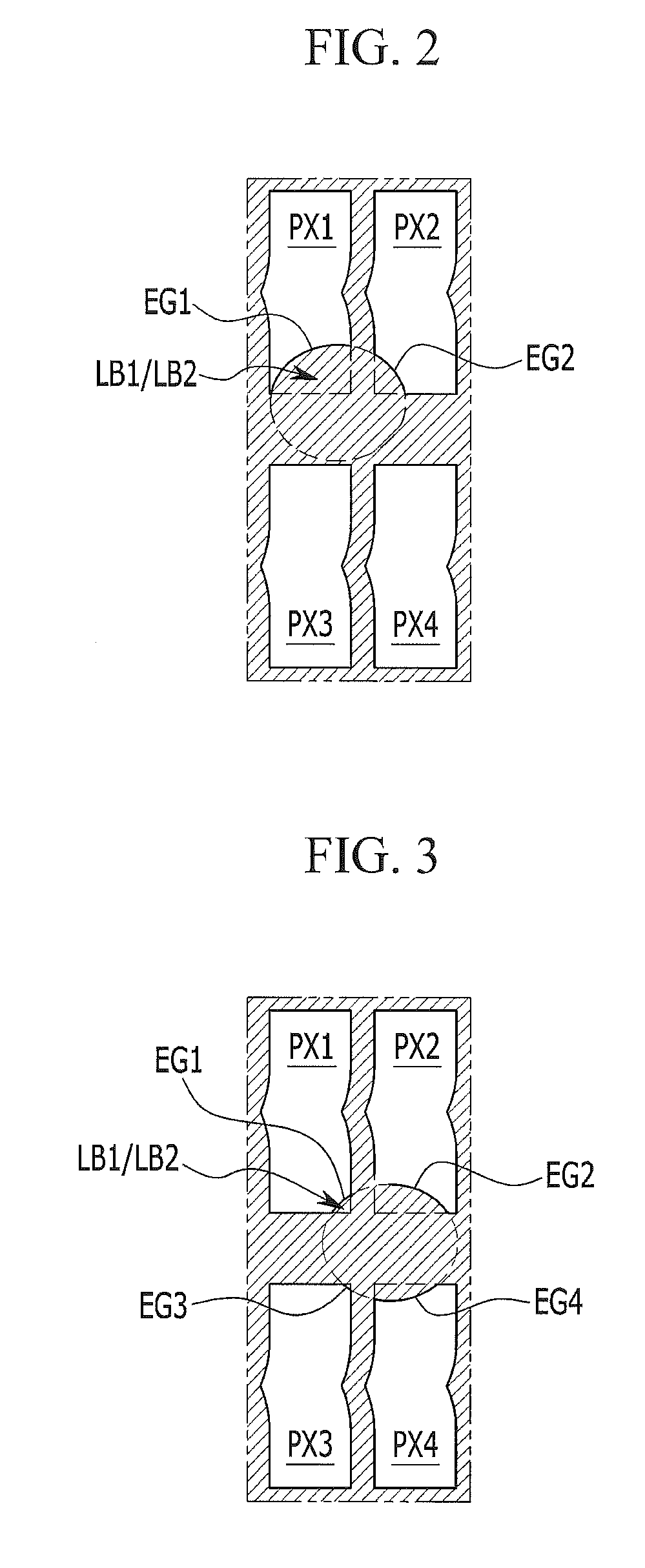

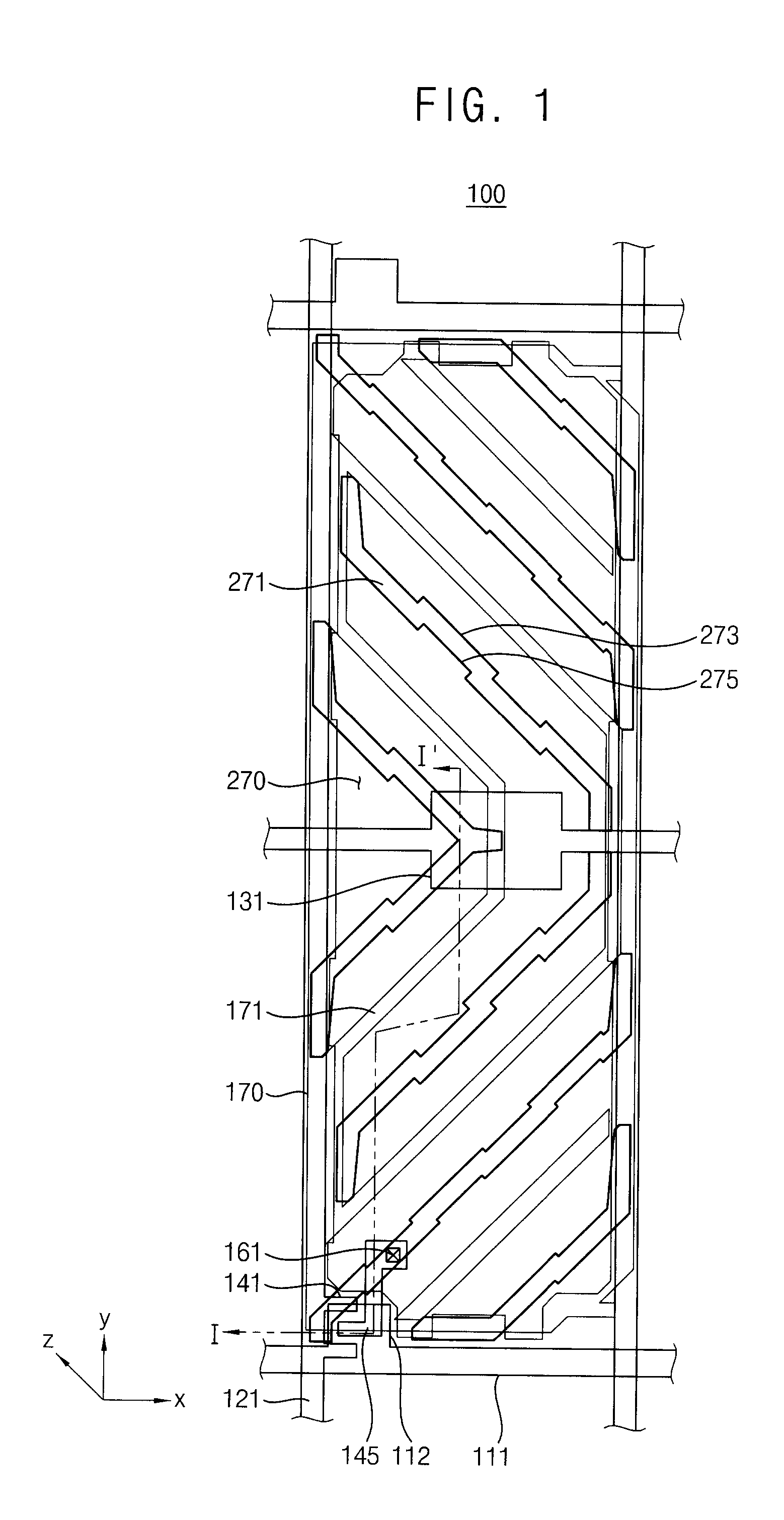

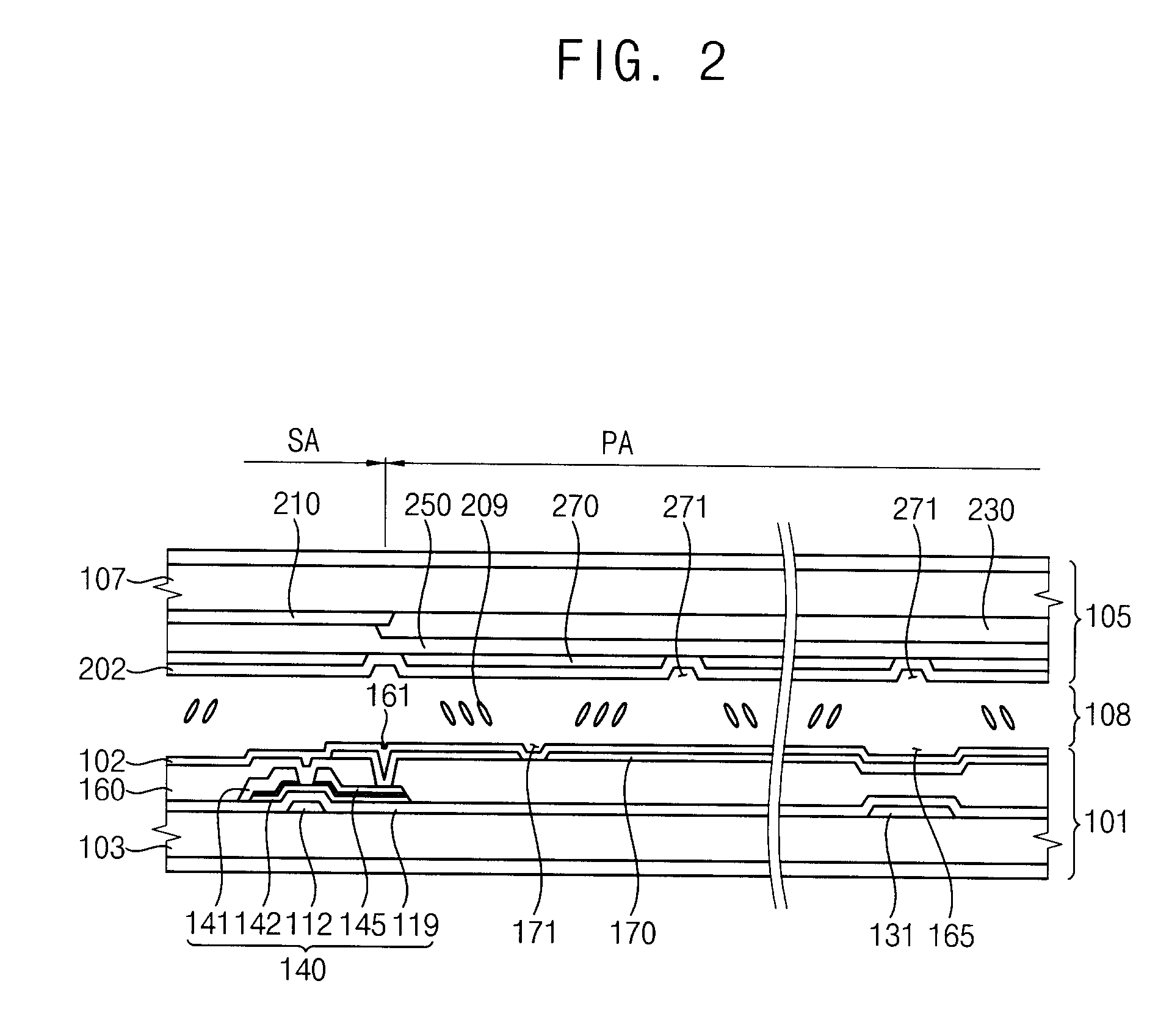

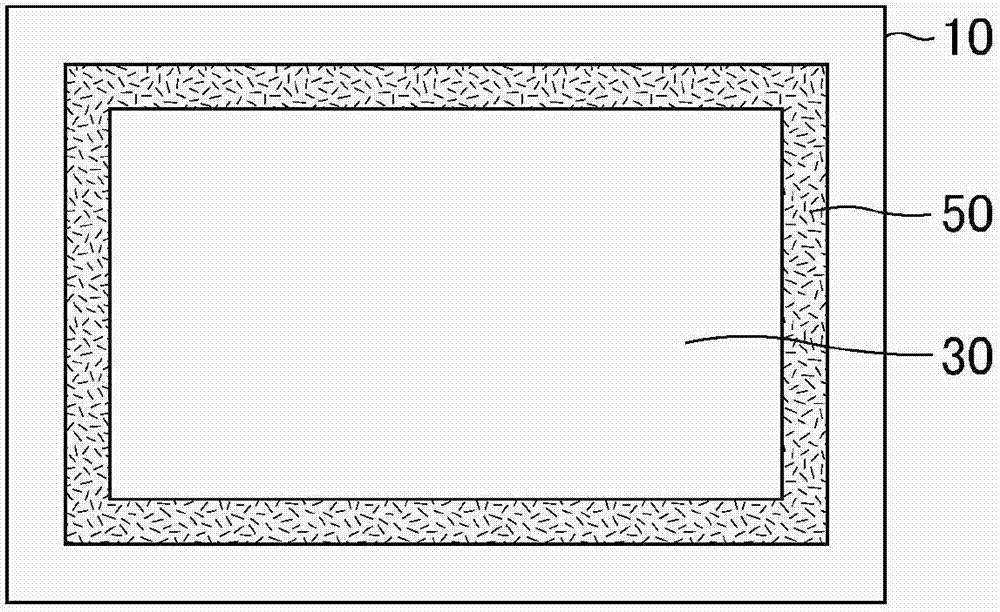

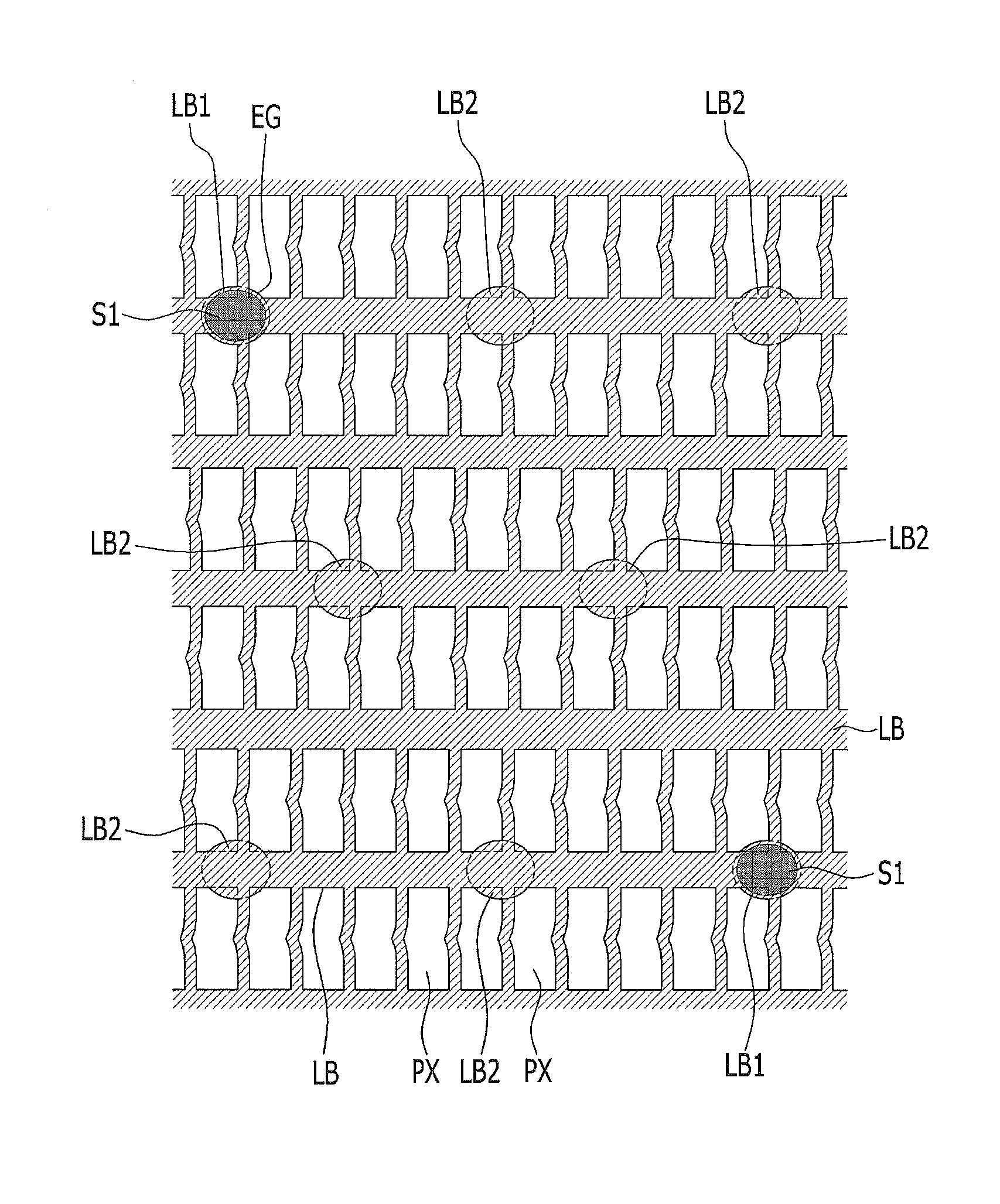

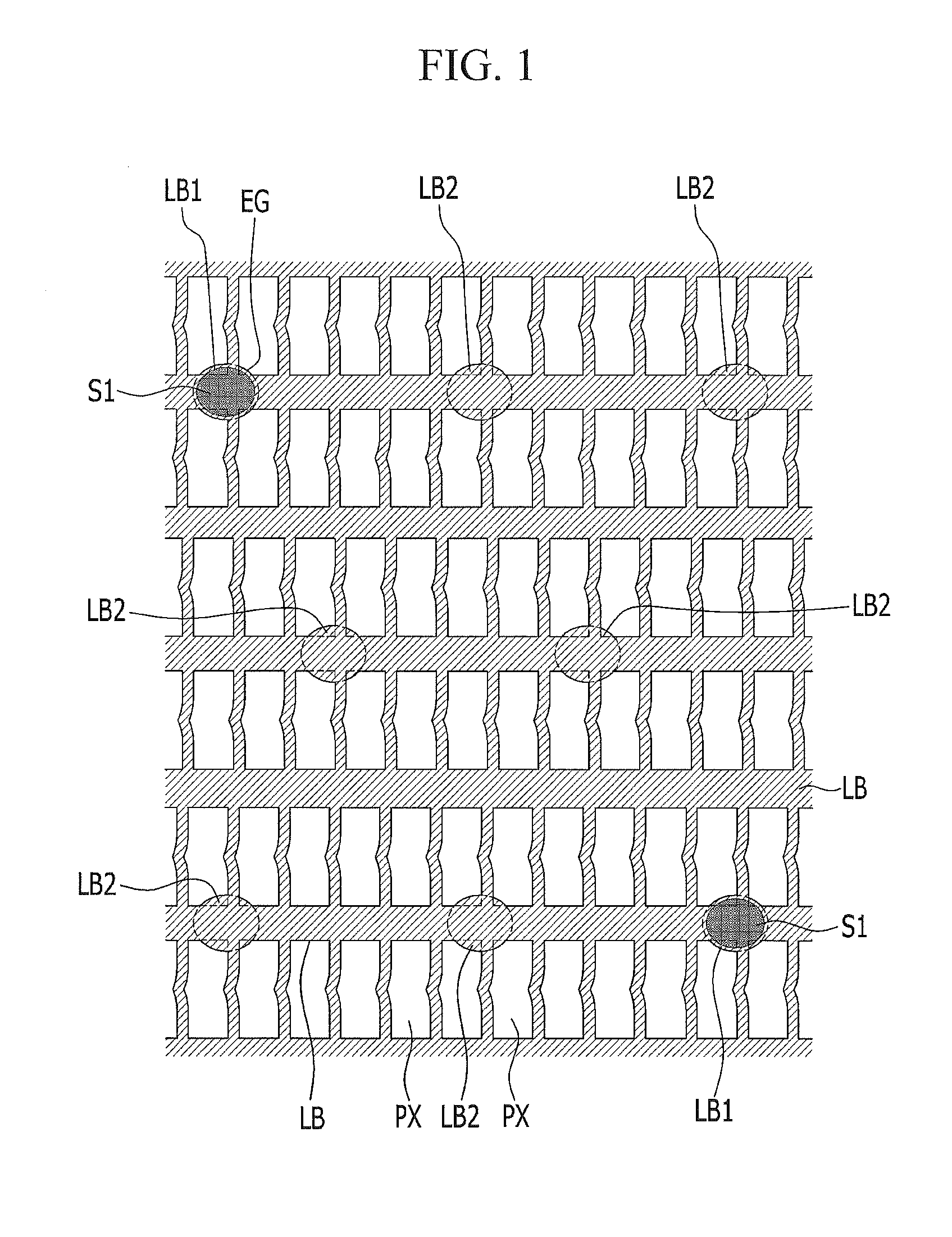

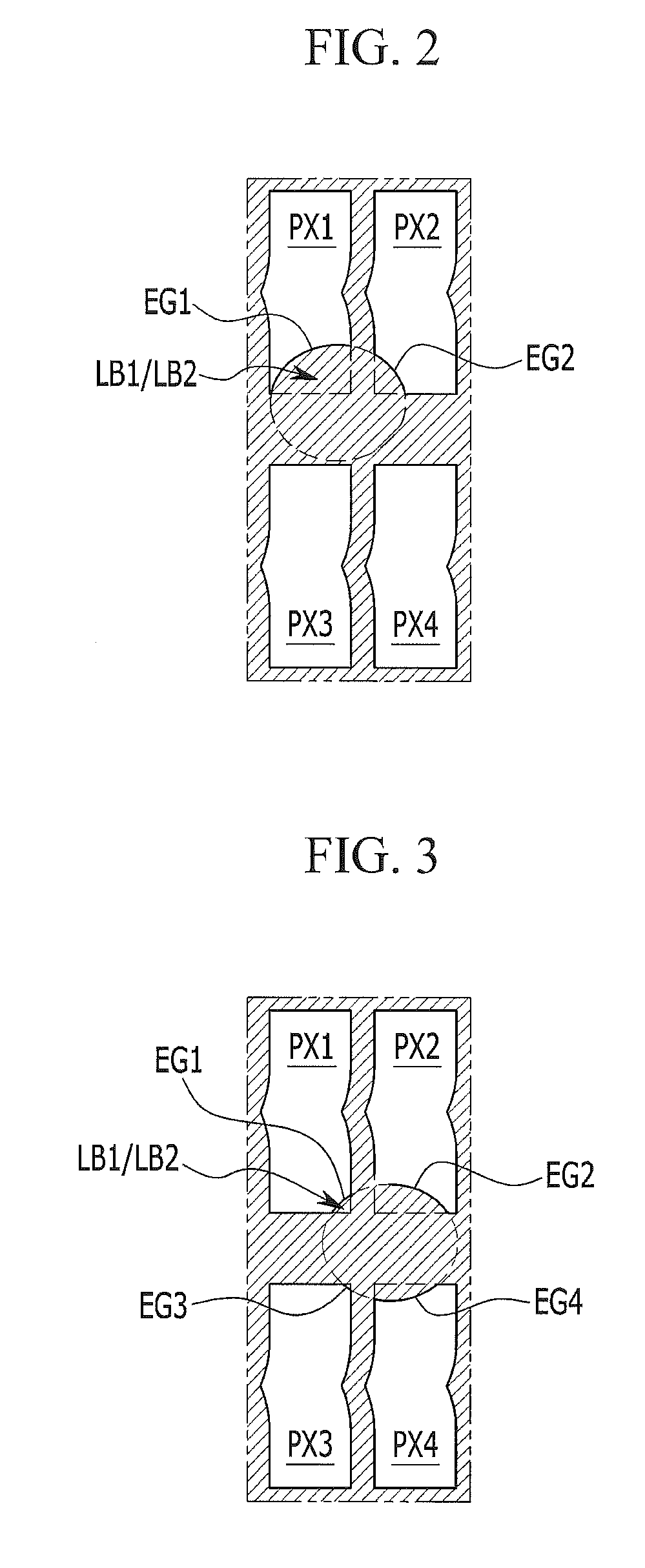

Liquid crystal display

ActiveUS20130342795A1Prevent display quality degradationReduce the differenceNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display includes: a first substrate; a second substrate disposed opposite to the first substrate; a light blocking member disposed on one of the first substrate or the second substrate, where the light blocking member is disposed in a display area including a plurality of pixel areas, and the light blocking member includes a plurality of extensions having a predetermined plane shape; and a plurality of first spacers disposed on one of the first substrate and the second substrate and contacting an upper surface of a plurality of thin films disposed on the other of the first substrate and the second substrate, in which the extensions of the light blocking member includes a first extension and a second extension, and the first extension overlaps the first spacers, and the second extension does not overlap the first spacers.

Owner:SAMSUNG DISPLAY CO LTD

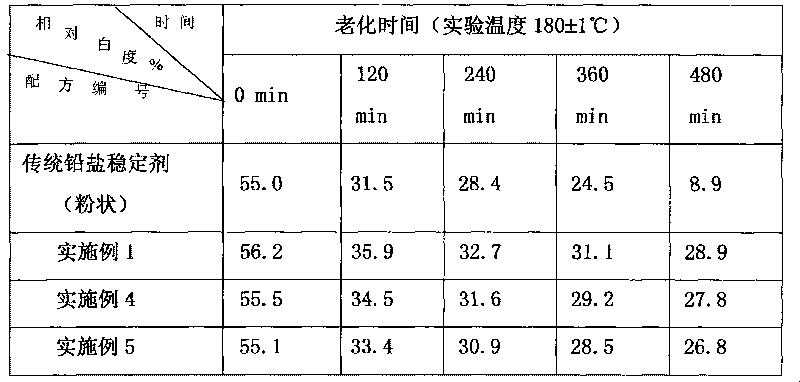

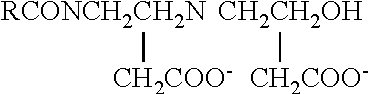

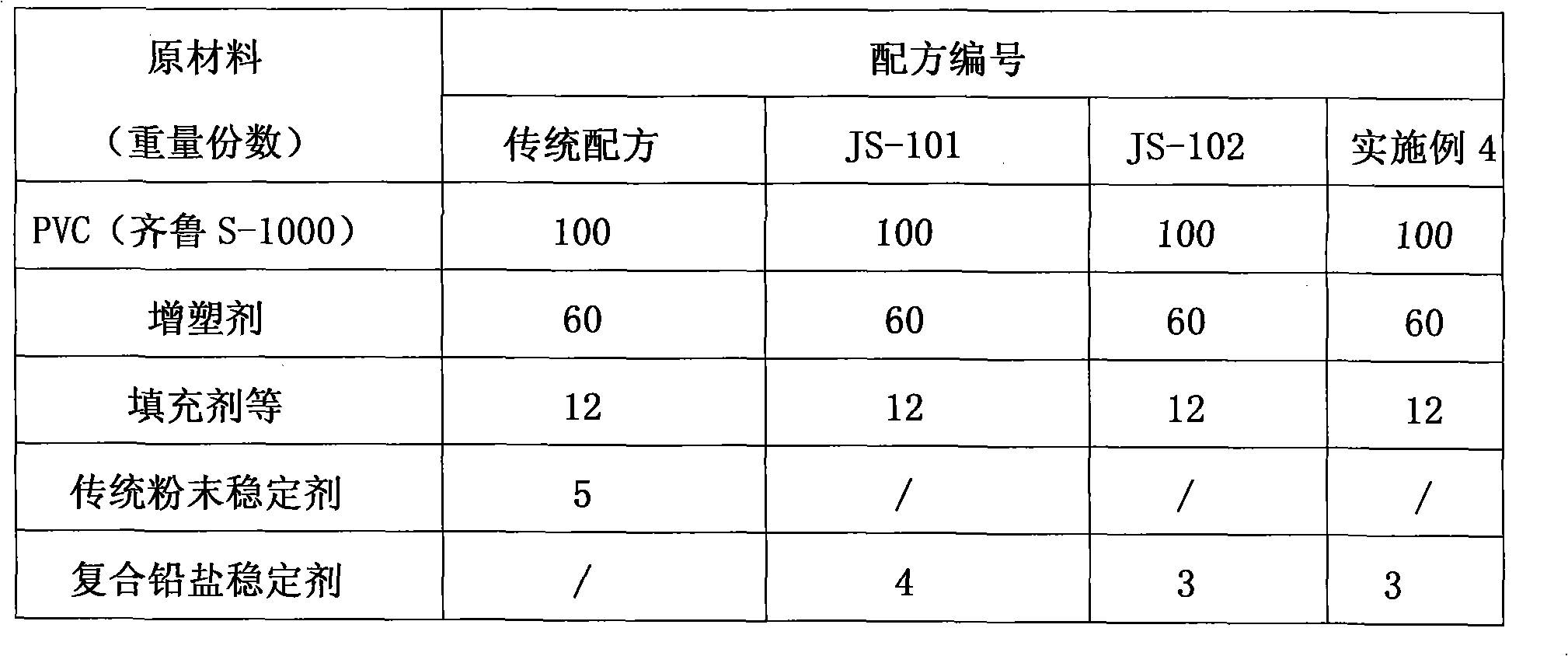

High weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer and preparation method thereof

InactiveCN101735532AImprove hydrophobicityGood miscibilityOxygen/ozone/oxide/hydroxidePolymer sciencePolyethylene glycol

The invention discloses a high weather-proof, multiple-effect, environmentally-friendly PVC composite heat stabilizer which is composed of the following raw materials in percentage by weight: 20-40% of calcium stearate, 15-25% of zinc stearate, 10-30% of hydrophobicity nano-hydrotalcite, 1-1.5% of hyperdispersant, 5-15% of lubricating agent, 4-7% of surface modifier and 5-15% of assistant heat stabilizer, wherein, hydrophobicity nano-hydrotalcite is prepared with a coprecipitation method by adding sodium oleate, and the molar ratio of Mg to AL in hydrophobicity nano-hydrotalcite is 2-3:1; the hyperdispersant is copolymer of maleic anhydride-sodium allyl sulfonate-crylic acid polyethylene glycol monoester. The nano-hydrotalcite prepared by the invention has better hydrophobic property and favorable compatibility with PVC matrix. Hydrophobicity nano-hydrotalcite and hyperdispersant are added to lower balancing torque, improve handling characteristics and weather resistance and lower cost. The preparation method of the invention has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

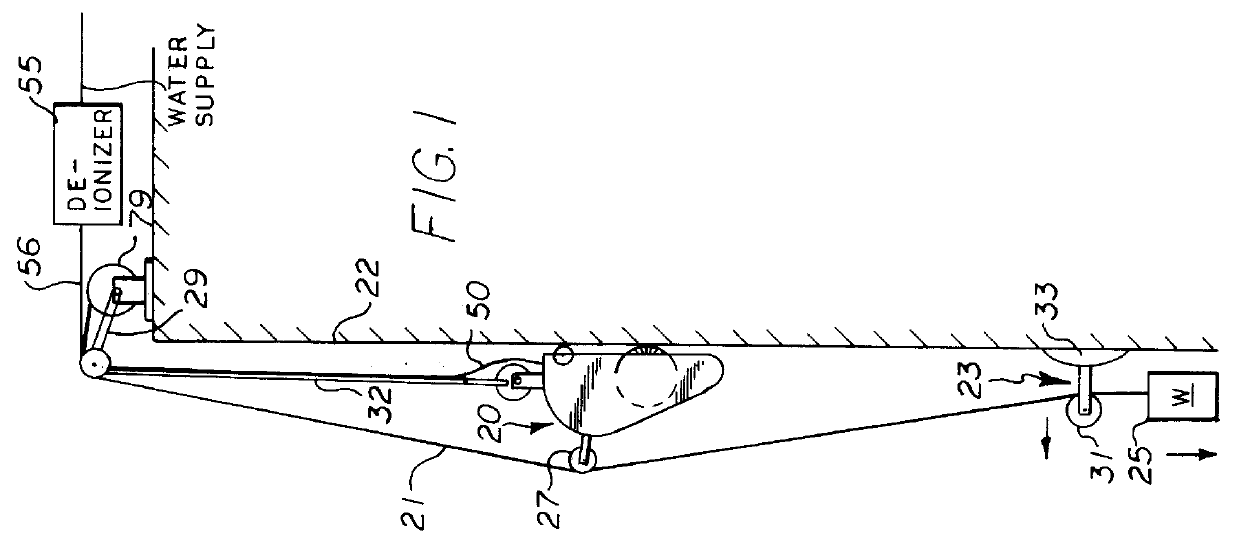

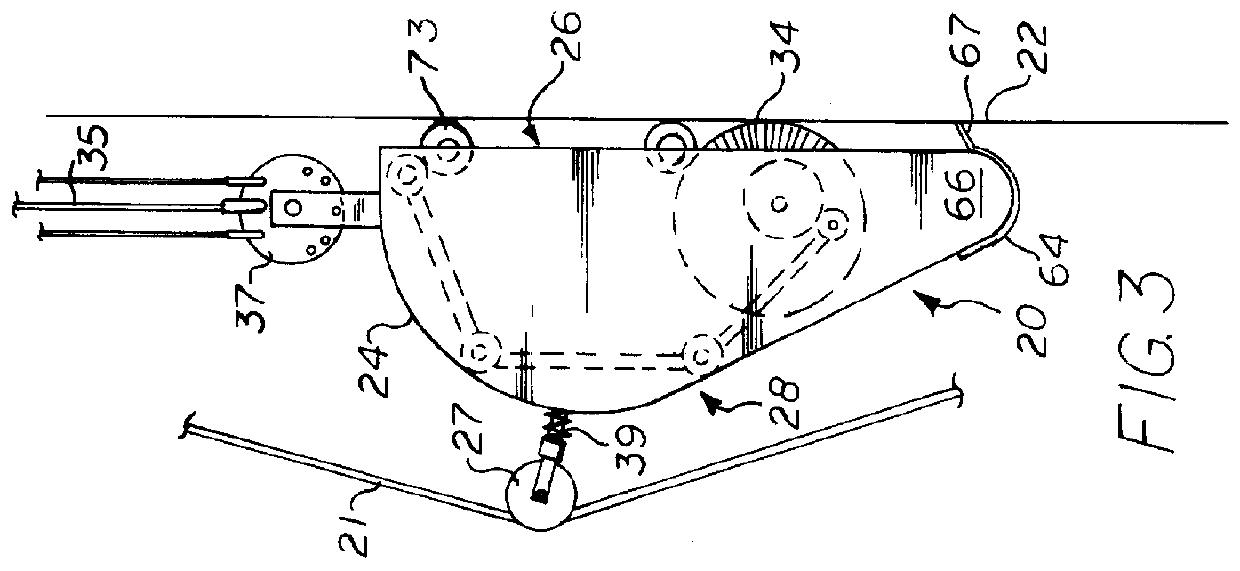

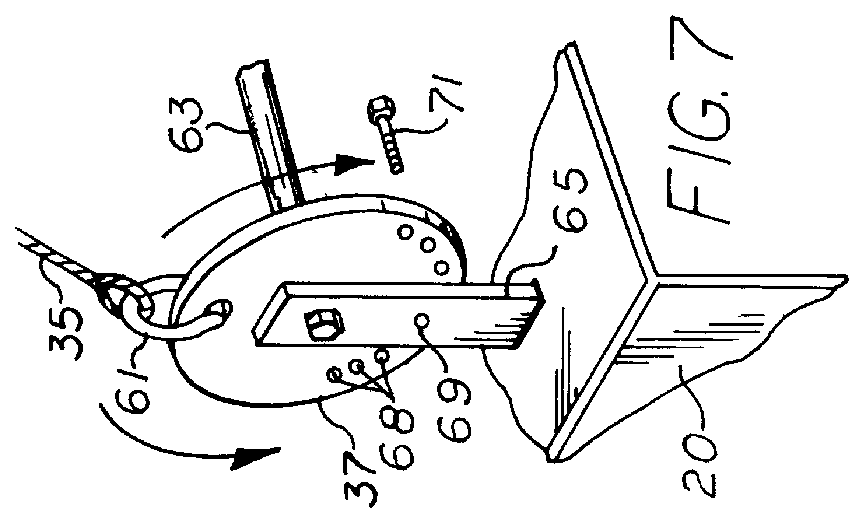

Apparatus and method for washing exterior building surfaces

InactiveUSRE36649E1Reduce weight and costAvoid spotLiquid processingCarpet cleanersElectric cablesCivil engineering

Owner:PACHANGA HLDG LLC

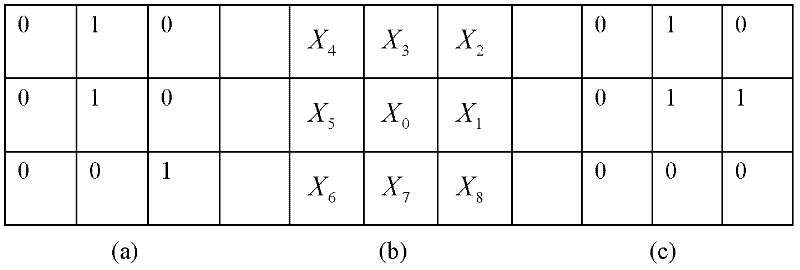

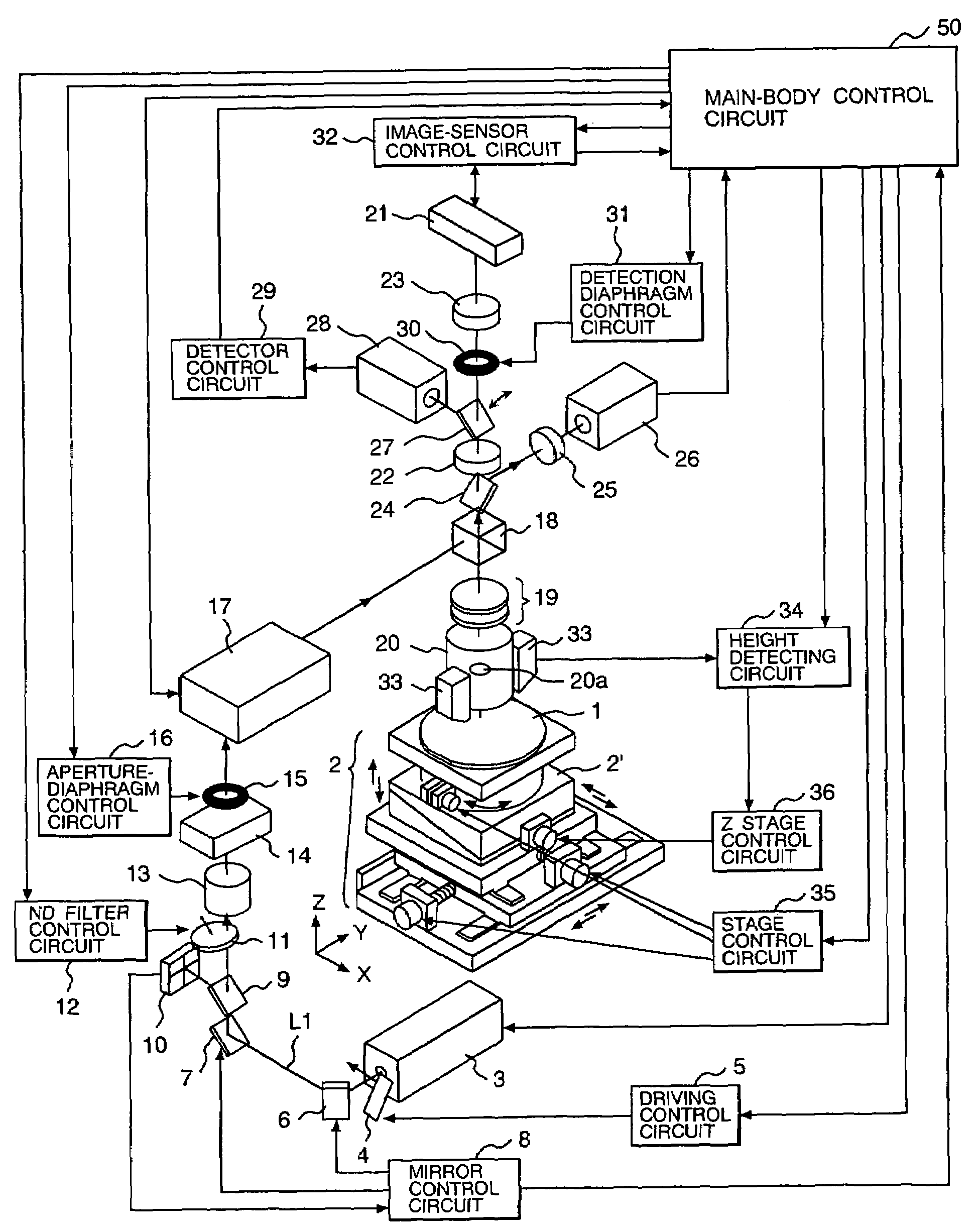

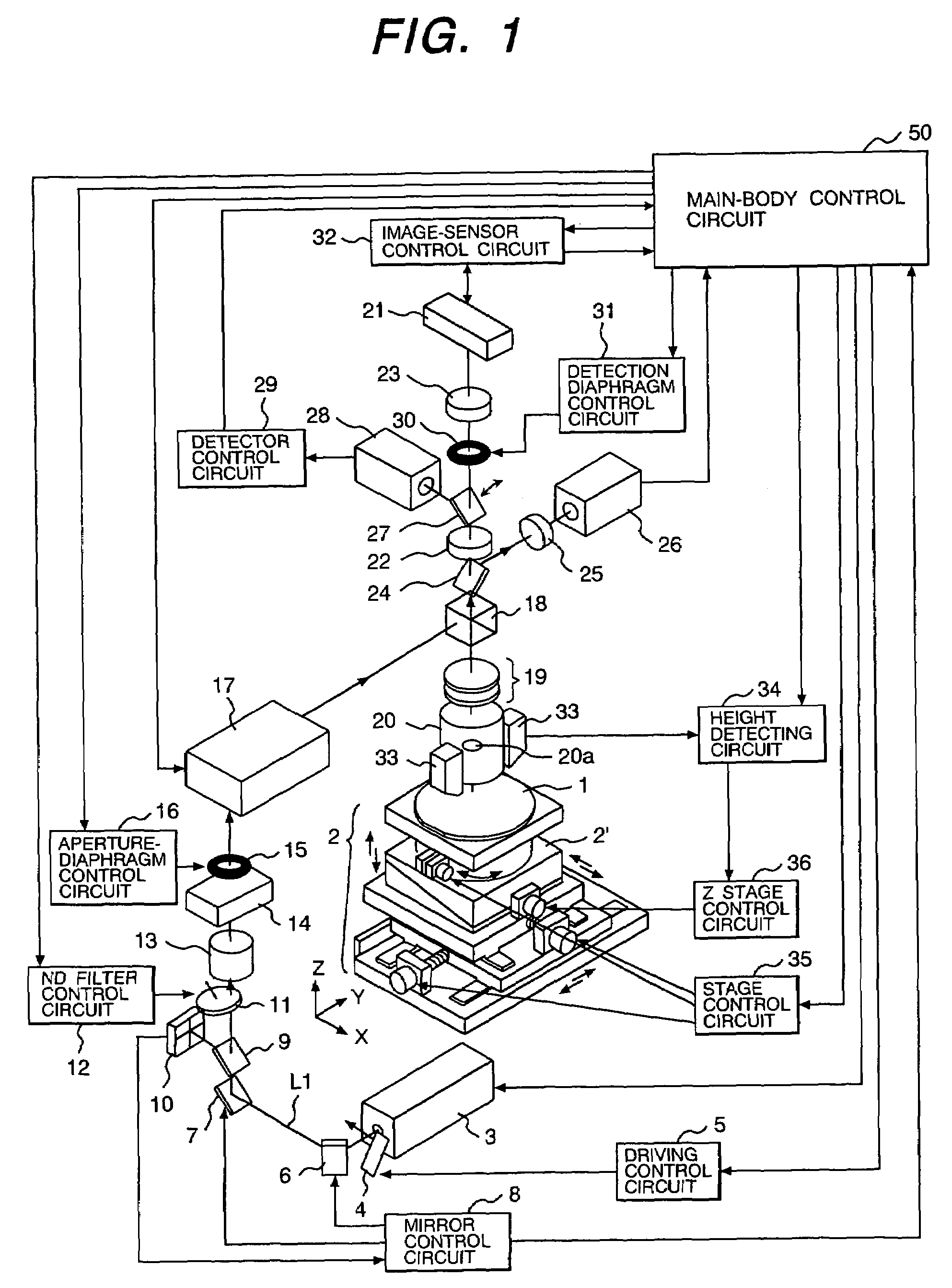

Pattern defect inspection method and its apparatus

InactiveUS7205549B2High resolutionIncrease speedMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementOptoelectronicsUltraviolet laser light

The pattern defect inspection apparatus and its method of the present invention comprises: a recipe setting unit for setting an inspection recipe and / or a review recipe; an illumination optical system including: a laser light source for emitting ultraviolet laser light; a quantity-of-light adjusting unit for adjusting a quantity of the ultraviolet laser light emitted from the laser light source; and an illumination range forming unit for forming on a sample an illumination range of the ultraviolet laser light; a coherence reducing system; and a detection optical system including: a condensing optical system; a diffracted-light control optical system; and a detecting unit.

Owner:HITACHI HIGH-TECH CORP

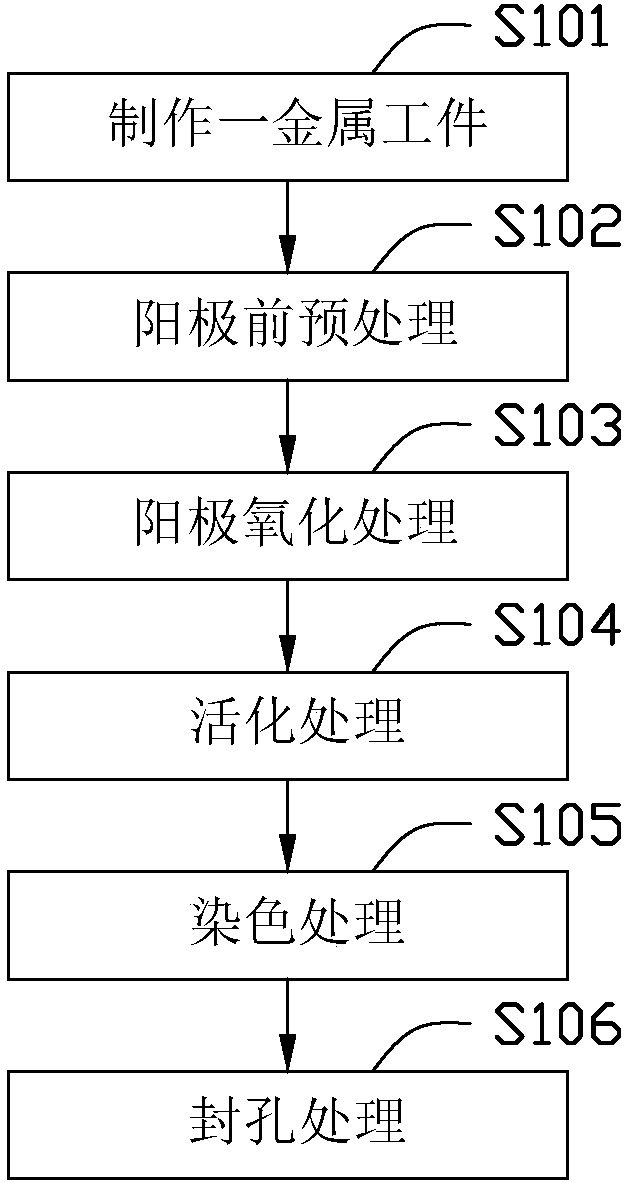

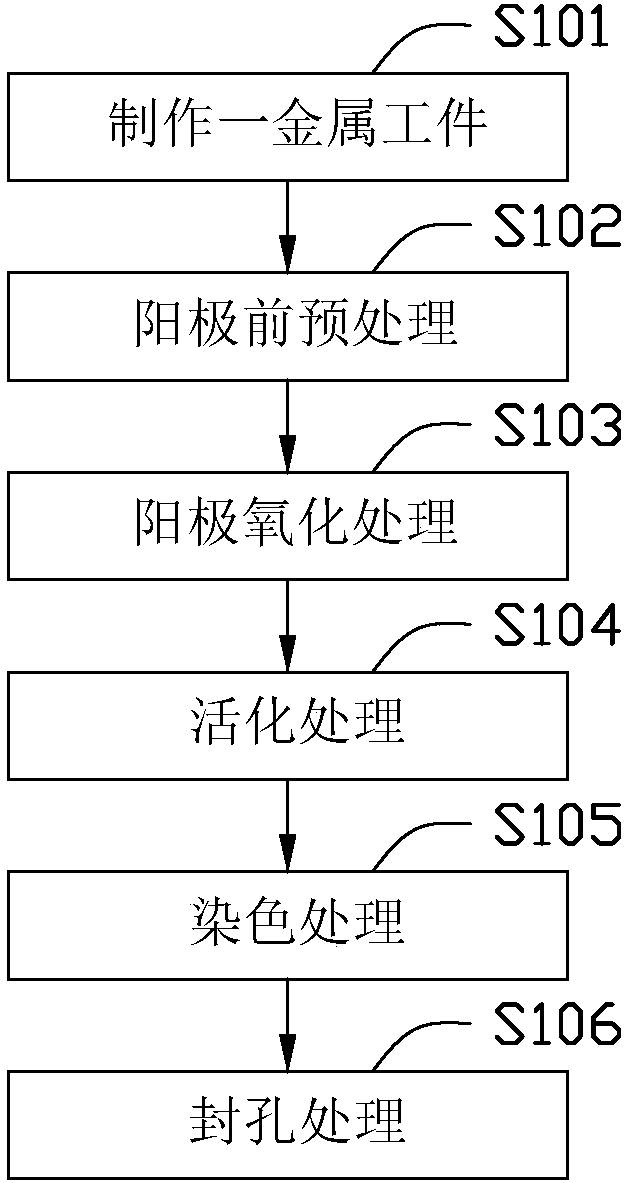

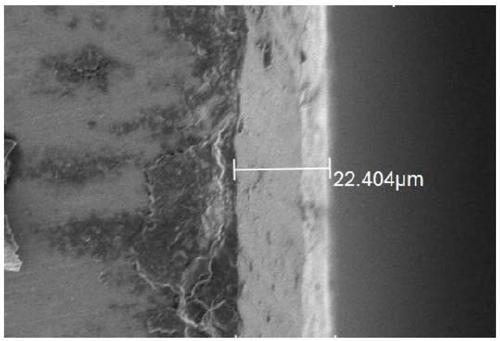

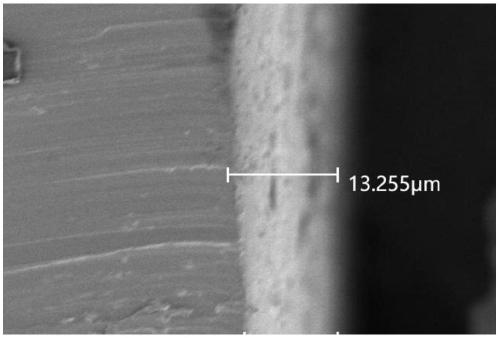

Surface treatment method for metal workpiece and dyeing pretreatment agent

The invention provides a surface treatment method for a metal workpiece. The surface treatment method comprises the following steps that anodic oxidation treatment is performed on a metal workpiece soas to form an anodic oxidation film on the surface of the metal workpiece; the metal workpiece subjected to anodic oxidation treatment is placed in a dyeing pretreatment agent for activating treatment, wherein the dyeing pretreatment agent comprises composite organic acid and sodium acetate; the metal workpiece is placed in a dyeing solution for dyeing treatment; and hole sealing treatment is performed on the metal workpiece. The invention also provides the dyeing pretreatment agent. The surface treatment method for the metal workpiece comprises the step of activating treatment so that the residual acidic solution in a through hole or a blind hole of the metal workpiece can be removed, the phenomenon of uneven dyeing is avoided, and the dyeing quality is improved.

Owner:HONGFUJIN PRECISION ELECTRONICS ZHENGZHOU +1

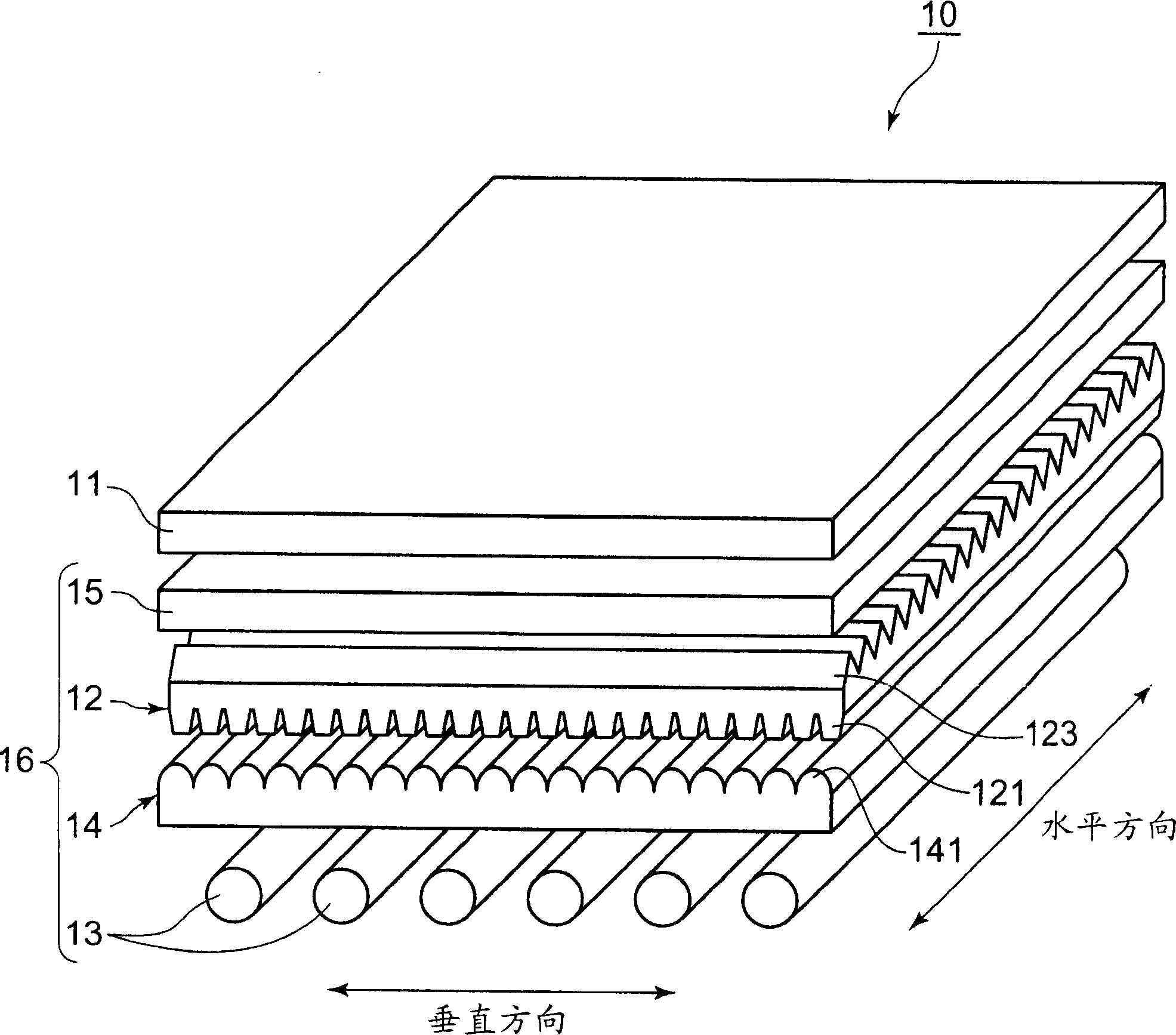

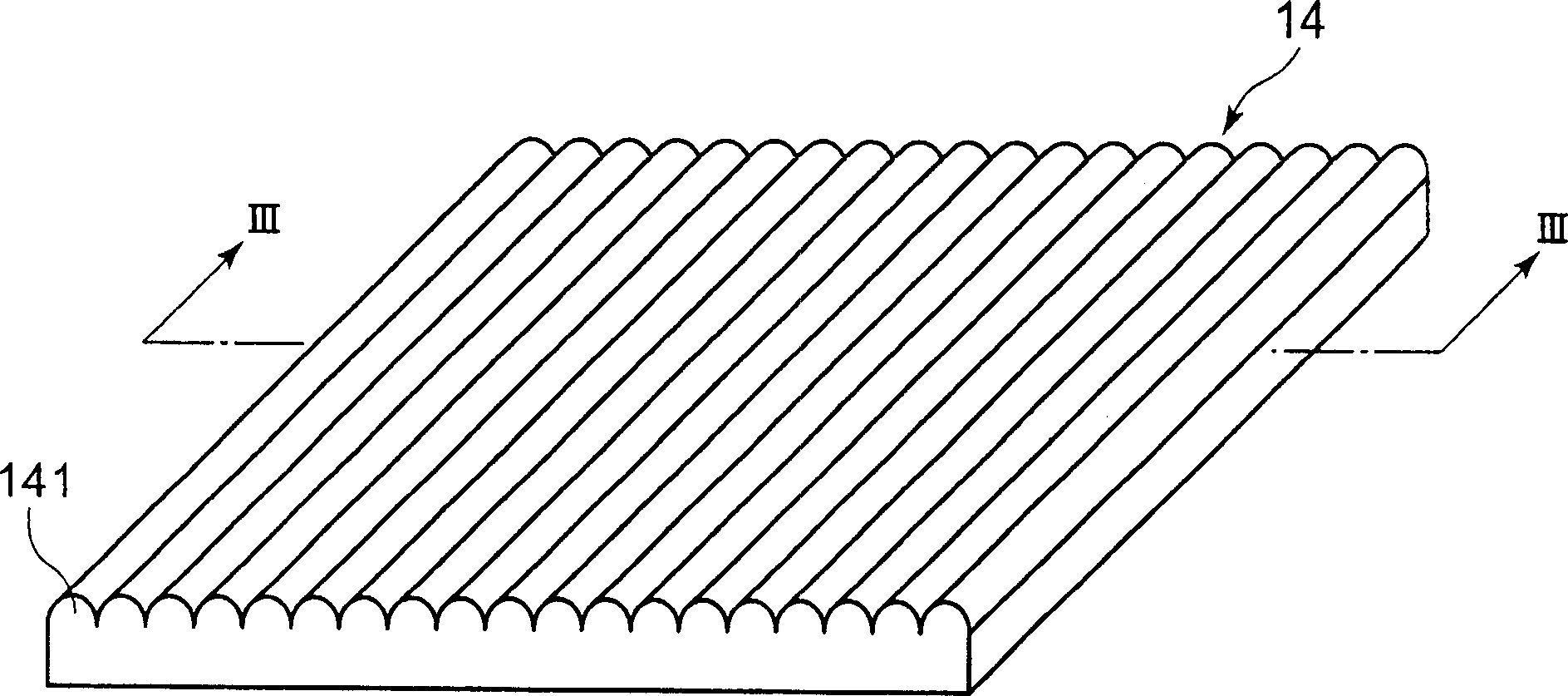

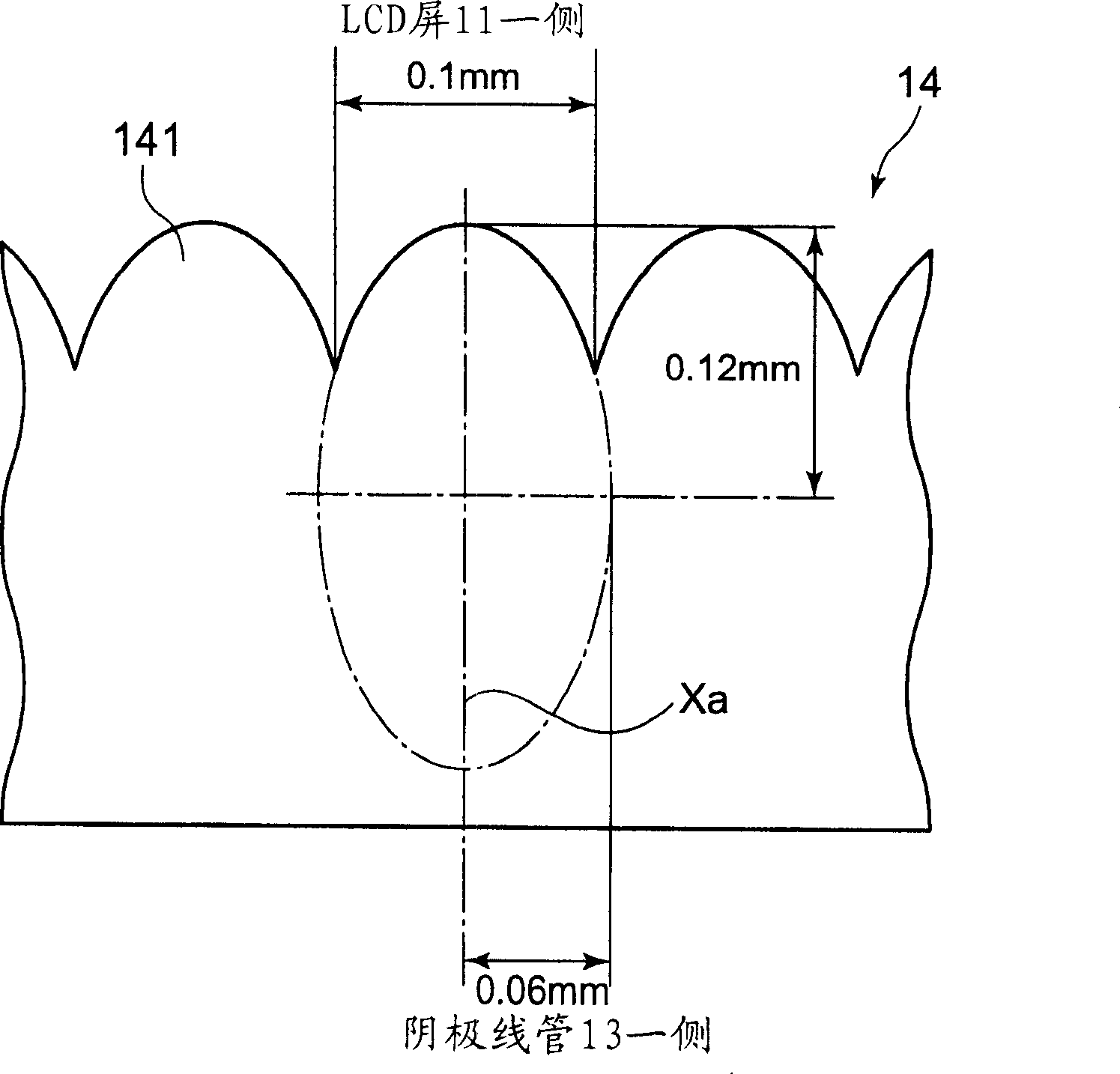

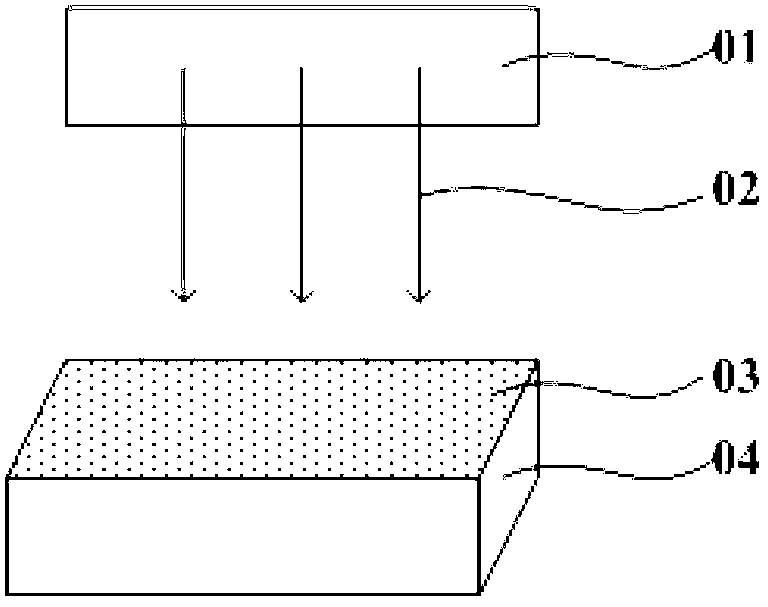

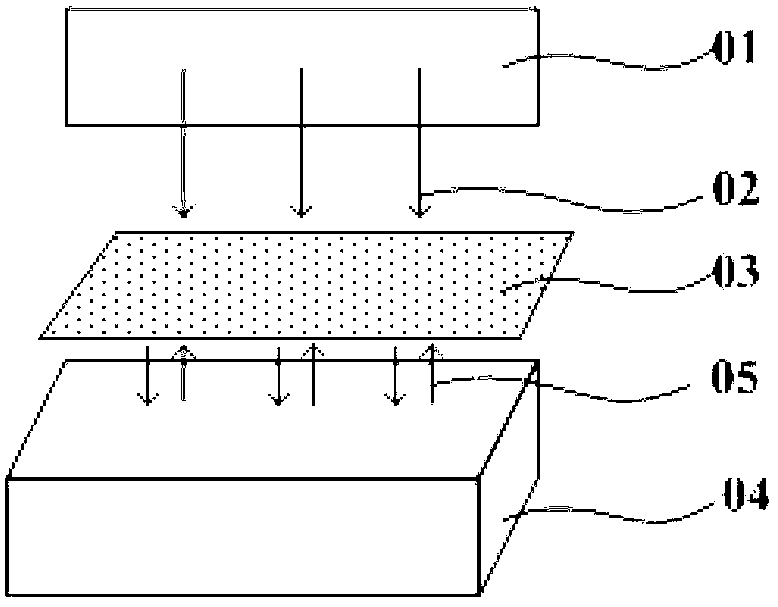

Diffusion plate, surface light source device and transmission type display device

InactiveCN1683974ANo reduction in utilization efficiencyUniform lightOther printing matterElongate light sourcesDiffusionEllipse

A diffusing sheet, a surface light source unit, and a transmission type display that can attain uniform illumination so that the brightness of light on the display screen appears uniform regardless of the position from which the display screen is observed. The diffusing sheet includes, on its light-emerging side surface, a diffusion lens array having a plurality of unit lenses, each unit lens being in a shape equivalent to a part of an elliptic cylinder having an elliptical cross section. The surface light source unit includes the diffusing sheet and a convergent sheet 12 that has a plurality of unit lenses 121 having almost trapezoidal cross sections, formed on one surface thereof. It is possible to attain uniform illumination by diffusing light from cathode ray tubes in the surface light source unit, and, at the same time, to converge the light serving as backlight to enhance optical efficiency.

Owner:DAI NIPPON PRINTING CO LTD

Preparation method for high-toughness monofilament blended cotton yarn

ActiveCN104651998AGood flexibilityIncrease elasticityDry-cleaning apparatus for textilesBleaching apparatusYarnCarding

The invention discloses a preparation method for high-toughness monofilament blended cotton yarn. The preparation method comprises the following steps of carrying out cotton feeding, rolling, cotton carding and drawing to obtain rough yarn after carrying out cotton opening and scutching on long staple cotton, fine staple cotton, prefabricated monofilament materials and mixed cotton, and obtaining the high-toughness monofilament blended cotton yarn through spinning and spooling, wherein the prefabricated monofilament materials are obtained through draining and drying after carrying out primary boiling and dehydrating, primary steaming, secondary boiling and dehydrating, secondary steaming, standing, bleaching and washing. The high-toughness monofilament blended cotton yarn prepared by the preparation method has the characteristics of high toughness, low cost and the like, meanwhile, the air permeability is good, and the comfort is strong.

Owner:福建新同兴针纺织有限公司

Nourishing type eye shadow cream

The invention discloses nutrition type eye shadow which is composed of four components of A, B, C and D. According to parts of the weight, the composition of the A, B, C and D is as follows: component A contains 50-60 parts of deionized water, 2-8 parts of propylene glycol, 0.5-2 parts of tiethanolamine, 0.1-0.3 parts of sodiumhydroxide, 1.5-2 parts of colloidality silicic acid magnalium, and 0.1-0.3 parts of methyl hydroxybenzoate; component B contains 3-5 parts of lanolin, 1-3 parts of myristic acid isopropyl ester, 3-8 parts of white oil, 1-2 parts of olive oil, 4-6 parts of stearic acid, and 6-10 parts of bees wax; component C contains 15-20 parts of talcum powder, 2-4 parts of kaolin, 4-6 parts of titanium dioxide, 3-5 parts of magnesium oxide, and 3-7 parts of white mica powder; and component D contains 0.5-1 parts of essence. The invention has the advantages that the usage is convenient, the effect is convenient and the price is low.

Owner:叶芳

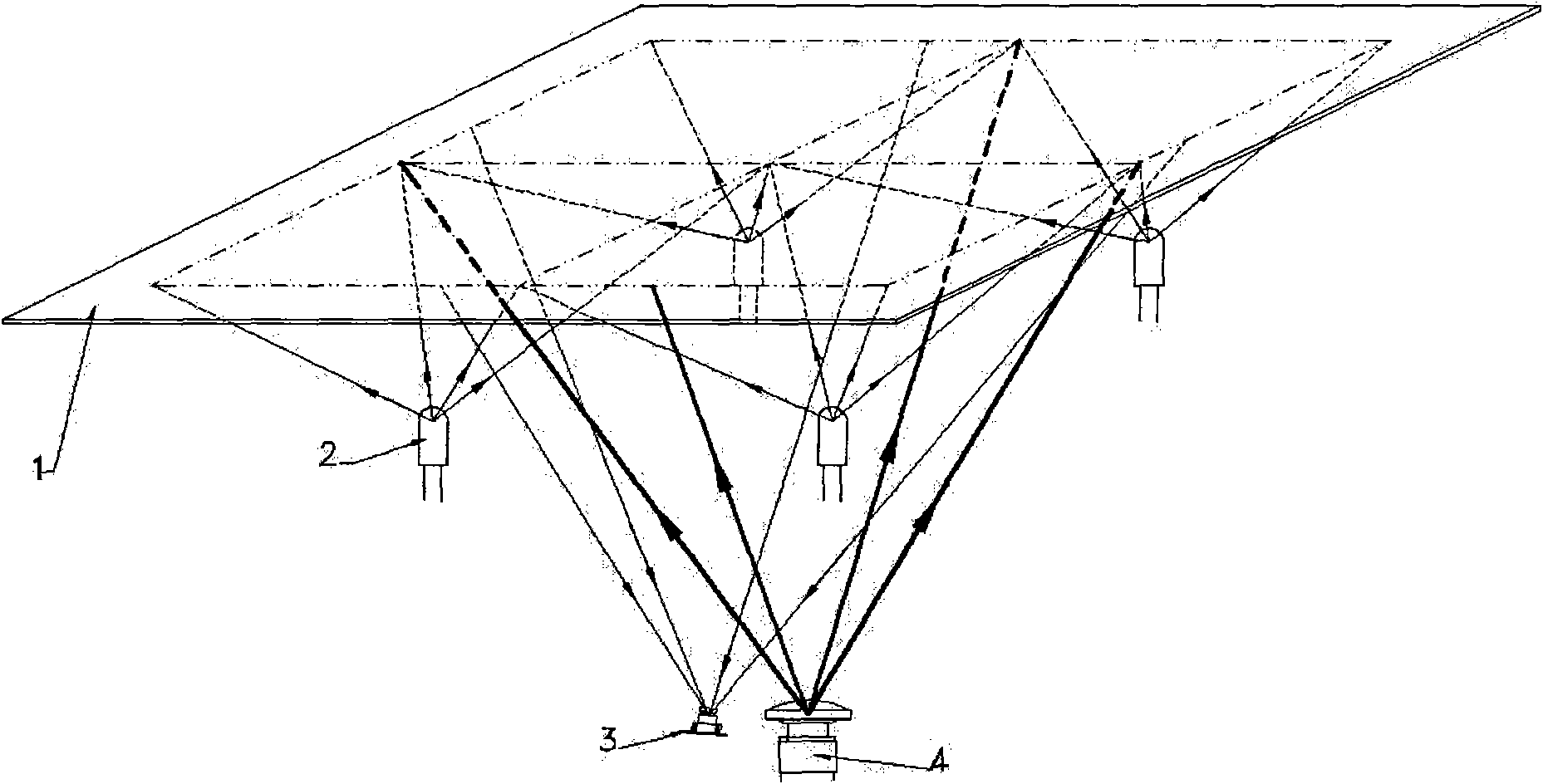

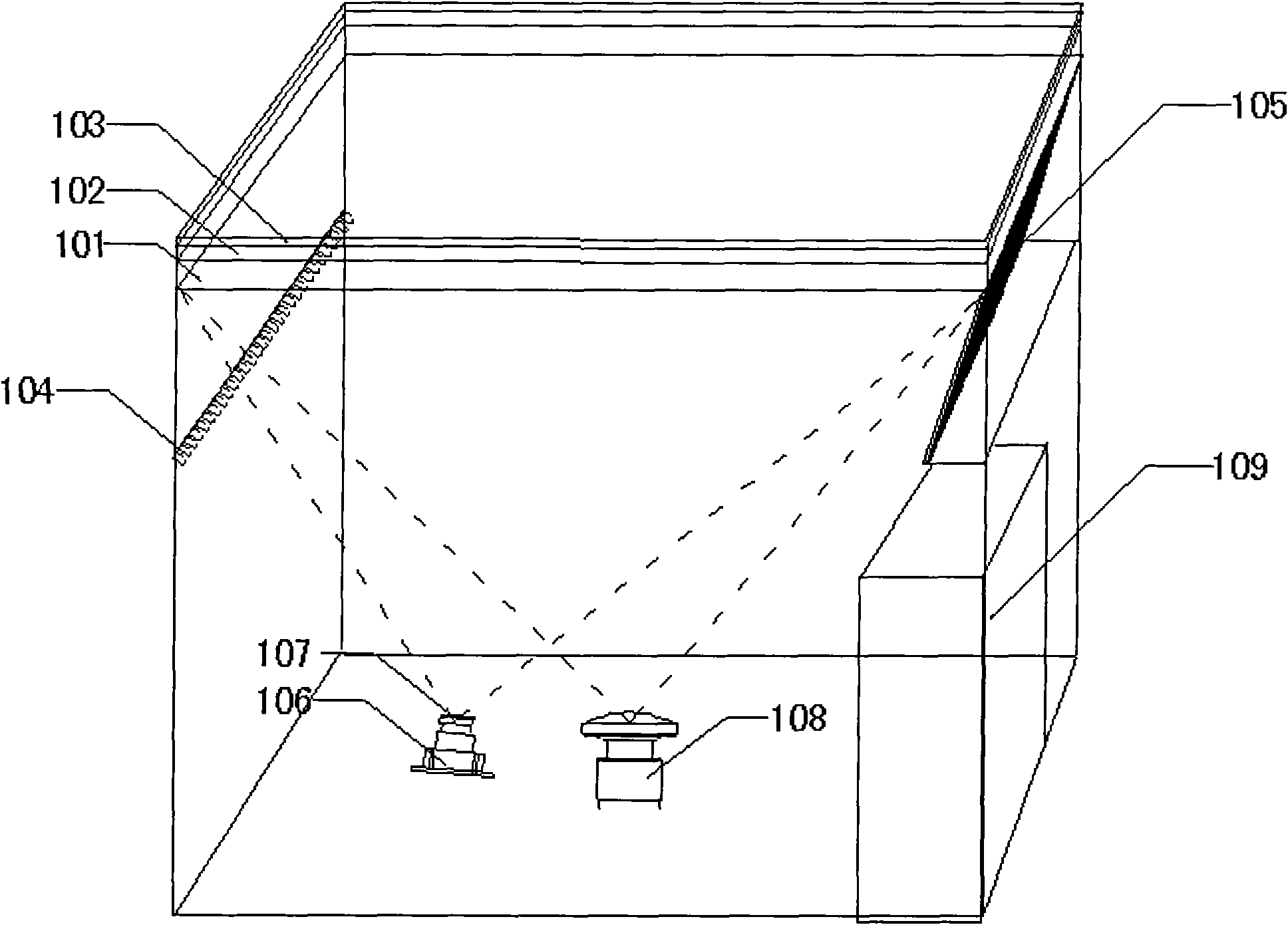

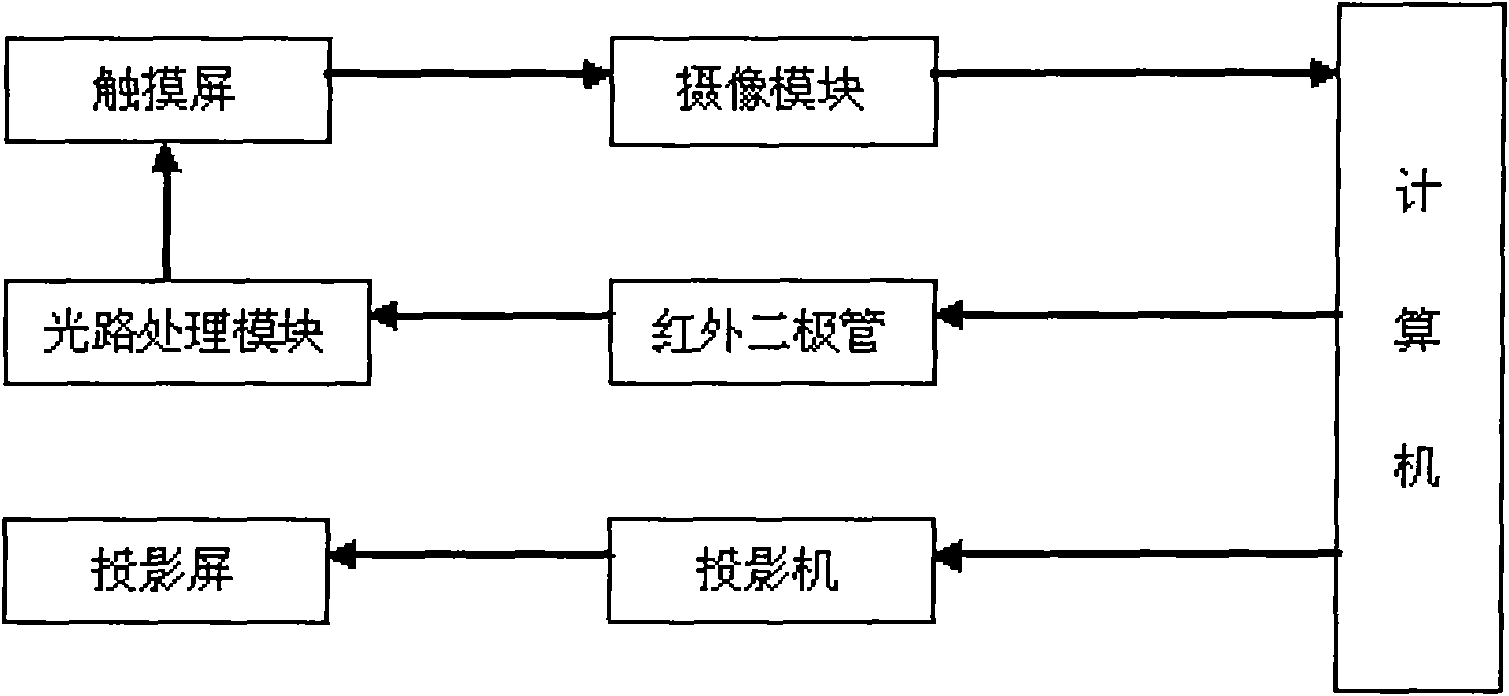

Post-positioning device and method based on pick-up head and application thereof

InactiveCN101587404AWith trackingRealize multilaterationInput/output processes for data processingProjection screenComputer science

The invention provides a post-positioning device and a method based on a pick-up head and an application thereof. The device comprises a touch screen, a projection screen, an invisible light transmission module for transmitting the invisible light to the touch screen, a shooting module shot the back of the whole touch screen display area, a master control module and a projection module covering the projection to the whole projection screen. The projection screen is adhered on the surface of the touch screen. The shooting module is positioned at the back of the touch screen. The projection module is arranged at the back of the projection screen. The master control module is respectively connected with the invisible light transmission module, the shooting module and the projection module. The invention can realize accurate multi-point positioning and is suitable for the post-positioning device of the various touch screens based on the pick-up head.

Owner:GUANGDONG VTRON TECH CO LTD

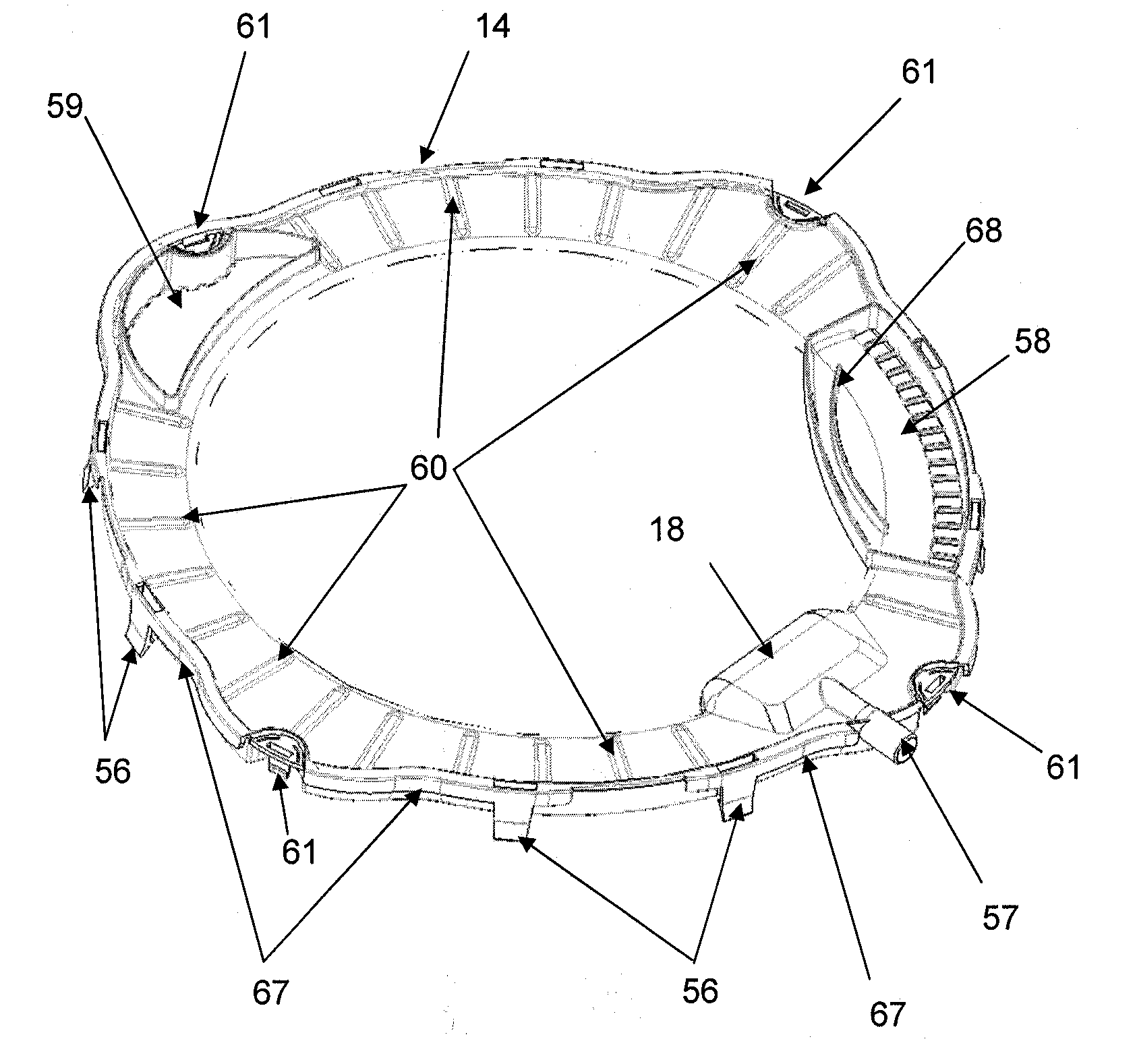

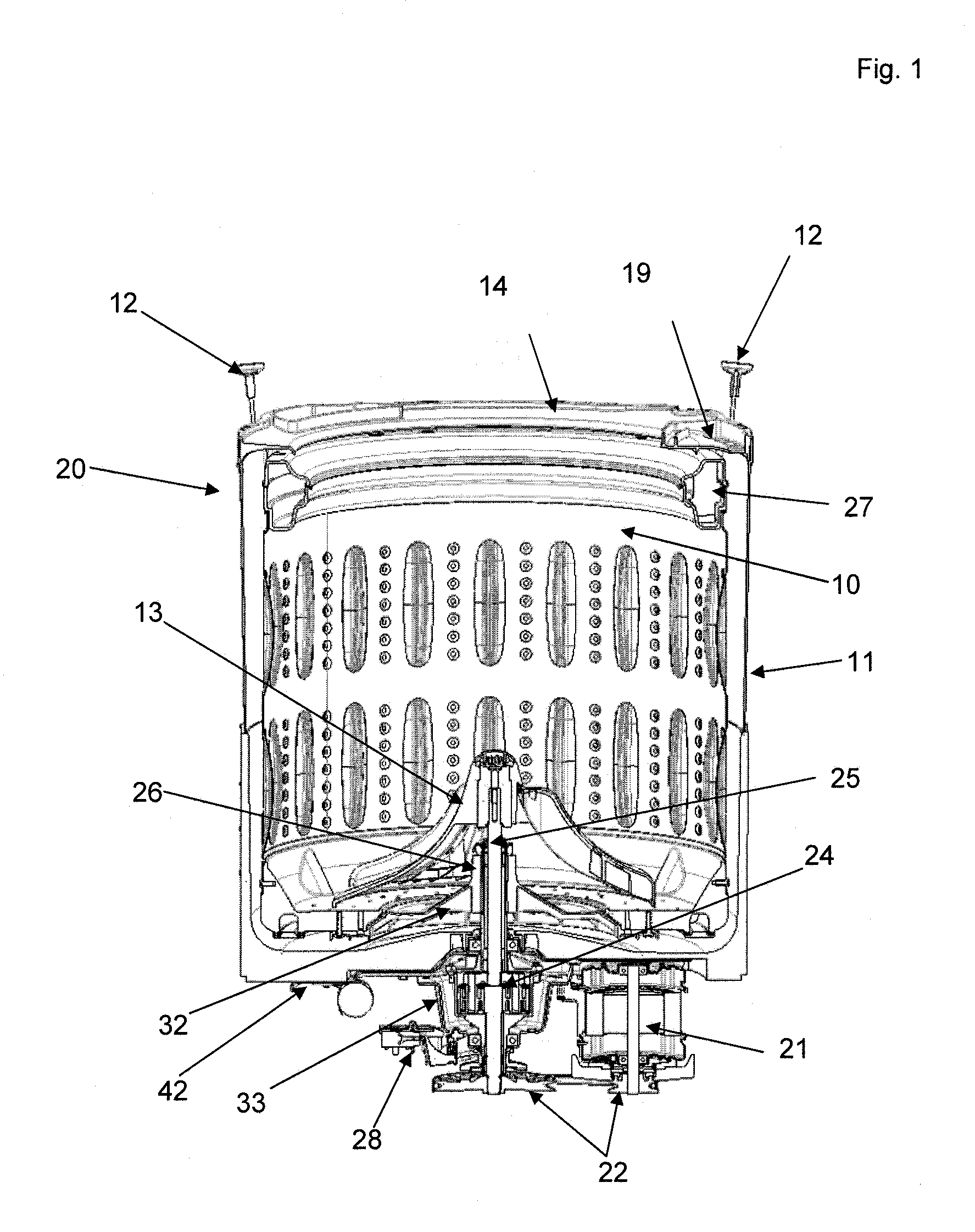

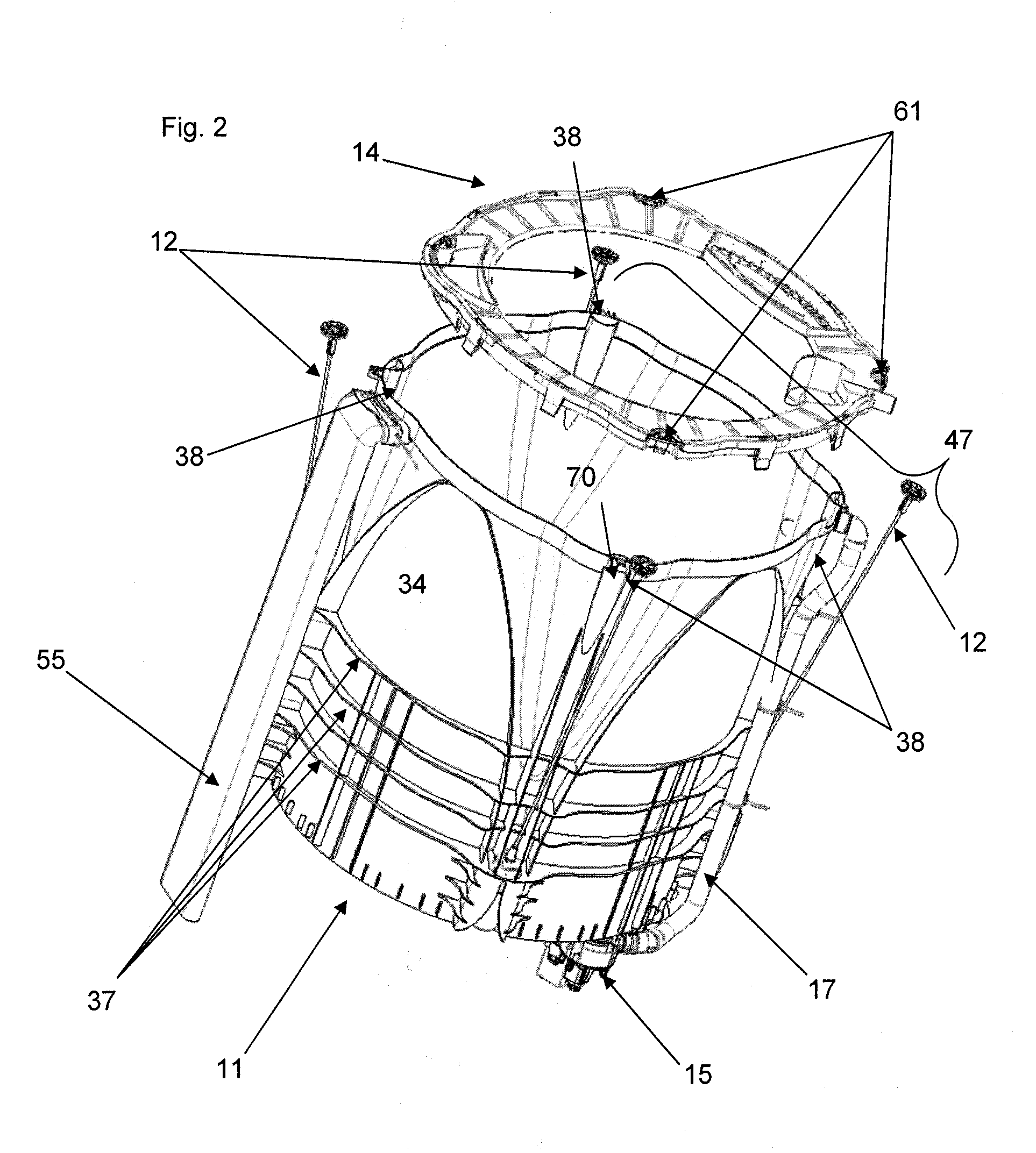

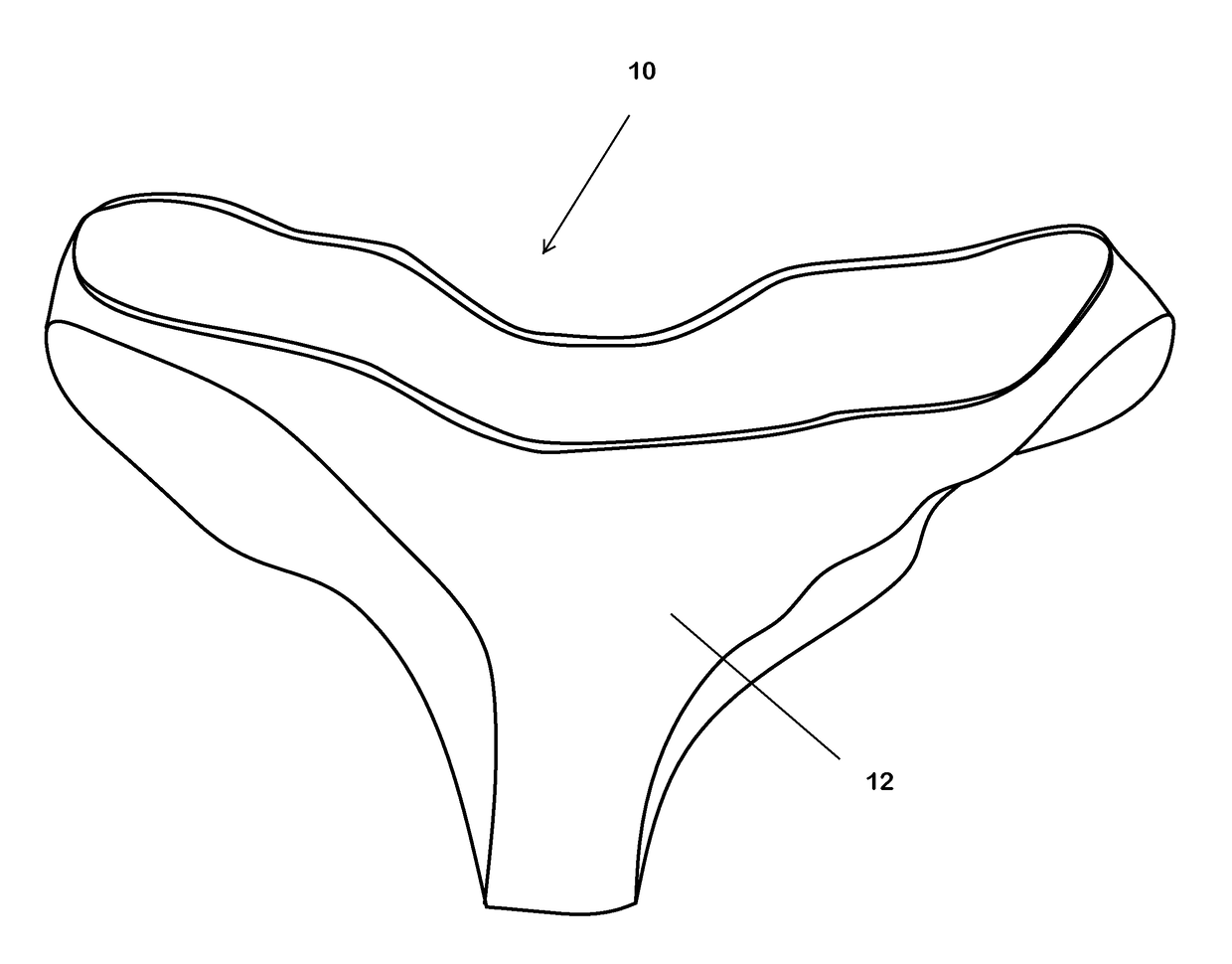

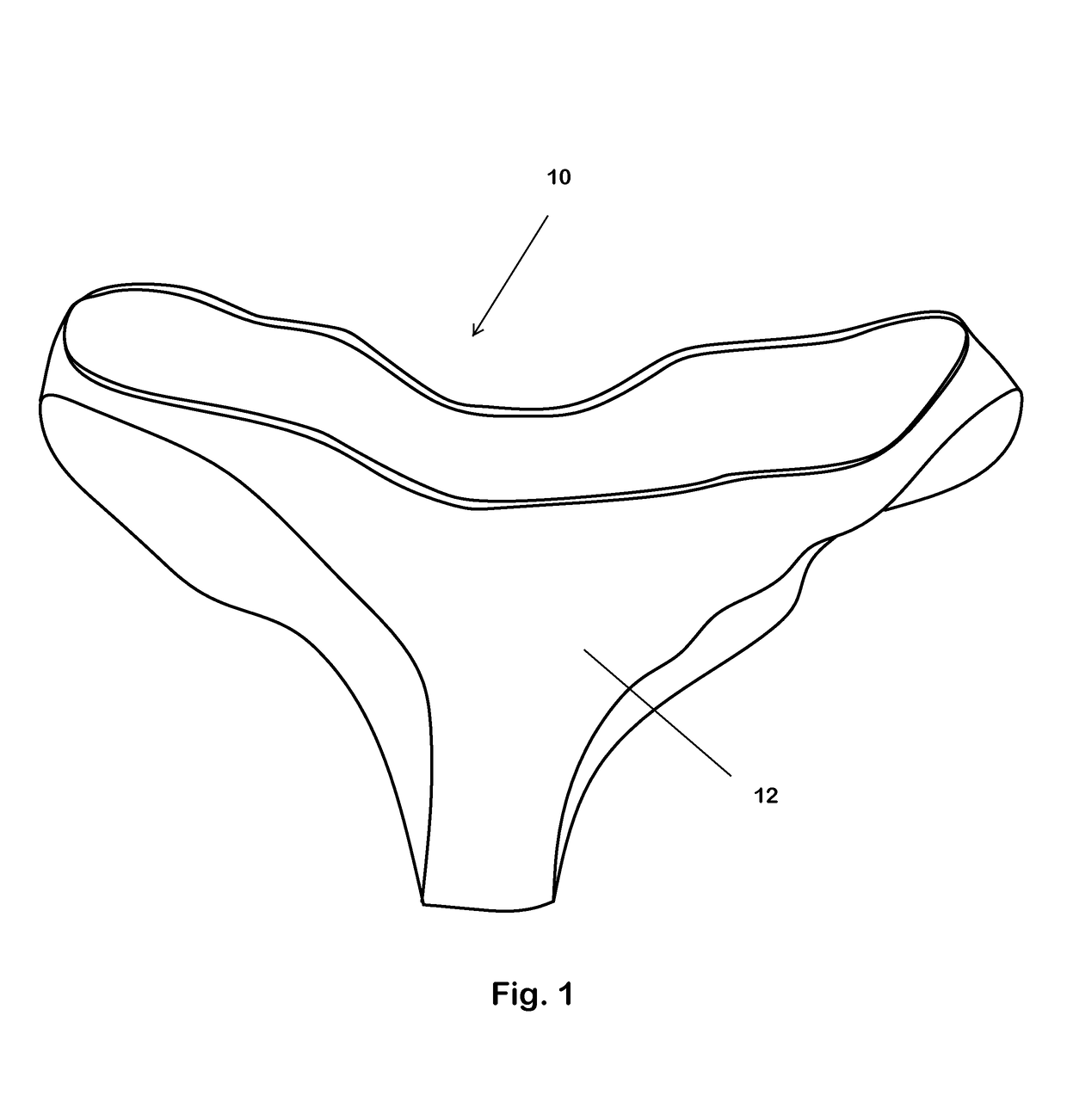

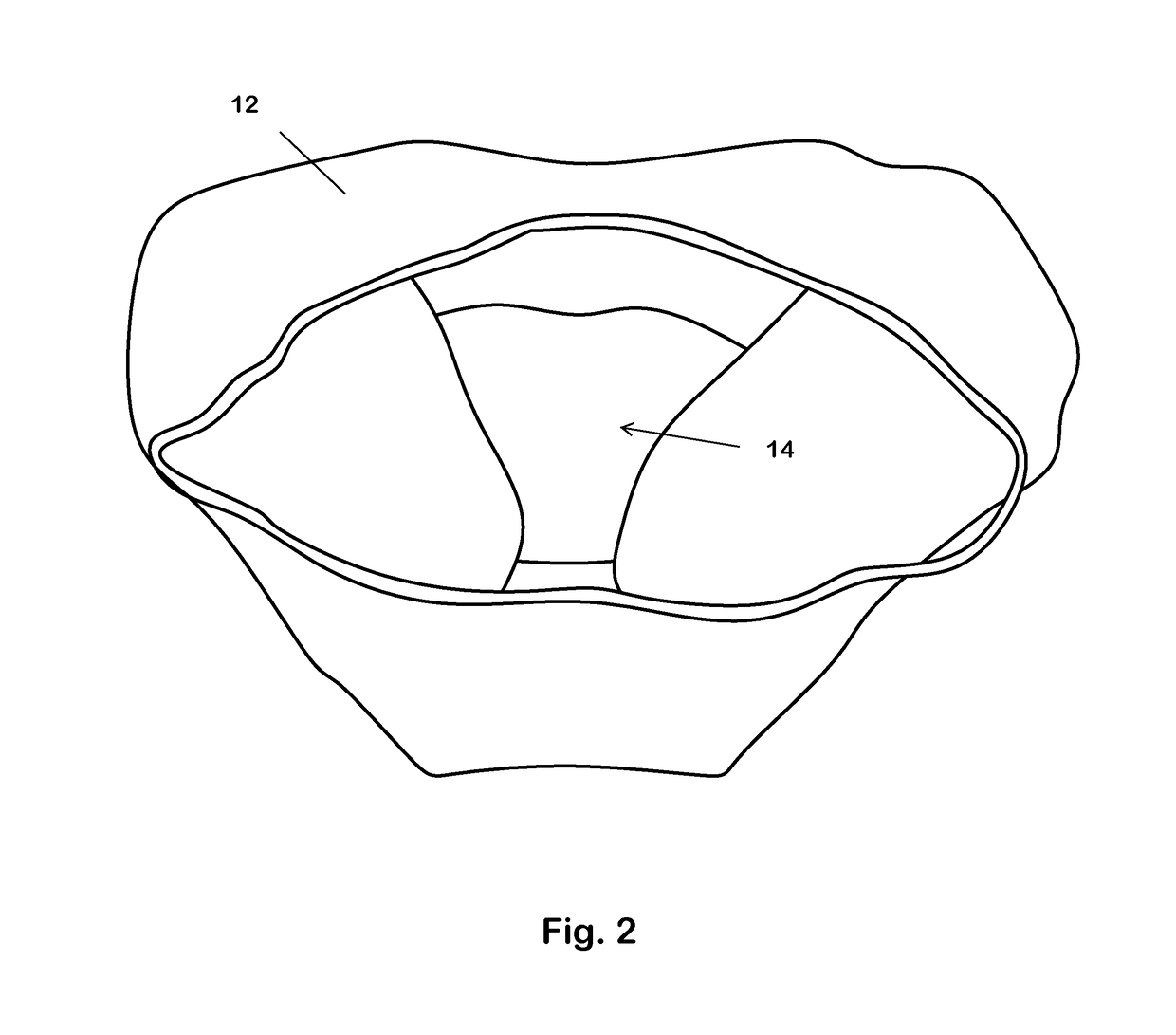

Tub Cover Design and Fastening Means of Tub Cover to Tub

InactiveUS20110148260A1Improve rigidityPrevent inward deformationWash-standsKitchenware cleanersEngineeringFlange

A cover for tub for a washer, the tub having a mouth and at least two balconies over which a cover is placed, wherein said cover comprises a housing channel placed on the periphery of said cover, which houses the upper end of the tub; at least one pair of locks facing each other on the periphery of said cover, wherein said locks have on their upper part some wedges; where each lock snaps unto the flange of the balcony of the tub: maintaining a drive tension between the lock and the balcony of the tub.

Owner:MABE SA DE CV

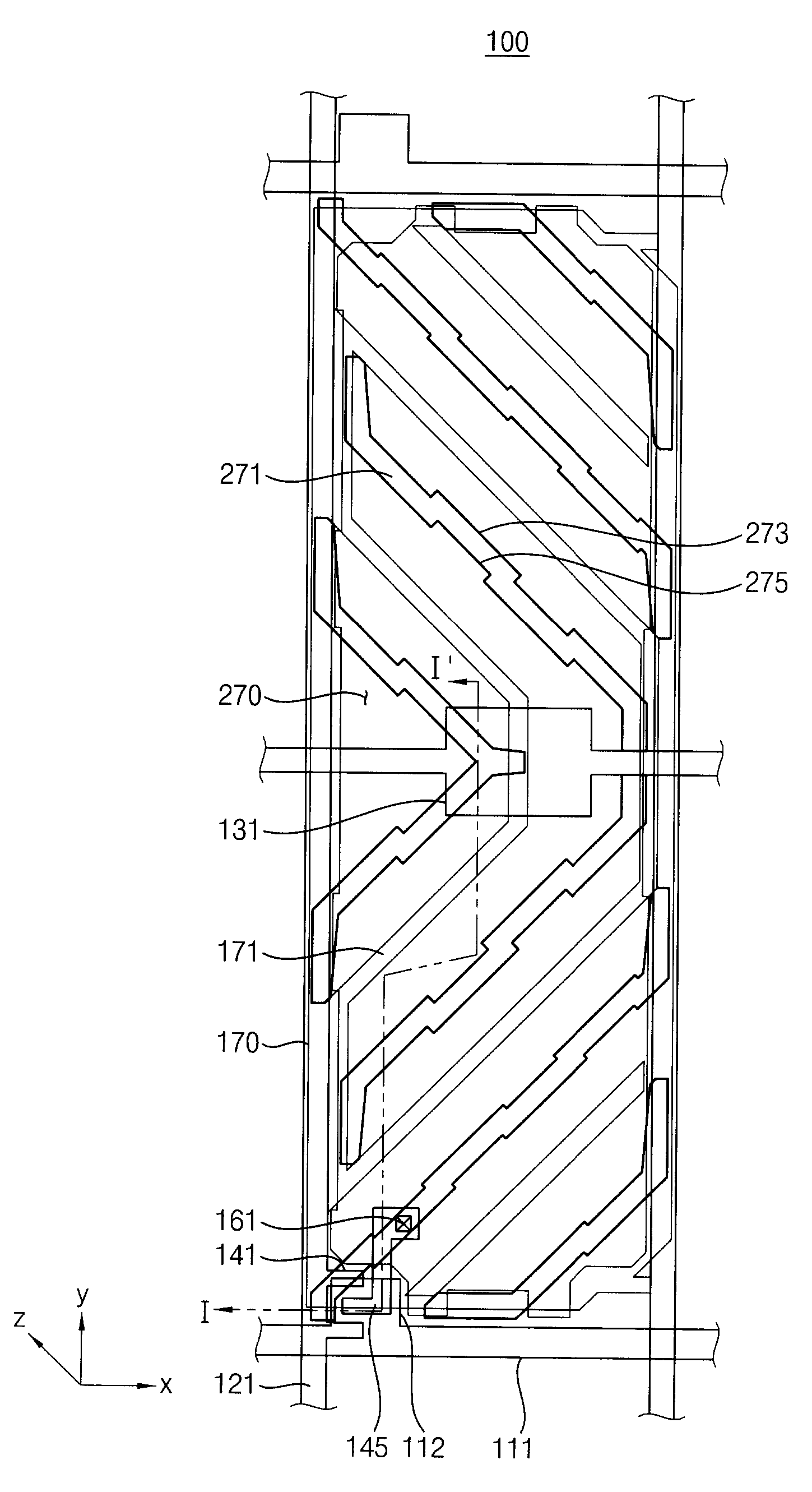

Display substrate and display panel having the same

In a display substrate and a vertical alignment display panel having the same, the display panel includes an array substrate and an opposite substrate. A plurality of first slit portions are arranged through a pixel area of a common electrode on the array substrate, and the first slit portions extend in a slanted direction. A plurality of grooves and a plurality of protruding portions are alternately arranged at edges facing each other on the first slit portion, so that the first slit portions are patterned. A positive singular point is generated on a side surface of a protruding portion, and a negative singular point is generated between the positive singular points.

Owner:SAMSUNG DISPLAY CO LTD

Exposure machine

InactiveCN103019041AAvoid spotImprove exposure qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringTriangular prism

The invention relates to the technical field of engineering exposure equipment, and discloses an exposure machine. The exposure machine comprises an object-carrying frame and a light source device, wherein a fixing element for fixing the exposed object is arranged at the inner side of the border of the object-carrying frame; and the light source device is located at one side of the plane on which the object-carrying frame is located, and the light-emitting direction is vertical to the plane on which the object-carrying frame is located. During exposure, the object-carrying frame cannot reflect the light ray which penetrates through the exposed object, thus avoiding the stops of an object-carrying stage. Additionally, the exposure machine adopts a vertical exposure mode, and can realize bidirectional exposure only by adding a triangular prism in the existing light source device, thus greatly increasing production efficiency.

Owner:BOE TECH GRP CO LTD +1

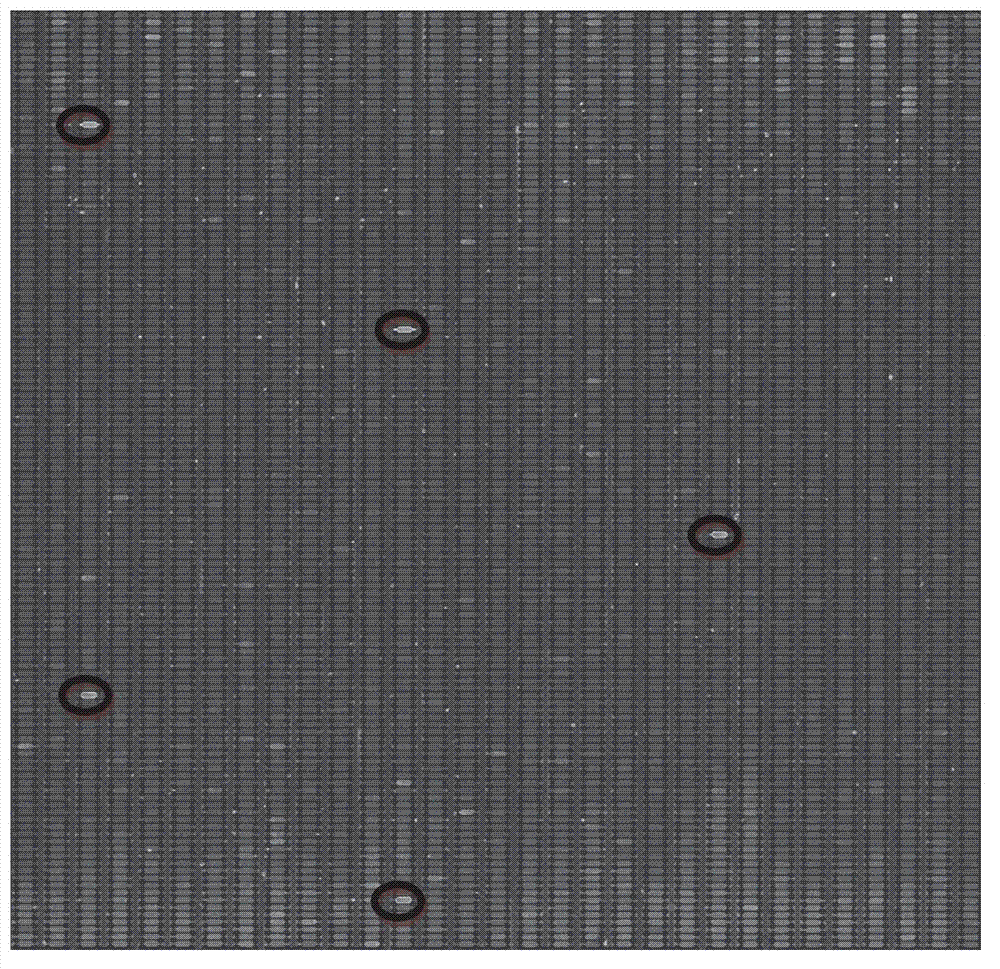

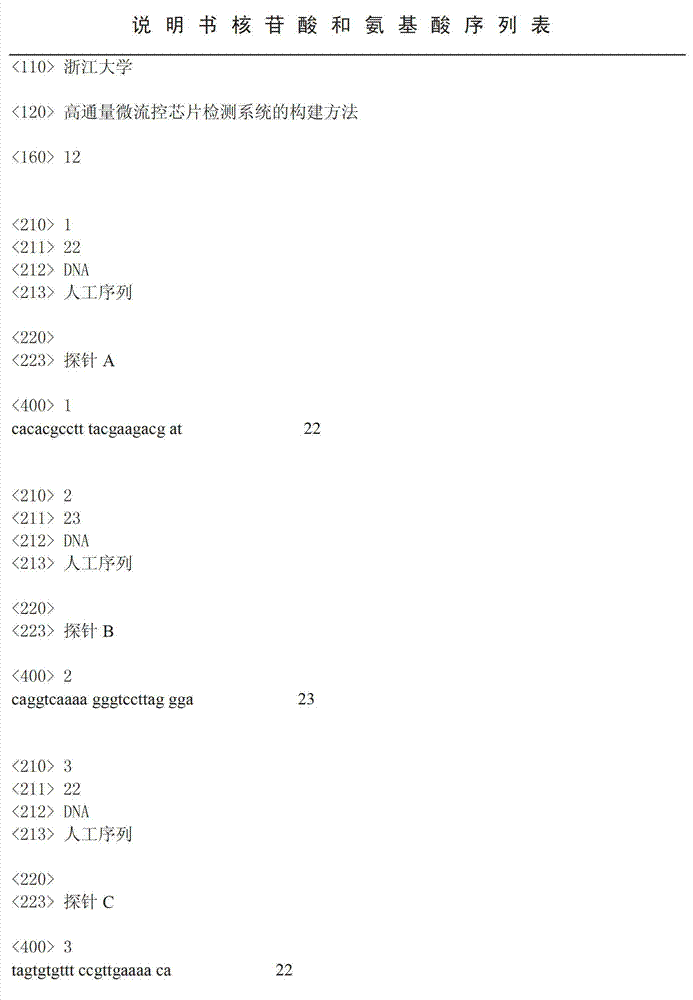

Construction method for high-throughput micro-fluidic chip detecting system

InactiveCN102901830ABreak through the bottleneck of low throughputKeep aliveBiological testingFluorescenceAntibody

The invention discloses a construction method for a high-throughput micro-fluidic chip detecting system. The construction method mainly comprises three processes, namely action of antibody and nucleotide crosslinking and the micro-fluidic chip, action of crosslinked antibody and nucleotide and a micro-fluidic chip, and action of fluorescent second antibodies and the micro-fluidic chip. The antibody and nucleotide crosslinking mainly comprises the following steps of: modifying and desalting antibodies; modifying and desalting nucleotide; and crosslinking and purifying the modified antibodies and the modified nucleotide and the like. The action of the antibody and nucleotide crosslinking and the high-throughput micro-fluidic chip mainly comprises the following steps of: eluting, melting and closing the chip; and reacting and eluting the crosslinking and the chip. The action of the fluorescent second antibodies and the micro-fluidic chip comprises the following steps of: idiosyncratically reacting Cy3 labelled second antibodies and a crosslinking antibody part connected to the chip; and performing subsequent eluting, scanning, melting and the like.

Owner:ZHEJIANG UNIV

Anti-slip heat insulation and sound isolation environment-friendly ground coating and preparation method thereof

InactiveCN108384390AImprove thermal insulation performanceImprove corrosion resistanceEpoxy resin coatingsPolyester coatingsCorrosion resistantEnvironmental resistance

The invention discloses anti-slip heat insulation and sound isolation environment-friendly ground coating and a preparation method thereof. The coating is prepared from the following raw materials inparts by weight: 90 to 100 parts of modified composite resin, 7 to 11 parts of sound insulation additives, 8 to 14 parts of heat insulation fillers, 6 to 10 parts of anti-slip additives, 20 to 30 parts of property enhancing resin, 2 to 4 parts of desinsectization and sterilization extraction liquid, 10 to 20 parts of mixed dibasic acid ester, 15 to 20 parts of propylene glycol methyl ether acetate, 3 to 5 parts of titanium dioxide, 0.5 to 1.5 parts of anti-settling agents, 1 to 2 parts of film forming agents, 0.4 to 0.8 part of anti-foaming agents, 0.8 to 1.4 parts of leveling agents and 2 to4 parts of dispersing agents. The coating is used as ground coating; the surface is fine; the leveling performance and the touch sense are excellent; the heat insulation and sound isolation performance is good; the anti-slip, friction resistant and anti-corrosion performance is good; meanwhile, the raw material ingredients are safe and reliable; no toxin and no harm exist; the raw materials can beeasily obtained; the cost is lower; the process is simple and clear; the operation is easy; the industrial production can be realized; higher practical value and good application prospects are realized.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

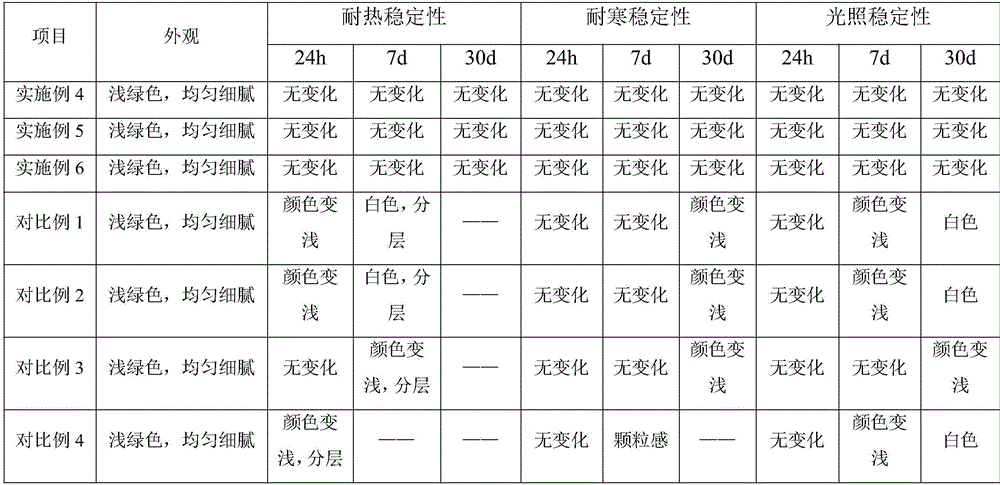

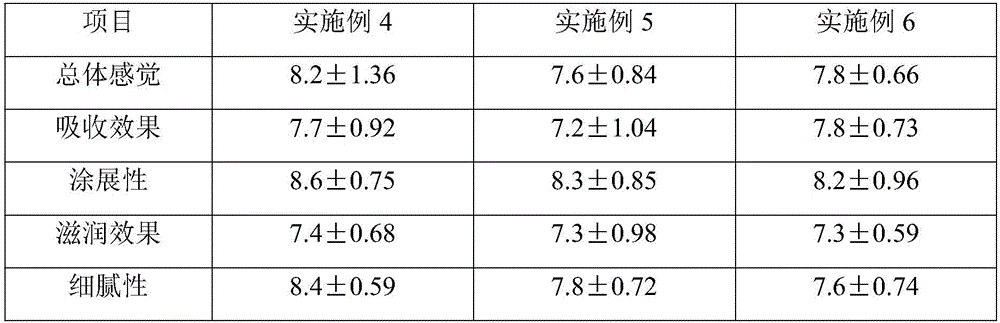

Chlorophyll-containing skincare product capable of resisting sunburn and repairing after sunburning

ActiveCN106511151AGood anti-photoaging functionEffective defenseCosmetic preparationsToilet preparationsJojoba oilUltraviolet

The invention belongs to the technical field of cosmetics and relates to a chlorophyll-containing skincare product capable of resisting sunburn and repairing after sunburning. The chlorophyll-containing skincare product capable of resisting sunburn and repairing after sunburning is prepared from chlorophyll compound liposome, hydrogenated jojoba oil, amygdalus pedunculata oil, squalane, cyclopentasiloxane, cetostearyl alcohol, PEG-100 stearate, tocopheryl acetate, bisabolol, butanediol, beta-glucan, sodium hyaluronate, carbopol, mycose, cetearyl glucoside, vitamin C ethyl ether, moringa oleifera leaf extract, triethanolamine, preservatives, essence and water. The chlorophyll-containing skincare product is stable in property, high in safety and high in usage comfort, is capable of effectively resisting ultraviolet rays of different wavebands, also has a good function of resisting photo-aging, and is also capable of preventing symptoms such as skin aging, freckles and desquamation and the like caused by sunburn and accelerating the repairing of the skin after sunburning.

Owner:广东省华桑丽皙生物技术有限公司

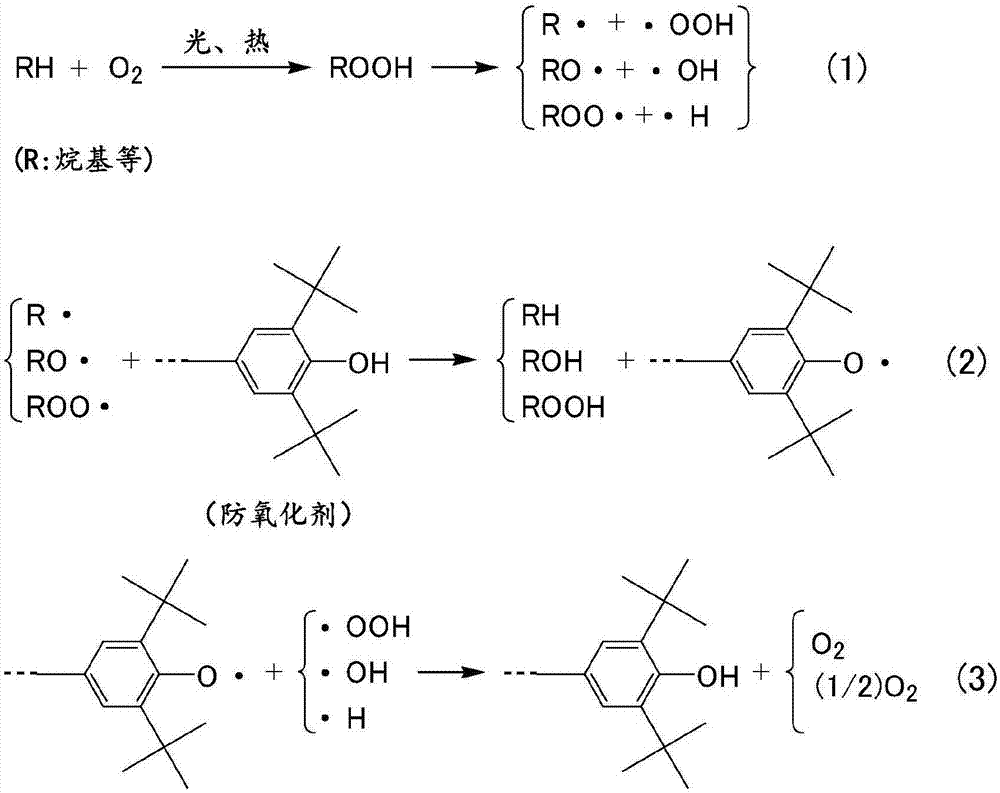

Liquid crystal display device

InactiveCN107111192AExcellent voltage retentionImprove adhesion strengthLiquid crystal compositionsNon-linear opticsAntioxidantPhenol

The present invention provides a liquid crystal display device whereby a good voltage holding ratio is maintained for a long time using an optical alignment film, and the occurrence of ghosting and spots in a display screen image is prevented. This liquid crystal display device is provided with: a liquid crystal layer containing liquid crystal molecules and an antioxidant; a sealing material obtained by curing a sealing resin containing a compound having at least one type of first connective functional group selected from the group consisting of an epoxy group, a methoxysilane group, and an ethoxysilane group; and an optical alignment film having at least one type of alignment film polymer having an ester group; the at least one type of alignment film polymer including an optical alignment film polymer having at least one type of photofunctional group selected from the group consisting of a cinnamate group, a carbonyl group, an azobenzene group, a coumarin group, a stilbene group, and a phenol ester group, and at least one type of second connective functional group selected from the group consisting of -COOH, -NH2, -NHR, -SH, and -OH being present on the surface of the optical alignment film.

Owner:SHARP KK

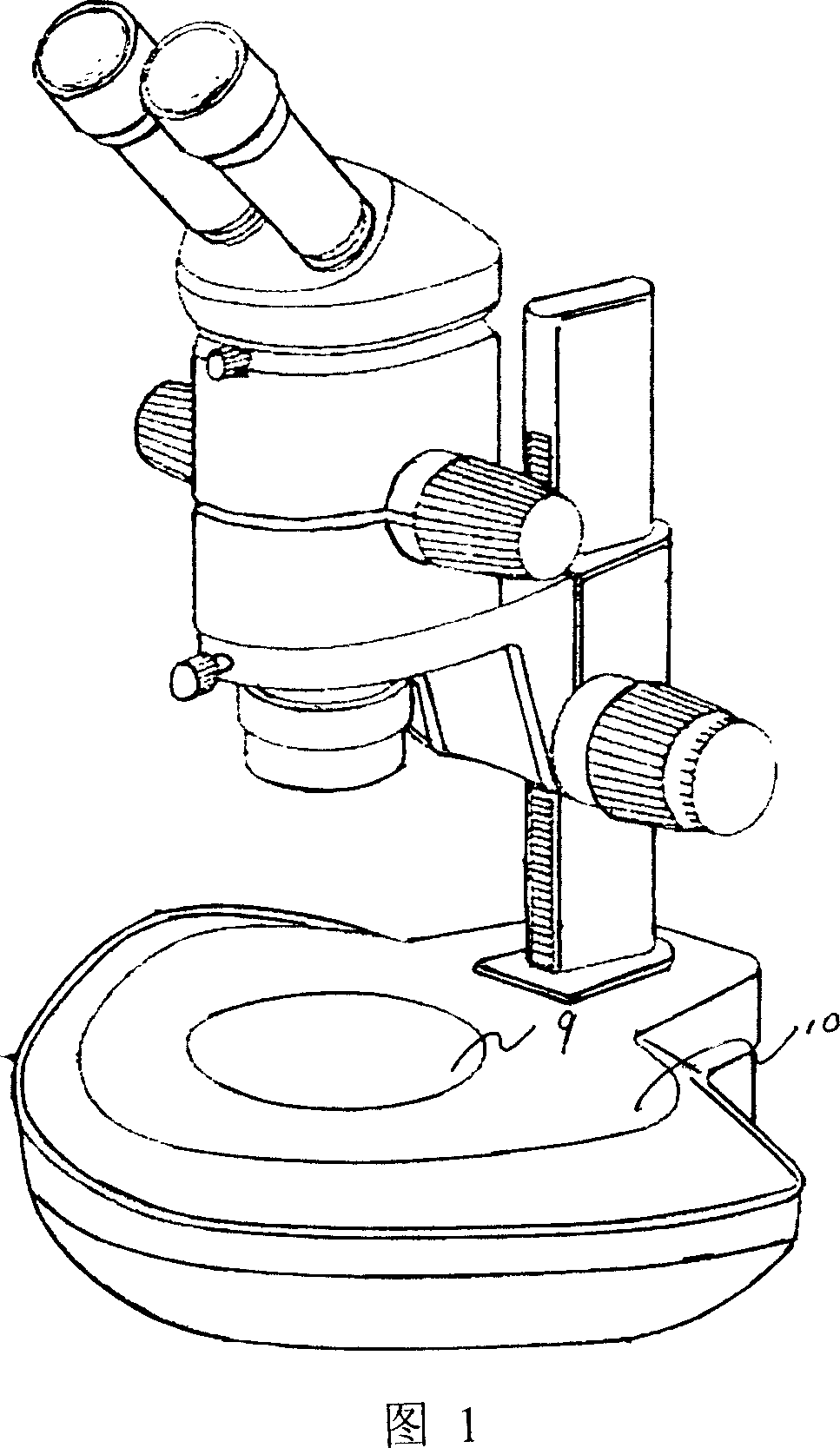

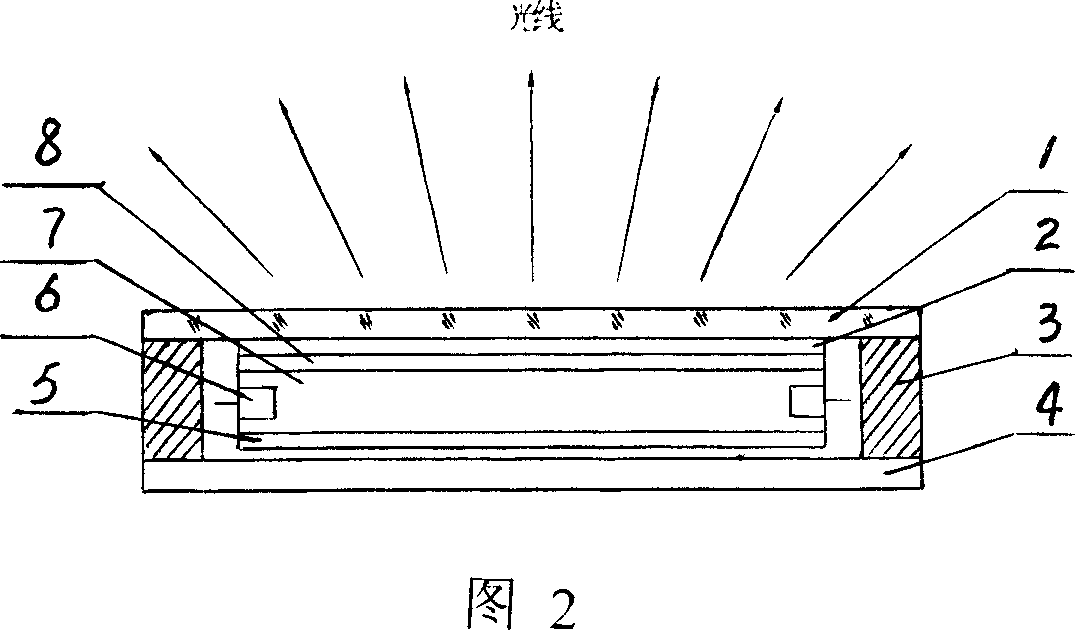

Microscope bottom illuminating light source made from LED lightback board

A microscope bottom lighting source formed by LED back light plate is featured as setting light intensification film on diffusion film in LED back light plate for obtaining uniform-lighting with brightness and color both being able to be adjusted.

Owner:蔡勇

Stabilised potassium bicarbonate and low-sodium leavening compositions

ActiveUS20130202758A1Effective protectionLarge particle sizeDough treatmentGlass/slag layered productsSilicon dioxideBaking powder

Potassium bicarbonate is coated with an anionic or amphoteric surfactant, which is preferably a metal soap, such as calcium stearate, to inhibit caking on storage, and premature loss of carbon dioxide when mixed with acidulant, e.g. in a baking powder or self-raising flour blend. Loss of carbon dioxide in the blend may be further inhibited by coating the acidulant with surfactant. Combination of surfactant coating with an inorganic anti-caking agent such as silicon dioxide gives synergistic protection against caking of the potassium bicarbonate. Preferably the bicarbonate has D50 of between 35 and 200μ and is free from particles greater than 400μ.

Owner:KUDOS BLENDS

Preparation method of prefabricated palm fiber material for cotton/palm fiber blending

ActiveCN104651955AGood flexibilityImprove breathabilityDry-cleaning apparatus for textilesBleaching apparatusKerosenePalm fiber

The invention discloses a preparation method of a prefabricated palm fiber material for cotton / palm fiber blending. The preparation method comprises the following steps: performing primary boiling-off and primary steaming to water, palm fibers, sodium hydroxide solution, kerosene, camellia oil, refining agent MRN and JFC to obtain primarily steamed palm fibers; then performing secondary boiling-off and secondary steaming to the water, sodium hydroxide solution, refining agent MOL-201, new synthetic fiber refining agent AV-SCOUR-81, chelating agent EDTA, kerosene, camellia oil and the primarily steamed palm fibers to obtain secondarily steamed palm fibers; standing the secondarily steamed palm fibers; mixing with the sodium hydroxide, hydrogen peroxide, stabilizer LTP-S128 and water to obtain bleached palm fibers; and then washing and bleaching the palm fibers twice with water at different temperatures, draining off and drying to obtain the prefabricated palm fiber material for cotton / palm fiber blending.

Owner:崇夕山

Near-neutral brush plating silvering solution and preparation and use methods thereof

The invention provides a near-neutral brush plating silvering solution and preparation and use methods thereof. The near-neutral brush plating silvering solution per litre is prepared form, by mass concentration, 20-45 g of silver nitrate, 90-150 g of potassium pyrophosphate, 6-12 g of methanesulfonic acid, 15-30 g of imidazole, 25-40 g of ammonium nitrate, 25-35 g of ammonium sulfate, 15-27.5 g of NH3.H2O, and a compound additive. The compound additive is prepared from 15-25 parts of polyethylene glycol, 25-40 parts of ethanediamine, 8-12 parts of fatty alcohol polyoxyethylene ether, 0.25-0.475 part of dimercaptobenzothiazole, 40-52 parts of ethanol, and 25-40 parts of deionized water. The near-neutral brush plating silvering solution has the advantages of a stable chemical property, non-toxicity and environmental friendliness; a silvered metal layer with excellent electrochemical performance, uniform structure, compactness and strong adhesion is formed on the surface of a copper-based material; the operation is simple and convenient; the preparation cost is low; and the near-neutral brush plating silvering solution is suitable for large-scale industrial applications.

Owner:HUBEI ENG UNIV

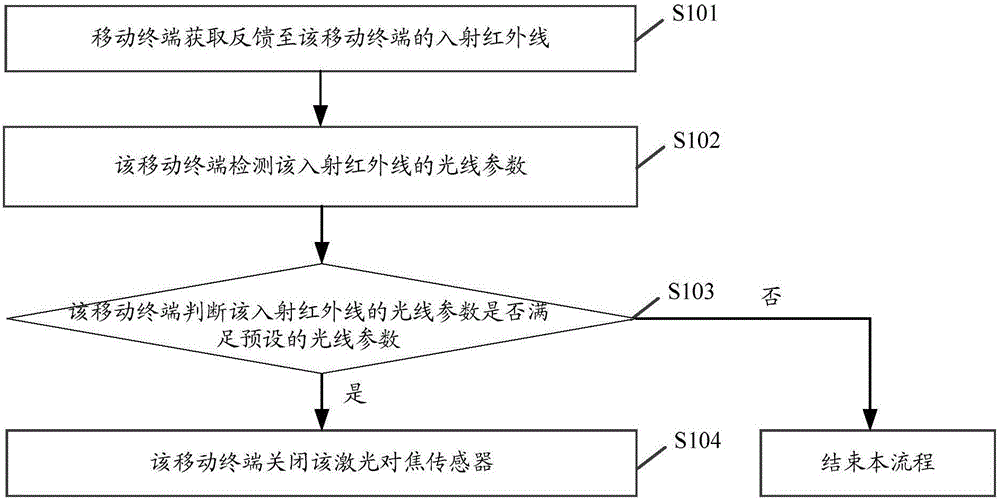

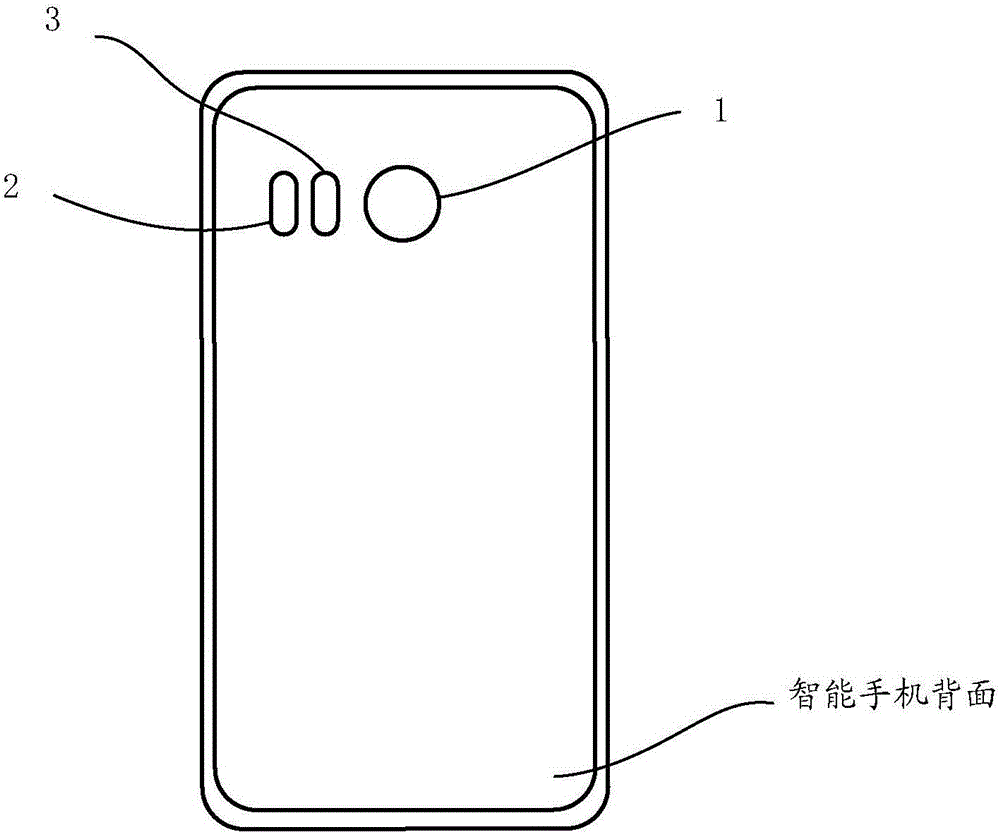

Control method for laser focusing sensor and mobile terminal

ActiveCN106101546AReduce intensityAvoid spotTelevision system detailsColor television detailsInfraredOptoelectronics

The invention discloses a control method for a laser focusing sensor and a mobile terminal. The method comprises that incident infrared rays, emitted by the mobile terminal, returned to the mobile terminal are obtained, a light parameter of the incident infrared rays is detected, and whether the light parameter of the incident infrared rays satisfies a preset light parameter is determined; and if it is determined that the light parameter of the incident infrared rays satisfies the preset light parameter, the laser focusing sensor is switched off. According to the invention, the intensity of the infrared rays, emitted by the laser focusing sensor, reflected to a camera can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

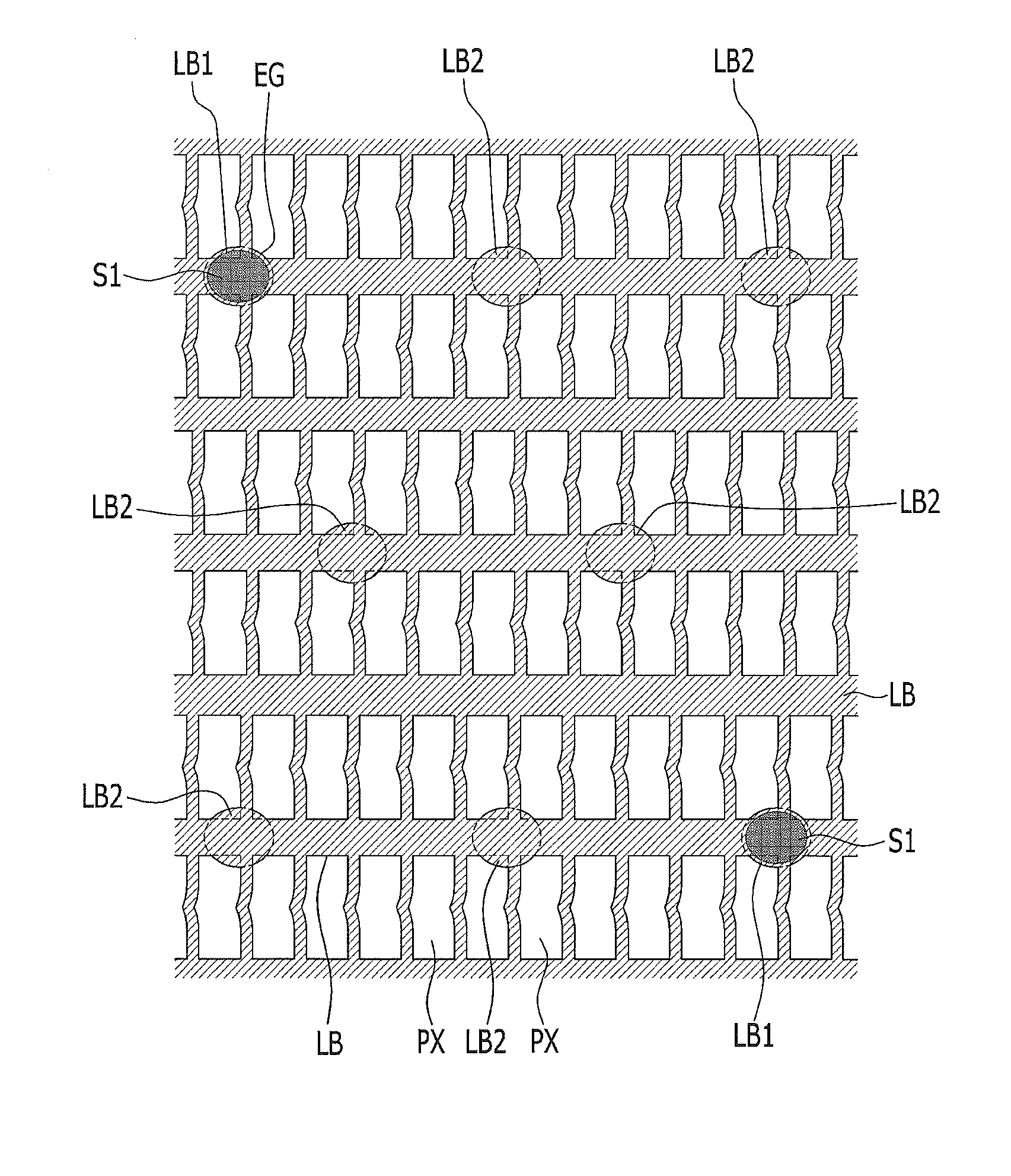

Liquid crystal display

ActiveUS9291859B2Deterioration in display quality such as spots is effectively preventedReduce the differenceNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display includes: a first substrate; a second substrate disposed opposite to the first substrate; a light blocking member disposed on one of the first substrate or the second substrate, where the light blocking member is disposed in a display area including a plurality of pixel areas, and the light blocking member includes a plurality of extensions having a predetermined plane shape; and a plurality of first spacers disposed on one of the first substrate and the second substrate and contacting an upper surface of a plurality of thin films disposed on the other of the first substrate and the second substrate, in which the extensions of the light blocking member includes a first extension and a second extension, and the first extension overlaps the first spacers, and the second extension does not overlap the first spacers.

Owner:SAMSUNG DISPLAY CO LTD

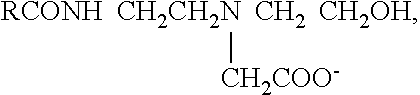

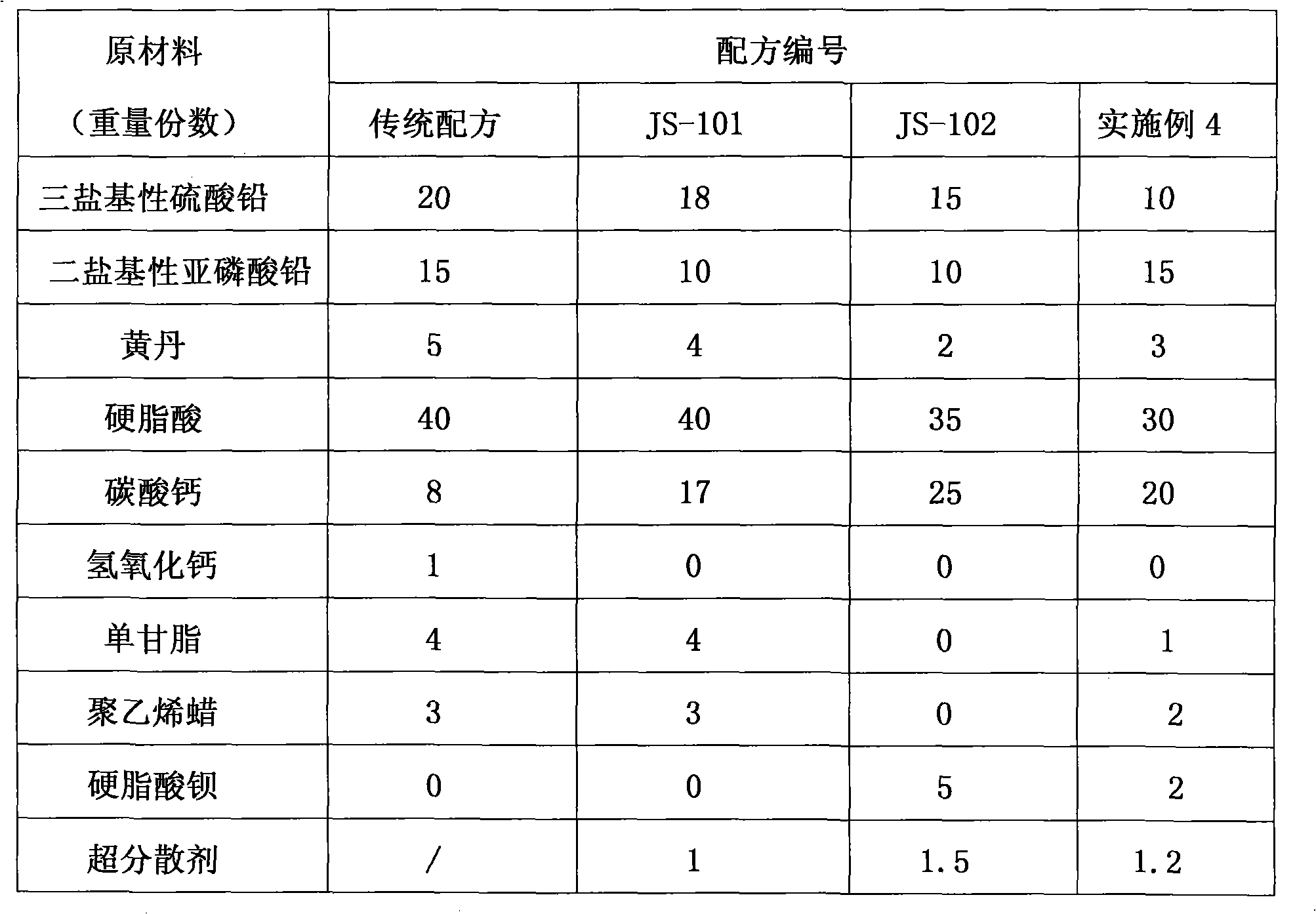

Ultra-dispersed composite stabilizer for polychloroethylene and preparation thereof

InactiveCN101302322AAvoid Agglomeration and PrecipitationGood dispersionDispersityPolyvinyl chloride

The invention relates to polyvinyl chloride ultra-dispersed composite stabilizer. The compositions by weight portion of the polyvinyl chloride ultra-dispersed composite stabilizer are: 10 to 20 portions of tribasic lead sulphate, 10 to 15 portions of dibasic lead phosphite, 2 to 4 portions of massicot, 0 to 5 portions of barium stearate, 0 to 4 portions of direactive glyceride, 0 to 4 portions of polyethylene wax, 30 to 40 portions of stearic acid, 1 to 1.5 portions of ultra-dispersed agent and 15 to 25 portions of light calcium carbonate, wherein, the ultra-dispersed agent is copolymers of maleic anhydride-sodium allylsulfonate-acrylate polyethylene glycol monoester. The composite stabilizer prepared can greatly improve the dispersity and the compatibility of the stabilizer and avoid variegation of the stabilizer during the process of processing sectional materials. Utilization of the ultra-dispersed agent also can improve the dispersity and the compatibility of PVC substrates and pigment. The polyvinyl chloride ultra-dispersed composite stabilizer has the advantages of superior performance, low toxity, high efficiency and multiple functions, namely the stabilizer simultaneously has the functions of improvement of the processability, plasticization, easy variegation, lubrication and so on. The method has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

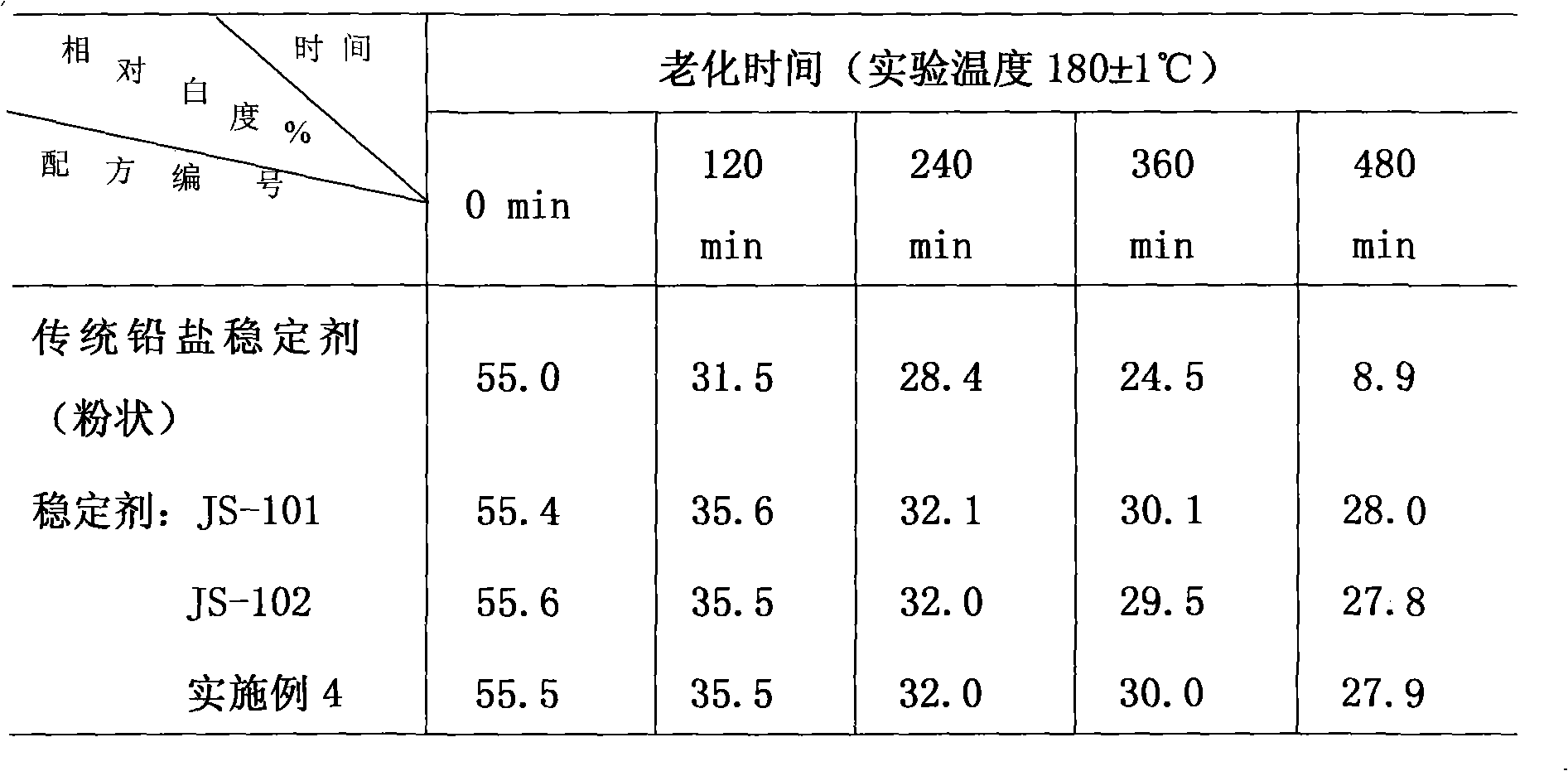

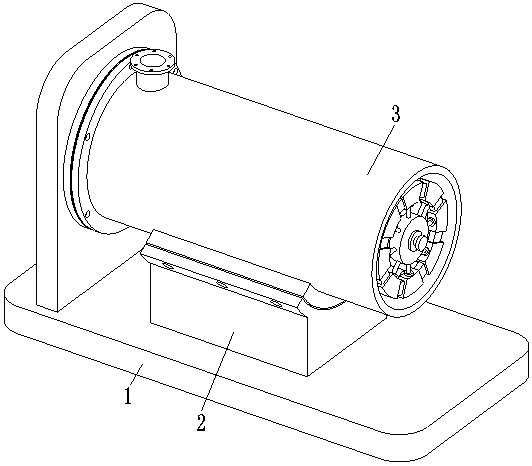

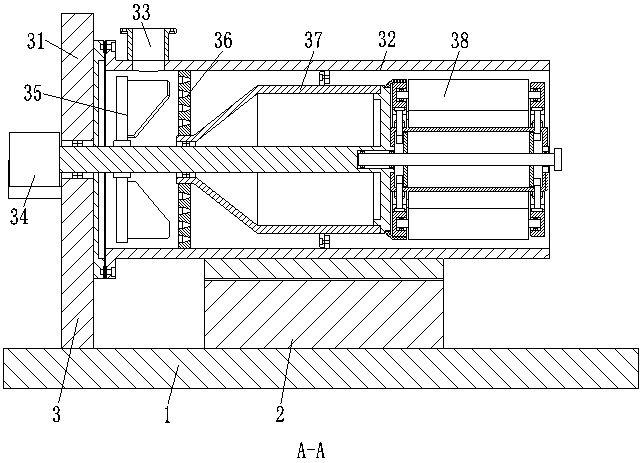

PE pipe extrusion molding device

The invention relates to a PE pipe extrusion molding device, which comprises a bottom plate frame, a supporting frame and an extrusion molding assembly, the supporting frame is installed in the middle of the upper end of the bottom plate frame, the extrusion molding assembly is installed on the left side of the upper end of the bottom plate frame, and the middle of the extrusion molding assembly is located at the upper end of the supporting frame. The problems are solved that when an existing PE pipe is machined, round machining cannot be effectively conducted on the interior of the PE pipe generally, so that the formed PE pipe is easily irregular, the defect that the inner wall of the PE pipe is easily rough and concaved and have bubbles and the like generally occurs, the follow-up using effect of the pipe is affected, and meanwhile when the existing PE pipe is machined, the wall thickness of the PE pipeline is generally adjusted by replacing different molds, the wall thickness of the PE pipeline cannot be accurately and conveniently adjusted, and the machining efficiency of the PE pipeline is affected.

Owner:林杨

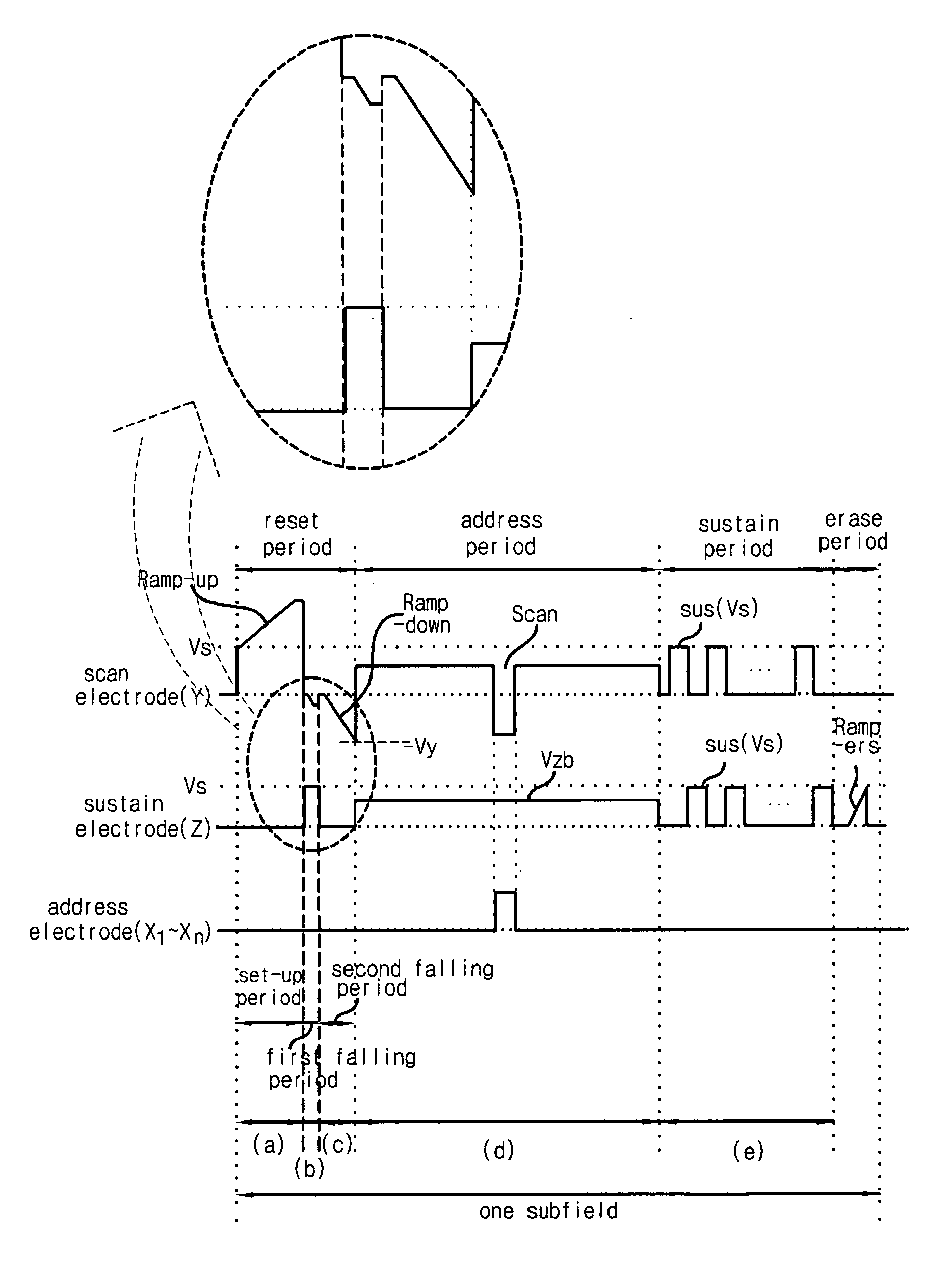

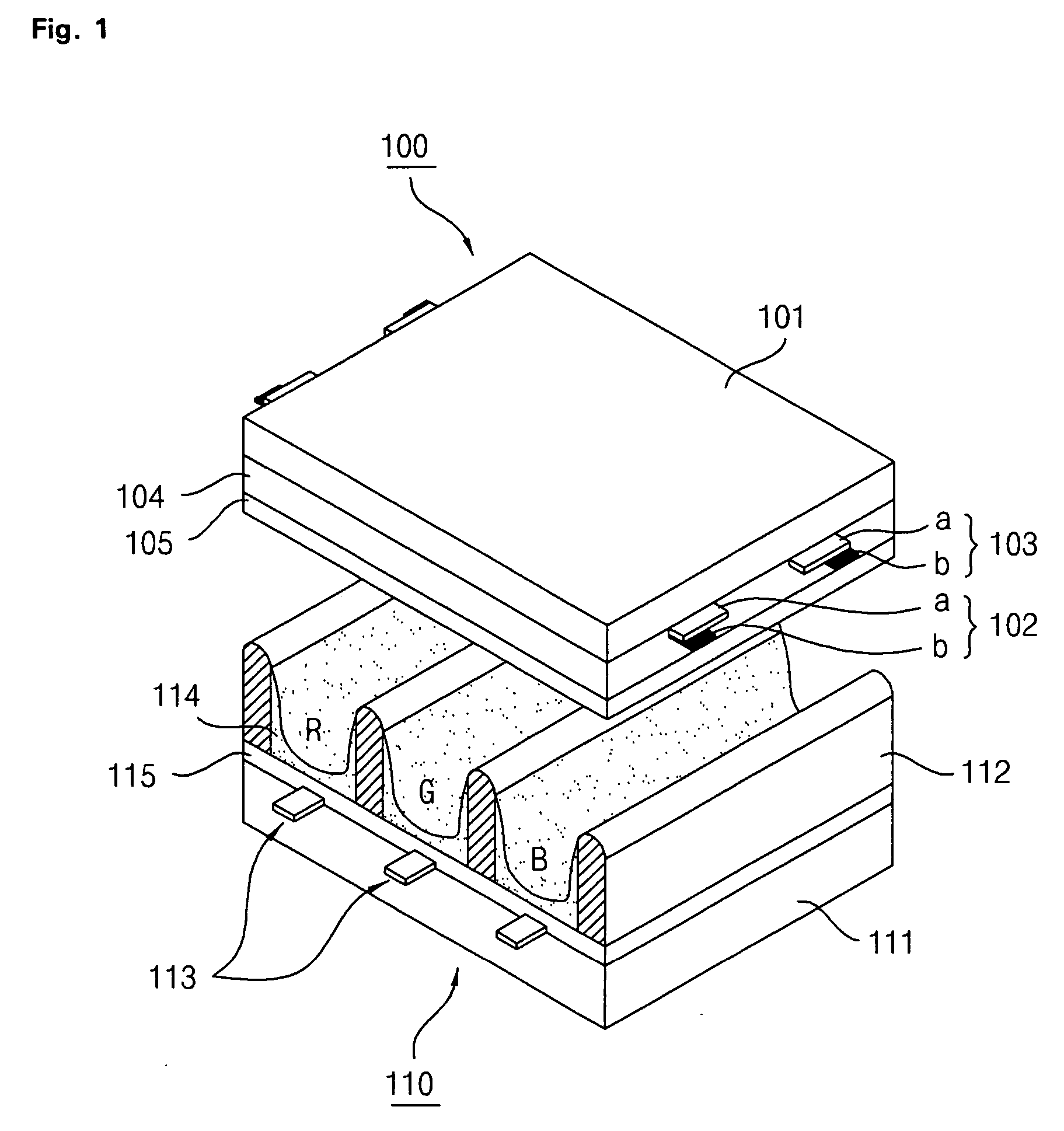

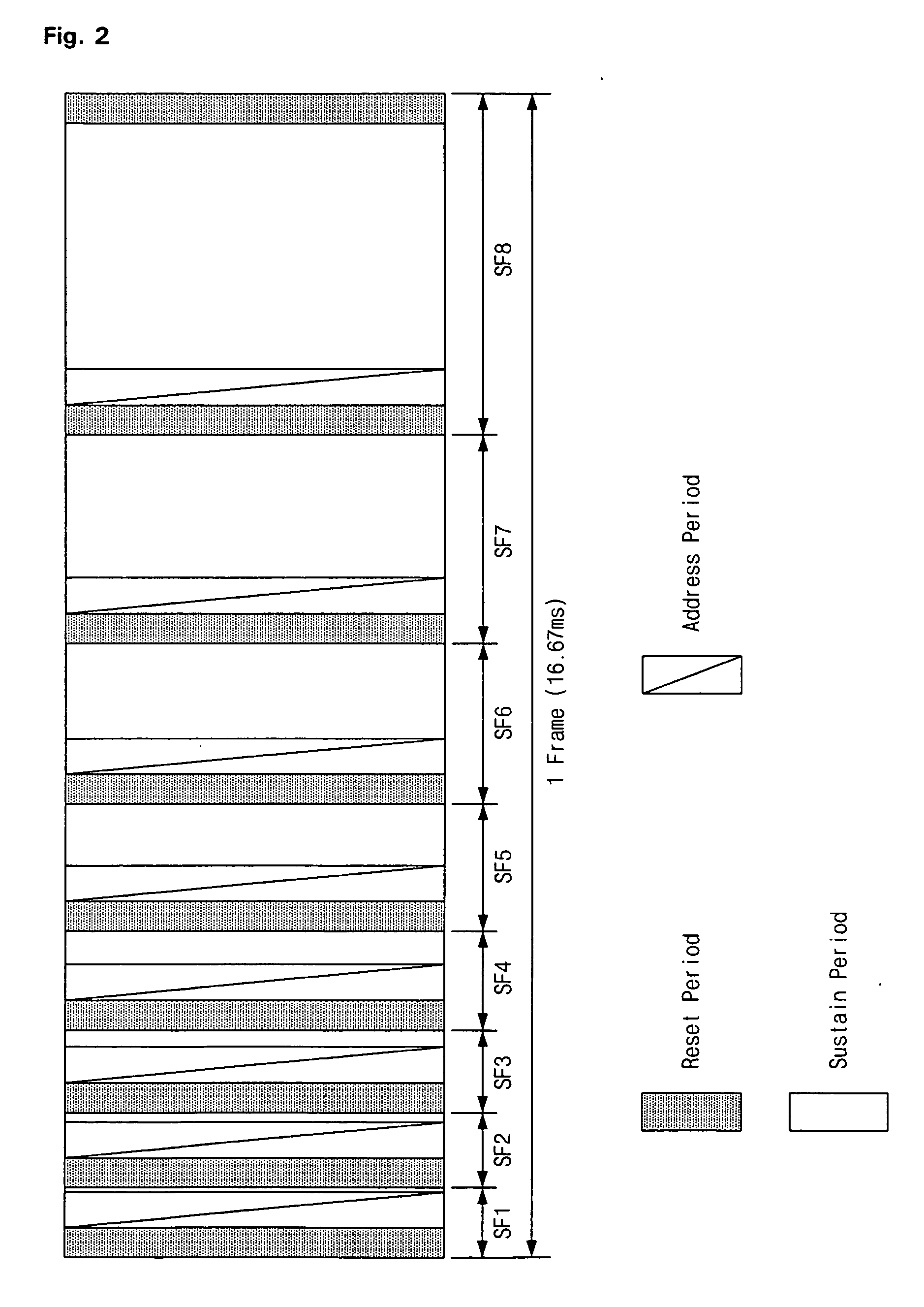

Plasma display apparatus and driving method thereof

The present invention relates to a plasma display apparatus, and more particularly to a plasma display apparatus and a driving method thereof, which are capable of preventing an afterimage-generating wrong discharge when a plasma display panel is driven. Provided is a plasma display apparatus, including: a plasma display panel on which a plurality of sustain electrode pairs, each including a scan electrode and a sustain electrode, are formed; a driver driving each sustain electrode pair; and a driving pulse controller which controls the driver to sequentially apply a first falling waveform and a second falling waveform to the scan electrode and to apply a positive waveform to the sustain electrode while applying the first falling waveform, in a reset period. In accordance with the present invention, it is possible to prevent afterimage-generating woring discharge by improving the structure of a plasma display apparatus and a driving method thereof. In accordance with the present invention, it is possbiel to prevent spots from being created on a displayed single color pattern by improving the structure of a plasma display apparatus and a driving method thereof.

Owner:LG ELECTRONICS INC

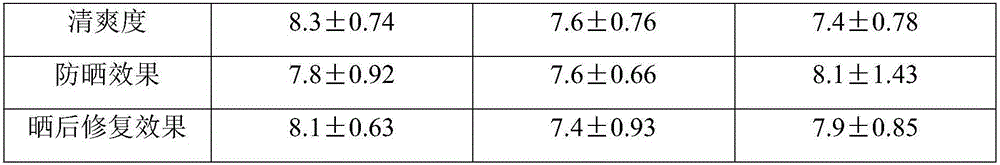

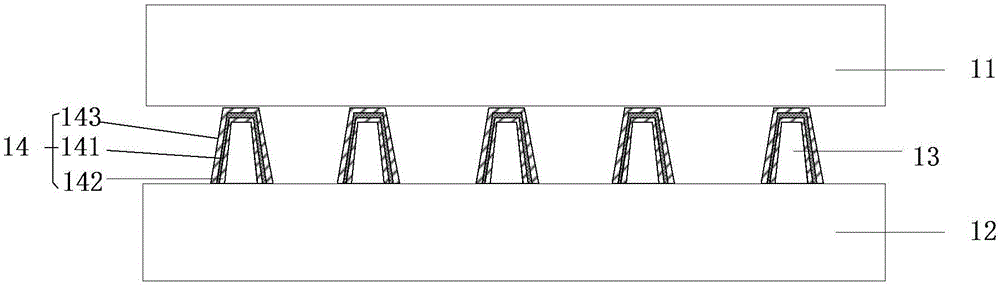

Liquid crystal lens, stereo display device, display method and manufacturing method

ActiveCN106773183AReduce reflectionAvoid spotNon-linear opticsOptical elementsTransmittanceLiquid-crystal display

The invention provides a liquid crystal lens, a stereo display device, a display method and a manufacturing method. The liquid crystal lens comprises a first substrate, a second substrate, a liquid crystal layer, spacers and a variable-color structure, and the liquid crystal layer, the spacers and the variable-color structure are arranged between the first substrate and the second substrate. An orthographic projection, on the first substrate or the second substrate, of the variable-color structure at least covers orthographic projections, on the first substrate or the second substrate, of the spacers. The variable-color structure is switchable between a transparent state and a black state. When a display panel displays black images, the variable-color structure can be controlled to be in the black state to reduce light reflection of the spacers, and accordingly light spots are avoided. When the display panel displays white images, the variable-color structure can be controlled to be in the transparent state, and consequently the problem of display dark areas in a region of the spacers due to light transmittance differences of the spacers and liquid crystal is avoided.

Owner:BOE TECH GRP CO LTD

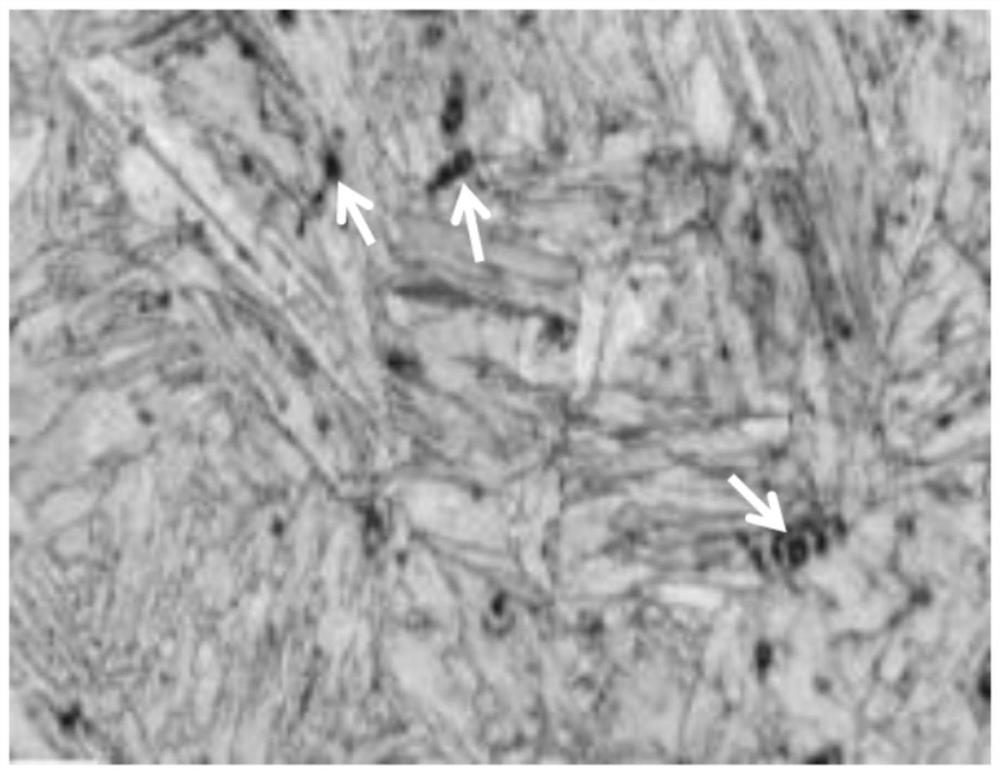

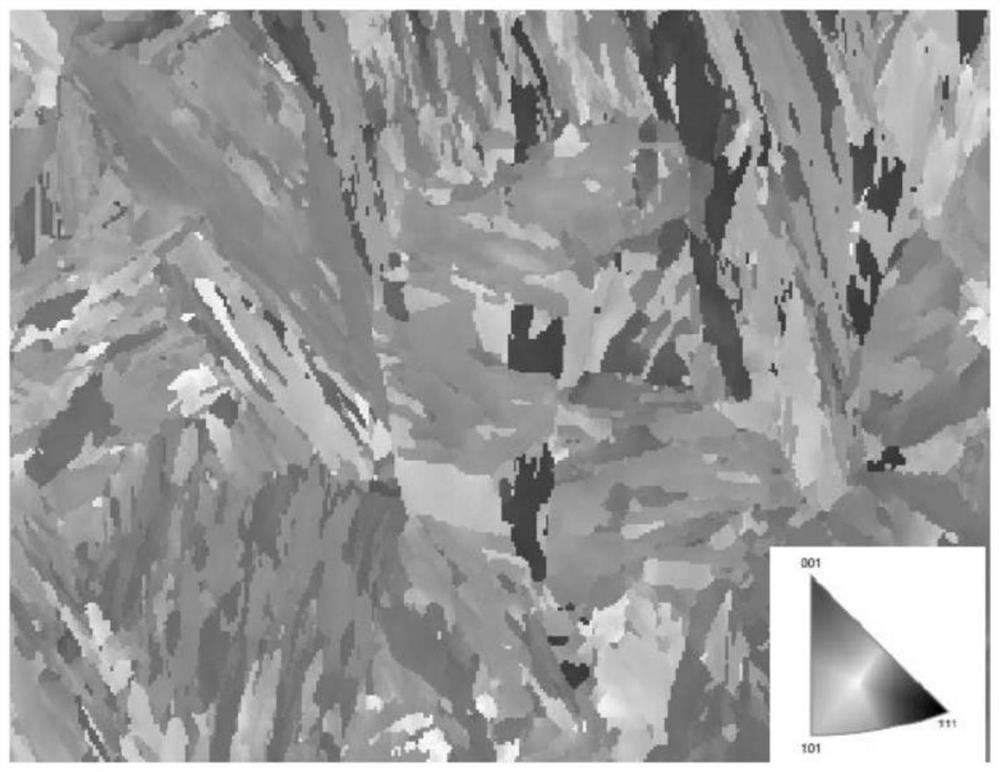

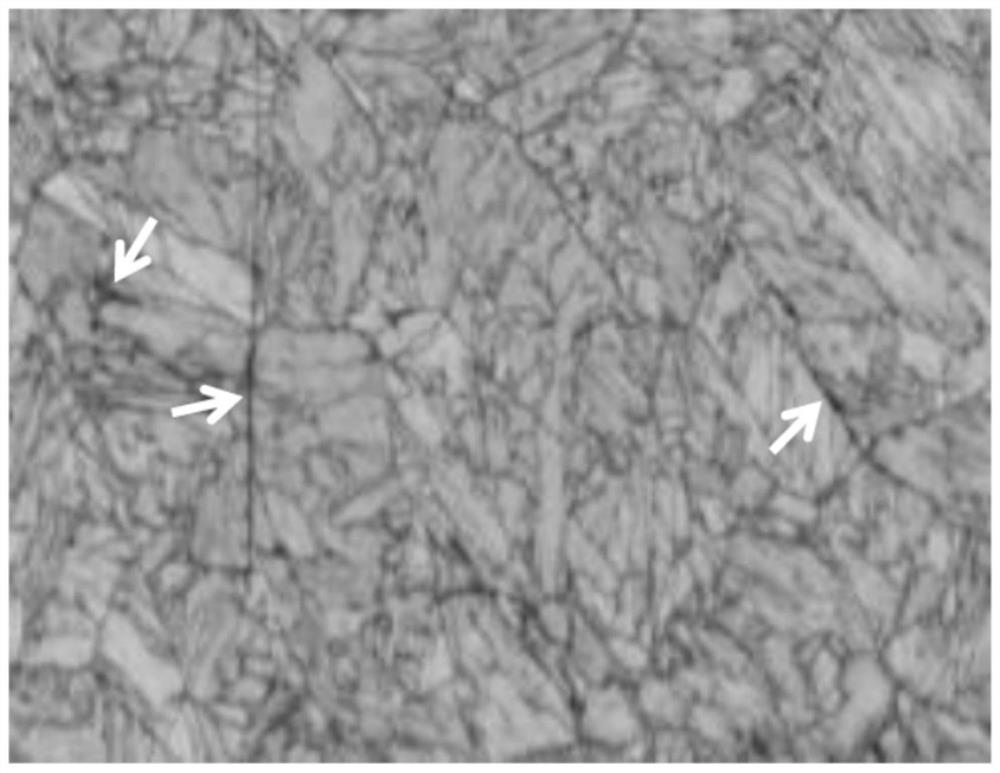

Method for preparing super martensitic stainless steel EBSD sample

ActiveCN112160018ASpeed up the flowFast dissolutionPreparing sample for investigationElectrolytic agentMetallurgy

The invention discloses a method for preparing a super martensitic stainless steel EBSD sample. The method comprises the steps of polishing solution preparation, sample grinding, electrolytic polishing and polished surface cleaning; a polishing solution is prepared by mixing HCLO4, CH3COOH and C2H5OH according to the volume ratio of (1 + / -0.1): (3 + / -0.1): (6 + / -0.1), a stainless steel sheet is used as a cathode, and the super martensitic stainless steel sample serves as an anode; then an electrolysis device is placed on a magnetic stirrer, liquid nitrogen is used for cooling the electrolyte,and the power voltage is adjusted; finally, a stainless steel clamp is used for immersing the sample into the electrolyte, the grinding face is parallel to the cathode stainless steel sheet, the powercurrent is adjusted, and polishing is started; and after polishing is completed, the sample is taken out to be wiped and dried. According to the method, the polishing time is short, the polishing efficiency is high, and the EBSD collecting and calibrating rate can reach 95% or above.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com