Near-neutral brush plating silvering solution and preparation and use methods thereof

A near-neutral, electric brush plating technology, applied in the field of electrochemistry, can solve the problems of unfavorable electric equipment repair site development, short storage time of plating solution, difficult industrialization, etc. Low corrosion hazard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

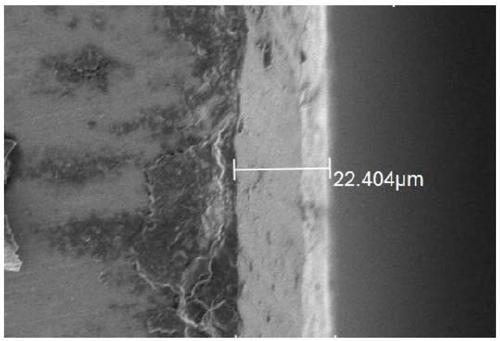

Examples

Embodiment 1

[0046] Add polyethylene glycol, ethylenediamine, fatty alcohol polyoxyethylene ether, and 2-mercaptobenzothiazole into the ethanol aqueous solution in sequence, and stir until dissolved. The dosage ratio of polyethylene glycol, ethylenediamine, fatty alcohol polyoxyethylene ether, 2-mercaptobenzothiazole, ethanol, and deionized water is: 20g: 30g: 10g: 0.35g: 54ml: 36ml.

[0047] Potassium pyrophosphate is dissolved in deionized water to obtain a potassium pyrophosphate solution with a concentration of 120g / L; a certain amount of silver nitrate is weighed and added to the above potassium pyrophosphate solution, and the concentration of silver nitrate in the gained solution is 22g / L to obtain The first mixed solution; adding a certain amount of methanesulfonic acid and imidazole to the first mixed solution, stirring, dissolving and mixing to obtain the second mixed solution; adding a certain amount of compound additives to the above second mixed solution to obtain the second mix...

Embodiment 2

[0051] The formula and usage method of this embodiment are the same as those of Embodiment 1, the difference being that the number of times of brush plating is 5 times.

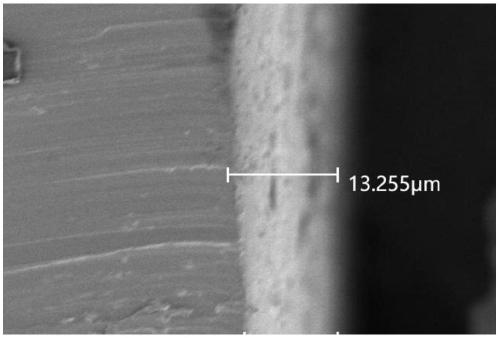

Embodiment 3

[0053] The formula and usage method of this embodiment are the same as those of Embodiment 1, except that the number of brush plating is 15 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com