Method for acquiring laser meat image by double-laser triangle method

A technology of image acquisition and triangulation, applied in the direction of using optical devices, optical testing flaws/defects, measuring devices, etc., can solve problems such as threats to consumer health, consumer ingestion, and impact on product taste and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

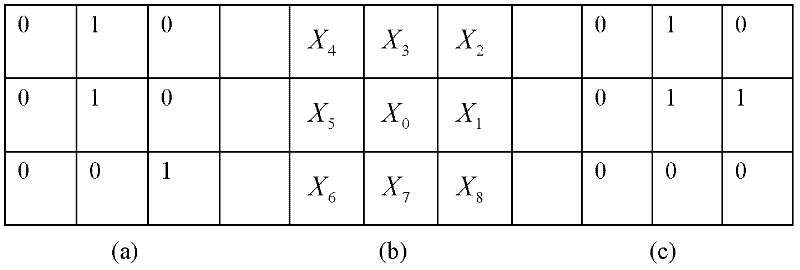

[0088] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0089] In this example, dual CCD cameras are used to collect laser images of meat from the left and right sides of the direct laser beam to obtain complete meat contour and thickness information.

[0090] 1. Analysis of meat thickness laser image measurement system

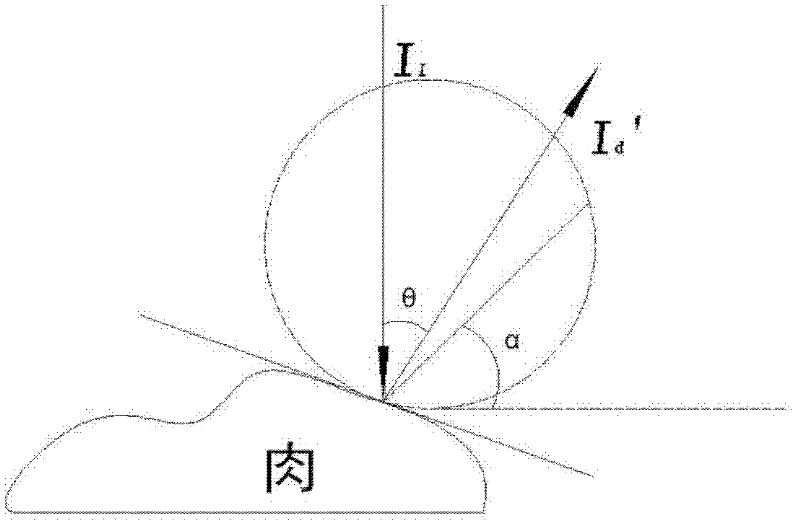

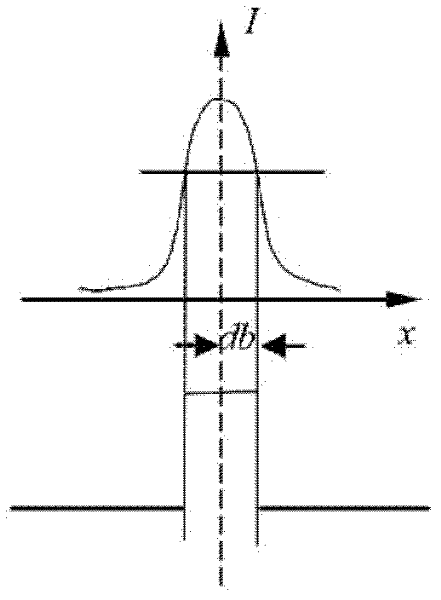

[0091] 1.1.1 Reflection analysis of light radiation meat

[0092] The reflection of light radiation on the surface of the medium is divided into two types: specular reflection and diffuse reflection. Different reflection characteristics have different distributions of reflected radiation intensity. The curved surface of the meat surface is complex, and the moisture content of each part of the same piece of meat varies greatly. Moreover, the distribution of fat meat and lean meat is uneven. When light is incident on the interface of two different media, it will be reflected accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com