Microscope bottom illuminating light source made from LED lightback board

A technology of LED backlight board and lighting source, applied in the direction of microscope, optics, optical components, etc., can solve the problems of wasting materials, affecting the use of operators, and affecting the observation effect of microscopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

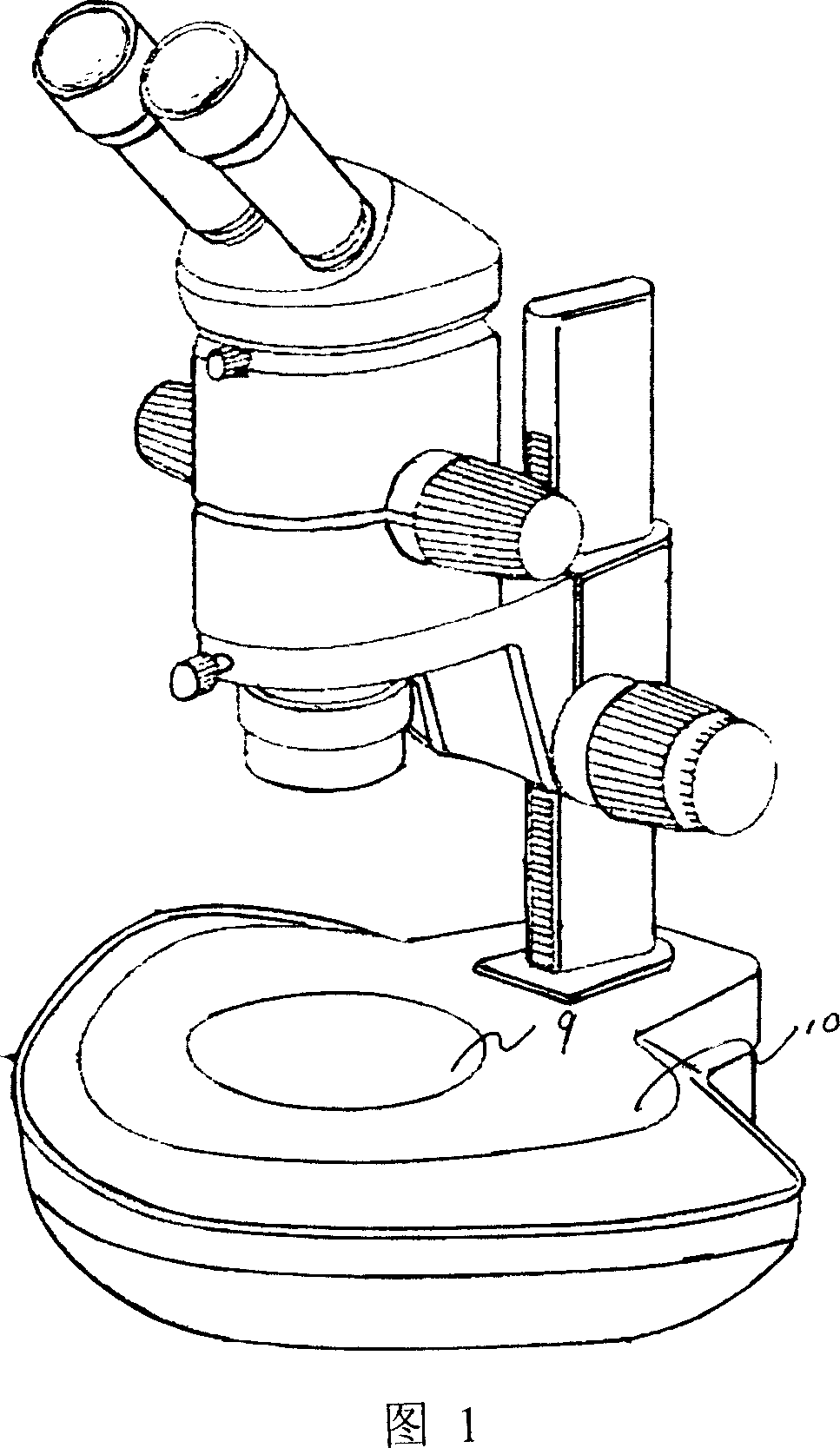

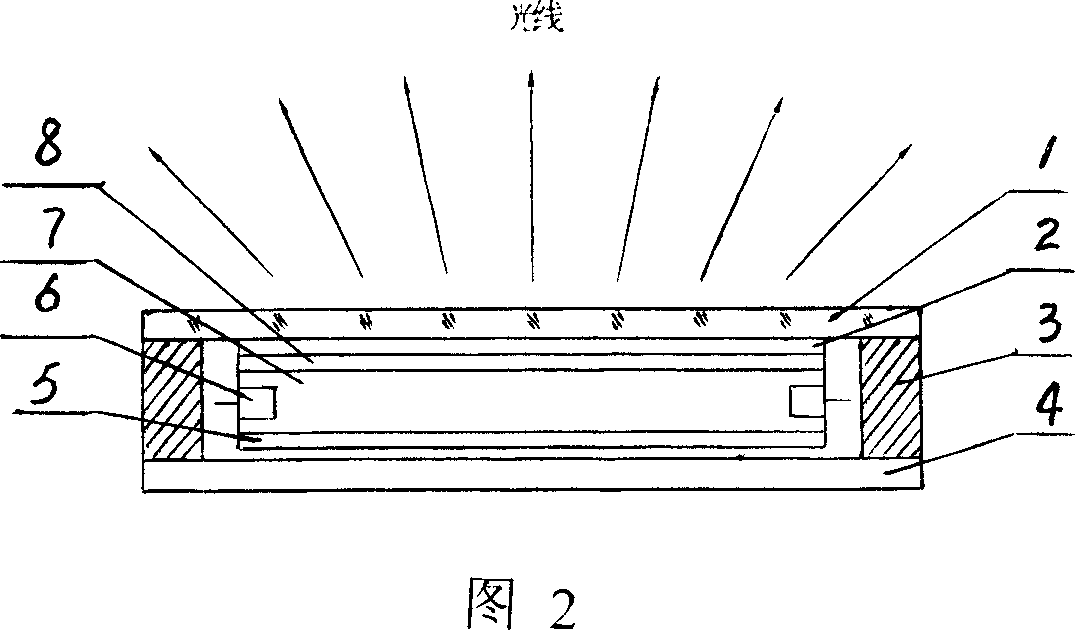

[0008] Embodiment 1: with reference to accompanying drawing 1 and 2. The microscope bottom light source composed of LED backlight board, the microscope bottom light source 10 adopts LED backlight board 9 . The light enhancement film 2 is an existing product and is located on the diffusion film 8 in the LED backlight panel 9, and the diffusion film 8 is an existing product, which will not be described here. The transparent protective glass 1 is positioned on the light-enhancing film 2, and the bottom plate 4 is a black plate and positioned on the reflective film 5, which is an existing product and will not be described here. The manufacturing process of LED backlight plate 9 is the prior art, that is, it is made of reflective film 5, LED (light emitting diode) 6, light guide plate 7, and diffusion film 8. ) is located at the side of the light guide plate 7 . The LED backlight panel 9 is assembled in the frame 3 . LEDs (Light Emitting Diodes) are white or red, green, blue, am...

Embodiment 2

[0009] Embodiment 2: On the basis of Embodiment 1, the LED backlight board power leads are connected to a light controller. The light controller is a prior art and can control the brightness and chromaticity of the backlight light source board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com