Method for preparing super martensitic stainless steel EBSD sample

A martensitic stainless steel and sample technology is applied in the field of preparing super martensitic stainless steel EBSD samples, which can solve the problem of insufficient calibration rate, and achieve the effects of easy temperature control, time-saving and convenient electropolishing process, and fast cooling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

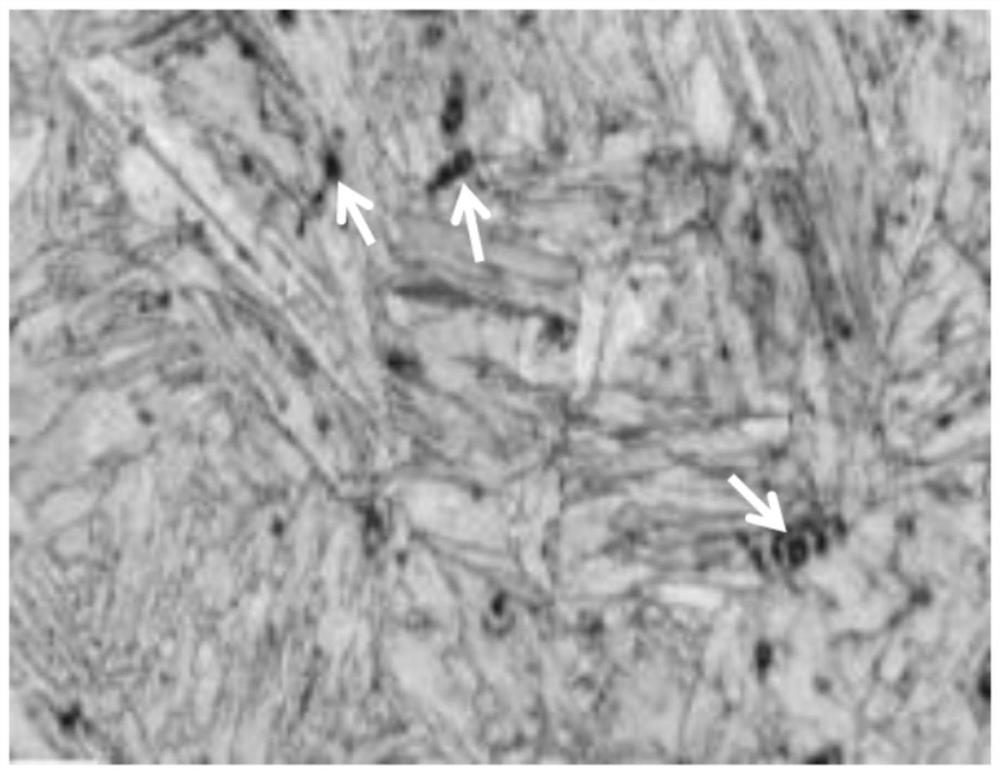

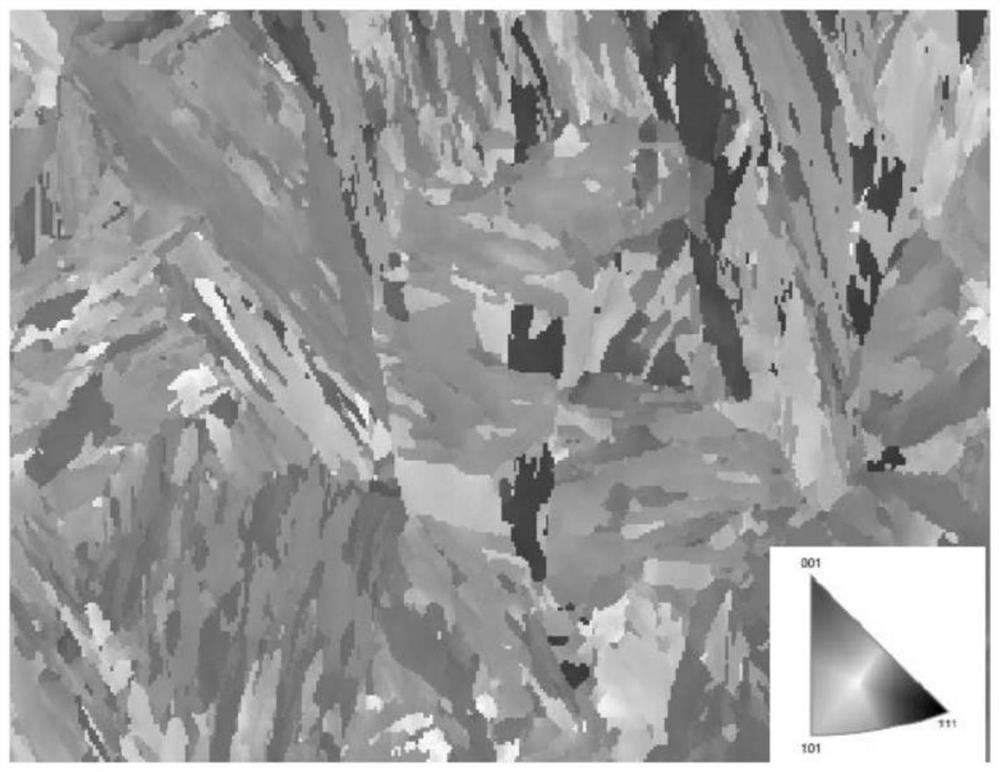

[0044]In this embodiment, the surface of a 10×10 sample of 0.03C13Cr0.23N super martensitic stainless steel is polished.

[0045] Step 1. Mechanically grind the surface of the sample, and use 400#, 600#, 1000#, 1500#, 2000# water-based sandpaper to grind in sequence. Each time you grind, put a sandpaper vertically until the last grinding mark is removed. until it wears off. Then use a polishing machine to polish, and the polishing time is set to 2 minutes to obtain a mechanically polished sample, and the polishing solution is an alumina polishing agent.

[0046] Step 2. Pour 240ml C into the beaker 2 h 5 OH and 120ml CH 3 COOH, then add 40ml HCLO 4 Drain with a glass rod and mix evenly to obtain a polishing solution.

[0047] Step 3. Put the polishing solution into the beaker and place it on a magnetic stirrer. The stirrer speed is set to 120r / min. Then put the stainless steel plate into the beaker and connect it to the negative pole of the power supply. Use the stainless...

Embodiment 2

[0052] In this embodiment, the surface of a 10×10 sample of 0.03C13Cr0.3N super martensitic stainless steel is polished.

[0053] Step 1. Mechanically grind the surface of the sample, and use 400#, 600#, 1000#, 1500#, 2000# water-based sandpaper to grind in sequence. Each time you grind, put a sandpaper vertically until the last grinding mark is removed. until it wears off. Then use a polishing machine to polish, and the polishing time is set to 2.5 minutes to obtain a mechanically polished sample, and the polishing solution is an alumina polishing agent.

[0054] Step 2. Pour 240mlC into the beaker 2 h 5 OH and 120mlCH 3 COOH, then add 40ml HCLO 4 Drain with a glass rod and mix evenly to obtain a polishing solution.

[0055] Step 3. Put the polishing solution into the beaker and place it on a magnetic stirrer. The stirrer speed is set to 140r / min. Then put the stainless steel plate into the beaker and connect it to the negative pole of the power supply. Use the stainless...

Embodiment 3

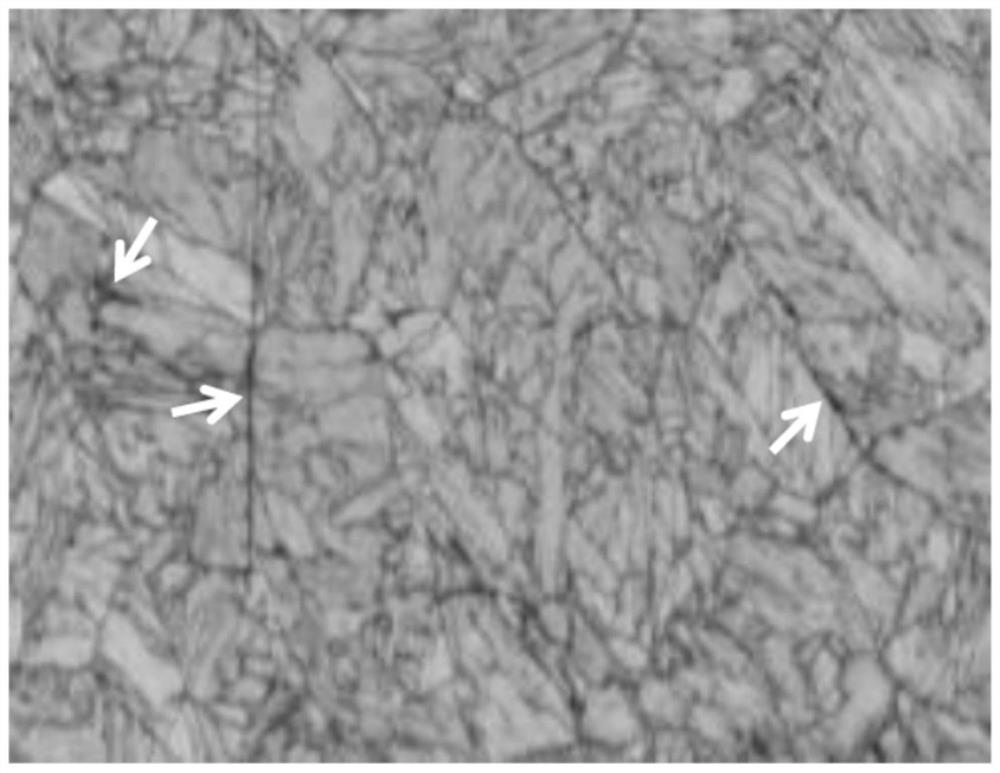

[0060] In this embodiment, the surface of a 10×10 sample of 0.03C13Cr0.35N super martensitic stainless steel is polished.

[0061] Step 1. Mechanically grind the surface of the sample, and use 400#, 600#, 1000#, 1500#, 2000# water-based sandpaper to grind in sequence. Each time you grind, put a sandpaper vertically until the last grinding mark is removed. until it wears off. Then use a polishing machine to polish, and the polishing time is set to 3 minutes to obtain a mechanically polished sample, and the polishing solution is aluminum oxide polishing agent.

[0062] Step 2. Pour 240mlC into the beaker 2 h 5 OH and 120mlCH 3 COOH, then add 40ml HCLO 4 Drain with a glass rod and mix evenly to obtain a polishing solution.

[0063] Step 3. Put the polishing solution into the beaker and place it on a magnetic stirrer. Set the stirrer speed to 120r / min. Then put the stainless steel plate into the beaker and connect it to the negative pole of the power supply. Use the stainless...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com