Liquid crystal display device

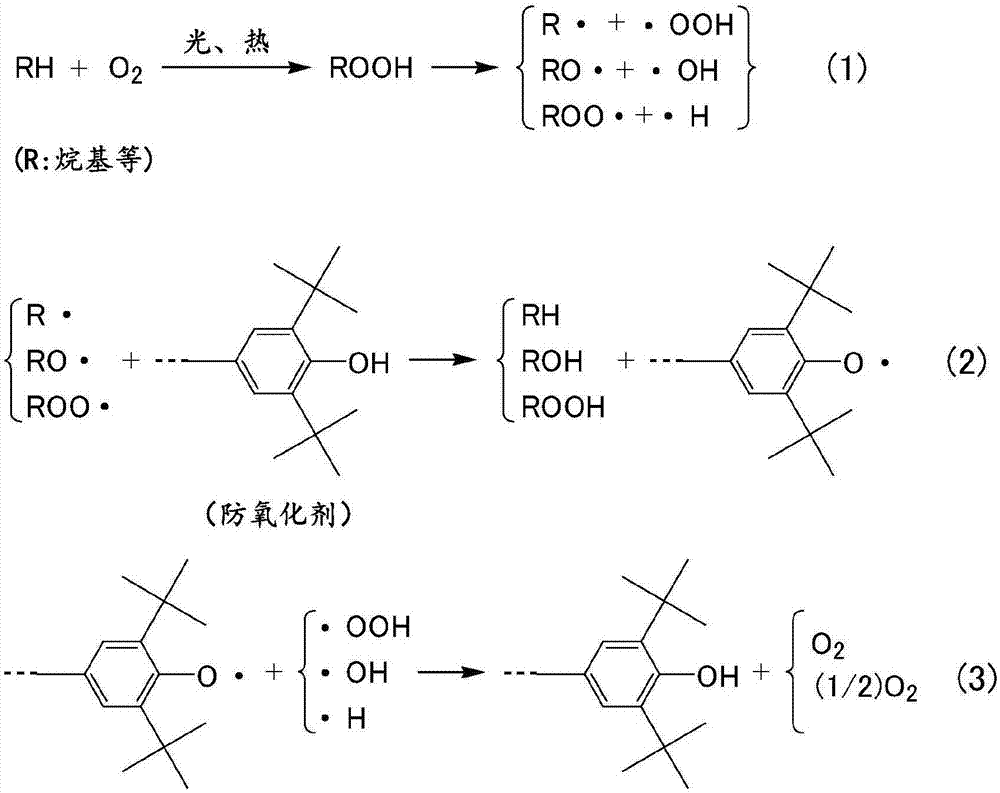

A liquid crystal display device and liquid crystal layer technology, applied in liquid crystal materials, optics, instruments, etc., can solve problems such as contrast reduction, achieve the effect of improving adhesion strength, preventing image retention and spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1~5

[0302] (Synthesis Examples 1 to 5 and Comparative Synthesis Example 1)

[0303] For the reactive polysiloxane, a copolymer in which the first side chain, the second side chain, and the third side chain are bonded is prepared. As the reactive polysiloxane, in the following formula (1), a compound in which X is 2-(3,4-epoxycyclohexyl)ethyl and Y is methoxy is used.

[0304] [chemical 18]

[0305]

[0306] As the above-mentioned first side chain, a functional group represented by the following formula (33) including a photofunctional group was used. As the above-mentioned second side chain, a functional group represented by the following formula (34) including a photofunctional group was used. As the above-mentioned third side chain, a functional group shown in the following formula (H-1-1) including a carboxyl group (—COOH) was used.

[0307] [chemical 19]

[0308]

[0309] [chemical 20]

[0310]

[0311] [chem 21]

[0312]

[0313] The introduction amount of t...

Embodiment 1~5 and comparative example 1

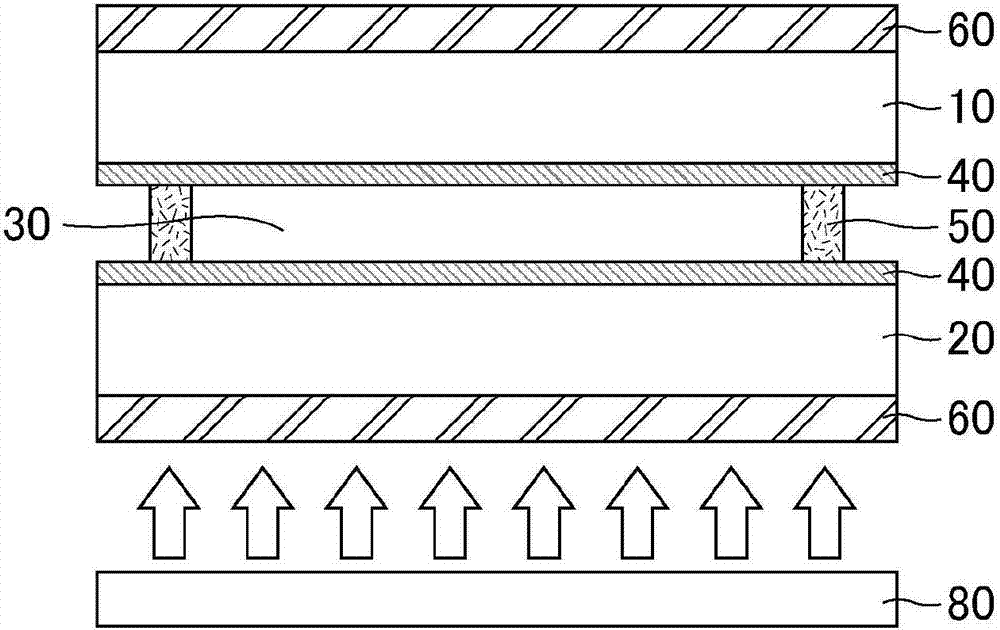

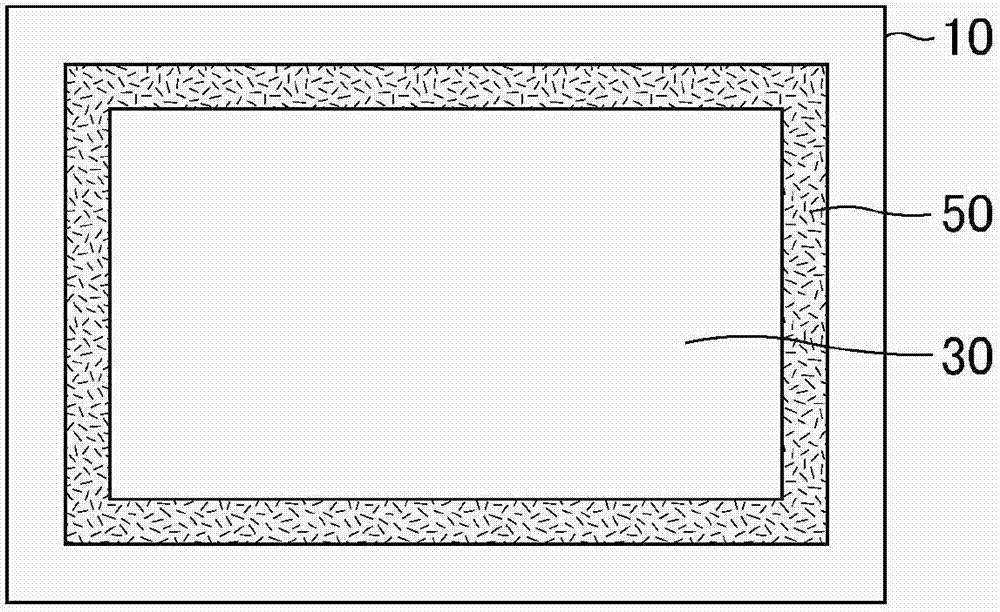

[0318] Using the liquid crystal alignment agents of Synthesis Examples 1 to 5 and Comparative Synthesis Example 1, the liquid crystal panels of Examples 1 to 5 and Comparative Example 1 were prepared according to the following procedures (1) to (6).

[0319] (1) While preparing a glass substrate (TFT substrate) with a TFT element and a transparent electrode made of Indium Tin Oxide (ITO), prepare a black matrix, a color filter, a spacer, and a glass substrate made of ITO The glass substrate (color filter substrate) of the transparent electrode.

[0320] (2) A liquid crystal alignment agent is applied to the surfaces of the cleaned two substrates on the transparent electrode side by an inkjet method. Next, provisional drying was performed at 80° C. for 2 minutes. Next, firing was performed at 230° C. for 40 minutes in a nitrogen atmosphere to produce a film having a film thickness of 100 nm.

[0321] (3) For the surface of each substrate, as an alignment treatment, 20mJ / cm 2 U...

Synthetic example 6~10

[0334] (Synthesis Examples 6-10 and Comparative Synthesis Example 2)

[0335] As a 3rd side chain, except having used the functional group shown by the following formula (H-2-1) containing two carboxyl groups, it prepared similarly to synthesis examples 1-5 and comparative synthesis example 1, and prepared a liquid crystal aligning agent. The introduction amount of the third side chain in Synthesis Examples 6 to 10 and Comparative Synthesis Example 2 was 0 mol% with respect to the silicon atoms contained in the siloxane main chain (reactive polysiloxane) (Comparative Synthesis Example 2), 10 mol% (Comparative Synthesis Example 6), 20 mol% (Synthesis Example 7), 30 mol% (Synthesis Example 8), 40 mol% (Synthesis Example 9) or 50 mol% (Synthesis Example 10).

[0336] [chem 22]

[0337]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com