Liquid crystal orientating agent and liquid crystal display element

A technology of liquid crystal orientation and vertical orientation, which is applied in the direction of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of uneven orientation and moisture absorption, and achieve the effect of excellent voltage retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

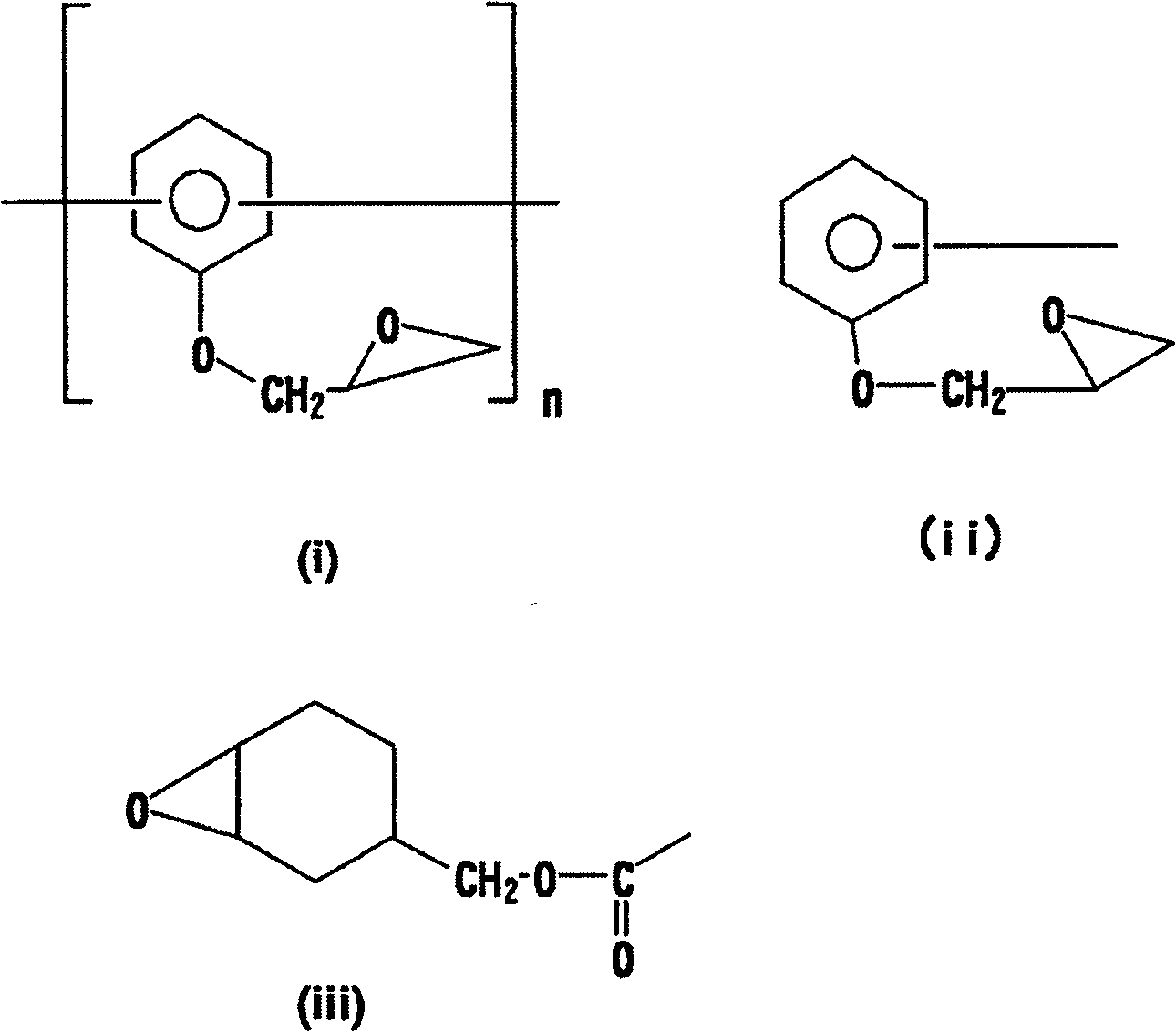

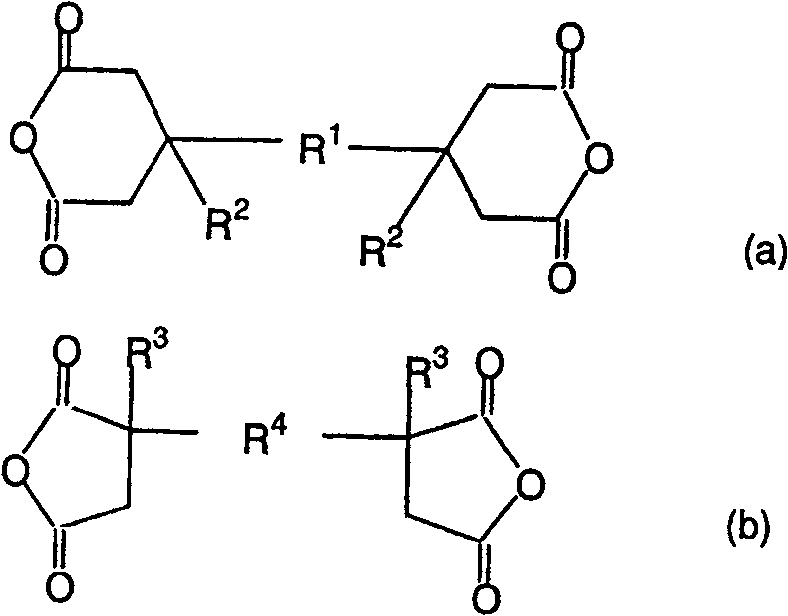

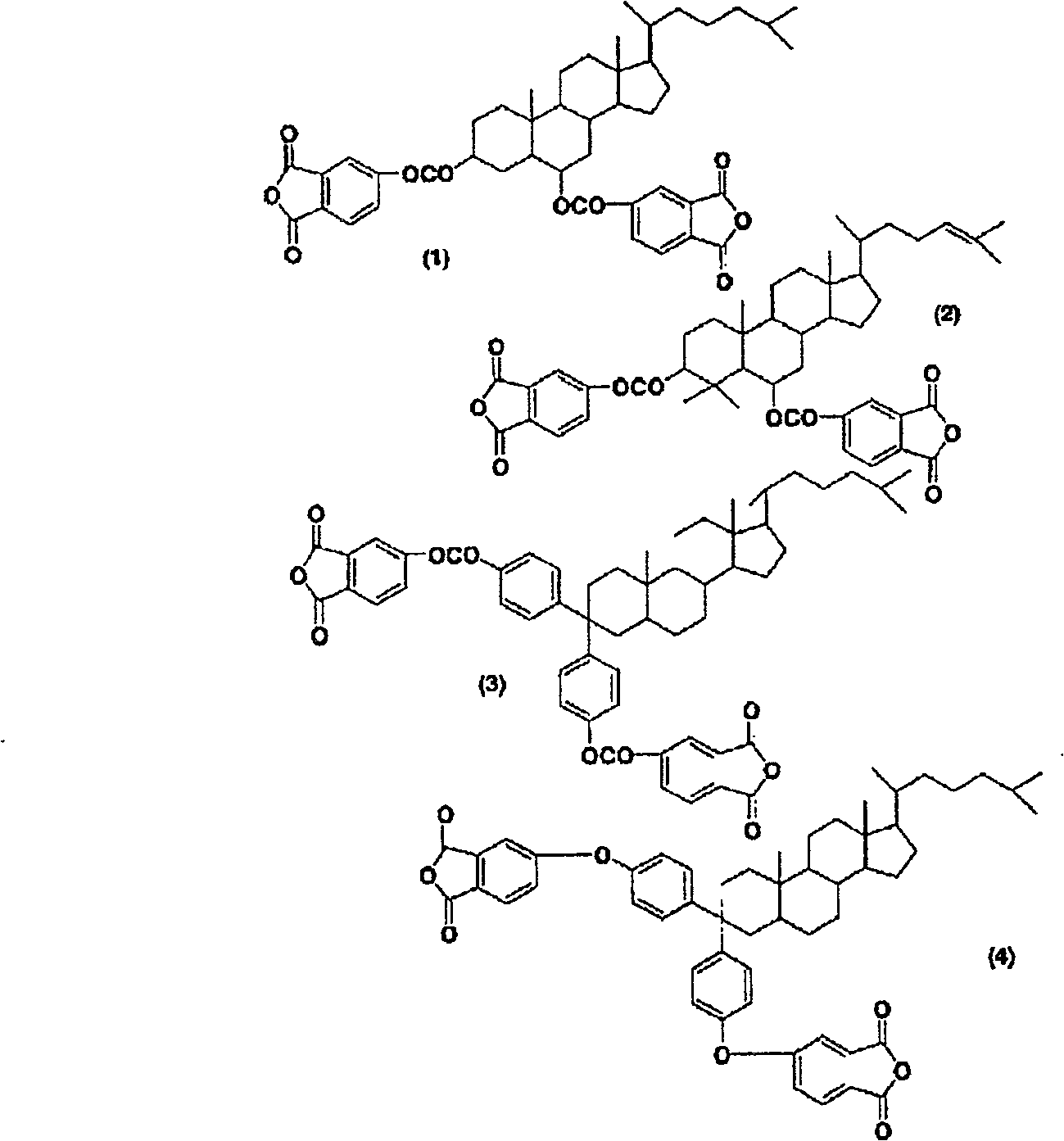

Method used

Image

Examples

Embodiment

[0078] Hereinafter, the present invention will be explained more specifically through examples, but the present invention is not limited by these examples. The evaluation items and evaluation methods of the liquid crystal aligning agents prepared in the following examples and comparative examples are as follows.

[0079] (Vertical orientation of liquid crystal molecules)

[0080] Regarding the vertical orientation of the vertical orientation type liquid crystal display element, when the voltage is OFF and the liquid crystal display element under AC 12V (peak-to-peak) is observed, it is judged as "good" without abnormal magnetic regions.

[0081] (Moisture resistance test of liquid crystal display element)

[0082] Regarding the humidity resistance of the vertical alignment type liquid crystal display element, it was placed in a room temperature and high humidity environment (90% RH), and when the voltage was turned on and off, no abnormal magnetic area occurred in the liquid cryst...

Synthetic example 1

[0088]2.3g of 2,3,5-tricarboxycyclopentaacetic acid dianhydride, 0.88g of p-phenylenediamine and 1.1g of the diamine compound represented by the above formula (9) were dissolved in 16.8g of N-methyl-2 -In pyrrolidone, react at 60°C for 5 hours. Then, the reaction mixture was poured into a large excess of methanol, and the reaction product was precipitated. Then it was washed with methanol and dried at 40°C under reduced pressure for 15 hours to obtain 55.6 g of specific polymer Ia.

[0089] The specific polymer Ia obtained in Synthesis Example 1 was dissolved in 39.0 g of N-methyl-2-pyrrolidone, 0.88 g of pyridine and 1.13 g of acetic anhydride were added, and imidization was performed at 110°C for 4 hours. Then, the reaction product liquid was precipitated in the same manner as in Synthesis Example 1, and 53.0 g of a specific polymer IIa having an intrinsic viscosity of 0.63 dL / g was obtained. The imidization rate of the obtained specific polymer IIa is shown in Table 1.

Synthetic example 2

[0091] Except that 1.89g of 2,3,5-tricarboxycyclopentaacetic acid dianhydride, 0.55g of p-phenylenediamine and 1.76g of the diamine compound represented by the above formula (9) are dissolved in 16.8g of N-methyl Except for the -2-pyrrolidone, 55.7 g of the specific polymer Ib was obtained in the same manner as in Synthesis Example 1.

[0092] The specific polymer Ib obtained in Synthesis Example 2 was dissolved in 39.0 g of N-methyl-2-pyrrolidone, 0.73 g of pyridine and 0.95 g of acetic anhydride were added, and imidization was performed at 110°C for 4 hours. Then, the reaction product liquid was precipitated in the same manner as in Synthesis Example 1, and 52.1 g of a specific polymer IIb having an intrinsic viscosity of 0.5 dL / g was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com