Patents

Literature

38 results about "Variegation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Variegation is the appearance of differently coloured zones in the leaves, and sometimes the stems, of plants. Variegated leaves occur rarely in nature. Species with variegated individuals are sometimes found in the understory of tropical rainforests, and this habitat is the source of a number of variegated house plants.

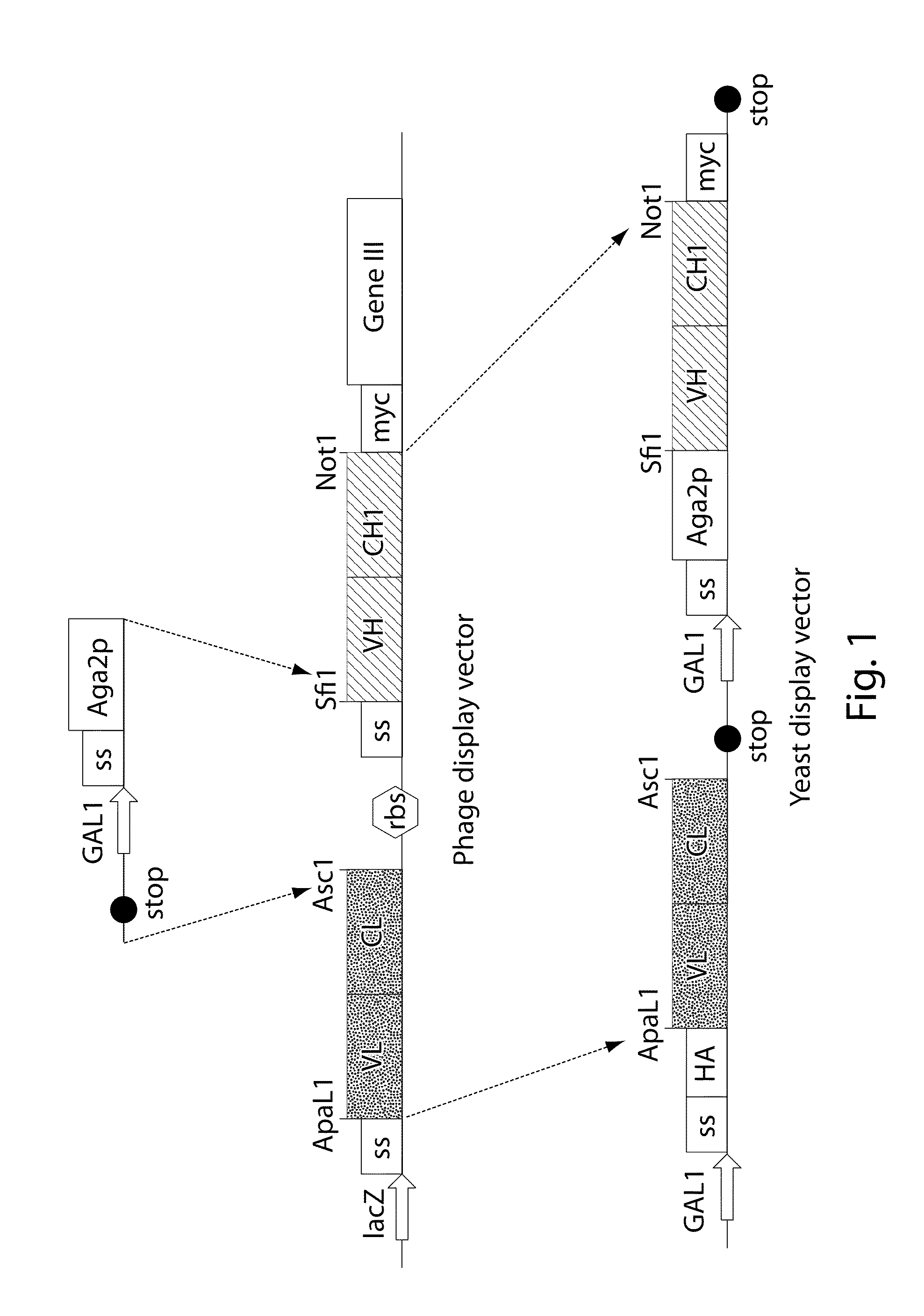

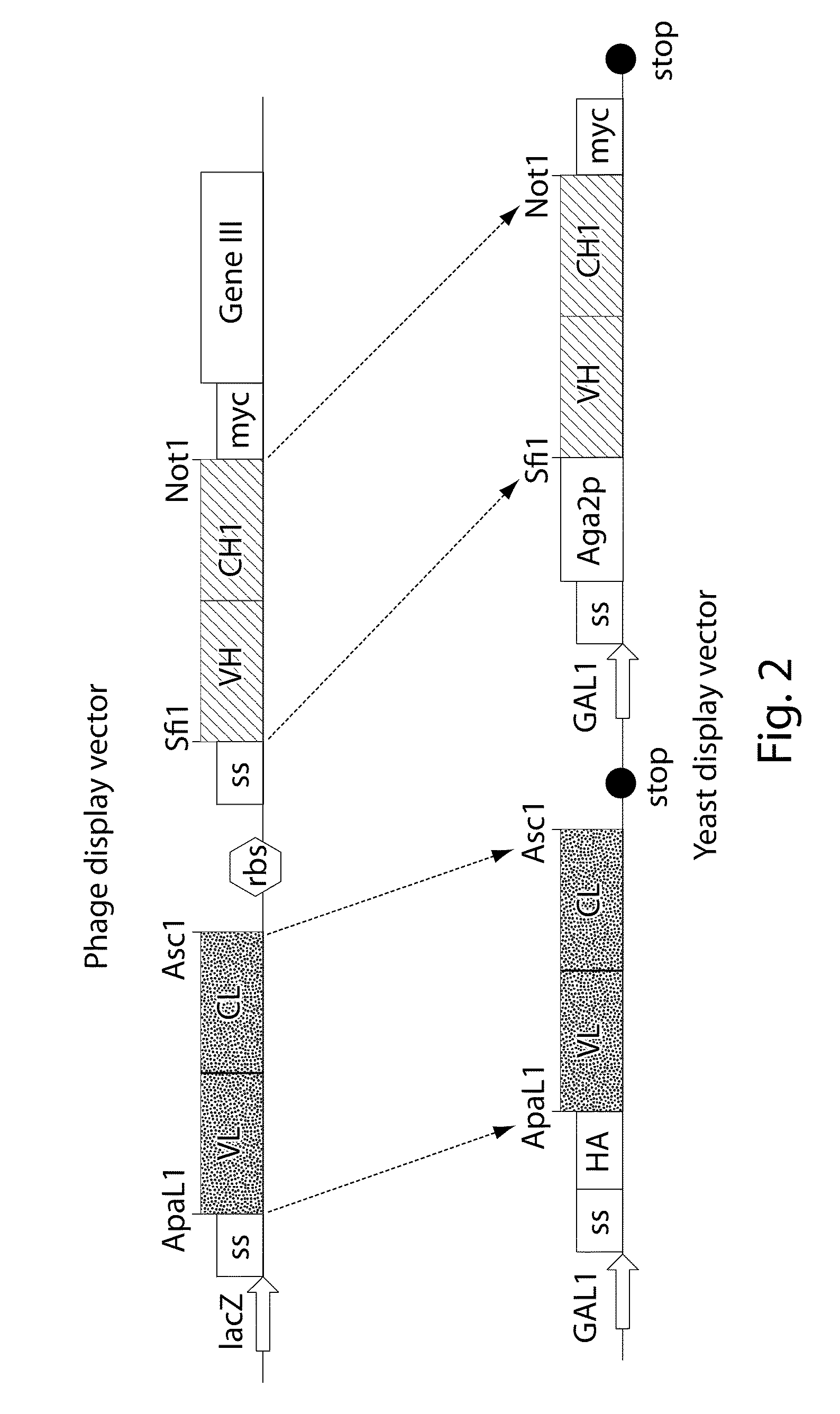

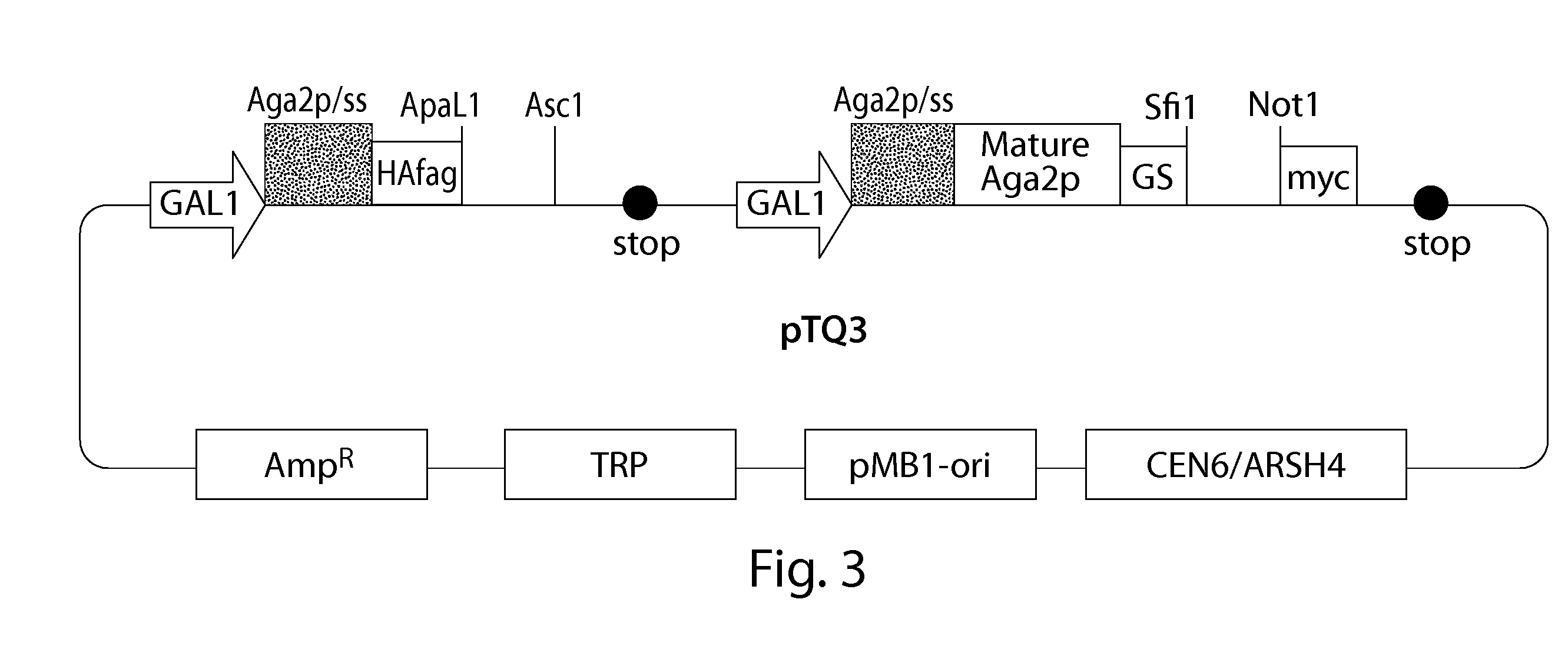

Multi-chain eukaryotic display vectors and uses thereof

A eukaryotic expression vector capable of displaying a multi-chain polypeptide on the surface of a host cell is provided, such that the biological activity of the multi-chain polypeptide is exhibited at the surface of the host cell. Such a vector allows for the display of complex biologically active polypeptides, e.g., biologically active multi-chain polypeptides such as immunoglobulin Fab fragments. The present invention describes and enables the successful display of a multi-chain polypeptide on the surface of a eukaryotic host cell. Preferred vectors are described for expressing the chains of a multi-chain polypeptide in a host cell separately and independently (e.g., under separate vector control elements, and / or on separate expression vectors, thus forming a matched vector set). The use of such matched vector sets provides flexibility and versatility in the generation of eukaryotic display libraries, for example the ability to generate and to display multi-chain polypeptides by combining and recombining vectors that express variegations of the individual chains of a multi-chain polypeptide. Entire repertoires of novel chain combinations can be devised using such vector sets.

Owner:TAKEDA PHARMA CO LTD

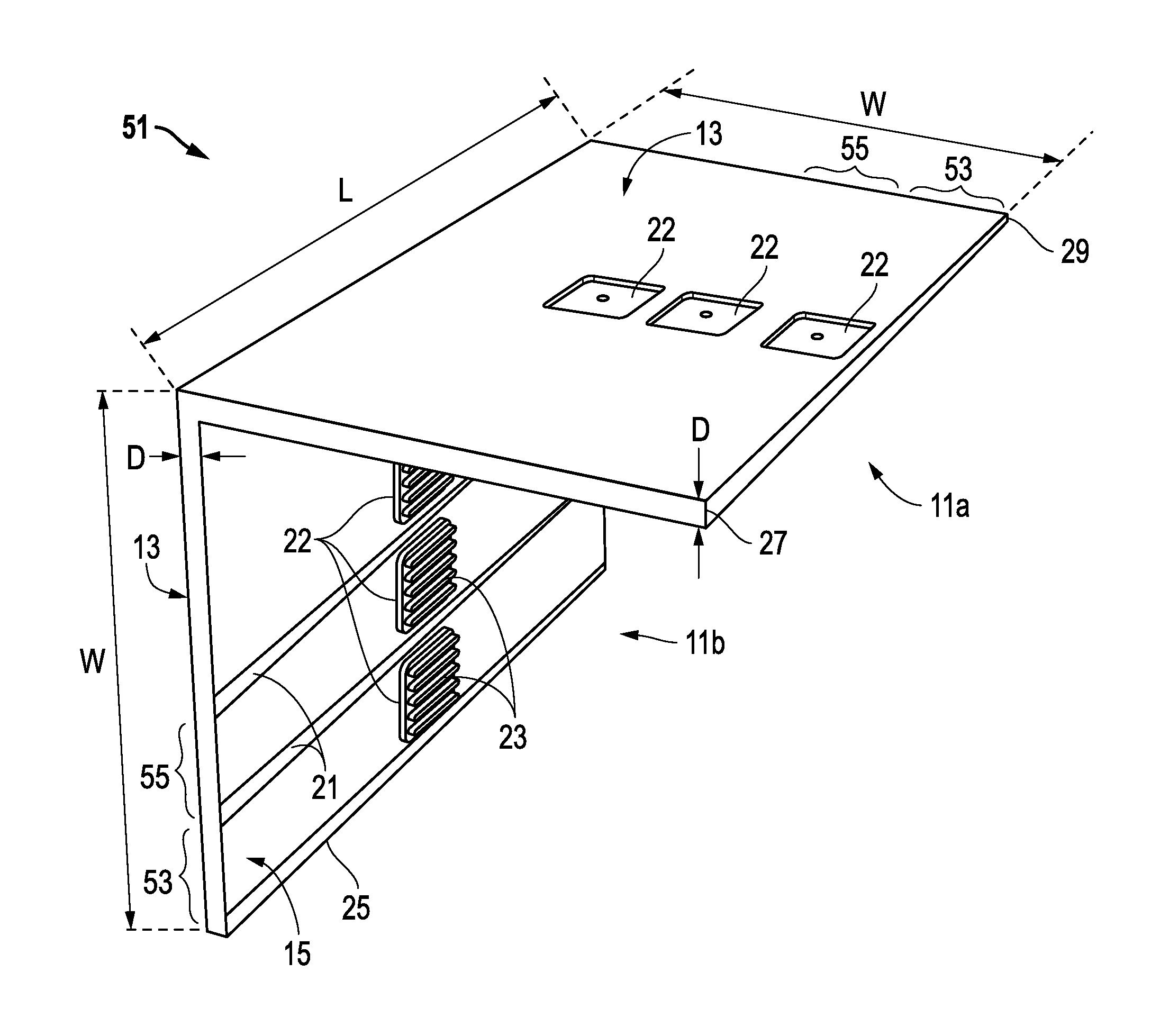

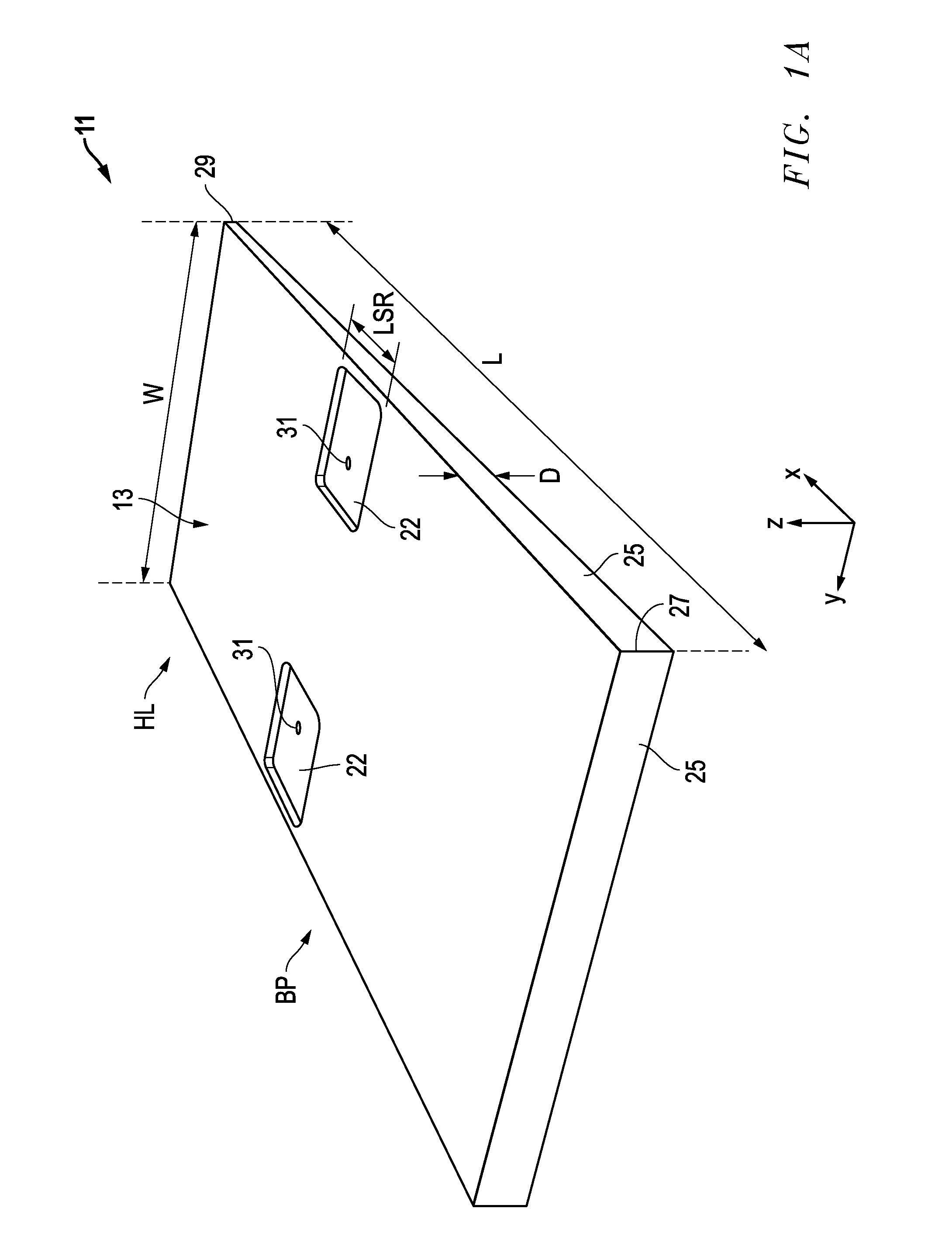

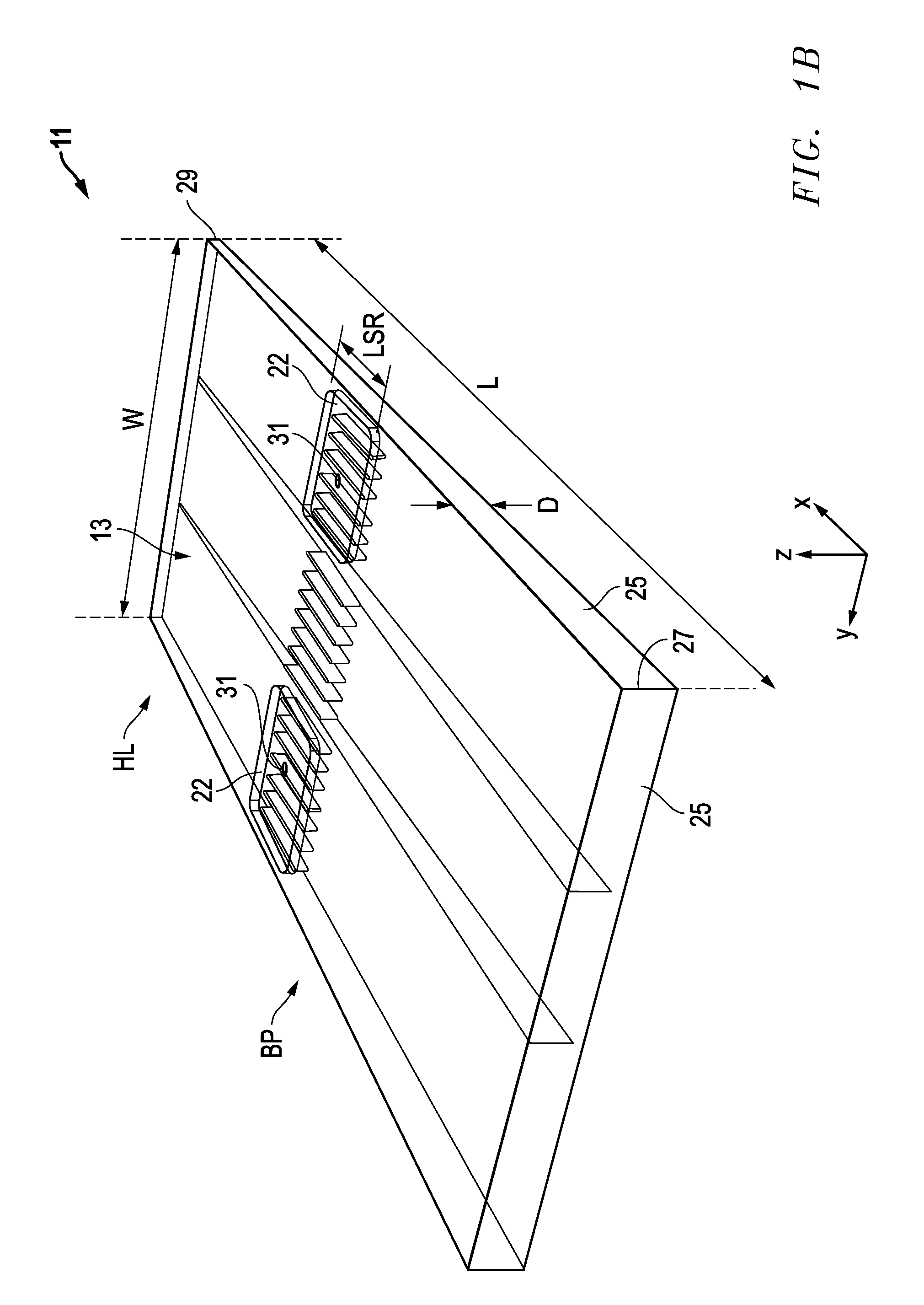

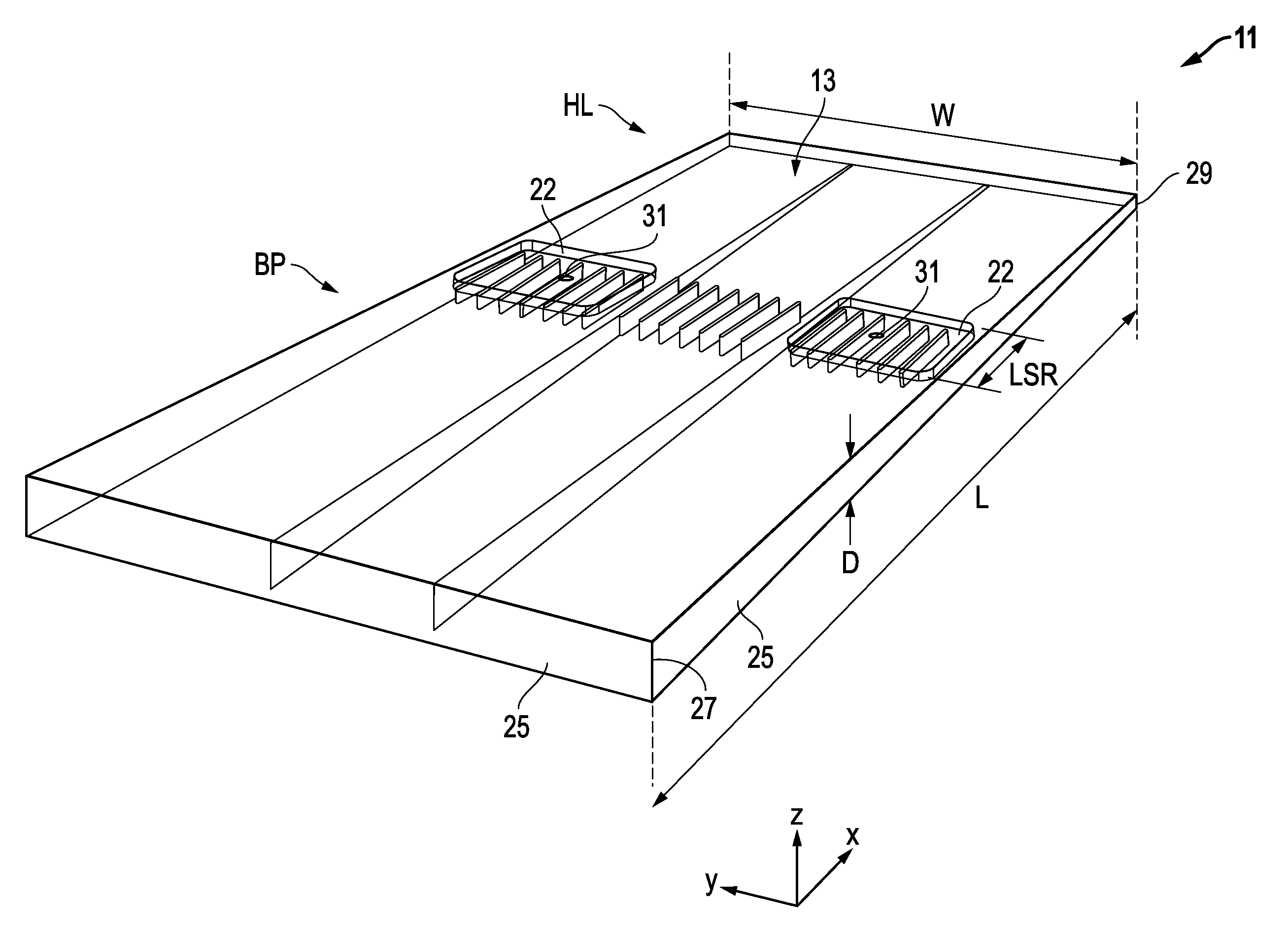

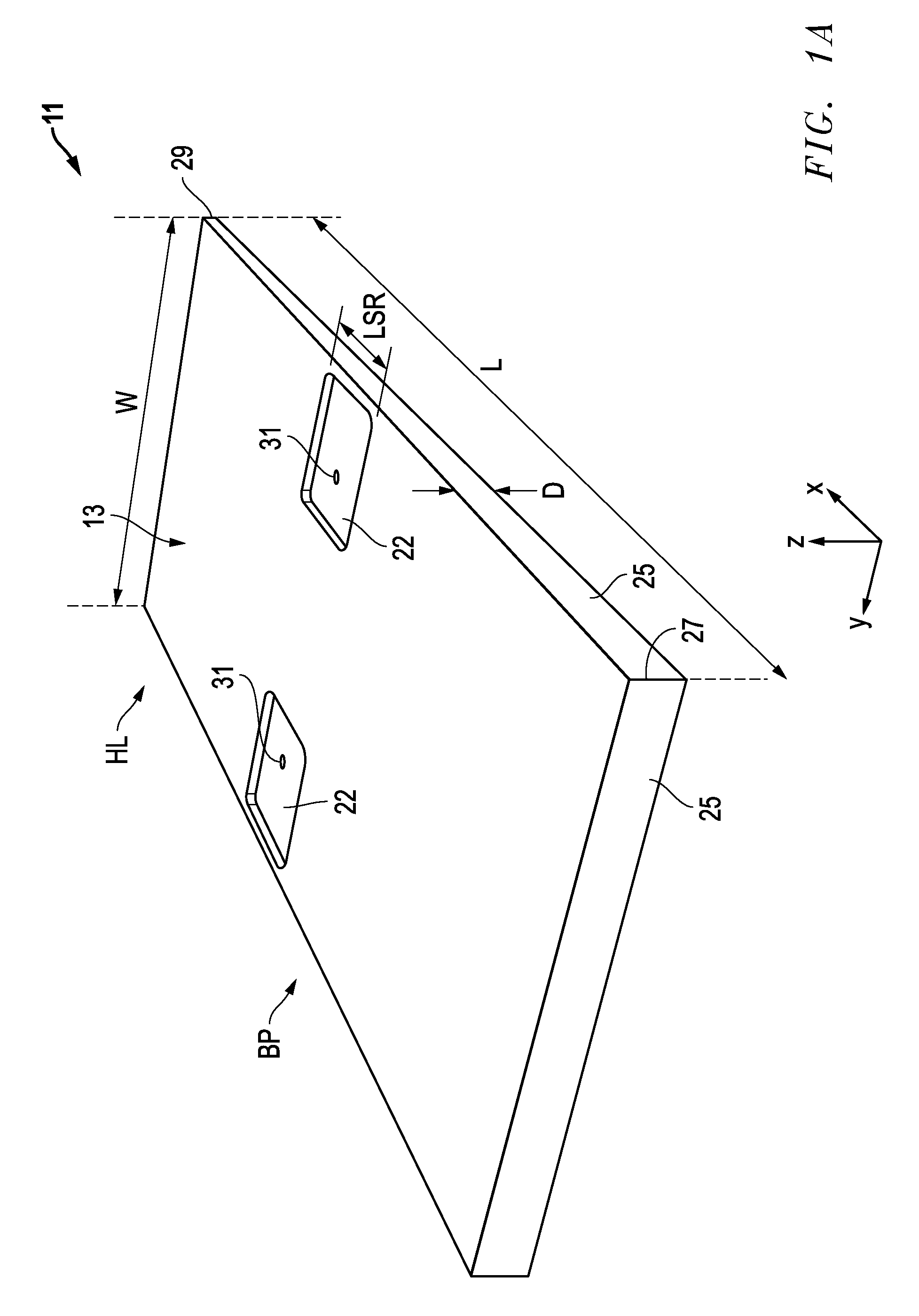

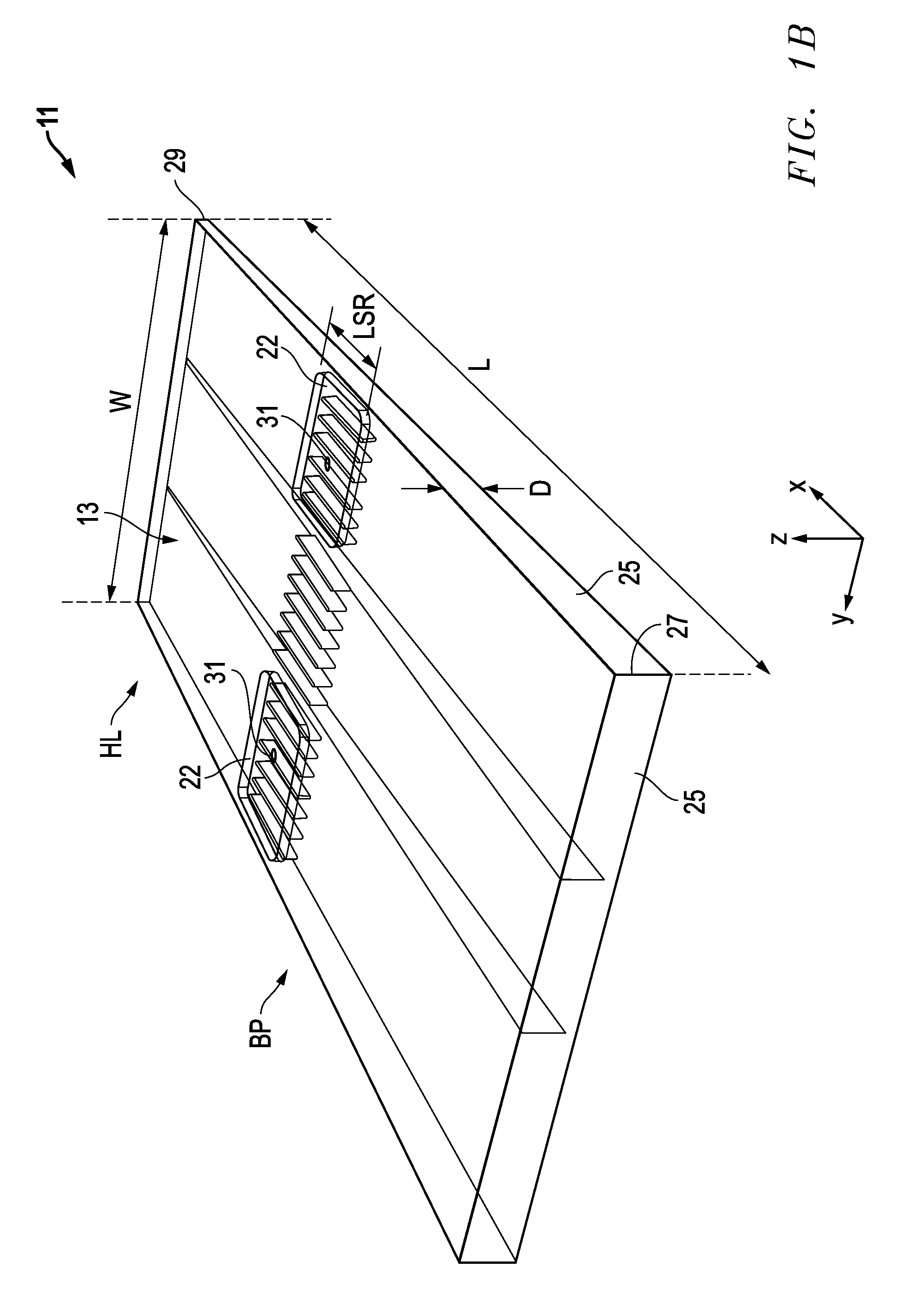

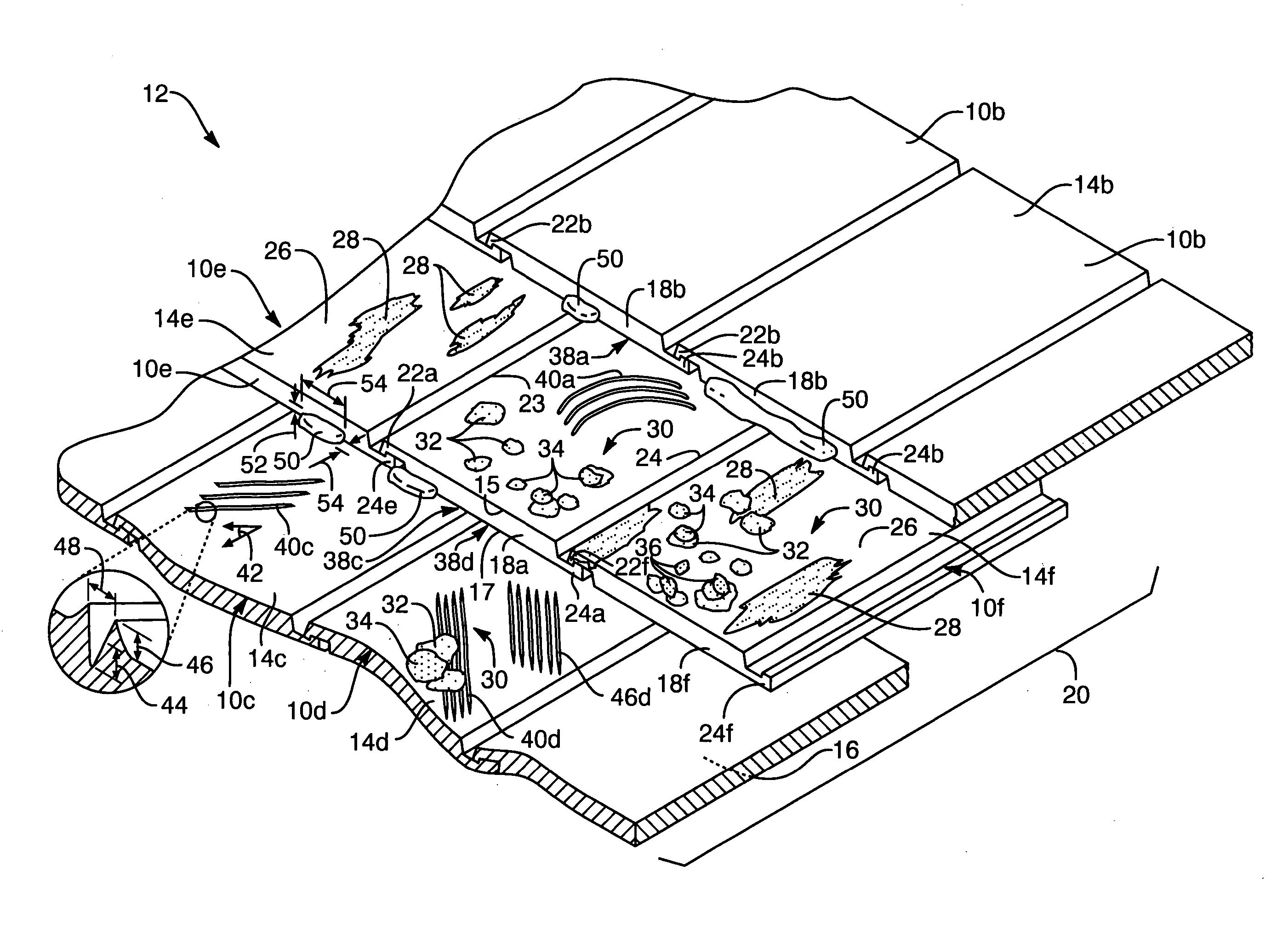

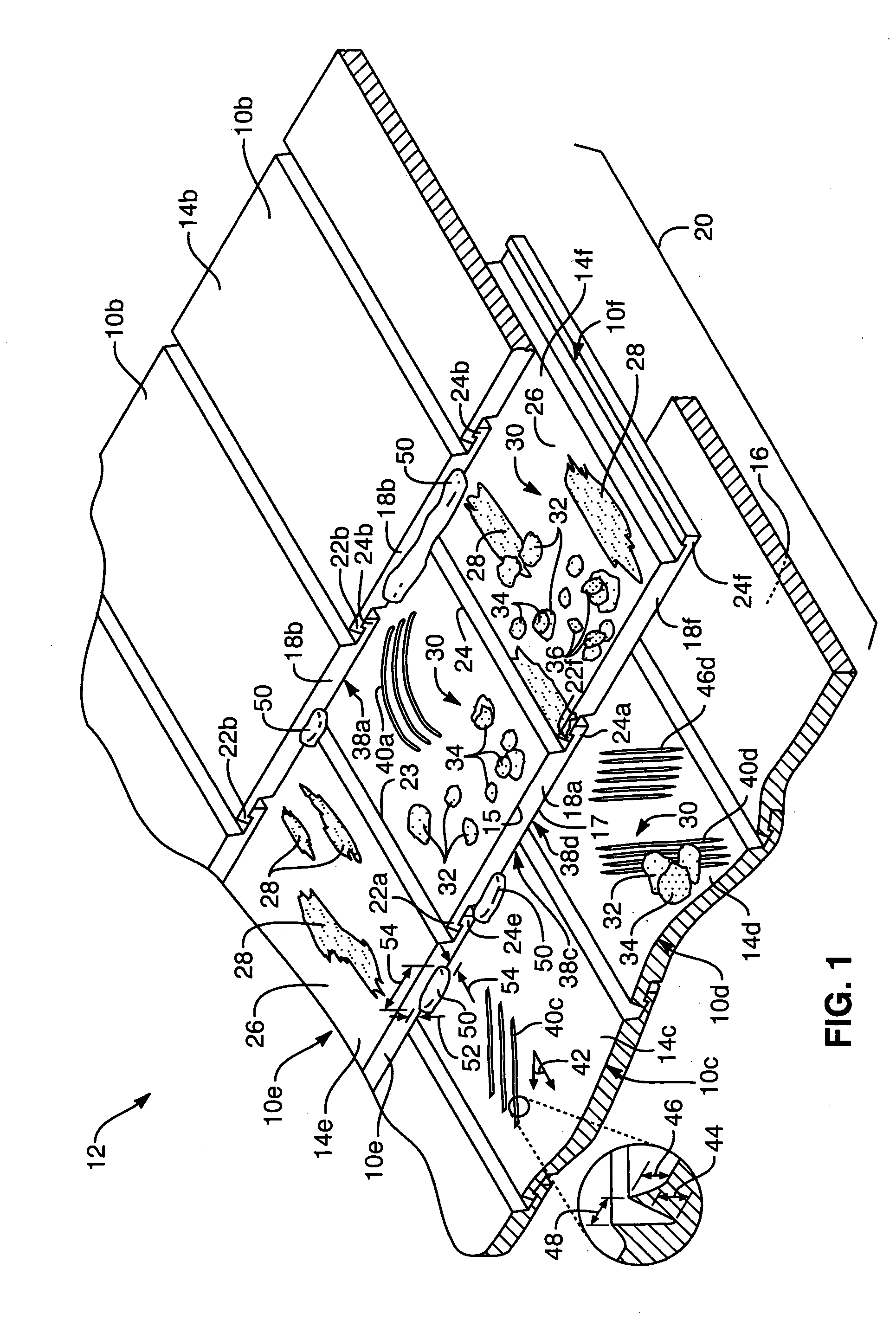

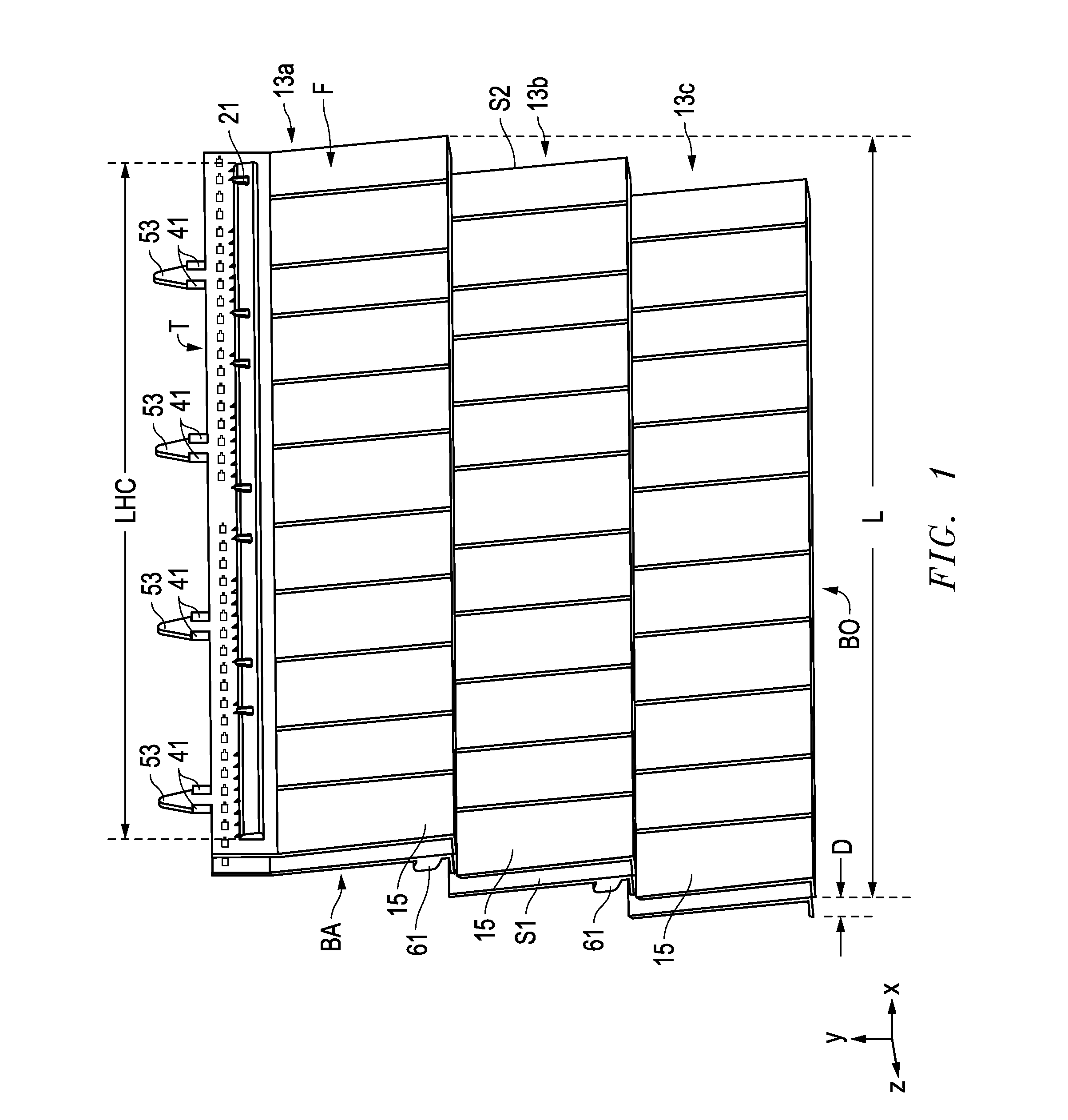

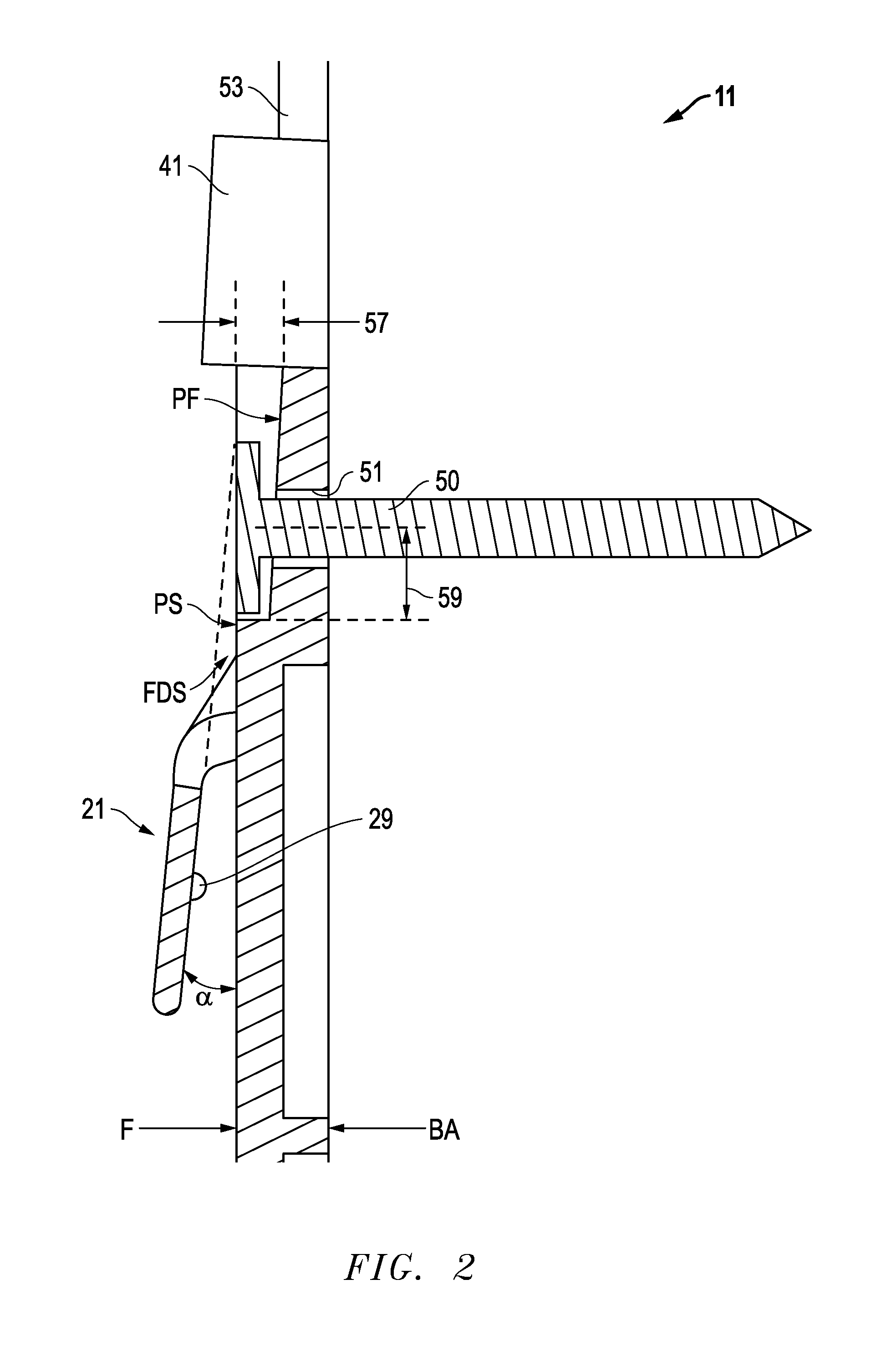

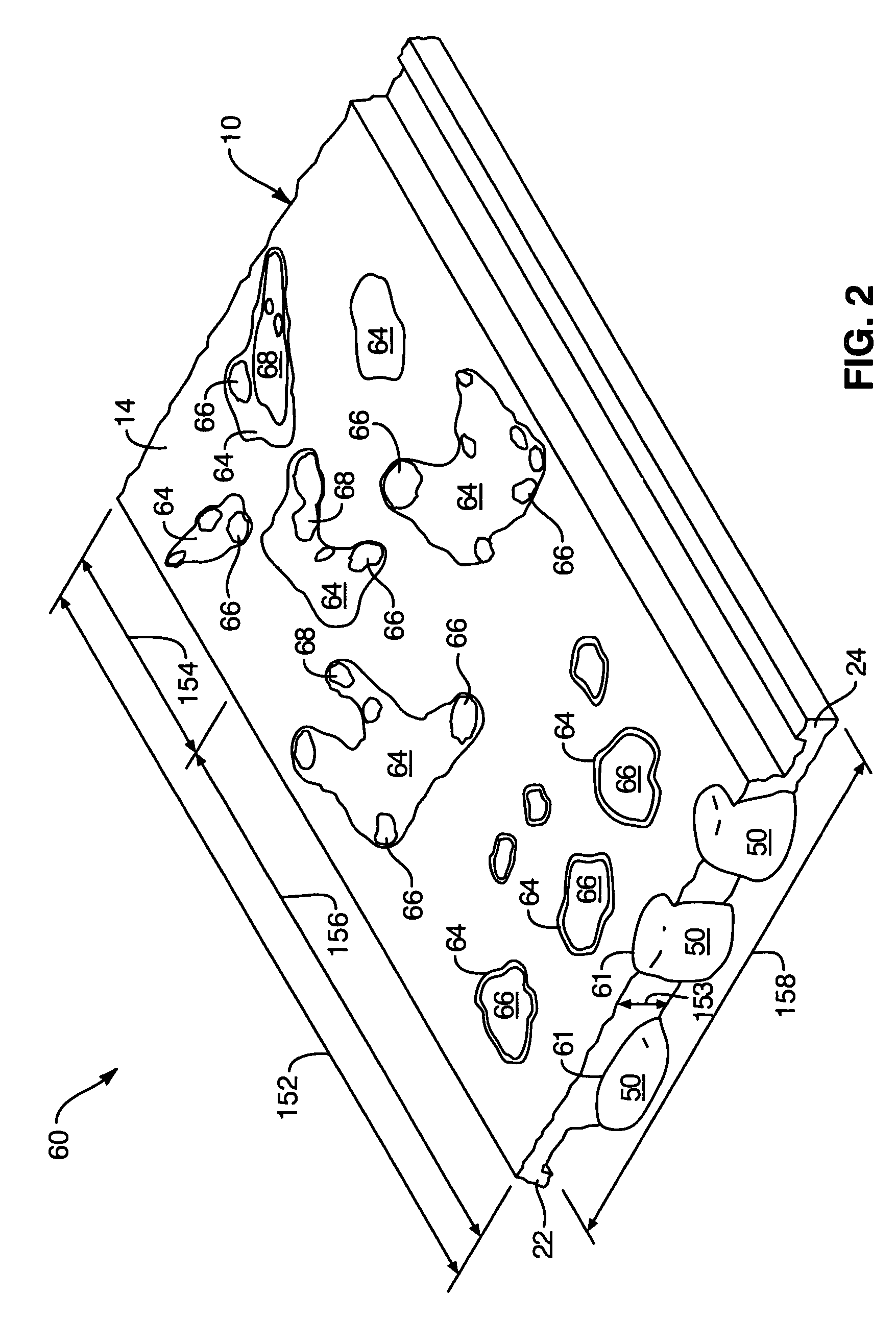

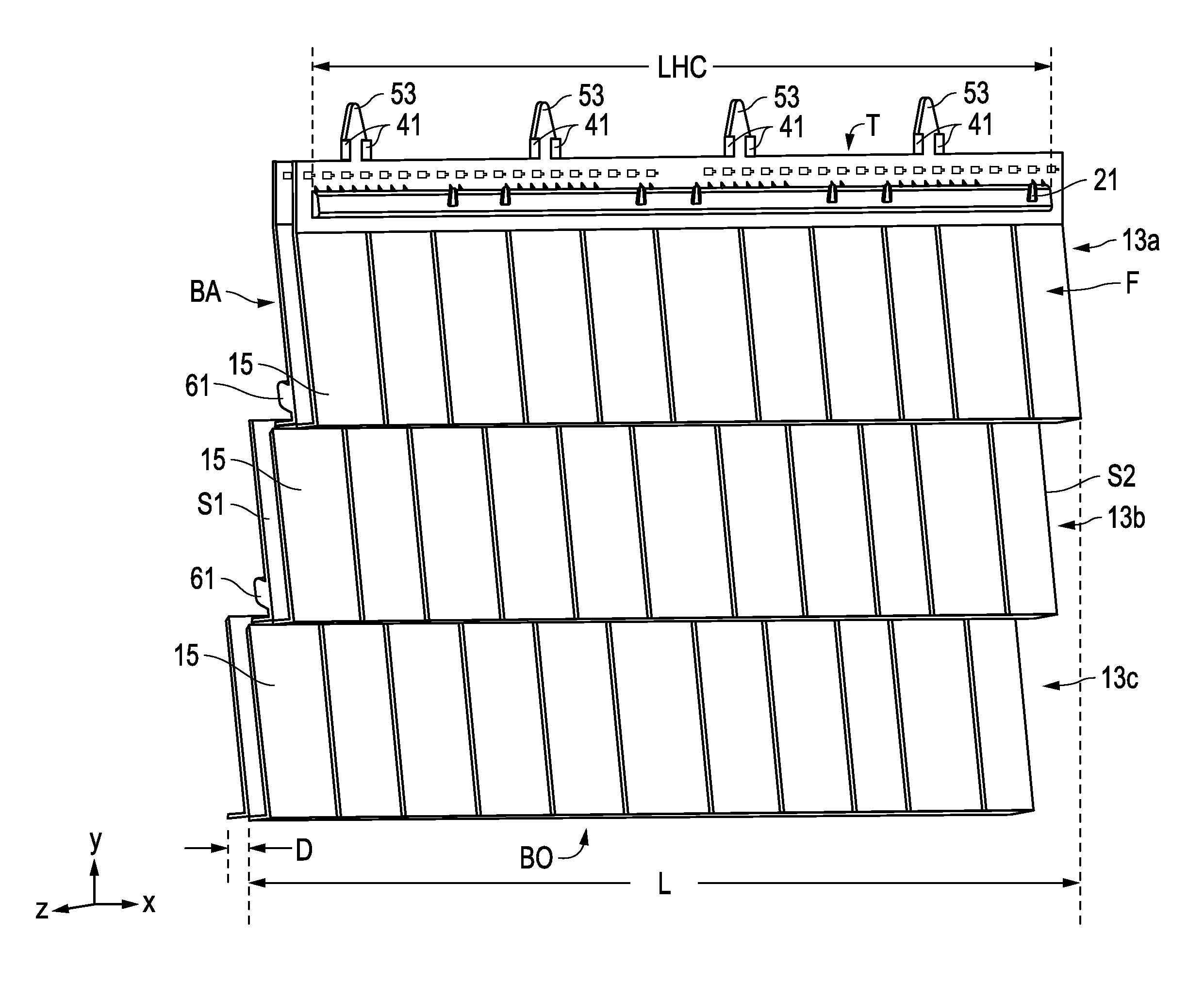

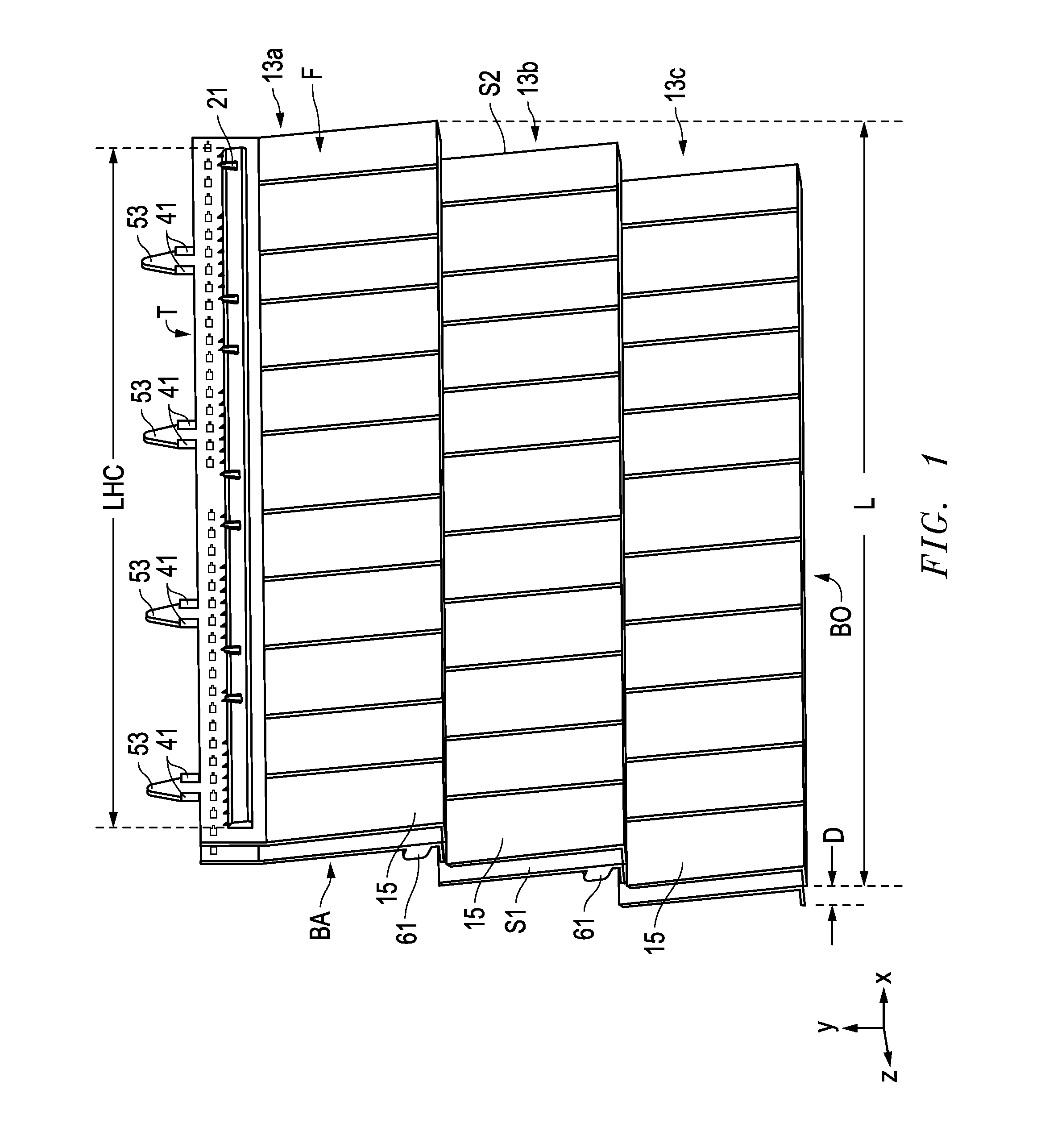

Single panel siding product

A siding product may include a panel having a substantially rectangular structure with a simulated pattern on a front face thereof. The panel may be formed from a polymer and may include color variegation. The panel may have a hollow back and be a single shake configuration that does not simulate more than one shake or more than one course of siding. The siding product may include a panel having a front face with a simulated pattern. The panel can include a hollow back, a longitudinal length extending in an x-direction, a lateral width extending in a y-direction, and a transverse depth extending in a z-direction. The panel can have a plurality of reinforcement ribs on the hollow back that extend longitudinally in the x-direction and transversely in the z-direction. In a version, none of the reinforcement ribs extend laterally in the y-direction.

Owner:CERTAINTEED CORP

Production process for extracting and preparing high-purity 5-hydroxytryptophan from Griffonia simplicifolia

InactiveCN101648900ACraft shortEfficient processOrganic chemistryBulk chemical productionGriffonia simplicifoliaSolvent

The invention provides a production process for extracting and preparing high-purity 5-hydroxytryptophan from Griffonia simplicifolia, belonging to the technical content of extracting 5-hydroxytryptophan from plants and solving the problems of low yield, low purity and influence on product quality, low extraction speed and the like due to variegation generated by other pigment in the process of extracting 5-hydroxytryptophan from plants in the prior art. The production process comprises the following steps: using Griffonia simplicifolia produced in Africa as raw material, carrying out supercritical extraction for degreasing, extracting the degreased material for 3-5 times by using water or alcoholic solvents or mixed solution of water and alcoholic solvents; merging the extraction solution, carrying out microfiltration, ultrafiltration, adsorption by using ion exchange resin, elution, vacuum concentration, lower-temperature crystallization, centrifugal separation and microwave drying to obtain high-purity 5-hydroxytryptophan dry powders. The process has the advantages of rapidness, high efficiency, high yield, good quality and the like, and is suitable for large-scale industrial production; and the purity of the obtained product can reach more than 99.5 percent, and the yield is more than 90 percent.

Owner:三明华健生物工程有限公司

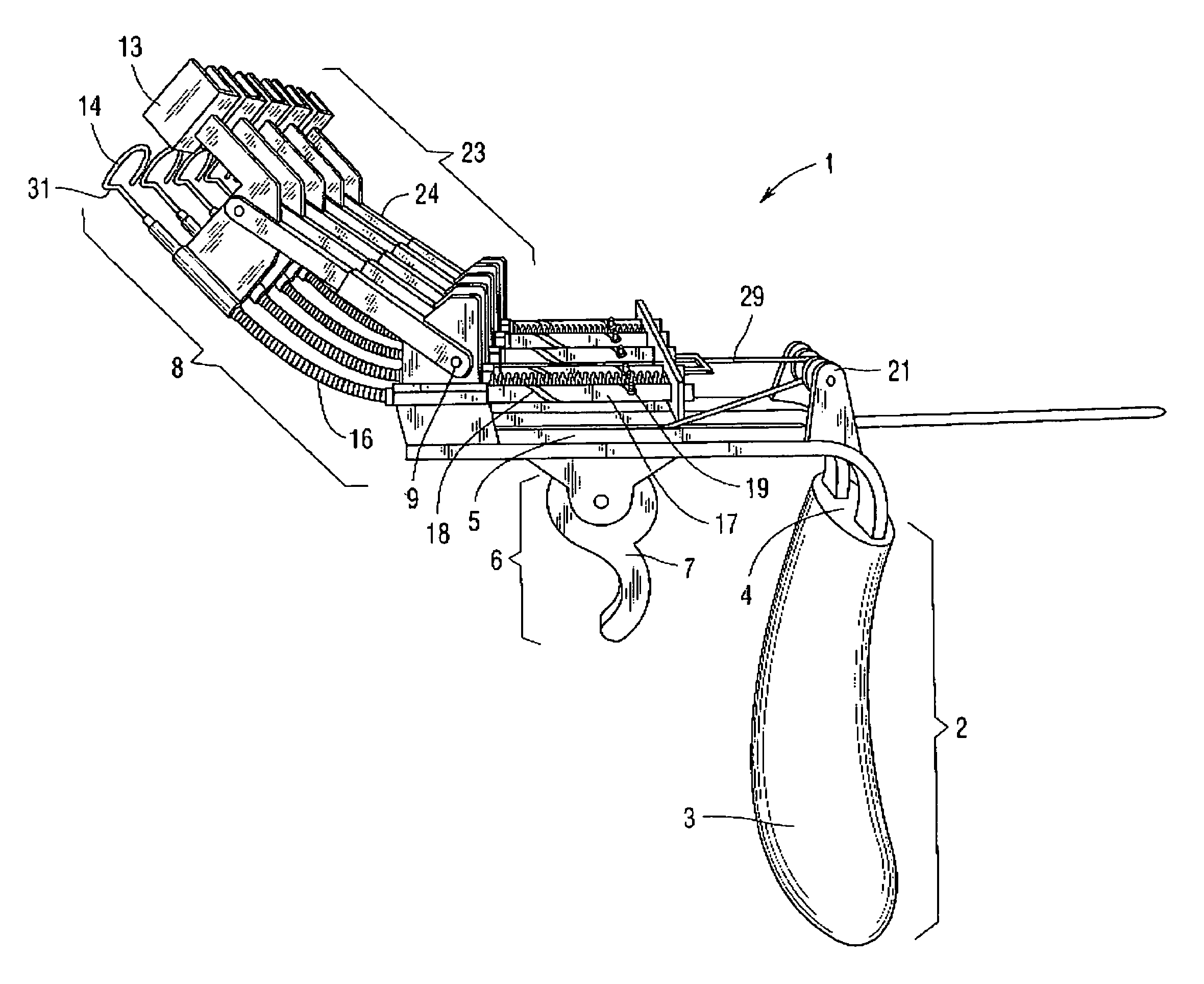

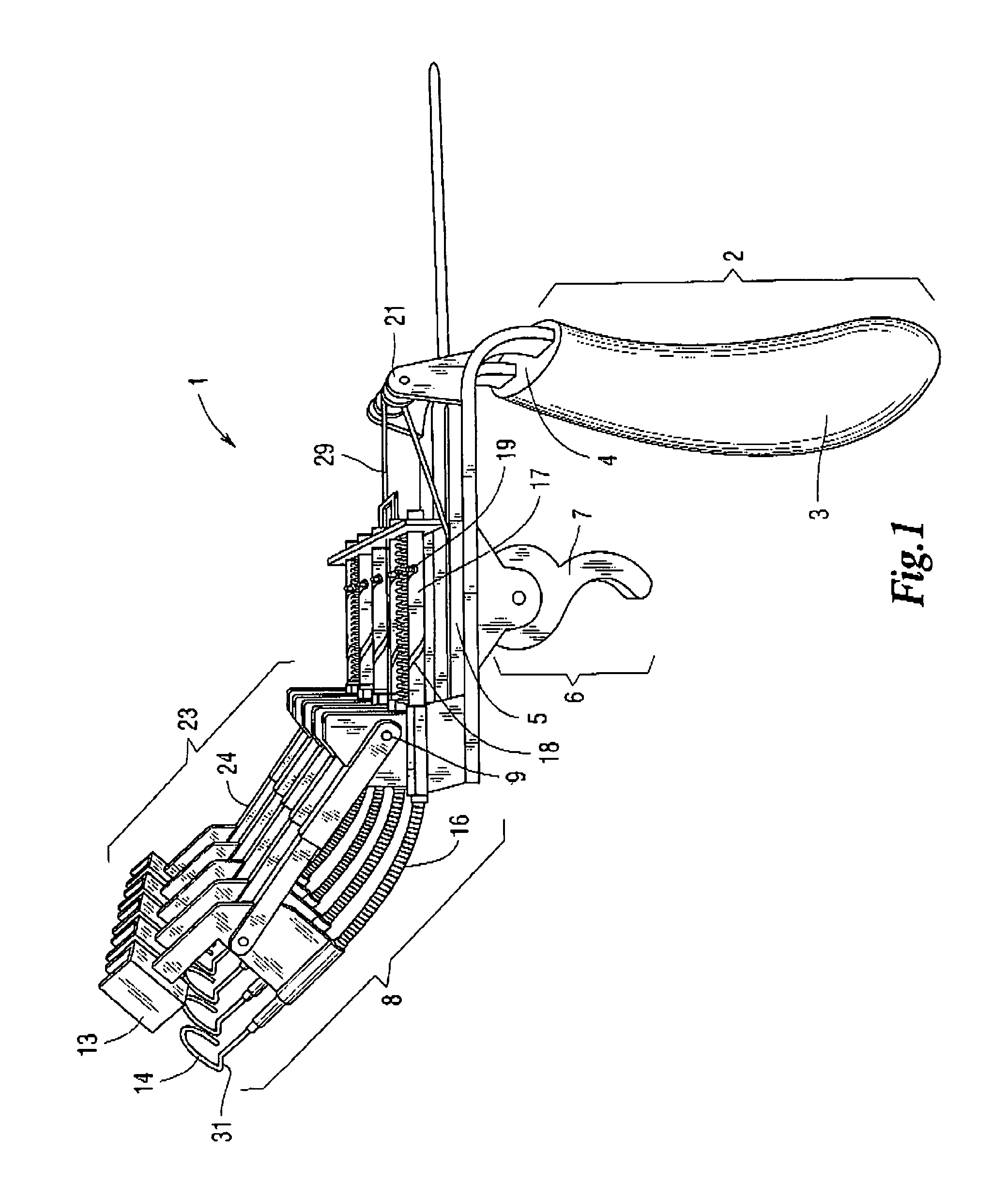

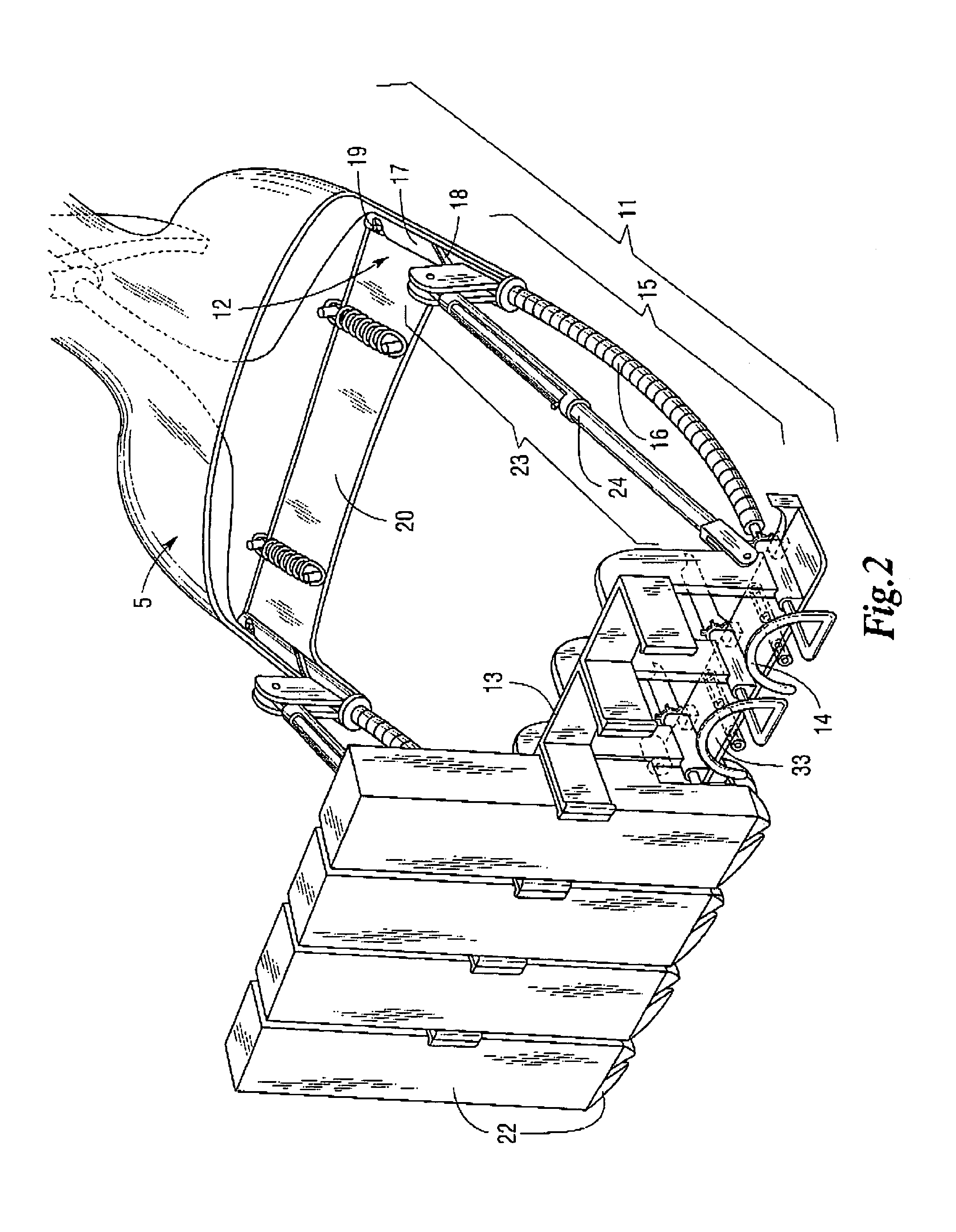

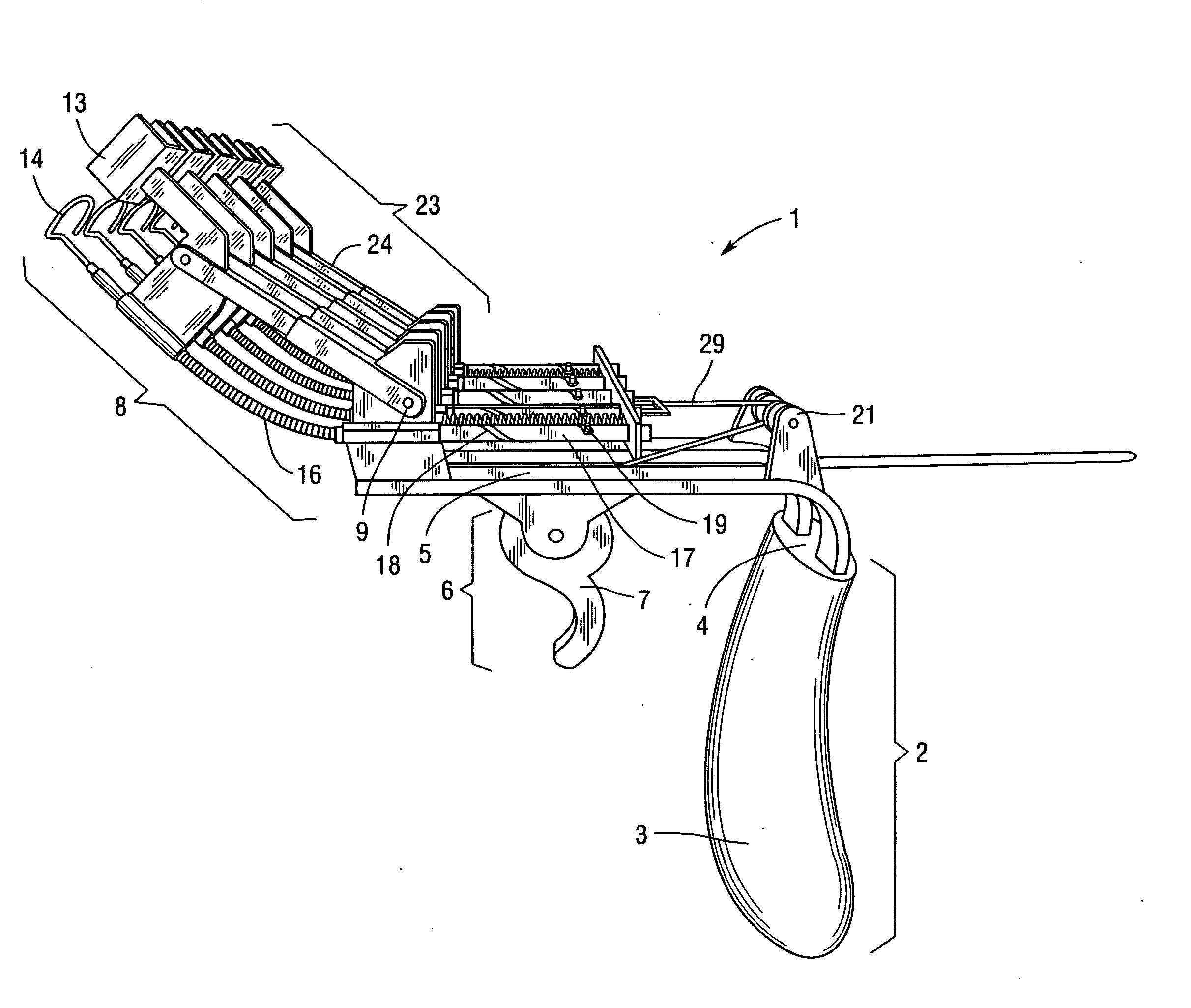

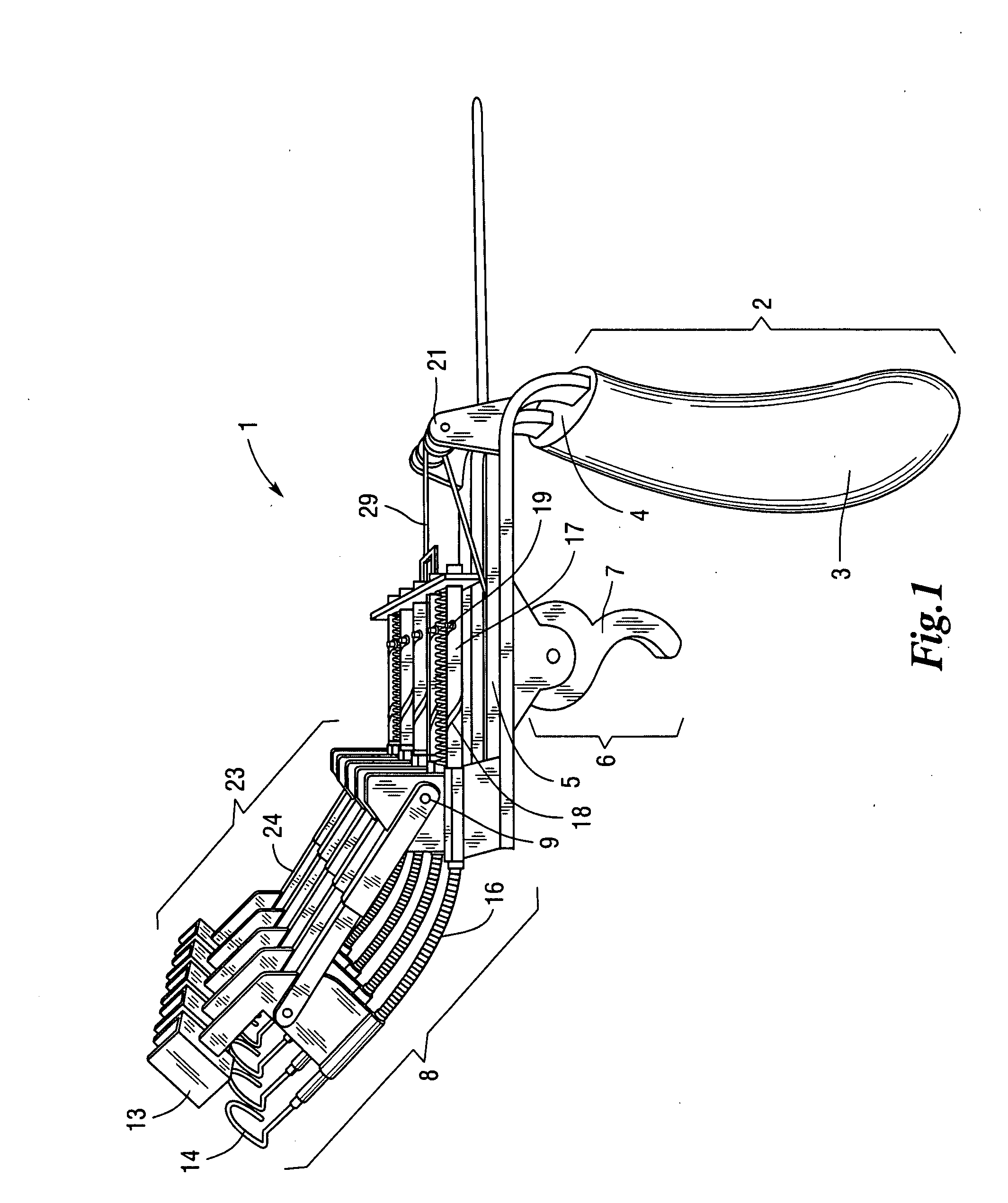

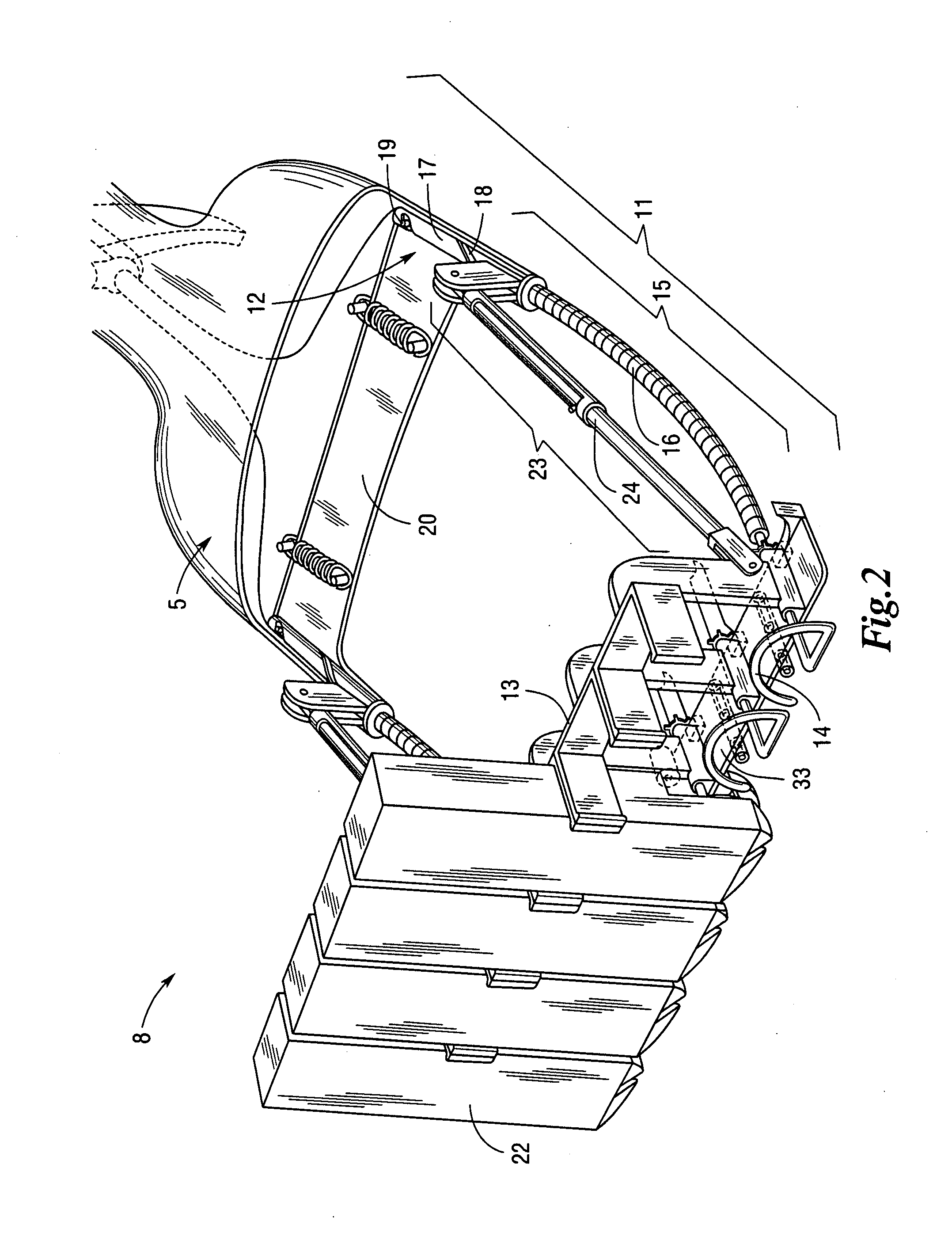

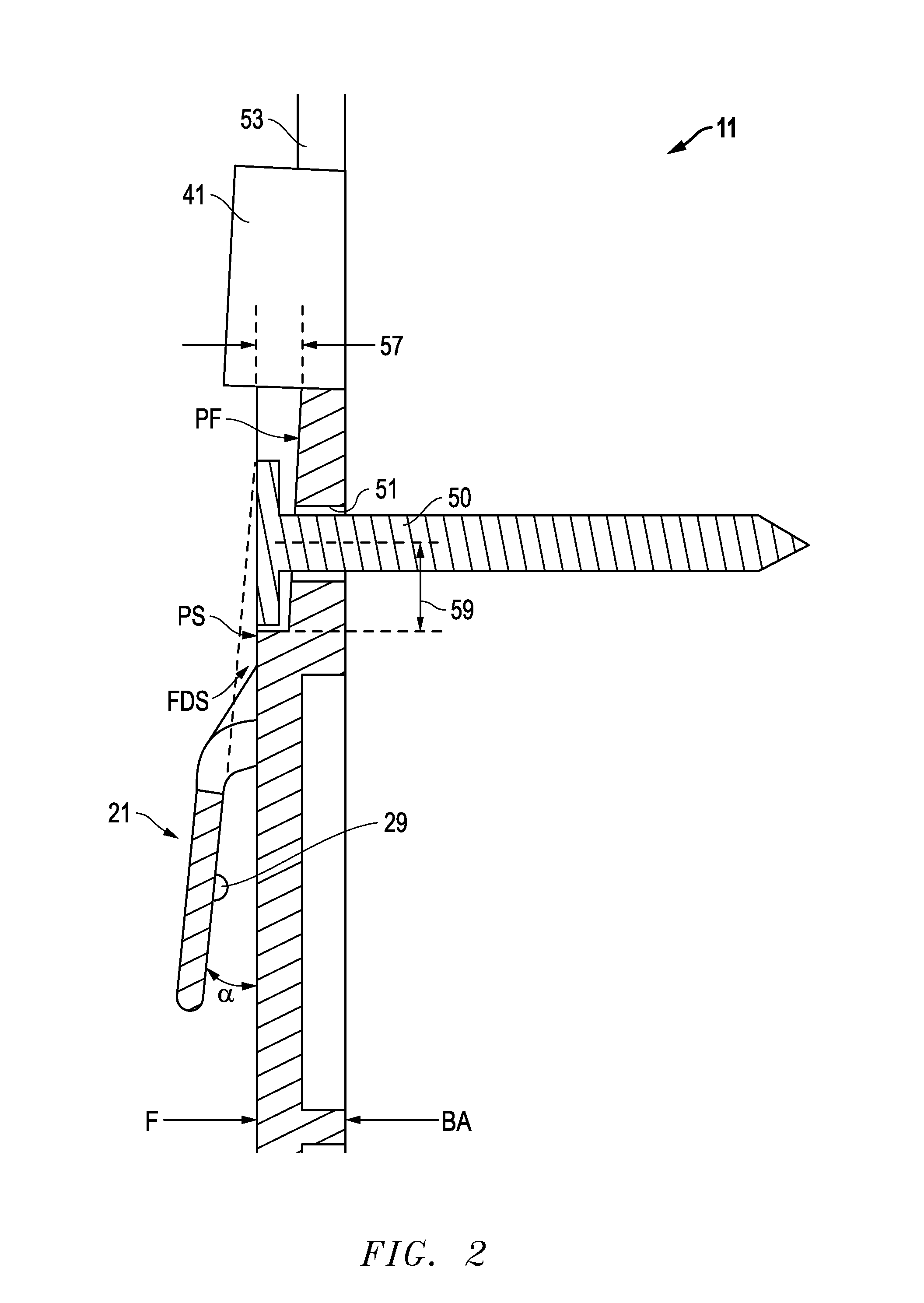

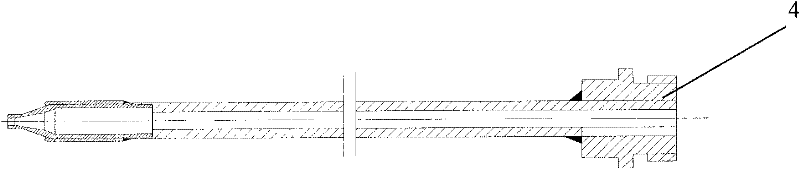

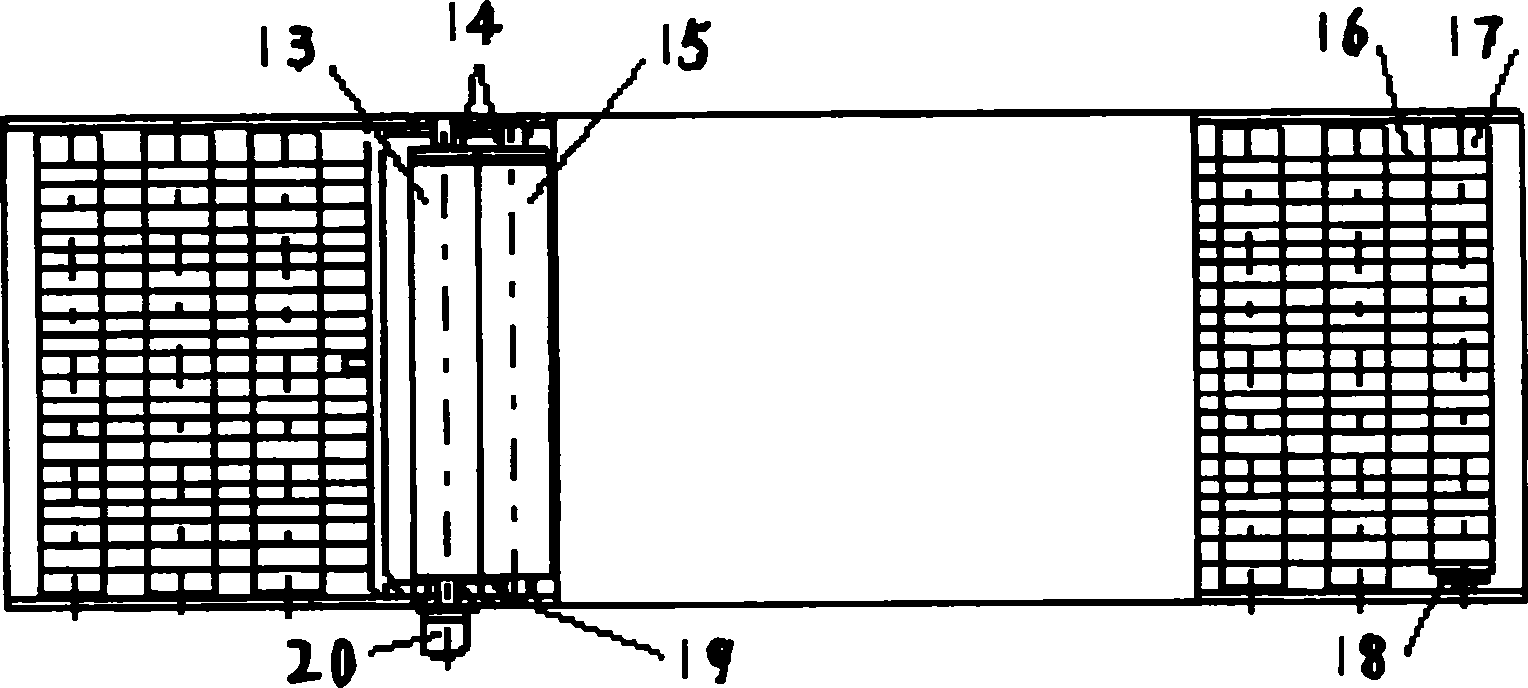

Hair color variegation device

InactiveUS7530358B2Accurate contactEasily brokenTravelling articlesHair cleaningEngineeringHair Colors

A device for applying artificial color to selected stands of human hair, the device comprising a handle, a means for selecting strands of human hair, and a hair color applicator. The device allows a user to quickly, accurately, and predictably apply artificial color to selected strands of human hair using only one hand.

Owner:F G ELLIOTT LLC

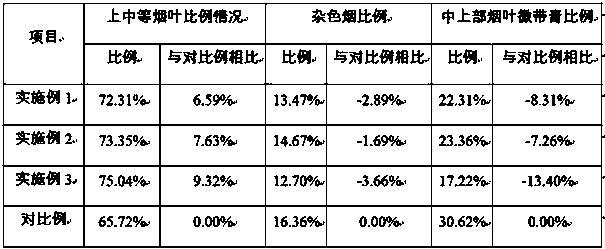

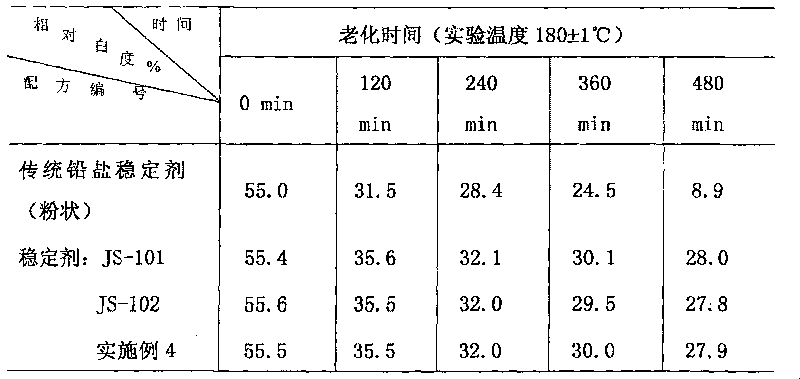

Method for roasting high-temperature drought premature tobacco leaves

The invention discloses a method for roasting high-temperature drought premature tobacco leaves. The method mainly includes the step of the early stage of yellowing, the step of the middle stage of yellowing, the steps o f the later stage of yellowing, the step of the early stage of color fixing, the step of the later stage of color fixing, and the step of the stem drying stage. According to the method, roasting losses of the high-temperature drought premature tobacco leaves are reduced by adjusting the roasting technological parameters, and the roasting quality of the tobacco leaves is remarkably improved. The proportion of the better-than-average tobacco leaves is obviously increased, the proportion of the variegated tobacco leaves is decreased, and the proportion of the tobacco leaves which are slightly greenish in the middle upper portions is greatly decreased.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

Nylon fabric dyeing technology

InactiveCN103276610ANot easy to creaseNot easy to form wrinklesHeating/cooling textile fabricsDry-cleaning apparatus for textilesProcess engineeringPre treatment

The invention discloses a nylon fabric dyeing technology. The technology adopts a process flow comprising the steps of blank pretreatment, presetting, jet dyeing, water washing, color fixation, water washing and air drying, the water washing and the high-temperature presetting treatments before dyeing make creases and wrinkles be difficultly formed in the dyeing process to obtain a special wrinkle effect, and the adoption of a jet dyeing machine for dying and the change cooperation addition of an assistant, a dye and the temperature effectively avoid variegation and color wrinkle phenomena and make the dyeing uniform and a finished product soft and fluffy, so the technology has a good coloring effect, is suitable for the large-scale industrial production and application, and has an improved market competiveness.

Owner:太仓市芸芸化纤有限公司

Mosaic variegation digital camouflage pattern setting on surface of shelter

InactiveCN102778176AEasy to camouflageFusion simpleCamouflage devicesProtective buildings/sheltersNatural satelliteAviation

The invention discloses a mosaic variegation digital camouflage pattern setting on the surface of a shelter. The technical scheme adopted by the invention is realized by the following steps: selecting a southern woodland type camouflage as a reference, wherein the middle green area accounts for 45 percent, the dark green area accounts for 30 percent, the lime-clay area accounts for 15 percent, the bright green area accounts for 10 percent, the size of each small check color block is 100mm*100mm; enabling a boundary lapping line of each small spot check to be at least 100mm; combining ten kinds of checks such as middle green, dark green, lime-clay and bright green into modules with different shapes and a digital camouflage pattern of the shelter; and automatically spraying the digital camouflage pattern to the shelter by a computer according to a digital camouflage pattern setting scheme. From a great distance, the digital camouflage pattern can achieve the deformation effect required by a traditional blotch design; spots with different colors can generate space mixing color and are easily fused with a surrounding background; and the digital camouflage pattern can simulate surface characteristics of background communities such as forests and mountains, so that enemy aviation and satellite imaging detection are difficult in differentiating.

Owner:贵州航天特种车有限责任公司

Hair color variegation device

InactiveUS20070221242A1Accurate contactEasily brokenTravelling articlesHair cleaningEngineeringHair Colors

A device for applying artificial color to selected stands of human hair, the device comprising a handle, a means for selecting strands of human hair, and a hair color applicator. The device allows a user to quickly, accurately, and predictably apply artificial color to selected strands of human hair using only one hand.

Owner:F G ELLIOTT LLC

Single panel siding product

A siding product may include a panel having a substantially rectangular structure with a simulated pattern on a front face thereof. The panel may be formed from a polymer and may include color variegation. The panel may have a hollow back and be a single shake configuration that does not simulate more than one shake or more than one course of siding. The siding product may include a panel having a front face with a simulated pattern. The panel can include a hollow back, a longitudinal length extending in an x-direction, a lateral width extending in a y-direction, and a transverse depth extending in a z-direction. The panel can have a plurality of reinforcement ribs on the hollow back that extend longitudinally in the x-direction and transversely in the z-direction. In a version, none of the reinforcement ribs extend laterally in the y-direction.

Owner:CERTAINTEED CORP

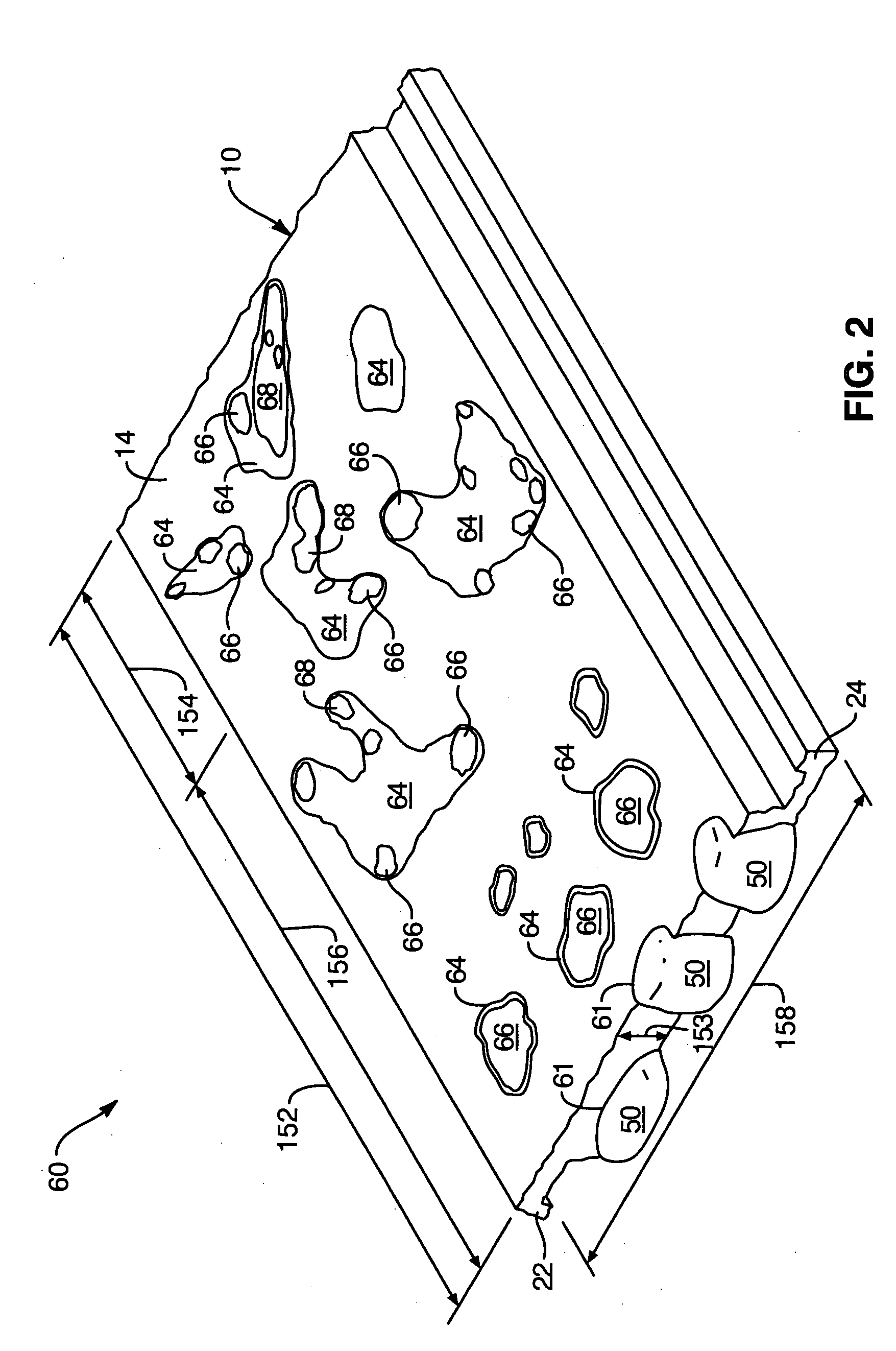

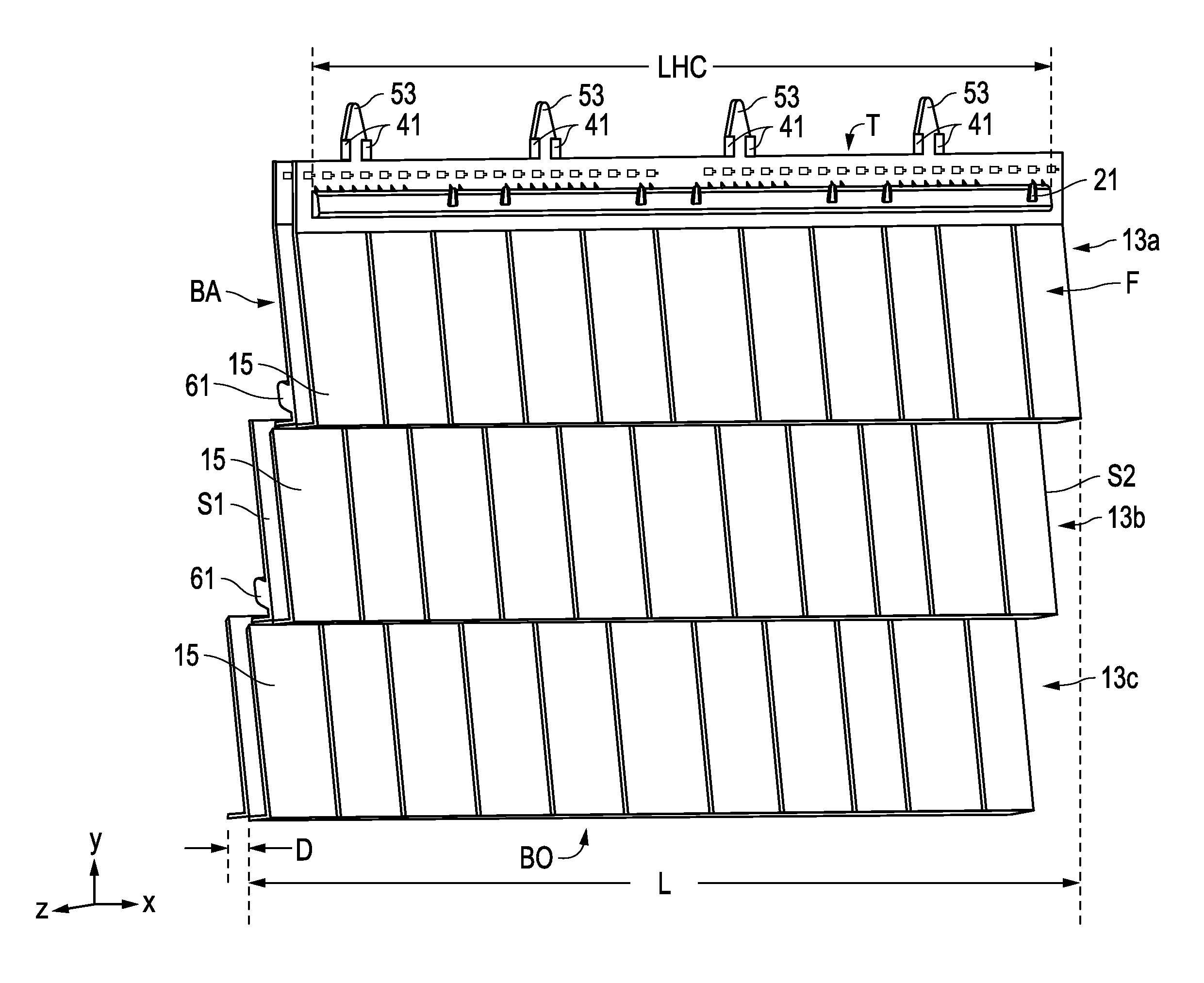

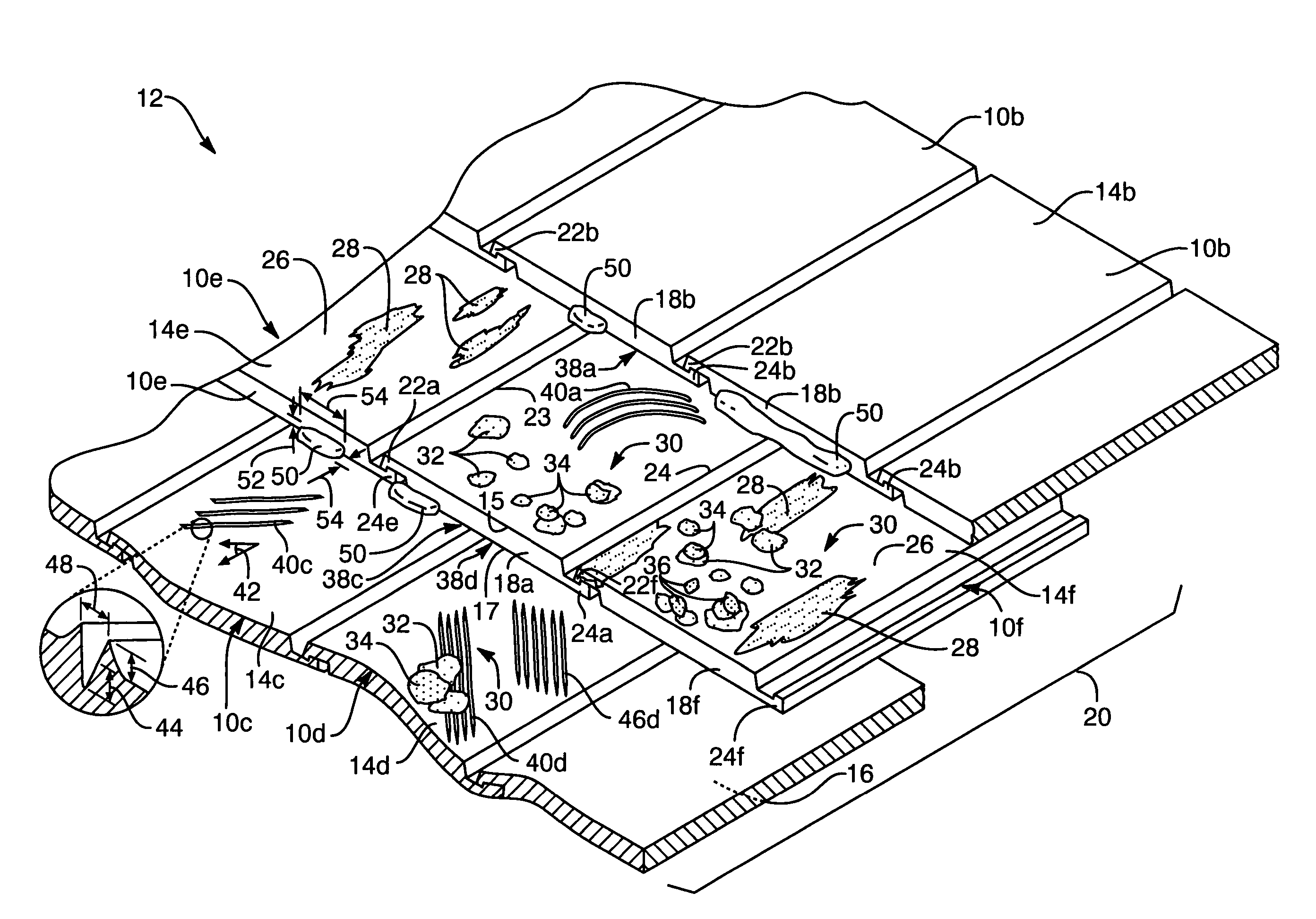

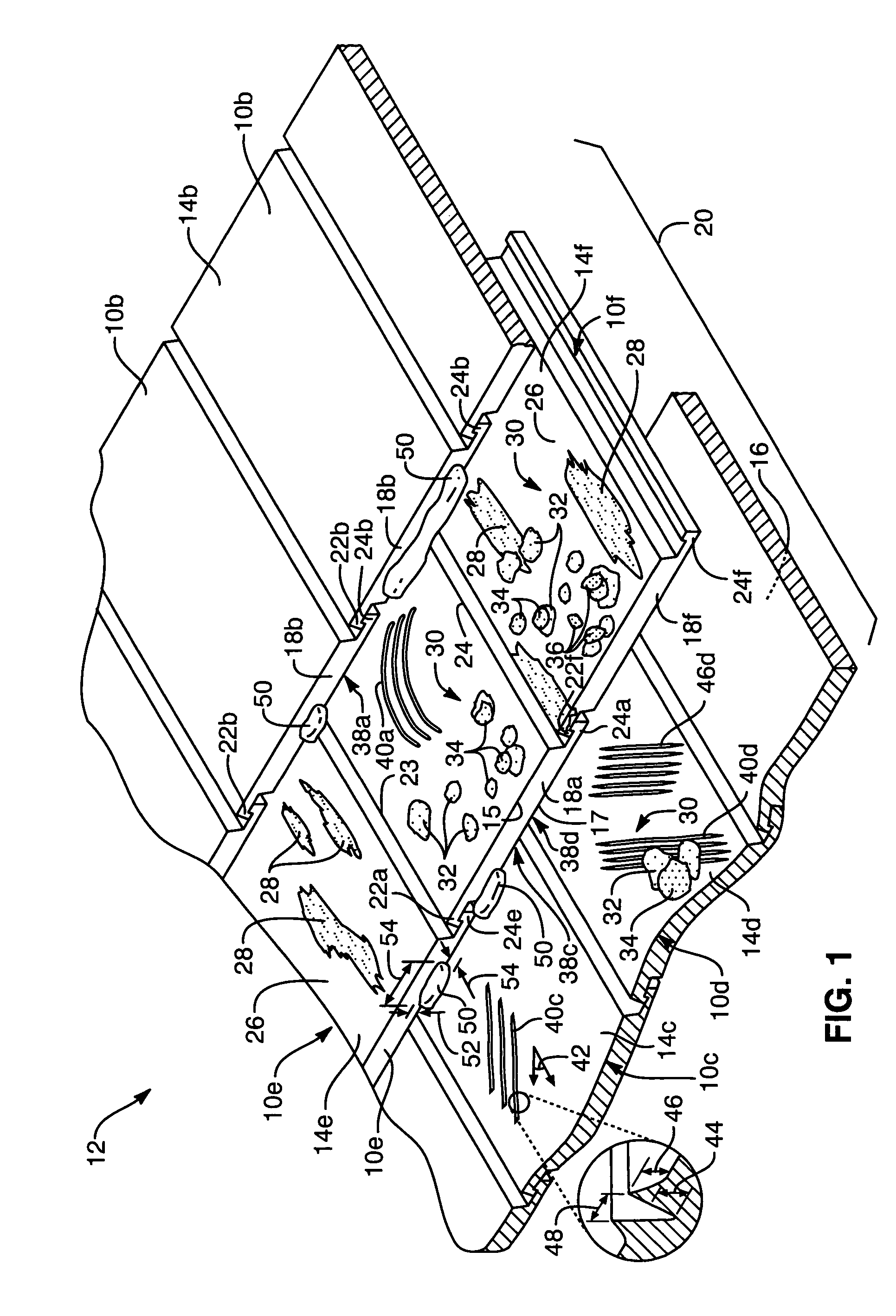

Aged roofing tile system

InactiveUS20050116373A1Improve adhesionRoof covering using tiles/slatesOther chemical processesEffect lightEngineering

A system, method, and apparatus for constructing and installing a roofing tile having an arbitrary design of color, patterns, textures, and the like in accordance with the requirements of a user, a designer, an architect, or the like, and provides an ability to select a color scheme for a base tile, variegations within the color of the base tile, as well as accent medallions having color, textures, and the like. Moreover, a texture may be provided to improve adhesion of the accent medallions to the base tile. In alternative embodiments, no texturing is required, but may be provided simply as a design element affecting shading in varied lighting.

Owner:EVANS BROS INVESTMENTS

Panel siding product

A siding product may include a panel having a substantially rectangular structure with a simulated pattern on a front face thereof. The panel may be formed from a polymer and may include color variegation. The panel may have a hollow back and be a single shake configuration that does not simulate more than one shake or more than one course of siding. The siding product may include a panel having a front face with a simulated pattern. The panel can include a hollow back, a longitudinal length extending in an x-direction, a lateral width extending in a y-direction, and a transverse depth extending in a z-direction. The panel can have a plurality of reinforcement ribs on the hollow back that extend longitudinally in the x-direction and transversely in the z-direction. In a version, none of the reinforcement ribs extend laterally in the y-direction.

Owner:CERTAINTEED CORP

Aged roofing tile system

InactiveUS7736557B2Improve adhesionRoof covering using tiles/slatesOther chemical processesBrickEngineering

A system, method, and apparatus for constructing and installing a roofing tile having an arbitrary design of color, patterns, textures, and the like in accordance with the requirements of a user, a designer, an architect, or the like, and provides an ability to select a color scheme for a base tile, variegations within the color of the base tile, as well as accent medallions having color, textures, and the like. Moreover, a texture may be provided to improve adhesion of the accent medallions to the base tile. In alternative embodiments, no texturing is required, but may be provided simply as a design element affecting shading in varied lighting.

Owner:EVANS BROS INVESTMENTS

Panel siding product

A siding product may include a panel having a substantially rectangular structure with a simulated pattern on a front face thereof. The panel may be formed from a polymer and may include color variegation. The panel may have a hollow back and be a single shake configuration that does not simulate more than one shake or more than one course of siding. The siding product may include a panel having a front face with a simulated pattern. The panel can include a hollow back, a longitudinal length extending in an x-direction, a lateral width extending in a y-direction, and a transverse depth extending in a z-direction. The panel can have a plurality of reinforcement ribs on the hollow back that extend longitudinally in the x-direction and transversely in the z-direction. In a version, none of the reinforcement ribs extend laterally in the y-direction.

Owner:CERTAINTEED CORP

Method for dissolving and processing hemp fibre by employing ionic liquid

InactiveCN101230496AAbundant resourcesExtensive resourcesWet spinning methodsSpinning solutions preparationTotal solid contentIonic liquid

The invention relates to a method of dissolving and processing a bamboo-hemp fibre by adopting an ionic liquid. The method has the following steps: firstly, the comminuted pulp of bamboo and hemp is well mixed with an ironic liquid, dissolved at a temperature of 35 to 160 DEG C, deaerated for 1 to 120 hours, and a homogeneous and stable spinning solution with a total solid content of 3 to 50 percent is formed, wherein, the mass ratio of bamboo and hemp is 1-99 percent to 99-1 percent; secondly, the spinning solution is filtered, deaerated, spinned and solidified through a coagulation bath; and thirdly, a bamboo-hemp blended composite fibre is obtained after the procedures of stretching, water cleaning, bleaching, oiling and drying. The ironic liquid used in the invention has high production efficiency, is easy for callback and conforms to the requirement of a green production. The prepared composite fibre has excellent mechanical strength and mechanical property and the fabric made of the composite fibre has the advantages of excellent hygroscopic property, strong ventilation property, soft handfeel, excellent fabric drapability, easy variegation and powerful bacterium resistance. Simultaneously, the prepared composite fibre provides a material used in the departments of medicine and health.

Owner:DONGHUA UNIV

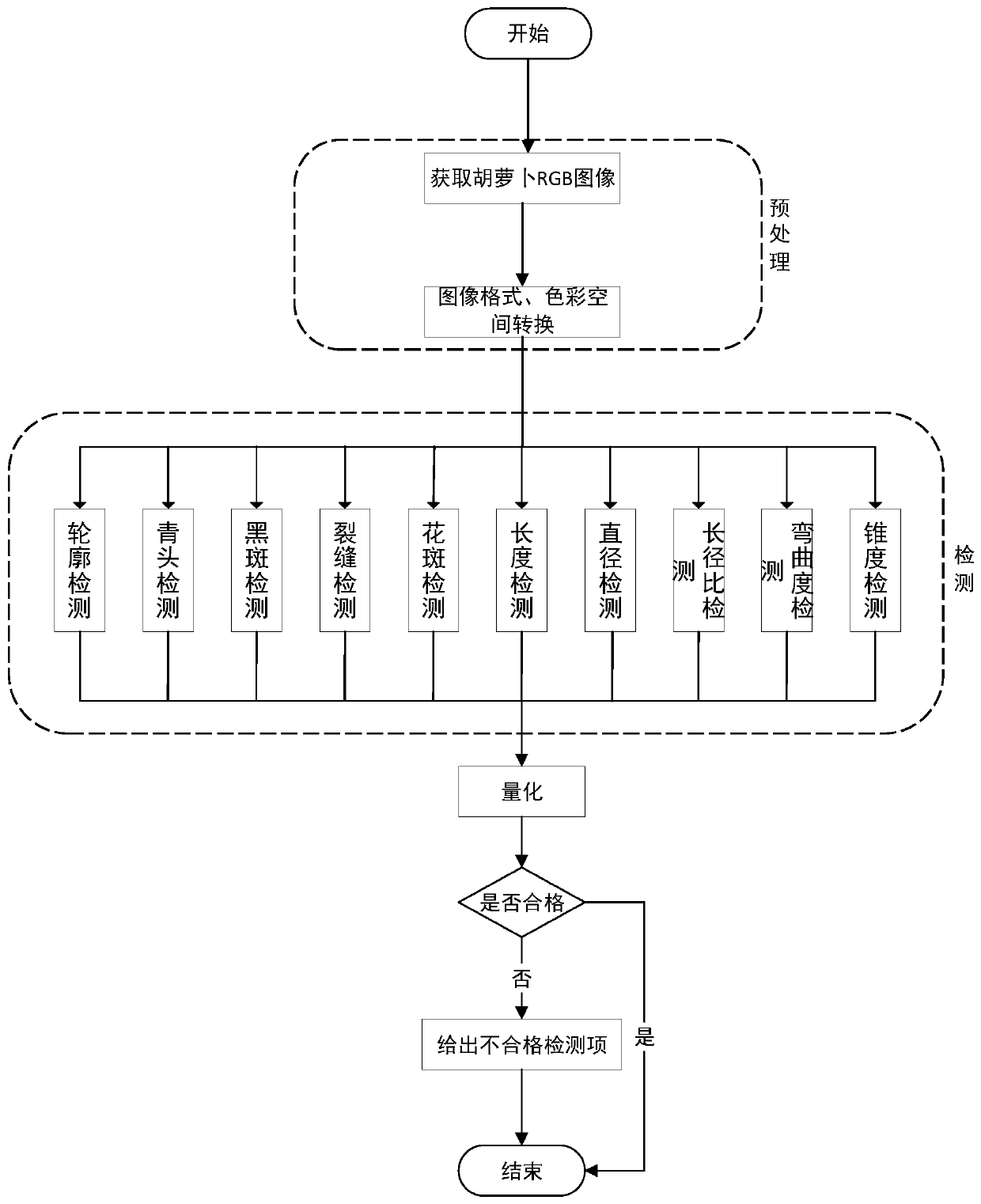

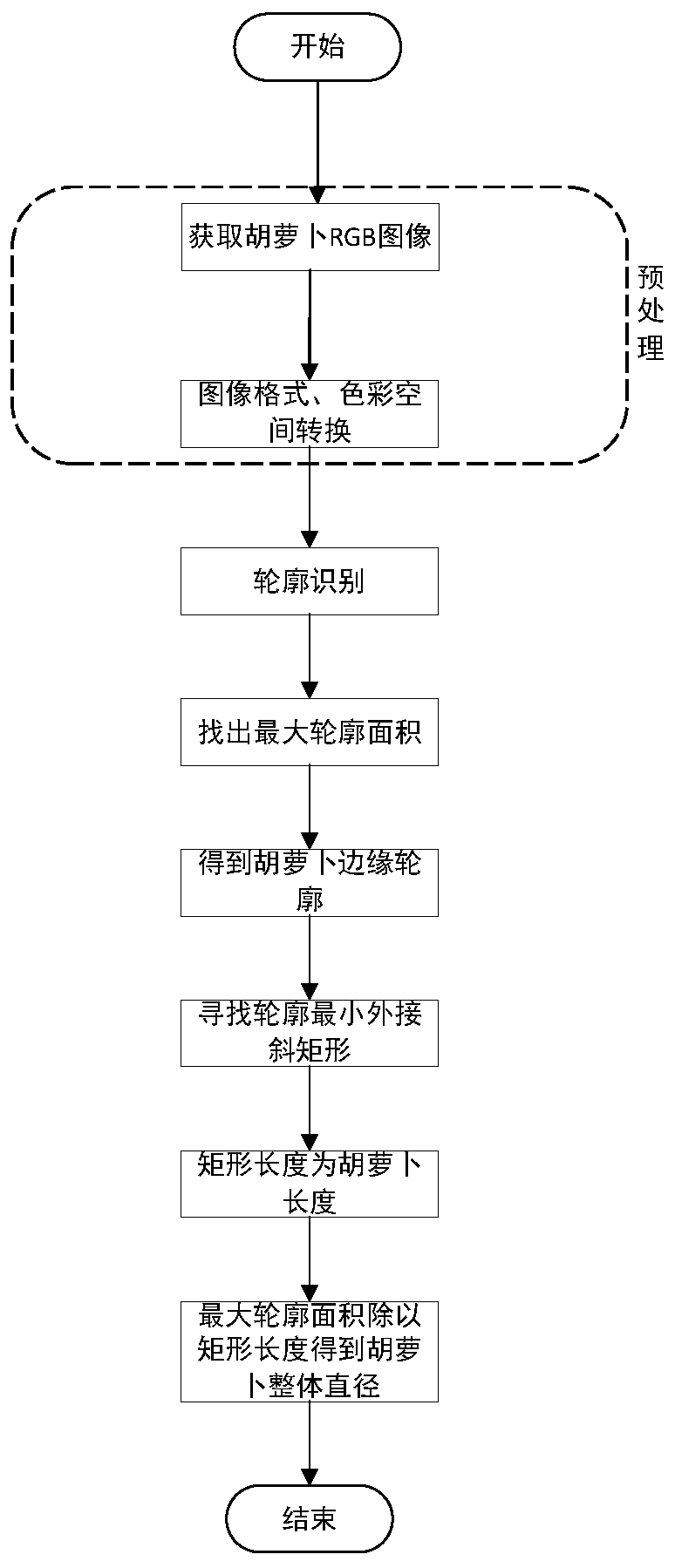

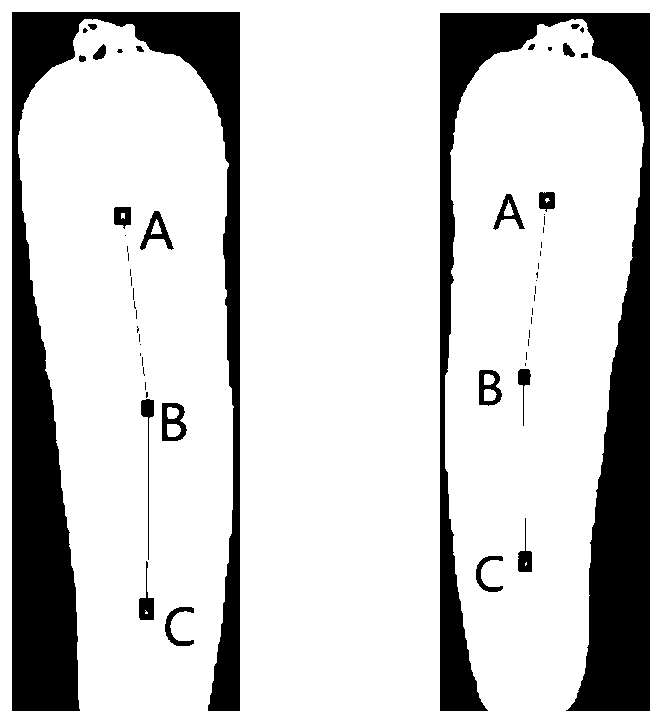

Carrot surface defect detecting method

InactiveCN110434090AReduce volumeReduce power consumptionMaterial analysis by optical meansSortingMachine visionBlack spot

The invention discloses a carrot surface defect detecting method which comprises the following steps: S1, pretreating: obtaining an RGB image of a carrot surface, carrying out image format conversionand color space conversion on the RGB image to output a target image file; S2, detecting: carrying out contour detection, green head detection, black spot detection, crack detection, variegation detection, length detection, diameter detection, draw ratio detection, tortuosity detection and taper detection on the carrot according to the target image file; and S3, quantizing: judging whether the detecting result information is qualified, if yes, quitting the detecting program, otherwise, outputting the unqualified detecting item. According to the carrot surface defect detecting method, machine vision is applied to automatic grading and sorting of agricultural products, so that strict unification of the quality standard of agricultural products, large scale of the agricultural product, and automatic production and processing of the agricultural products are facilitated.

Owner:中山德著智能科技有限公司

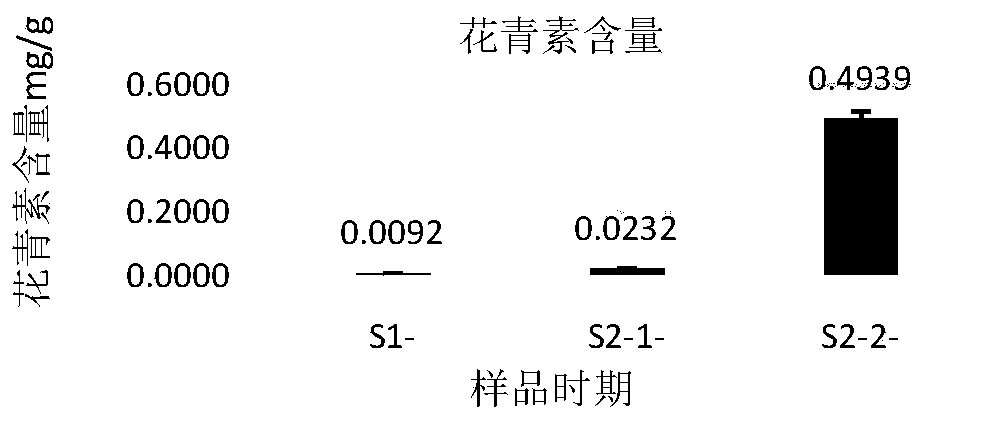

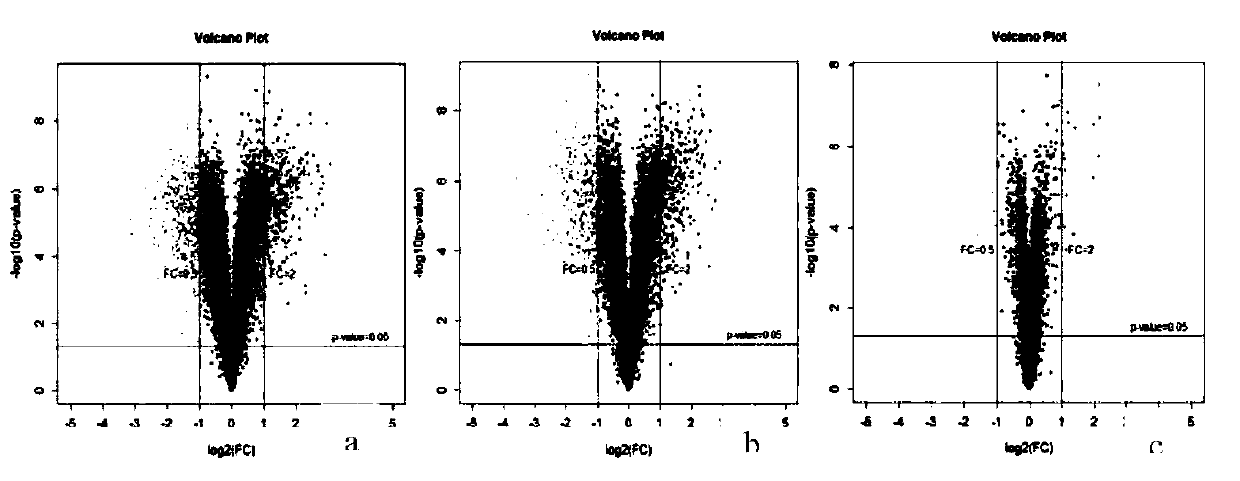

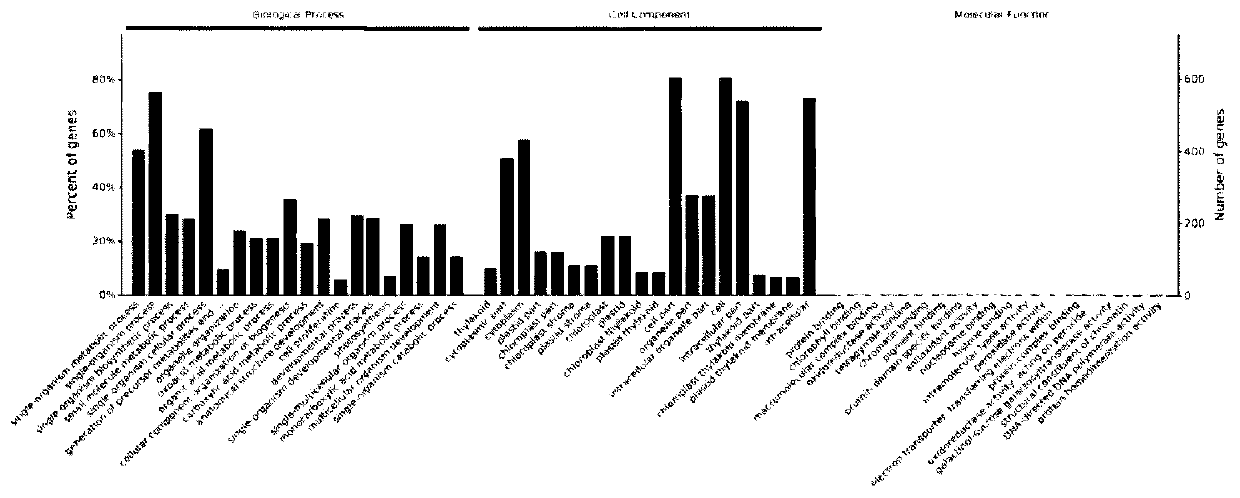

Analysis method for researching formation of variegation of nelumbo nucifera based on combination of transcriptomics with proteomics TMT

PendingCN110331225ADecor optimizationQuantitative and qualitativeMicrobiological testing/measurementBiological material analysisBiologyGene association

The invention relates to an analysis method for researching formation of variegation of nelumbo nucifera based on combination of transcriptomics with proteomics TMT, and provides a new method for disclosing a molecular mechanism of the formation of the variegation of plants. Samples of "Dasajin" nelumbo nucifera petals are collected, through transcriptome Illumina HiSeq sequencing, expression difference genes on an anthocyan metabolic pathway are screened, besides, proteins in the samples are extracted, the concentration of the proteins is determined, the quality is detected, through TMT labelmarking and 2D-LC-MS analysis, bioinformatics analysis is performed through combining with the proteomics, the proteins for adjusting and controlling expressing level differences on the anthocyan metabolic pathway are screened, the genes having differences in the transcriptome are related into the proteomics, and key proteins and corresponding genes for adjusting and controlling the variegation of "Dasajin" nelumbo nucifera are screened, so that the purpose of understanding a manner of the proteins and the genes for adjusting the formation of the variegation of the "Dasajin" nelumbo nuciferais achieved, and a new thinking and a new method are provided for the formation mechanism of the variegation of other plants.

Owner:CHINA THREE GORGES CORPORATION

Yellow-feathered broiler breeding method

InactiveCN101849527AImprove meat performanceImprove egg production performanceAnimal husbandryFledgeBroiler chick

The invention relates to a yellow-feathered broiler breeding method which is characterized in that the second generation is bred in the following steps that: 0-day: chicks which are lighter than the average weight, have variegated feathers or blue foot skin are eliminated; 10-day: individuals which do not have tail, and have variegated feathers or blue foot skin are eliminated; 10-week: individuals which are lighter than the average weight, have variegated feathers or blue foot skin are eliminated; and 18-week: cocks which have the crown height lower than 3cm, chest expansion angle smaller than 60 degrees, tibial diameter smaller than 1.2cm or blue foot skin, and hens which have pale face, lack energy, and have the tibial diameter smaller than 1cm and blue foot skin or bend toes are eliminated. The yellow-feathered broiler breeding method can make the chicken performance progress for generations and not degenerate for a long time.

Owner:SHANGHAI TAIPINGYANG POULTRY BREEDING

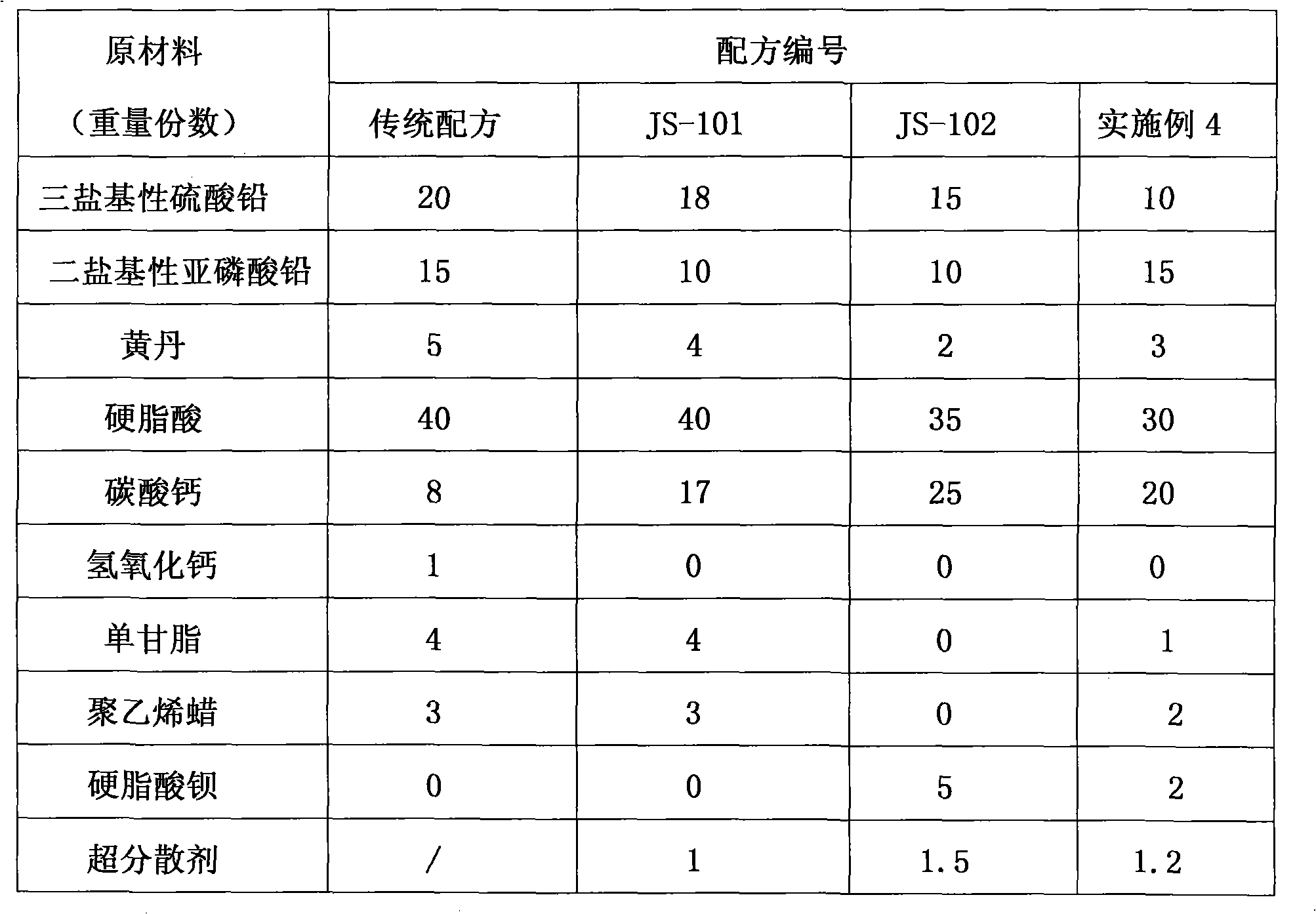

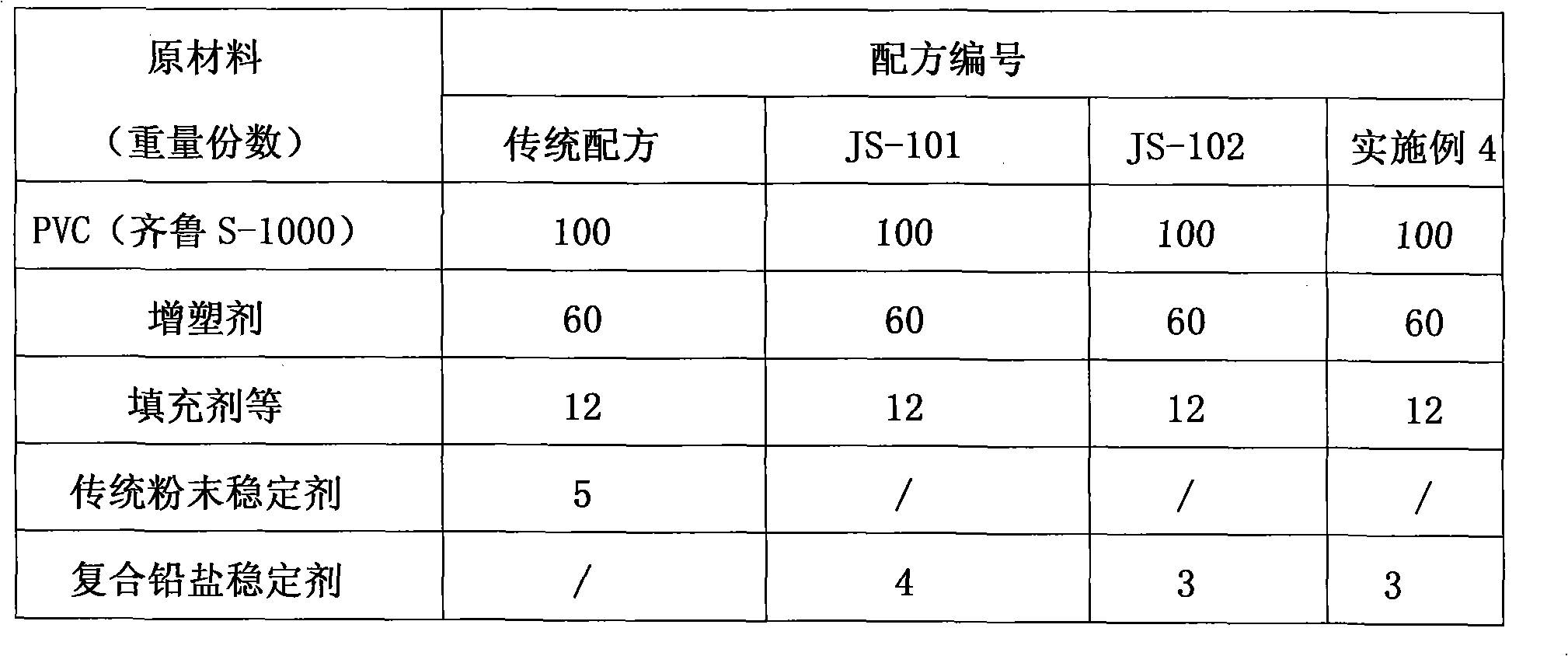

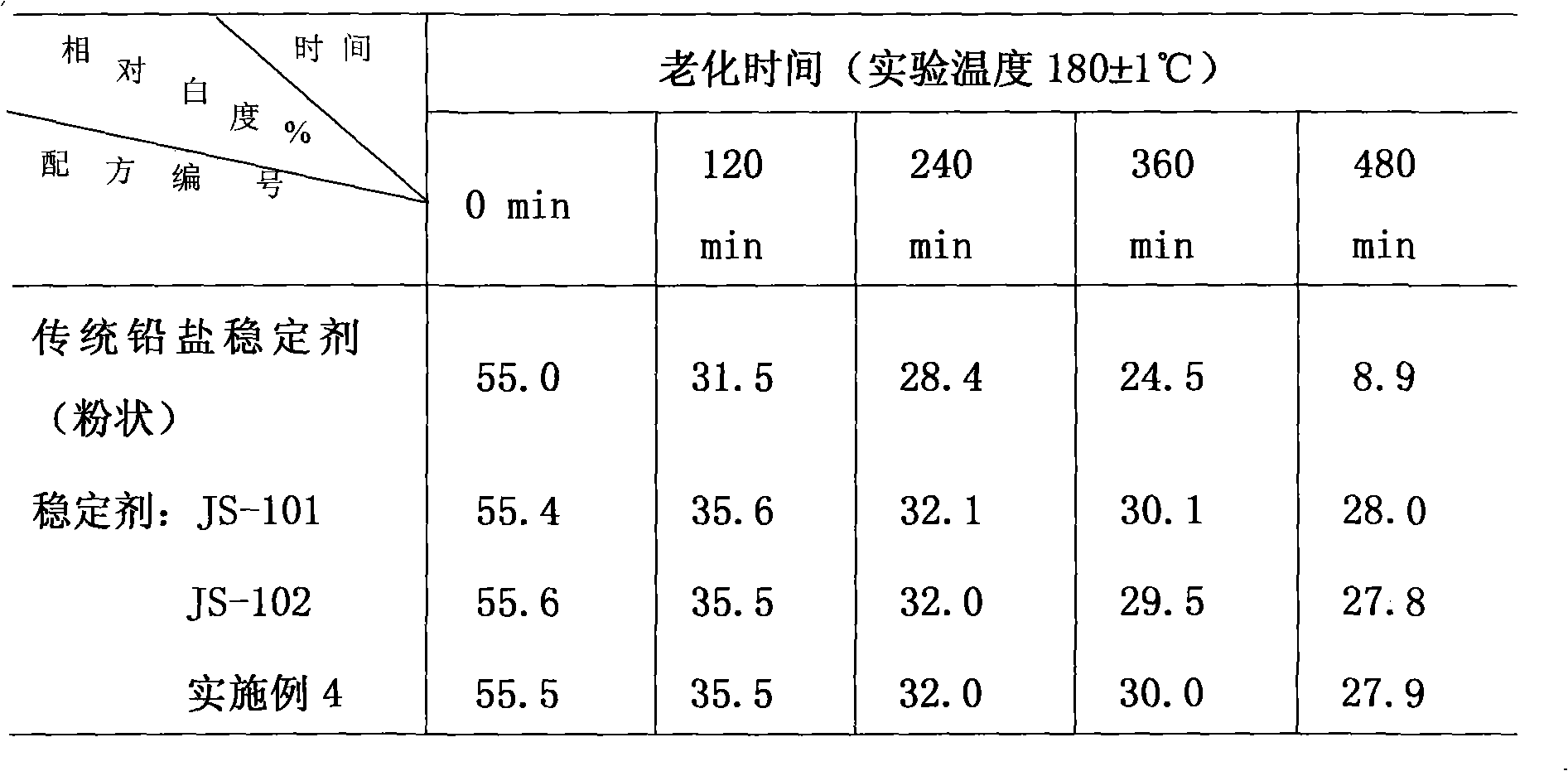

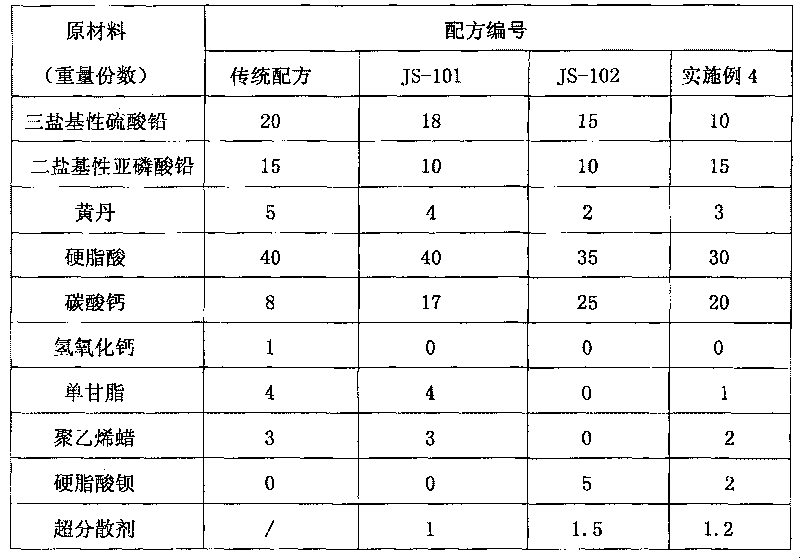

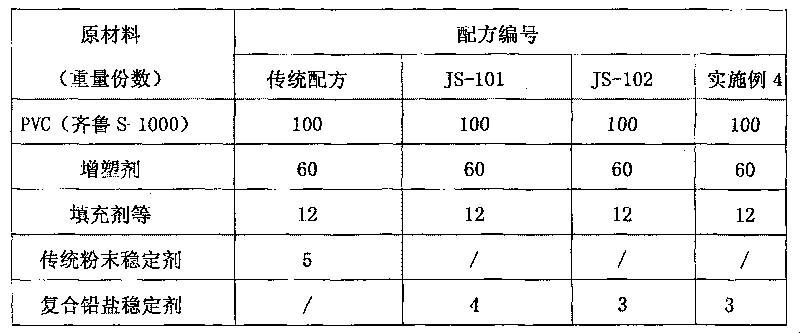

Ultra-dispersed composite stabilizer for polychloroethylene and preparation thereof

InactiveCN101302322AAvoid Agglomeration and PrecipitationGood dispersionDispersityPolyvinyl chloride

The invention relates to polyvinyl chloride ultra-dispersed composite stabilizer. The compositions by weight portion of the polyvinyl chloride ultra-dispersed composite stabilizer are: 10 to 20 portions of tribasic lead sulphate, 10 to 15 portions of dibasic lead phosphite, 2 to 4 portions of massicot, 0 to 5 portions of barium stearate, 0 to 4 portions of direactive glyceride, 0 to 4 portions of polyethylene wax, 30 to 40 portions of stearic acid, 1 to 1.5 portions of ultra-dispersed agent and 15 to 25 portions of light calcium carbonate, wherein, the ultra-dispersed agent is copolymers of maleic anhydride-sodium allylsulfonate-acrylate polyethylene glycol monoester. The composite stabilizer prepared can greatly improve the dispersity and the compatibility of the stabilizer and avoid variegation of the stabilizer during the process of processing sectional materials. Utilization of the ultra-dispersed agent also can improve the dispersity and the compatibility of PVC substrates and pigment. The polyvinyl chloride ultra-dispersed composite stabilizer has the advantages of superior performance, low toxity, high efficiency and multiple functions, namely the stabilizer simultaneously has the functions of improvement of the processability, plasticization, easy variegation, lubrication and so on. The method has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

Method for manufacturing coloured copperplate etching

InactiveCN1579816AHigh degree of simulationEasy to operatePhotomechanical apparatusArtistic surface treatmentScreen printingEtching

The invention relates to a kind produce method of colorful cooper board picture, there are fowling steps of the process: producing menu film, besmearing sensitive coat film on the cooper board, press film to cooper and make sensitive management, then developing, eroding, fading sensitive coat film, variegation, antisepsis, cutting, framing up and so on; its character is producing the menu to tricolor microdot film after computer dichroism process; printed circuit sensitive film on the cooper board by silk screen technology; electrochemistry electroanalysis eroding; dyeing the cooper board to white at first, then make tricolor color filling or colorful spray color filling. The colorful cooper board which is produced with this method, has high emulator degree, the color and line of the menu is hairlike, no brushwork imprint, very vivid. It is not special for art automobileeer man, others can also produce, easy operation, and can be volume-produced.

Owner:高绿荣

Transferring printing process for natural fabric

Owner:WUJIANG LINGZHI TEXTILE

Method for making boomerang target based on target filament

The invention discloses a preparation method of the dart target based on the target wire, which collects the drawbench level polypropylene PP and the calcium bicarbonate as the raw materials, wherein the materials are mixed and fed to the belt packing machine and made into the tabletting-shape strip by the belt packing technics, then the strip is ripped into a plurality of target wires, and the strip is cut into the target wire, and through the target wire compression, the target wire levelness, the mould arrangement, the mould composition, the mould injection, the cooling, the mould disassembly and the like, the target and the target back (namely the motherboard) are formed into an integer. The target has the advantages of simple production, low production cost, no resilience of the made dart target, easy variegation of the dart target, level surface of the dart target without polishment, integral shape of the motherboard with the target wire without the stickiness.

Owner:聂晓庆

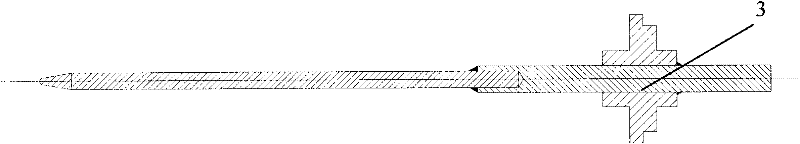

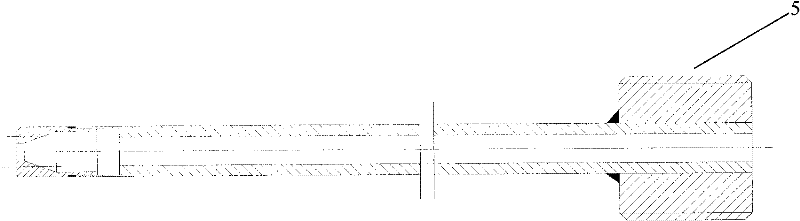

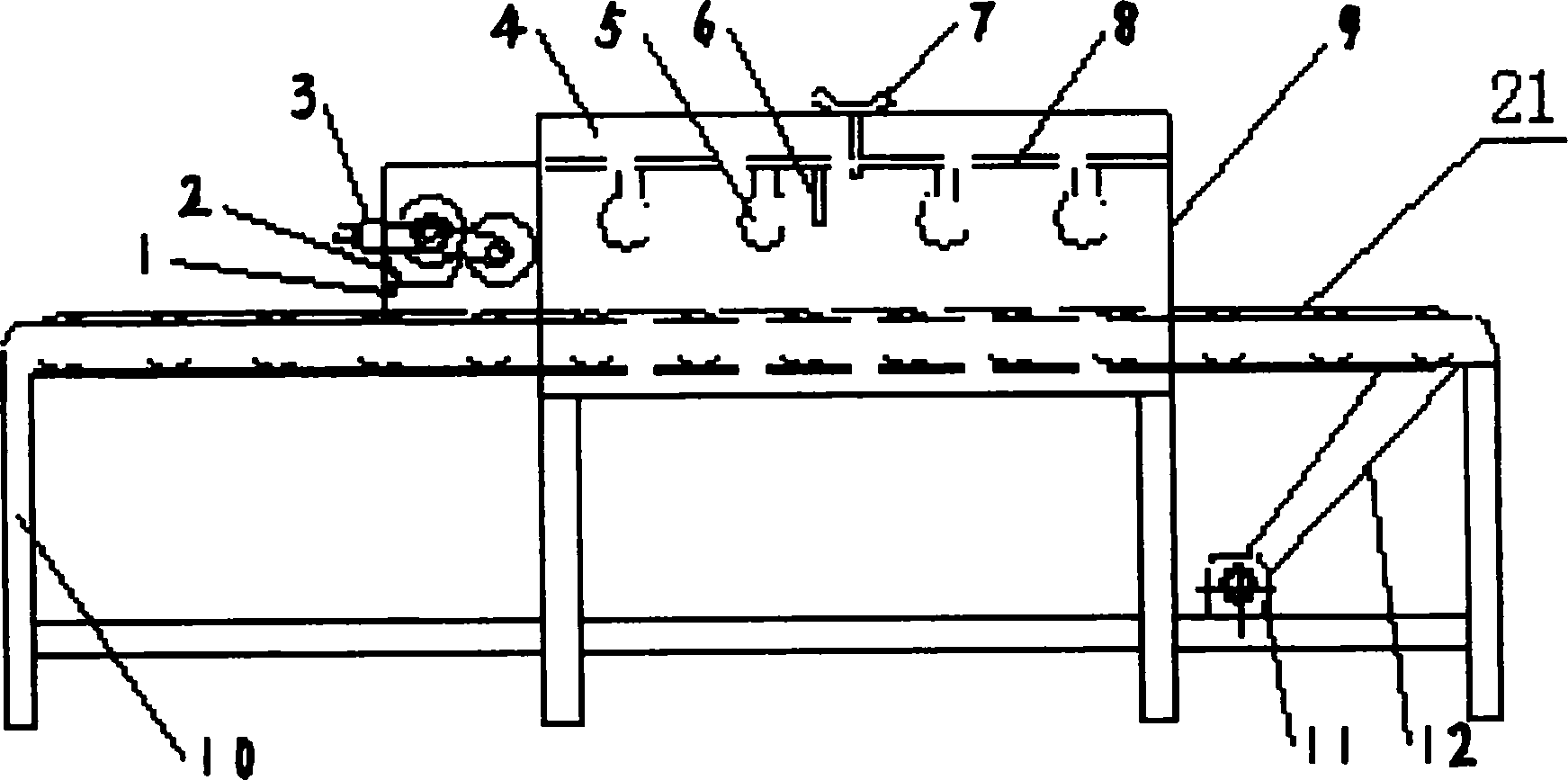

Inner spray method and device for medical packing aluminum tube

InactiveCN102451805AEffective isolationThe effect is positive and obviousLiquid spraying apparatusEngineeringScrew thread

The invention discloses an inner spray method for a medical packing aluminum tube. The inner spray method comprises a process for spraying a coating onto the inner side face of the thin top of the medical packing aluminum tube and a process for spraying the coating onto the inner side face of the tube body of the medical packing aluminum tube, and comprises the following specific steps of: inserting a thin-top spray gun from an opening on the tail part of the aluminum tube for spraying on the inner side of the thin top; and inserting two tube body spray guns for spraying onto the tube shoulder and the tube body of the aluminum tube, wherein an angle of 15-25 degrees is formed between the spray direction of the coating and the central axis of the medical packing tube. The pressures of the coating and air current passing through the thin-top spray gun and the tube body spray guns are adjusted according to the temperature and specifications of the medical packing aluminum tube. The invention further discloses an inner spray device, which comprises a thin-top spray gun and two tube body spray guns. In the invention, the coating is sprayed onto the medical packing aluminum tube through the tube body spray guns and the thin-top spray gun, so that screw threads on a coat are prevented after spraying, air bubbles do not appear on the shoulder, variegation and slobbering inside are prevented, coating is uniform, the aluminum tube is isolated effectively from a medicament, and the effects of resisting corrosion and isolating are achieved.

Owner:上海佳田药用包装有限公司

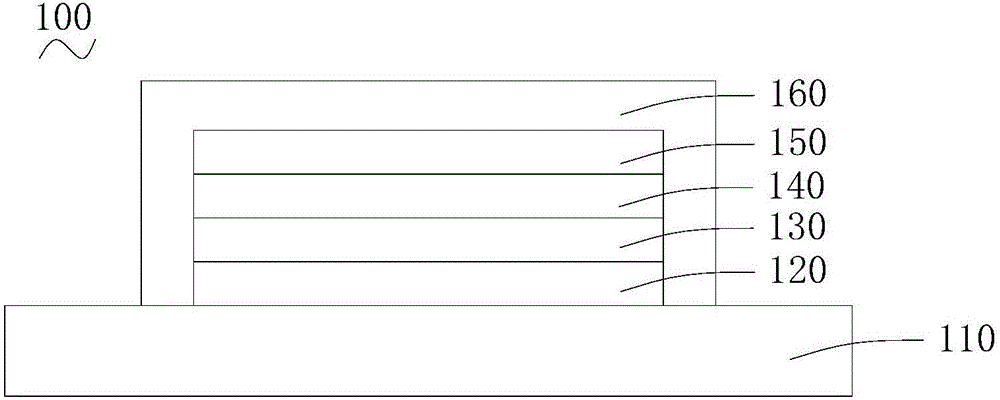

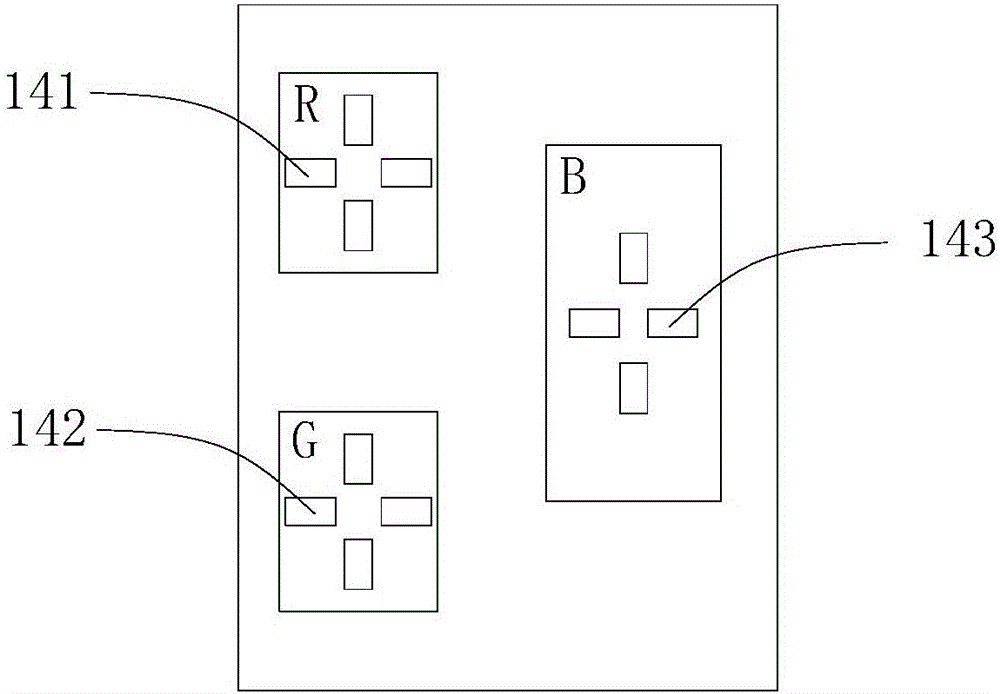

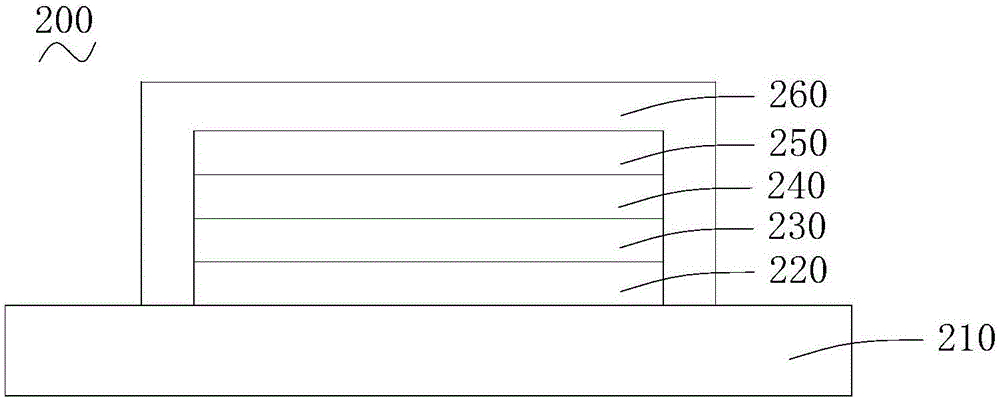

Display and preparation method thereof

ActiveCN106684260AUniform brightnessFacilitate transmissionSolid-state devicesSemiconductor/solid-state device manufacturingElectricityEvaporation

The present invention relates to a display and a preparation method thereof. The display comprises: a luminous element consisting of a plurality of subpixels; a first dielectric layer located at the emergent light sides of the subpixels; and a metal film structure located at one side, far away from the luminous element, of the first dielectric layer and correspondingly arranged with the subpixels, wherein the metal film structure can enhance the transmission of the light of the center wavelengths of the subpixels of the corresponding positions. The surface, close to the first dielectric layer, of the metal film structure of the display can generate metal surface plasmon polariton, when the wavelength of the emergent light is subjected to deviation caused by the evaporation deviation of the display, the size of the metal film structure is regulated to enhance the transmission of the light of the center wavelengths of the subpixels of the corresponding positions and weaken the transmission of the light of deviating the center wavelength range through adoption of the metal local area surface plasmon polariton filter effect and the light enhancement effect so as to reach the effect of relieving variegation Mura or edge Mura and allow the brightness of the display to keep uniform.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

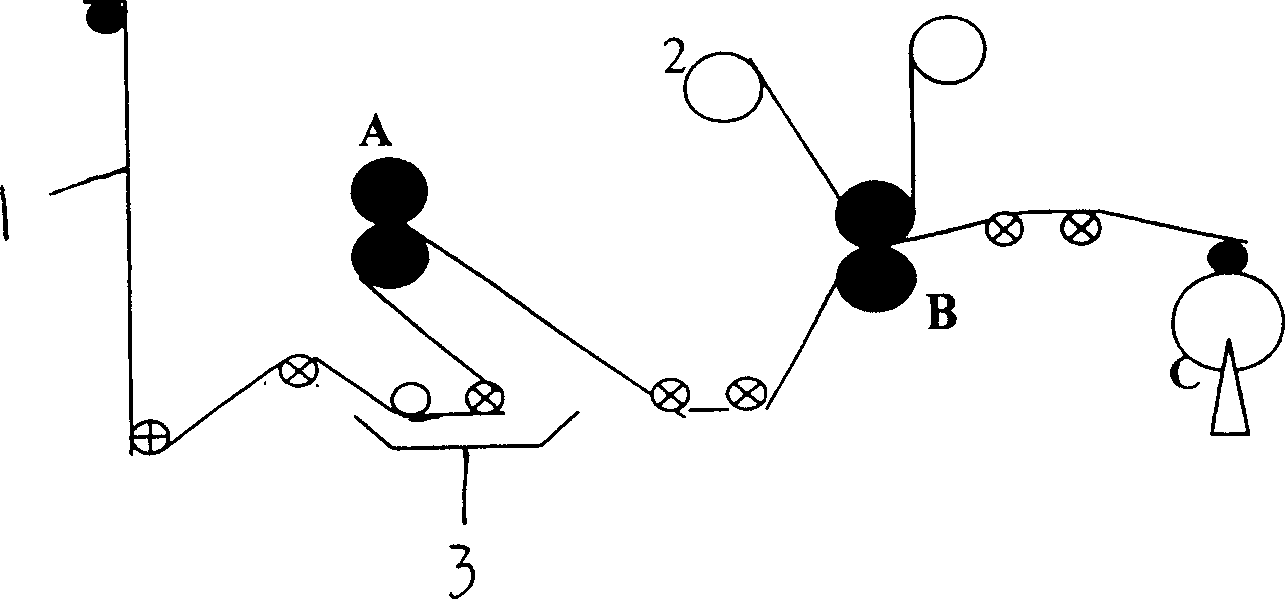

Fur illumination radiation bleaching device

InactiveCN1298921CMeet production needsEasy and flexible operationPhysical treatmentBleaching apparatusEngineeringTransfer mechanism

Fur illumination radiation bleaching device comprises frame and integrated case body and case cap fixed to the frame, engaged application roller and brush roller with the outer coated felt jacket on the frame at one side of the case body, in which the application roller connects to the electromotor. The lower terminal of the application roller sets a discharging agent groove. At the upper terminal of the case body sets an illuminating device. The invention sets a case with the illuminating device on the frame, delivers the fur to the brush roller for variegation through transfer mechanism and processes discharging by illuminating device. The invention changes the light source at any time, regulates the discharging chamber temperature, discharging time and the distance between the light source and fur according to different fur species and the discharging white content requirement.

Owner:SHAANXI UNIV OF SCI & TECH

Ultra-dispersed composite stabilizer for polychloroethylene and preparation thereof

InactiveCN101302322BAvoid Agglomeration and PrecipitationGood dispersionDispersityPolyethylene glycol

The invention relates to polyvinyl chloride ultra-dispersed composite stabilizer. The compositions by weight portion of the polyvinyl chloride ultra-dispersed composite stabilizer are: 10 to 20 portions of tribasic lead sulphate, 10 to 15 portions of dibasic lead phosphite, 2 to 4 portions of massicot, 0 to 5 portions of barium stearate, 0 to 4 portions of direactive glyceride, 0 to 4 portions ofpolyethylene wax, 30 to 40 portions of stearic acid, 1 to 1.5 portions of ultra-dispersed agent and 15 to 25 portions of light calcium carbonate, wherein, the ultra-dispersed agent is copolymers of maleic anhydride-sodium allylsulfonate-acrylate polyethylene glycol monoester. The composite stabilizer prepared can greatly improve the dispersity and the compatibility of the stabilizer and avoid variegation of the stabilizer during the process of processing sectional materials. Utilization of the ultra-dispersed agent also can improve the dispersity and the compatibility of PVC substrates and pigment. The polyvinyl chloride ultra-dispersed composite stabilizer has the advantages of superior performance, low toxity, high efficiency and multiple functions, namely the stabilizer simultaneously has the functions of improvement of the processability, plasticization, easy variegation, lubrication and so on. The method has no pollution and low energy consumption.

Owner:慧科高新科技股份有限公司

Method for roasting high-temperature drought premature tobacco leaves

Owner:LUZHOU CO LTD SICHUAN TOBACCO

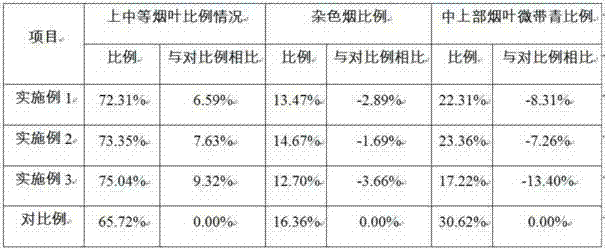

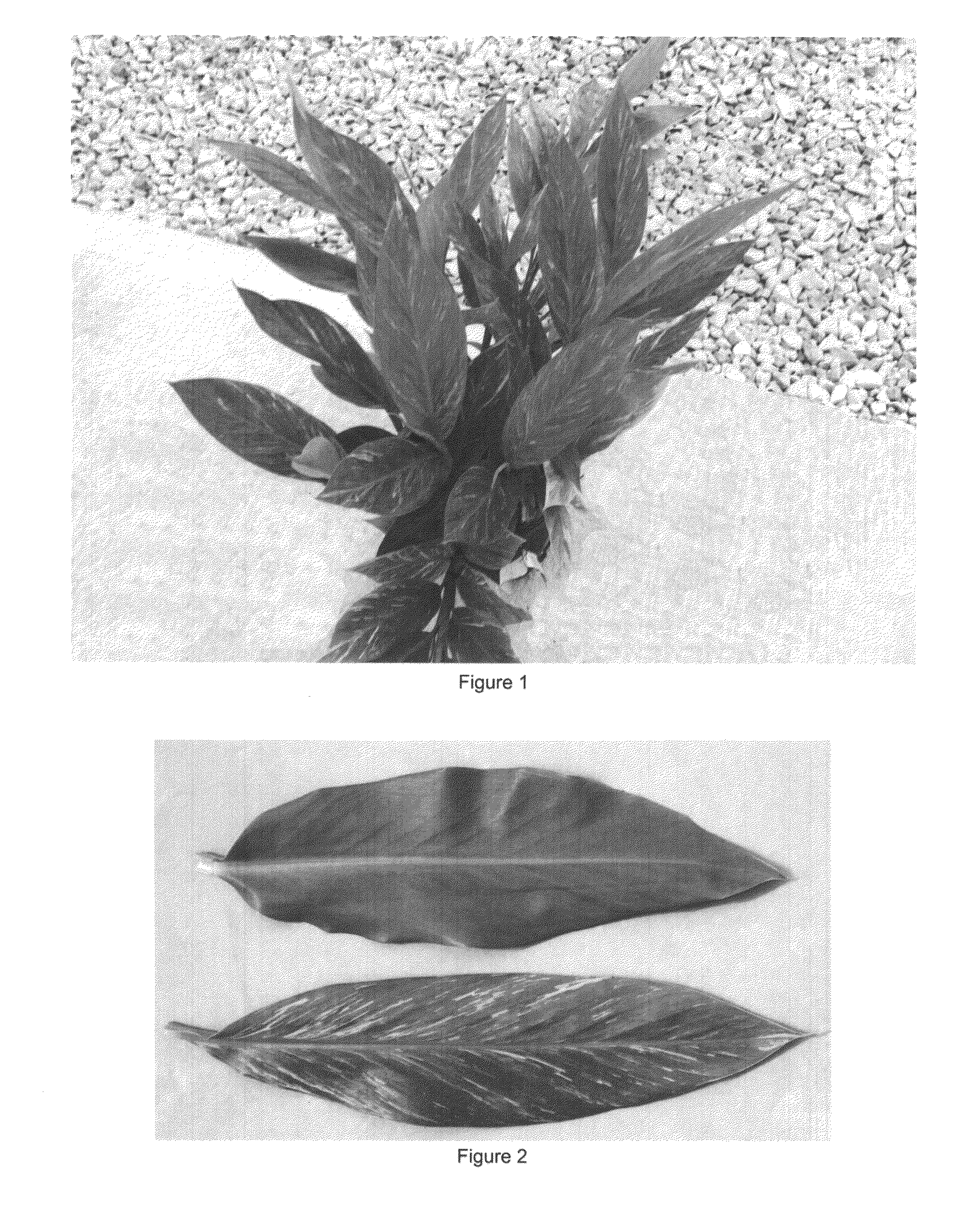

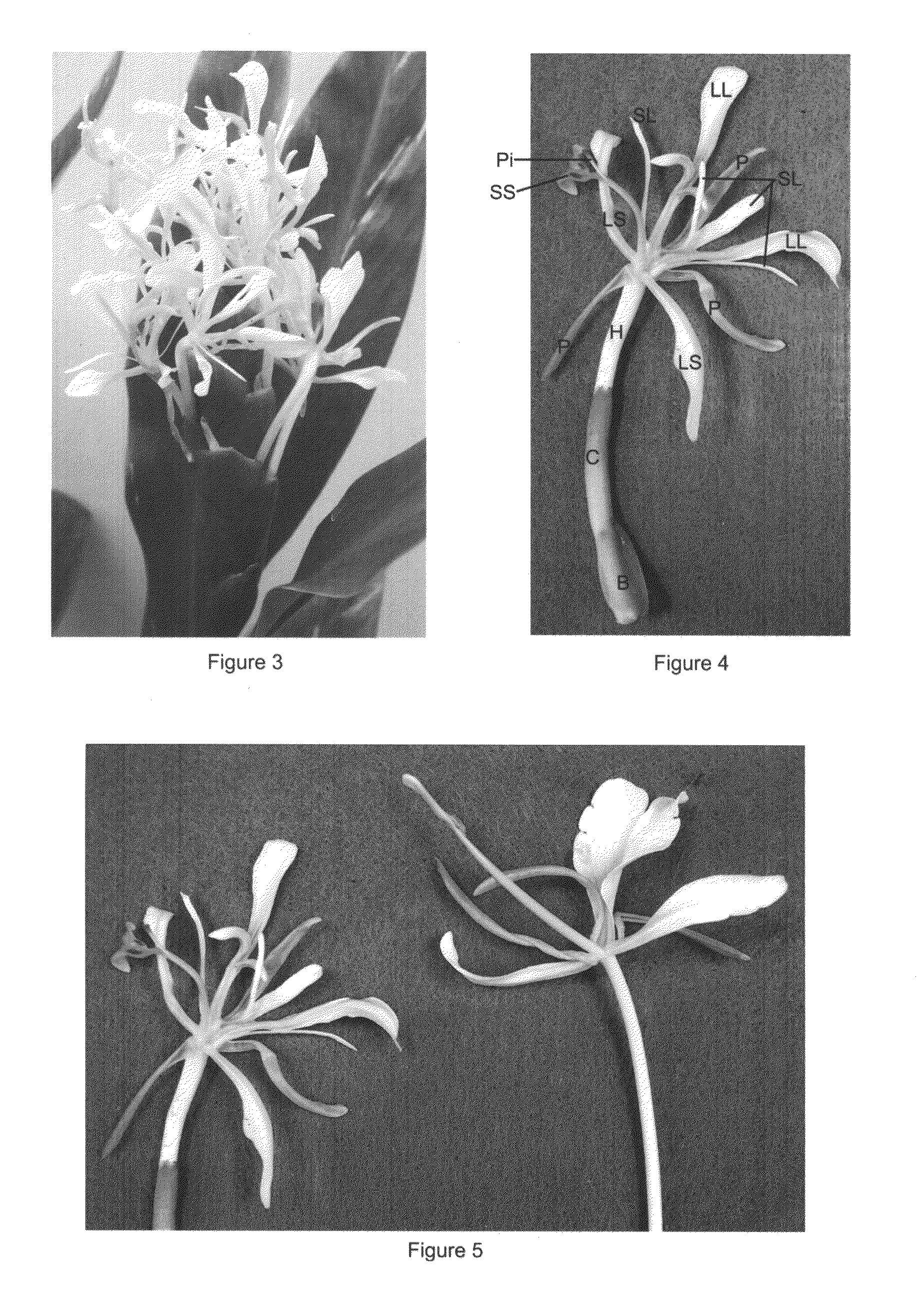

Hedychium plant named Ramata

A new and distinct cultivar of Hedychium plant named ‘Ramata’, characterized by a compact, broad rounded appearance, unique leaf variegation which is uniformly distributed and stable, and mildly fragrant staminate flowers. ‘Ramata’ is the onlyHedychium cultivar that combines both dwarfism and leaf variegation.

Owner:UNITED STATES OF AMERICA

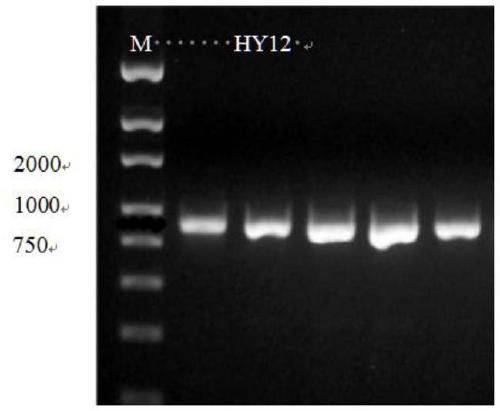

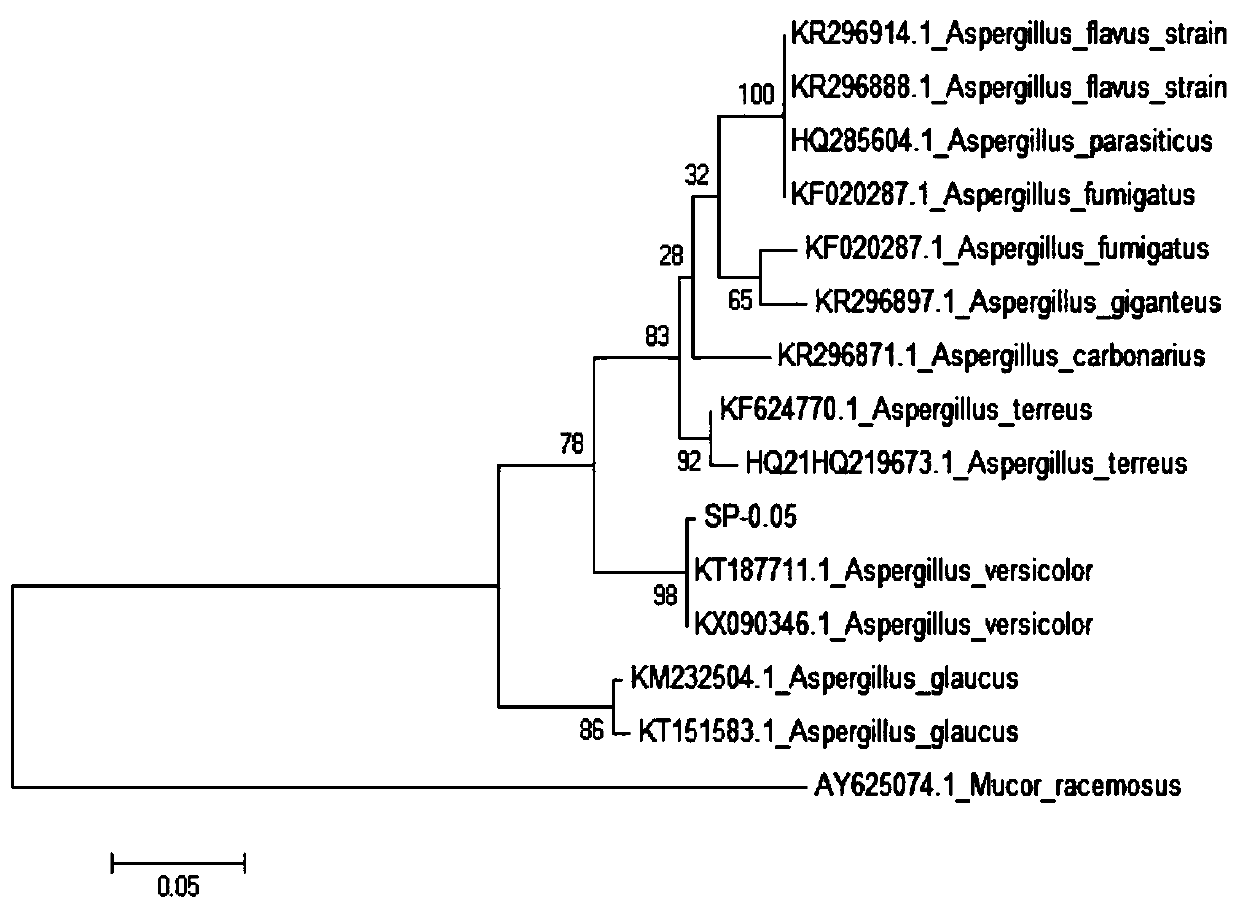

A strain of Aspergillus versicolor hy12

ActiveCN109628325BHigh fatality rateFast growth and reproductionFungiMicroorganism based processesSporeVermin

The invention provides a strain of Aspergillus versicolor HY12, the colony of Aspergillus versicolor HY12 is round, dense and soft in texture, mycelium is in the shape of white cotton wool, and can produce a large number of conidia. The wheel pattern is raised. The invention provides a strain of Aspergillus versicolor HY12, which has extremely high growth and reproduction speed in a short period of time, can produce a large number of conidia, can infect Spodoptera litura, and has a relatively high lethality and teratogenicity to Spodoptera litura The rate will lay the experimental foundation for the control of Spodoptera litura in the later stage, and provide a favorable reference for the control of other pests in this field.

Owner:HUNAN AGRICULTURAL UNIV

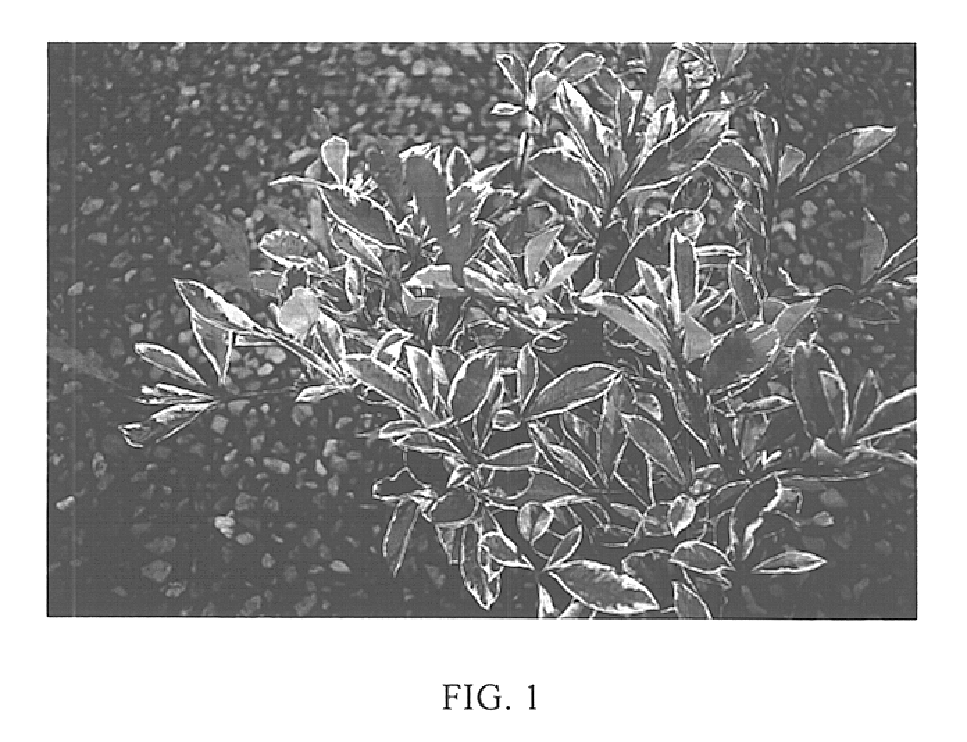

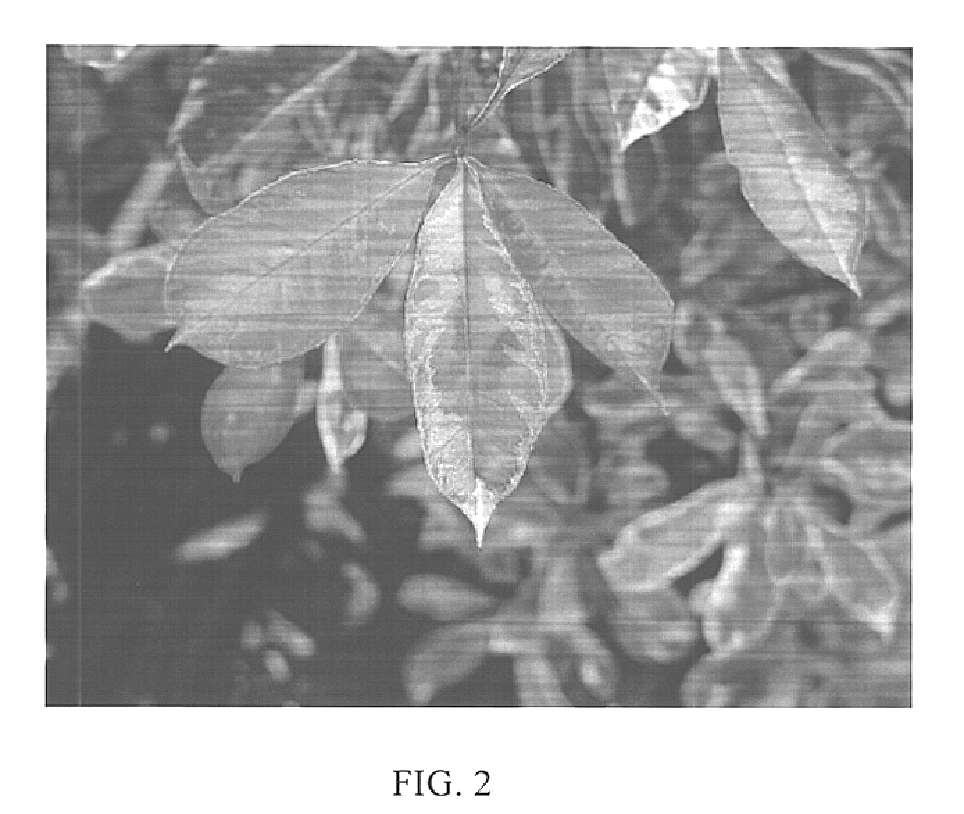

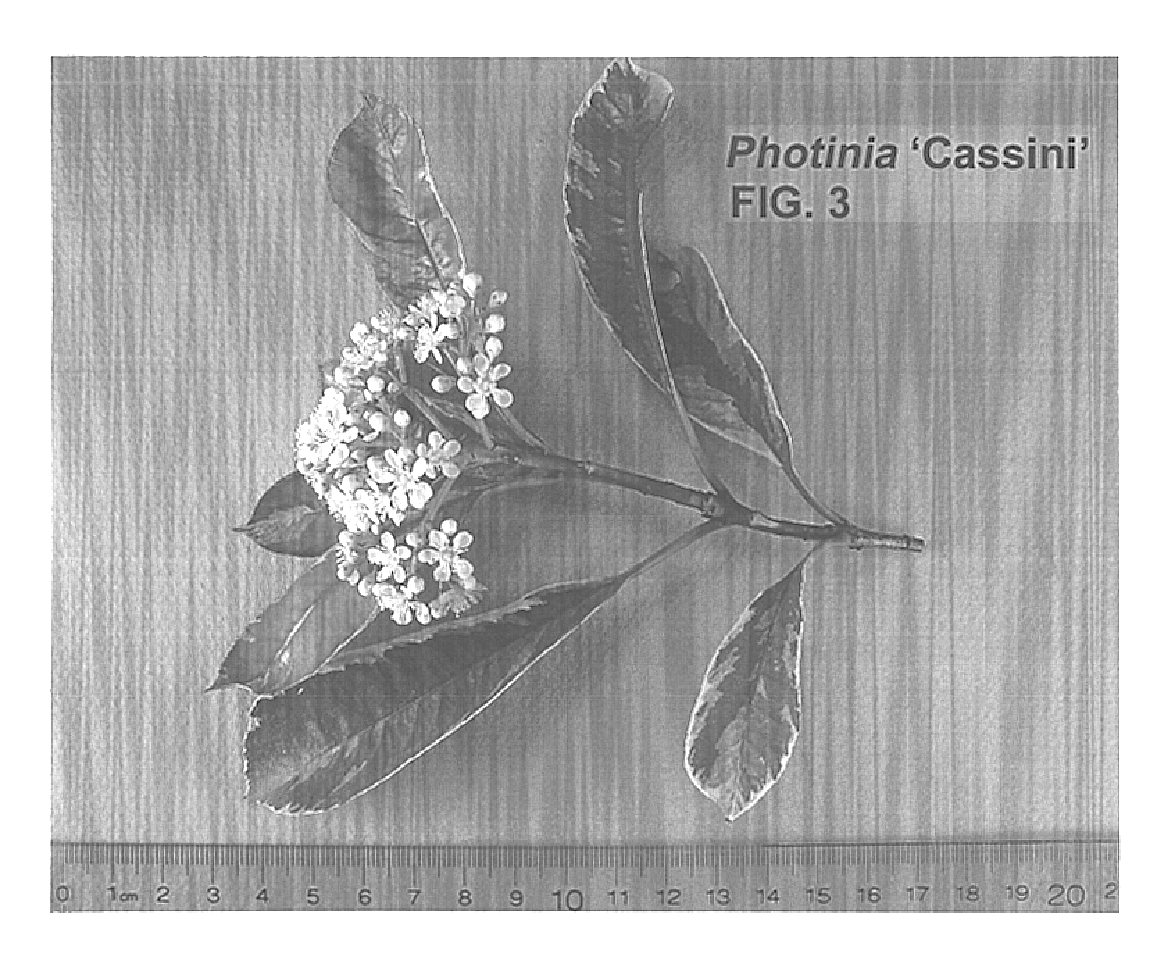

Photinia plant named `Cassini`

A new and distinct highly ornamental variety of Photinia.times.fraseri plant is provided. An upright outwardly-spreading shrub is described that has a more compact growth habit as the plant ages than commonly is displayed by Photinia.times.fraseri. Attractive variegated foliage is displayed. Initially the foliage is reddish with pink margins that changes to green with pink margins. Finally the leaf margins mature to near white with near white and silver splashes over the green medial upper surfaces of the leaves. The new variety propagates well by the use of stem cuttings and grows well in U.S.D.A. Hardiness Zone Nos. 6(b) to 10. The plant is well suited for growing as an ornamental specimen or in the form of a distinctive hedge. Also, the unusual color foliage can be used to advantage as a part of flower arrangements.

Owner:CONARD PYLE

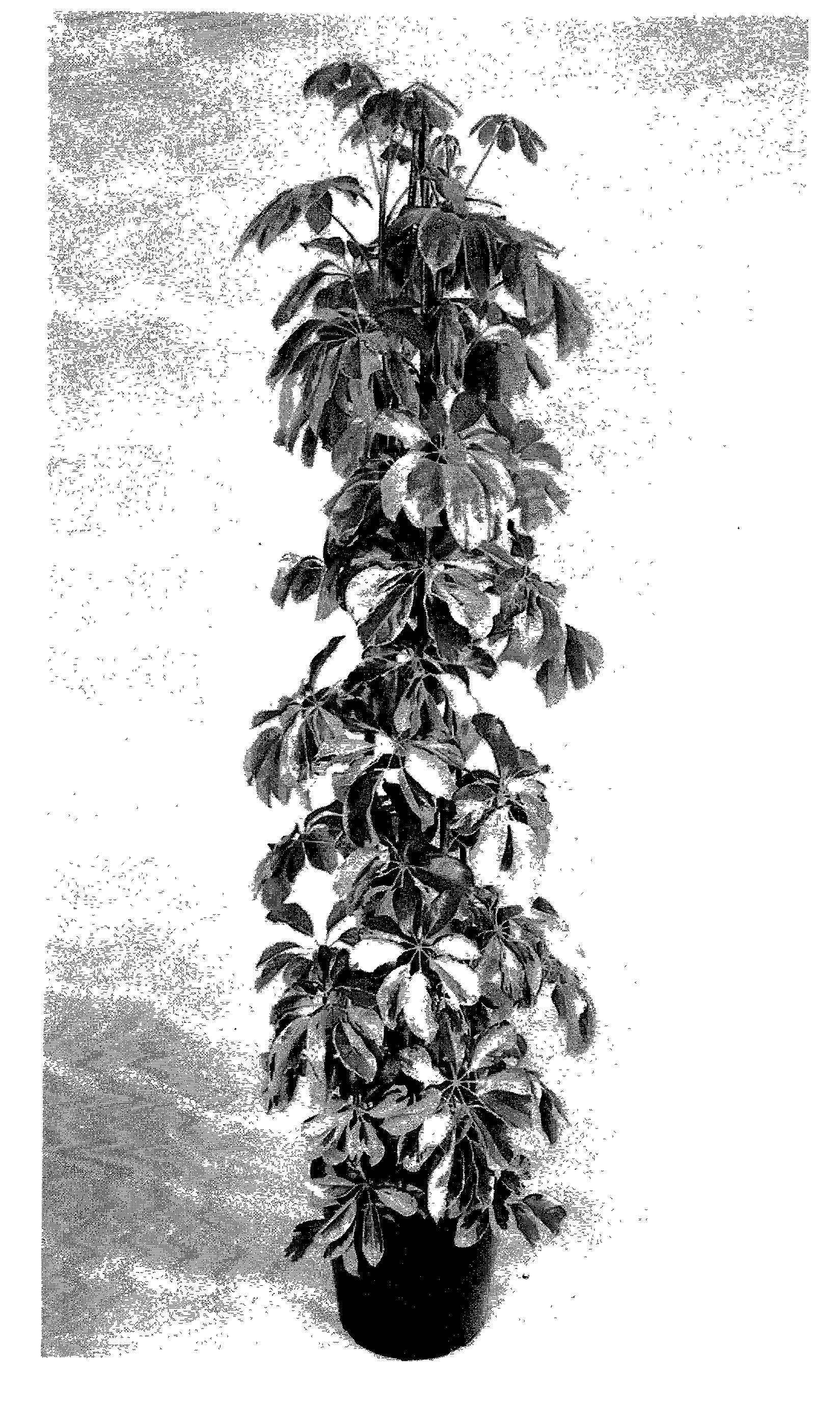

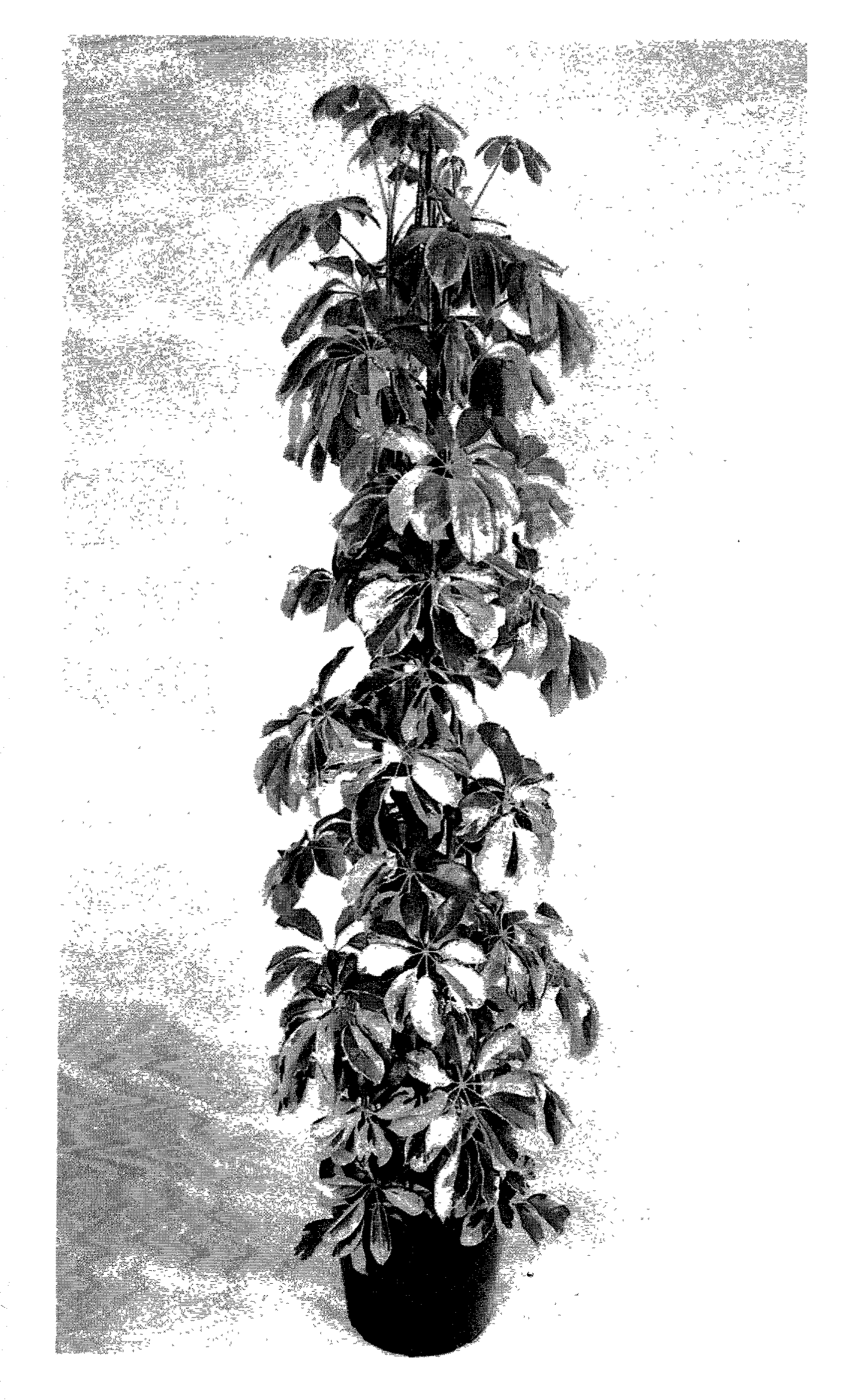

Schefflera plant named ' Dazzle'

A new and distinct cultivar of Schefflera arboricola named `Dazzle` as shown and described, and particularly characterized by the uniqueness of combined characteristics of heavily variegated foliage, large oblanceolate-shaped leaves with a cuspidate tip approximately 15-20 centimeters in length.

Owner:MIAMI AGRA STARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com