Inner spray method and device for medical packing aluminum tube

A technology of internal spraying and aluminum tubes, which is applied in the field of transportation and operation, can solve the problems of coating thread, internal coating mottle, drooling, etc., and achieve the effect of uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

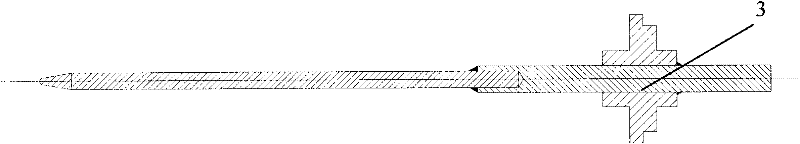

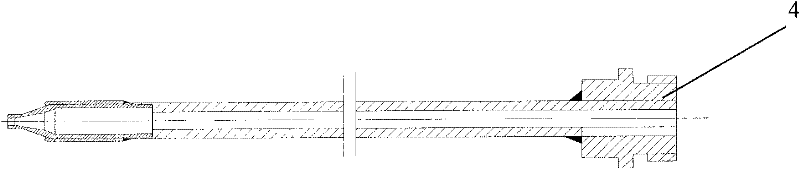

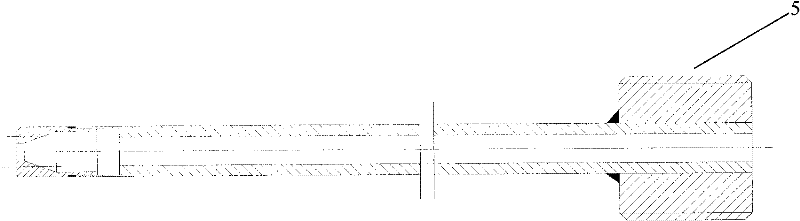

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 As shown, the internal spraying method of the pharmaceutical packaging aluminum tube 9 of the present invention includes a process of coating the inner surface of the pharmaceutical packaging aluminum tube 9, wherein the coating is applied to the pharmaceutical packaging aluminum tube 9 includes a process of coating the inner surface of the thin top of the pharmaceutical packaging aluminum tube 9 and a process of coating the inner surface of the tube body of the pharmaceutical packaging aluminum tube 9. In the process of coating the paint on the inner side of the thin top of the medicinal packaging aluminum tube 9, a thin top spray gun 1 is inserted into the medicinal packaging aluminum tube 9 from the tail opening of the medicinal packaging aluminum tube 9, and the thin top spray gun When the front end of 1 is located in the plane of the junction betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com