Patents

Literature

227results about How to "Good color fixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transferring printing process for natural fabric

InactiveCN1584196AGood coloring and color fixing performanceGood colorTransfer printing processNatural fiberSolubility

The technology of transfering printing for natural fabric, involves the follow working procedure: first, coat the surface of the web; secondly, printing on the surface of the web, finally, marinate the crude fabric to make the dye dissociate out of the paper and transfer to infiltrate crude fabric. Variegation and fastness ability of the natural fabric is great due to using water-solubility active dye and every firm target is advanced by 1-1.5 level. In short, this working procedure can make the images clearer and various transition.

Owner:WUJIANG LINGZHI TEXTILE

Method for tobacco slice cigarette paper coloring by adopting Millard reaction

Disclosed is a method for tobacco slice cigarette paper coloring with Millard reaction. The method comprises the following steps: (1) tobacco patches or stems are put into hot water with temperatures from 40 degrees to 70 degrees and extracted for 20 minutes-40 minutes, and extract liquor is obtained. (2) The extracted tobacco patches or the stems are put into the hot water with 1 to 3 times total weight of the tobacco patches or the stems after being shoved initially by a shoving machine. The temperature of the hot water is controlled at 45 DEG C + / - 5 DEG C. The tobacco patches or the stems are extracted for 20 minutes. The tobacco patches or the stems are pulped from 25 degrees SR to 40 degrees SR by the pulping machine after the tobacco patches or the stems are shoved, thus tobacco syrup is obtained. (3) Additional fibers are pulped by the pulping machine to 40 degrees SR to 75 degrees SR. Cigarette paper is mixtured by mixturing the additional fibers and the tobacco syrup. (4) Extracted liquors are concentrated after the extracted liquors are combined. Sylvite, compound Millard reaction liquid and spices are added to the concentrated extracted liquors and made into coating liquid. The coating liquid is coated on the cigarette paper with the way of coating. (5) The coated cigarette paper is put under temperature condition of from 70 DEG C to 130 DEG C to conduct the Millard reaction.

Owner:HUBEI XINYE TOBACCO SLICE DEV +1

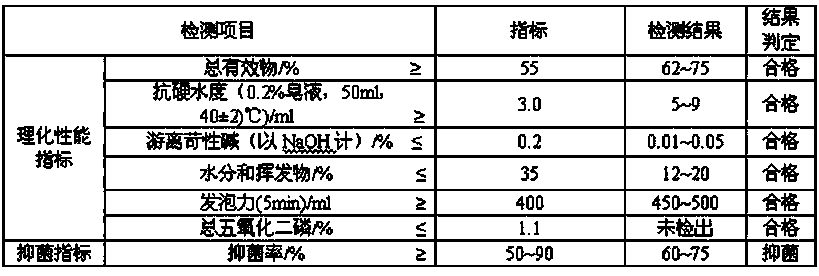

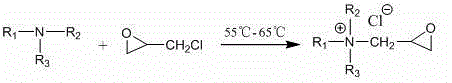

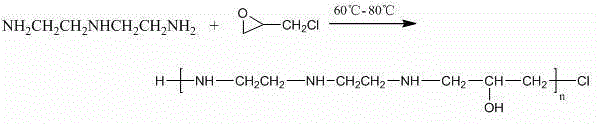

Manufacturing technology of formaldehydeless colour fixing agent

A color fixating agent without formaldehyde is prepared from diethylenetriamine (AE) and epoxy chloropropane (EP) through adding water and AE to reactor, stirring, dropping EP at temp lower than 50 deg.C, heating to 55-65 deg.C, holding the temp for 0.5-2 hr, heating to 75-90 deg.C, holding the temp for 20-40 min while reacting, measuring viscosity and cooling.

Owner:JINSHENG FINE CHEM SANSHUI CITY

Cotton fibre and blended fabric printing and dyeing method

The invention relates to the dye printing technology of cotton fiber and blend fabric, in particular to a dye printing processing method of cotton fiber and blend fabric. A double blade coating machine is adopted, the dyeing and the printing are simultaneously realized on one machine; invention comprises the following steps: firstly, the pad dyeing is performed to the textile in colored or colorless padding dye liquor, the padding liquor comprises the following components according to the weight percentage: penetrating agent organosilicon fluroxene poly occupies 0 to 2 percent, branched chain aliphatic condensed alcohol ethylene oxide occupies 1 to 2 percent, softening agent organosilicon occupies 0 to 2 percent, modified 2D resin occupies 0 to 8 percent, water is quantified to 100 percent; secondly, the single side dyeing and drying of the textile is performed through a first blade, thirdly, color pastes which have more than two colors and can not be mixed and dissolved are scraped to the textile and the textile is dried. The invention cause two styles of synthesis dyeing and printing of textile can be completed on single coating equipment, the process is simple, and no waste water is discharged.

Owner:DANDONG UNIK TEXTILE

Composite hydrosol color fixing finishing agent, synthesizing method and use thereof

InactiveCN1546781AReduce pollutionReduce washing waste waterFibre treatmentDyeing processFiberPolymer science

The invention refers to a kind of compound lyosol fixing arrangement agent, a synthesizing method and the usage. The arrangement agent is made up of following products: (1) the silicon sol is made up of gamma-glycidol ether oxygen propyl trimethoxy-silane, water and hydrochloric acid, whose mol proportion is: 1:5-100:1í‡10 -5-1í‡10 -1; (2) the titanium sol is made up of titanic acid butyl ester, water and hydrochloric acid whose proportion is 1:0.1-10:10-200: 1í‡10 -4-1í‡10 -1; (3) the product is produced by mixing above mentioned silicon sol and titanium sol, the mol proportion of silicon and titanium is 1:0.05-1.0. The arrangement agent may form a mesh particle film on the surface of the fiber, realizes the color fixing aim.

Owner:DONGHUA UNIV

Biodegradable film packaging material and preparation method thereof

InactiveCN104119654AGood film surface tensionPromote degradationFlexible coversWrappersImidePolymer science

The invention discloses a biodegradable film packaging material and a preparation method thereof. The biodegradable film packaging material is prepared from the following components in parts by weight: 45-66 parts of polylactic acid, 20-30 parts of starch, 10-18 parts of polyvinyl alcohol, 8-10 parts of lignin, 0.5-2 parts of sodium humate, 0.5-1 part of poly(ethylene imine) and 4-6 parts of glutaraldehyde. The biodegradable film packaging material prepared by using the method disclosed by the invention is favorable in crystallinity, mechanical strength and elongation at break, free of special treatment on the surface, good in film surface tension and capable of favorably bonding ink and the film packaging material.

Owner:江苏古沙农业科技发展有限公司

Textile printing and dyeing pigment color fixing agent and preparation method thereof

InactiveCN103343464AGood color fixing effectShade effect is smallDyeing processTextile printerEngineering

The invention relates to a textile printing and dyeing pigment color fixing agent and a preparation method thereof. The textile printing and dyeing pigment color fixing agent mainly comprises acrylic ester, epichlorohydrin, organic siloxane, 2.2-azodi(2-methopropoxy acid)polyvinyl polypyrrolidone, dicyandiamide and deionized. The textile printing and dyeing pigment color fixing agent has a good color fixing effect on textiles which are dyed by pigments and small influences on textile colored lights, free formaldehyde is not generated in a synthetic process, and the textile printing and dyeing pigment color fixing agent belongs to an environment-friendly color fixing agent.

Owner:ZHANGJIAGANG DONGFANG SPECIAL DYEING

Sol-gel color fixing method

The present invention belongs to the field of chemical technology and is a kind of sol-gel color fixing method. Reagent capable of producing chemical combination with fabric fiber is selected as material for sol finishing liquid to finish fabric at 100-180 deg.C. Thn and transparent complicated network film is formed on the inner and outer surface of fiber to fix the dye on the fabric and to raise the color fastness of fabric.

Owner:DONGHUA UNIV

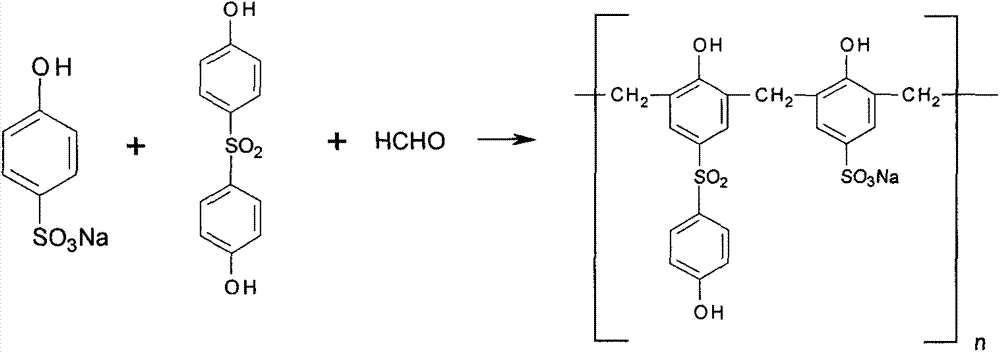

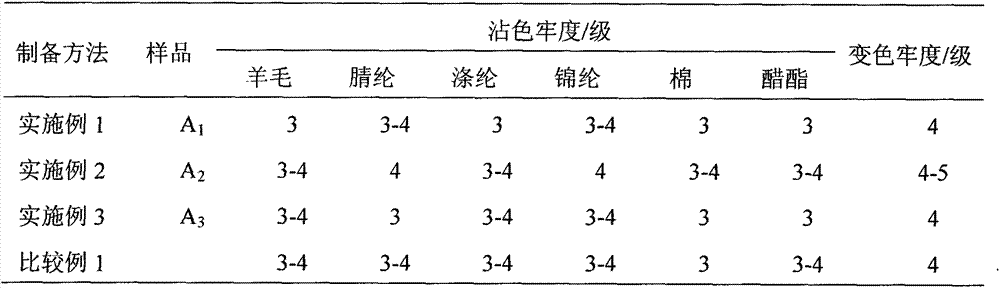

Acidic dye-fixing agent and preparation method thereof

InactiveCN104513349AGood color fixing effectSimple preparation processDyeing processSODIUM PHENOLSULFONATEBisphenol S

The invention relates to an acidic dye-fixing agent and a preparation method thereof. The dye-fixing agent is a condensation product prepared through the condensation polymerization reactions among bisphenol S, sodium phenolsulfonate, and formaldehyde in the presence of a catalyst. The obtained acidic dye-fixing agent has the advantages of good dye-fixing effect, simple preparation technology, easily-available raw materials, and low cost.

Owner:WUYI UNIV

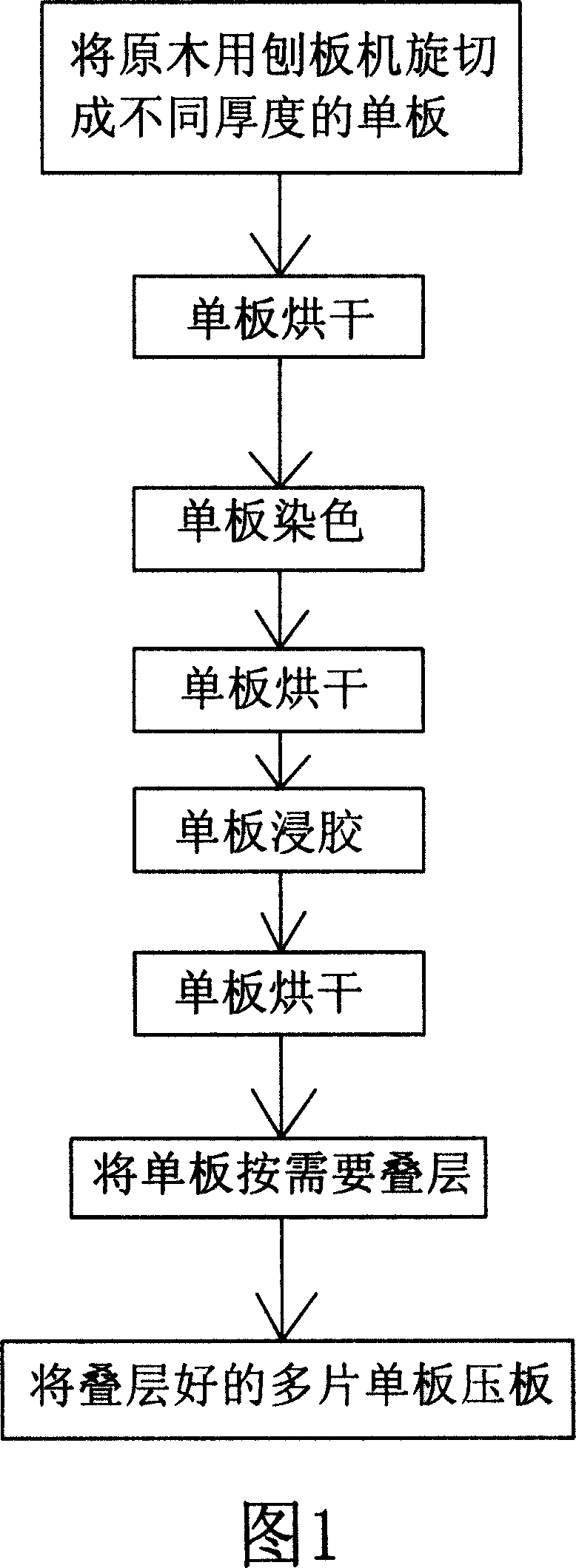

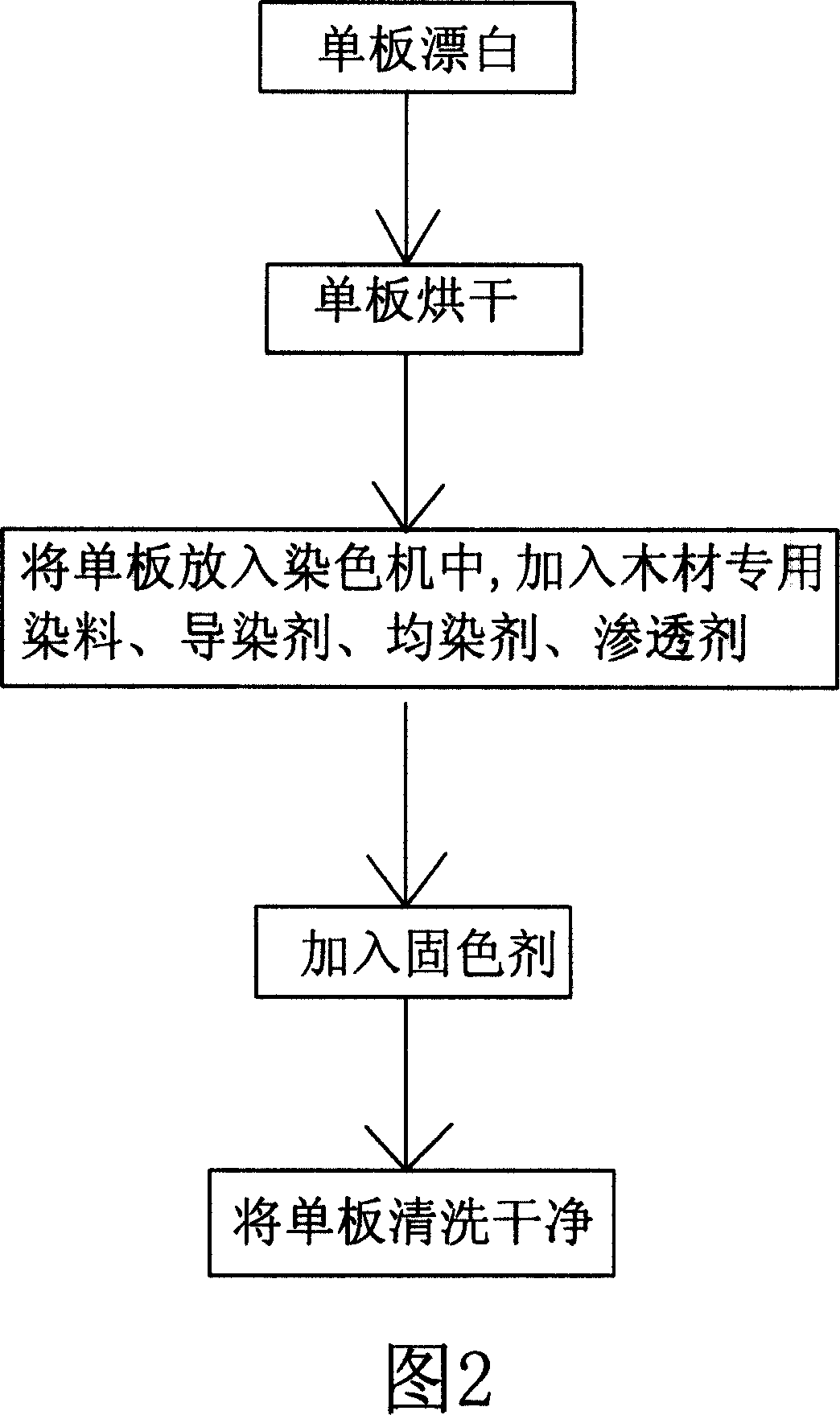

Process of producing color laminated board

InactiveCN101020322AGood color fixing effectColorfulDrying solid materials with heatWood treatment detailsWood machiningHigh color

The present invention belongs to the field of timber production technology, and is especially process of producing color laminated board with high color fastness, flowery color and environment friendship. The production process includes the following steps: peeling log into sheet in required thickness, stoving sheet, dyeing, stoving, soaking glue, stoving, laminating, and pressing the laminated sheets into color laminated board.

Owner:冯中清

Jean fabric color fixing agent

InactiveCN103556510AGood color fixing effectMeet environmental protection requirementsDyeing processChemistrySiloxane

The invention discloses a jean fabric color fixing agent, which is prepared from the following raw materials in parts by weight: 10-20 parts of a high efficiency penetrating agent, 5-10 parts of octadecyl dimethyl amine, 10-15 parts of epoxy chloropropane, 8-10 parts of organic siloxane, 5-8 parts of triethylene tetramine, 100-200 parts of distilled water and 4-6 parts of an emulsifier. The jean fabric color fixing agent is good in color fixing performance and color fixing effect, and meets the environmental protection requirement.

Owner:谢化业

Method for producing formeldehyde-free colour fixing agent

The present invention relates to a preparation method of formaldehyde-free dye-fixing agent. Said method includes the following steps: (1), adding (by weight portion) 40-50 portions of ethyl acrylate, 1-2 portions of acrylic acid and 60-65 portions of sodium metabisulfite into a reaction still, stirring and uniformly mixing them, heating to 65 plus or minus 2 deg.C, heat-insulating and making reaction for 2 hr plus or minus 0.5 hr; (2), drop-adding 80-85 portions of di-ethylene triamine and controlling temperature below 70 deg.C; (3), adding proper quantity of water, after 10 min, drop-adding 70-75 portions of epichlorohydrin and controlling temperature below 70 deg.C so as to produce transparent or light yellow color, cooling; and (4), cooling to room temperature, adding concentrated hydrochloric acid to regulate pH value and make it be 6-7, regulating solid content so as to obtain the invented finished product.

Owner:华明扬

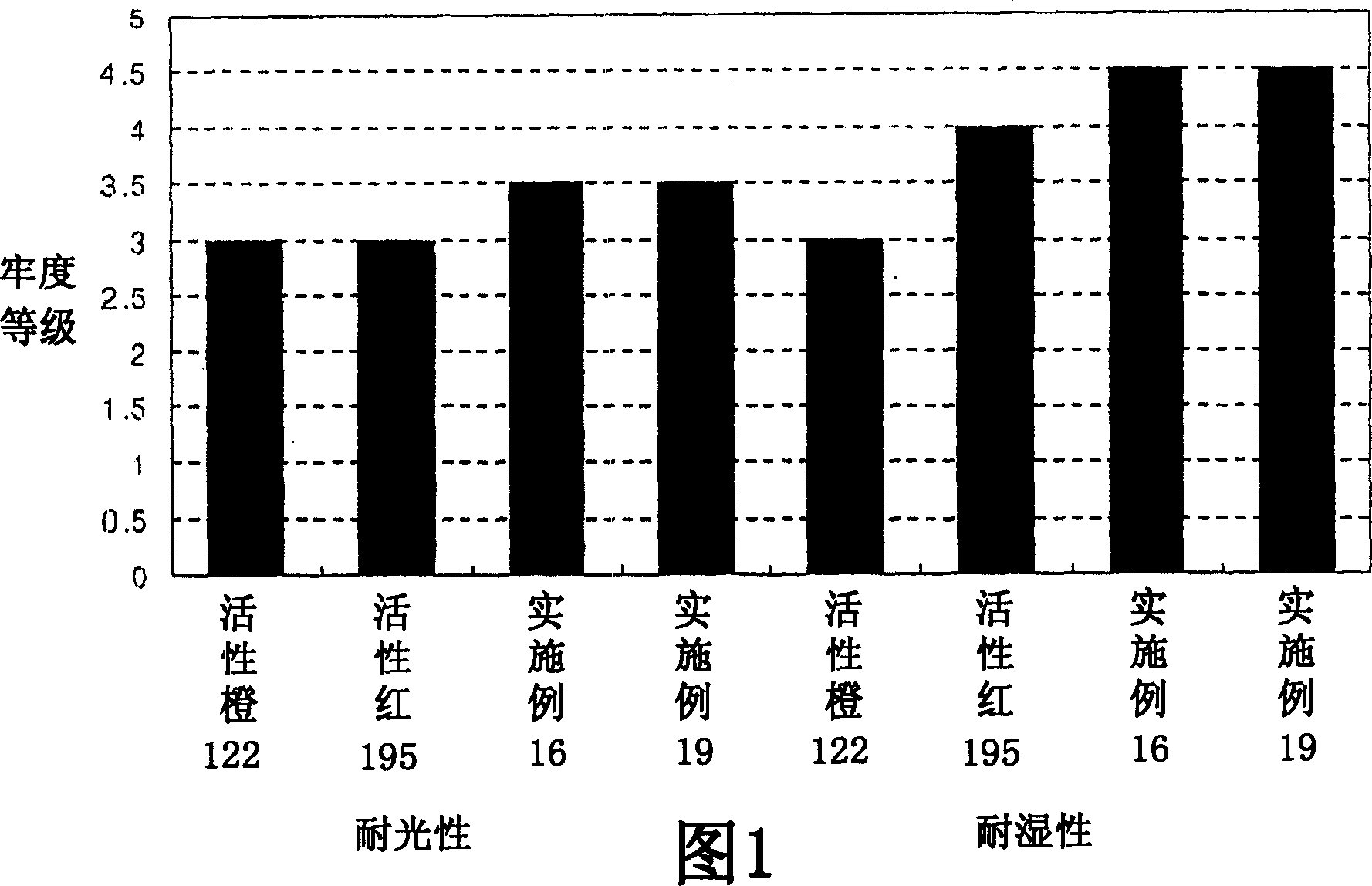

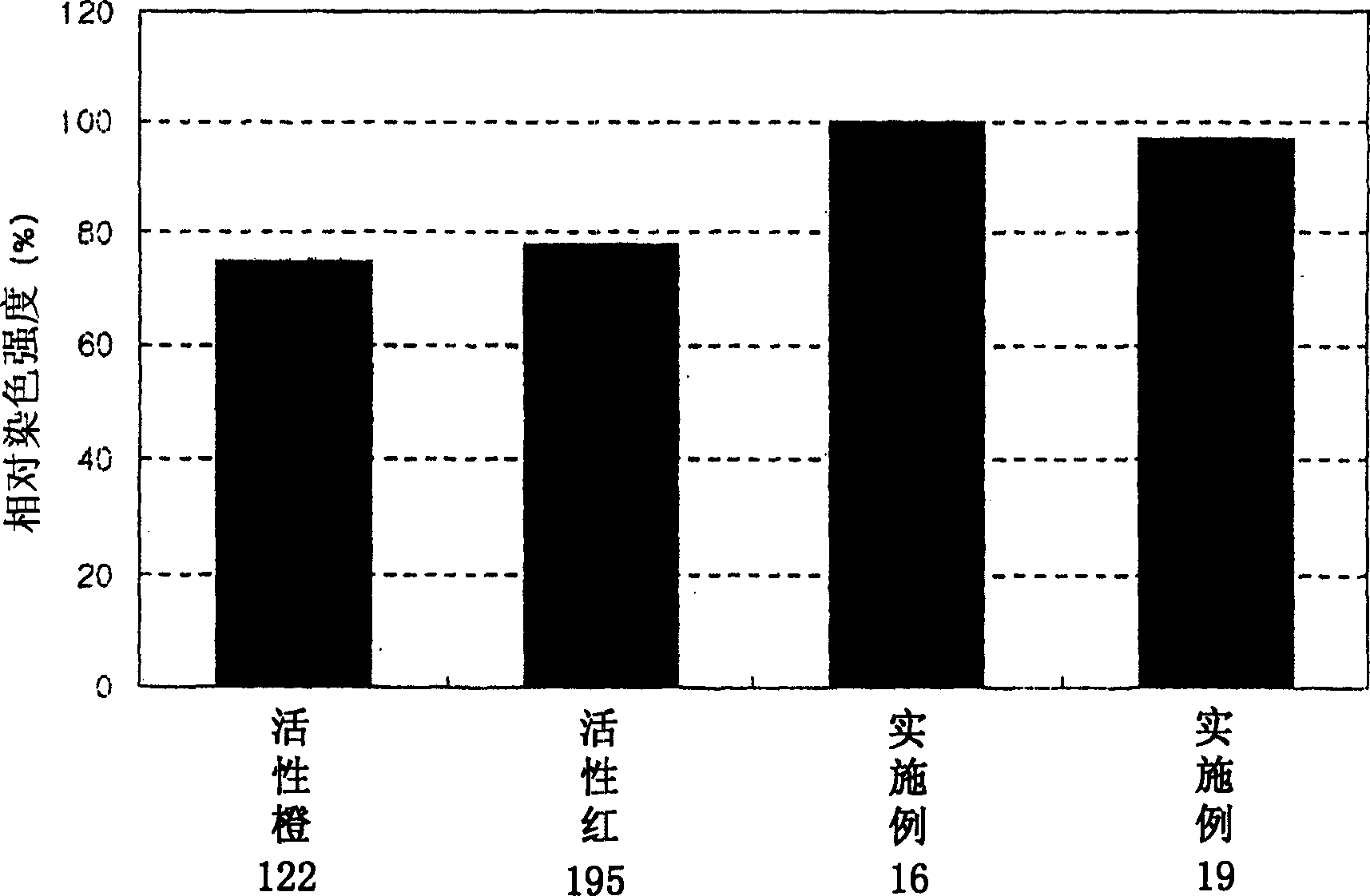

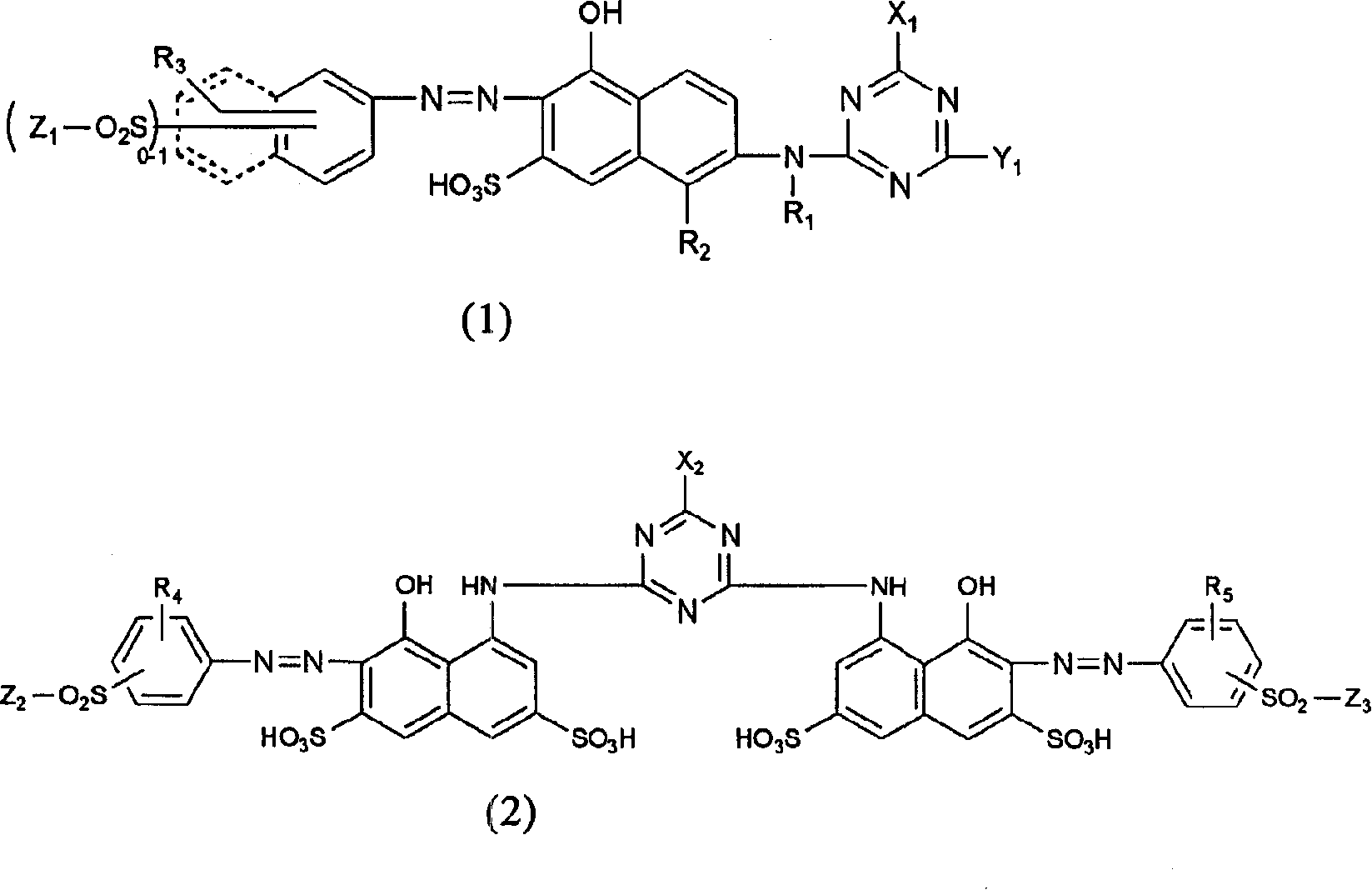

Mixture of fiber reactive dye compounds and dyeing method using the same

InactiveCN1810893AGood light fastnessIncrease lifting powerOrganic dyesDyeing processNitrogenCellulose fiber

Provided is a fiber-reactive dye mixture, comprising (i) one or more reactive dyes represented by Formula 1, and (ii) one or more reactive dyes represented by Formula 2: and a dyeing method using the same. The dye mixture of the present invention exhibits superior adsorptivity and fixability when dyeing a fiber material containing nitrogen or hydroxyl group, particularly a cellulose fiber material, and particularly very high light fastness and wet fastness, and thus provides a variety of balanced physical properties which are required in dyeing.

Owner:京仁洋行

Montan wax washing soap and preparation method thereof

InactiveCN103834512ALess irritatingImprove decontamination abilitySurface-active non-soap compounds and soap mixture detergentsHigh resistanceHard water

The invention discloses a montan wax washing soap and a preparation method thereof, belonging to the technical field of daily detergents. The montan wax washing soap is prepared scientifically from montan wax, high-grade grease, sodium hydrate, a compound surfactant, a lime soap dispersing agent, a sterilizing agent, compound enzyme, other aids and deionized water. A multifunctional novel washing soap is developed by partially or totally replacing the conventional soap base with saponated montan wax. Compared with an ordinary washing soap, the montan wax washing soap has the advantages of higher detergency, softer sense of touch, higher resistance to hard water, sterilizing and bacteria inhibiting functions, high color fixing capacity, easiness in biodegradation, excellent handfeel, simple preparation process and wide market prospect, and is suitable for industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Method for improving color fastness of photochromic fabric

InactiveCN103572621AFormaldehyde freeColor becomes smallerDyeing processColour fastnessTextile fiber

The invention relates to a method for improving the color fastness of a photochromic fabric. The method comprises the following steps: (1), at the room temperature, mixing tetraethoxysilane and glutamic-pyruvic transamine with ethyl alcohol, stirring until uniform mixing, then dripping hydrochloric acid drop by drop under stirring, and stirring unceasingly for 5 hours so as to obtain a finishing liquor; (2), at the room temperature, carrying out two times of soaking and two times of rolling to the photochromic fabric in the finishing liquor, then drying, and finally baking the photochromic fabric. The method provided by the invention has the advantages that the color fixing is convenient, the consumed time is short, the cost is low, pollutions to the environment are small, and the effect in improving the color fastness of the photochromic fabric is obvious; an agent capable of being in reaction with and combined with textile fiber is selected as a raw material to prepare a colloidal sol finishing liquor, when finishing is performed on the photochromic fabric, overhigh temperature is not required, not only can the effect of improving the color fastness of the photochromic fabric be improved, but also damage to fabrics can be prevented.

Owner:DONGHUA UNIV

Silk fibroin based antibacterial nano-fibers and preparation method thereof

InactiveCN108385182AHigh antibacterial effect and antibacterial rateImprove stabilityMonocomponent protein artificial filamentArtifical filament manufactureChemistryAntibacterial effect

The invention provides silk fibroin based antibacterial nano-fibers. The silk fibroin based antibacterial nano-fibers are prepared from the following components in parts by weight: 100 to 150 parts ofsilk fibroin, 4 to 8 parts of titanium dioxide, 20 to 30 parts of chitosan, 10 to 15 parts of nano copper oxide and 10 to 15 parts of polyethylene oxide. The invention further provides a preparationmethod of the silk fibroin based antibacterial nano-fibers; the silk fibroin based antibacterial nano-fibers, prepared by the preparation method, have good biocompatibility, anti-sticking performance,good antibacterial effect and excellent color fixing effect.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

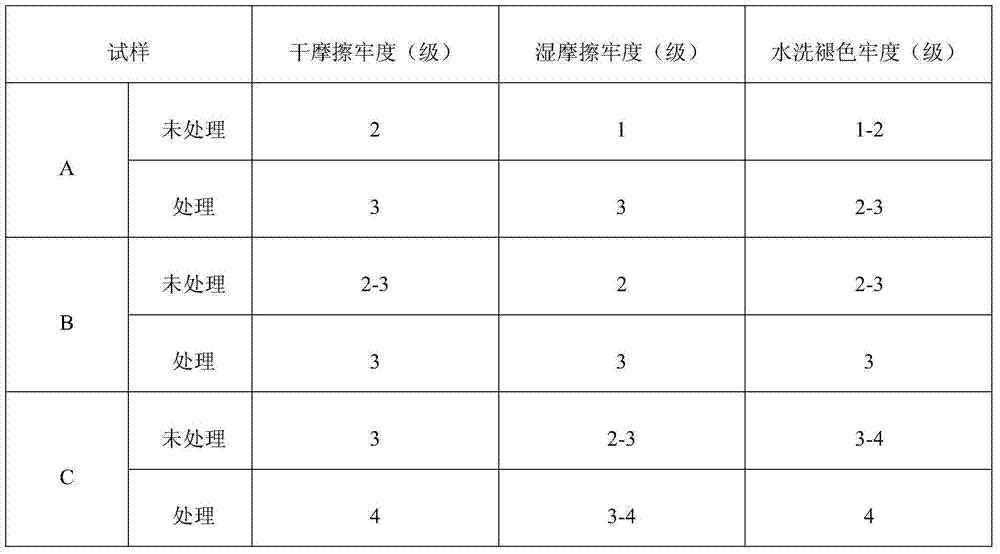

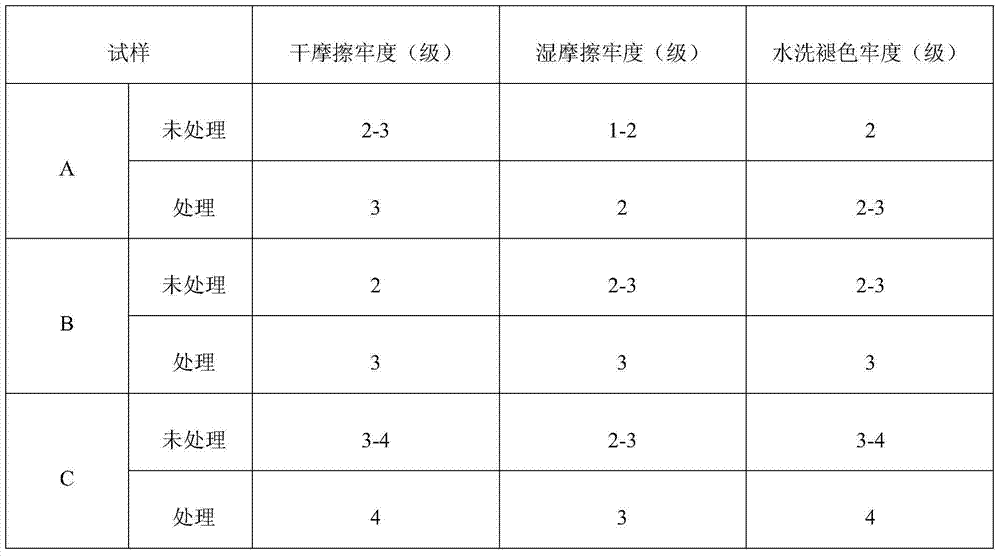

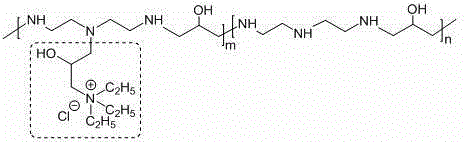

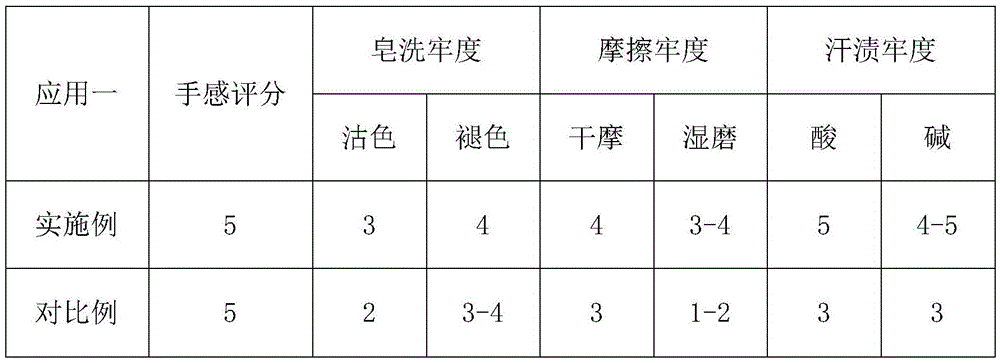

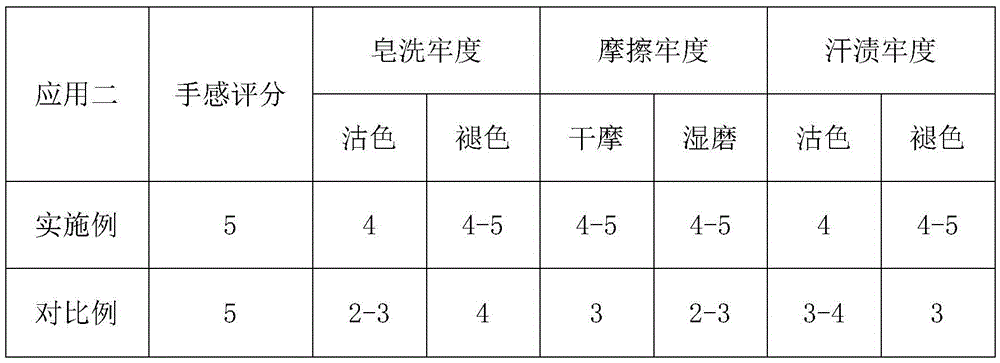

Polyquaternium cationic formaldehyde-free fixing agent and preparing method thereof

InactiveCN105155311AImproved color fastness to wet rubbing and color fastness to dry rubbingGood color fixing effectDyeing processMicrofiberColour fastness

The invention relates to a fixing agent and a preparing method thereof, in particular to a polyquaternium cationic formaldehyde-free fixing agent used for dyeing superfine fiber synthetic leather and a preparing method thereof. According to the fixing agent, quaternary ammonium branches are grafted on a molecular chain of a polymeric polyamine condensation compound to form a comb-shaped polymer in which quaternary ammonium and tertiary amine cations coexist. The fixing agent can effectively improve wet friction color fastness and dry-rubbing-resisting color fastness of the dyed superfine fiber synthetic leather and has a good fixing effect on the superfine fiber synthetic leather, and the preparation method of the fixing agent is simple and low in cost and has high industrial application value.

Owner:北京德成嘉化工科技有限责任公司

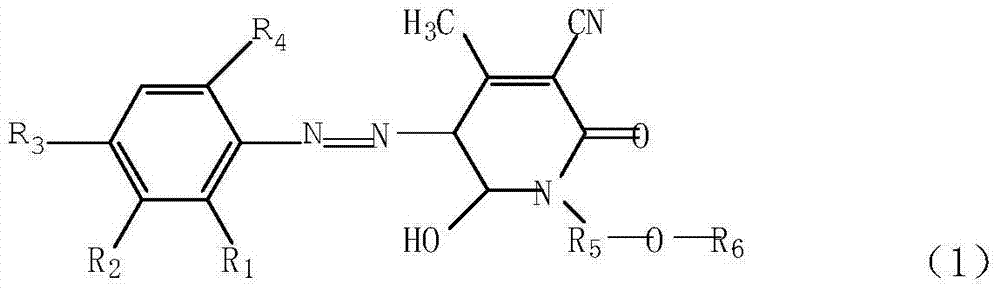

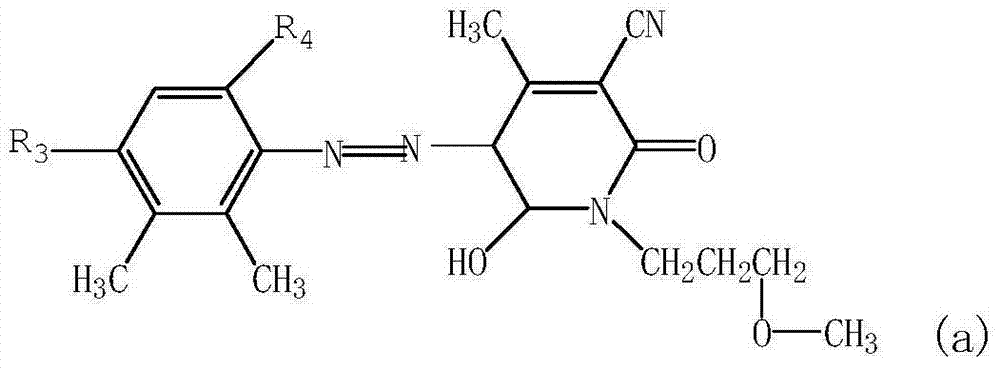

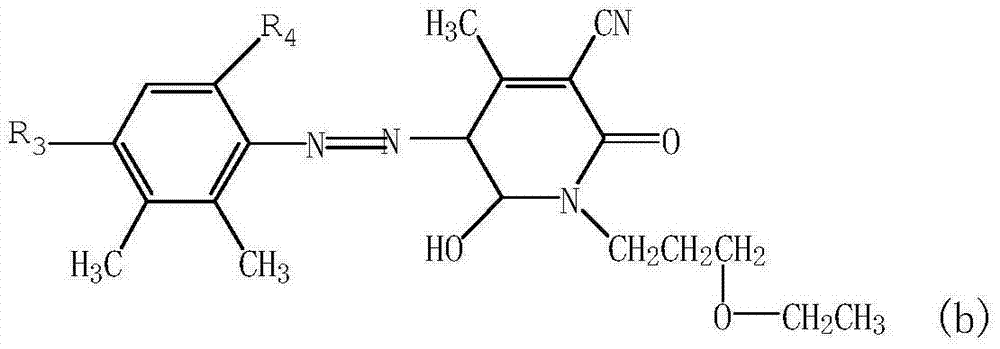

Mono-azo disperse dye compound and preparation method thereof

InactiveCN103881412AGreat suctionGood color fixing effectMonoazo dyesDyeing processDisperse dyeNitrite

The invention relates to a mono-azo disperse dye compound and a preparation method thereof. The mono-azo disperse dye compound is prepared by a method comprising the following steps: diazotizing an aniline compound in an acidic medium by use of nitrite or in a sulfuric acid medium by use of nitrosyl sulfuric acid and then coupling the diazotized aniline compound with a pyridine coupling component. The mono-azo disperse dye compound prepared by the method disclosed by the invention is used for dyeing of dacron / cotton fabrics and has a good application performance.

Owner:ZHEJIANG SHANYU TECH CO LTD

Synthesis method for cationic waterborne polyurethane acid dye fixing agent

InactiveCN105568723AImprove color fixationSimple methodDyeing processSynthesis methodsPolymer chemistry

The invention discloses a synthesis method for a cationic waterborne polyurethane acid dye fixing agent, and belongs to the technical field of textile chemicals. The cationic waterborne polyurethane acid dye fixing agent is obtained by polymerization by taking polyethylene glycol, polypropylene glycol, dimethyl diallyl ammonium chloride, N-methyldiethanolamine, sodium chloride and zinc sulfate as raw materials and manganese chloride as a catalyst. The synthesis method disclosed by the invention is simple, low in temperature and short in time, and is beneficial to industrial production and popularization; meanwhile, the fixing agent has an ideal fixing effect in fixing treatment on cotton fabric, real silk fabric and wool fabric after being dyed by acid dye, meanwhile, is capable of improving wear resistance and soil resistance of fabric, has less influence on brightness of dyed fabric, and has relatively high economic benefit and industrial popularization value.

Owner:SUZHOU INSILK CO LTD

Ultralow-twist velvet cotton fabric and weaving and dyeing process thereof

The invention discloses an ultralow-twist velvet cotton fabric. A weaving and dyeing process of the ultralow-twist velvet cotton fabric comprises performing compact and siro spinning on a yarn A composed of 50-100% of long-staple cotton and 0-50% of combed cotton, and a yarn B composed of 0-50% of long-staple cotton and 50-100% of combed cotton to obtain a pure cotton ultralow-twist yarn with a degree of twist of 0-30 twist per inch; weaving the pure cotton ultralow-twist yarn solely or with other yarns into ultralow-twist velvet cotton raw fabric; performing dyeing, aftertreatment, fixation,softening and shaping processes on the ultralow-twist velvet cotton raw fabric to obtain the ultralow-twist velvet cotton fabric. The invention also provides a preparation process of the ultralow-twist velvet cotton fabric. The prepared ultralow-twist velvet cotton fabric achieves the excellent properties of good overall fluffy touch feeling, soft and dry hand feeling, rapid drying after absorbingwater during washing and fabric twist and twilling reduction, and is less prone to losing color, thereby meeting the demands of people on high-grade fabrics.

Owner:盐城福汇纺织有限公司

Dyeing process of red vegetable dyes

ActiveCN106351033AWith health functionGood colorNatural dyesDyeing processPre treatmentAqueous solution

The invention discloses a dyeing process of red vegetable dyes. The process comprises the following steps: a, treating safflower cakes by an acidic solution, so as to obtain a filter residue A; b, rinsing and filtering the filter residue A by an alkaline solution, so as to obtain a dyeing liquor; c, making a dye C1; d, mixing the dye C1 and a dye C2, so as to obtain a dye D; e, mixing the dye D and a weakly alkaline aqueous solution, so as to obtain a dyeing liquor E1 and a dyeing liquor E2; f, respectively pretreating the heated dyeing liquors (E1 and E2), so as to obtain the dyeing liquors (F1 and F2); g, pretreating a silk fabric, so as to obtain a product G; h, adding the product G into the dyeing liquor F1 for dyeing, so as to obtain a product H; i, adding the product H into the dyeing liquor E2 for dyeing, so as to obtain a product I; j, treating the product I, so as to obtain a finished product J. The dyeing process disclosed by the invention has the characteristics of low production cost, good coloring effect, high color fastness, convenience in large-scale production, and capacities of improving the extraction rate of haematochrome and the impurity removal rate and facilitating safflower storage.

Owner:义乌市惠侬丝服饰有限公司

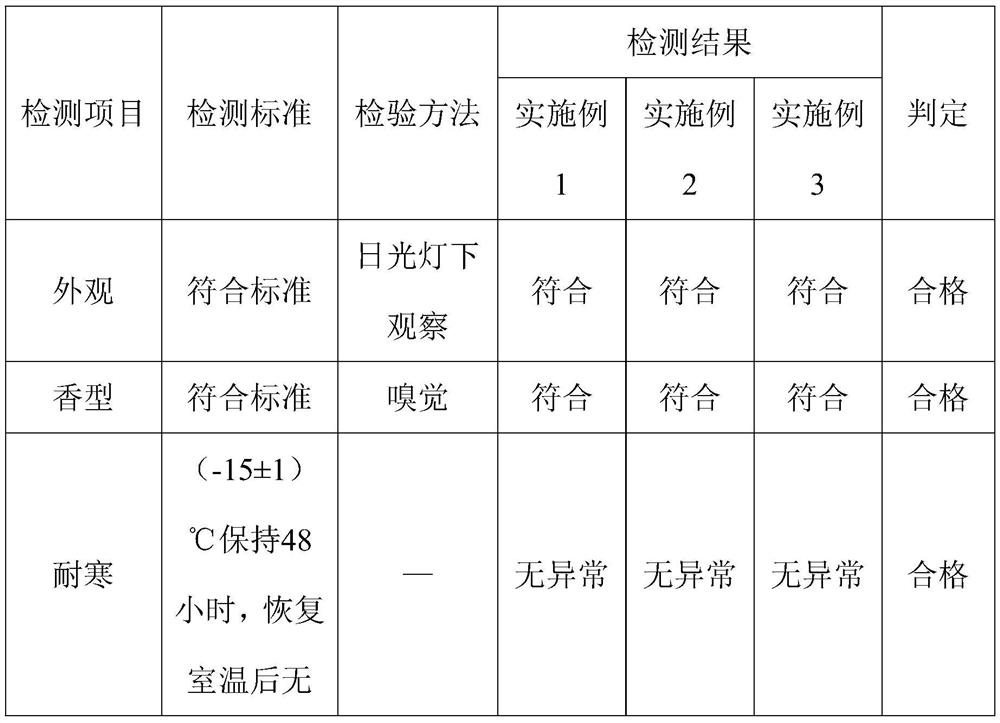

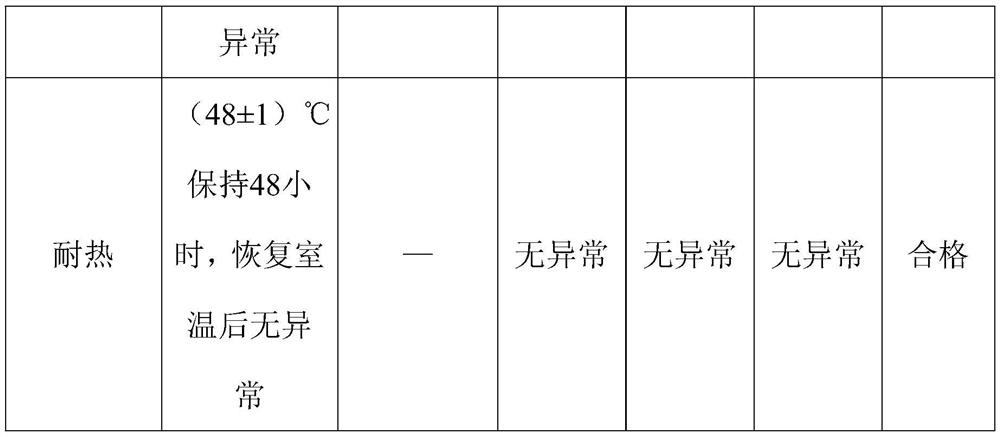

Bright and smooth matt lipstick and production technology thereof

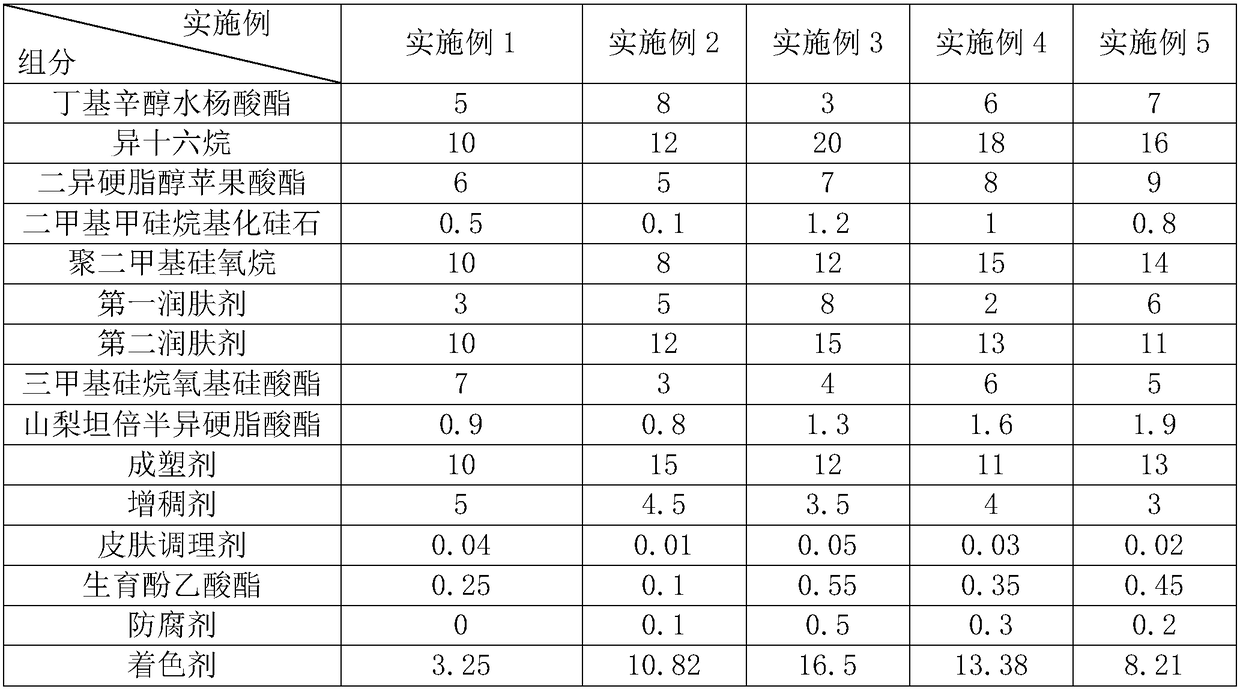

ActiveCN109044889AImprove the sense of fogGood moisturizing effectCosmetic preparationsMake-upPolymer scienceSalicylic acid

The invention discloses a bright and smooth matt lipstick and a production technology thereof. The bright and smooth matt lipstick comprises the following components in parts by weight: 3-8 parts of butyloctyl salicylate, 10-20 parts of isohexadecane, 5-9 parts of diisostearyl malate, 0.1-1.2 parts of silica dimethyl silylate, 8-15 parts of polydimethylsiloxane, 2-8 parts of a first emollient, 10-15 parts of a second emollient, 3-7 parts of trimethylsiloxysilicate, 0.8-1.9 parts of sorbitan sesquiisostearate, 10-15 parts of a plastizing agent, 3.5-5 parts of a thickening agent, 0.01-0.05 partof a skin conditioning agent, 0.1-0.55 part of tocopheryl acetate and 3.25-16.50 parts of a coloring agent. The bright and smooth matt lipstick has the advantages of being moisture, smooth, fresh andmatt.

Owner:虞琼斐 +1

Real silk dyeing method

The invention discloses a real silk dyeing method, and relates to the dyeing process, in particular to a dyeing process of real silk fabric. The method comprises the steps of pretreatment, pre-medium dyeing, dyeing, cold water washing, deionized water washing and drying, wherein the mordant is ferrous sulfate; the natural pigment is tea tree fruit pigment. The method has the benefits that the process is simple; the coloring is uniform; the fixation effect is good; the acid-alkali degree is moderate; damage on fabric during dyeing is avoided; the operation is safe and healthy; the quality of dyed real silk fabric can be improved.

Owner:XINYUAN COCOON SILK GROUP

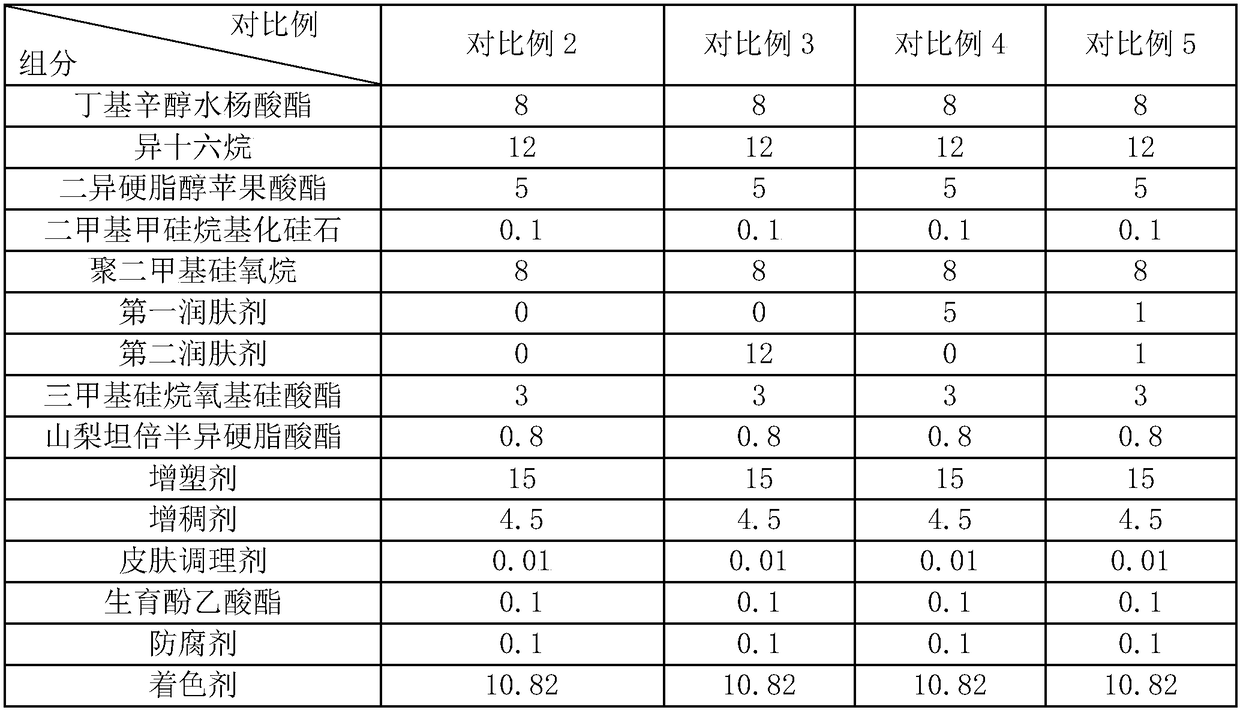

Transfer coating ink-jet printing high-gloss photographic paper

ActiveCN105970724AGood ink absorptionGood color fixing effectWater-repelling agents additionDuplicating/marking methodsEmulsionPolyvinyl acetate

The invention relates to a paper and especially relates to a transfer coating ink-jet printing high-gloss photographic paper. The paper comprises a surface coating, a base coating, a raw paper layer and a back coating. The surface coating is an ink absorption water-resistant gloss coating. The base coating is an ink absorption fixation coating. The back coating is a water-resistant coating for balancing two surface tensions of a photographic paper. The base coating comprises light calcium carbonate, a sodium polycarboxylate dispersant, a polyvinyl acetate emulsion adhesive, a polyvinyl alcohol glue solution and a fixer. The surface coating comprises aqueous silica sol and a polyvinyl alcohol glue solution. The back coating comprises polyvinyl alcohol. The photographic paper surface is a high-gloss mirror surface, images obtained by color ink-jet printing have plump colors and realizes real restoration and ink absorption and fixing performances are good.

Owner:ZHEJIANG JUNMA DIGITAL TECH

Long-lasting eyeliner

InactiveCN109431862AImprove water resistanceNot easy to smudgeCosmetic preparationsMake-upAdhesiveTrimethylsilane

The invention discloses a long-lasting eyeliner which comprises trimethyl silane oxy silicate ester, octyl polymethylsiloxane, phenyl polytrimethyl siloxane, a skin feeling adjusting agent, an adhesive, a solvent and a coloring agent, wherein the trimethyl silane oxy silicate ester accounts for 9-16% by weight in the eyeliner; the octyl polymethylsiloxane accounts for 0.5-3% by weight in the eyeliner; the phenyl polytrimethyl siloxane accounts for 0.5-3% by weight in the eyeliner. The eyeliner disclosed by the invention is good in water resistance, long-lasting in effect without blending, goodin color fixation capability, good in cleaning property, soft, smooth, easy in eyeliner makeup, thick in color and good in use feeling.

Owner:I&B GUANGZHOU BIOLOGICAL TECH CO LTD

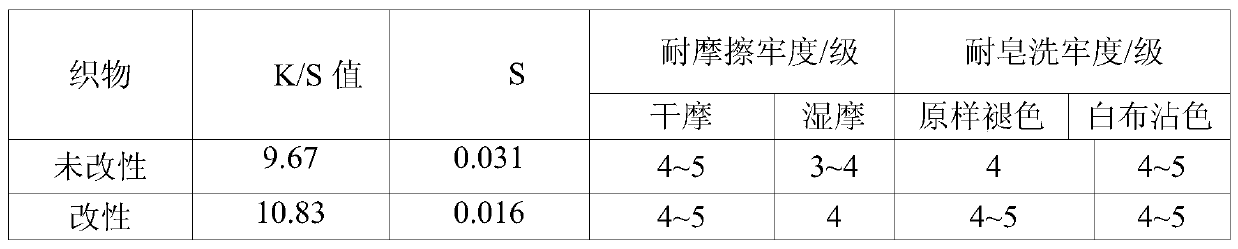

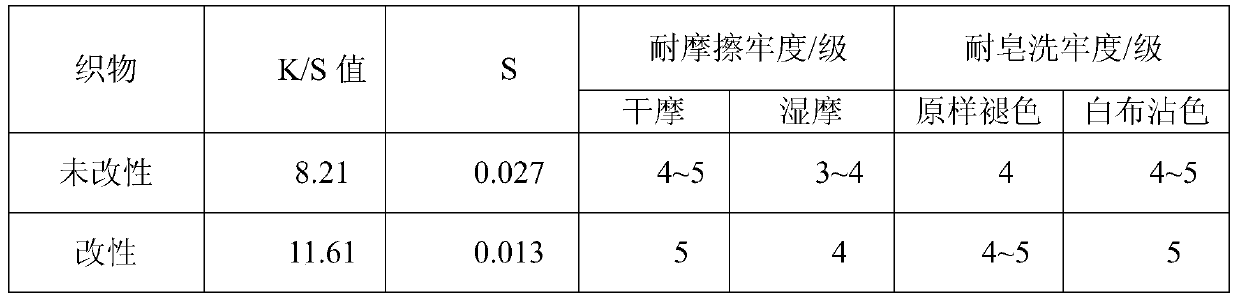

Salt-free dyeing method of cationic ion modified cotton fabric

The invention relates to a salt-free dyeing method of cationic ion modified cotton fabric. The method includes: soaking cellulose fiber fabric in treatment liquid, baking, washing with water, drying,putting modified cellulose fiber fabric into a dyeing vat, adding a polyamine color fixator for color fixation, washing with water, soaping, washing with water, and drying. By the method, the cationicion modified cotton fabric is high in leveling performance, free of darkening of color light and high in color fastness, especially high in wet friction fastness in the process of active dye salt-free dyeing.

Owner:DONGHUA UNIV +1

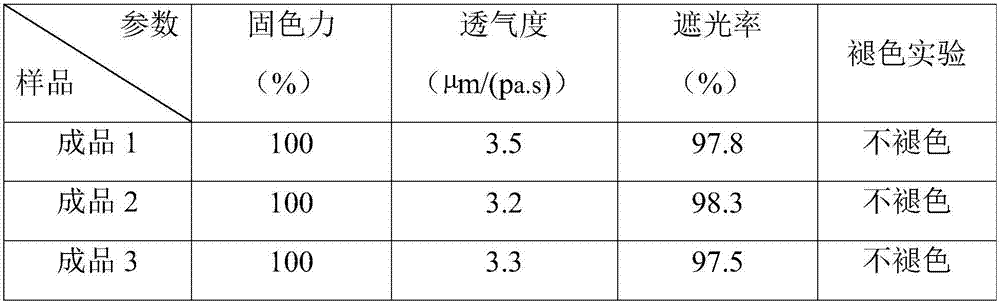

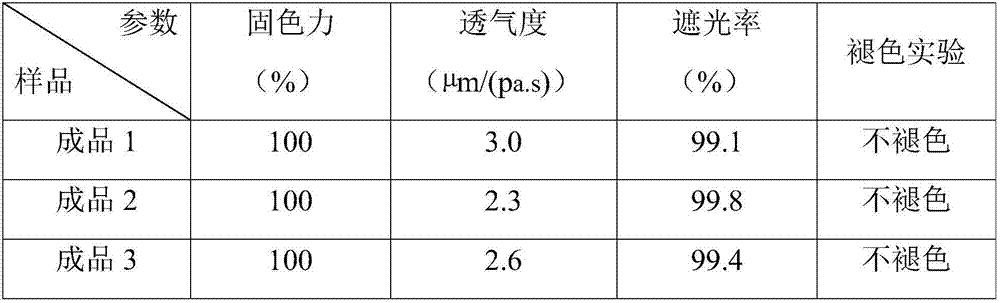

Water-based black paint for fruit bag paper and preparation method of water-based black paint

The invention relates to the technical field of fruit bag paper, and particularly relates to a water-based black paint for fruit bag paper and a preparation method of the water-based black paint. The water-based black paint is prepared from the following components in percentages by weight: 20-23% of carbon black, 25-30% of kaolin, 29-43.5% of deionized water, 4-5% of carboxylic butadiene-styrene latex, 3-5% of waterborne acrylic resin, 0.5-1% of polyethylene glycol and 4-7% of propanediol butyl ether. The paint coats single-color paper of the fruit bag paper, is capable of replacing a traditional fruit bag paper manufacturing technology, which adopts a cylinder mould machine for internal drying, is high in wastewater discharge, low in vehicle speed, high in energy consumption and high in pollution, and has the characteristics of being free of wastewater discharge, high in carbon black utilization rate, low in pollution, safe and environmentally friendly; and the obtained fruit bag paper is good in fixing property, colorfast, good in breathability and low in price, and has potential market value.

Owner:李臣忠

Silky moisturizing matte lip glaze and preparation method thereof

PendingCN112168745AEasy to remove makeupWater and oil repellentCosmetic preparationsMake-upPolymer sciencePropyl ether

The invention relates to silky moisturizing matte lip glaze. The silky moisturizing matte lip glaze is prepared from the following components in parts by weight: 0.5 to 2 parts of an emulsifier, 4 to10 parts of a film forming agent, 70 to 85 parts of an emollient, 3 to 5 parts of a skin conditioner and 4 to 8 parts of a coloring agent. According to the silky moisturizing matte lip glaze, a noveltechnology is adopted to perfectly combine polyperfluoromethyl isopropyl ether and a polydimethylsiloxane / vinyl polydimethylsiloxane cross-linked polymer, so that the silky moisturizing matte lip glaze has a matte and silky velvet effect of common velvet lip glaze and also has a color fixing effect of non-stick cup lip gloss. When the lip glaze is used, the polyperfluoromethyl isopropyl ether andthe polydimethylsiloxane / vinyl polydimethylsiloxane cross-linked polymer in the film forming agent can rapidly form a protection film on the surface of a lip part and have a protection effect; the silky moisturizing matte lip glaze has the advantages of uneasiness of makeup removal and excellent color fixing effect; and after the lip glaze is used, the lip part is not tight and does not peel off,and the lip part is matte and is not dry.

Owner:GUANGZHOU BAOYAN BIOTECH

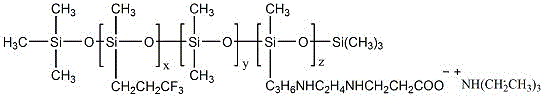

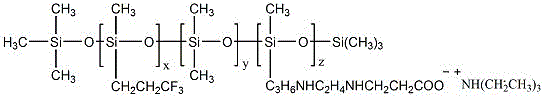

Modified amino organic fluorosilicone oil emulsion color-deepening finishing agent and preparation method thereof

InactiveCN106436327ARaw materials are easy to getEasy to prepareGrip property fibresAnimal fibresChemistryEmulsion

The invention discloses a modified amino organic fluorosilicone oil emulsion color-deepening finishing agent. The color-deepening finishing agent is characterized by being prepared from, by mass, 50%-95% of octamethylcyclotetrasiloxane, 1%-30% of 1,3,5-trimethyltris-1,5-(3,3-trifluoropropyl)-cyclotrisiloxane, 1%-20% of N-(beta-aminoethyl)-gamma-aminopropyl methyl dimethoxy silicane, 0.01%-0.1% of an end capping agent, 0.01%-0.1% of a high-alkalinity catalyst, 0.1%-2% of an emulsifying agent and the balance deionized water. The modified amino organic fluorosilicone oil emulsion color-deepening finishing agent has the following structural formula (please see the formula in the description), wherein X ranges from 10 to 100, Y ranges from 80 to 1,000, Z ranges from 7 to 70, and X, Y and Z are all integers. A preparation method has the advantages that the raw materials are easy to obtain, and operation is convenient. The color-deepening finishing agent prepared through the method is used for finishing a real silk fabric, the finished real silk fabric has the excellent color fixing property and washing resistance, the reflected light amount on the fiber surface is decreased, and the color-deepening effect is obvious.

Owner:SHANGHAI UNIV

Scouring-bleaching and active dye dyeing one-bath process technology for cotton woven fabric

The invention relates to a scouring-bleaching and active dye dyeing one-bath process technology for cotton woven fabric. Compared with conditions of conventional dyeing technology, the dye uptake of the disclosed technology is same, and a dyed finished product processed by using the disclosed technology has the fixation rate, the capillary effect, the tearing strength, the dry friction fastness, the dyeing reappearance and the like all according to basic requirements of a conventional dyeing method, and compared with a conventional dyeing technology, the disclosed technology has the advantages of time saving, energy saving, water saving, high production efficiency, light sewage processing burden and the like.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com