Polyquaternium cationic formaldehyde-free fixing agent and preparing method thereof

A technology of formaldehyde-free color-fixing agent and polyquaternium salt, which is applied in the field of formaldehyde-free color-fixing agent and its preparation, can solve the problem of little effect of color-fixing effect on superfine fiber base cloth, increase of dyeing cost and difficulty of wastewater treatment, super The poor dyeability of fine fiber base fabrics and other problems can achieve high industrial application value, good color fixing effect, and the effect of improving color fastness to wet rubbing and color fastness to dry rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

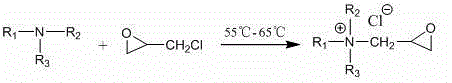

Method used

Image

Examples

Embodiment 1

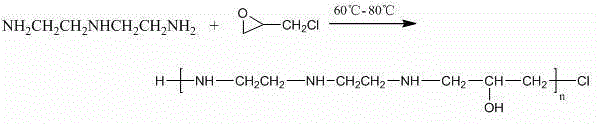

[0027] (1) Synthesis of intermediate product 1

[0028] In reactor 1, add diethylenetriamine (10.3kg) and deionized water (10L), stir, blow in nitrogen, heat up to 60°C, start to drop epichlorohydrin (9.3kg), and control the reactor The temperature does not exceed 80°C. After the epichlorohydrin is added dropwise, the temperature is controlled at 75°C. After 1.5 hours of reaction, the reaction stops. The product is light yellow transparent slightly viscous liquid, pH=8-9, solid content is 66.18% .

[0029] (2) Synthesis of intermediate product 2

[0030] In reactor 2, add deionized water (10L), methanol (20L), epichlorohydrin (9.3kg), stir, add triethylamine (12.2kg) in batches, heat up to 55°C, and control the reaction temperature The temperature does not exceed 60°C, and the reaction stops after 2 hours. The product is a colorless and transparent solution, pH=9-10, and the solid content of the product is 45.4%.

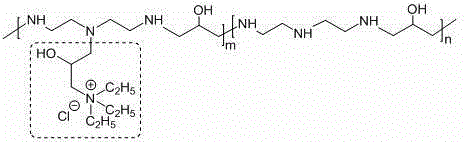

[0031] (3) Grafting reaction

[0032] Combine the reaction...

Embodiment 2

[0035] (1) Synthesis of intermediate product 1

[0036] In reactor 1, add ethylenediamine (3.0kg) and deionized water (5L), stir, blow in nitrogen, heat up to 65°C, start adding epichlorohydrin (4.6kg) dropwise, and control the temperature of the reactor No more than 80°C. After the epichlorohydrin is added dropwise, the temperature is controlled at 75°C. After 2 hours of reaction, the reaction stops. The product is a light yellow transparent slightly viscous liquid, pH=8, and the solid content is 68.38%.

[0037] (2) Synthesis of intermediate product 2

[0038] In reactor 2, add trimethylamine aqueous solution (23.3kg, trimethylamine mass fraction is 33%), methanol (30L), epichlorohydrin (9.3kg), stir, heat up to 55°C, control the reaction temperature not to exceed 60°C, the reaction stopped after 2.5 hours, the product was a colorless and transparent solution, pH=9, and the solid content of the product was 46.8%.

[0039] (3) Grafting reaction

[0040] Combine the reactio...

Embodiment 3

[0043] (1) Synthesis of intermediate product 1

[0044]In reactor 1, add triethylenetetramine (14.6kg) and deionized water (10L), stir, blow in nitrogen, heat up to 60°C, start to add epichlorohydrin (9.3kg) dropwise, and control the reactor The temperature does not exceed 80°C. After the epichlorohydrin is added dropwise, the temperature is controlled at 75°C. After 1 hour of reaction, the reaction stops. The product is a light yellow transparent slightly viscous liquid, pH=9, and the solid content is 65.16%.

[0045] (2) Synthesis of intermediate product 2

[0046] In reactor 2, add deionized water (10L), methanol (20L), epichlorohydrin (9.3kg), stir, add triethylamine (12.2kg) in batches, heat up to 55°C, and control the reaction temperature The temperature does not exceed 60°C, and the reaction stops after 2 hours. The product is a colorless and transparent solution, pH=9-10, and the solid content of the product is 45.4%.

[0047] (3) Grafting reaction

[0048] Combine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com