Silky moisturizing matte lip glaze and preparation method thereof

A silky, moisturizing, matte technology, used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of easy decolorization and makeup removal, poor makeup removal, long film formation time, etc., to avoid dry lips. Skin, the effect of maintaining skin moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A silky moisturizing matte lip gloss comprising, by parts by weight, the following components:

[0026] Emulsifier: cetyl PEG / PPG-10 / 1 polydimethylsiloxane: 1 part;

[0027] Emollient: Dimethicone / Dimethicone Crosspolymer: 82.98 parts;

[0028] Skin Conditioner: Camellia Seed Oil: 4 parts;

[0029] Colorant: titanium dioxide: 2 parts; iron oxide: 2 parts; red No. 6: 2 parts;

[0030] Film former: polyperfluoromethyl isopropyl ether: 3 parts; dimethicone / vinyl dimethicone crosspolymer: 3 parts;

[0031] Aroma: edible dark chocolate aroma: 0.02 parts.

[0032] The preparation method of above-mentioned lip gloss comprises the following steps:

[0033] (1) Add the emollient to the pot, then add the colorant and stir evenly, then grind it three times with a three-roller mill until the toner is completely dispersed and fine without particles, and then put it into the pot again;

[0034] (2) Add emulsifier, skin conditioning agent and film forming agent into the pot and s...

Embodiment 2

[0037] A silky moisturizing matte lip gloss comprising, by parts by weight, the following components:

[0038] Emulsifier: cetyl PEG / PPG-10 / 1 polydimethylsiloxane: 2 parts;

[0039] Emollients: Dimethicone / Dimethicone Crosspolymer: 60 parts; Silicone 11: 21.98 parts;

[0040] Skin Conditioners: Camellia Seed Oil: 2 parts; Jojoba Seed Oil: 2 parts;

[0041] Coloring agent: titanium dioxide: 2 parts; iron oxide: 2 parts; red No. 6: 1 part; blue No. 1: 1 part;

[0042] Film former: polyperfluoromethyl isopropyl ether: 3 parts; dimethicone / vinyl dimethicone crosspolymer: 3 parts;

[0043] Aromatic agent: 0.02 parts of edible strawberry fragrance.

[0044] The concrete preparation steps of above-mentioned lip gloss are the same as embodiment 1.

Embodiment 3

[0046] A silky moisturizing matte lip gloss comprising, by parts by weight, the following components:

[0047] Emulsifier: Cetyl PEG / PPG-10 / 1 Dimethicone: 1 part; Sorbitan Sesquioleate: 1 part;

[0048] Emollient: Dimethicone / Dimethicone Crosspolymer: 40 parts; Dimethicone: 32 parts; Silicone 11:10 parts;

[0049] Skin Conditioners: Camellia Seed Oil: 2 parts; Jojoba Seed Oil: 1 part; Tocopheryl Acetate: 1 part;

[0050] Colorant: iron oxide: 2 parts; red No. 6: 2 parts; blue No. 1: 2 parts;

[0051] Film former: polyperfluoromethyl isopropyl ether: 3 parts; dimethicone / vinyl dimethicone crosspolymer: 3 parts.

[0052] The concrete preparation steps of above-mentioned lip gloss are the same as embodiment 1.

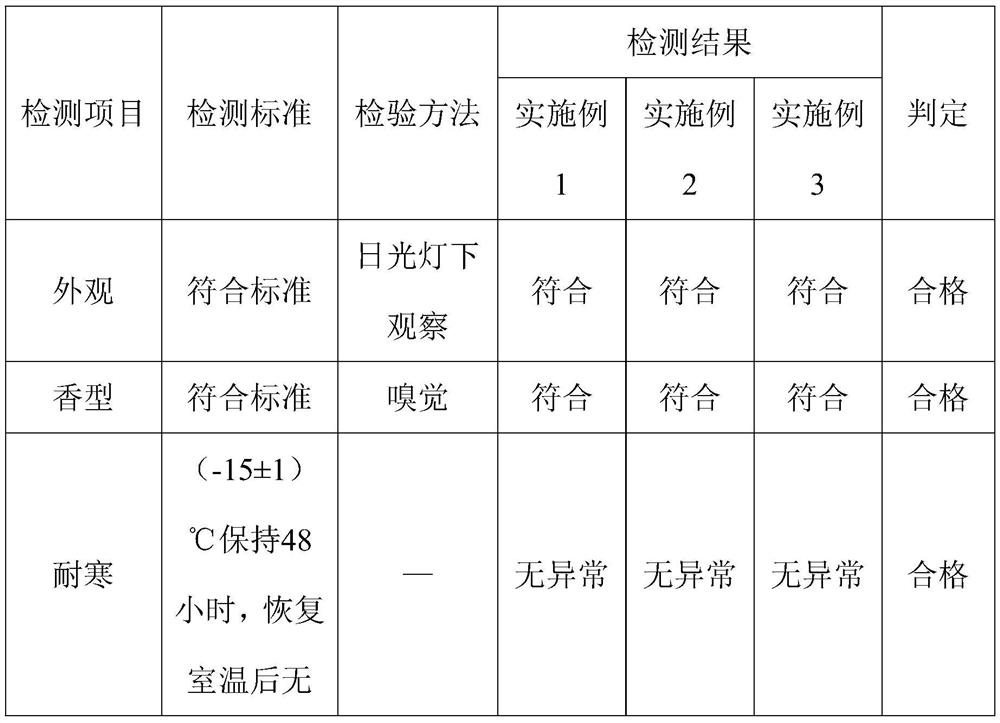

[0053] The silky smooth moisturizing matte lip gloss prepared in the above examples is tested, and the specific test results are shown in Table 1 below:

[0054] Table 1:

[0055]

[0056]

[0057] Table 2:

[0058] Executive standard GB / T 27576 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com