Water-based black paint for fruit bag paper and preparation method of water-based black paint

A technology of black paint and bagging paper, applied in paper coating, coating, papermaking, etc., can solve the problems of serious pollution, less fruit bagging paper, and low pigment retention, so as to reduce pollution, protect the environment, Good color fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

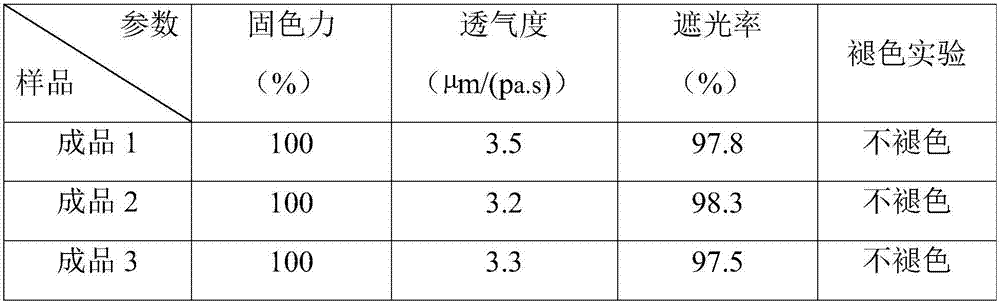

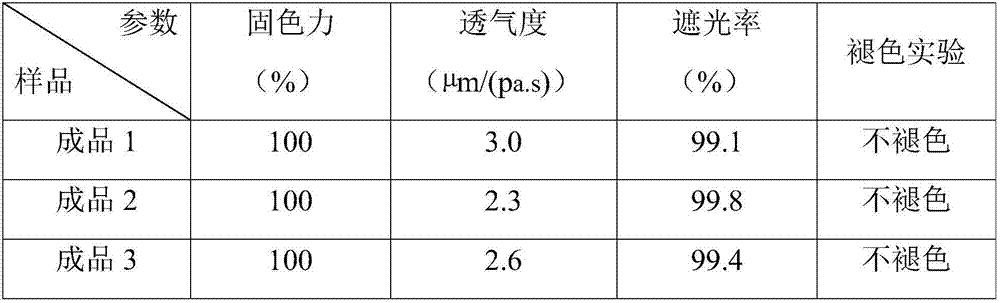

Embodiment 1

[0016] The composition and parts by weight of the water-based black paint for fruit bagging paper of the present invention are as follows: 20% of N330 carbon black; 25% of 1500-2000 mesh kaolin; 43.5% of deionized water; 4% of carboxylated styrene-butadiene latex; water-based acrylic resin 3%; polyethylene glycol 0.5%; propylene glycol butyl ether 4%.

[0017] A kind of fruit bagging paper water-based black coating preparation step of the present invention is:

[0018] (1) After adding water to the disperser, add polyethylene glycol and stir at 2000rpm for 5 minutes to fully dissolve; (2) Add 1500-2000 mesh kaolin and continue stirring for 5 minutes to fully disperse; (3) Add N330 Carbon black, stir 12min at a high speed with the speed of 8000rpm, make its particle fully disperse; (4) above-mentioned mixture is put into grinder and grind 3 times; The above grinds were put into a mixer respectively, and stirred at a speed of 500 rpm for 10 min; (6) adding sodium hydroxide to a...

Embodiment 2

[0020] The composition and parts by weight of the water-based black paint for fruit bagging paper of the present invention are as follows: 23% of N330 carbon black; 30% of 1500-2000 mesh kaolin; 29% of deionized water; 5% of carboxylated styrene-butadiene latex; water-based acrylic resin 5%; polyethylene glycol 1%; propylene glycol butyl ether 7%.

[0021] The preparation method is the same as in Example 1, and the finished product 2 is obtained after filtration.

Embodiment 3

[0023] The composition and parts by weight of the water-based black paint for fruit bagging paper of the present invention are as follows: 22% of N330 carbon black; 28% of 1500-2000 mesh kaolin; 35.3% of deionized water; 4.5% of carboxylated styrene-butadiene latex; water-based acrylic resin 4%; polyethylene glycol 0.7%; propylene glycol butyl ether 5.5%.

[0024] The preparation method is the same as in Example 1, and the finished product 3 is obtained after filtration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com