Modified amino organic fluorosilicone oil emulsion color-deepening finishing agent and preparation method thereof

A technology of organofluorosilicone oil and finishing agent, which is applied in the direction of fiber treatment, improved hand-feeling fibers, textiles and papermaking, etc., can solve the problems of rough hand, low color fixation rate, poor washing resistance of silk fabrics, etc., and achieve excellent color fixation. With washing resistance, the effect of darkening is obvious, the effect of reducing the amount of reflected light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a modified aminoorganofluorine silicone oil emulsion darkening finishing agent of the present invention, the steps are as follows:

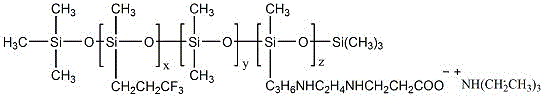

[0038] (1). Preparation of aminoorganofluorosilicone oil: Add 90g of octamethylcyclotetrasiloxane into the first flask, heat up to 90°C, and add 10g of N-(β-aminoethyl)-γ-aminopropyl Dimethoxysilane was mixed with 2g of deionized water, stirred evenly, and slowly added dropwise to the above-mentioned three-necked flask, then 0.05g of KOH was added, reacted for 3 hours, and then added 10g of trifluoropropylmethyl Continue to react cyclotrisiloxane for 4 hours; add 0.1 g of hexamethyldisiloxane to the above solution, react for 1 hour, cool down to 60°C, continue to react for 20 hours, and obtain uniform translucent viscous amino Organic fluorosilicone oil;

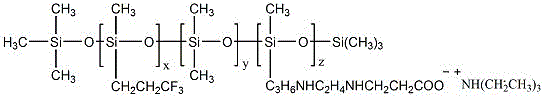

[0039] (2). Prepare triethylamine acrylate: dissolve 14.4g of acrylic acid in 30g of isopropanol, add it to the second flask, raise the temperature to 40°C, then...

Embodiment 2

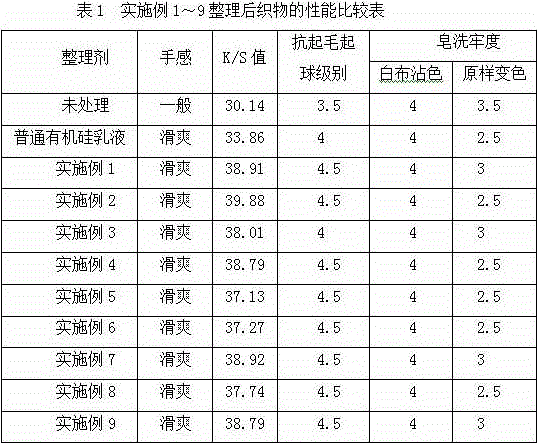

[0043] The present embodiment is the same as Example 1, and its difference is that the trifluoropropylmethylcyclotrisiloxane of 10g described in step (1) uses the trifluoropropylmethylcyclotrisiloxane of 12g Instead, the performance testing results of the modified aminoorganofluorosilicone oil emulsion darkening finishing agent prepared in this example are shown in Table 1.

Embodiment 3

[0045] The present embodiment is the same as Example 1, the difference is that 10g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane described in step (1) is used with 12g N -(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane instead, the modified aminoorganofluorosilicone oil emulsion deepening finishing agent prepared in this example, its performance test results are shown in Table 1 Show.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com