Patents

Literature

102 results about "Cylinder mould" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

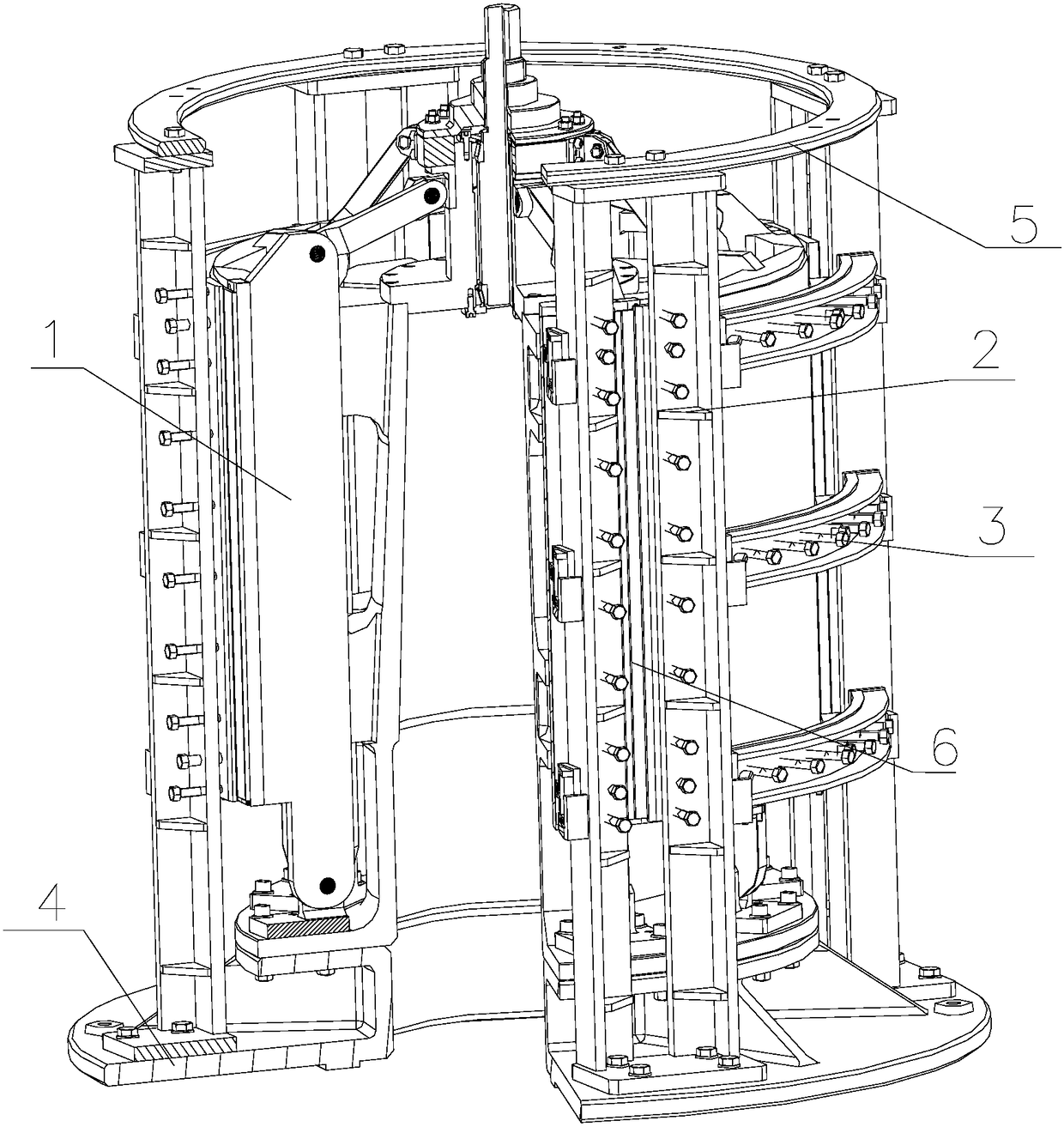

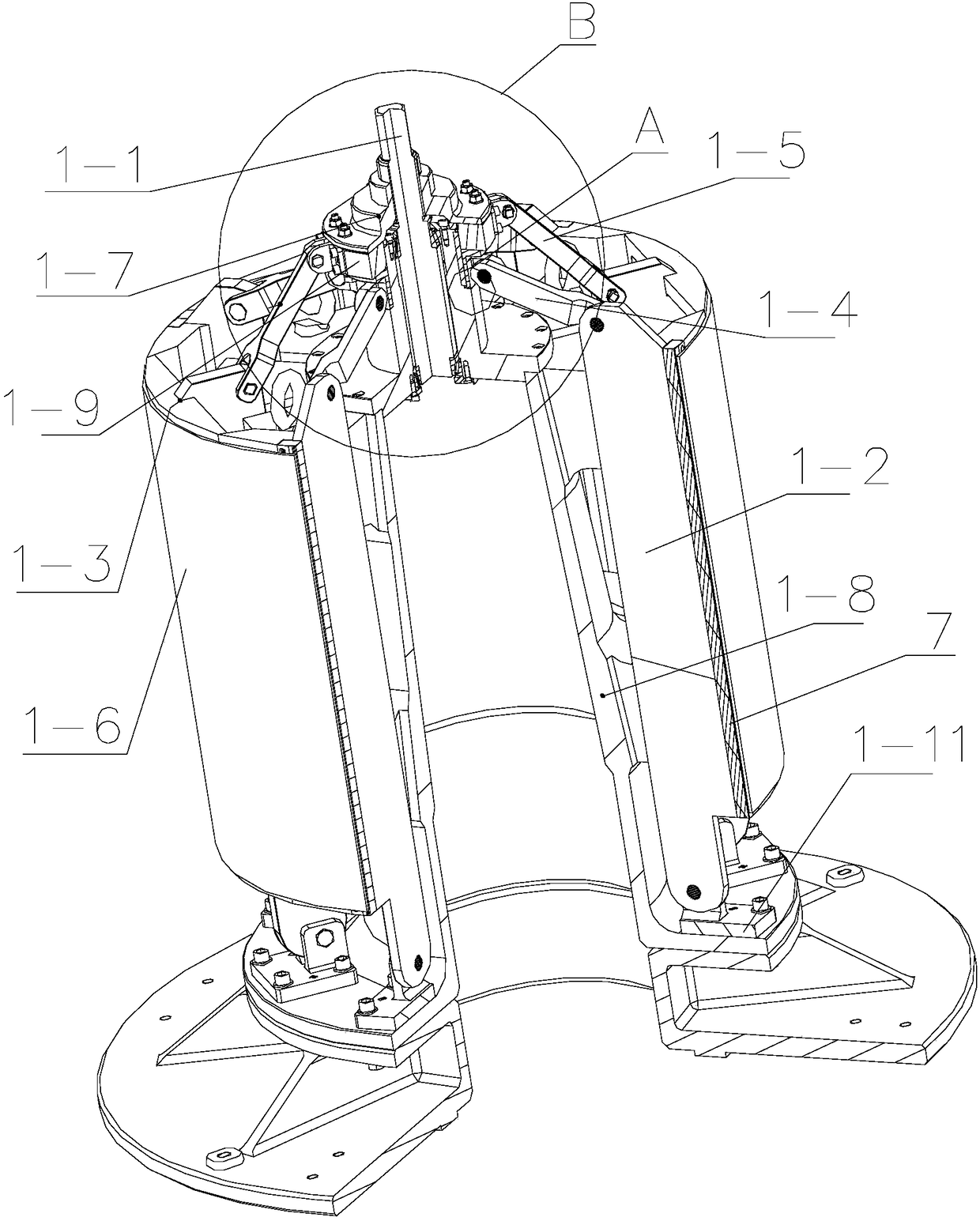

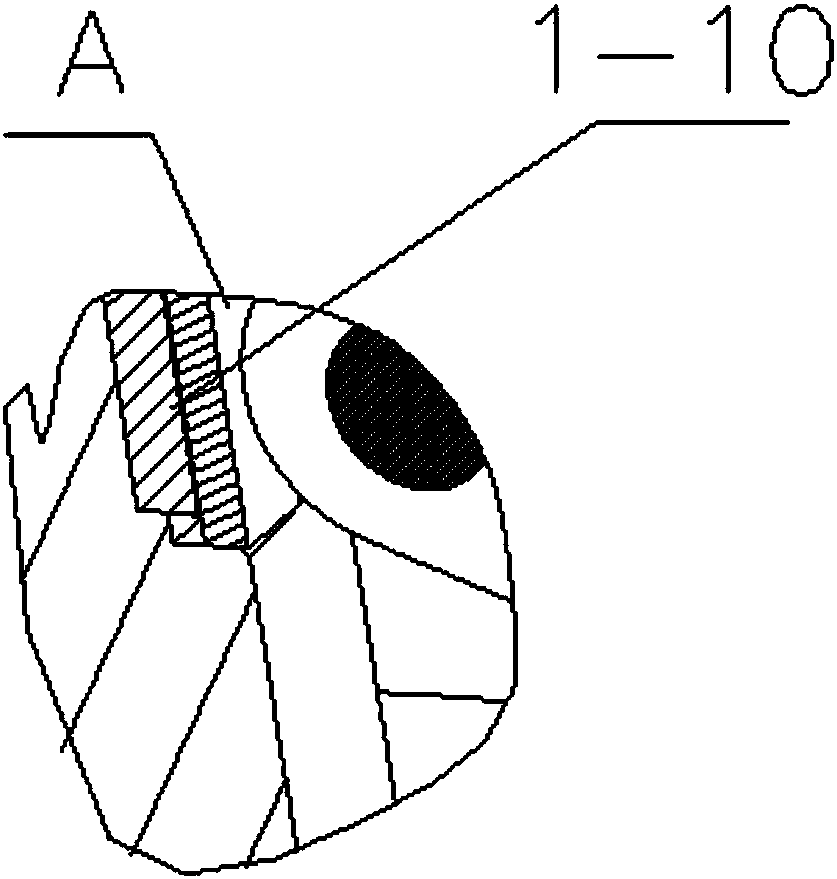

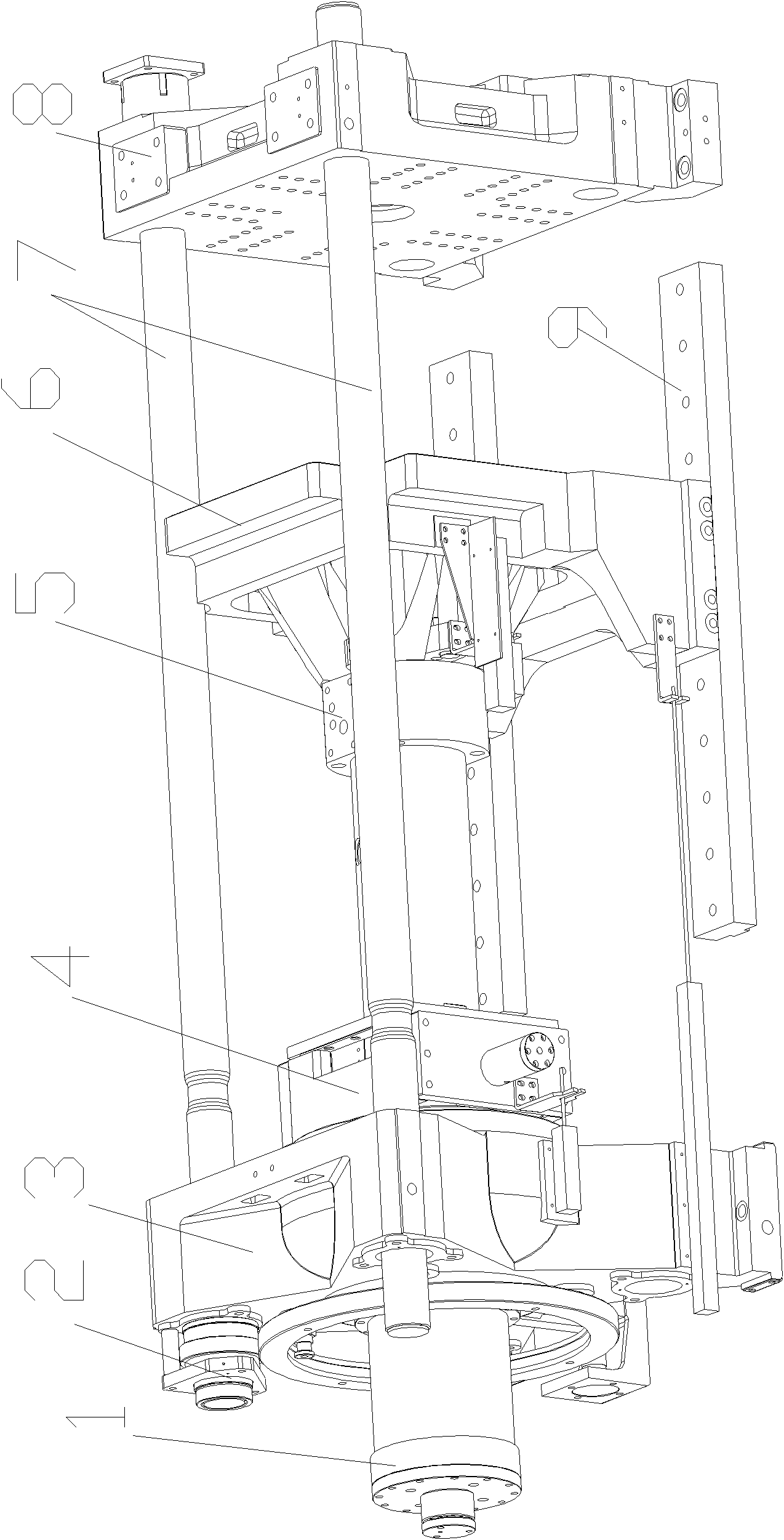

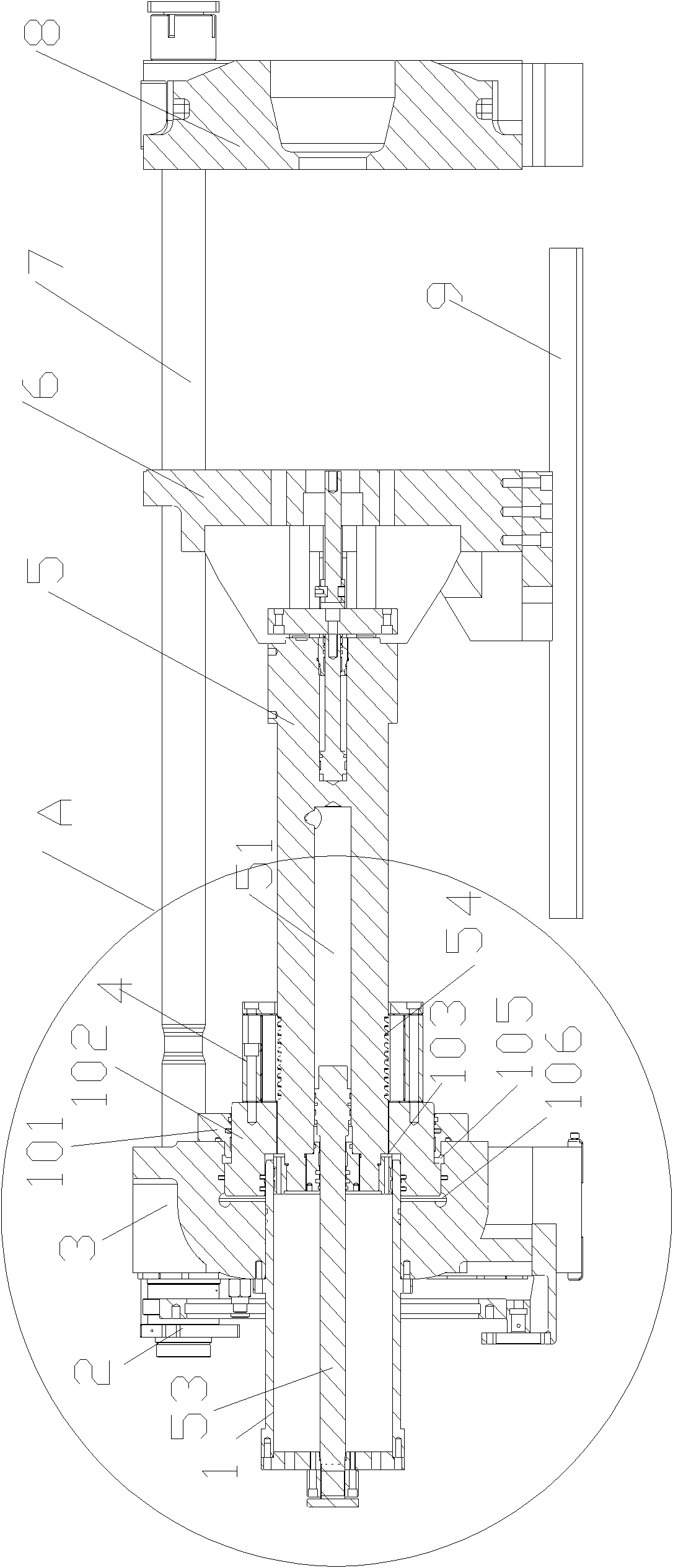

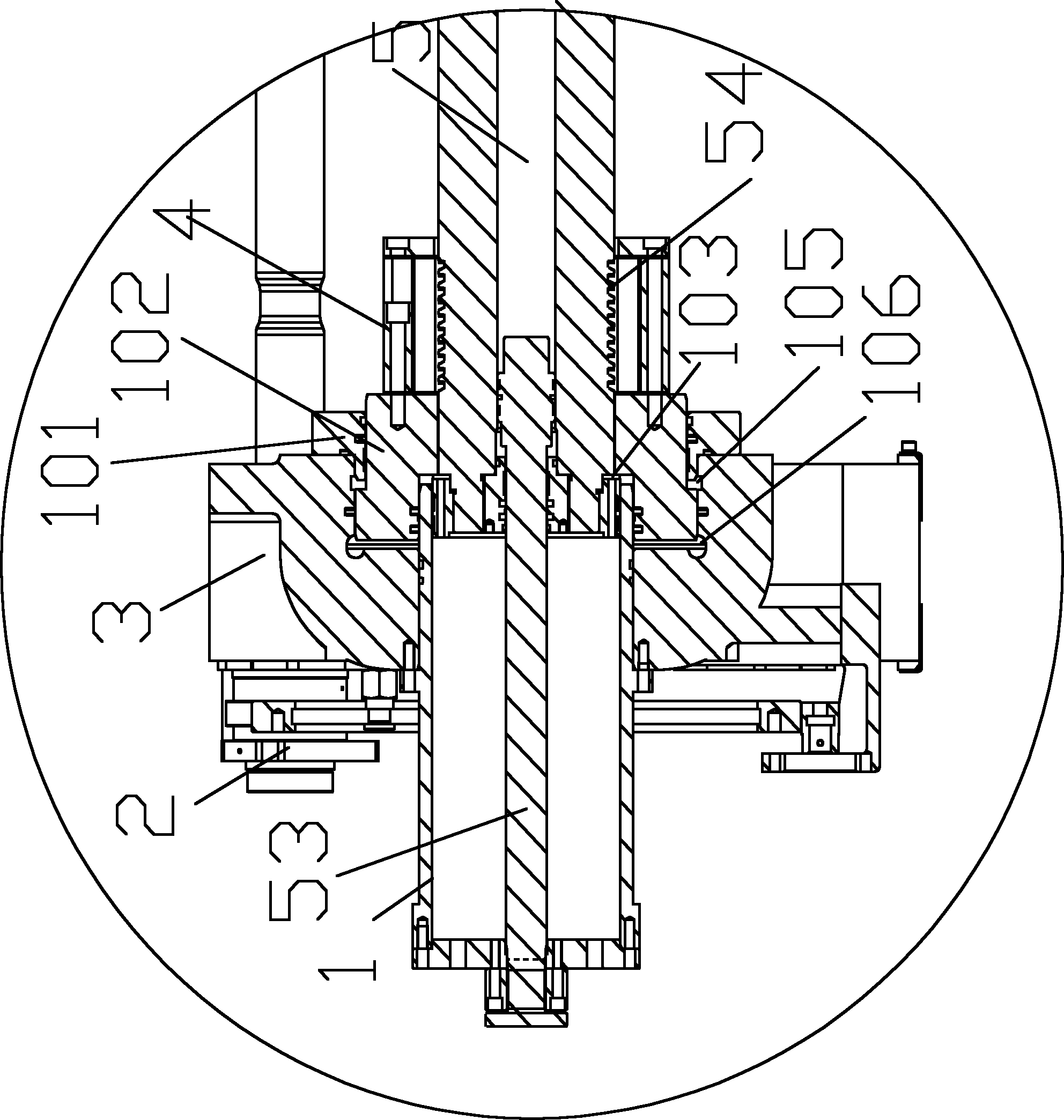

Tailor welding forming positioning device used for large-sized thin-wall cylinder type shell section

ActiveCN108098245AInstalled and disassembledImprove consistencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a tailor welding forming positioning device used for a large-sized thin-wall cylinder type shell section. The tailor welding forming positioning device used for the large-sizedthin-wall cylinder type shell section comprises a base, an inner supporting assembly, a longitudinal pressing assembly and an annular pressing assembly; the base is a flange plate which is horizontally arranged; the flange plate comprises an upper annular disk and a lower annular disk; the external diameter of the lower annular disk is larger than the external diameter of the upper annular disk.According to the device, a fixed diameter cylinder mould base is formed by the inner supporting assembly, main longitudinal supporting for external pressing of shell body products during welding is formed by the longitudinal pressing assembly and main annular supporting for the external pressing of the products during welding is formed by the annular pressing assembly; the annular pressing assembly is fixed on the longitudinal pressing assembly, so that the mounting and dismounting are convenient; the device is capable of improving the conformity and stability of the accuracies, such as diameter, circular degree and the like of the large-sized thin-wall cylinder type shell section products during welding machining and improving the qualified rate of the products greatly.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

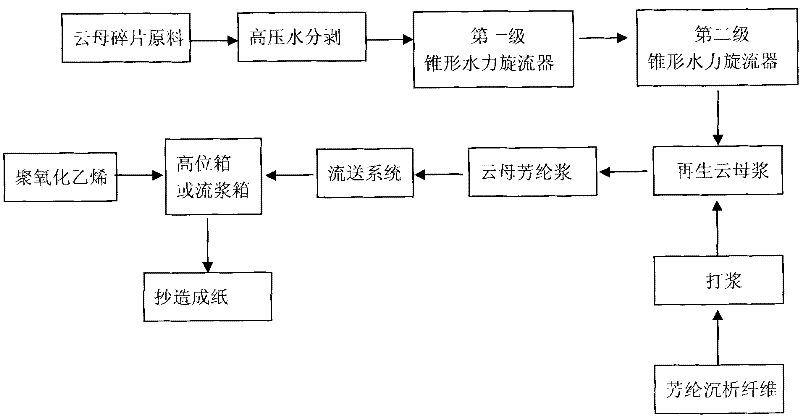

Method for regenerating mica paper through reinforcement of aramid precipitated fiber

InactiveCN101748647AHigh strengthImprove copyabilitySynthetic cellulose/non-cellulose material pulp/paperPulp material addition processesPolyethylene oxideSlurry

The invention discloses a method for regenerating mica paper through reinforcement of aramid precipitated fiber. The method comprises the following steps: pulverizing mica flakes through high-pressure waterpower, selecting a conical hydrocyclone for hydraulic classification of the mica flakes, introducing the mica flakes to a second-stage conical hydrocyclone for classification and selection to make the mica flakes form a sizing agent suitable for papermaking; according to the requirement of the mica paper, selecting a proper classifying screen for further classification, selecting mica slurry with proper size and distribution, adding 2 to 20 percent aramid precipitated fiber into the mica slurry, uniformly mixing, performing certain beating treatment on the aramid precipitated fiber, and controlling the beating degree between 30 and 50 degree SR; introducing the aramid precipitated fiber to a front-net approach flow system of a paper machine, adding 0.005 to 0.1 percent of polyethylene oxide before a head box or a flow box of the approach flow system; and finally, performing papermaking on an uphill wire or cylinder mould paper machine, drying, and producing qualified paper. The method reduces the paper breaking in papermaking and improves the speed of the paper machine and the production efficiency.

Owner:SHAANXI UNIV OF SCI & TECH

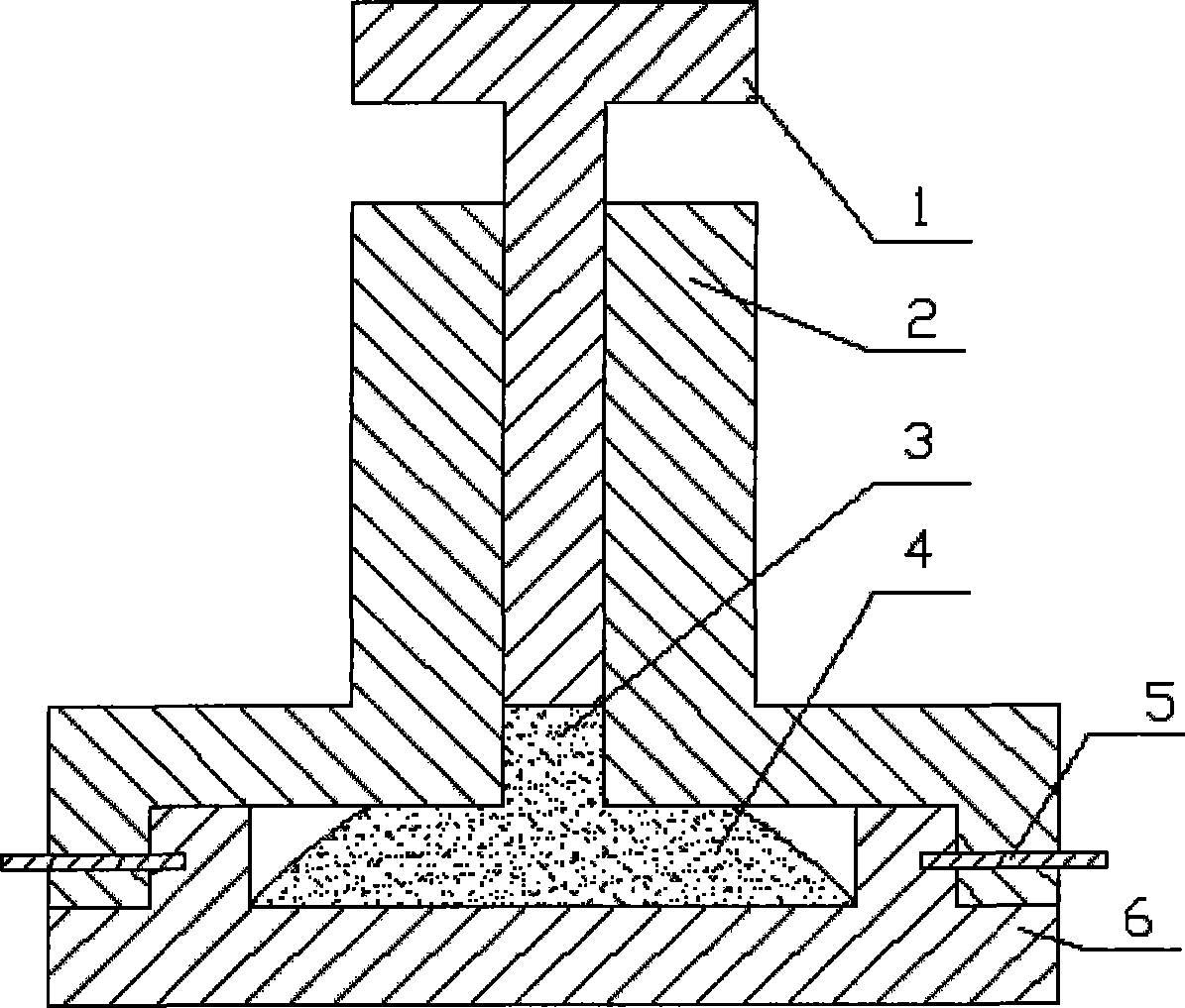

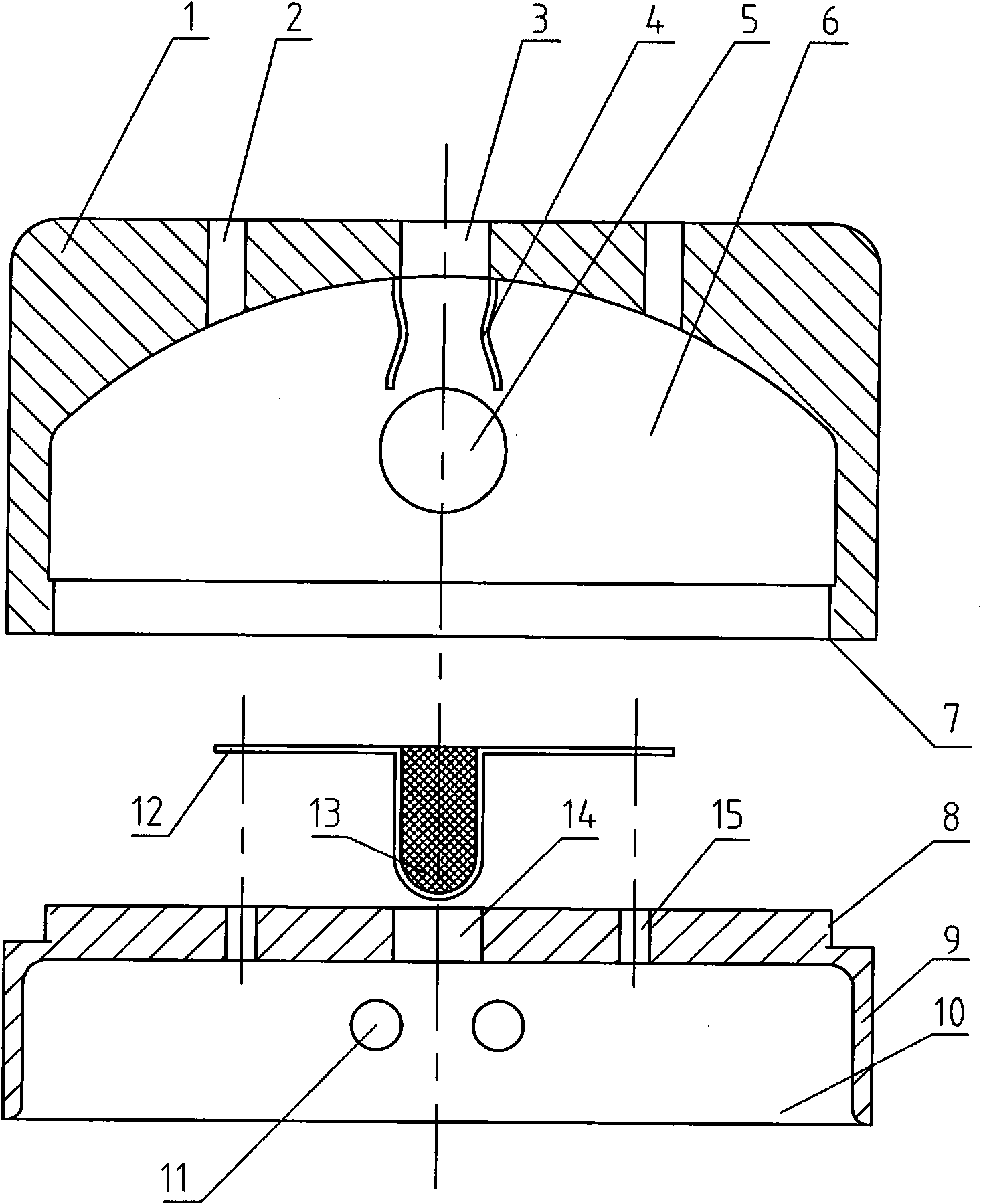

Press die for preparing agglomerate ultra-fine crystal material

InactiveCN101116880AEasy to processWide range of applicationsExtrusion diesFree accessCrystalline materials

The invention relates to an upsetting press die for preparation of bulk ultrafine crystalline materials, which belongs to the materials processing field. The invention comprises an extruding punch, an upper die and a lower die, wherein, the upper die is provided with a vertical square throughhole; the extruding punch is connected to a power plant for free access to the vertical square throughhole and is formed into a mould top chamber together with the upper die after entering into the upper die; the mould top chamber is a vertical square larger in height and length and smaller in width; the lower die is provided with a square or cylinder groove; the upper die and the lower die constitute a square or cylinder mould bottom chamber together. By the artful design of the mould top chamber and the mould bottom chamber, materials can return to the original shape after upsetting press deformation each time. The invention has the advantages of simple structure and strong grain refining capacity, and can prepare bulk ultrafine crystalline materials with even tissue and an average grain size ranging from 100 nm to 1 um.

Owner:SHANGHAI JIAO TONG UNIV

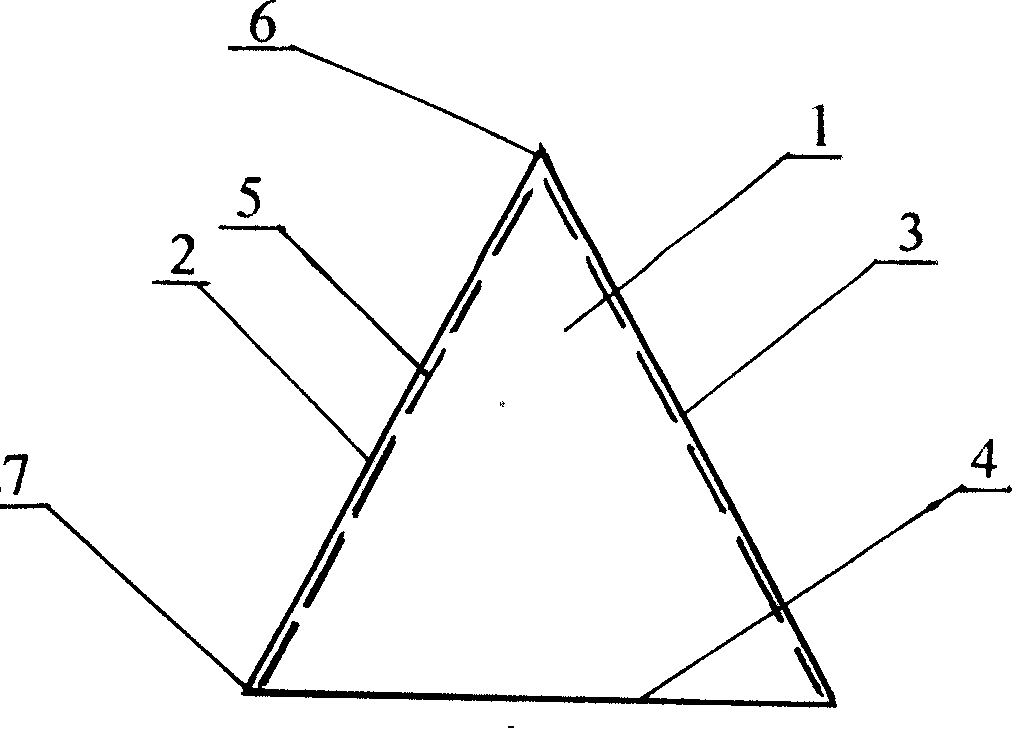

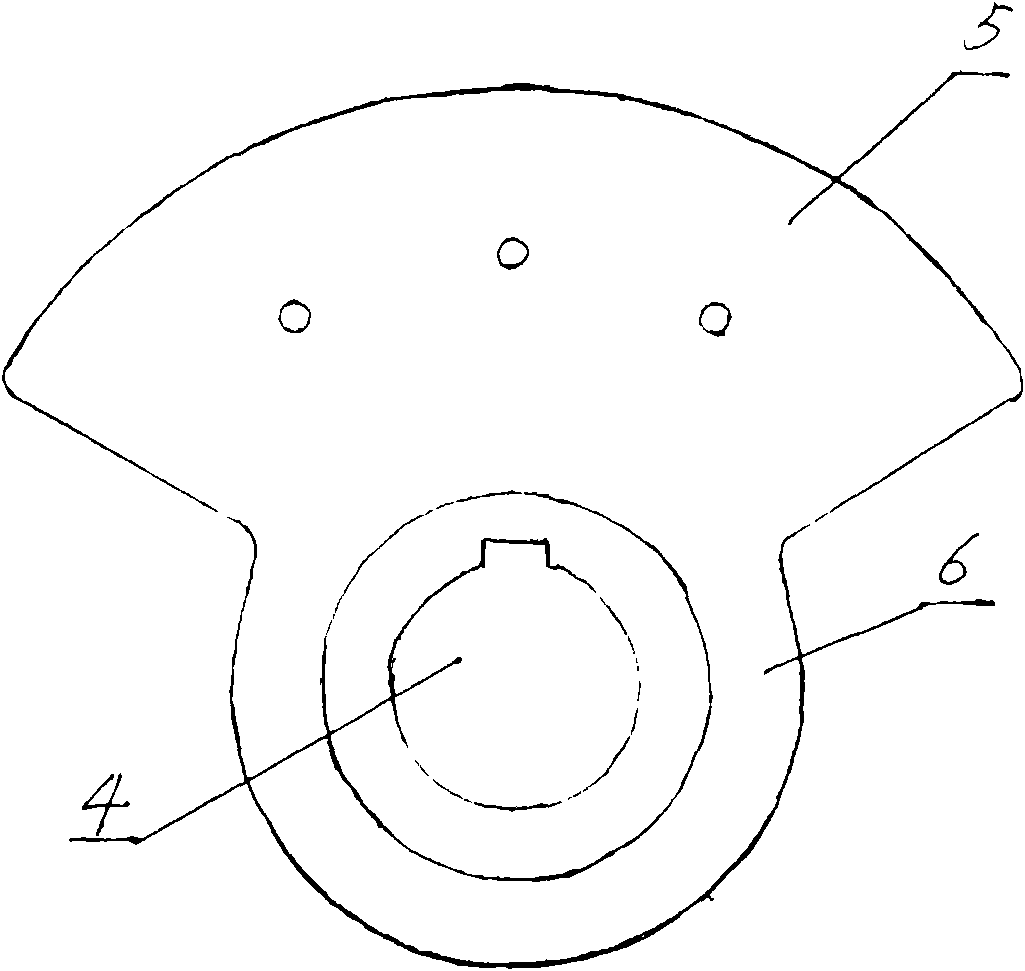

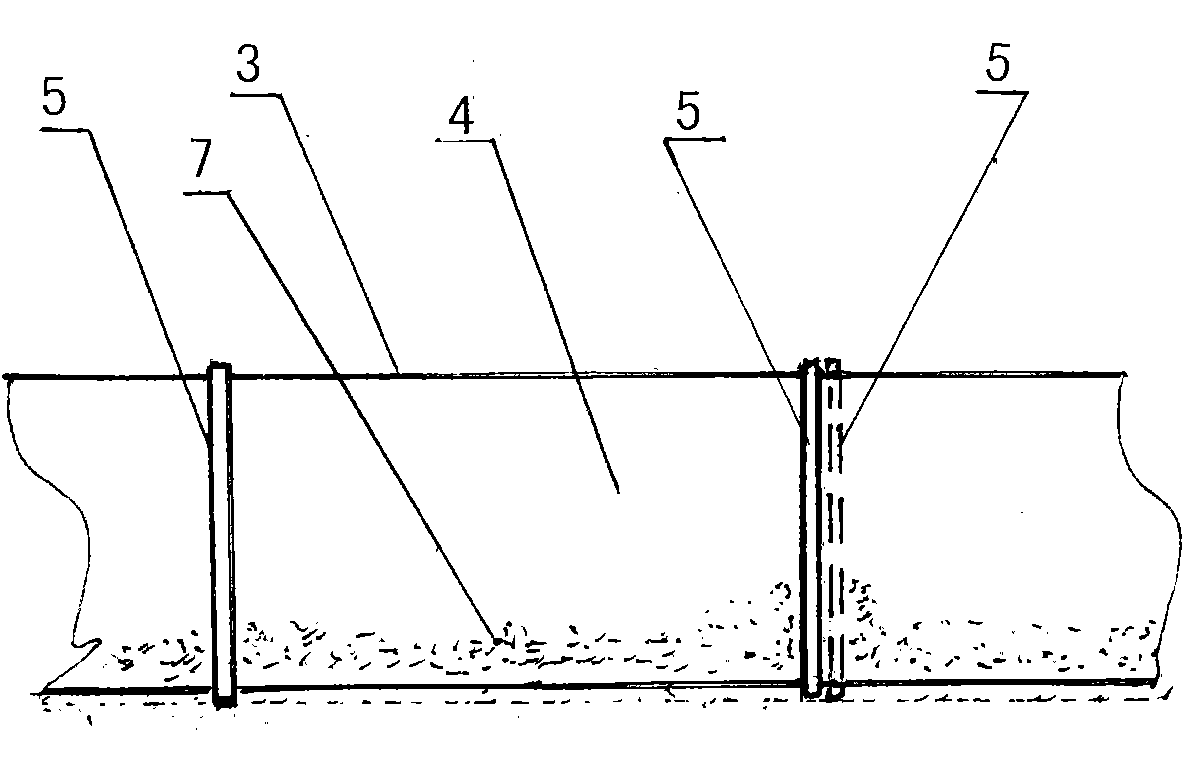

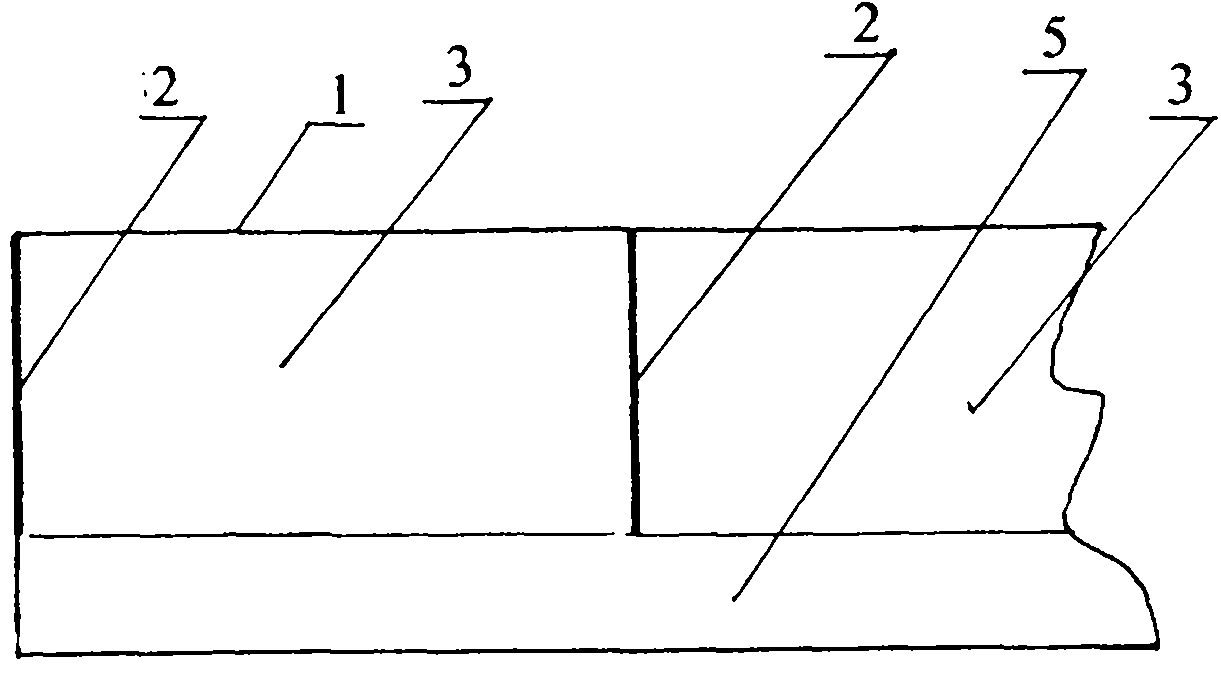

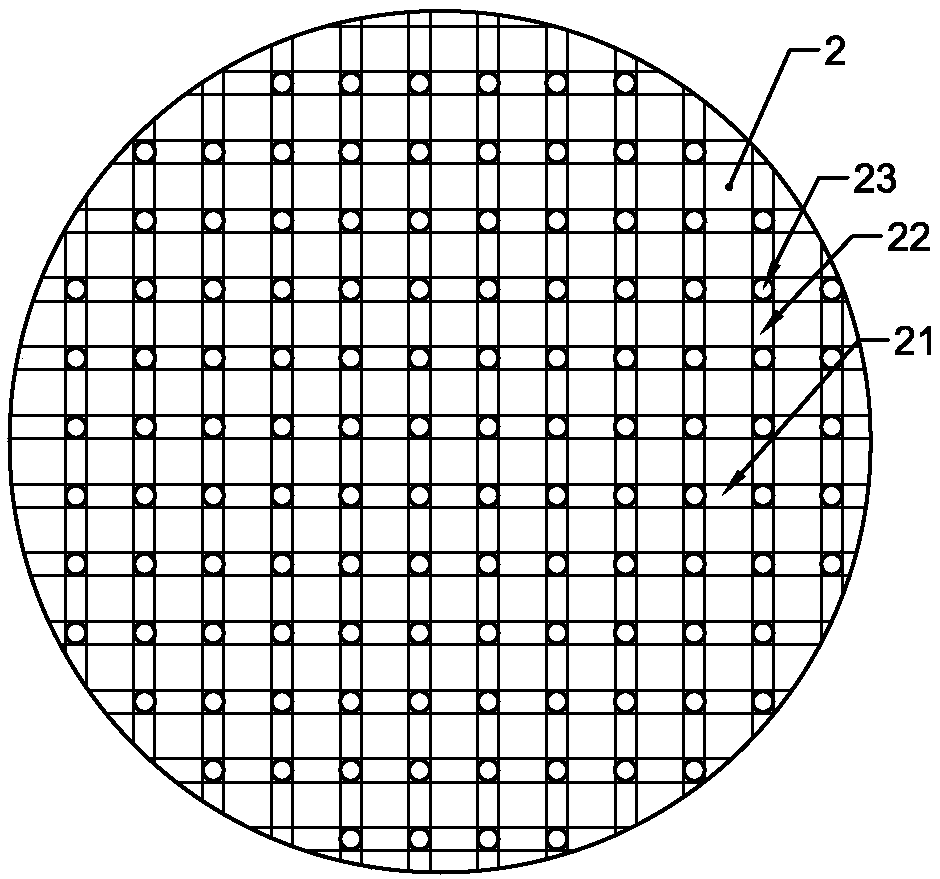

Tandem cylinder mould for manufacturing sand barrier, sediment storage dam, sand dyke and sand wall

The invented method provides a series mesh cage for constructing sand barriers, sediment storage dams, sand banks and sand walls, comprising a triangular cage body composed of a mesh cage front surface 2, a mesh cage rear surface 3, and a mesh case bottom surface 4, the inner of the front surface 2 and rear surface 3 of the mesh cage have earthwork cloth liners 5. The series mesh cage is used to construct sand barriers, sediment storage dams, sand banks and sand walls. Thereby sand in desert is used as building material for fathering desert. The invented mesh cage can be produced mechanically in large scale, and sand barriers, sediment storage dams, sand banks and sand walls made of mesh cages can be constructed mechanically.

Owner:娄成城

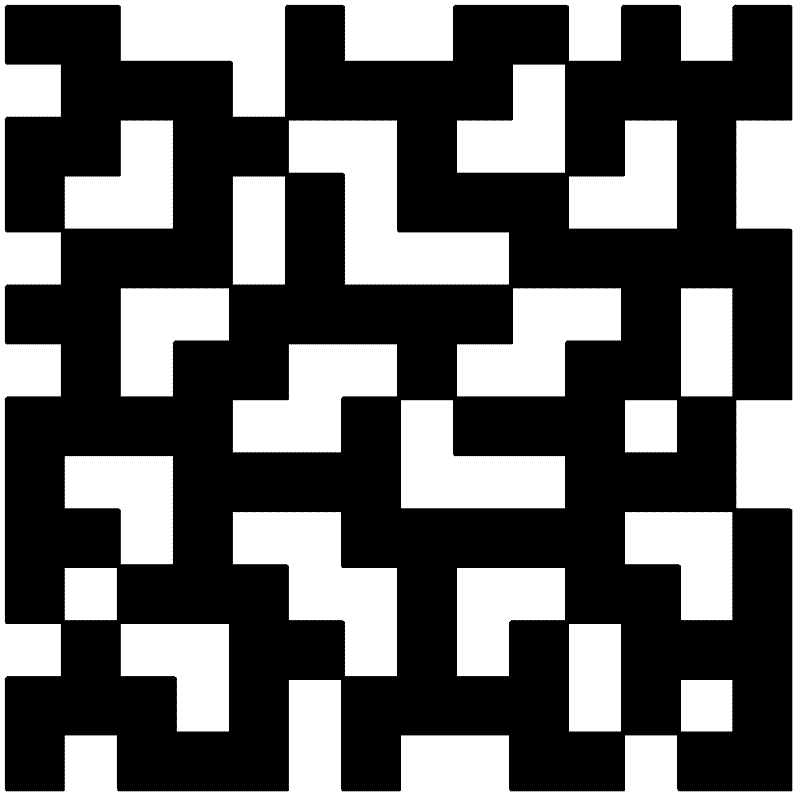

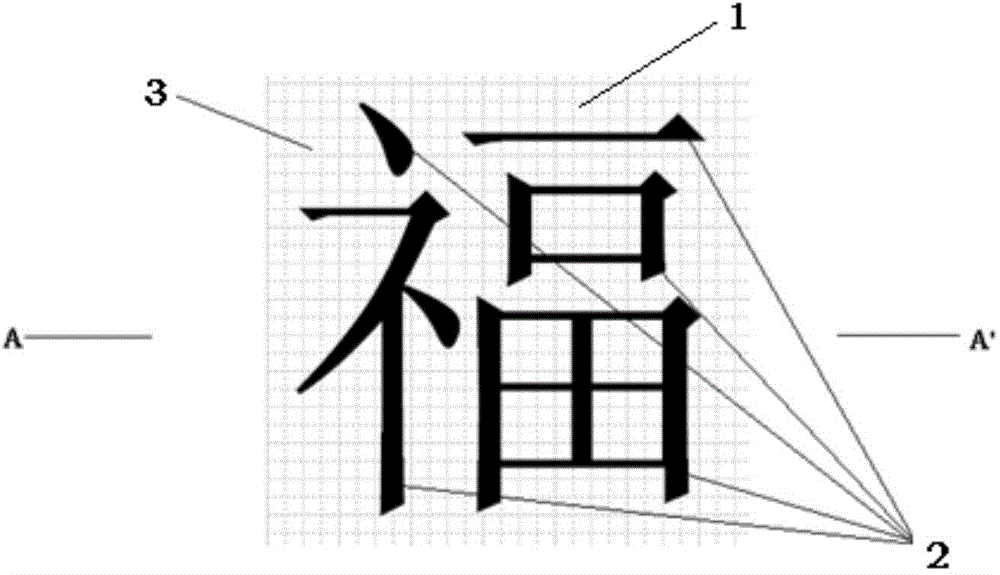

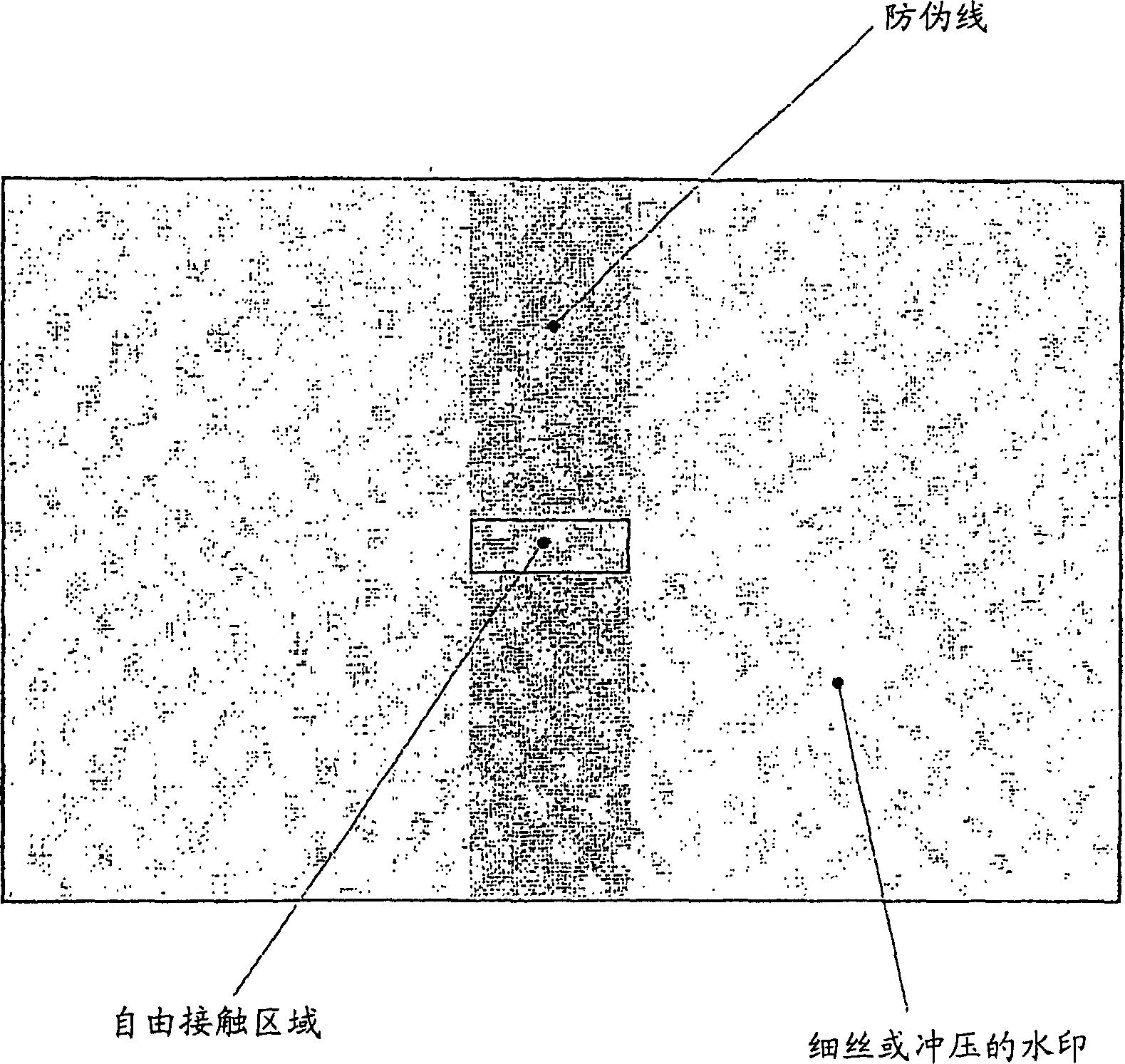

Two-dimension code watermark anti-counterfeiting paper and manufacture method thereof,as well as watermark cylinder mould

ActiveCN102373642AExquisitely madeStrong first-line anti-counterfeitingMachine wet endLight whiteBarcode

The invention relates to a manufacture method of two-dimension code watermark anti-counterfeiting paper. The two-dimension code watermark anti-counterfeiting paper has two-dimension code watermark in a high light white watermark form. The manufacture method of the two-dimension code watermark anti-counterfeiting paper comprises the following steps that: a watermark mould sheet is manufactured according to the patterns of the two-dimension code, or the watermark mould sheet is manufactured according to the combined patterns of the two-dimension code and a one-dimension bar code, the watermark mould sheet is welded or pasted on a watermark net to obtain a net sleeve, the net sleeve is fastened on a round cylinder mould in an expansion way, the round cylinder mould is placed on a paper machine for paper making, the two-dimension code watermark anti-counterfeiting paper with the two-dimension code watermark is prepared, or the two-dimension code watermark anti-counterfeiting paper with the combination of the two-dimension code watermark with the one-dimension bar code watermark is prepared. The two-dimension code watermark anti-counterfeiting paper manufactured by the invention has the advantages that the manufacture is exquisite, the appearance is novel and attractive, the authenticity identification can be easily realized by people, and strong one-line anti-counterfeiting and two-line anti-counterfeiting functions are realized.

Owner:BAODING BANKNOTE PAPER CO LTD +1

High mesh size print cylinder mould production method

ActiveCN101284438AUniform thicknessExtended service lifePrinting pre-treatmentForme preparationPrinting inkEngineering

Owner:山东同大镍网有限公司

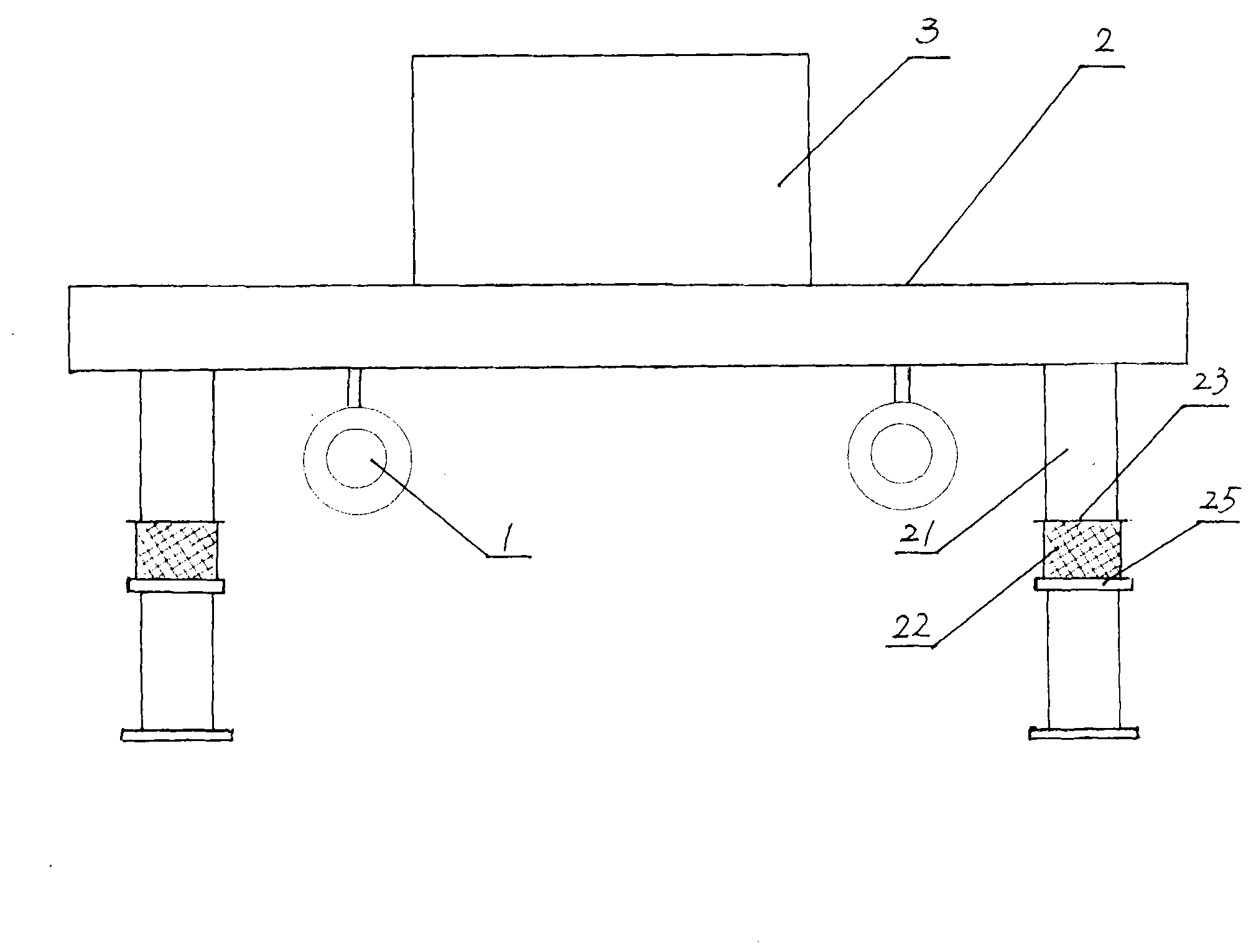

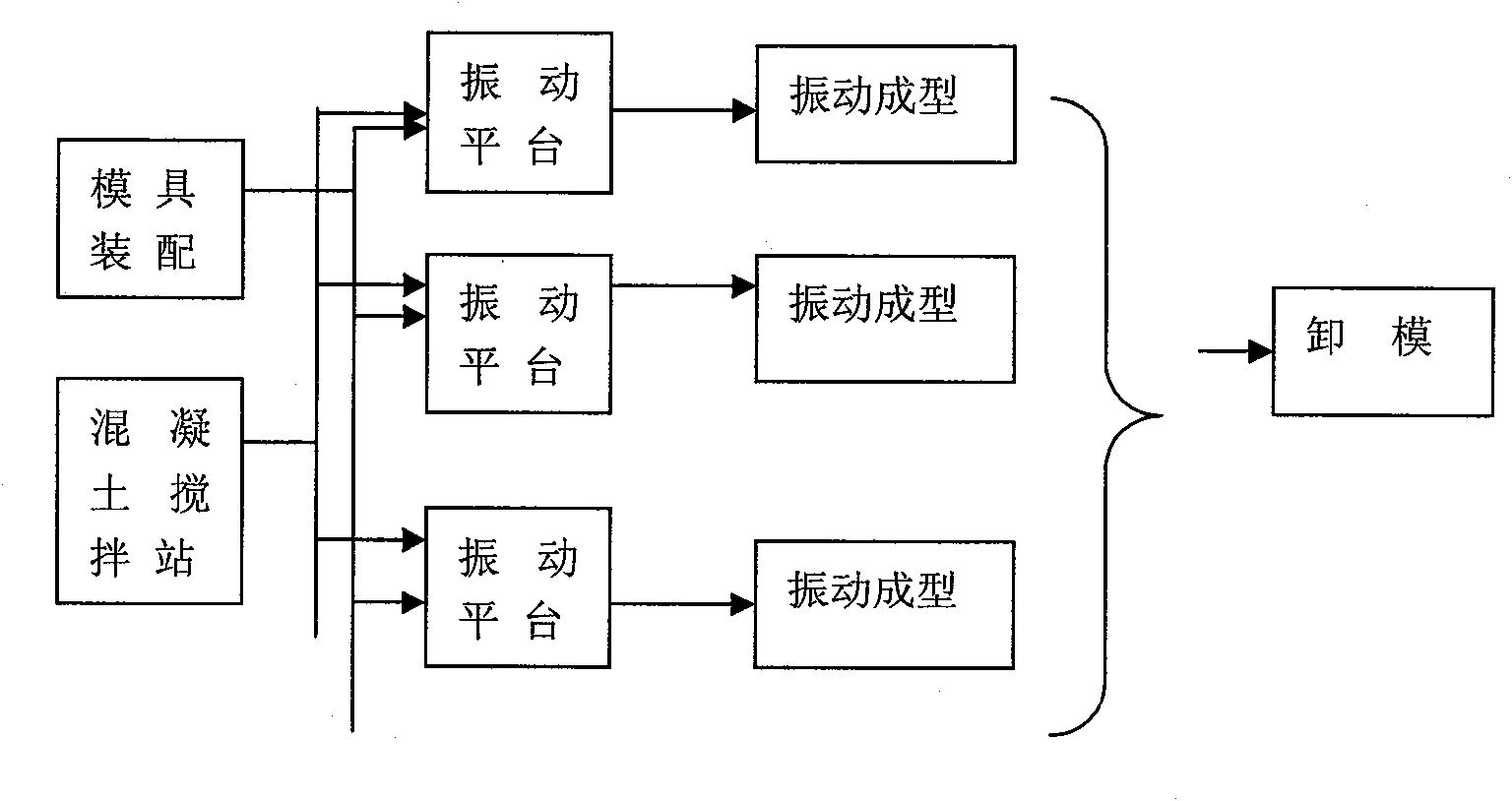

Concrete pipe platform vibration moulding process and device thereof

The invention relates to a concrete pipe production process. The process includes the following steps: a vibration platform is set, the vibration platform is a mechanical vibration machine with double amplitude vibration sources and amplitude of 1-2, a movable or nonmovable mould is made, the specification Phi of the mould is 1000-3600mm; concrete is prepared; assembling is carried out and the mould is fixed, namely a core mould and an external mould are lifted and mounted and are connected with the base of the mould, and a skeleton steel bar cylinder mould is placed into the mould, and the mould is fixed on the vibration platform to be poured and vibrated; and a moulding opening is arranged on the vibration platform, and concrete is poured into the mould by virtue of an automatic pouring device. A vibration glue pier is arranged between landing legs of the vibration platform, and swing amplitude of eccentric block is reduced. The invention has high vibration frequency, low energy consumption, reasonable vibration distribution and high product moulding compaction rate, and no undesirable influence can be produced on longitudinal and transverse vibrations; vibration moulding speed is fast, equipment cost thereof is only one fourth that of core mould vibration equipment; besides, motor power is low, vibration time is short, and energy sourced is saved.

Owner:朝阳市天龙大型水泥管道(集团)有限公司

Preparation method of fractured carbonate rock core

The invention provides a preparation method of a fractured carbonate rock core. The method includes: mixing evenly carbonate, an inorganic glue and a soluble organic gel powder, laying the mixture on two semicircular cylinder moulds; laying a proppant of a certain particle size on the surface of one of the semicircular cylinder mixture according to the needs; filling soluble organic gel prepared in advance between the proppant; keeping the two semicircular cylinders containing the materials at a constant temperature in a constant temperature box, and preliminarily molding the materials in the semicircular cylinders; and then assembling the two semicircular cylinders into a cylinder; placing the cylinder in a pressurizing device of a core preparation device for pressing, then soaking in distilled water for 20min, taking out, and displacing the soluble organic gel with distilled water to obtain the support crack rock core with certain width. The preparation method of fractured carbonate rock core not only can prepare the fractured carbonate rock core with proppant support, but also can obtain support fractured carbonate rock cores of different widths through selection of proppant size.

Owner:SOUTHWEST PETROLEUM UNIV

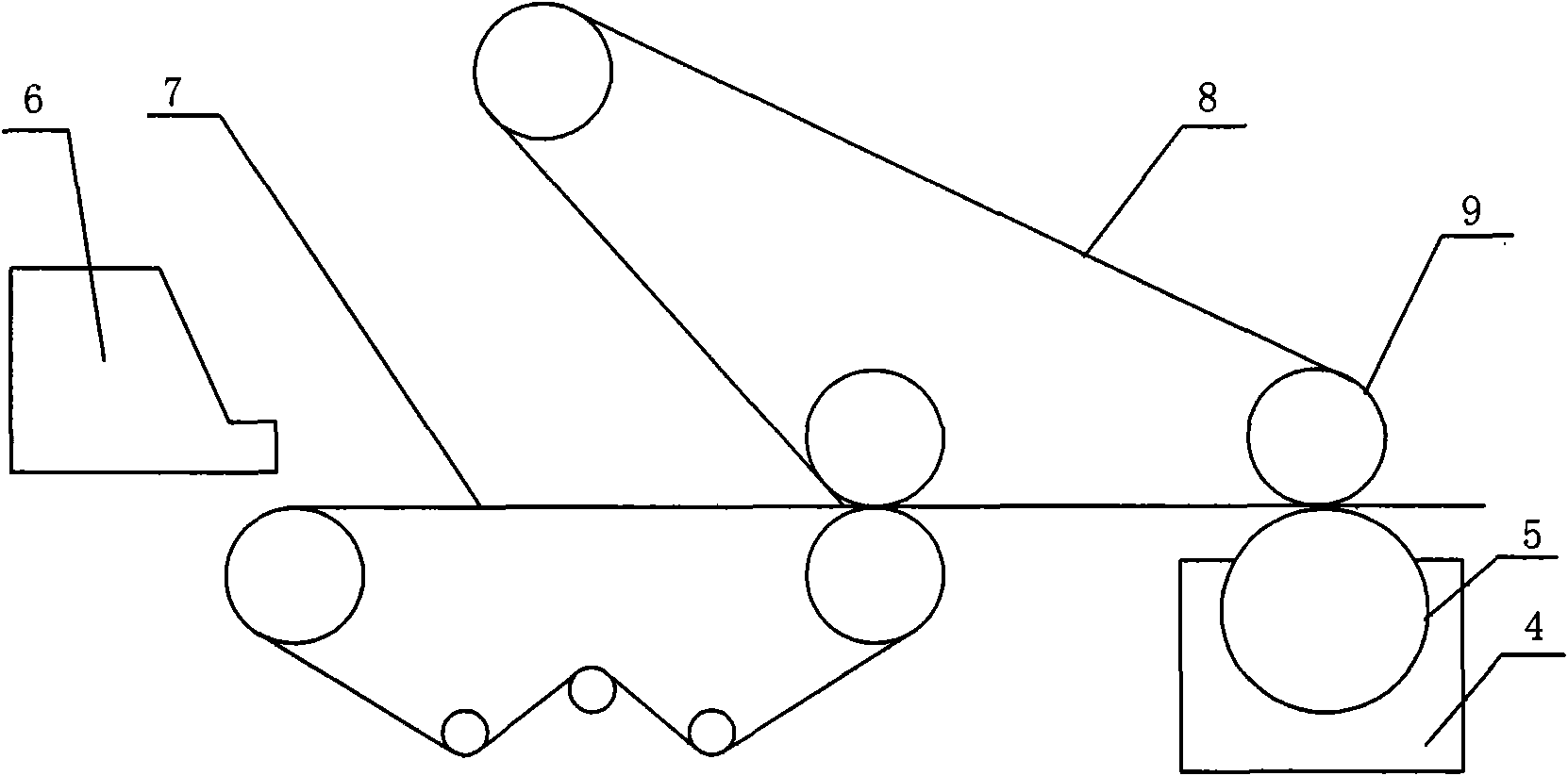

Equipment for producing reflection film with microprism array structure by using cylinder mould

ActiveCN102354009ASimple production processReduce processing costsOptical elementsUltravioletThin membrane

The invention relates to equipment for producing a reflection film with a microprism array structure by using a cylinder mould. As photosensitive resin is used as a microprism molding material in the prior art, the defects that the selection range is narrow, the production cost is high, the subsequent processability is low, the application range is narrow and the like exist. The equipment for producing the reflection film with the microprism array structure by using the cylinder mould comprises the cylinder mould, a hot melting resin coating device and a mould pressing device, wherein the cylinder mould is provided with an inner surface and an outer surface; the outer surface is provided with a sunk continuous microprism array structure; hot melting resin is coated to one side surface of a resin film by the hot melting resin coating device; the side surface of the resin film clings to the outer surface of the cylinder mould; and the gap of the sunk microprism array structure is filledwith the hot melting resin through mould pressing. As the hot melting resin molding microprism array structure is used in the equipment for producing the reflection film with the microprism array structure by using the cylinder mould, the subsequent processability of the manufactured reflection film is more excellent, and the application range is wider; a drying or ultraviolet (UV) solidifying device is not needed by the equipment, thereby, the processing cost is low, the production speed can be obviously increased, and the production process is more environmentally friendly.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

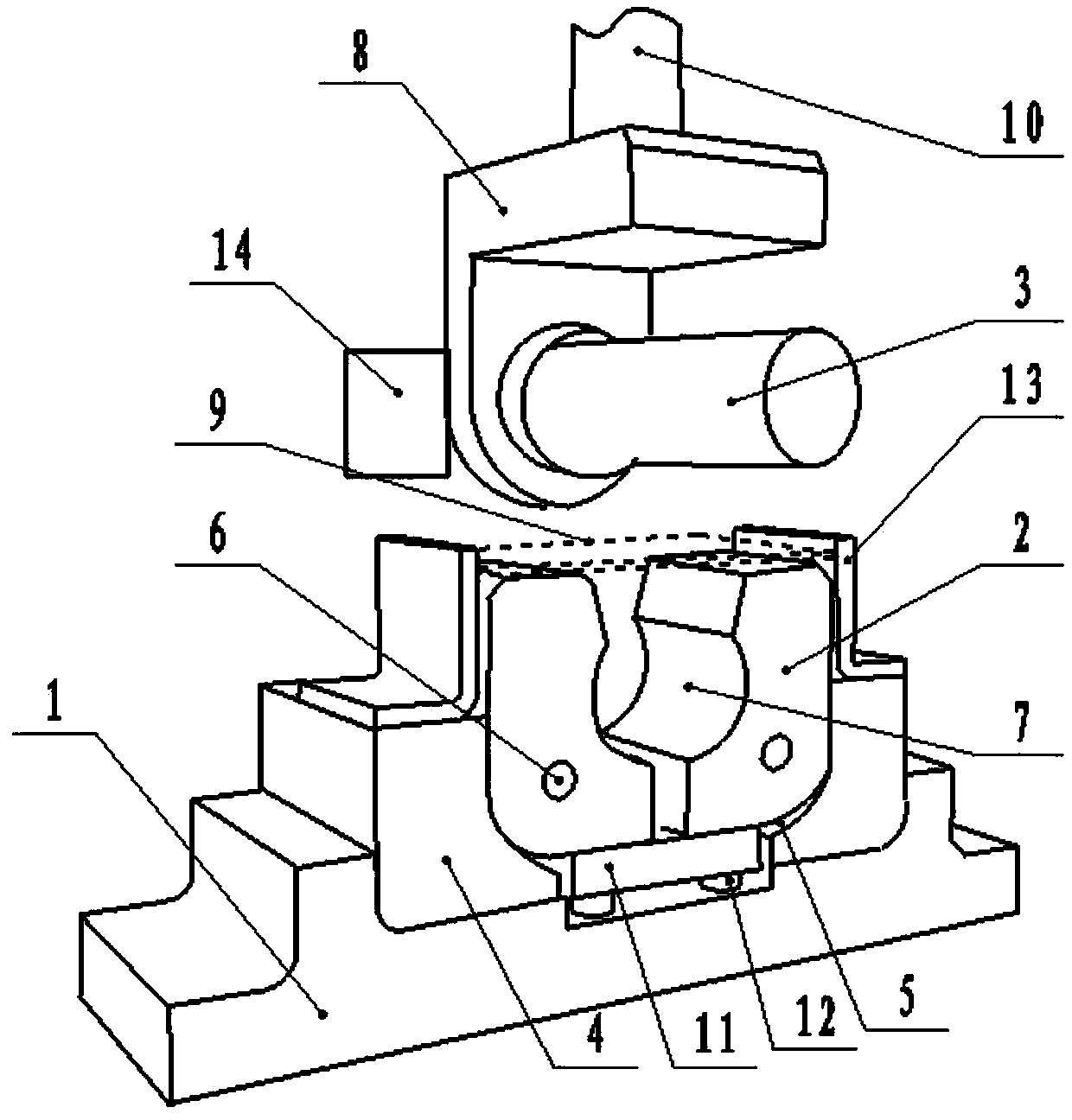

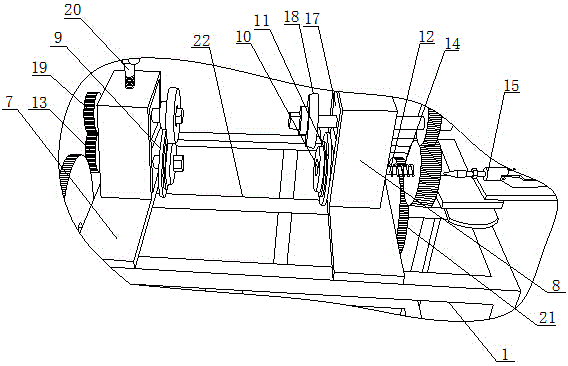

Automatic stamping system and method for cylinder part with automatic unloading function

InactiveCN107755474ARapid stampingReturn quicklyEjection devicesMechanical engineeringCylinder mould

The invention discloses an automatic stamping system and method for a cylinder part with an automatic unloading function. The automatic stamping system comprises a stamping base, stamping female mouldblocks and a stamping male mould rod, wherein two stamping limiting blocks are symmetrically arranged on the stamping base, and limiting arc-shaped surfaces are arranged on inner surfaces of the stamping limiting blocks; the two stamping female mould blocks are correspondingly arranged on the limiting arc-shaped surfaces of the two stamping limiting locks through limiting shafts; circular-arc shaped surfaces matched with outer-circle dimensions of stamped cylinder parts are arranged on the inner surfaces of the stamping female mould blocks; the stamping male mould rod is horizontally arrangedabove the stamping base and is connected with a stamping block; an unloading air cylinder is arranged at the rear side of the stamping block which corresponds to the stamping male mould rod; the unloading air cylinder is mounted on the stamping block through a mounting frame; a telescopic arm end head of the unloading air cylinder is equipped with a pushing frame; the stamping male mould rod is used for introducing the stamping plate into a cylinder mould formed by the two stamping female mould blocks; and under stamping action of the stamping male mould rod, the stamping female mould blocksrotate around the limiting shafts for stamping the stamping plate into the cylinder part.

Owner:巴中市新越不锈钢有限公司

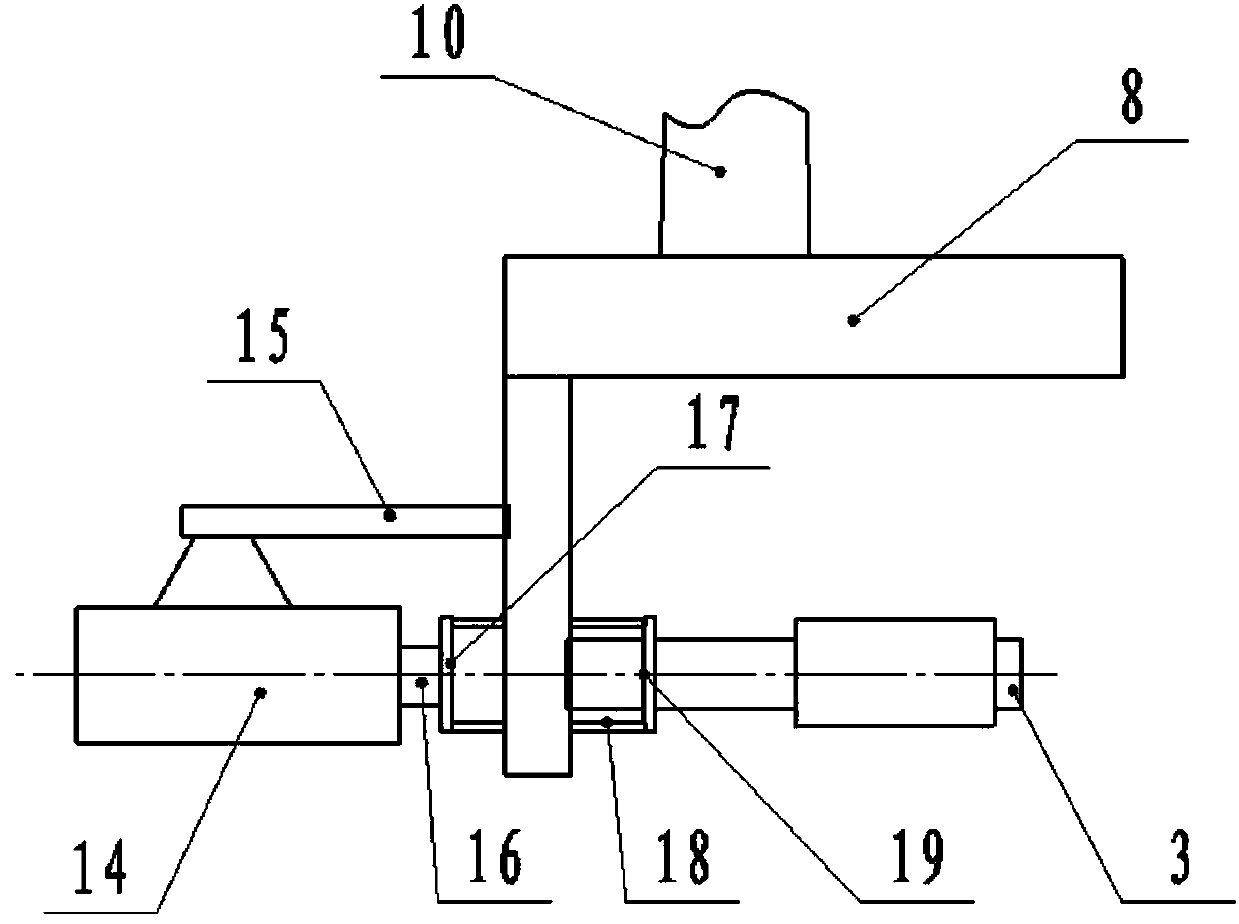

Preparation method for composite processed absorbent paper by using cylinder mould machine

InactiveCN108867149AReduce dosageReduce manufacturing costDryer sectionRaw material divisionFluff pulpSlurry

The invention provides a preparation method for composite processed absorbent paper by using a cylinder mould machine. The method comprises the following steps that 1, wood pulp and fluff pulp are mixed according to a certain proportion; 2, fiber defiberizing is carried out after the mixed pulp liquid is repulped; 3, blending is carried out on the defiberized pulp liquid in a blending pool; 4, thefully mixed blended pulp is sent into the cylinder mould machine to produce single-layer wrinkling base paper; 5, pressing fitting is carried out on the single-layer wrinkling base paper produced instep 4 and single-layer semi-synthetic base paper, wherein the single-layer semi-synthetic base paper is continuously produced, runs synchronously in the same direction with the single-layer wrinklingbase paper, and is loaded with uniformly spread macromolecular water-absorbent resin particles; 6, the pressed and fitted double-layer base paper enters a drying cylinder to be dried, wrinkled and shaped; 7, the shaped product is cut into various sizes according to demands of customers. The prepared absorbent paper is ultrathin, soft, air-permeable and dry and has stable quality.

Owner:卢秀霞

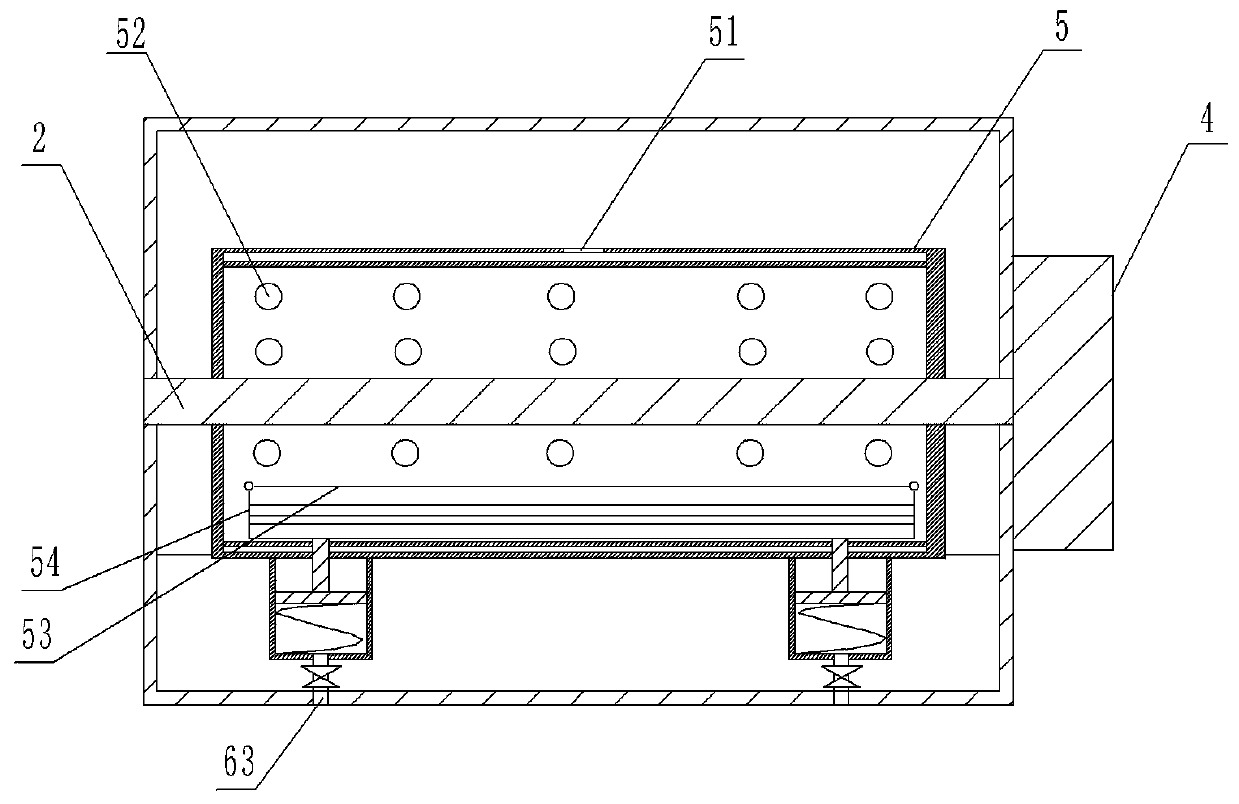

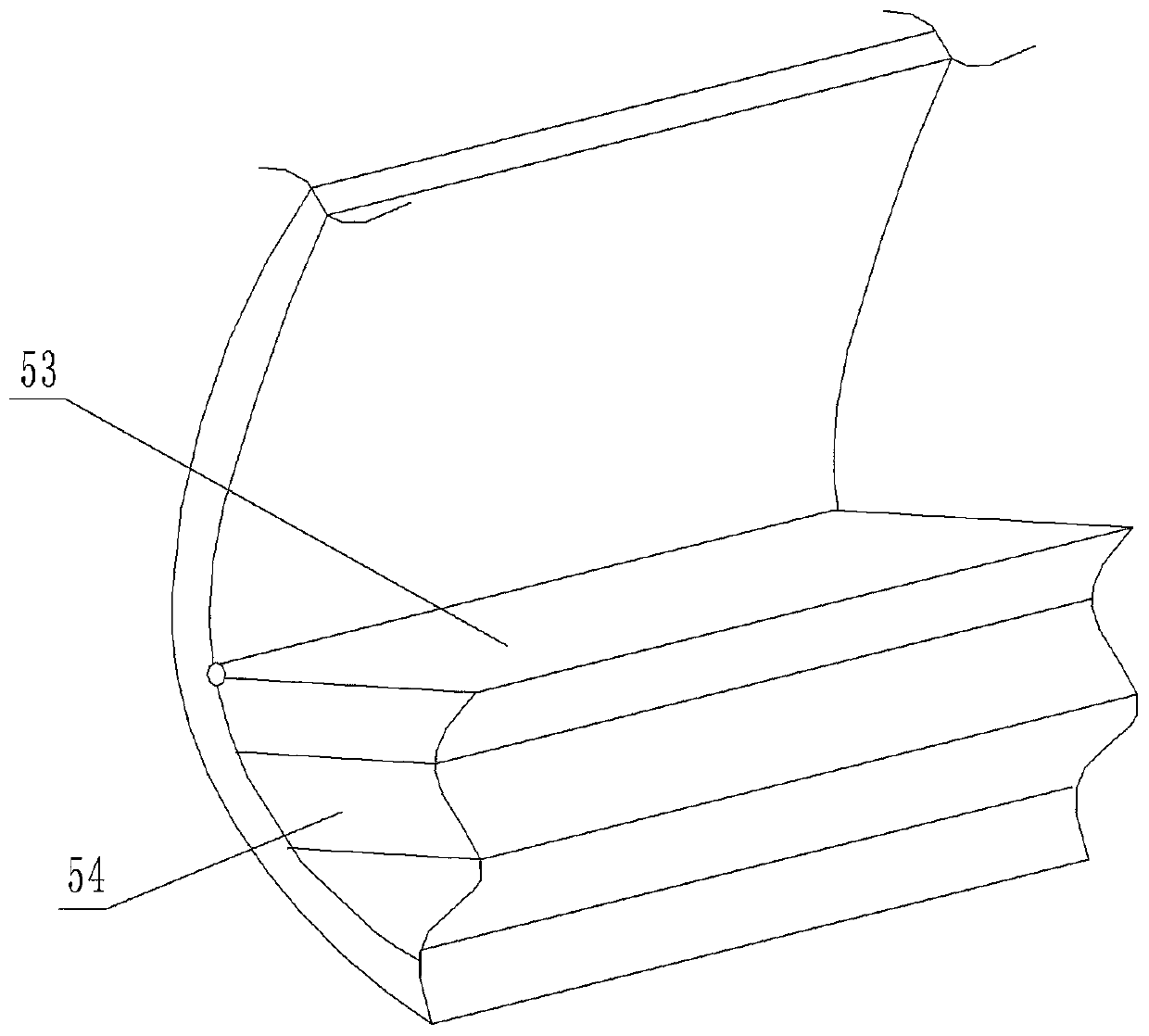

Composite vertical compression mould clamping device

The invention discloses a composite vertical compression mould clamping device comprising a tail board, a second board, a pull rod, a head board and a mould clamping cylinder, wherein the head board is connected in front of the pull rod; the tail end of the pull rod is connected with the tail board; the second board is arranged on a guide rail but not sleeved on the pull rod and is also provided with a support pillar; one end of the support pillar is fixed on the second board, and the other end is arranged in a guide sleeve of the support pillar after passing through a mould clamping piston and is also provided with a support pillar inner cavity in which a piston rod is arranged; one side of the piston rod forms a rodless cavity together with the support pillar inner cavity, and the other side forms a rod cavity; the rod cavity and the rodless cavity are both connected with an external oil path; the mould clamping cylinder comprises a mould clamping piton sleeve and a mould clamping piston; the mould clamping piston sleeve is fixed on the tail board; a mould clamping cylinder mould breaking cavity is formed between the mould clamping piston and the tail board; and mould clamping cylinder mould protecting cavities are respectively formed between the mould clamping piston and the tail board and between the mould clamping piston and the support pillar guide sleeve. The invention has the advantages that the pull rod is well stressed and not easy to break off; the second board is flexible and convenient to move; and the whole mechanism has strong adaptability on a mould and good whole rigidity.

Owner:HAITIAN PLASTICS MACHINERY GRP

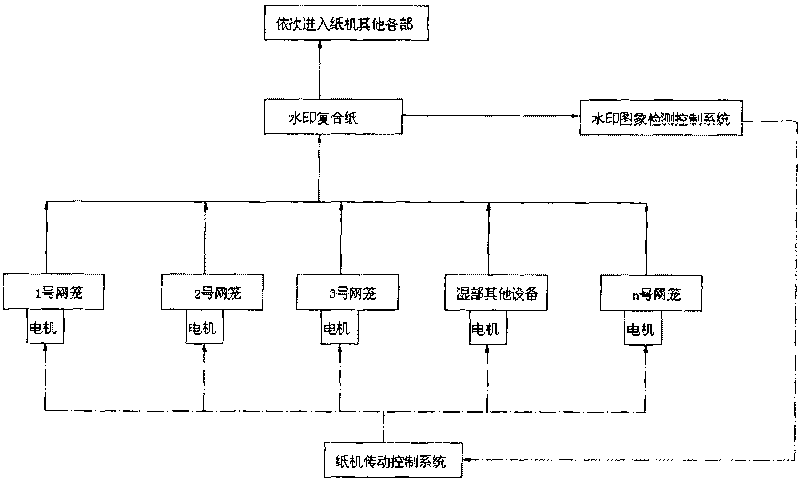

Compound watermark anti-counterfeiting paper and manufacturing method thereof

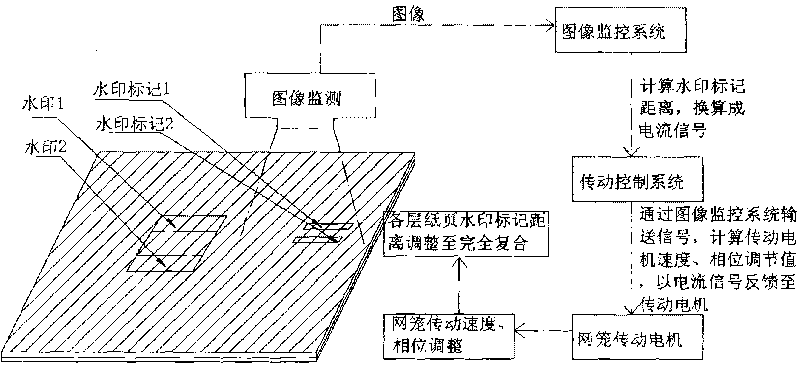

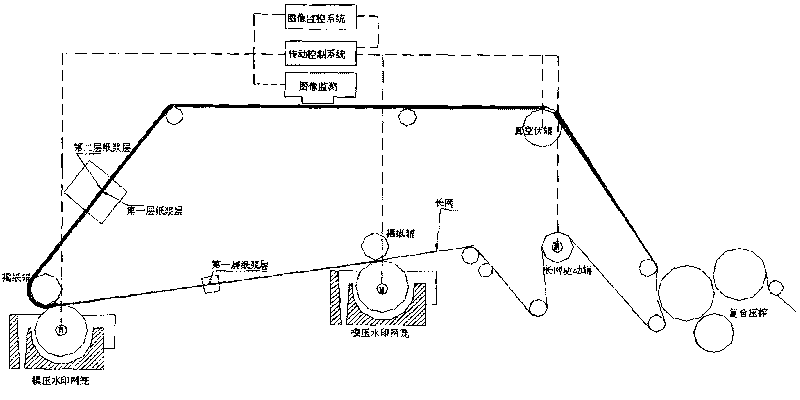

ActiveCN101748638AStrong anti-counterfeiting featuresEasy to identifySpecial paperPaper/cardboardPhase adjustmentCylinder mould

The invention provides a manufacturing method of compound watermark anti-counterfeiting paper, comprising a first part paper feeding flow: (1a) a pulp layer is provided for the cylinder mould of a multivat machine for compounding, wherein the cylinder mould comprises a first cylinder mould and a second cylinder mould; the pulp layer at least comprises a first pulp layer with a first watermark and a second pulp layer with a second watermark; the pulp layer is respectively provided with a mark capable of being detected; the first pulp layer is distributed on the first cylinder mould, and the second pulp layer is distributed on the second cylinder mould. (1b) The first pulp layer and the second pulp layer are revealed and compounded and are transmitted into a second part flow by a fourdrinier wire; the second part flow is a watermark position adjusting flow comprising: (2a) monitoring the compound precision marked between pulp layers to obtain feedback information; and (2b) according to the feedback information, adjusting the watermark: using a synchronized drive technology to adjust rotation speed and carry out phase adjustment of longitudinal watermark compound position; and using a cylinder mould horizontal position adjusting technology to adjust the horizontal watermark compound position to form the compound watermark anti-counterfeiting paper.

Owner:CHINA BANKNOTE PRINTING & MINTING

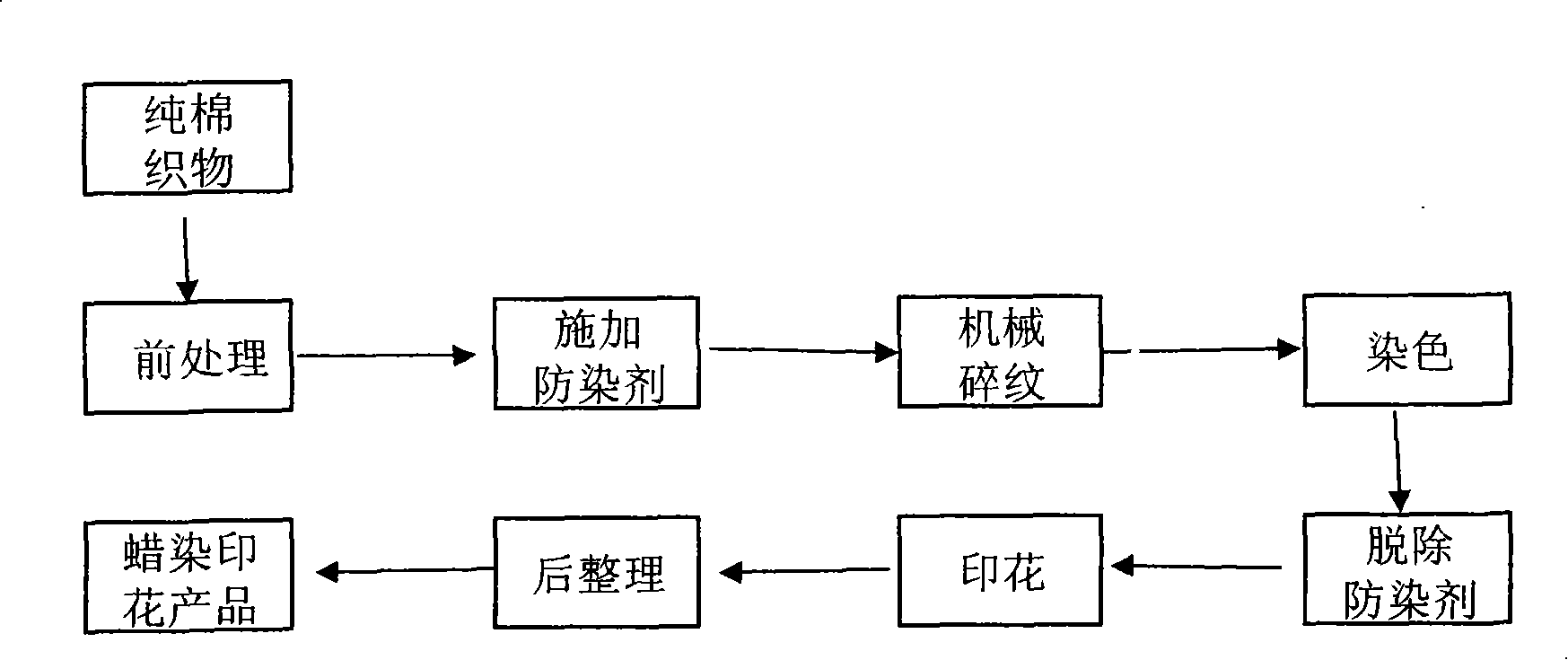

Process for continuously printing patterns on purified cotton textiles by wax printing

The invention relates to a method for continuous printing of wax dyeing of pure cotton fabrics. The method comprises steps of pretreatment of fabrics and post-processing of fabrics; the method is characterized in that the pretreatment of fabrics orderly comprises the following steps of dye resisting agent applying, mechanical crackle treatment, dyeing, dye resisting agent removal and printing; the dye resisting agent comprises the following components in percentage by weight: 70 to 90 percent of paraffin wax and 10 to 30 percent of wax dyeing modifying agent; the dye resisting agent is used by the padding or cylinder mould coating method; the mechanical crackle treatment is completed by scraping and grinding fabrics with dye resisting agent by adding a scraping-grinding roller in a conventional padding groove, and the scraping-grinding roller can be provided with scrapers in different shape according to technological requirements; the dyeing adopts the convention dyeing method; the dye resisting agent removal is to adopt the hot water suspension separation method to remove and recover the dye resisting agent; the printing is to adopt the conventional printing method to print dyed crackles.

Owner:济宁如意印染有限公司

Method for producing anti-counterfeiting card paper with windowed security thread

ActiveCN101581053AAvoid laminationEasy to processNatural cellulose pulp/paperPaper-making machinesFiberPulp and paper industry

The invention relates to a method for producing anti-counterfeiting card paper with a windowed security thread. The anti-counterfeiting surface paper with the windowed security thread is produced by a cylinder mould, the bottom paper is produced by a fourdrinier, and a joint between the wet bottom paper produced by the fourdrinier and the wet anti-counterfeiting surface paper with the windowed security thread, which is produced by the cylinder mould, is pressed to be dewatered by a press roll with felt; the water content in the surface paper and the bottom paper are controlled, so that hydrogen bonds between the surface paper and the bottom paper are combined to form the anti-counterfeiting card paper with the windowed security thread; and the anti-counterfeiting card paper with the windowed security thread is dried and reeled into a finished product. The surface paper and the bottom paper are made of the same pulp, which comprises the following raw materials in proportion: 65 percent of needle pulp and 35 percent of kargeleaf pulp; the degree of beating is between 45 and 48 degrees of SR; and during the combination, the water contents in the surface paper and the bottom paper are controlled to be between 62 and 63 percent. The method has the advantages of being easily processed, having low cost, avoiding lamination processing of the surface paper and the bottom paper, simplifying production flow, and improving the production efficiency. The anti-counterfeiting card paper produced by the method is applied to anti-counterfeiting garment hangtags, covers of anti-counterfeiting books and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

Moxibustion instrument

InactiveCN101658465ASpecific heatImprove thermal conductivityDevices for heating/cooling reflex pointsCombustion chamberEngineering

The invention discloses a moxibustion instrument, in particular relaes to a moxibustion instrument for the moxibustion. The moxibustion instrument comprises an instrument body made of woodblock stonematerials and a cover detachably connected with the instrument body; the instrument body and the cover form a combustion chamber, and the combustion chamber is communicated with outside by a hole forthe insertion of a moxa roll located at the bottom of the cover, pores uniformly distributed on the circumference of the hole and at least two side holes located at the side surface of the combustionchamber; a base is provided with a groove with an opening facing towards the surface of the moxibustion surface; the upper bottom of the groove is provided with a through hole coaxial with the hole; and a drug containing cylinder mould with an opening at the upper end is embedded in the through hole. The invention provides the moxibustion instrument with good moxibustion effect and convenient drugapplication, and well utilizes the heat generated by combusting the moxa rolls.

Owner:沈学谦

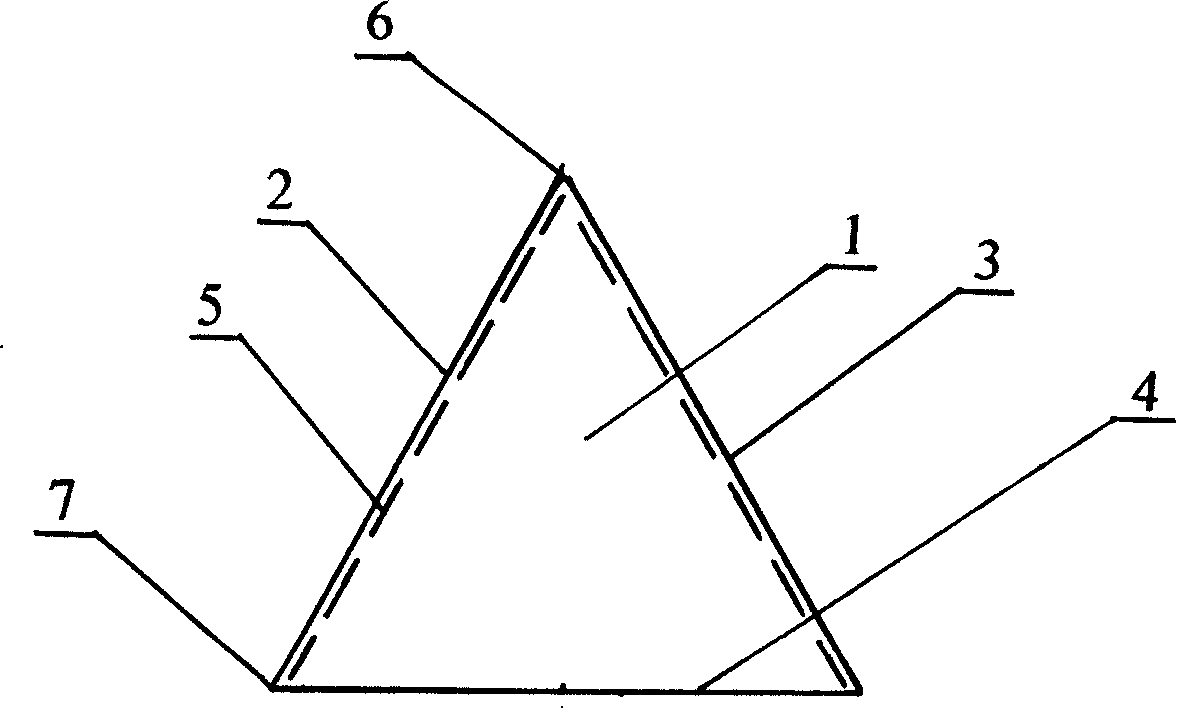

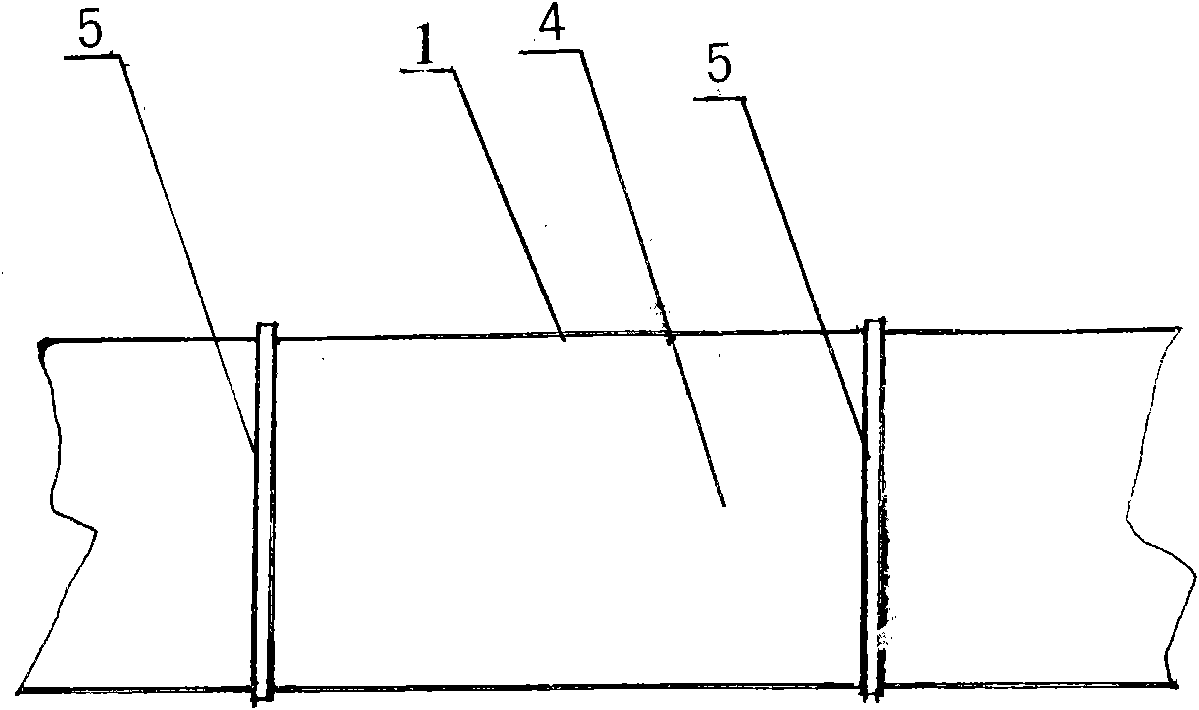

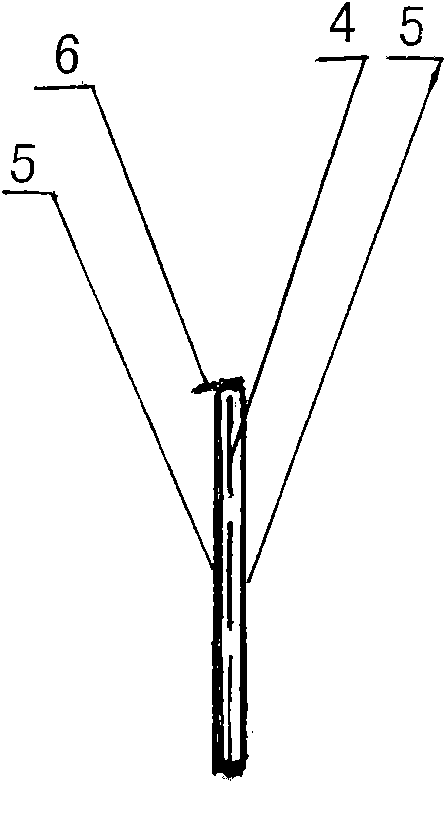

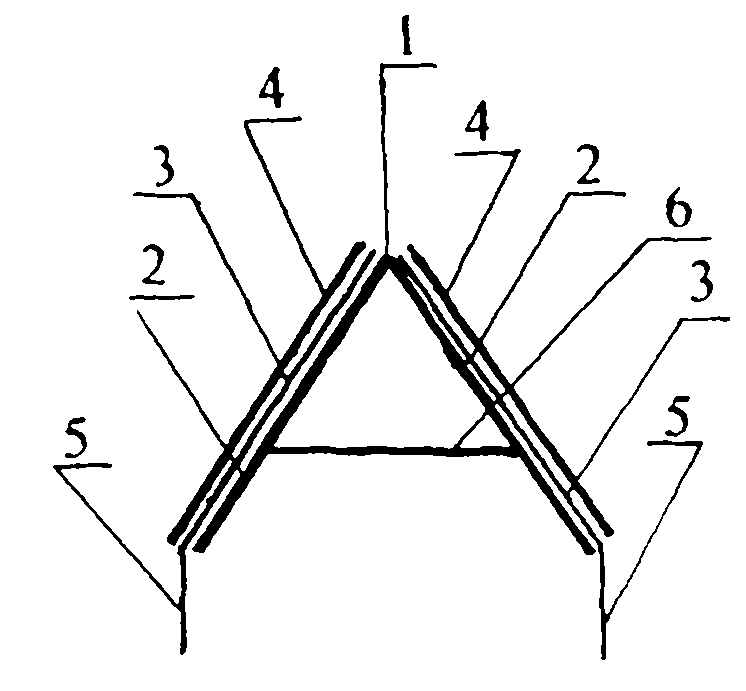

Splayed cylinder mould sand barrier and construction structure thereof

InactiveCN102002915AGood sand blocking effectTo achieve the purpose of fixed mobile desertProtective constructionSoil preservationPorosityMaterials science

The invention relates to the technical field of engineering, in particular to a splayed cylinder mould sand barrier and a construction structure thereof. The splayed cylinder mould sand barrier is formed by combining a front cylinder mould sheet and a rear cylinder mould sheet, wherein the front cylinder mould sheet and the rear cylinder mould sheet have the same structure and the same dimension and can be interchanged; in the cylinder mould sheets, plastic screen meshes of which the porosity is between 10 and 25 percent and the width is between 25 and 50cm are used as cylinder mould surfaces; a supporting rod is arranged on each cylinder mould surface at intervals of 50cm respectively and supporting rods are fixed with the cylinder mould surfaces to form the cylinder mould sheets; the front cylinder mould sheet and the rear cylinder mould sheet are tightened in the left and right directions; the top edges of the front cylinder mould sheet and the rear cylinder mould sheet are mutually close, and the bottom edges of the front cylinder mould sheet and the rear cylinder mould sheet are separated to form a splayed shape; the top of the supporting rod of the front cylinder mould sheet and the top of the supporting rod of the rear cylinder mould sheet are mutually close and are staggered and intersected; and a clamp hook at the top of the supporting rod faces down to clamp the top edge of the opposite cylinder mould sheet to form the splayed cylinder mould sand barrier. Splayed cylinder mould sand barriers are spliced one by one left and right on a desert in the same construction structure, and the splayed cylinder mould sand barriers extend dozens of meters, hundreds of meters, thousands of meters, dozens of kilometers and hundreds of kilometers along a design line.

Owner:娄志平

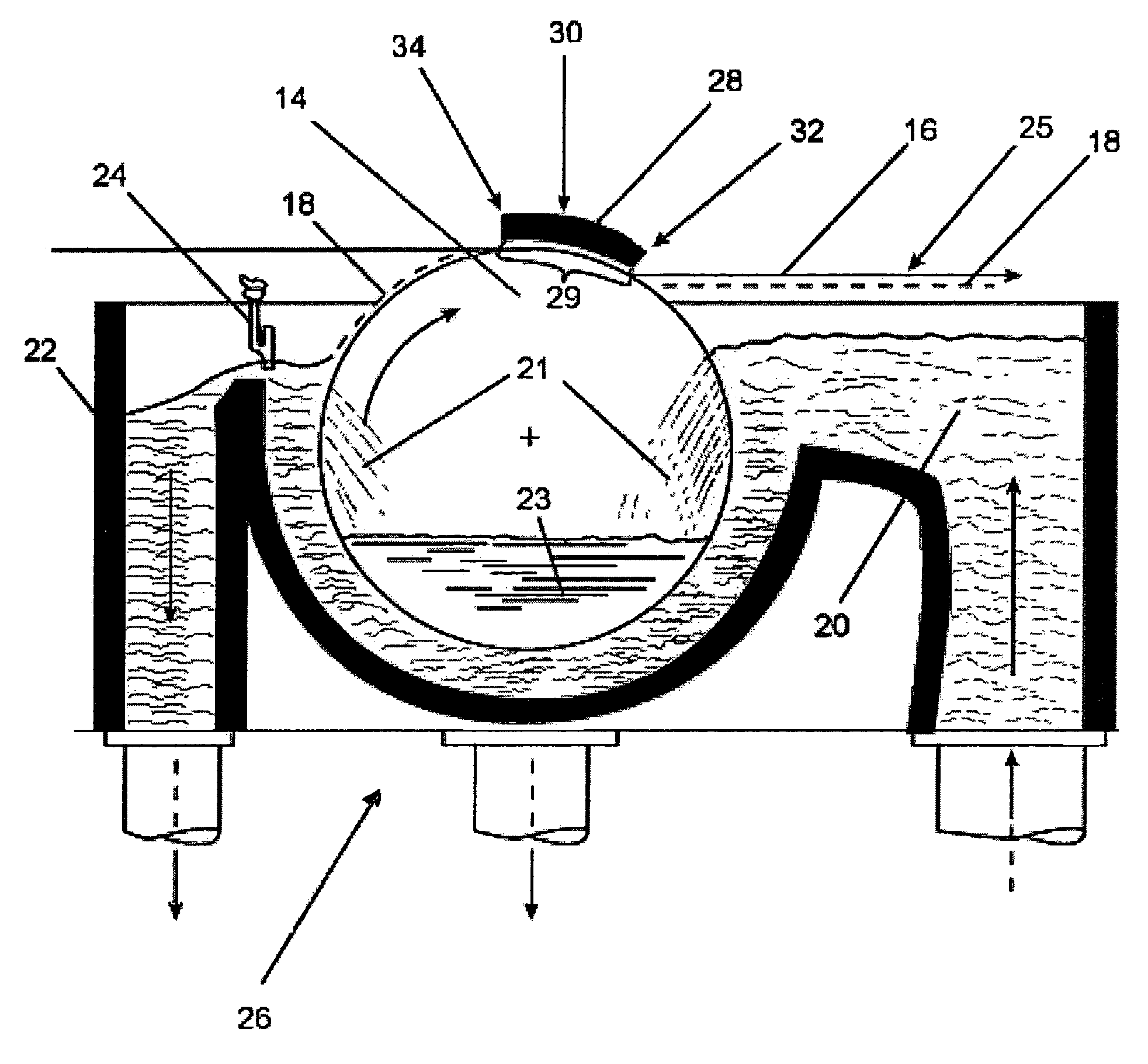

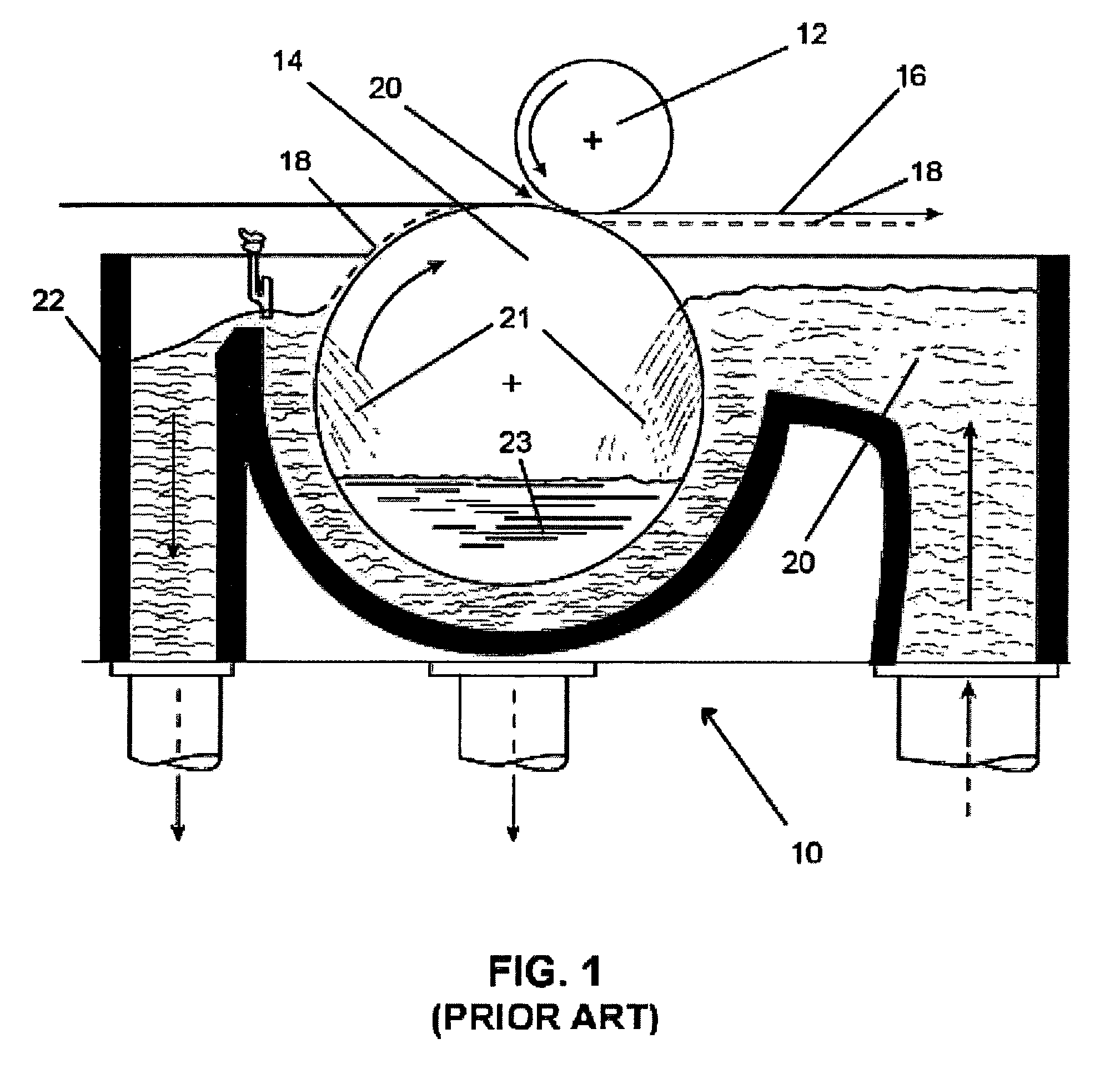

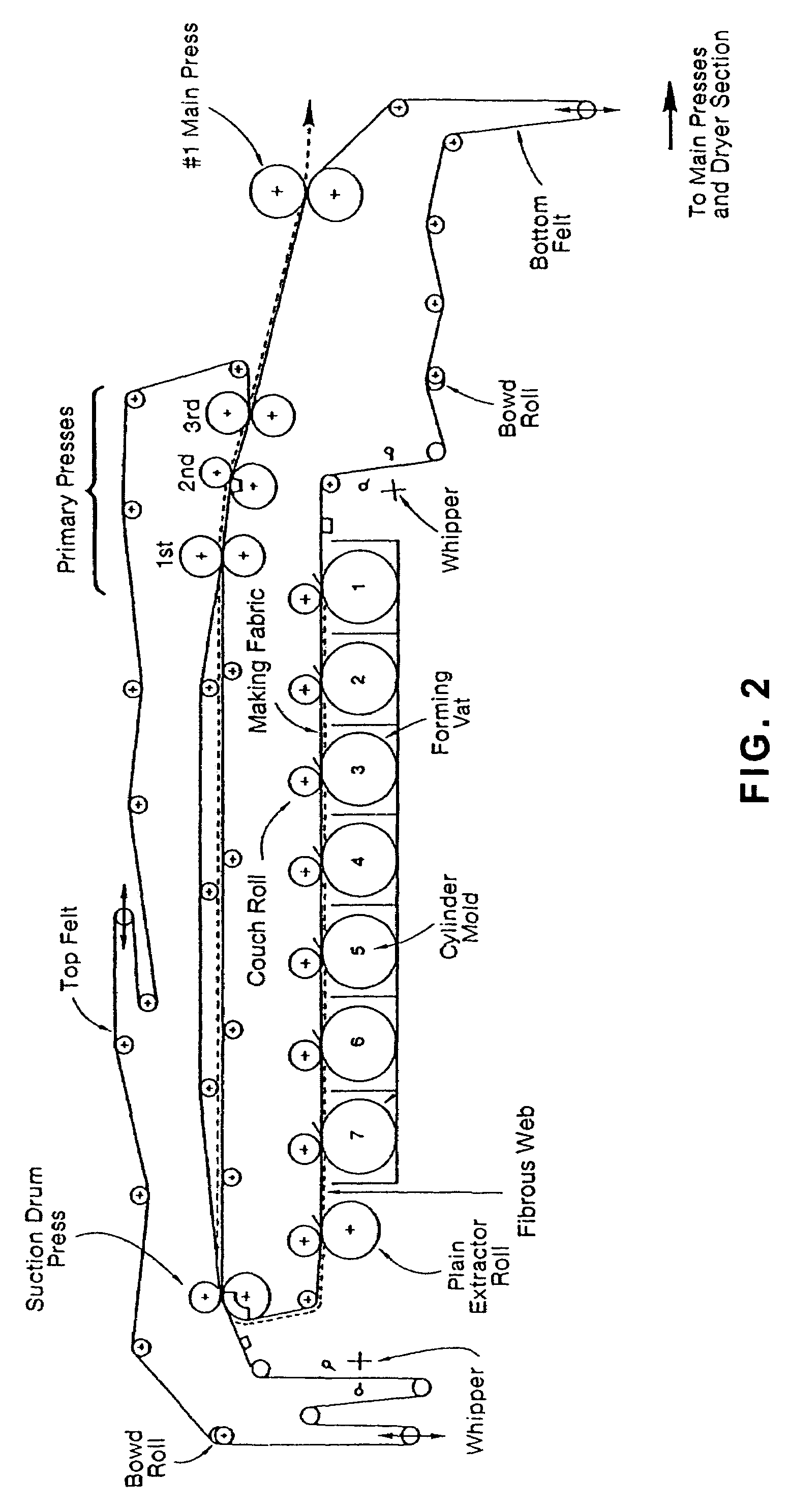

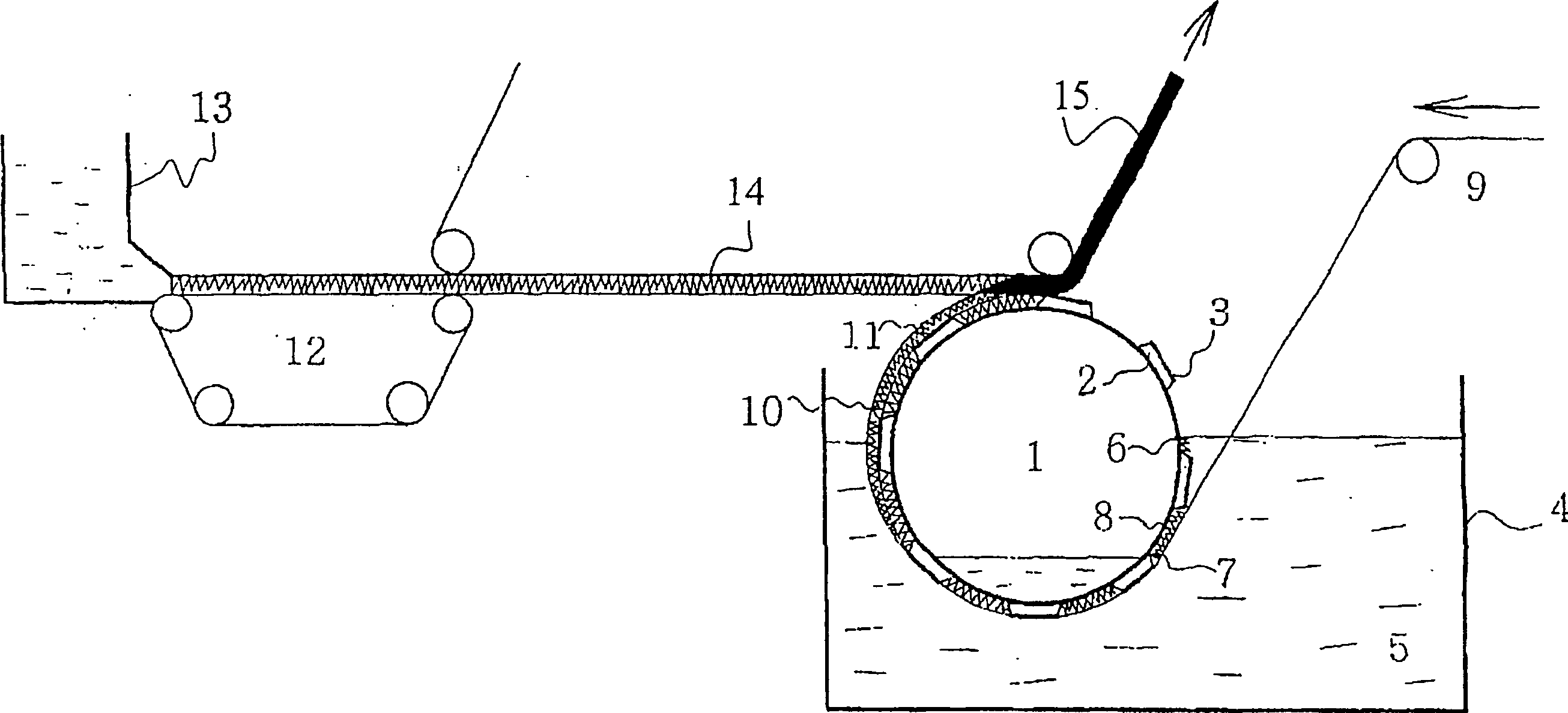

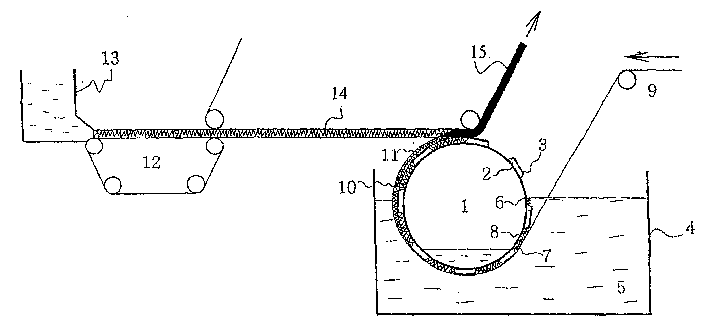

Extended couch nip on cylinder former

InactiveUS7510630B2Effective transmission torqueIncrease the amount of wrap a making fabricFibreboardMachine wet endEngineeringMechanical engineering

An apparatus for use in a cylinder machine having a shoe with a concavely-shaped pressure surface that forms a substantially mating relationship with a cylinder mould or sieve. The concavely-shaped pressure surface of the shoe increases the amount of wrap that a making fabric has on a cylinder mould or sieve thereby increasing the amount of friction generated between the making fabric and the cylinder mould or sieve. The increased friction results in an improved torque transfer between the making fabric and the cylinder mould or sieve.

Owner:JAMES HARDIE TECH LTD

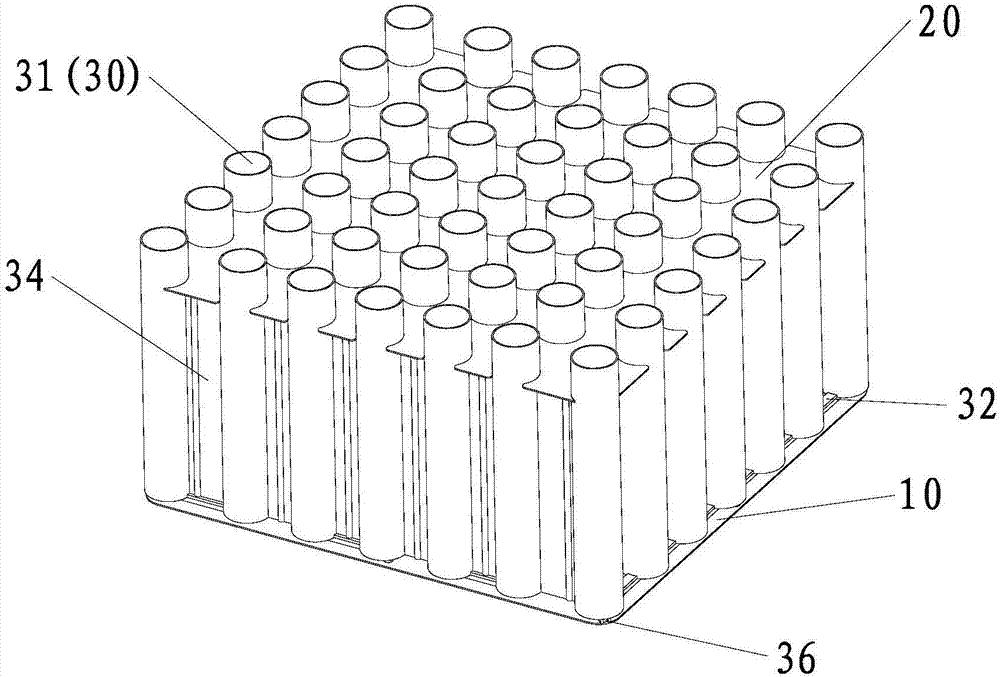

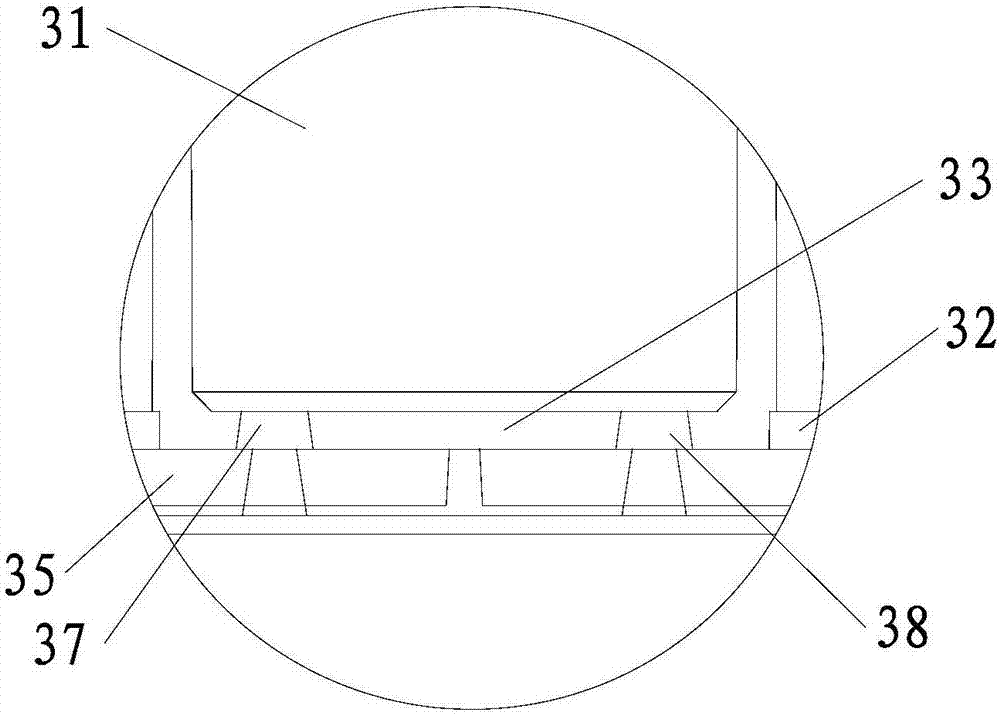

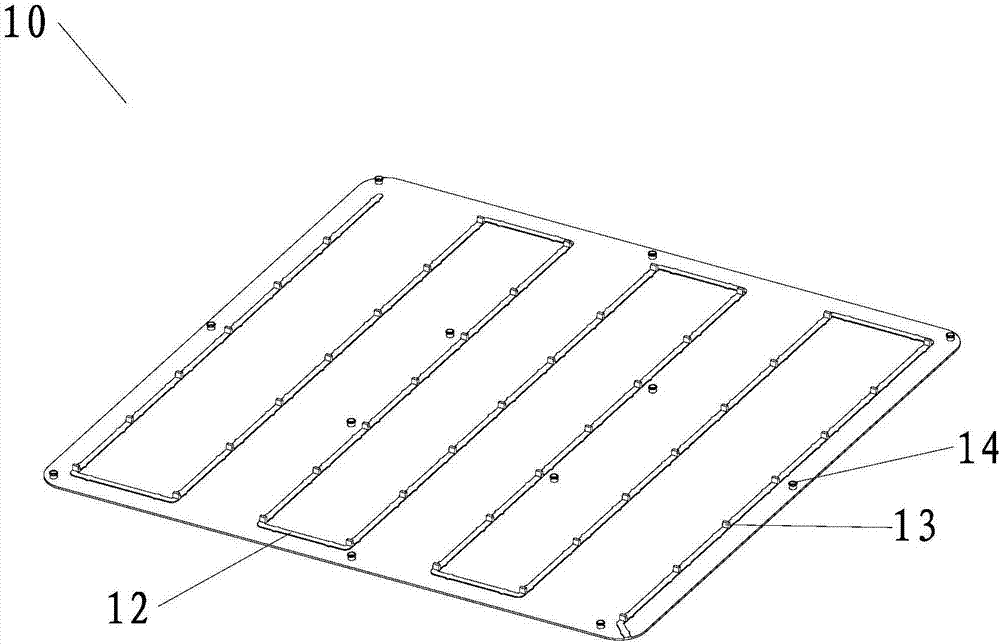

Firework plastic launching basin

The invention provides a firework plastic launching basin comprising a base, blocking pieces and a launching main body buckled on the base. The launching main body comprises a plurality of launching cylinders arranged longitudinally and transversely; a ribbed plate is arranged between the two adjacent launching cylinders on the same longitudinal row; and the blocking pieces are arranged on the launching cylinders or abut against the launching cylinders of the adjacent transverse columns correspondingly. Each ribbed plate is arranged between the corresponding two adjacent launching cylinders on the longitudinal row, the launching cylinders on the transverse columns are not connected by limited through the blocking pieces, so that the relative angles between the launching cylinders on the different longitudinal rows, and the relative positions of the opening parts of the launching cylinders on the different longitudinal rows can be changed, accordingly different patterns can be obtained after fireworks are ejected without the need of re-manufacturing of launching cylinder moulds, and thus the cost is relatively low; and meanwhile, bottom plates connected integrally are arranged at the lower ends of the launching cylinders, so that gunpowder is filled without splicing and is not liable to be ejected out in use, and the production efficiency is relatively high, and safety is achieved.

Owner:福建省安协安全技术咨询有限公司

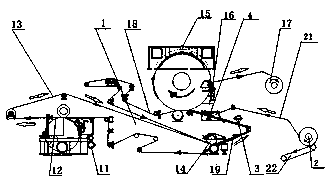

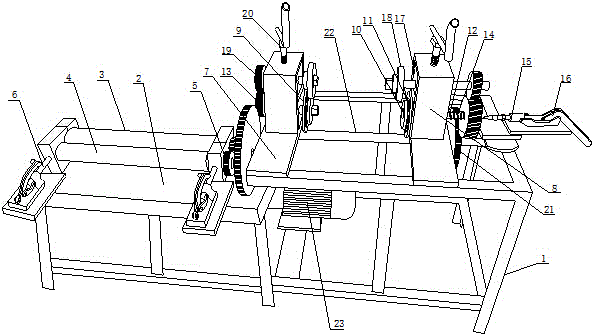

Cylinder moulding and capping all-in-one machine

The invention discloses a cylinder moulding and capping all-in-one machine which comprises a frame body, a moulding plate and a capping plate, wherein the moulding plate and the capping plate are installed on the frame body, a moulding roller is installed on the moulding plate, and a clamping groove is arranged in the moulding roller. A squeezing roller is installed parallel to the moulding roller, two mounting bases are symmetrically installed on the capping plate, and a left sleeve seat and a right sleeve seat are respectively arranged on the left and right mounting bases. Second gears are installed on the other side of the mounting bases, the right sleeve seat is connected with the second gears through rotating shafts, and springs sleeve the rotary shafts between the second gears and the mounting bases. A push rod connected with a hand-pressing bar is moveably installed on the frame body. Slide blocks are slidingly installed on the upper ends of the two mounting bases, and pressing blocks are arranged on the inner sides of the slide blocks. Third gears are installed on the other sides. Hand-operated rods in threaded installation on the top surfaces of the two mounting bases are connected to the slide blocks, a motor under the frame body is connected with an interlocking bar, and a driving gear is arranged on the interlocking bar. The cylinder moulding and capping all-in-one machine is novel in structure, convenient for operation, and high in machining efficiency, and integrates cylinder moulding and capping.

Owner:方明

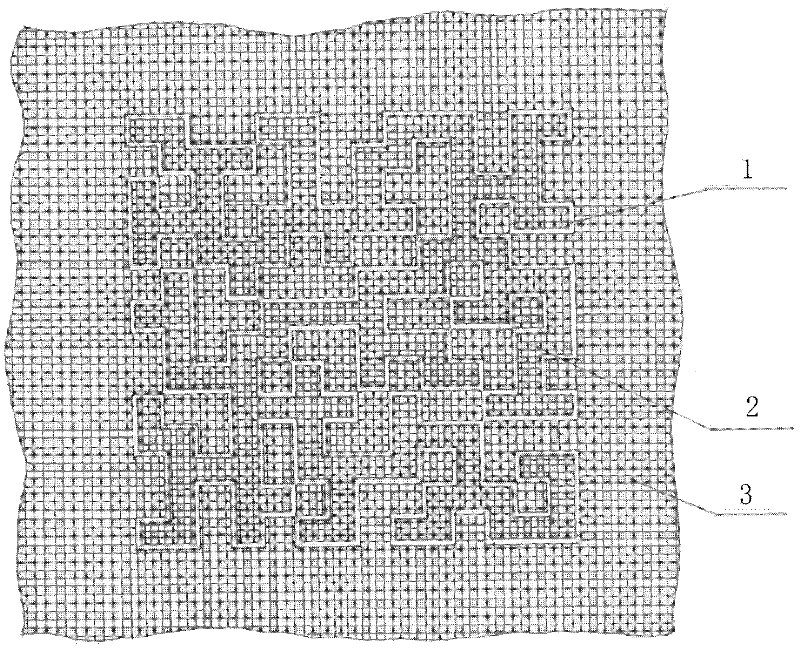

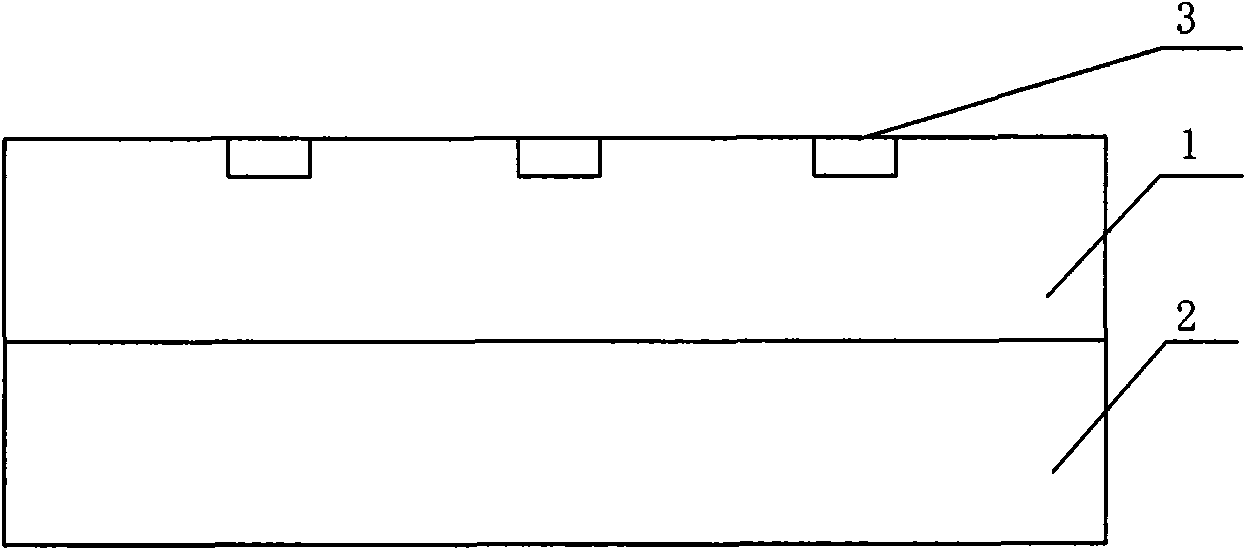

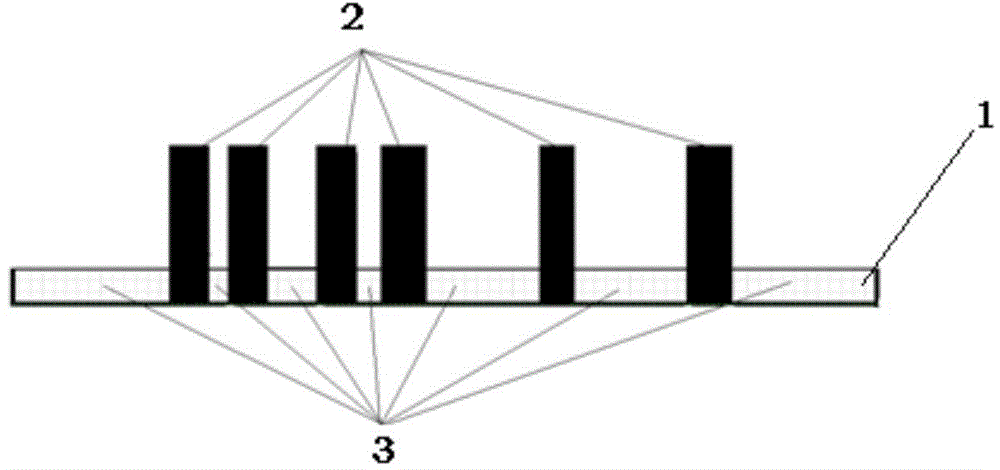

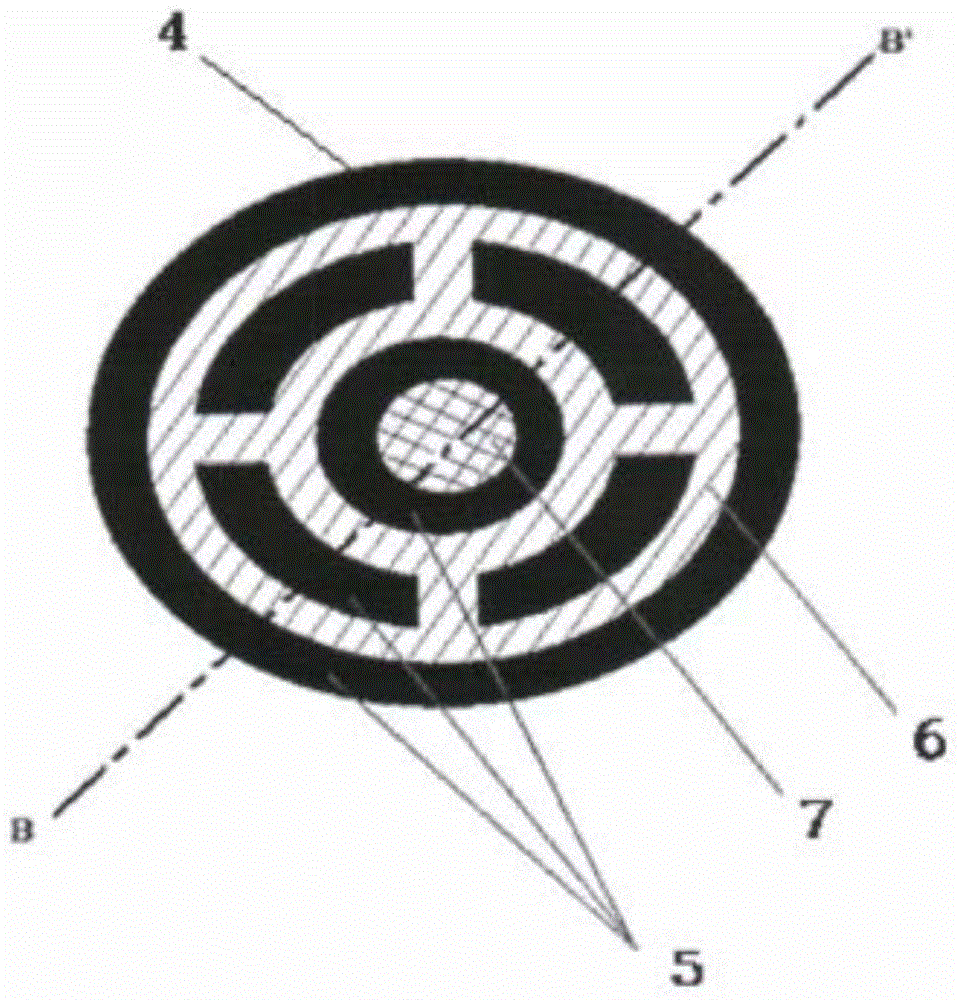

White watermark mould plate, white watermark cylinder mould and prepared anti-counterfeit paper

InactiveCN104562824AImprove anti-counterfeiting performanceAdd artistryNon-fibrous pulp additionSpecial paperComposite materialCylinder mould

The invention discloses a white watermark mould plate, a white watermark cylinder mould and prepared anti-counterfeit paper, wherein the white watermark mould plate is composed of at least two parts with different thicknesses and at least partially contains a hollow-out area capable of drainage. The white watermark mould plate is composed of at least two parts with different thicknesses and at least partially contains a hollow-out area capable of drainage; when the top mesh of the white watermark mould plate is applied to print money, because the different areas of the white watermark mould plate are different in height and drainage, the amounts of painting deposited at the corresponding positions are different; the white watermark areas of the obtained anti-counterfeit paper has multi-layer transmission of light and has better anti-counterfeitness and artistry compared with the traditional white watermarks.

Owner:KUNSHAN BANKNOTE PAPER +1

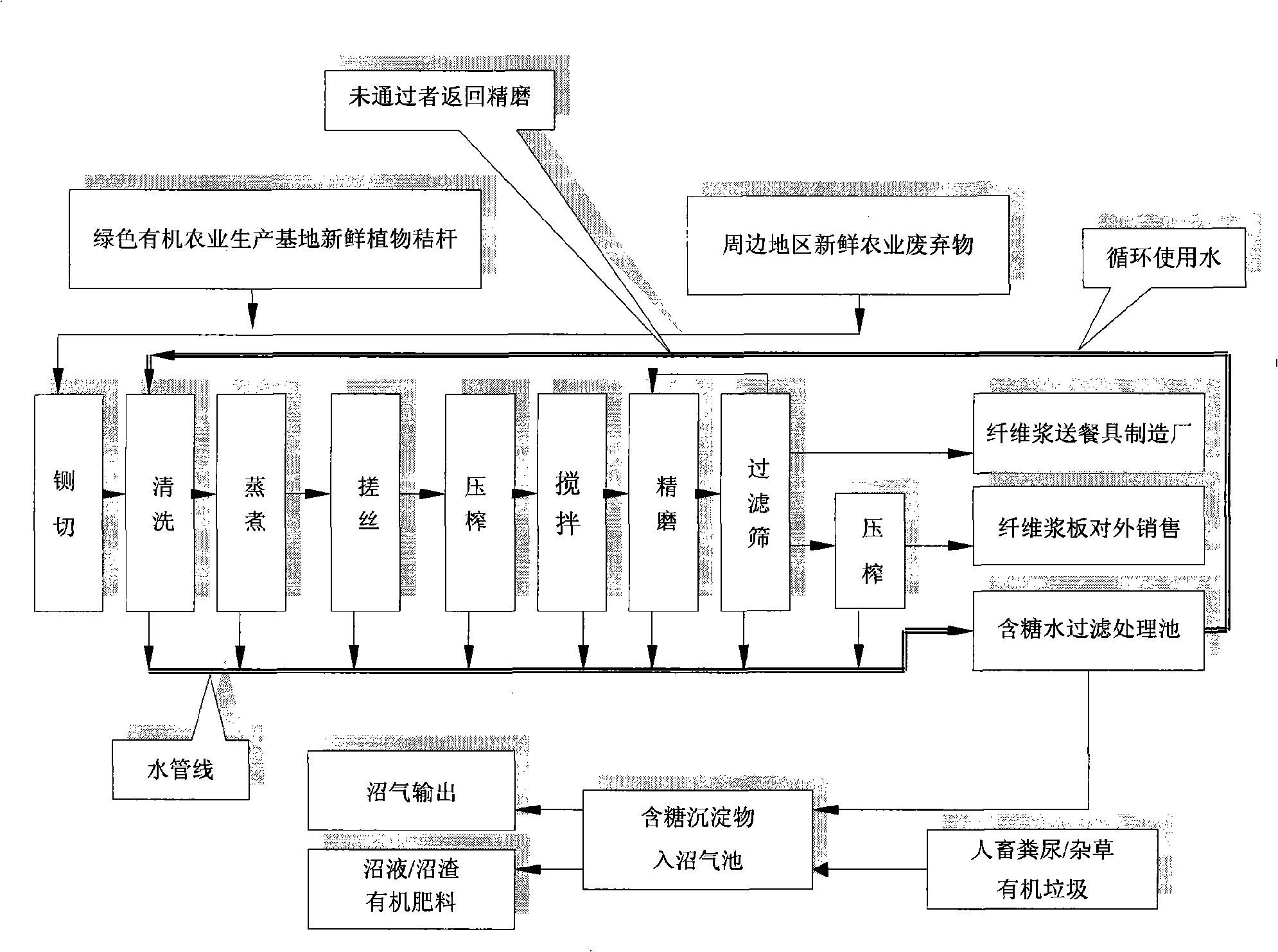

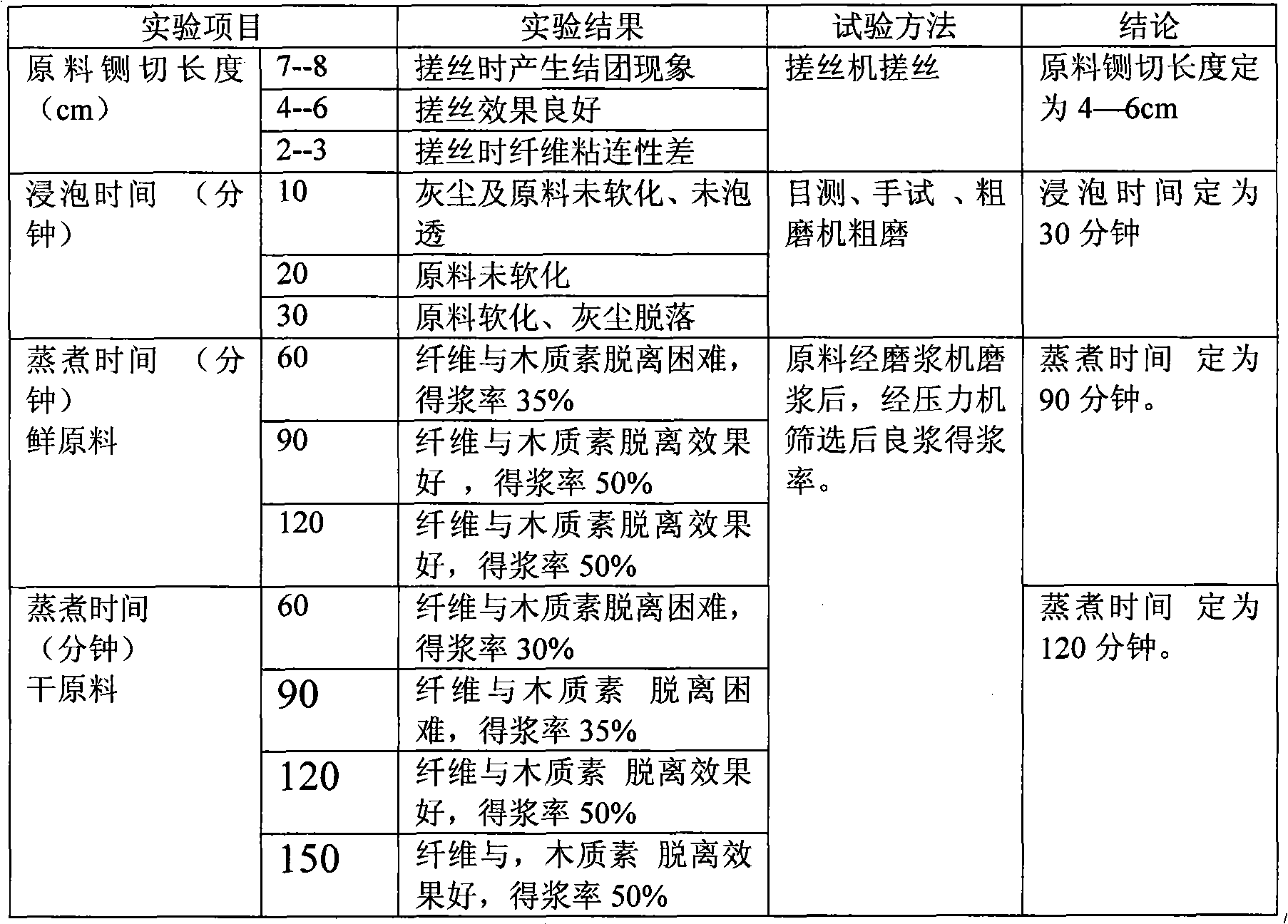

PPDM extraction method for agriculture waste straw fibre

InactiveCN101260635ARetain natural colorSave energyCellulosic pulp after-treatmentFibreboardFiberPesticide residue

The invention relates to a technique for PPDM extracting the agricultural wasted straw fiber, belonging to the straw fiber extracting technical field. The technique for PPDM extracting the agricultural wasted straw fiber comprises the following steps of the detecting, the cutting, the dipping and washing, the boiling, the thread rolling, the pressing, the mixing, the accurate grinding, the filtering and screening and the bleeding. The technique has the advantages that: 1. the pesticide residue is processed by dipping, washing and boiling; 2. the invention studies the constant boiling temperature and the boiling time; 3. an underground low-pressure concrete boiling pool is adopted, a cylinder mould is adopted to charge materials arranged by three rows. The technique saves water by more than 70 percent compared with the soda boiling fiber breaking technique, eliminates waste water, absorbs and digests the organic domestic garbage for protecting the environment; meanwhile, the technique adopts the marsh gas technique to exploit and adopt the new energy, the water can be used repeatedly completely, the electric energy is saved, the investment is saved and the security is high.

Owner:烟台兴达投资有限公司

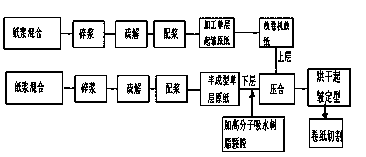

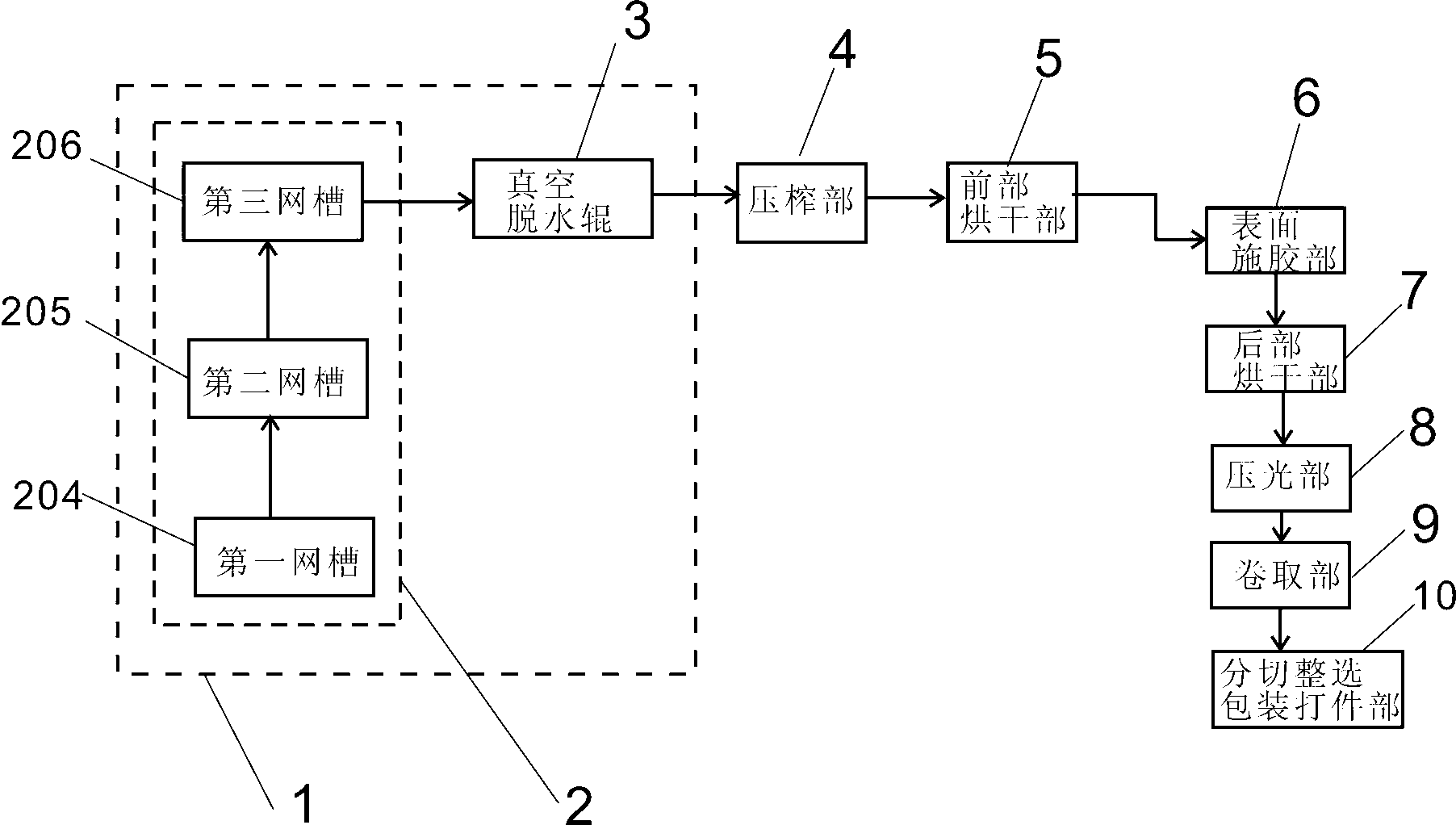

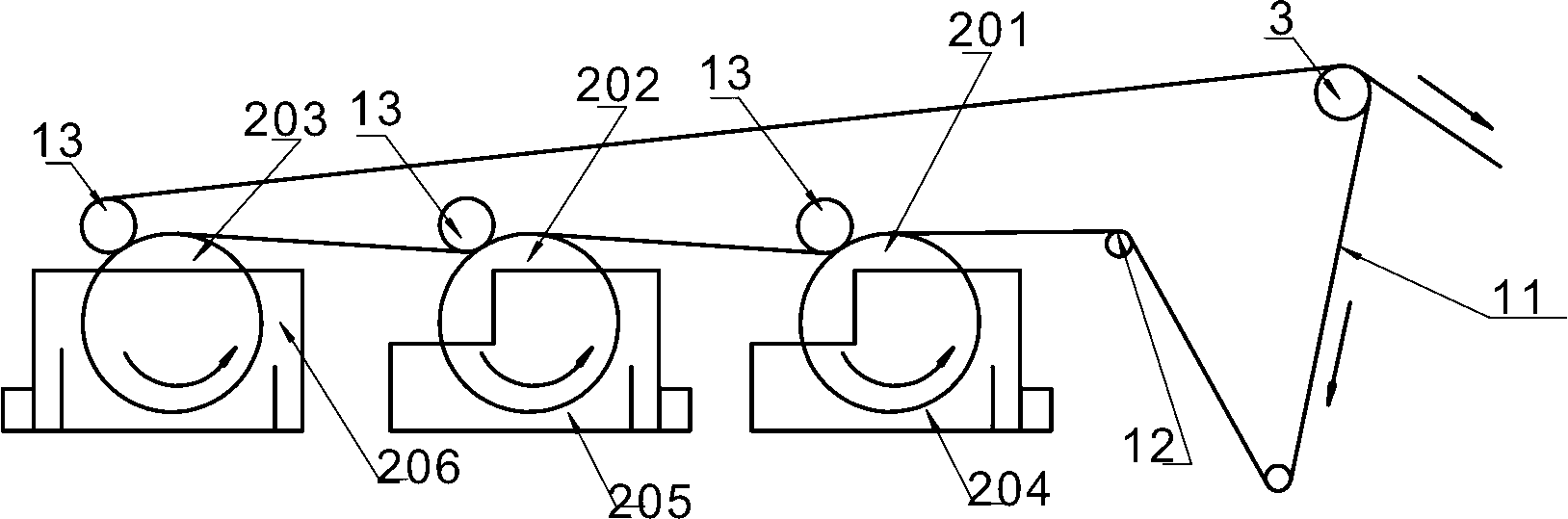

Fiber anti-counterfeit element anti-counterfeit paper forming and making with pulp method and paper making with pulp production line

ActiveCN102704315AIncrease the difficultyExpand the scope ofSpecial paperPaper/cardboardProduction lineFiber

The invention discloses a fiber anti-counterfeit element anti-counterfeit paper forming and making with pulp method and a paper making with pulp production line. The method includes the following steps: anti-counterfeit paper forming, dewatering, drying, surface gluing, press polishing, batching, and slitting-sorting-packaging. The method and production line are improved from single cylinder mould forming, and adopt the three cylinder mould forming to solve the technical problems that two cylinder moulds or more than four cylinder moulds can't simultaneously solve the problems that the non-plant fiber is easy to slip off due to artificial reason and the paper is overthick, are inconvenient for observing the anti-counterfeit element with naked eyes, and influence the detection sensitivity of the electronic detecting equipment. The fiber anti-counterfeit element anti-counterfeit paper forming and making with pulp method and the paper making with pulp production line realize multiple anti-counterfeit element combinations, and improve the anti-counterfeit difficulty and the gram weight range of the anti-counterfeit paper, so as to sufficiently satisfy the special anti-counterfeit requirements of different clients.

Owner:SICHUAN JINCHENG PAPER

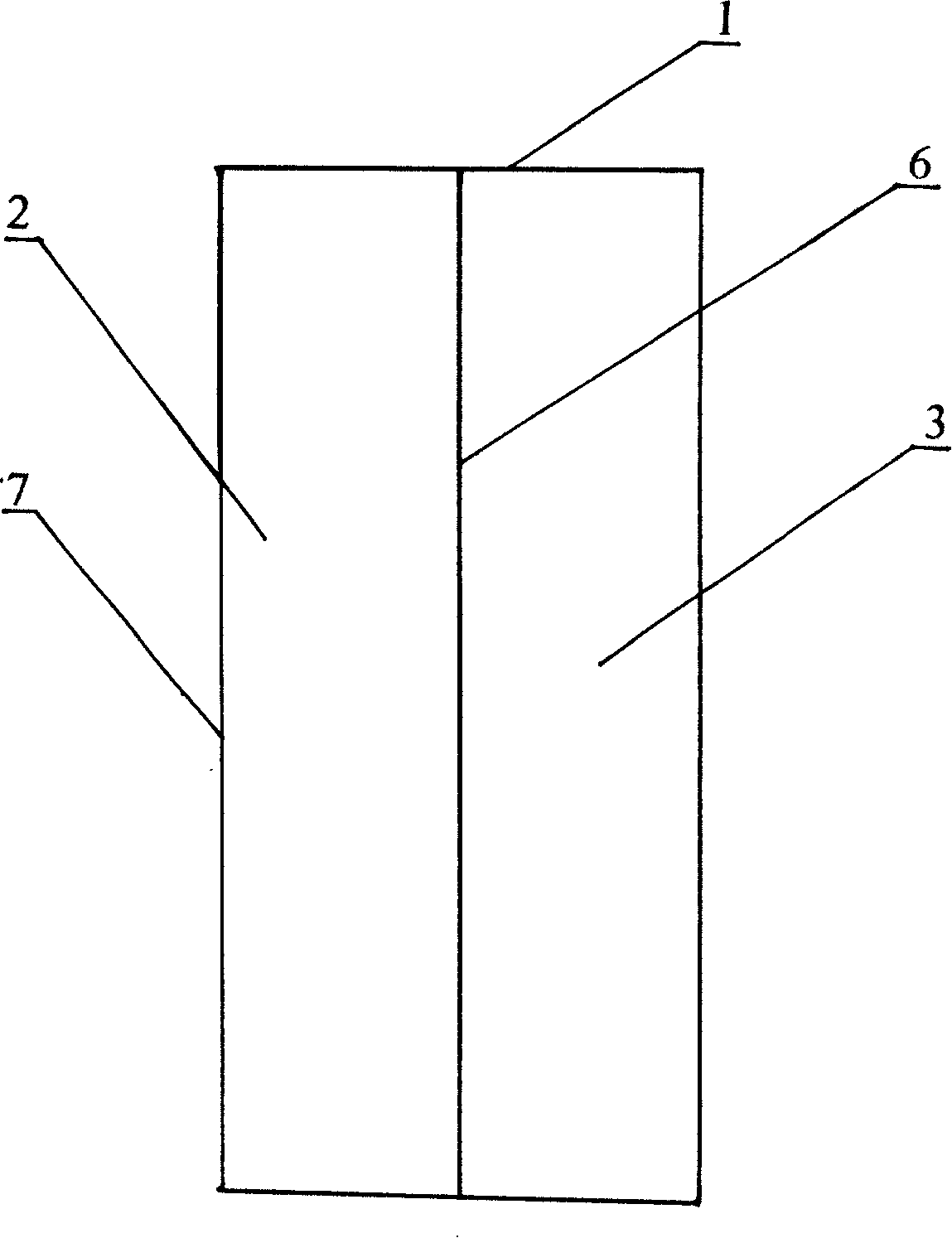

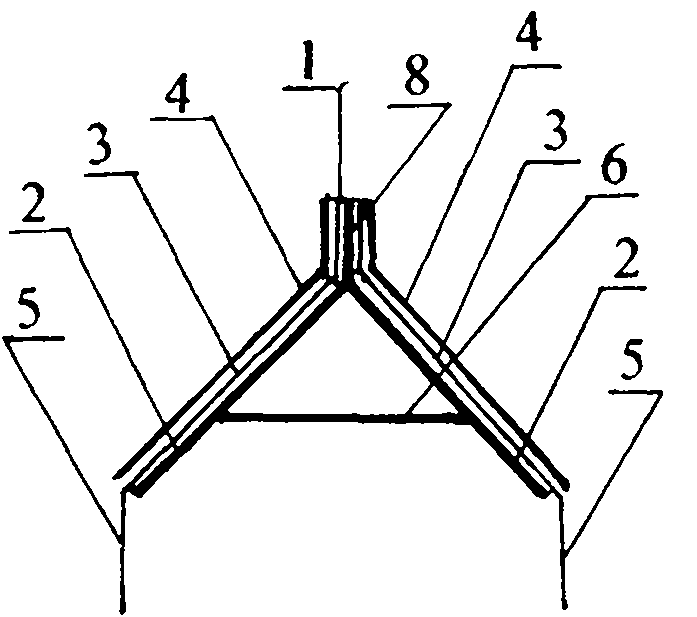

Shirt rim type cylinder mould sand barrier and sand blocking and fixing construction method thereof

InactiveCN102031773ASimple structureEasy constructionSoil preservationEngineeringStructural engineering

The invention aims at providing a shirt rim type cylinder mould sand barrier capable of blocking and fixing a shifting desert and a sand blocking and fixing construction method thereof, belonging to the technical field of engineering. The shirt-rim type cylinder mould sand barrier comprises a cylinder mould support frame, a fixing holding strip, a cylinder mould surface and a cylinder mould shirt rim. The sand blocking and fixing construction method of the shirt rim type cylinder mould sand barrier comprises the following steps of: stacking sand of a desert into a sand pit with height more than 15 cm; spanning the shirt rim type cylinder mould sand barrier over the top of the sand pit; embedding shirt rims positioned at both sides of a cylinder mould into the sand pit; and lifting the shirt rim type cylinder mould sand barrier from the sand when only the top edge of the cylinder mould is not buried by the shifting sand of the desert to only remain, wherein the shirt rims of the cylinder mould are completely embedded into the sand pit when the lifting is finished.

Owner:娄志平

Method and device for producing fraud-proof paper and fraud-proof paper

InactiveCN1675430AImprove anti-counterfeiting performanceNon-fibrous pulp additionOther printing matterFiberFree access

The invention relates to fraud-proof paper and to a method and device for the production thereof. The inventive method consists in forming a first paper web provided with a protective band whose width is equal to or less than 2 mm and which is incorporated into the web during the formation thereof with the aid of a cylinder mould machine in such a way that free-access areas (windows) are formed on protruded elements of the face side of the web. Said protective band is incorporated into the first paper web during the formation thereof and after formation of the free access areas which is associated with the formation of a fibre layer representing 35-50 % of the mass of the first paper web. A second paper web devoid of the protective band is produced simultaneously with the first web and afterwards is applied to the back side thereof in such a way that when they are connected to each other the defects of the said back side are hidden. Afterwards, the thus obtained two-layer material is pressed and dried. The protruded elements are embodied in the form of waterproof elements. An additional protective element is incorporated into the first and / or the second paper web during the production thereof. For the purpose of said invention, a protective band having a width ranging from 2 to 20 mm and comprising additional protective elements is used.

Owner:国企控股造币公司("GOZNAK"控股)

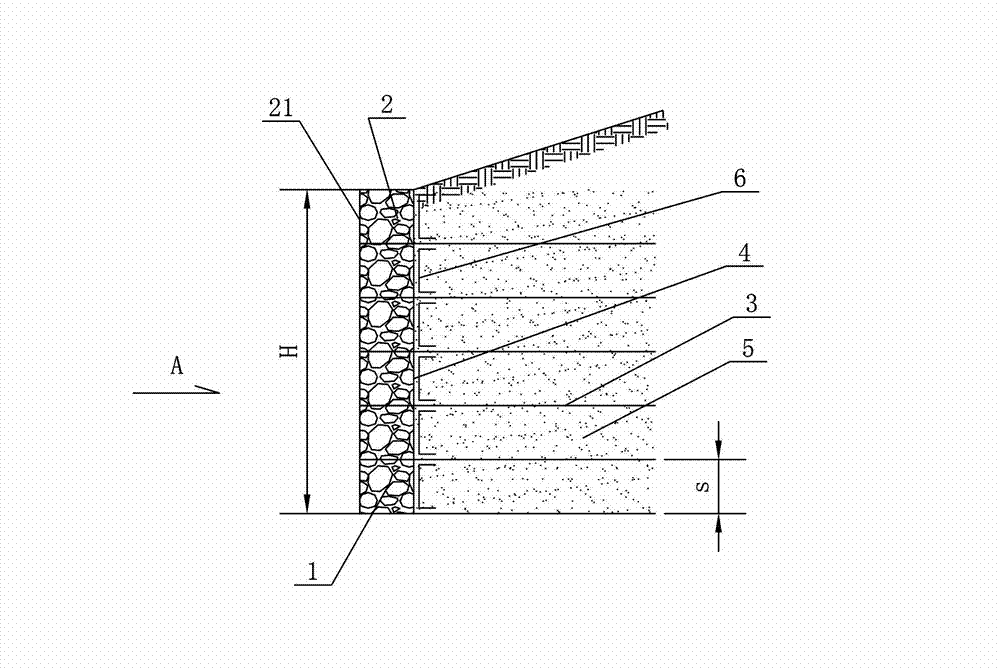

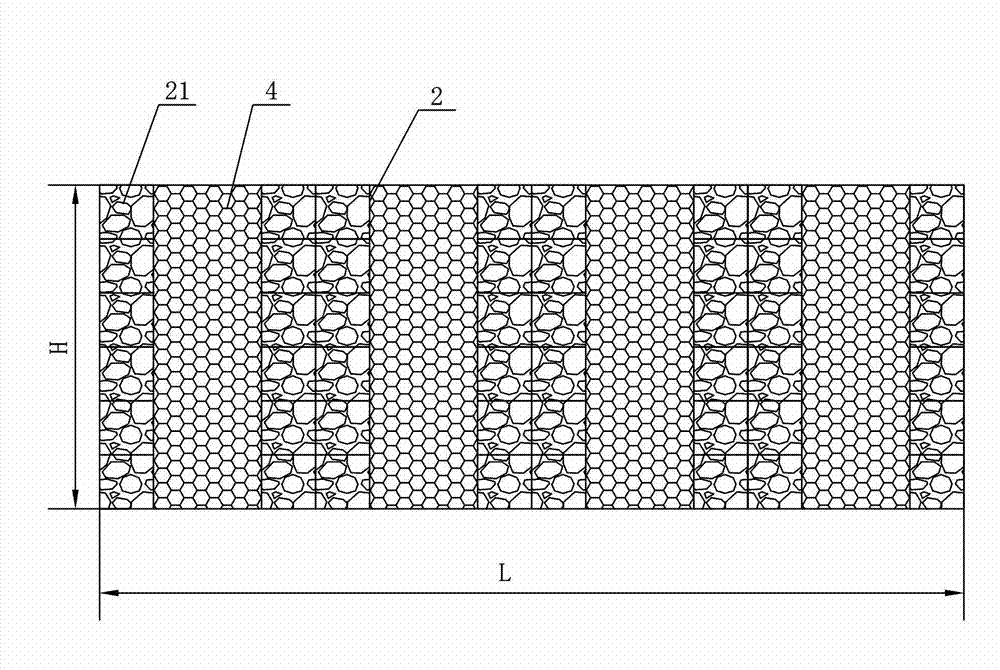

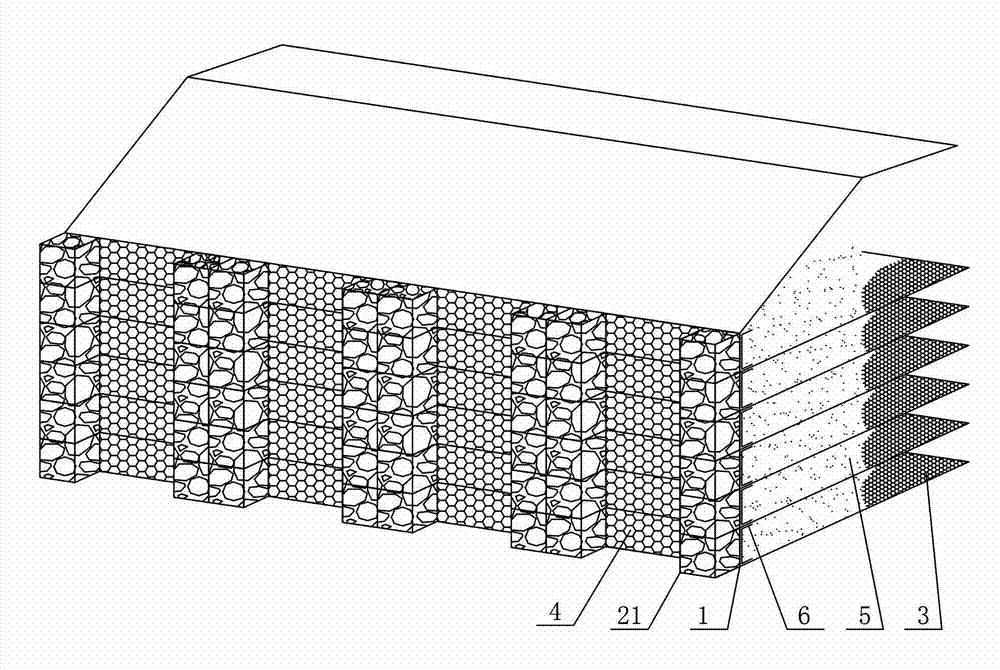

Columnar reinforced gabion retaining wall and construction method thereof

ActiveCN102733417AMeet the requirements of a harmonious societyLow costArtificial islandsUnderwater structuresMaterials preparationGabion

The invention discloses a columnar reinforced gabion retaining wall comprising more than one auxiliary wall body, wherein the auxiliary wall body mainly comprises a plurality of reinforced gabion units, which are sequentially overlapped from the bottom up, the reinforced gabion unit comprises a gabion assembly and a trailing type reinforcement strip net connected with the gabion assembly, backfill is tamped above the reinforcement strip net, the gabion assembly comprises at least two gabion cylinder moulds, which are isolated from each other, the isolated gabion cylinder moulds are integrally connected through vertical surface wall nets on the side faces of the gabion cylinder moulds, building stones are filled in the gabion cylinder moulds, and the gabion cylinder moulds in the two upper and lower adjacent reinforced gabion units are mutually overlapped to form gabion columns distributed at intervals. The invention further discloses a construction method of a columnar reinforced gabion retaining wall, which comprises the steps of preparing materials, forming the reinforced gabion units, forming the auxiliary wall body and integrally forming the columnar reinforced gabion retaining wall, etc. The columnar reinforced gabion retaining wall disclosed by the invention has the advantages of capability of surface greening, convenience in construction, low manufacturing cost, extensive adaptation range and good mechanical property, etc.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

'Color watermark' anti-falsification paper and preparation method thereof

ActiveCN104131495ANot easy to imitate and counterfeitIncrease anti-counterfeiting effortsNon-fibrous pulp additionSpecial paperFiltrationPulp and paper industry

The invention relates to a 'color watermark' anti-falsification paper and a preparation method thereof. The 'color watermark' anti-falsification paper at least comprises two fiber layers, wherein the first layer is a basic layer formed by white paper pulp, the second layer is a color watermark layer formed by color paper pulp; the color watermark layer and the white basic layer are combined on the net part of a cylinder mould machine to form the 'color watermark' anti-falsification paper with one white surface and the other surface formed by a white base and the color paper pulp. The preparation method of the 'color watermark' anti-falsification paper comprises the following steps: a part of a common black watermark net without watermark patterns cannot carry out water filtration caused by being coated by resin so as not to be coated with paper pulp, and therefore a color watermark net is formed; the color paper pulp forms a 'color watermark' with special patterns after being coated, and the 'color watermark' is difficult to imitate and counterfeit due to limitation of the color, and therefore the anti-falsification capability and the anti-falsification effect are enhanced. According to the preparation method disclosed by the invention, the traditional cylinder part is transformed and the wet paper moisture of a second cylinder mould is reduced. The produced 'color watermark' anti-falsification paper accords with the national standard.

Owner:互联智慧信息科技(北京)有限公司

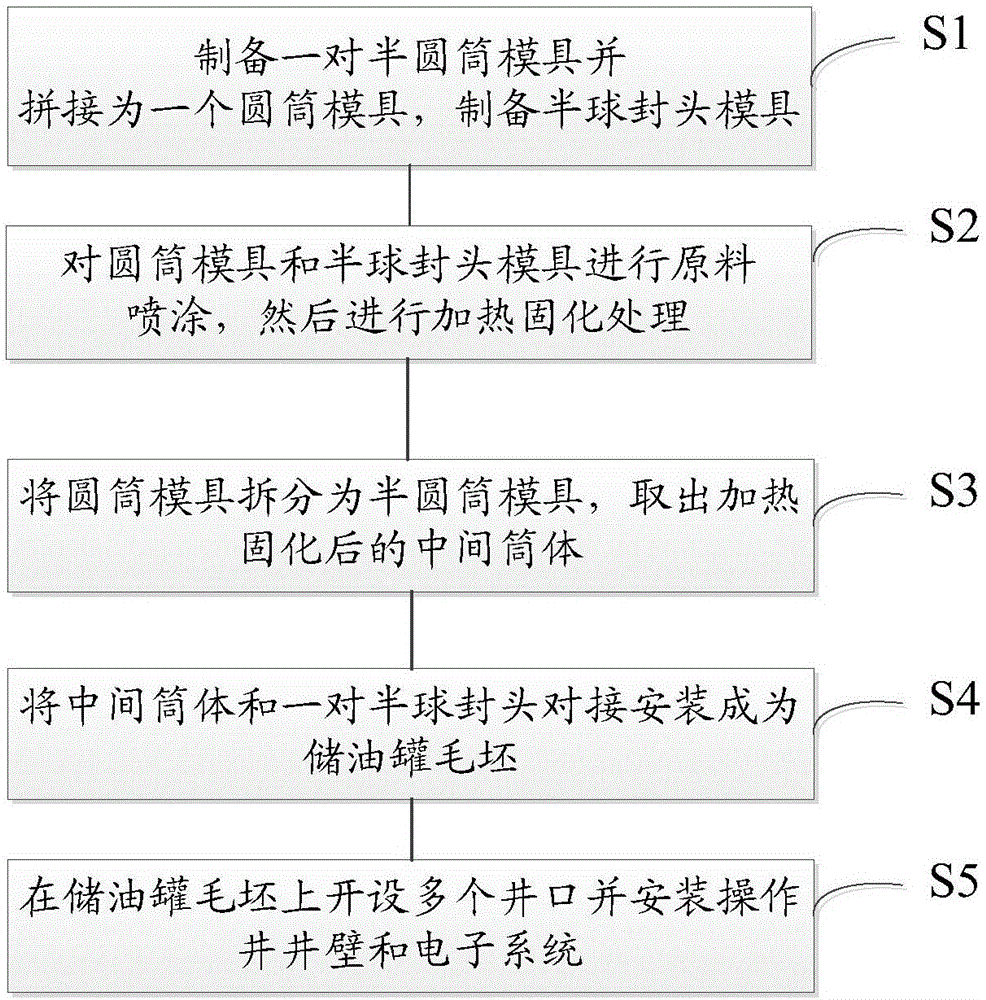

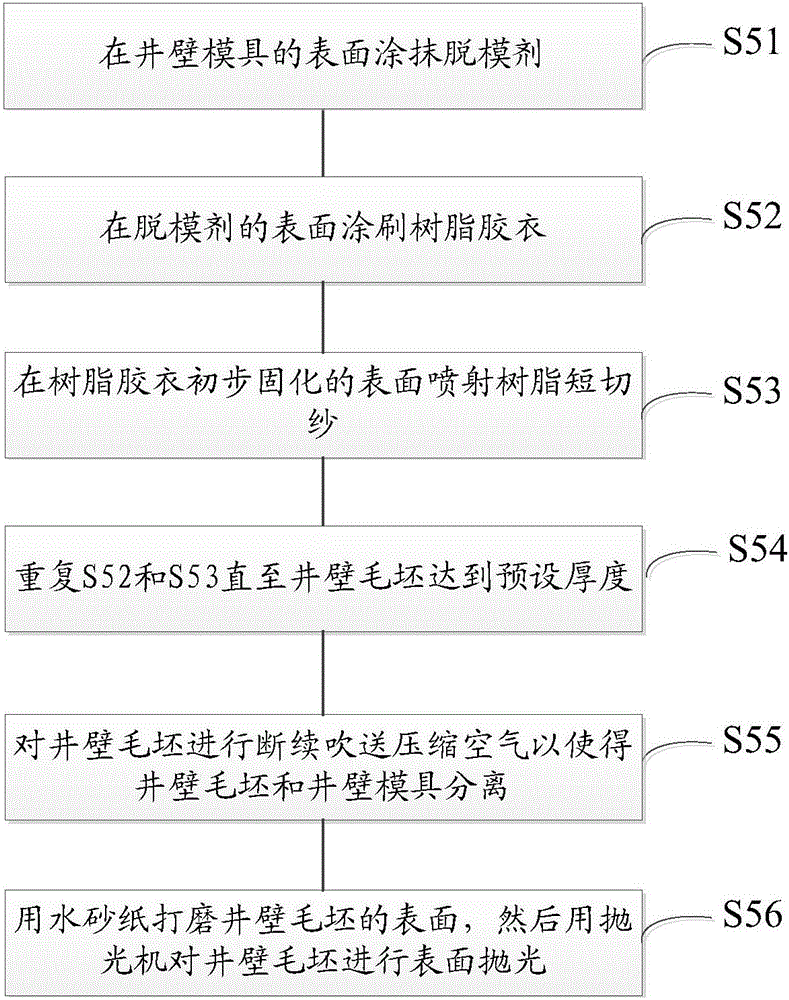

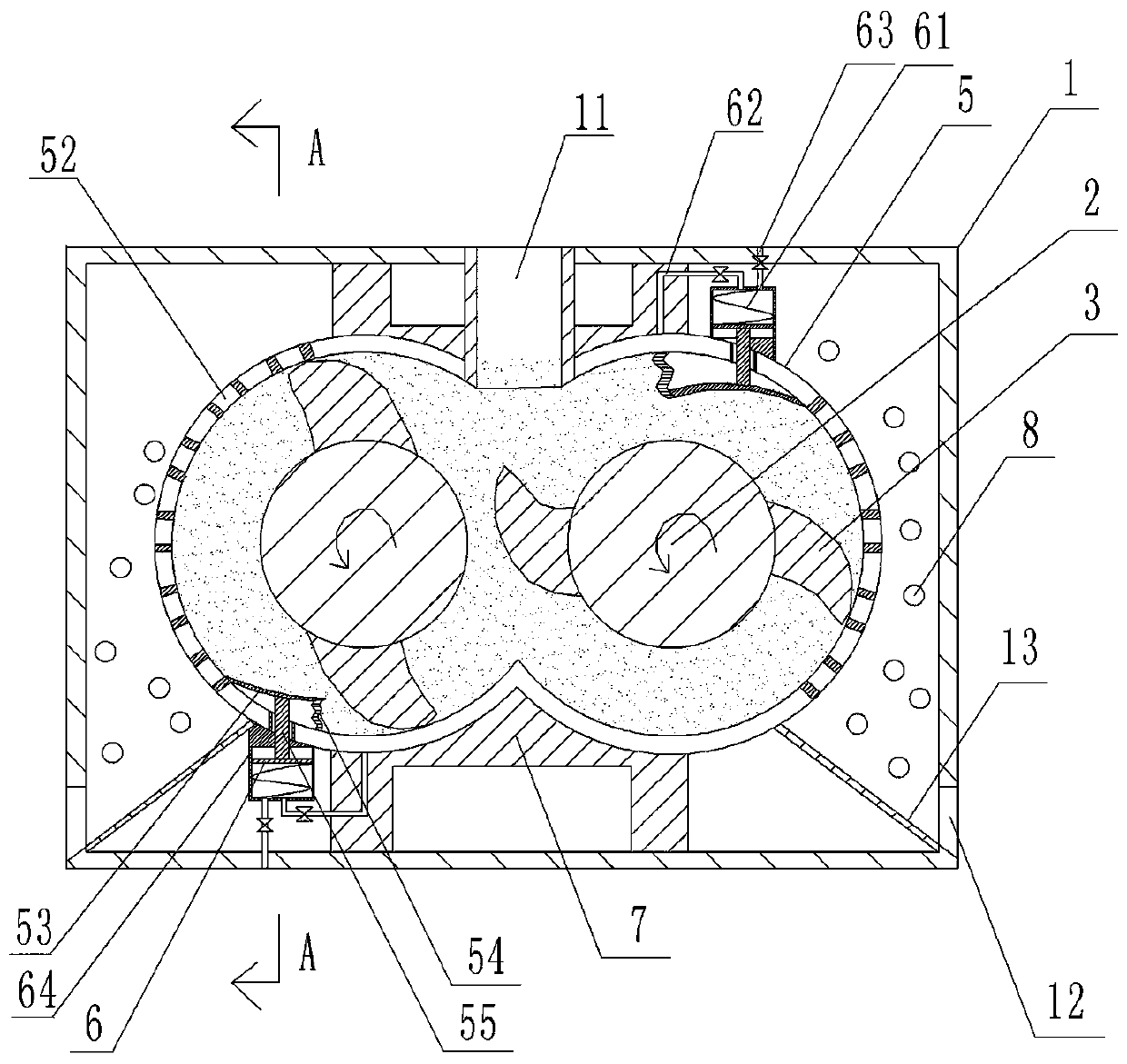

Preparation process for glass fibre reinforced plastic dual-layer oil storage tank

InactiveCN106584734AStrong ability to withstand external forcesReduce process complexityDomestic articlesCoatingsStress concentrationElectronic systems

The invention discloses a preparation process for a glass fibre reinforced plastic dual-layer oil storage tank. The preparation process comprises the following steps: preparing a pair of semicircular cylinder moulds, splicing the semicircular cylinder moulds into a circular cylinder mould, preparing hemispherical sealing head moulds, respectively performing raw material spraying on the circular cylinder mould and the hemispherical sealing head moulds, then performing heating curing treatment, disassembling the circular cylinder mould into the semicircular cylinder moulds, taking out an intermediate cylinder body, butting the intermediate cylinder body and the pair of semicircular cylinder moulds to install an oil storage tank blank, forming a plurality of well mouths in the oil storage tank blank, and installing operating well walls and electronic systems. The intermediate cylinder body is prepared in the mode of performing spraying moulding on the circular cylinder mould which is spliced by the semicircular cylinder moulds, so that the processes of spraying and de-moulding can be performed highly effectively; the preparation process complexity is greatly reduced; meanwhile, butting openings of the oil storage tank blank are transferred out of the intermediate cylinder body from the intermediate cylinder body, so that the butting openings avoid a stress concentration area; the oil storage tank cannot crack easily to cause the situations of oil leakage and liquid leakage, so that the reliability of a finished product is improved.

Owner:河南田川威尔森石油设备科技有限公司

Granulating chamber of biological particle fuel extruding machine

ActiveCN107597022AExtended service lifeReduce frictional heatBiofuelsSolid fuelsPulp and paper industryEngineering

The invention relates to the technical field of extruding and granulating and especially relates to a granulating chamber of a biological particle fuel extruding machine. The granulating camber comprises a granulating chamber body, a rotating shaft, a stirring and extruding blade, a cylinder mould and a power device, wherein the cylinder mould is arranged in the granulating chamber body, a feedingpipe and a discharging opening are arranged on the granulating chamber body, the rotating shaft is arranged in the cylinder mould, the stirring and extruding blade is arranged in the peripheral direction of the rotating shaft, a cavity is formed in a mould wall of the cylinder mould, an air outlet is formed in an outer wall of the cylinder mould, a plurality of granulating pipes are arranged on the mould wall of the cylinder mould, an air blowing device is arranged in the granulating chamber body, a swinging plate is hinged to an inner wall of the cylinder mould, the stirring and extruding blade can extrude the swinging plate intermittently, an elastic cover is arranged between the inner wall, close to the swinging plate, of the cylinder mould and the swinging plate, a push portion is connected to the swinging plate, and the upper end of the push portion is arranged in the elastic cover. By means of the scheme, heat generated by the walls of the cylinder mould is reduced, further an effect on quality of a raw material in the cylinder mould is reduced, and meanwhile service life of the cylinder mould is prolonged.

Owner:遵义双河生物燃料科技有限公司

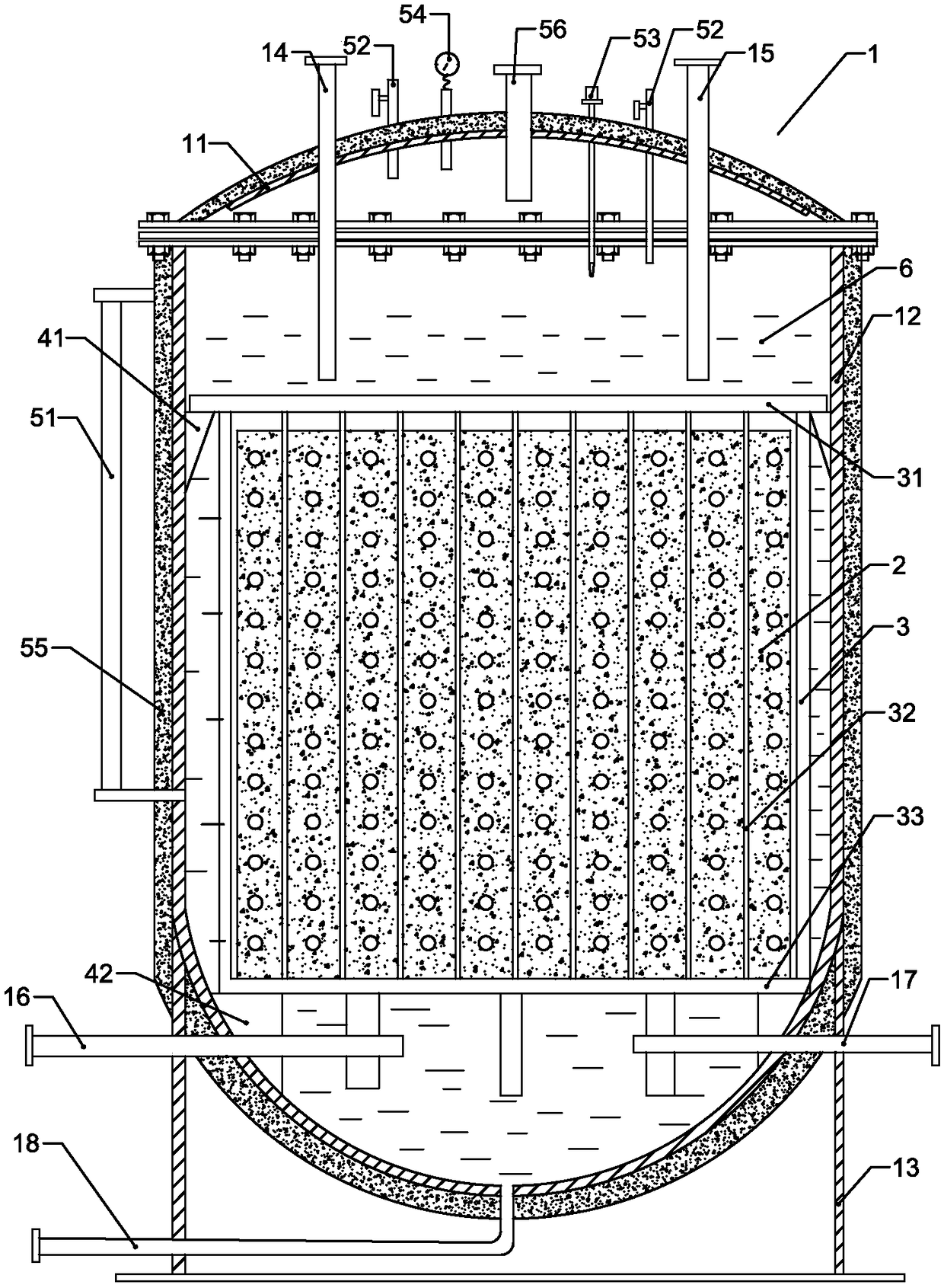

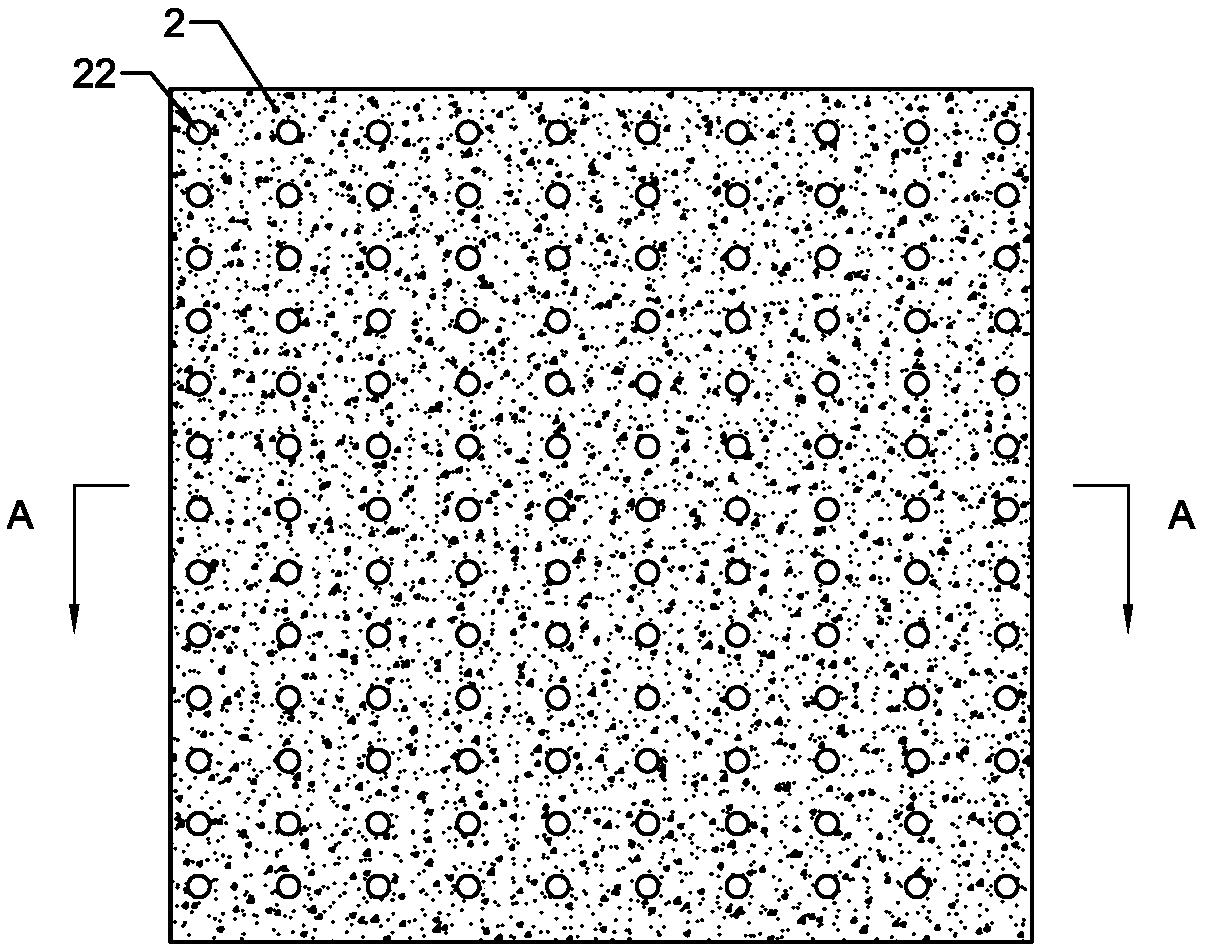

Built-in prefabricated concrete heat-storage body energy-storage tank

PendingCN108106477AIncrease profitAchieve continuous power generationSolar heating energyHeat storage plantsSolar energy storageVapor generator

The invention belongs to the technical field of solar energy storage, in particular to a built-in prefabricated concrete heat-storage body energy-storage tank. The built-in prefabricated concrete heat-storage body energy-storage tank includes a tank body, a prefabricated concrete heat-storage body, conduction oil and a cylinder mould which is arranged at the periphery of the prefabricated concreteheat-storage body, and the bottom of the tank body is in a round shape; the prefabricated concrete heat-storage body is arranged in the tank body, and the conduction oil is filled over the prefabricated concrete heat-storage body; and the upper of the tank body is provided with a hot oil inlet pipe which is connected with a solar energy collecting device and a guide hot oil outlet pipe which is connected with a vapor generator, and the lower of the tank body is provided with a cold oil outlet pipe which is connected with the solar energy collecting device and a cooling guide hot oil inlet pipe which is connected with the vapor generator. According to the built-in prefabricated concrete heat-storage body energy-storage tank, the prefabricated concrete heat storage body is used for storingthe solar energy, the heat energy is stored in the prefabricated concrete heat storage body, the usage amount of the conduction oil is reduced, the heat storage energy of the energy-storage tank is improved, the heat storage capacity is enlarged, and the use ratio of the solar energy is improved.

Owner:ZHEJIANG BOTHWELL ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com