Cylinder moulding and capping all-in-one machine

An all-in-one machine and cylinder technology, applied in the field of cylinder forming and capping all-in-one machines, can solve the problems of automobile noise pollution, affecting work, play, and low output, and achieve the effects of high processing efficiency, novel structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

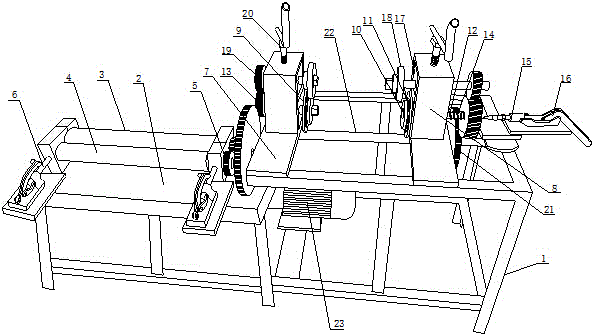

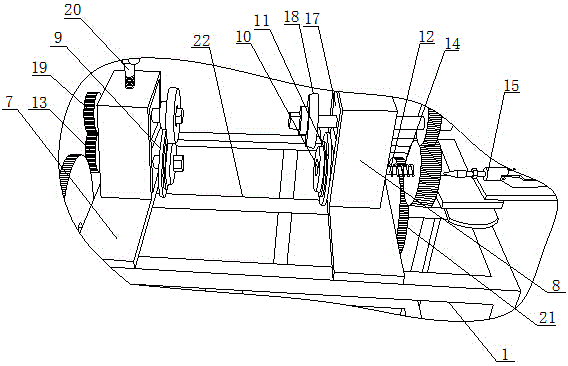

[0012] Such as figure 1 , 2 As shown, a cylinder forming and capping integrated machine includes a frame body 1, a forming plate surface 2, a forming roller 3, an extrusion roller 4, a capping plate surface 7, an installation seat 8, a left sleeve seat 9, and a right sleeve seat 11. Slider 17, pressing block 18, hand lever 20, driving gear 21, the frame body 1 is equipped with forming plate surface 2 and cover plate surface 7, and forming plate surface 2 is equipped with forming roller 3 Forming roll 3 is provided with clamping grooves, extrusion roll 4 is installed parallel to forming roll 3, push rods 6 are installed on both sides of one side of extrusion roll 4, and gears are installed on one side of forming roll 3 and extrusion roll 4 5. Two mounts 8 are installed symmetrically on the cover plate 7, the left and right mounts 8 are respectively provided with a left sleeve 9 and a right sleeve 11, the other side of the mount 8 is equipped with a gear 2 13, and the right sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com