Columnar reinforced gabion retaining wall and construction method thereof

A retaining wall and column technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as unfavorable post-maintenance, high material consumption, unfavorable on-site construction, etc., and achieve simple repetitive operations, simple construction technology, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

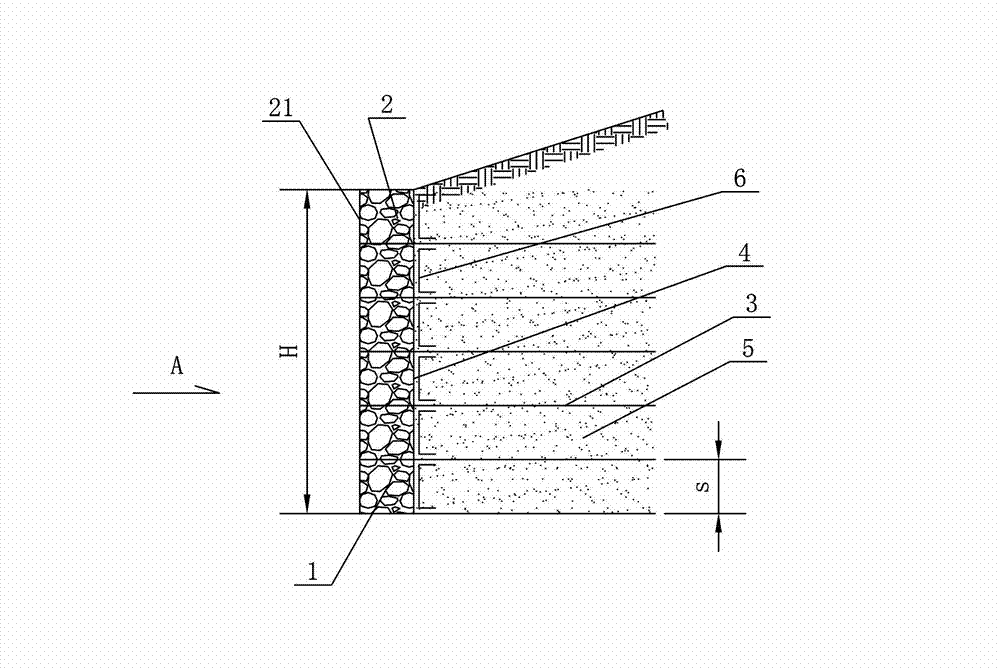

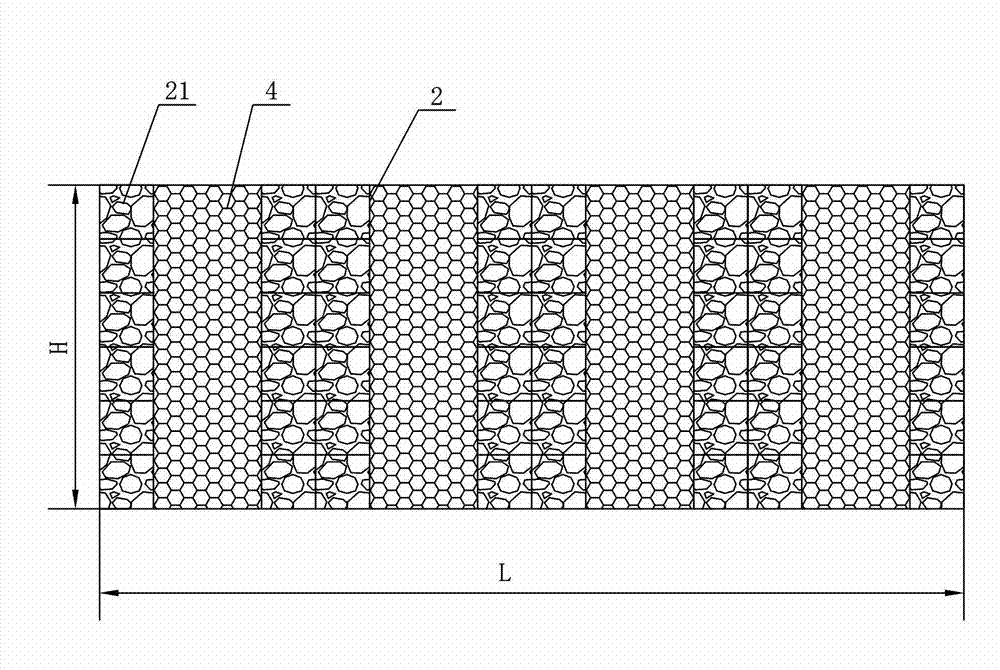

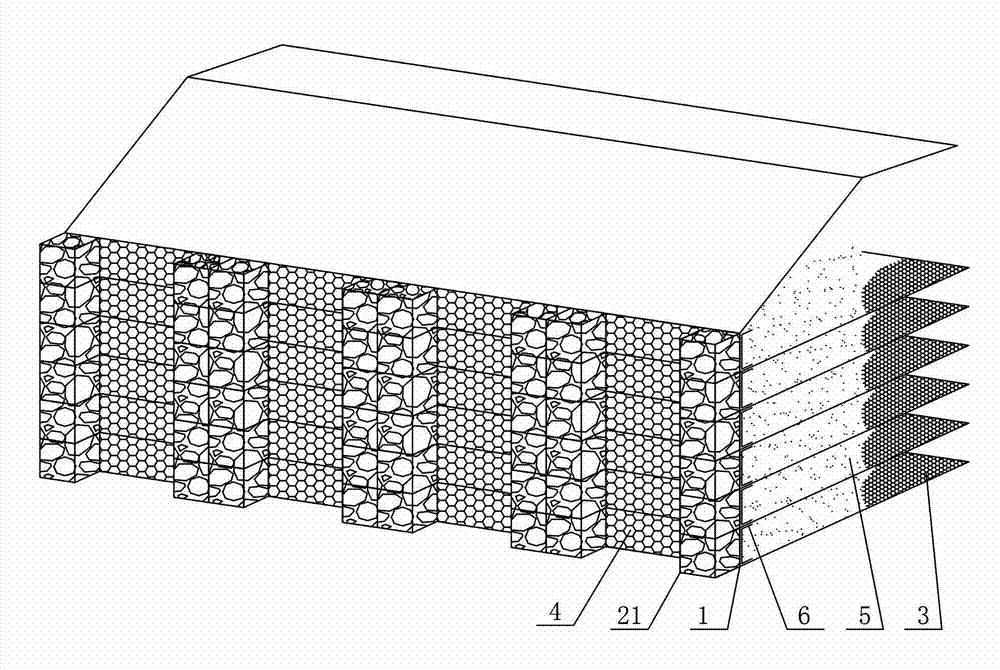

[0033] a kind of like Figure 1 to Figure 3 The vertical column type reinforced gabion retaining wall of the present invention is shown. The retaining wall has a length L of 10m and a height H of 6m.

[0034] The upright column-type reinforced gabion retaining wall in this embodiment is mainly composed of four sub-walls (the length of each side sub-wall in the horizontal direction is 2.5m) arranged closely to each other along the horizontal direction, and each side sub-wall It is mainly composed of 6 reinforced gabion units 1 (the height s of each reinforced gabion unit 1 is 1m) stacked in sequence from bottom to top. The reinforced gabion unit 1 includes gabion components 2 and is connected The tailing type ribbed net 3, the top of the ribbed net 3 is compacted with a structural fill 5 (the structural fill 5 is a mixture of gravel, coarse sand, and clay, and the bulk density of the structural fill 5 in this embodiment is 1.85 t / m 3 , the friction angle is 30°), the gabion a...

Embodiment 2

[0045] a kind of like Figure 8 to Figure 10 The shown ladder-column reinforced gabion retaining wall of the present invention has roughly the same structure and manufacturing method as in Example 1, the difference being that in Example 2, when the wall is divided into parts for construction, in order to reduce the lateral earth pressure, Each reinforced gabion unit 1 is stacked in steps along the vertical direction, that is, the gabion column formed by the stacking of gabion cages 21 has a slope. For the specific stacking method, refer to Figure 8 and Figure 9 , and finally get as Figure 8 , Figure 10 The ladder-column reinforced gabion retaining wall is shown, in which the gabion column maintains a slope of 1:0.3. The length L of the stepped column type reinforced gabion retaining wall of the present embodiment is 10m, and the height H is 10m. s is 1m) are formed by stacking from bottom to top. In practice, the slope of the gabion cage 21 can also be adjusted accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com