Patents

Literature

58results about How to "Affect molding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

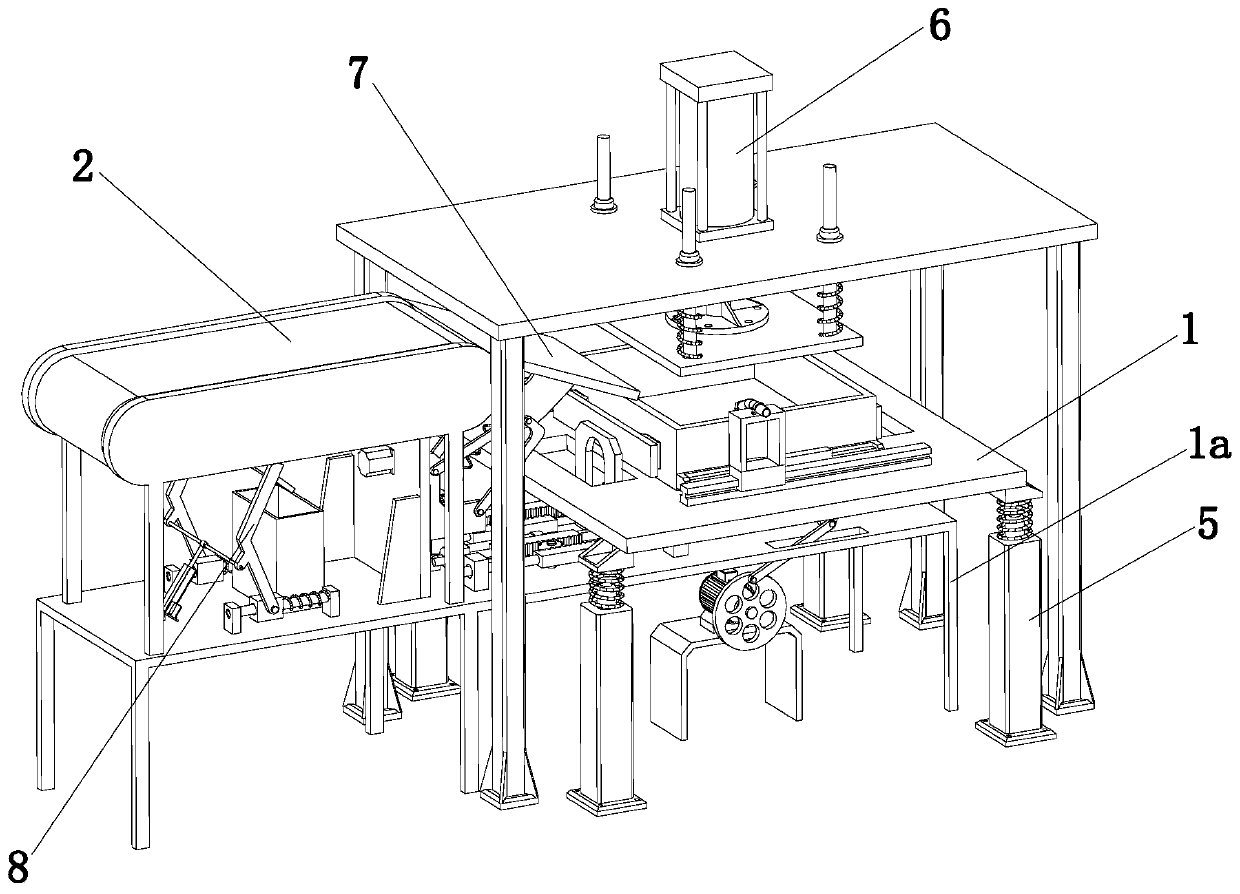

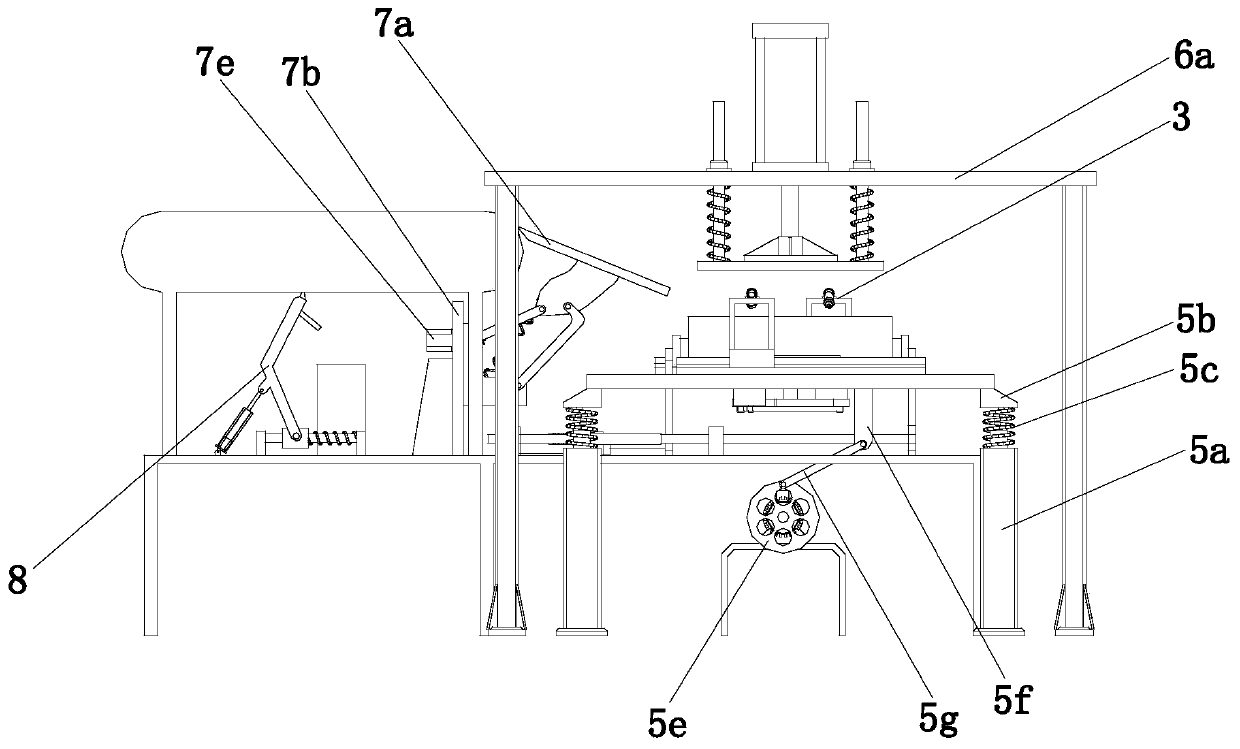

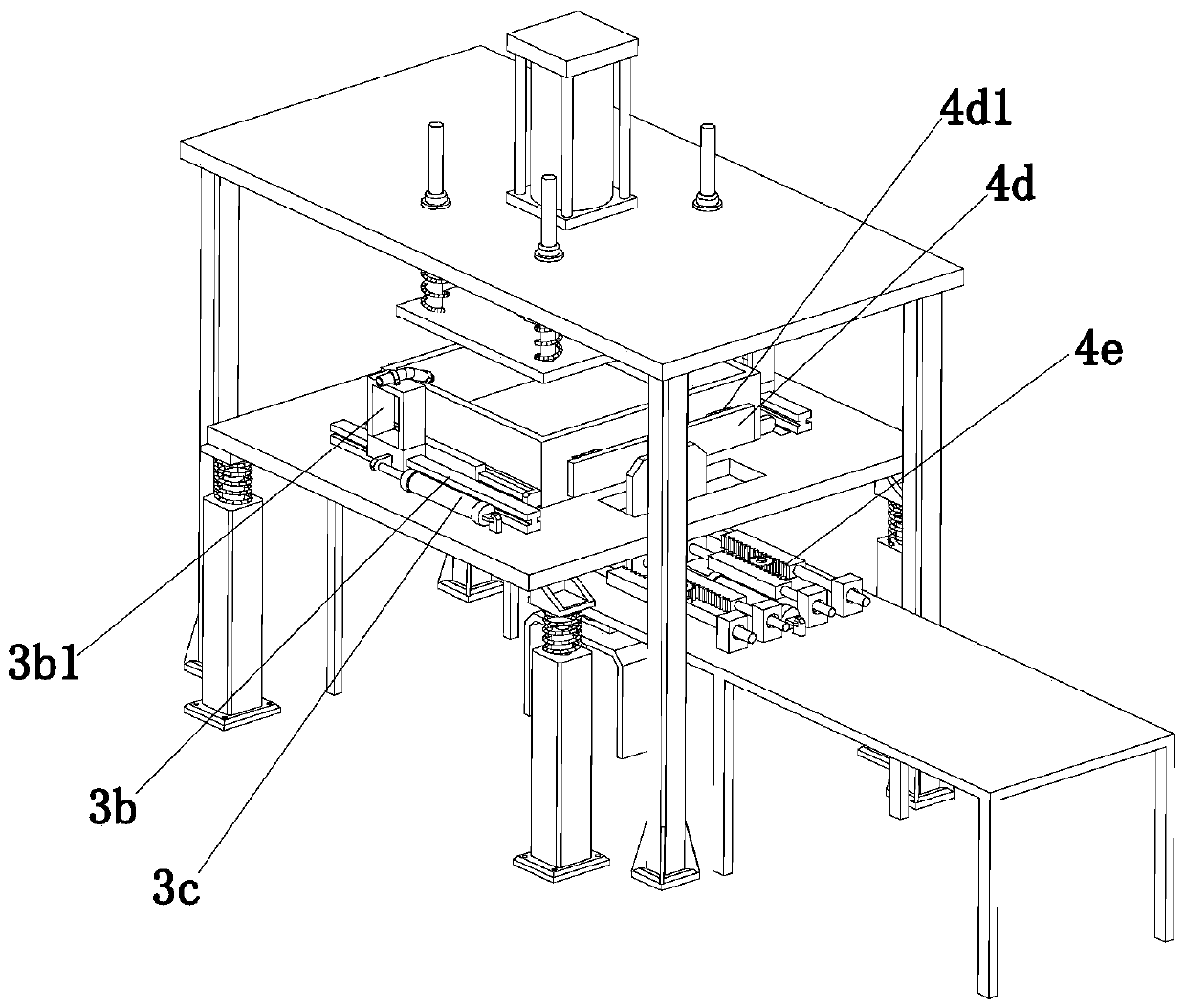

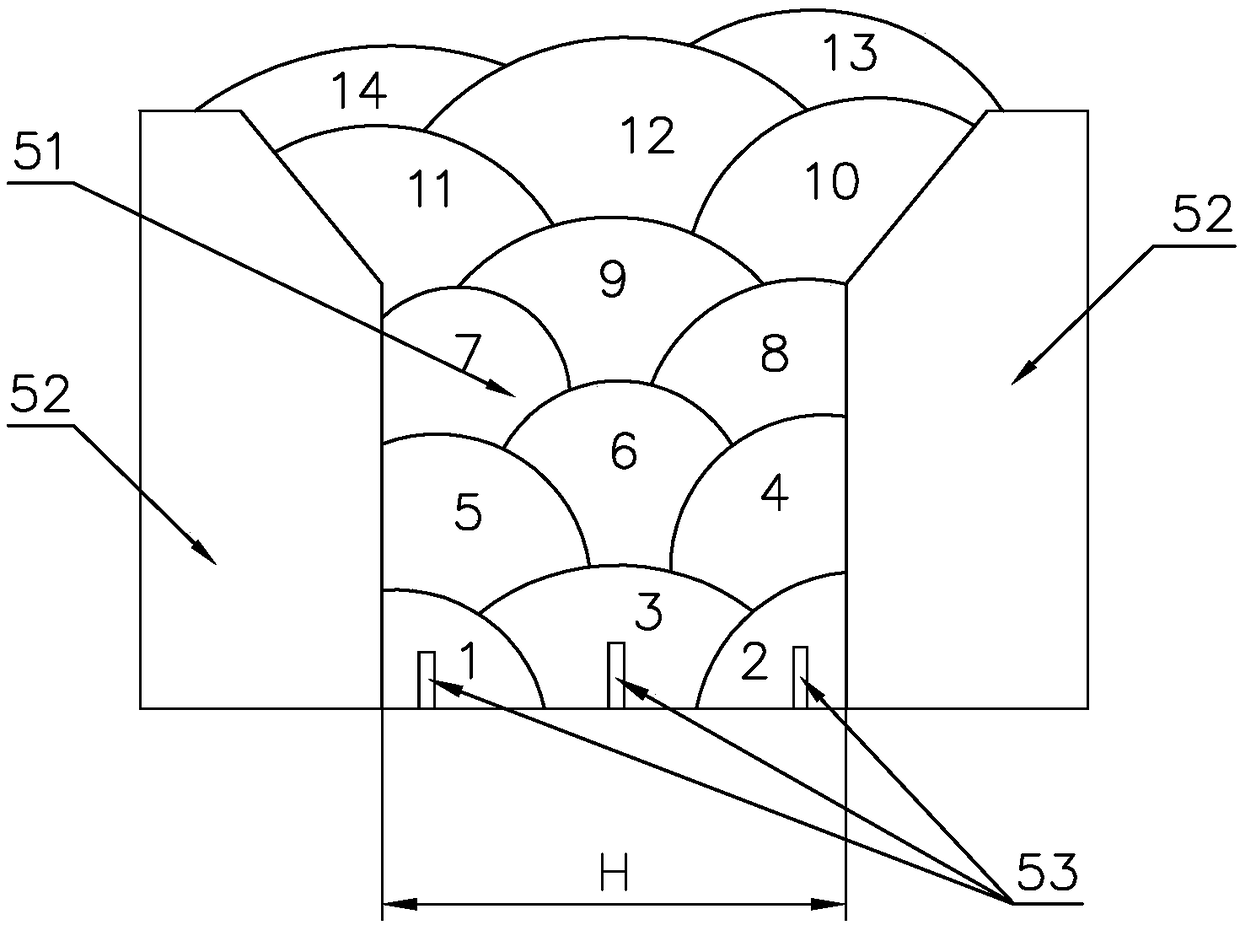

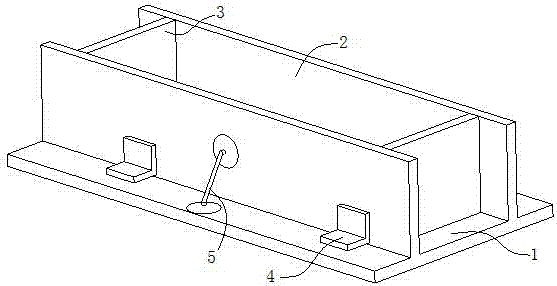

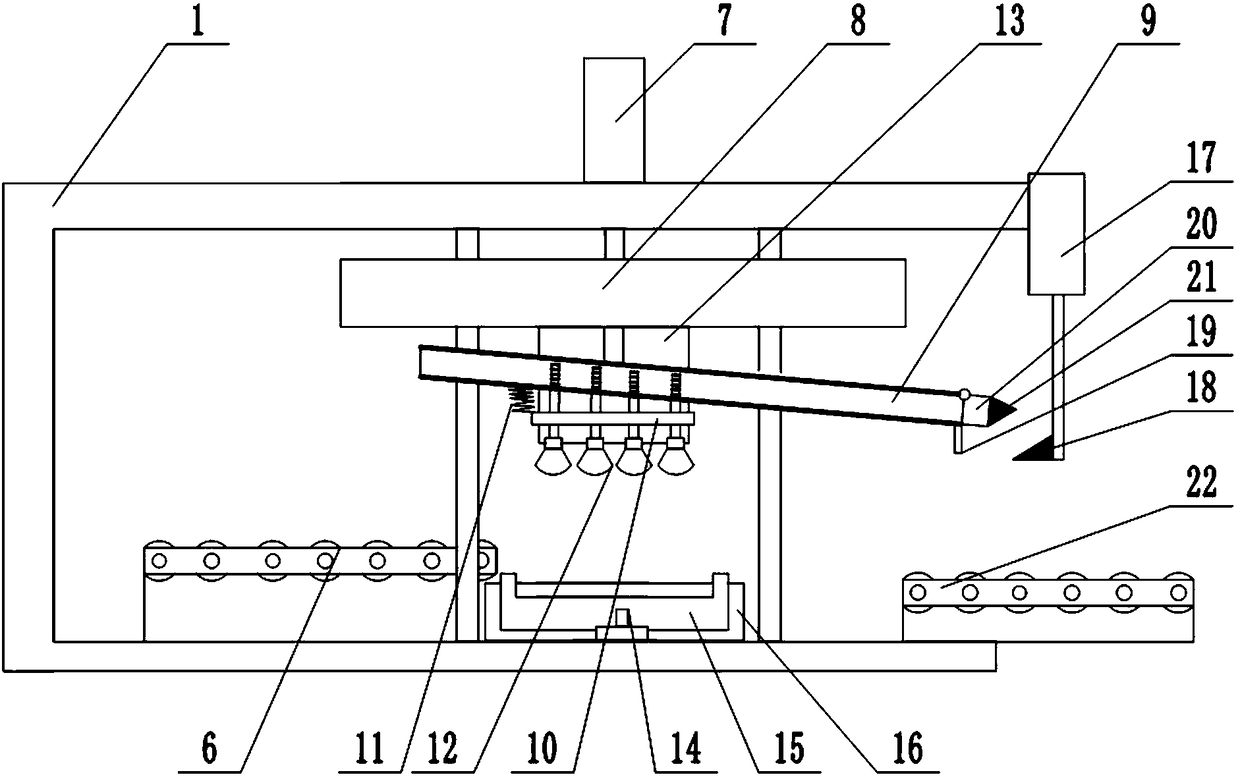

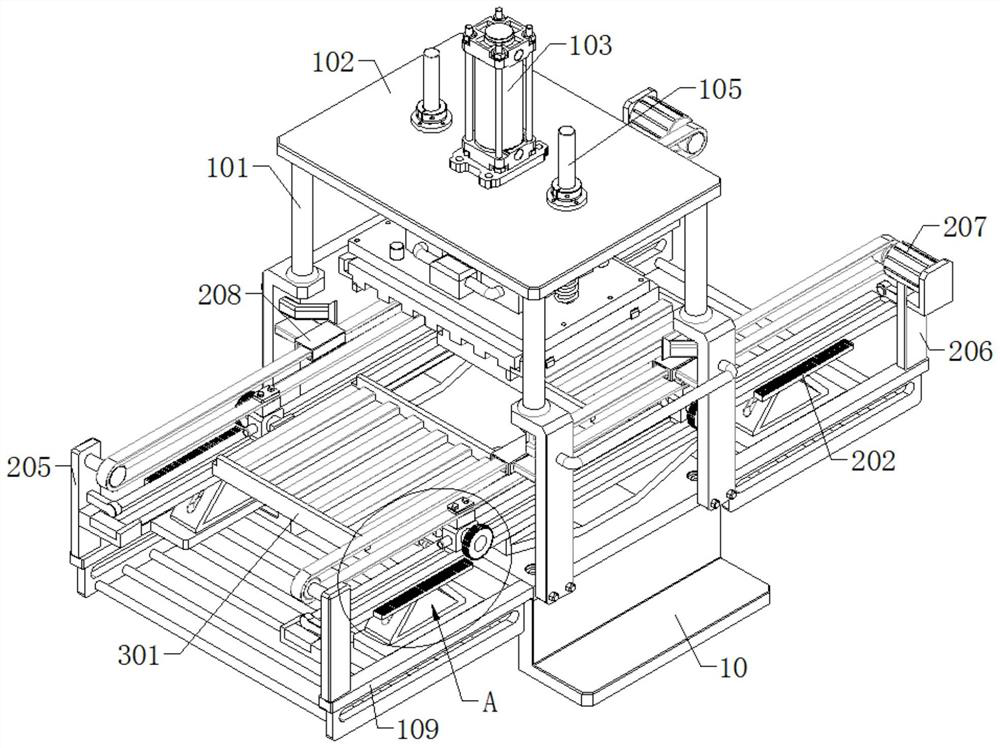

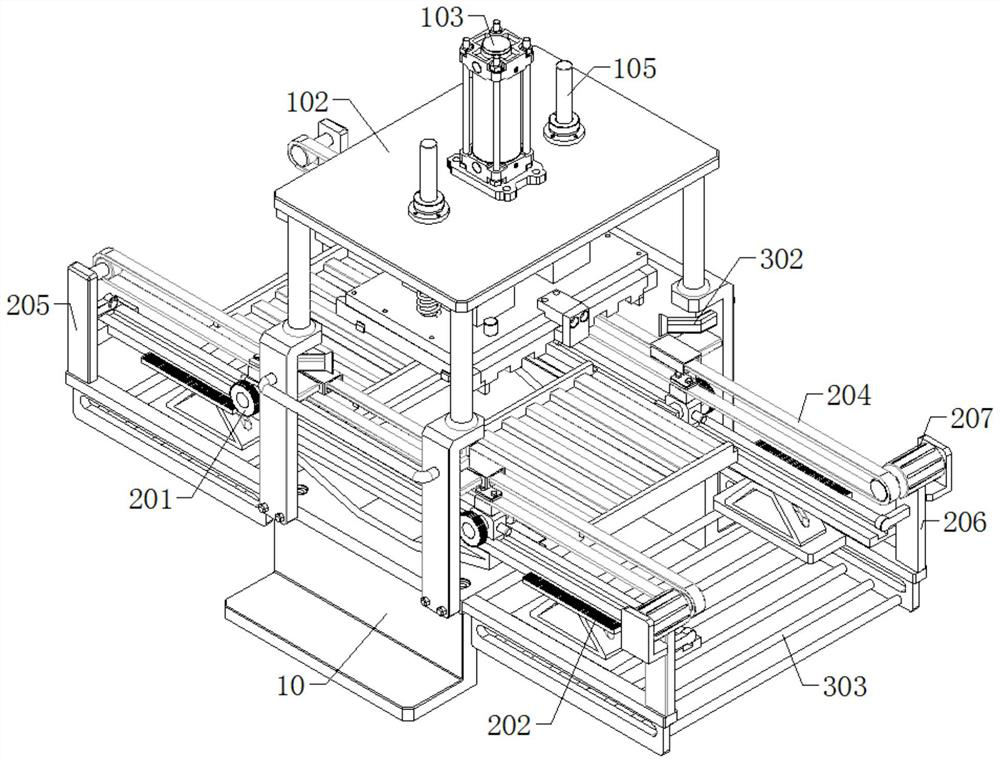

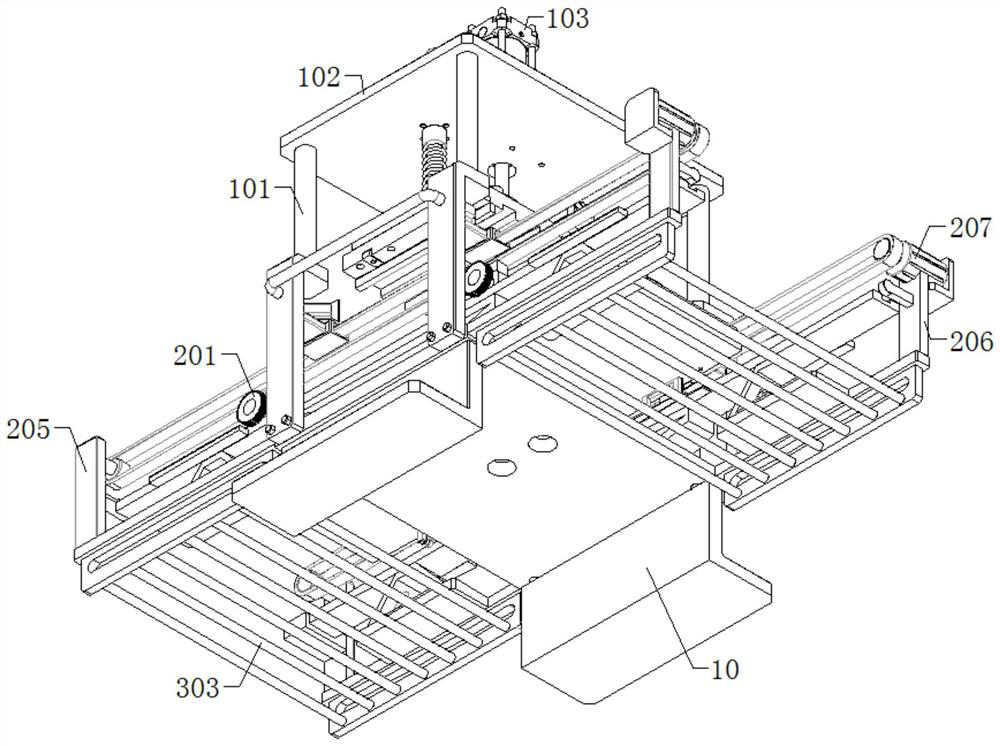

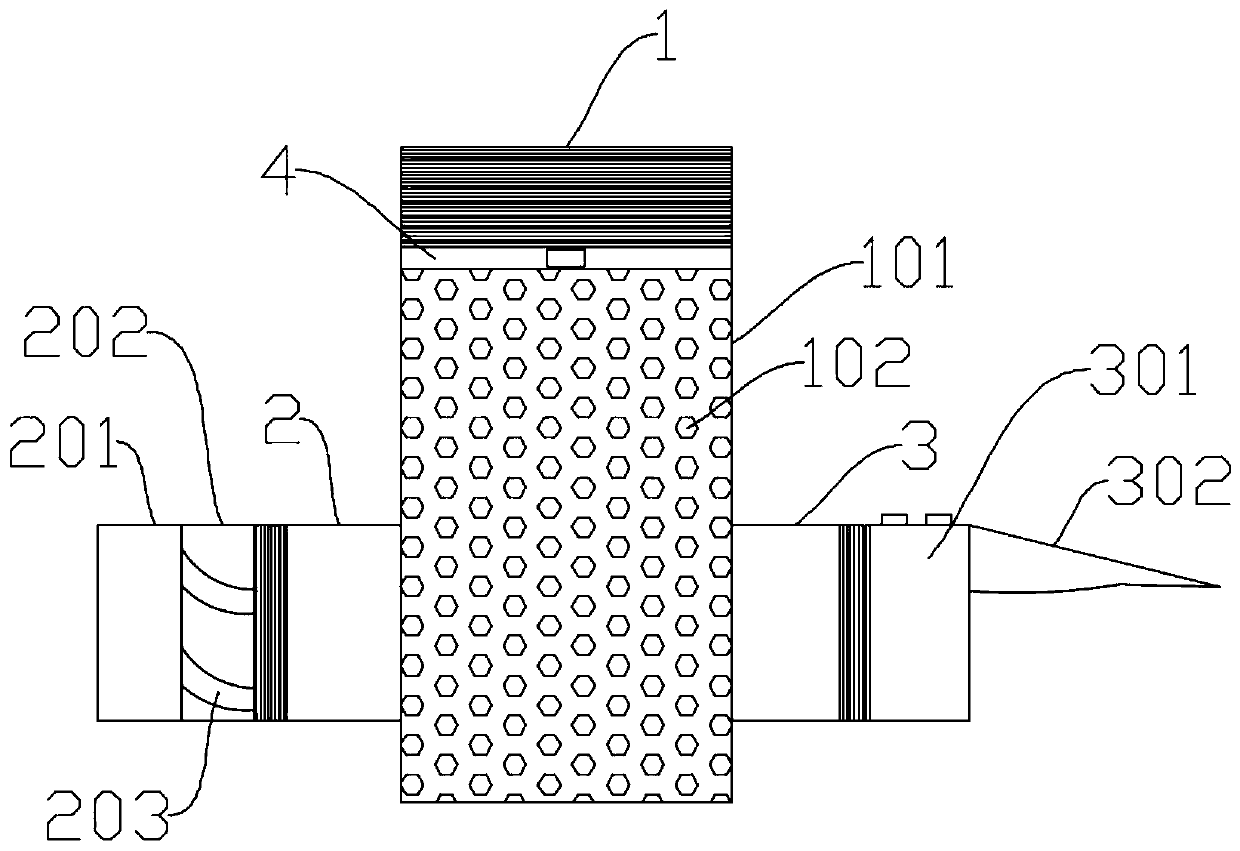

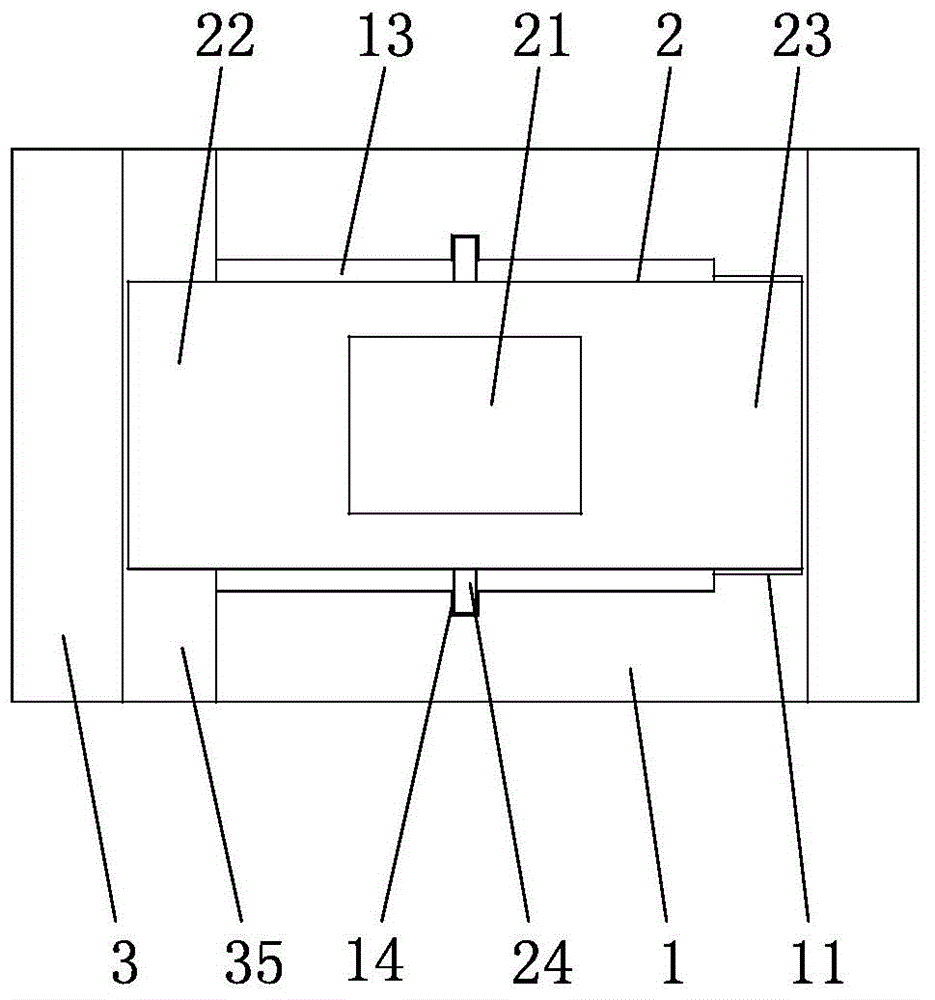

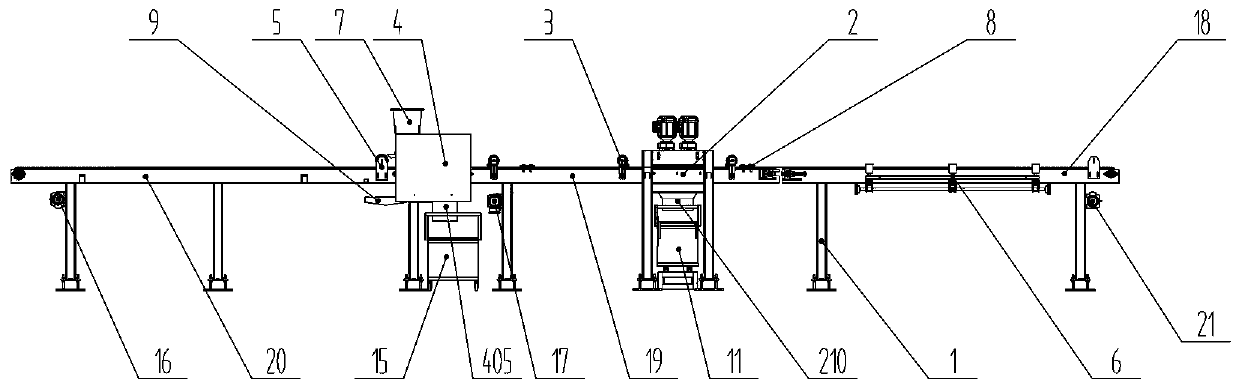

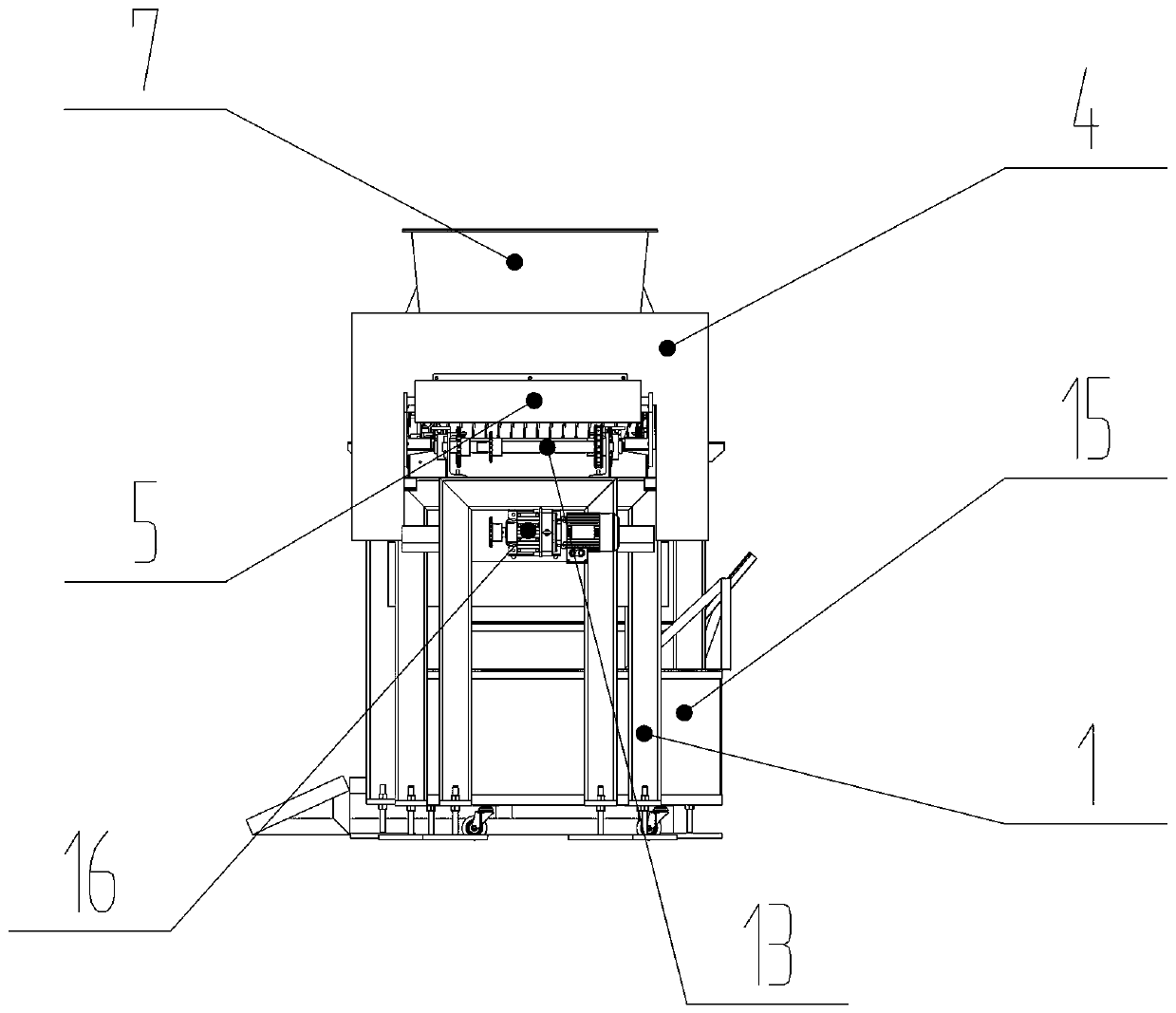

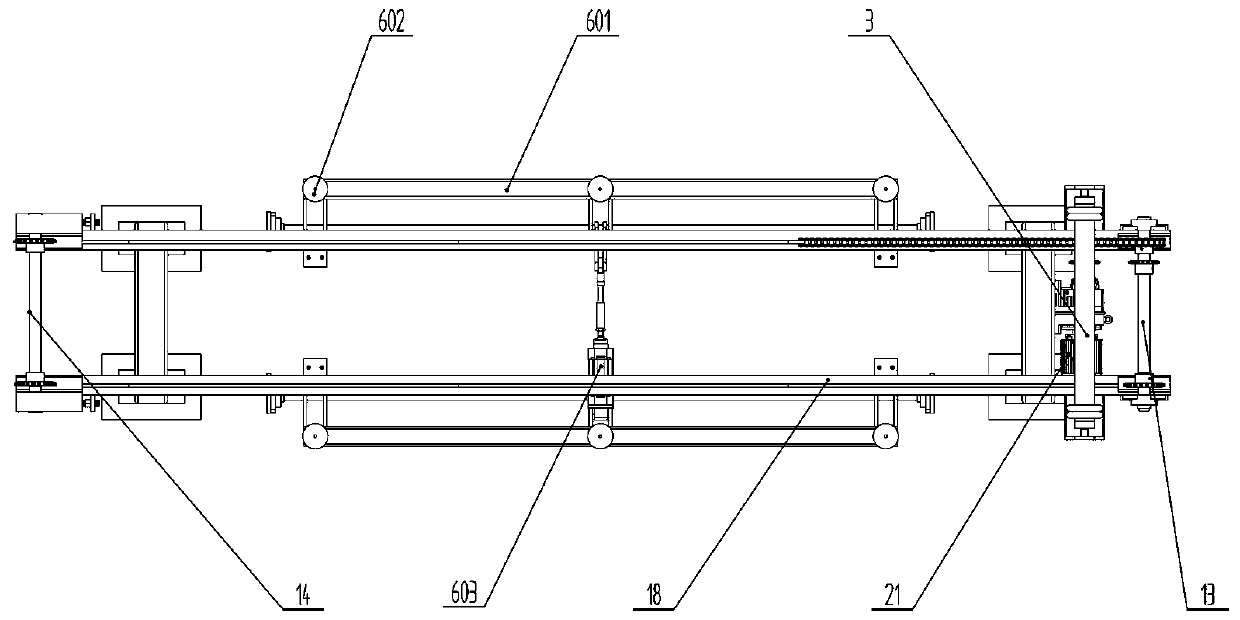

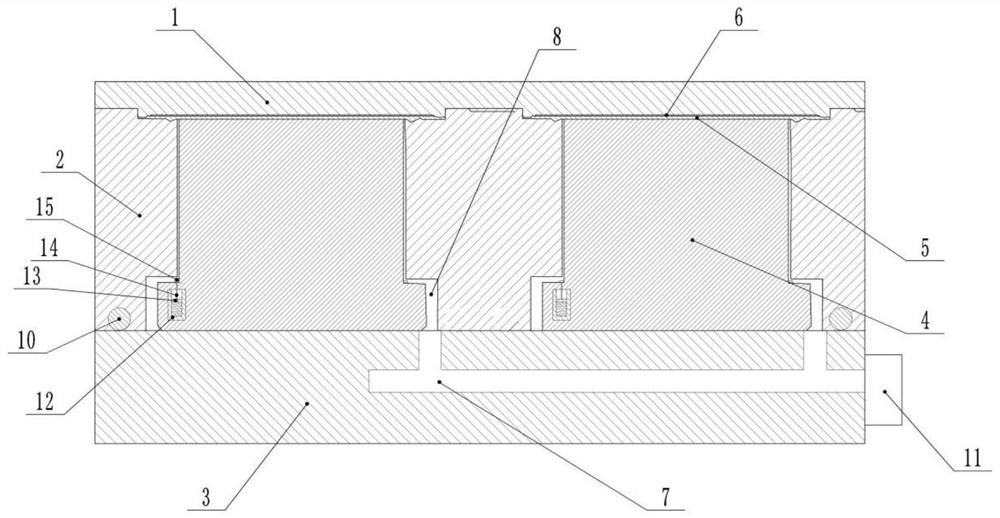

Building concrete block forming device

ActiveCN110466045AAffect molding qualityChange humidityCeramic shaping plantsFeeding arrangmentsConveyor beltRaw material

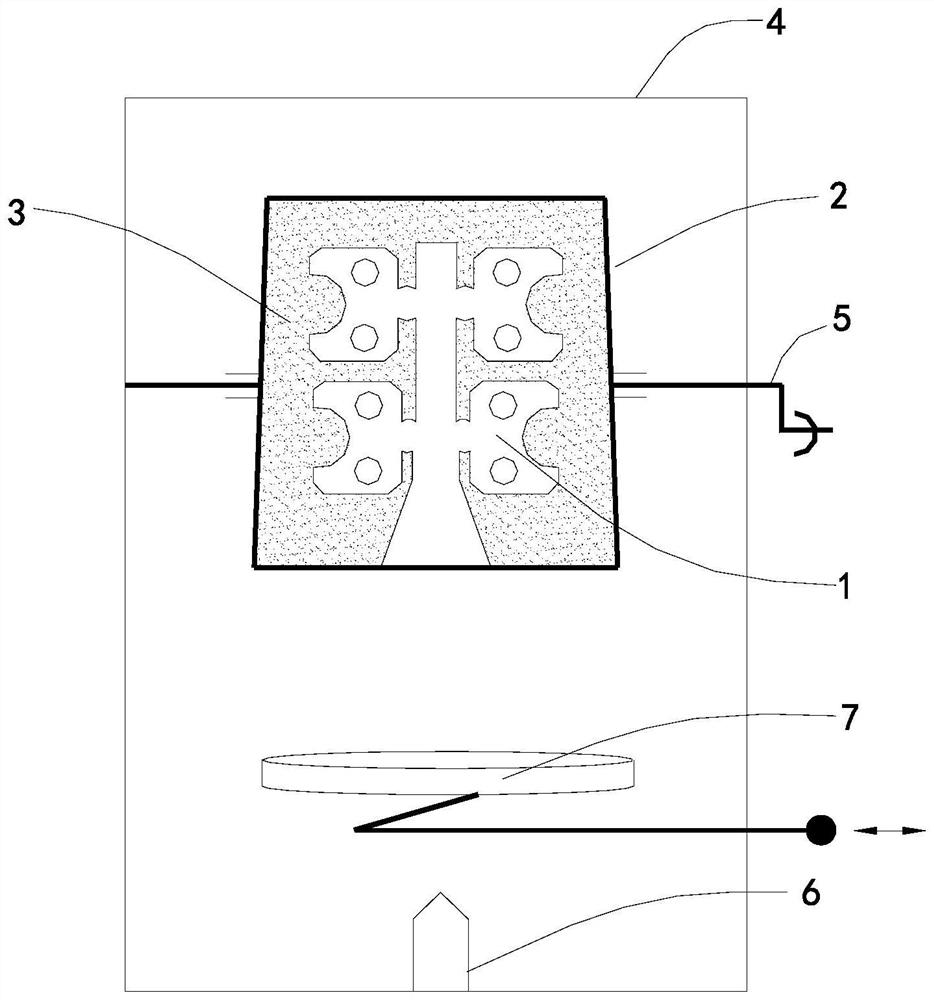

The invention discloses a building concrete block forming device, and belongs to the technical field of building block forming. The building concrete block forming device comprises a raw material humidity improving mechanism, a centering mechanism, a conveyor belt and a workbench, wherein a vibrating mechanism is arranged at the bottom of the workbench; a block forming mechanism is arranged abovethe workbench; a guide mechanism is arranged between a rack and the conveyor belt; a support is arranged below the workbench; a residual material scraping mechanism is arranged at the left end of thesupport; the raw material humidity improving mechanism comprises two moving blocks and two moving assemblies; and the top of the workbench is provided with two horizontally arranged sliding rails. According to the building concrete block forming device, the humidity of the block raw materials in a forming mold can be adjusted through the raw material humidity improving mechanism, so that the blockraw materials are prevented from being stored in the forming mold for a long time to influence the forming quality of the block; and a guide plate can be enabled by the guide mechanism to guide the block raw materials into the forming mold, so that the situation that the block raw materials cannot accurately fall into the forming mold when falling off the conveyor belt is avoided.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

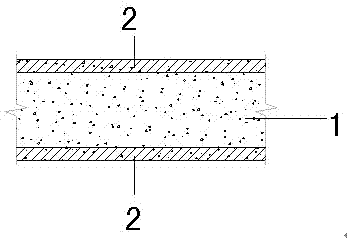

Stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method

The invention discloses a stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method. A base plate and a doubling plate are included. The base plate is carbon steel, the doubling plate is stainless steel, and the thickness ratio of the doubling plate to the base plate is 10%-30%. The stainless steel-carbon steel composite plate preparing method comprises the first step of base plate and doubling plate surface treatment, the second step of composite blank assembling, the third step of welding, the fourth step of purging, the fifth step of composite blank vacuum pumping, the sixth step of heating, the seventh step of rolling, the eighth step of dephosphorization and the ninth step of acid pickling. By means of the stainless steel-carbon steel composite plate hot continuous rolling large-scale preparing method, the large-scale production of stainless steel-carbon steel composite plates is achieved, the shearing strength of the formed stainless steel-carbon steel composite plates reaches up to 480-530 MPa, usage of an isolation agent or an obstruction agent is avoided, accordingly, oxidization of a composite interface is prevented, and the qualityof the composite plates is guaranteed.

Owner:山东盛阳金属科技股份有限公司

Gypsum built-in mould

InactiveCN103613354AHigh pressure bearing surface strengthIncreased bearing surface strengthFloorsFiberUltimate tensile strength

The invention discloses a gypsum built-in mould and a preparation method thereof. The gypsum built-in mould comprises gypsum powder, water, high-strength fibers and organosilicon waterproof powder. The waterproof ability of the gypsum built-in mould is realized by two ways: 1, the organosilicon waterproof powder is added into the raw materials of the gypsum built-in mould, thereby realizing the waterproof ability of the gypsum built-in mould; 2, a method of coating the surface of the gypsum built-in mould in a waterproof manner is adopted, i.e., a layer of organosilicon waterproofing agent solutions are coated on the surface of the molded and dried gypsum built-in mould, so that a waterproof layer is formed on the surface of the gypsum built-in mould, thereby realizing the waterproof ability of the gypsum built-in mould. The gypsum built-in mould has the strength and the waterproof performance, thereby being especially suitable for in-situ concrete hollow floors.

Owner:GUIZHOU ZHONGJIAN SPACE ENG TECH

Cast-in-place method for small concrete members

ActiveCN106894633AEasy to assemble and disassembleImprove turnover rateForms/shuttering/falseworksEngineeringRebar

The invention discloses a cast-in-place method for small concrete members. The cast-in-place method comprises the following steps that S1, the following members comprising a bottom plate, side plates, end plates and glass connecting pieces are obtained firstly, wherein the bottom plate, side plates, the end plates and the glass connecting pieces are made of anti-explosion tempered laminated glass, the glass connecting pieces comprises connecting plates bending to be in an L-shaped, and sucking discs are arranged on the two mutually-vertical side faces deviating from the bending direction of the connecting plates; S2, formworks are assembled; and S3, casting is conducted, specifically, the inner sides of the assembled formworks are coated with demoulding agents, bound steel bars are put into formworks, concrete is cast, compacted by vibration through a vibrator and maintained till the strength of the concrete reaches 20%-40% of the strength when the concrete is fully hardened, the side plates and the end plates are dismantled, and the concrete members are maintained continuously till the concrete is fully hardened. The cast-in-place method has the advantages of being capable of improving the turnover rate of the formworks, high in production efficiency, favorable for reducing the labor intensity of workers, cost saving and the like.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Production technology for one-shot dry forming of car ceilings

InactiveCN105946329AIncreased melt flow rateEvenly distributedLamination ancillary operationsLaminationAutomotive engineeringElectric heating

The invention discloses a production technology for one-shot dry forming of car ceilings, and belongs to the field of processing of car interior decorative parts. The technology comprises the following steps: sending a composite material with a sandwich structure, formed by nonwoven fabric PET, glass fiber GF, PE rubber powder, PE rubber films or PP rubber films and PU plates, to a heating furnace, and preheating the composite material; cutting the preheated composite material; sending the cut composite material to an electric heating zone, and heating the cut composite material; and sending the heated composite material to a die, laminating the heated composite material to a face decoration, and carrying out car ceiling pressure forming. The technology adopting the above technical scheme to carry out one-shot dry forming of the car ceilings has the advantages of simple process, low cost and excellent quality.

Owner:芜湖正海汽车内饰件有限公司

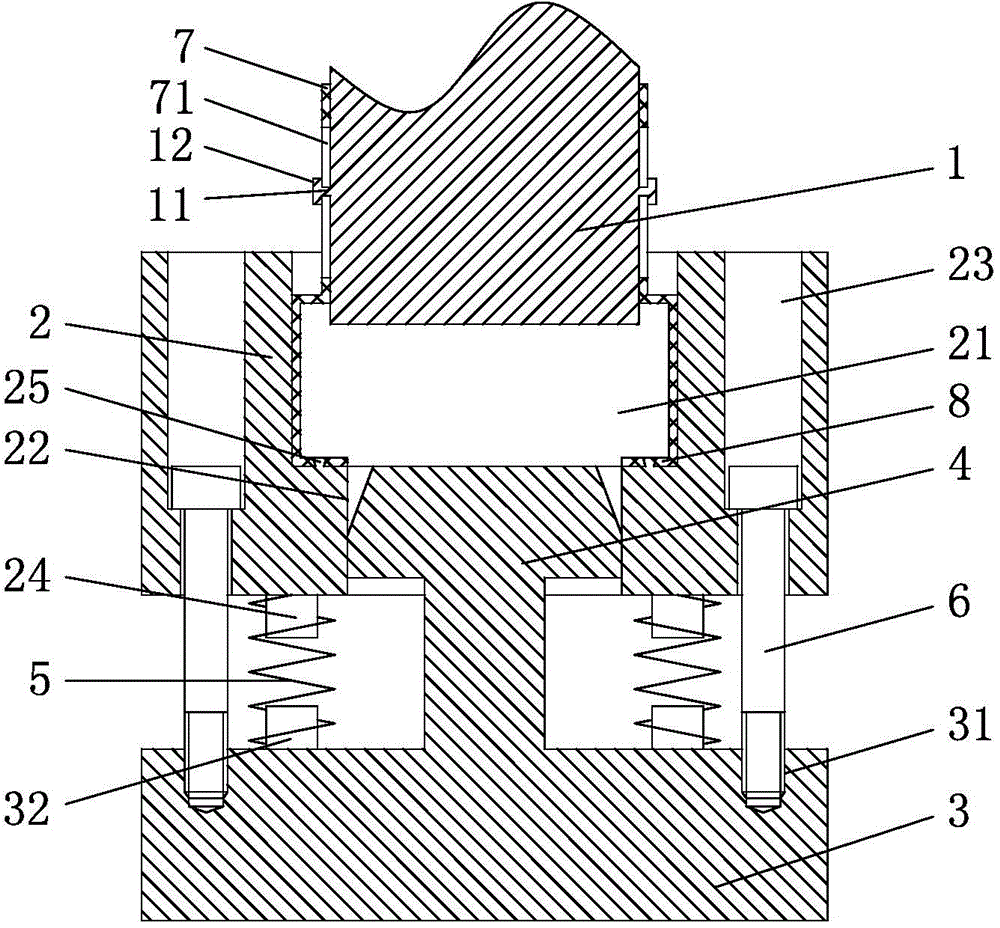

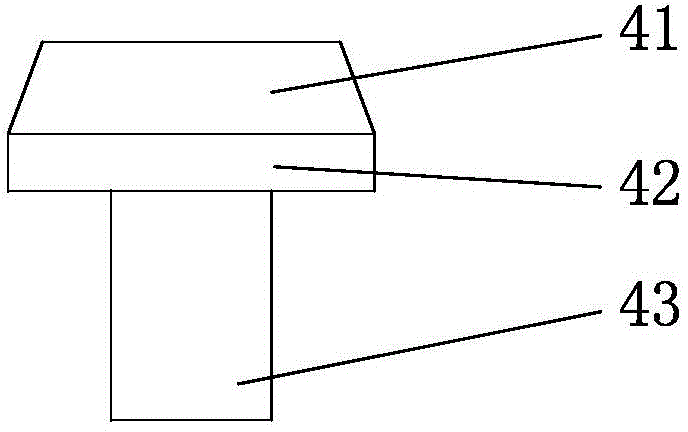

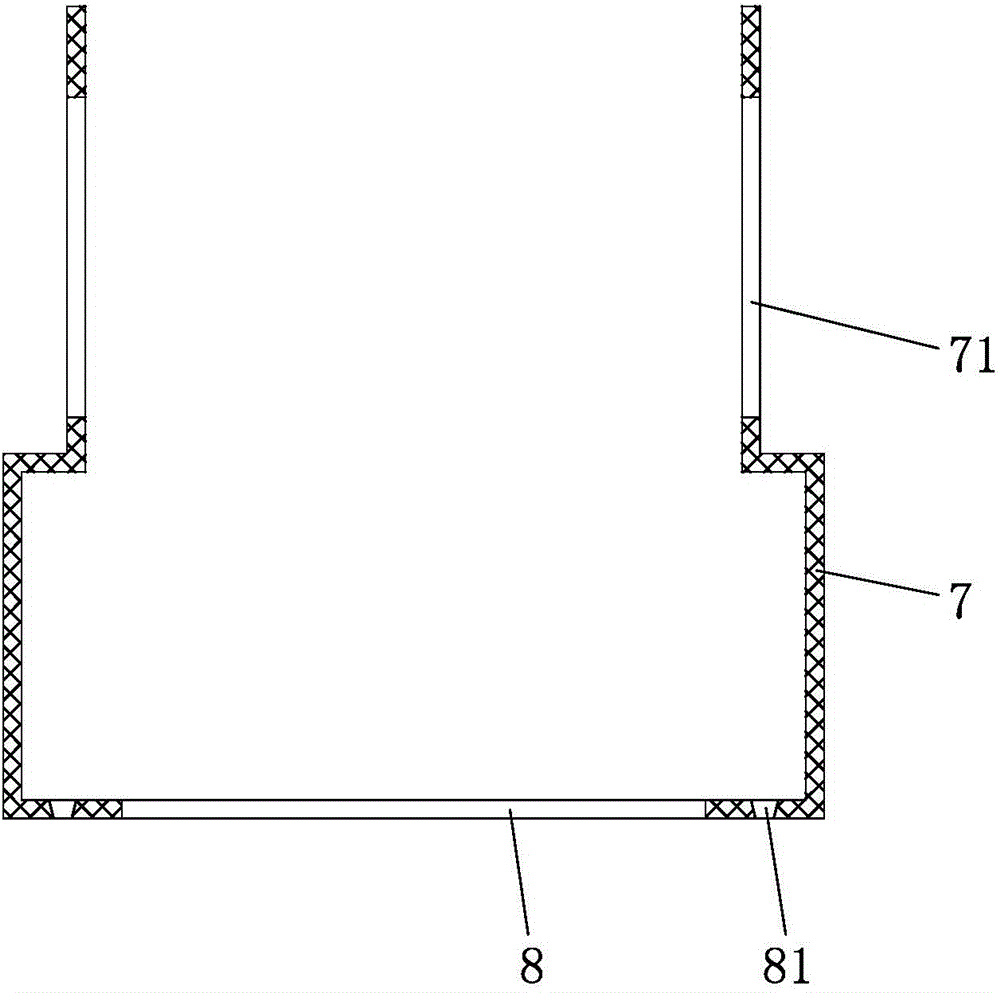

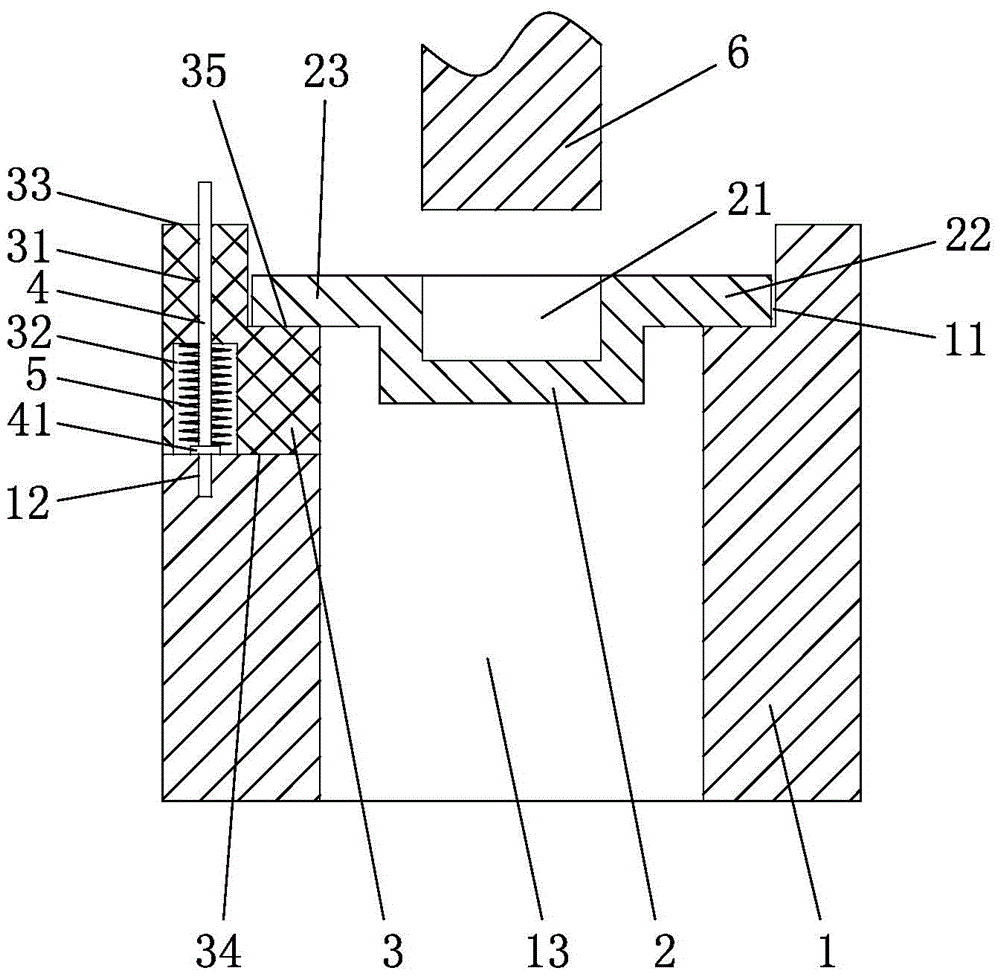

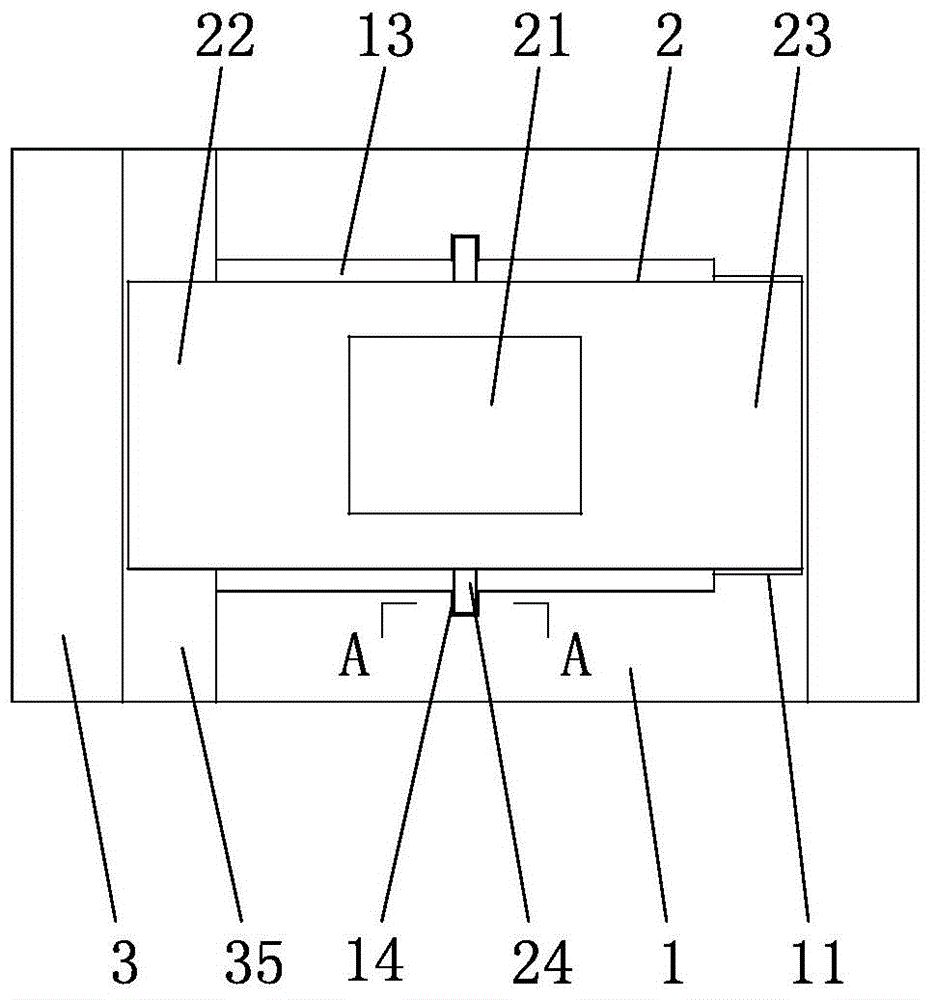

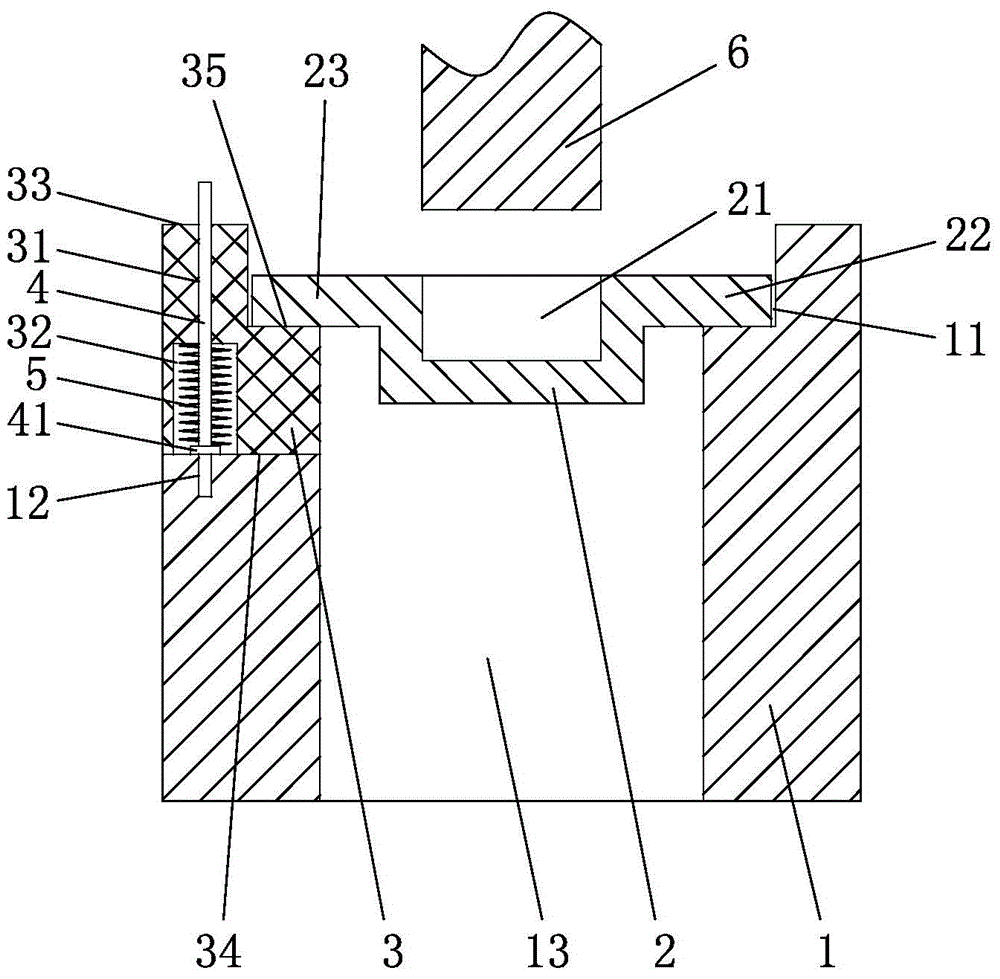

Compacting die for refractory brick

InactiveCN104128985AEasy to moveImprove fastnessCeramic extrusion diesShaping press ramBrickBlock match

The invention relates to a compacting die for a refractory brick and belongs to the field of compacting dies. The compacting die solves the problem that annular protruding ribs of the refractory brick are not high enough. The compacting die comprises a punch and a die holder component, wherein a forming groove matched with the punch is formed in the die holder component, the die holder component comprises a forming die, reset springs, bolts and a fixed base, the forming die is connected with the fixed base through the bolts and can move in the axial direction along the bolts, a material taking part capable of moving in the axial direction along the punch is arranged on the punch, positioning holes are formed in the material taking part, positioning protrusions can be inserted into the positioning holes so that the material taking part can be fastened to the bottom wall of the forming groove, a punch block matched with a limiting hole is arranged on the fixed base and is provided with a punch portion, and the distance between a first limiting block and a second limiting block is smaller than or equal to the height of the punch portion.

Owner:浙江立鑫高温耐火材料有限公司

Preparation method for high-strength amorphous alloy magnetic strip material

The invention discloses a preparation method for a high-strength amorphous alloy magnetic strip material. The preparation method comprises the following steps that amorphous alloy preparation materials including 4-6% of silicon, 2-3% of boron, 1.0-1.5% of aluminum, 0.8-1.1% of cobalt, 0.05-0.10% of yttrium, 0.2-0.4% of molybdenum, 0.10-0.15% of gallium and the balance ferrum are weighed; the amorphous alloy preparation materials are input into a medium frequency induction melting furnace with gas tightness to be subjected to heating and melting; and the melted alloy liquid is guided to flow into alloy pouring tundish, the alloy pouring tundish is provided with two alloy pouring mouths, the melted alloy liquid is poured to a roller face peak of a rapid-quenching single-roller through one of the two alloy pouring mouths, the melted alloy liquid is poured to the downstream position of the roller face peak of the rapid-quenching single-roller through the other alloy pouring mouth, the melted alloy liquids flowing out of the two alloy pouring mouths are cooled on the roller face of the rapid-quenching single-roller, and the amorphous alloy strip material is prepared. By means of the preparation method for the high-strength amorphous alloy magnetic strip material, the high-strength amorphous alloy magnetic strip material with larger thickness can be prepared.

Owner:河北瑞煜鑫泽科技有限公司

Stamping device for vehicle parts

ActiveCN108311603AAvoid safety hazardsCompression and extraction action is continuousMetal-working feeding devicesPositioning devicesEngineeringConveyor belt

The invention belongs to the technical field of production equipment for vehicle parts and particularly discloses a stamping device for vehicle parts. The stamping device for vehicle parts comprises arack and a fixing board; the rack is provided with a drive mechanism; the fixing board is connected with an upper stamping mold and an inclined board; the inclined board is of a hollow structure; theupper inclined end of the inclined board is closed, and a cover is hinged to the lower inclined end of the inclined board; the cover is provided with a first wedge block; a first cylinder is fixed tothe rack and connected with a second wedge block; the upper portion of the inclined board is in sliding connection with a suction and pressing device; the suction and pressing device comprises a plurality of hollow columns and a suction cup; the hollow columns are provided with a supporting board; one side of the supporting board is connected with the inclined board through a spring; a check block is arranged on the lower portion of the inclined board; a lower stamping mold is arranged under the suction cup; a feeding mechanism is arranged on one side of the lower stamping mold; and a discharging conveyor belt is arranged on the other side of the lower stamping mold and located under the lower inclined end of the inclined board. By adoption of the technical scheme, the problems that the production efficiency is low, the forming quality is poor, discharging is inconvenient and potential safety hazards exist are solved.

Owner:沛县奔腾工贸有限公司

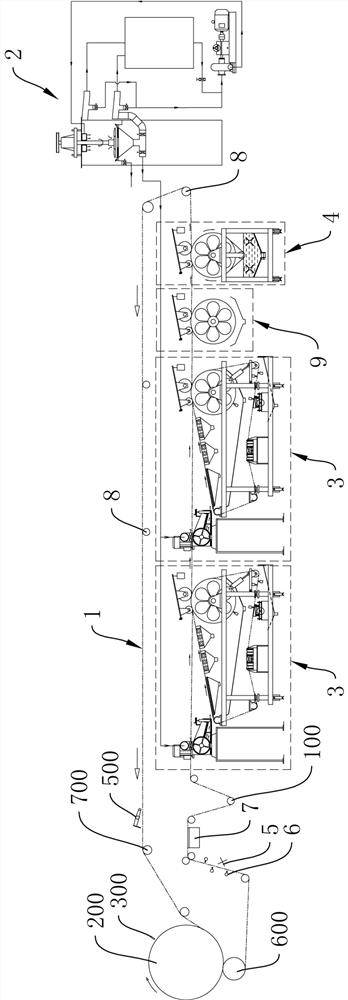

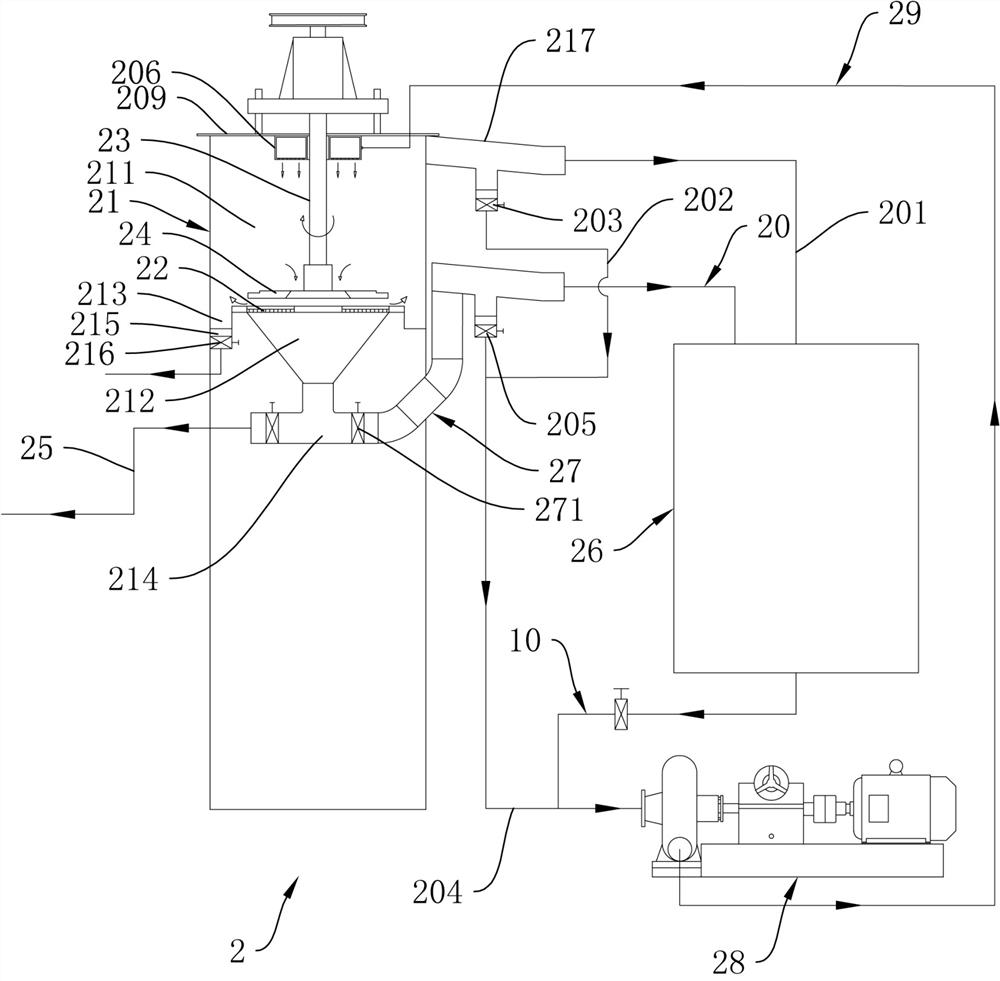

Efficient environment-friendly papermaking production line

ActiveCN112342811AQuality improvementReduce labor intensityWashing/displacing pulp-treating liquorsPaper recyclingPaper dustPapermaking

The invention relates to an efficient environment-friendly papermaking production line, belonging to the technical field of papermaking mechanical equipment. The efficient environment-friendly papermaking production line is characterized by comprising pulping equipment, wherein a feeding device of the pulping equipment can feed waste paper raw materials into a coarse crushing device; the coarse crushing device can crush the waste paper raw materials into coarse paper pulp; the coarse paper pulp is conveyed into a screening device through water flow assistance; the coarse paper pulp enters a pulp washing device after being screened and filtered by the screening device; and the pulp enters a fine grinding device after being cleaned by the pulp washing device, and enters a storage device after being finely ground by the fine grinding device. According to the invention, fine paper pulp can be finally obtained through automatic feeding, coarse crushing, paper material circulating and infiltrating, screening and paper scrap grinding and refining, and is stored for papermaking operation.

Owner:山东海天造纸机械有限公司

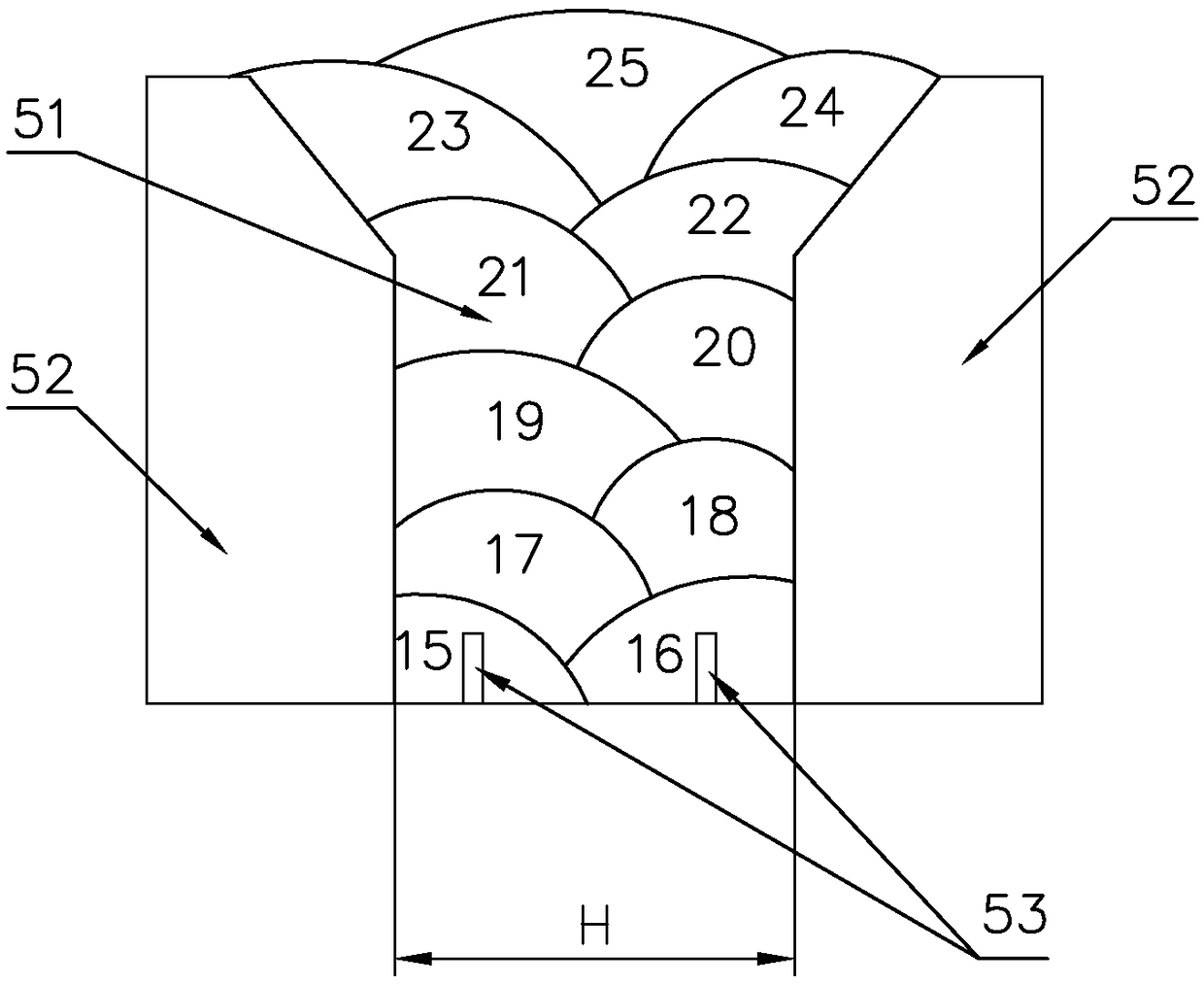

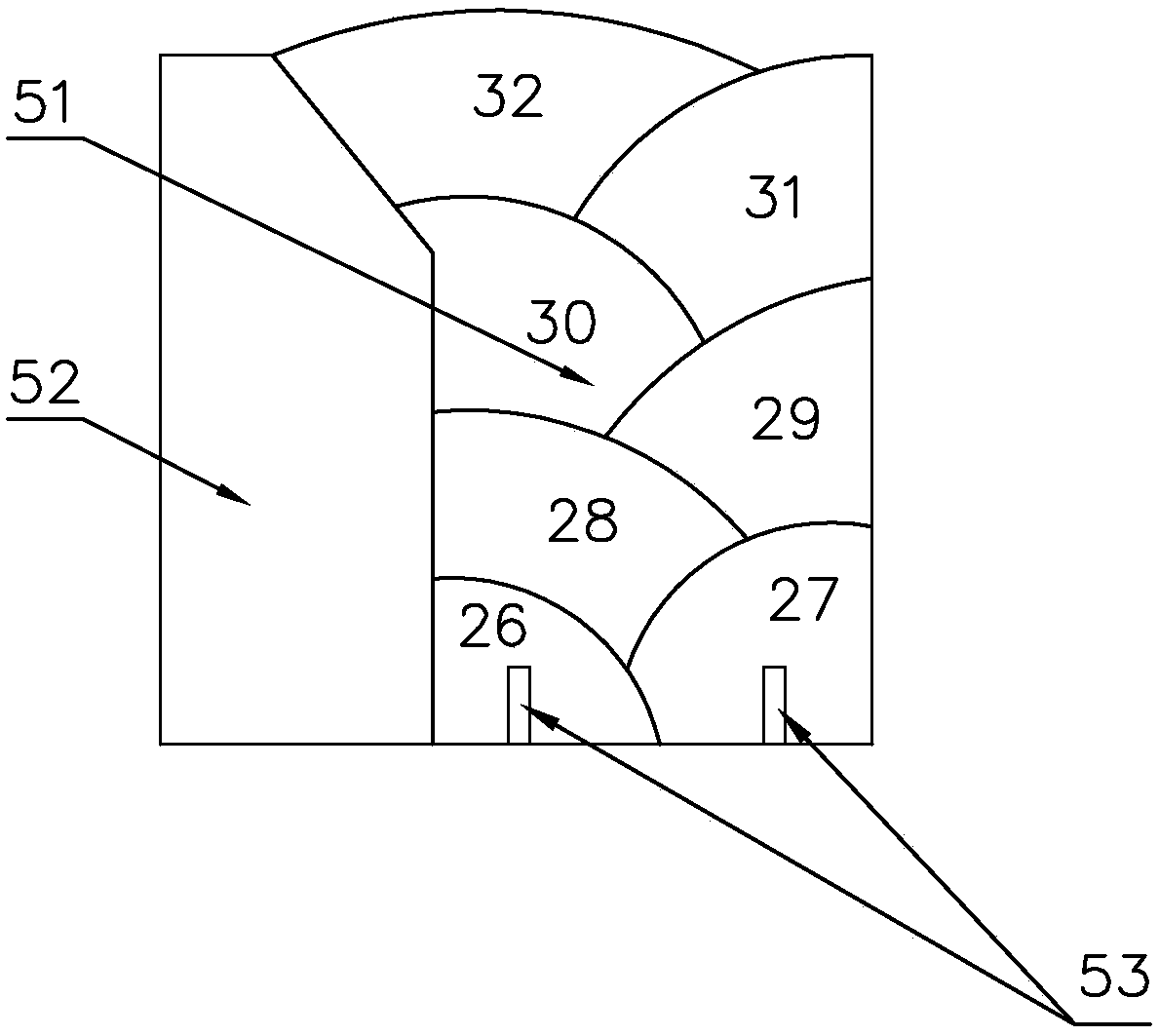

Manufacturing mold of honeycomb filler for water supply and drainage and use method of manufacturing mold

PendingCN114161651AReduce processing costsImprove work efficiency and practicalityMoulding deviceProcess engineering

The invention provides a water supply and drainage honeycomb filler manufacturing mold and a using method thereof.The water supply and drainage honeycomb filler manufacturing mold comprises a workbench and further comprises a supporting platform fixedly connected to the top of the workbench through a connecting column, an air cylinder is arranged at the top of the supporting platform, the telescopic end of the air cylinder penetrates through the supporting platform and is connected with a heat dissipation assembly through a fixing base, and the bottom wall of the heat dissipation assembly is connected with an upper mold; the upper die is matched with the supporting platform through a sliding part; the placing plate is fixedly connected to the side wall of the workbench, the inner wall of the sliding rail is provided with two sets of sliding forming devices, the two sets of sliding forming devices are arranged along the interior of the sliding rail, and the atomization device is arranged in the workbench, matched with the upper mold and the sliding forming devices and used for completing spraying of a release agent. The device is simple in structure and convenient to operate, continuous model machining operation and automatic material taking and placing are achieved, the production efficiency of the device is greatly improved, the production cost of an enterprise is reduced, meanwhile, the cold cutting effect of the device is enhanced, and the molding effect and forming quality of a mold are guaranteed.

Owner:袁燚

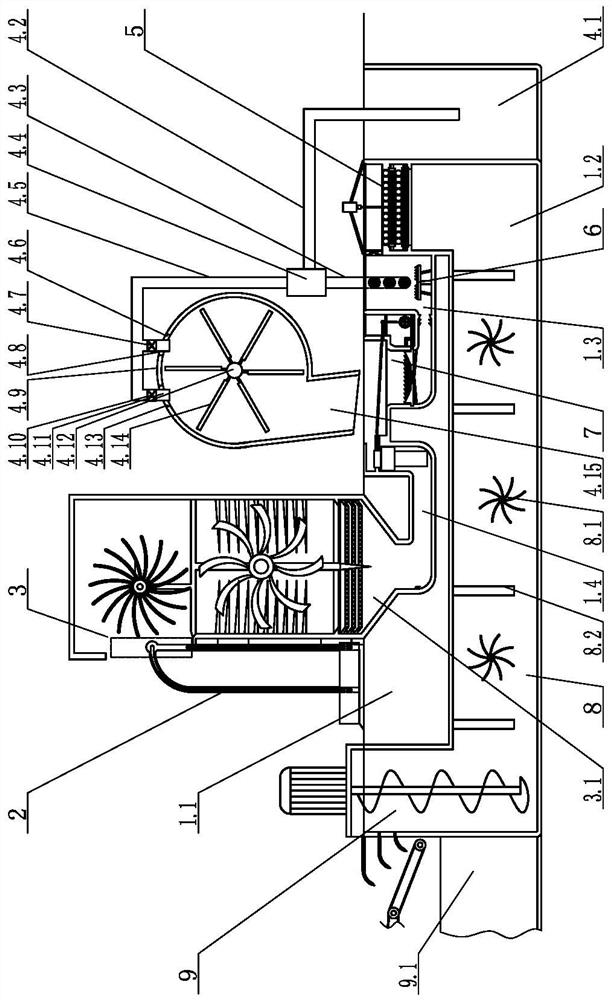

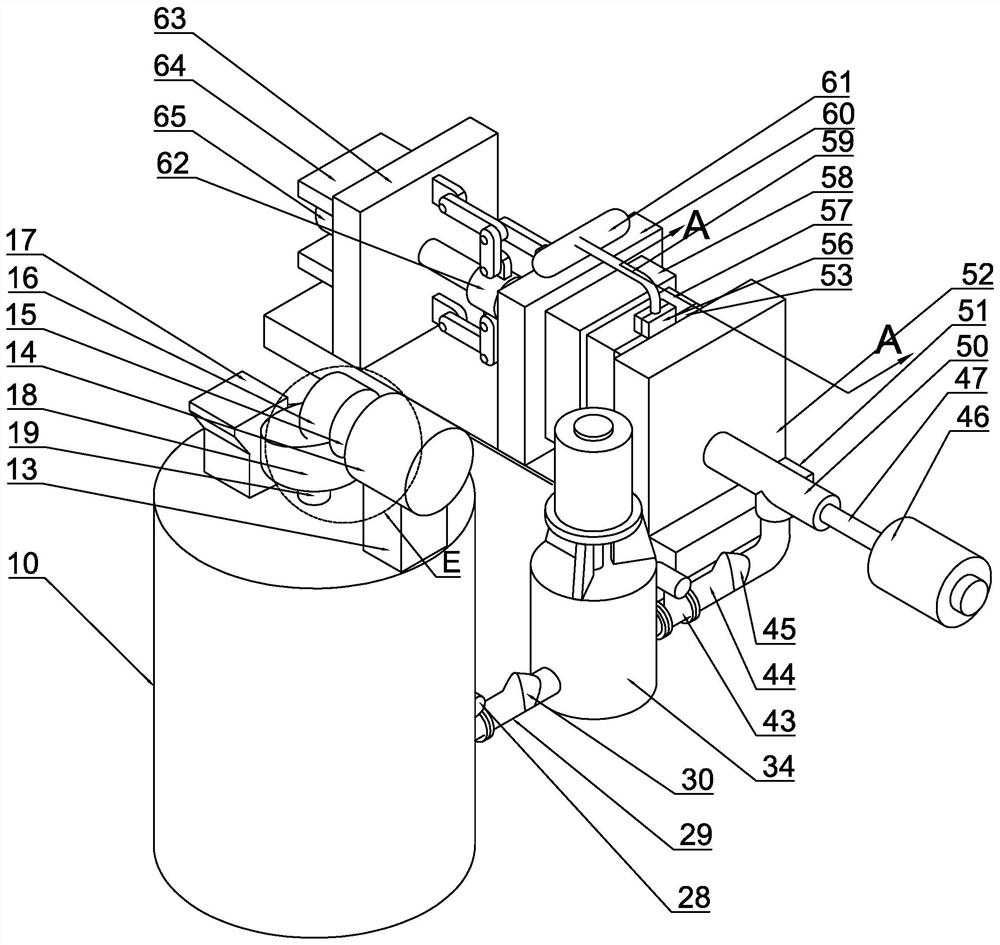

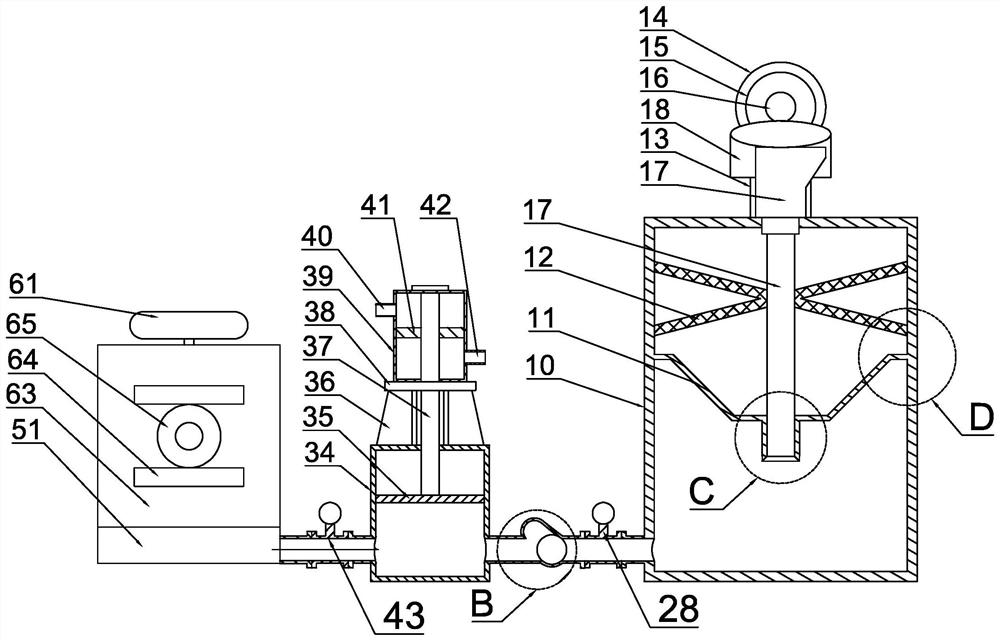

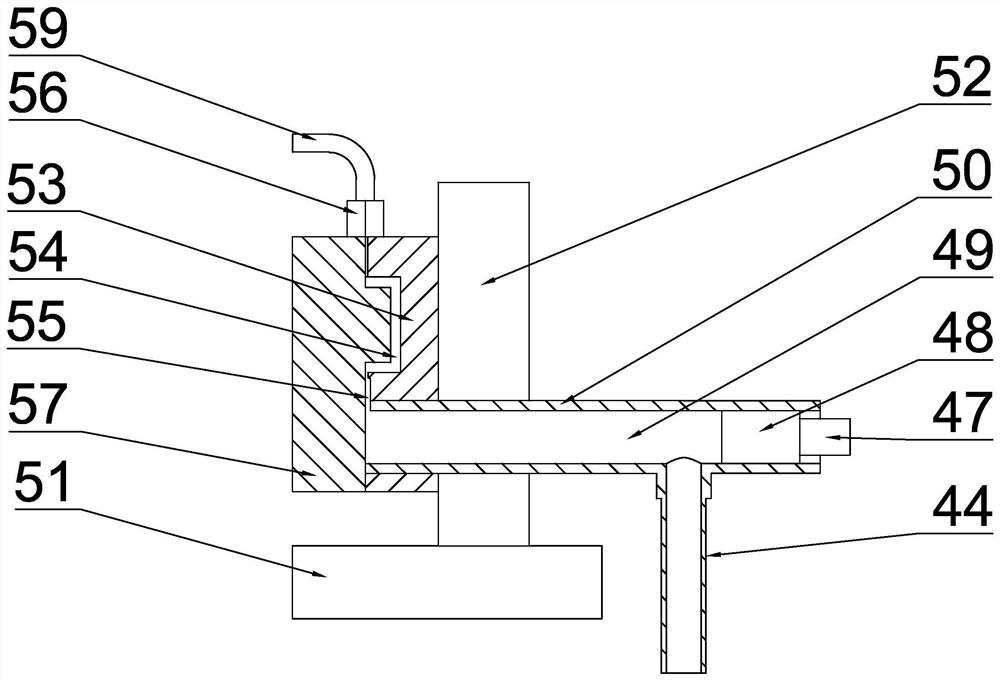

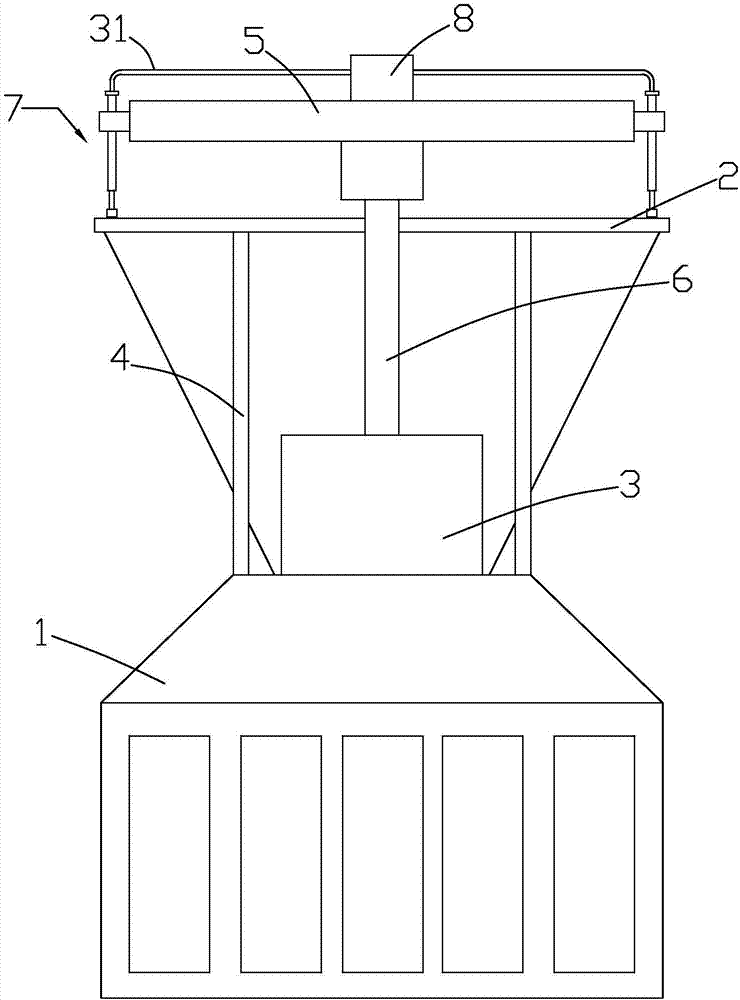

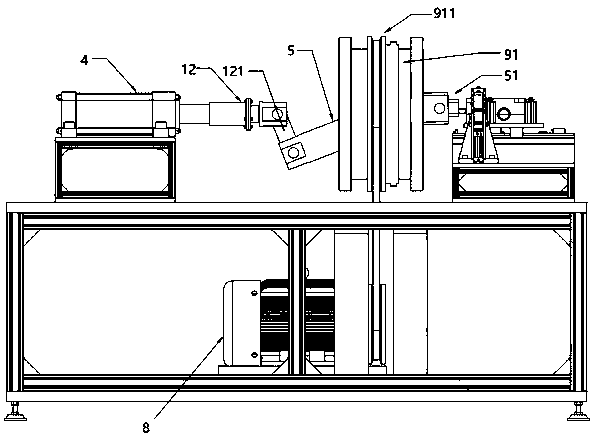

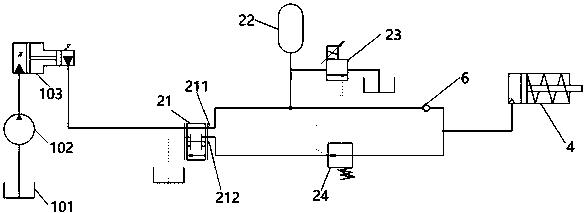

Heat preservation automatic quantitative feeding system for vacuum cold die casting

InactiveCN113560520AAffect molding qualityStable and pureCasting cleaning apparatusThermodynamicsDie casting

The invention belongs to the field of die casting, and relates to a heat preservation automatic quantitative feeding system for vacuum cold die casting. The heat preservation automatic quantitative feeding system for vacuum cold die casting comprises a heating and heat preservation tank fixedly arranged on the ground, a flow guide plate is fixedly arranged in the middle of the inner side of an inner cavity of the heating and heat preservation tank, and the inner cavity of the heating and heat preservation tank is divided into an upper cavity and a lower cavity by the guide plate. In the production process of a horizontal cold chamber die-casting die, a die-casting system is vacuumized, used solid metal materials are subjected to melting, filtering, heat preservation and storage, molten metal used in the die-casting process is automatically and quantitatively fed, and the problems that a traditional feeding mode is not beneficial to vacuumizing, the feeding efficiency is low, fed materials have impurities, the temperature and the feeding amount are not stable, and product defects and material waste are caused are solved.

Owner:车飞

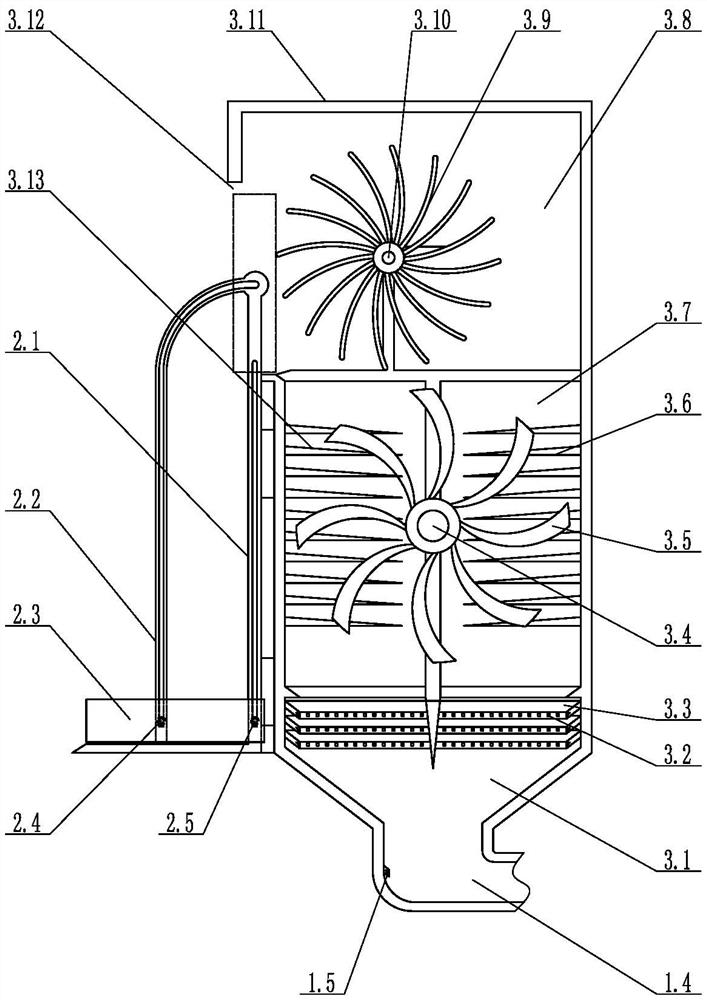

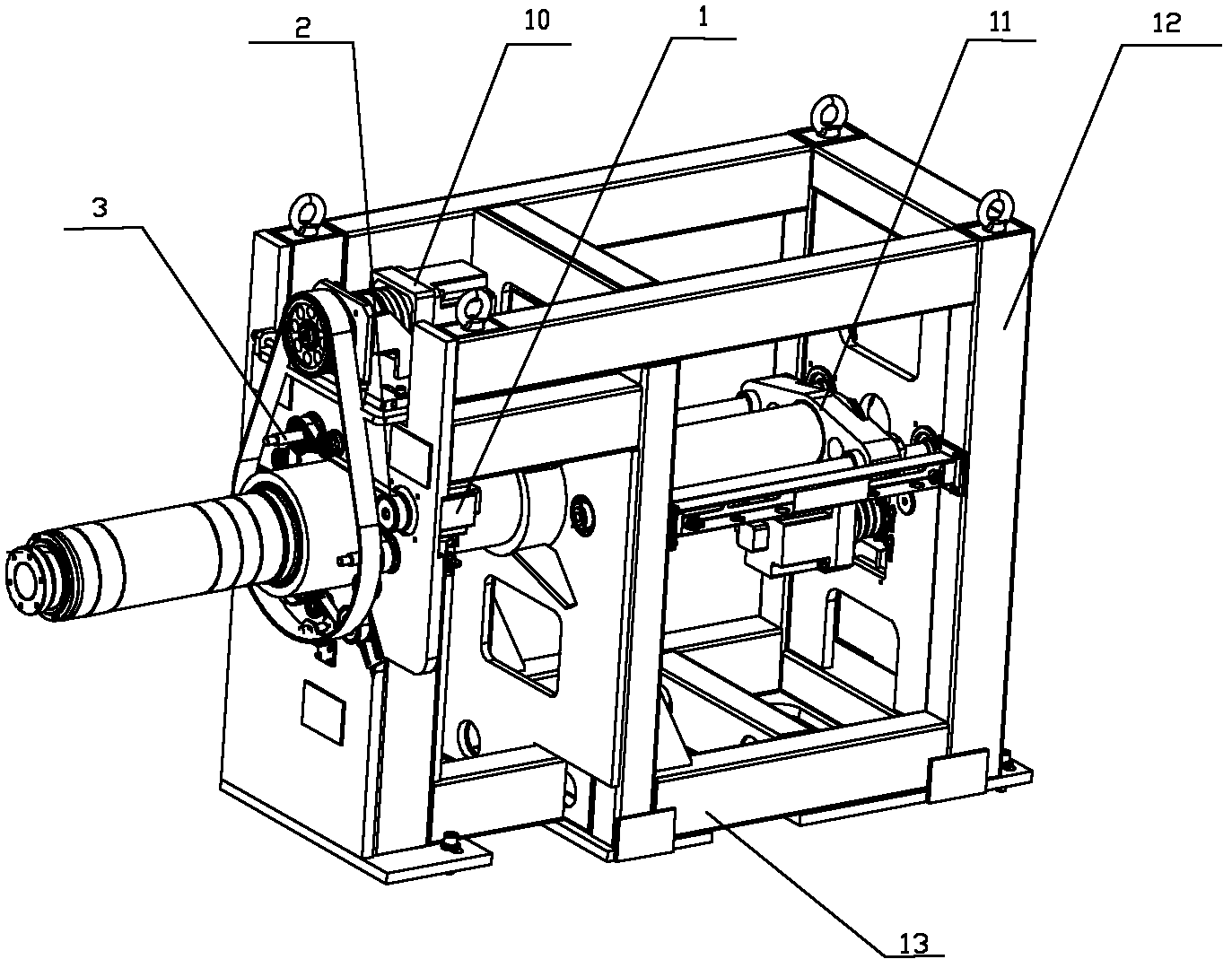

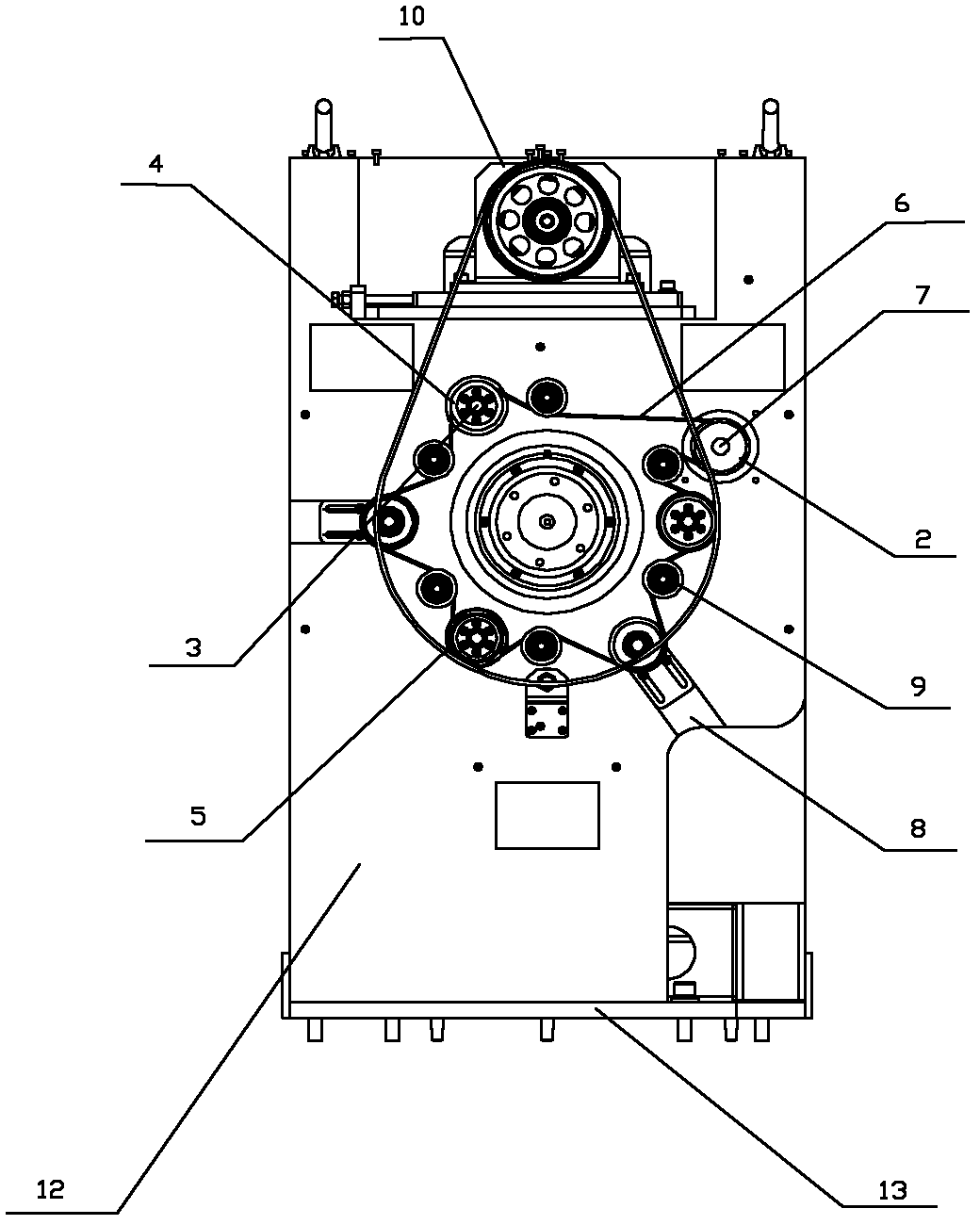

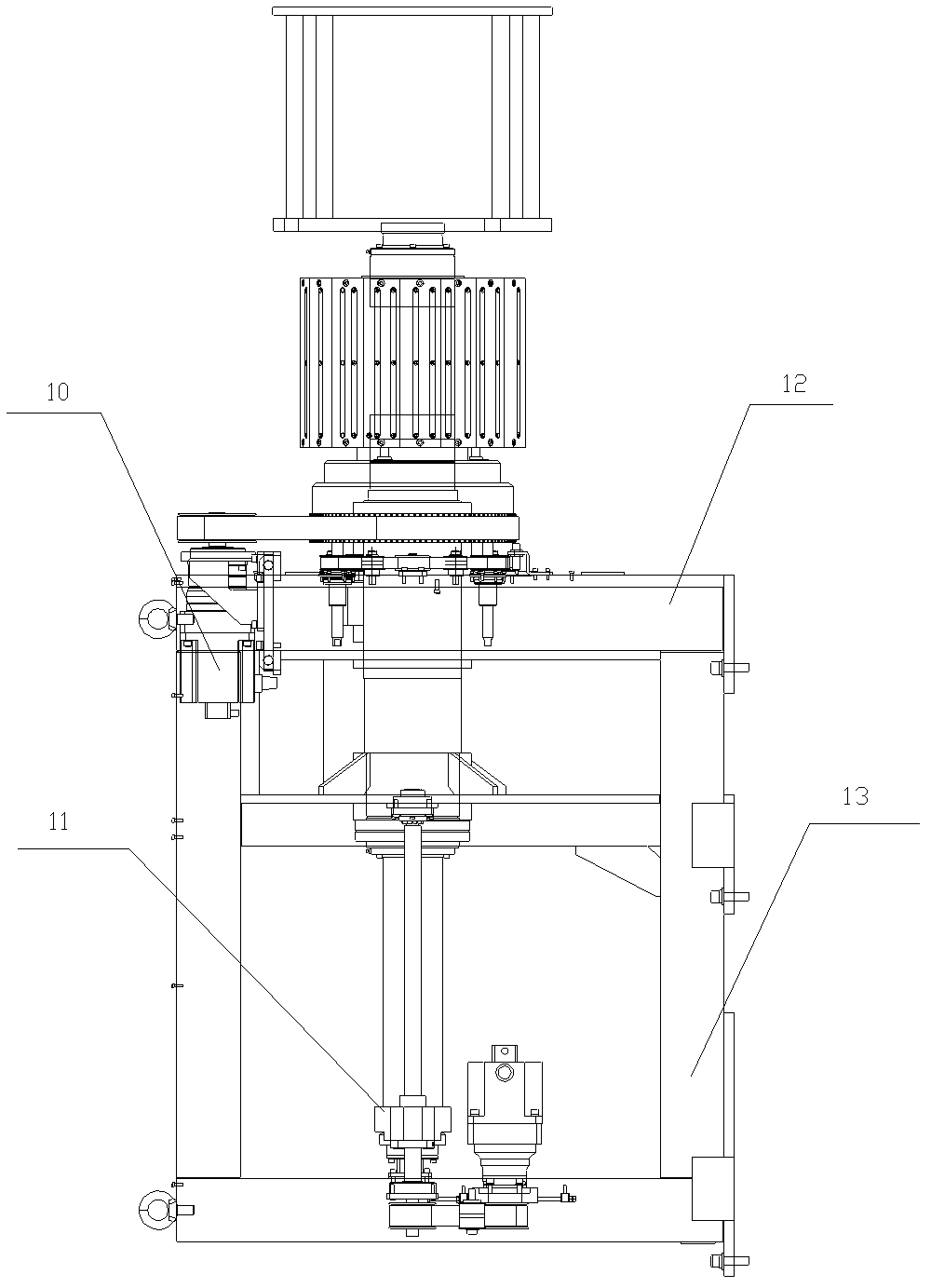

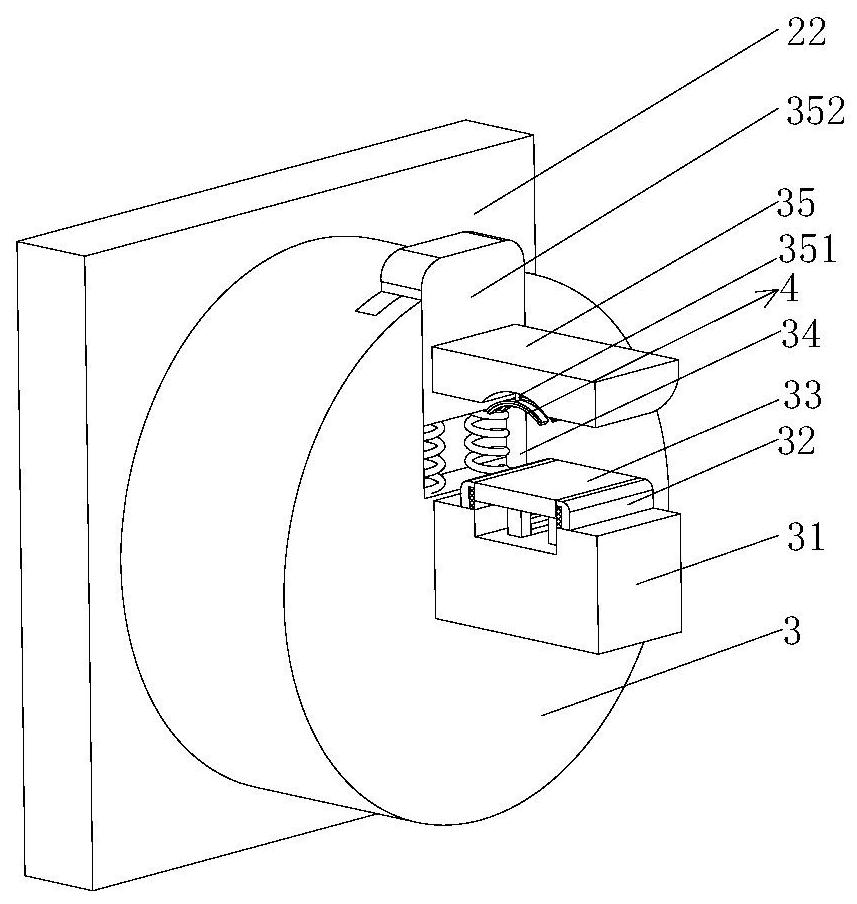

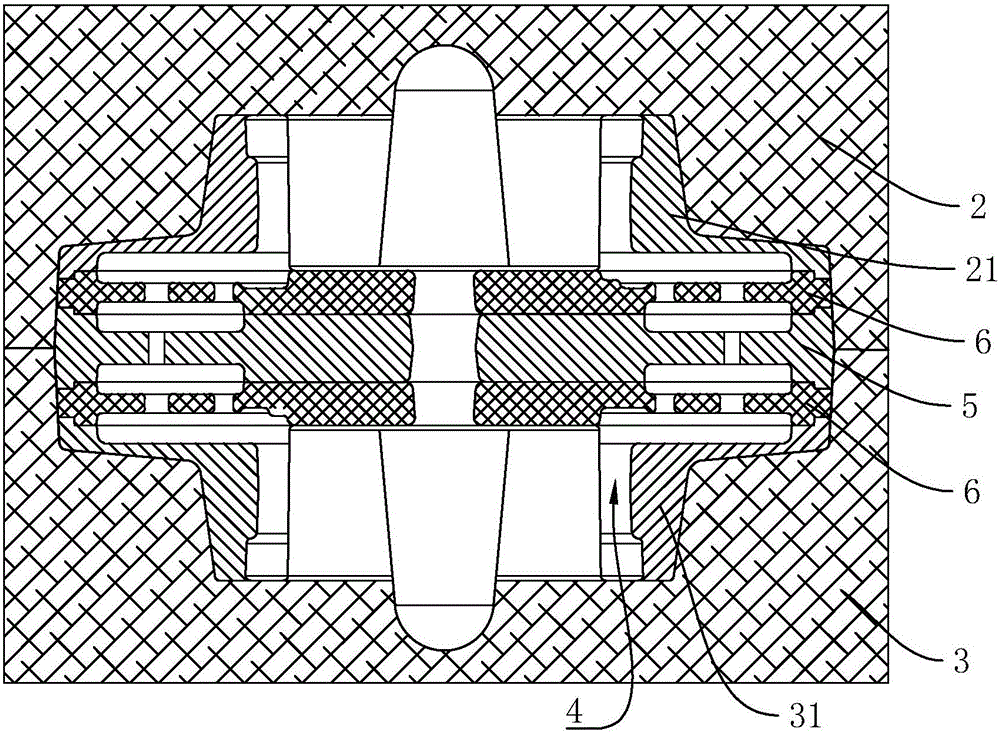

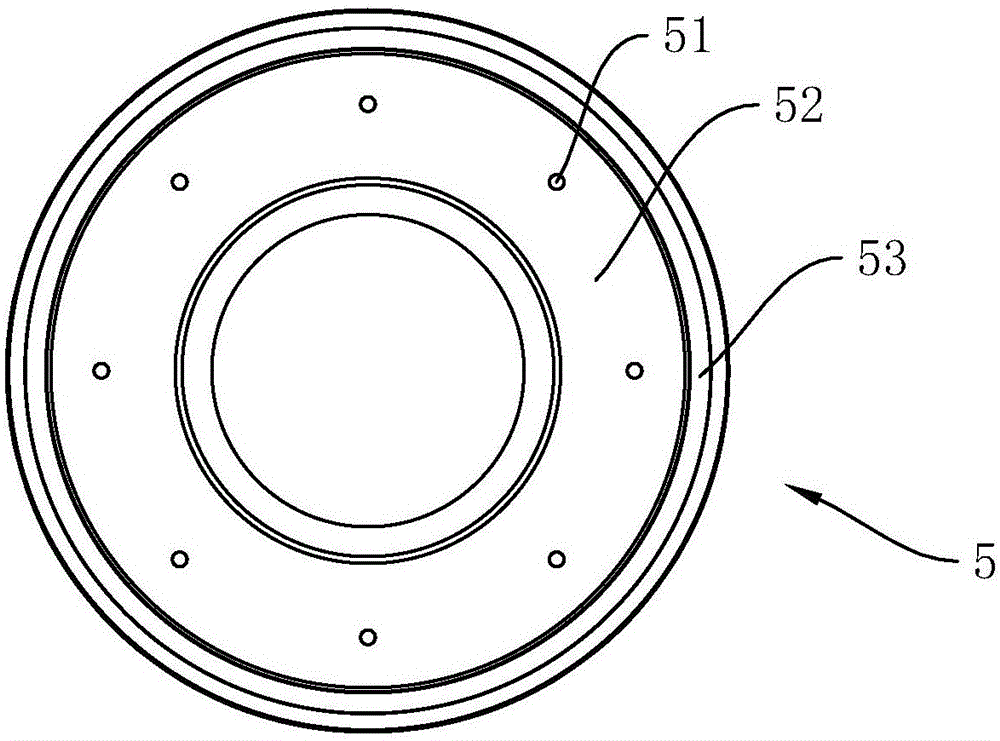

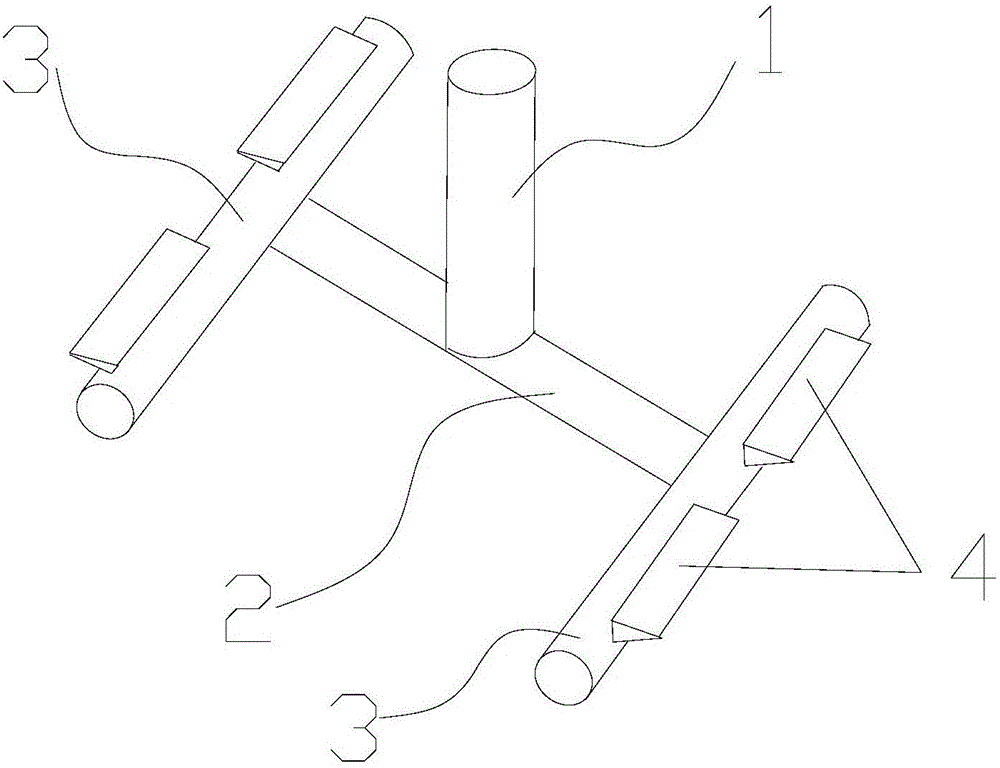

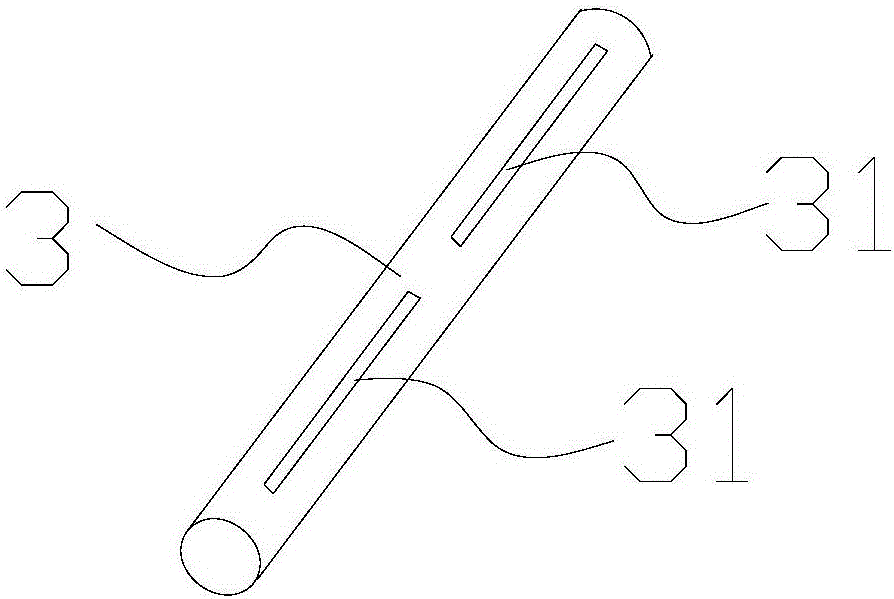

Belt ply drum host and drive method thereof

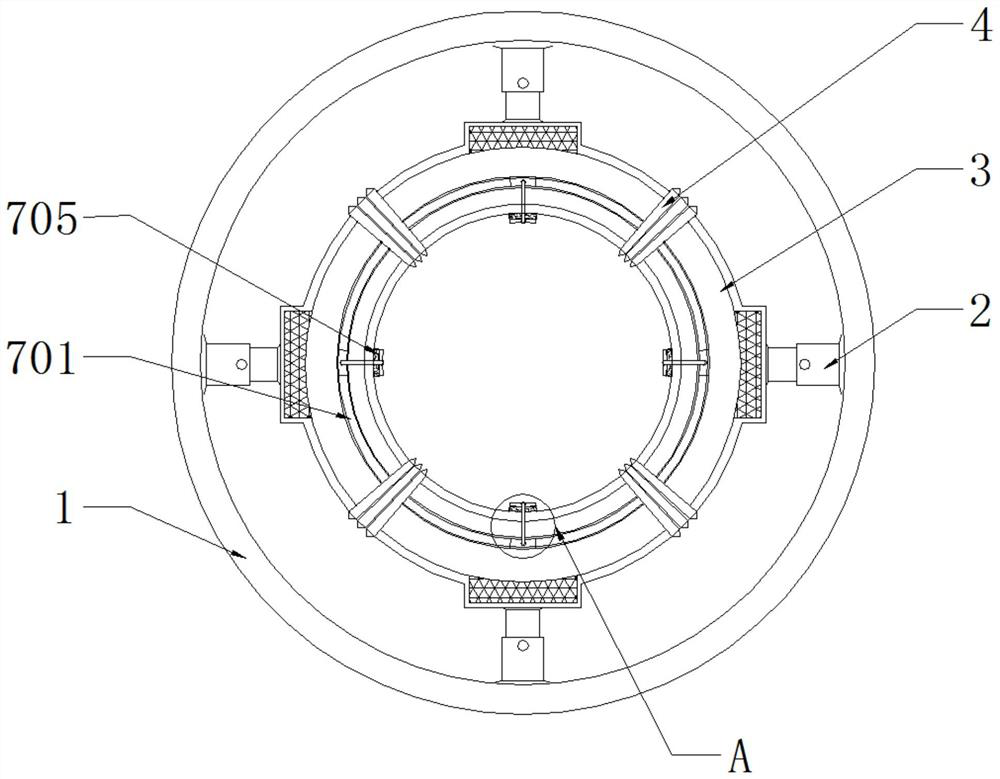

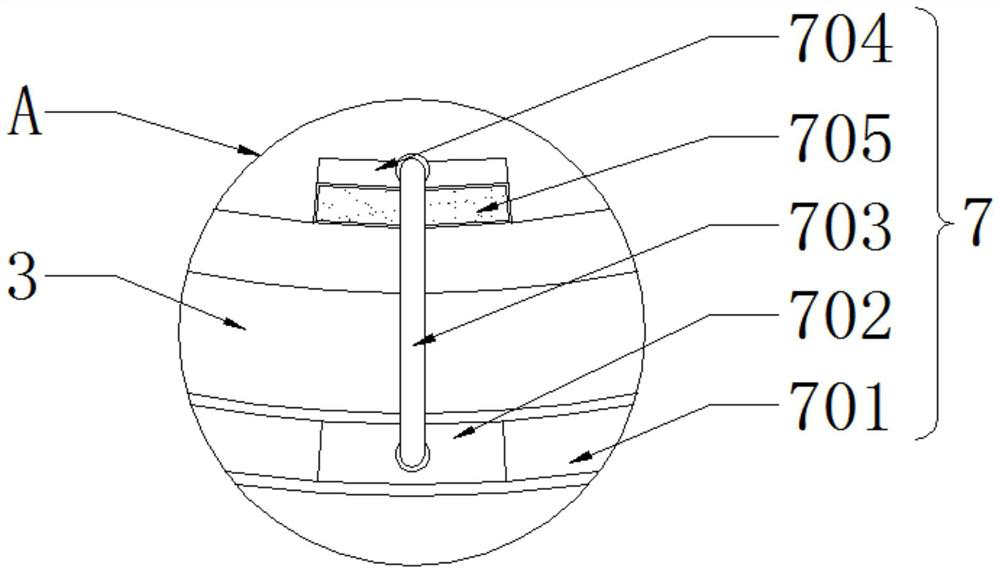

InactiveCN103182788AGuaranteed uniformityImproved Synchronous MobilityTyresEngineeringMechanical engineering

The invention provides a belt ply drum host and a drive method thereof, and the belt ply drum host of a forming machine for preparing a tire, belongs to a machinery manufacturing field. Aiming at a problem of fitness precision of a belt ply in a fitting process, the belt ply host is provided for raising radially-stretching precision and implementing multi-point control in a belt play drum one-step fitting technology process, wherein a second driving mechanism for supplying power for radially moving the belt ply drum, and a plurality of synchronization assemblies for implementing synchronous and radial movement of the belt ply drum, and the plurality of synchronization assemblies are circumferentially and fixedly matched in a certain distance, and are arranged in a same circumference surface. Precision requirement in a belt ply material fitness technology is satisfied.

Owner:MESNAC

Combination process of precious metal and porcelain

The invention discloses a combination process of precious metal and porcelain. The combination process comprises the following steps of S1, forming a body, namely selecting proper chinastone and kaolin as blank making raw materials, crushing the raw materials, finely selecting, washing, weighing ingredients according to a production formula, carrying out ball milling and fine crushing through ball milling equipment to achieve required fineness, carrying out impurity removal treatment on raw material powder, carrying out filter pressing dehydration on slurry for machine-made molding, and carrying out vacuum pugging, carrying out rolling forming on the blank mud according to requirements so as to obtain the body; and S2, firing the body, namely drying the body through ceramic drying equipment, and finishing the body after drying is finished. According to the combination process, the precious metal is combined with the porcelain, and the precious metal is attached to the surface of the porcelain at high temperature, so that sheet-shaped and dot-shaped imaging is formed, and the ornamental value of the porcelain can be greatly improved; and meanwhile, in the process of firing the porcelain, the processing rate of the porcelain can be effectively improved by increasing the drying rate of the body.

Owner:深圳市信德缘珠宝首饰有限公司

Pressing mold base capable of being rotated safely

The invention relates to a pressing mold base capable of being rotated safely and belongs to the field of pressing molds for refractory bricks. By the adoption of the pressing mold base capable of being rotated safely, the manufacturing cost of pressing molds is reduced, and the forming quality of the refractory bricks is improved. The pressing mold base capable of being rotated safely comprises a punching base and a fixed assembly, wherein the punching base is provided with a forming groove and rotary shafts, the punching base can rotate on the fixed assembly through the rotary shafts, a first connecting block and a second connecting block are arranged on the punching base, the fixed assembly comprises a fixed block body and a step block, a clamping groove and positioning grooves matched with the rotary shafts are formed in the fixed block body, the first connecting block can be inserted into the clamping groove, each positioning groove comprises a rotation stopping part and a rotation part located below the rotation stopping part, the rotary shafts can move in the axial direction in the rotation stopping parts, and the rotary shafts can rotate in the axial direction in the rotation parts.

Owner:浙江立鑫高温耐火材料有限公司

Punching mold of railway truck bearing sealing cover cold punching process

The invention discloses a punching mold of a railway truck bearing sealing cover cold punching process. The punching mold comprises a base; a support rod is fixed above the top of the base; a mounting base is fixed above the top of the support rod; a positioning column and a spring are fixed above the top of the mounting base; the spring is positioned on the inner side of the positioning column; the top of the spring is fixedly connected with a limiting connecting plate; the limiting connecting plate is positioned above the top of the mounting base; the top of the limiting connecting plate is fixed with a connecting block; and a bottom screw of the limiting connecting plate is fixedly connected with an upper convex mold. Through matching use of such structures as a servo motor, a first gear and a second gear, a thread hole can be screwed out from a lower concave mold structure, so that a lower concave mold body is convenient to take or replace, the disassembly and the assembly are convenient, meanwhile, the replacement of the lower concave mold body needs no replacement of the whole mold, and the use is flexible.

Owner:无锡市舒洋模具有限公司

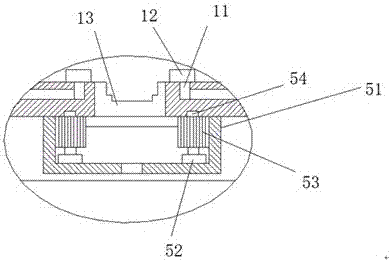

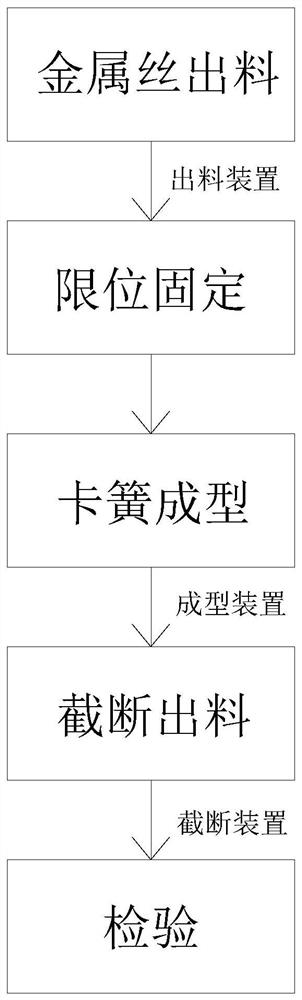

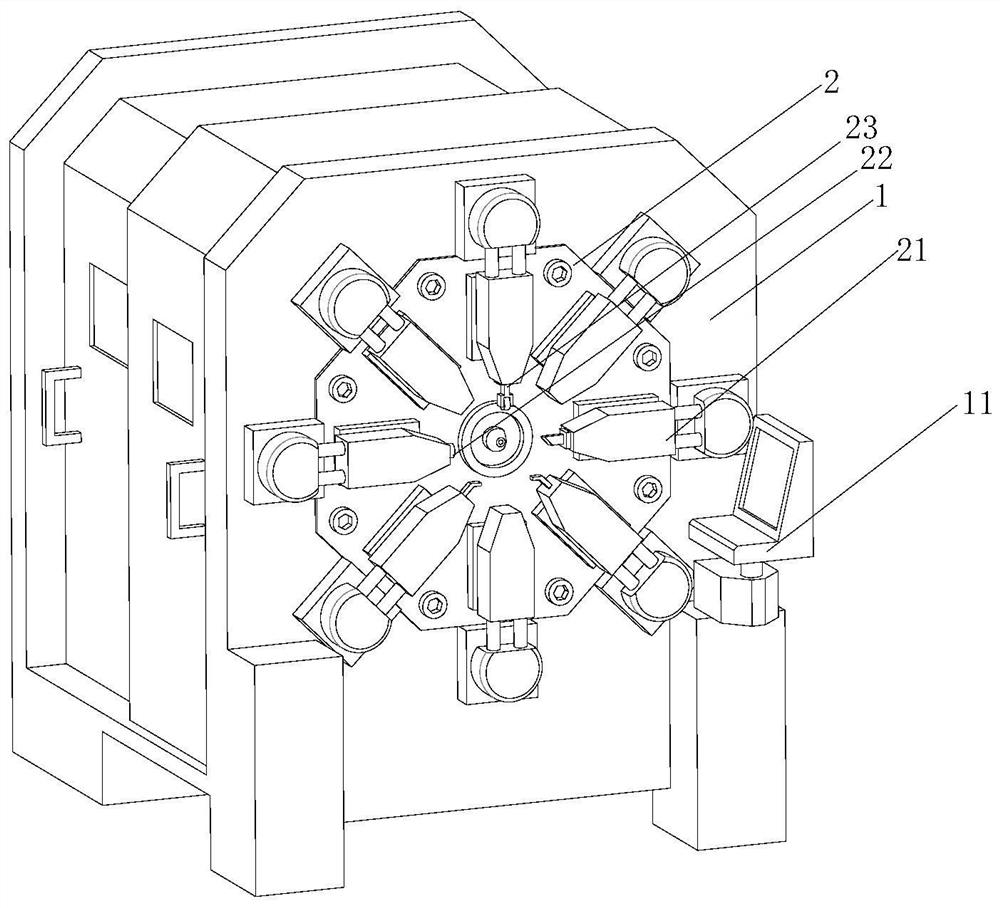

Efficient forming process of snap spring

ActiveCN113305243AAffect molding qualityReduce shockWire springsHydraulic cylinderStructural engineering

The invention discloses an efficient forming process of a snap spring. A forming device, a discharging device and a cutting device are included, a fixed disc is fixedly installed on the surface of the forming device, the discharging device comprises a discharging port, the discharging port is fixedly installed on the surface of the fixed disc, and a plurality of hydraulic cylinders are fixedly installed on the surface of the fixed disc; and a movable rod is fixedly mounted at the output end of each hydraulic cylinder, a connecting rod, a mounting plate and a limiting shaft are conical and fixedly connected to one end of each movable rod, the cutting-off device comprises a cutting-off knife, one end of the cutting-off knife is clamped on the movable rods on one sides, and a connecting seat is fixedly connected to one end of the mounting plate. Compared with the prior art, buffering blocks move inwards, special-shaped rods can be pushed to move in sliding grooves, the clamping plates can abut against the surface of a metal wire, the metal wire is driven to move along with movement of the buffering blocks, the situation that the metal wire is rapidly reset after being bent is avoided, and the situation that the bending effect is not ideal due to the fact that the diameter of the metal wire is large is reduced.

Owner:绍兴市三阳弹簧股份有限公司

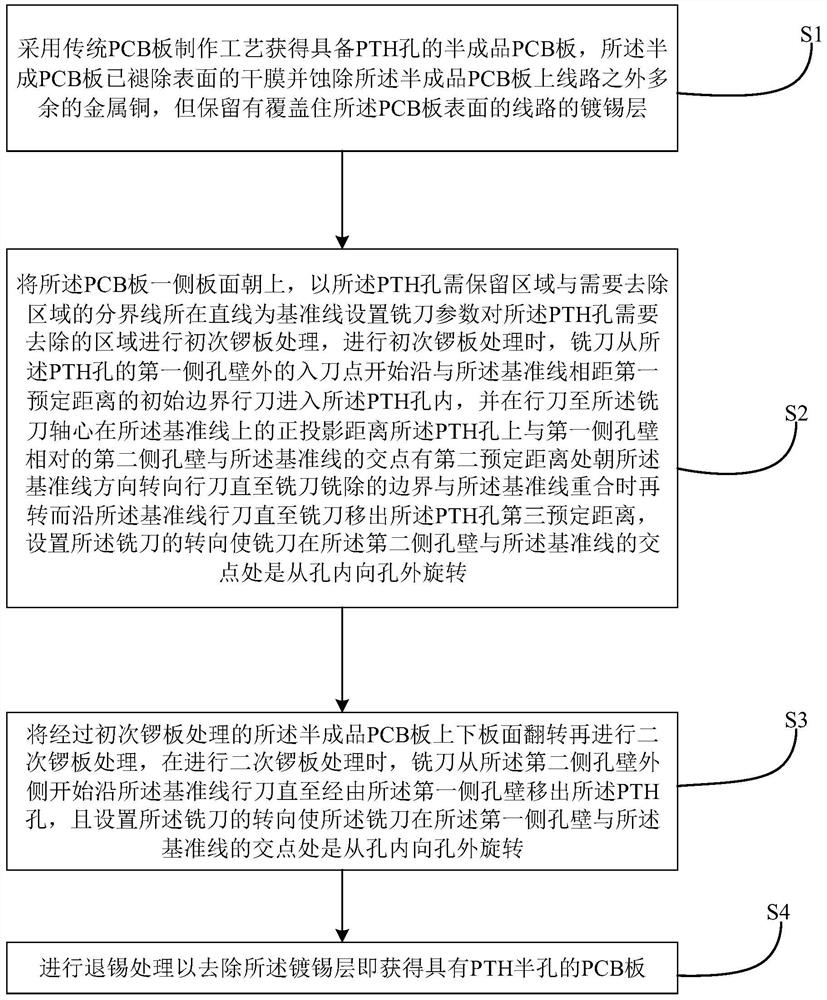

Manufacturing method of PTH half hole of PCB

PendingCN114666988AAffect subsequent power-upsAffect molding qualityInsulating layers/substrates workingMilling cutterStructural engineering

The embodiment of the invention provides a method for manufacturing a PTH half hole of a PCB, and the method comprises the steps: taking a semi-finished PCB, setting milling cutter parameters by taking a boundary between a PTH hole reservation region and a PTH hole removal region as a reference line, carrying out the primary milling of a PTH hole, and enabling a cutter entering point of a milling cutter located on a first side hole wall of the PTH hole to be away from the reference line by a first preset distance, moving the cutter along the datum line until the orthographic projection of the axis of the milling cutter on the datum line is a second preset distance away from the intersection point of a second side hole wall opposite to the first side hole wall on the PTH hole and the datum line, rotating the cutter to move along the datum line until the milling cutter moves out of the PTH hole by a third preset distance, and turning over the upper and lower plate surfaces to carry out secondary milling treatment on the PCB, and the milling cutter moves from the outer side of the second side hole wall along the datum line until the milling cutter moves out of the PTH through the first side hole wall, and the milling cutter rotates from the inside to the outside of the hole at the first side hole wall and the second side hole wall. According to the embodiment of the invention, the high-quality PTH half hole is obtained by scientifically setting the distance position of the cutter feeding point relative to the reference line and the rotation direction of the milling cutter.

Owner:科惠白井(佛冈)电路有限公司

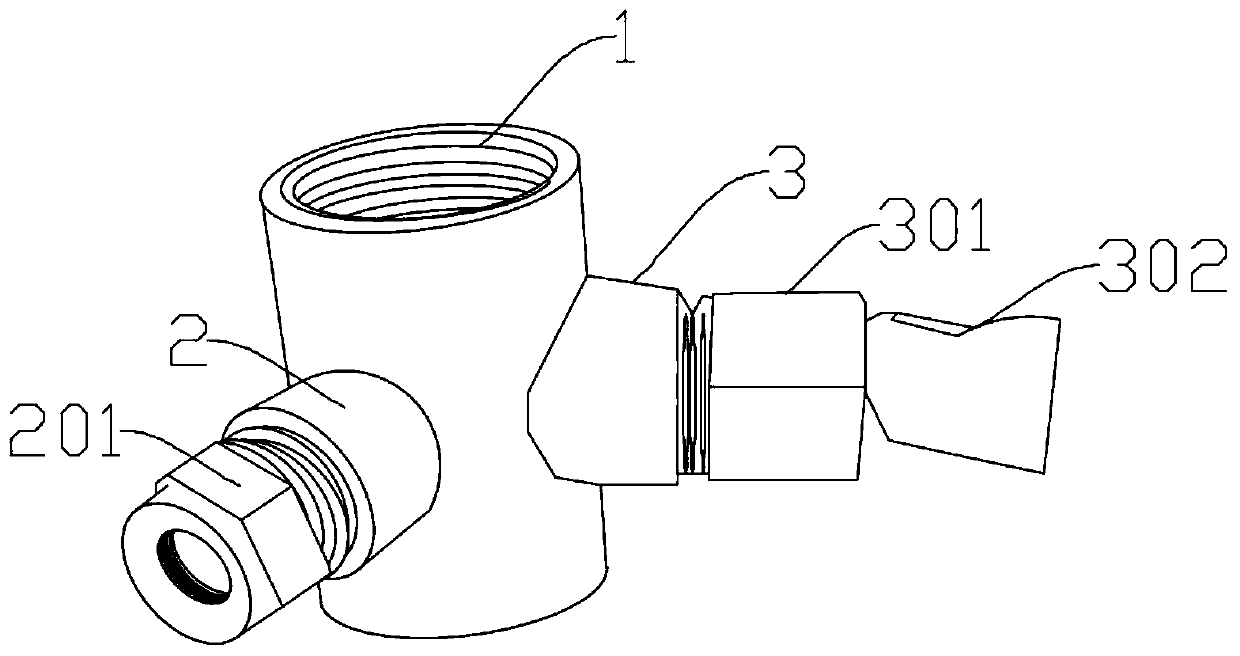

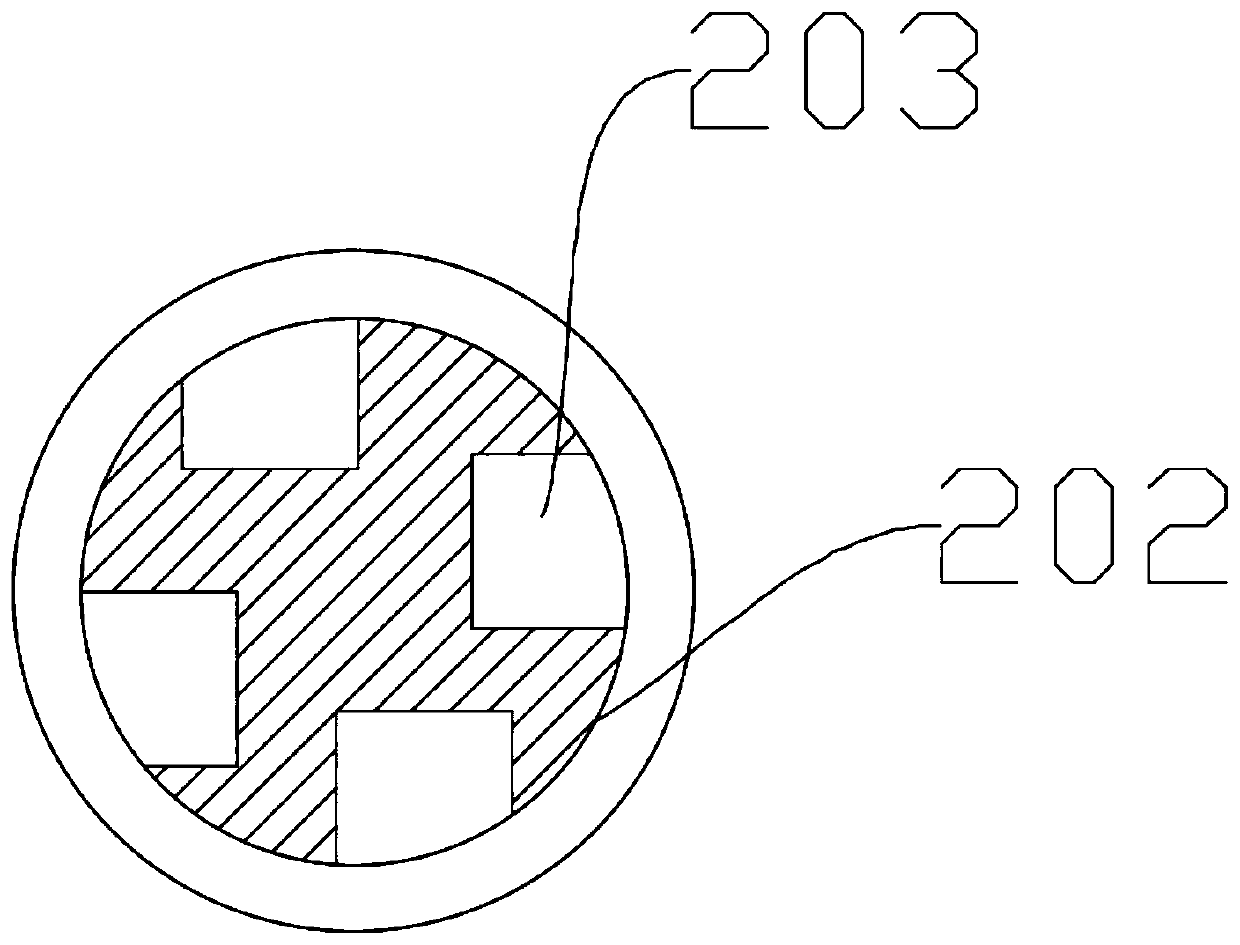

Compressed air foam sprayer used for high-risk complex environment

InactiveCN110448842AImprove stabilitySolve the problem of uniform distribution of multi-point densityFire rescueSpray nozzleFire - disasters

The invention discloses a compressed air foam sprayer used for the high-risk complex environment. A sprayer body is included. A liquid inlet is formed in one end of the sprayer body, and the other endis a closed end. The side wall of the sprayer body is at least provided with a first liquid outlet and a second liquid outlet. A mixing cavity is formed in the sprayer body. The mixing cavity communicates with the liquid inlet, the first liquid outlet and the second liquid outlet. A foam divider is arranged on the inner wall of the mixing cavity. The first liquid outlet is connected with a centrifugal nozzle, and the second liquid outlet is connected with a limiting sprayer. Compared with a single sprayer, after compressed air foam is output, the media distribution density at each point is more consistent, the blind area phenomenon likely to happen during large-range fire disaster area suppressing is avoided, the single-point multi-direction fire behavior restraining effect is formed, andthe adaptation performance under the system high-risk complex environment can be better improved.

Owner:九江中船长安消防设备有限公司

Rotatable pressing mould base

InactiveCN104149174AEasy to move axiallyAvoid breakingMouldsShaping press ramBrickMechanical engineering

The invention belongs to the field of refractory brick pressing moulds and relates to a rotatable pressing mould base. The rotatable pressing mould base comprises a pressing seat and a fixing component, the pressing seat is provided with a forming groove and a rotating shaft and capable of rotating on the fixing component through the rotating shaft, and a first connection block and a second connection block are arranged on the pressing seat. The fixing component comprises a fixing block body and a stepped block, the fixing block body is provided with a clamping groove and a positioning groove matched with the rotating shaft, the first connection block can be inserted into the clamping groove, the second connection block can be placed on the stepped block, the stepped block is fastened onto the fixing block body through an elastic locking device which comprises a lock rod extending outside the stepped block, and the lock rod is capable of axially moving to penetrate through the stepped block to be inserted into the fixing block body. Pressing mould manufacturing cost is reduced, and refractory brick forming quality is improved.

Owner:浙江立鑫高温耐火材料有限公司

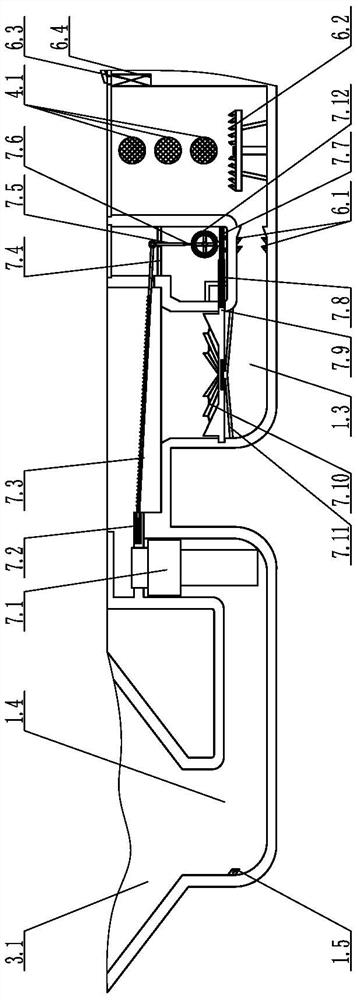

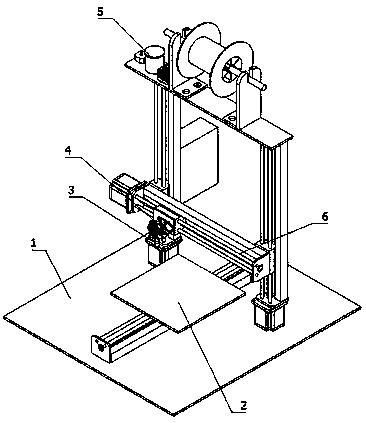

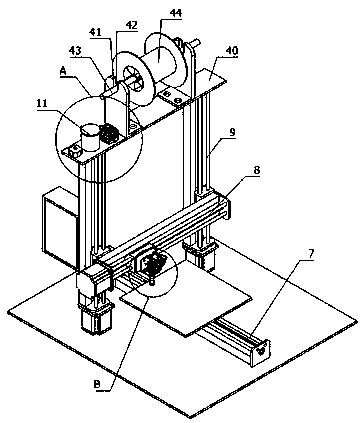

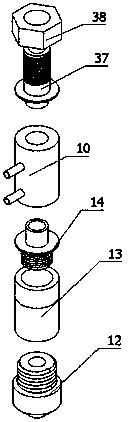

3D printer with water-cooling spray heads

InactiveCN110281521AAchieve installationImprove cooling effectAdditive manufacturing apparatus3D object support structuresSlide plateEngineering

The invention relates to the field of 3D printers, in particular to a 3D printer with water-cooling spray heads. The 3D printer comprises a bottom plate, a three-axis driving mechanism, a sliding plate, the printing spray heads, a booster and a water cooling mechanism. The three-axis driving mechanism comprises a transverse driving mechanism, a longitudinal driving mechanism and two vertical driving mechanisms. The booster and the printing spray heads are fixedly arranged on the longitudinal driving mechanism. The booster is located on the top of a feed port of one printing spray head. The water cooling mechanism comprises a condenser pipe and a cooling mechanism. The condenser pipe is fixed to one printing spray head. The cooling mechanism is fixedly arranged on the top of the vertical driving mechanism. The cooling mechanism is connected with the interior of the condenser pipe through a guide pipe. Each printing spray head comprises an extrusion head, a heating pipe and a heat insulation pipe which are coaxially arranged. The 3D printer conducts cooling through the condenser pipe and the cooling mechanism instead of a fan. The influence generated from running of the cooling fan on the forming quality of the 3D printing machine is avoided.

Owner:刘雪侠

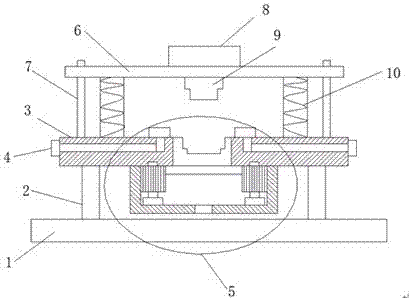

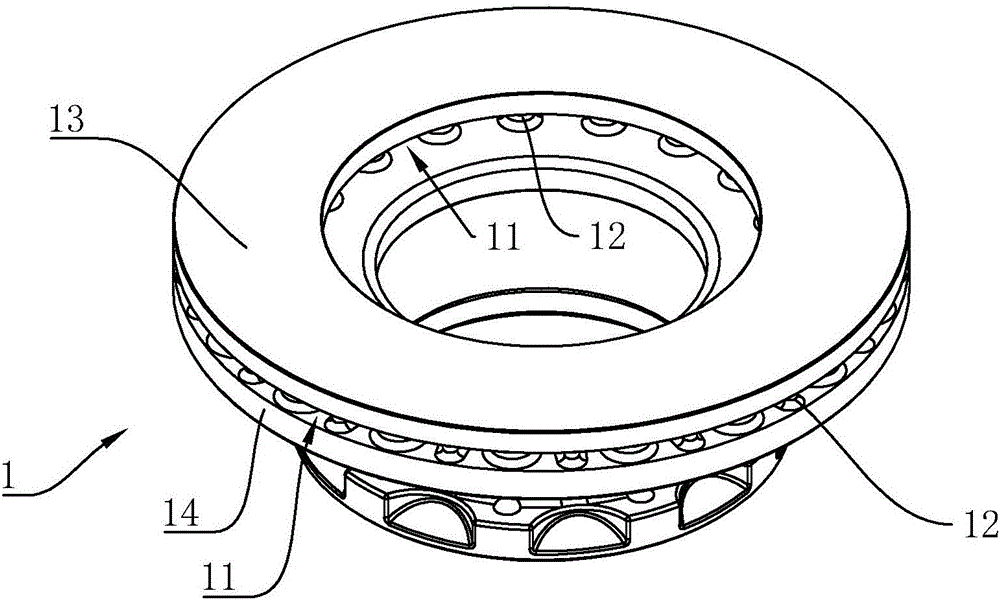

Double-layer brake disc molding device

ActiveCN105689652AAvoid it happening againGuarantee molding qualityFoundry mouldsFoundry coresAir channelCasting

The invention discloses a double-layer brake disc molding device which comprises an upper mold box and a lower mold box. An upper sand core is arranged in the upper mold box. A lower sand core is arranged in the lower mold box. A middle isolating core is arranged between the upper sand core and the lower sand core. An air channel molding core is arranged between the middle isolating core and the upper sand core. An air channel molding core is arranged between the middle isolating core and the lower sand core. Multiple through holes are formed in each air channel molding core. Molding cavities are formed among the upper sand core, the lower sand core, the air channel molding cores and the middle isolating core. The molding cavity in the lower sand core communicates with a casting system. Communicating channels communicating with the two molding cavities are formed in the middle isolating core. By the adoption of the double-layer brake disc molding, double-layer casting is achieved; within the same period, the molding number of brake discs is doubled, and production efficiency is improved; and meanwhile, the space of the upper mold box is utilized, so that during casting, the use amount of the sand is lowered greatly, the utilization rate of the sand in a sand bin is increased, the sand adhering to the brake discs is reduced, and thus a foundation can be conveniently established for shakeout on a shakeout machine.

Owner:康迈(南京)机械有限公司

Steel supporting plate cleaning machine for partition plate production

PendingCN109570093AExtended service lifeFix damageLiquid surface applicatorsCleaning using toolsBristleMilling cutter

The invention discloses a steel supporting plate cleaning machine for partition plate production, and relates to the field of partition plate production equipment. The machine comprises a machine frame, a chain conveyer is arranged on the machine frame in the conveying direction of a steel supporting plate, a plate milling mechanism and a cleaning and brushing mechanism are sequentially arranged on the chain conveyer along the conveying direction of the steel supporting plate, the plate milling mechanism comprises a plate milling box body, a disc-shaped milling cutter is arranged on the innerwall of the plate milling box body, the disc-shaped milling cutter is coaxially connected with a driving motor I, a slag discharging hopper I is arranged at the lower end of the plate milling box body, the cleaning and brushing mechanism comprises a cleaning and brushing box body, cleaning and brushing pair rollers are arranged in the cleaning and brushing box body, brush bristles are uniformly distributed on the outer side walls of the cleaning and brushing pair rollers, the cleaning and brushing pair rollers are connected with a driving motor through a transmission device, a slag discharginghopper is arranged at the lower end of the cleaning and brushing box body, a liquid storage box used for storing an isolating agent is arranged on the cleaning and brushing box body, and an inclineddownward discharging hopper is arranged on the cleaning and brushing box body. According to the machine, automatic conveying is conducted, first cleaning and milling treatment and second cleaning andbrushing as well as coating treatment are combined, so that the method has the advantages that the cleaning efficiency is high, the formed steel supporting plate is prevented from being damaged and the repeated utilization life of the steel supporting plate is prolonged.

Owner:HENAN ZHONGBANG WEIYE TECH CO LTD

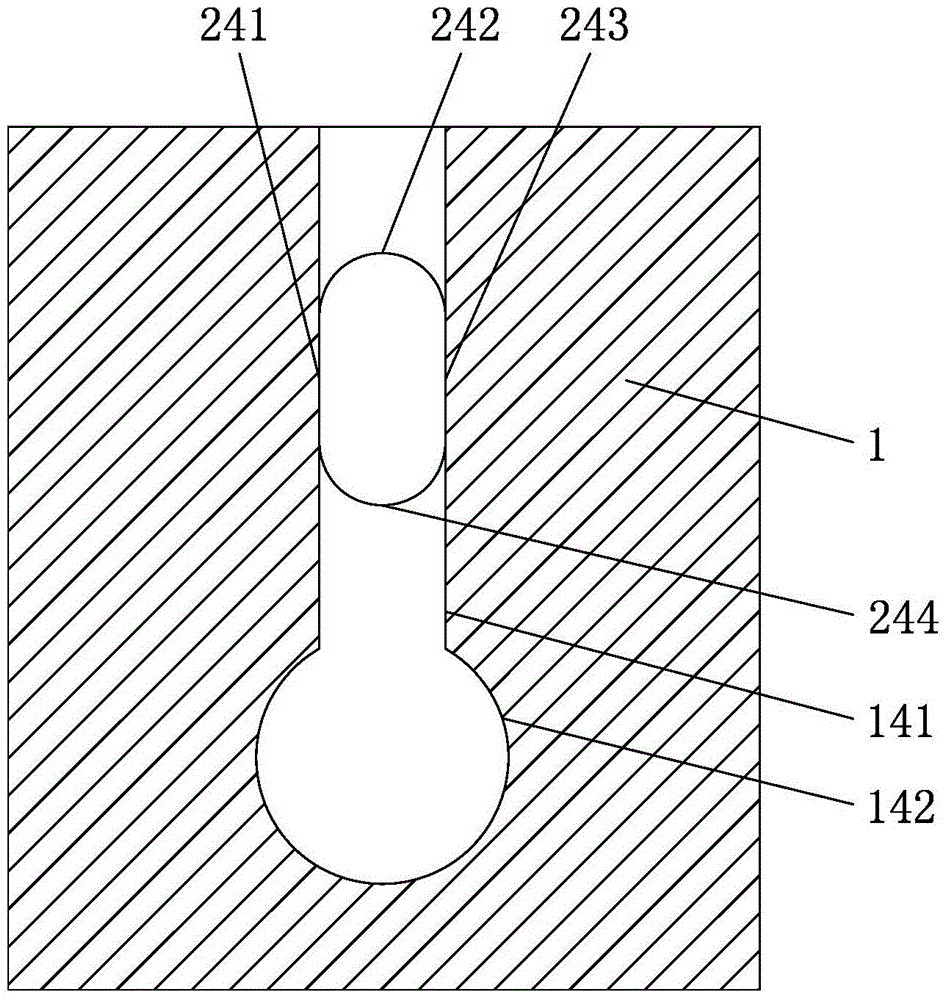

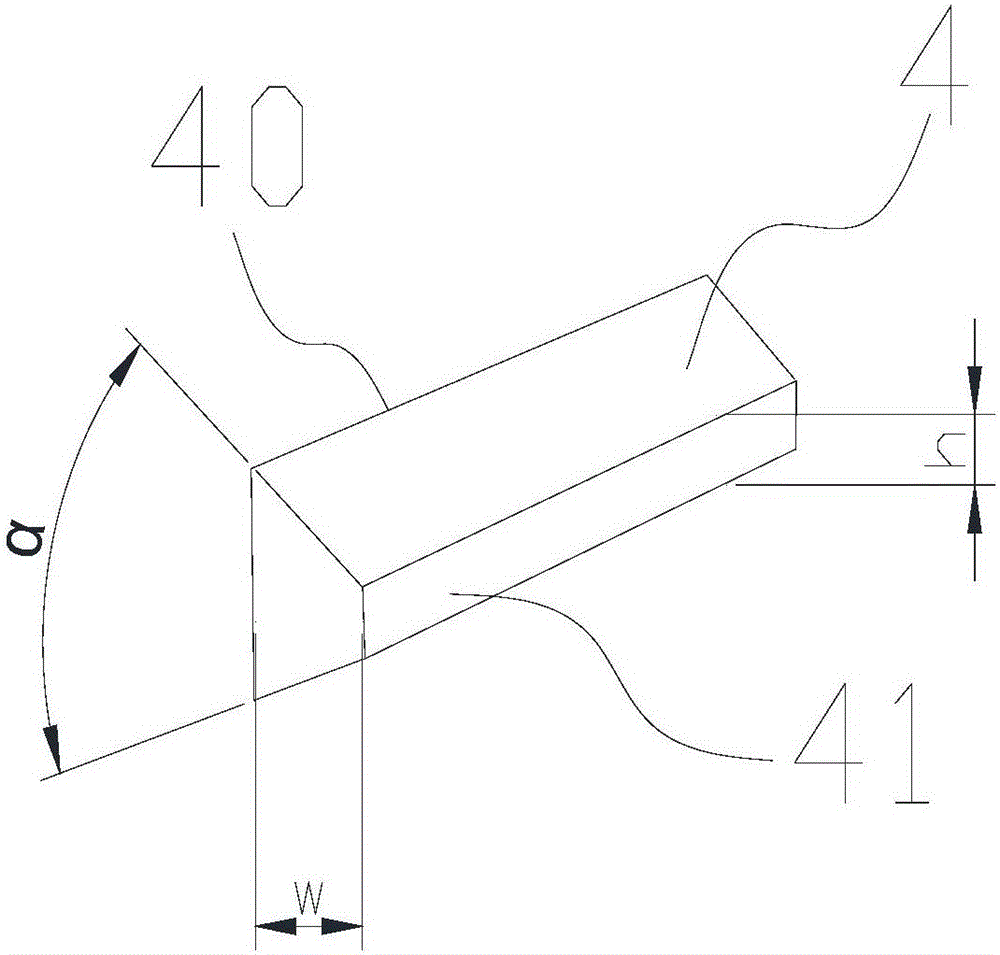

Runner system for production of ultrathin light guide plate

The invention relates to a runner system for production of an ultrathin light guide plate. The runner system comprises a main runner, branch runners and sprues. The main runner is communicated with the branch runners which are communicated with the sprues. The runner system is characterized in that the sprues are wedged sprues, each wedged sprue comprises a feeding end and a discharging end, and each feeding end is higher than the corresponding discharging end; the included angle of each wedged sprue is 45-160 degrees, the width of each wedged sprue is 0.03-0.2 mm, and the height of the discharging end of each wedged sprue is 0.07-0.3 mm. The runner system for production of the ultrathin light guide plate has the advantages of being capable of reducing pressure losses of melted plastic, improving the liquidity of the melted plastic, improving the production quality of the ultrathin light guide plate and the like.

Owner:LITEGO OPTICAL TECH CO LTD DONGGUAN BRANCH

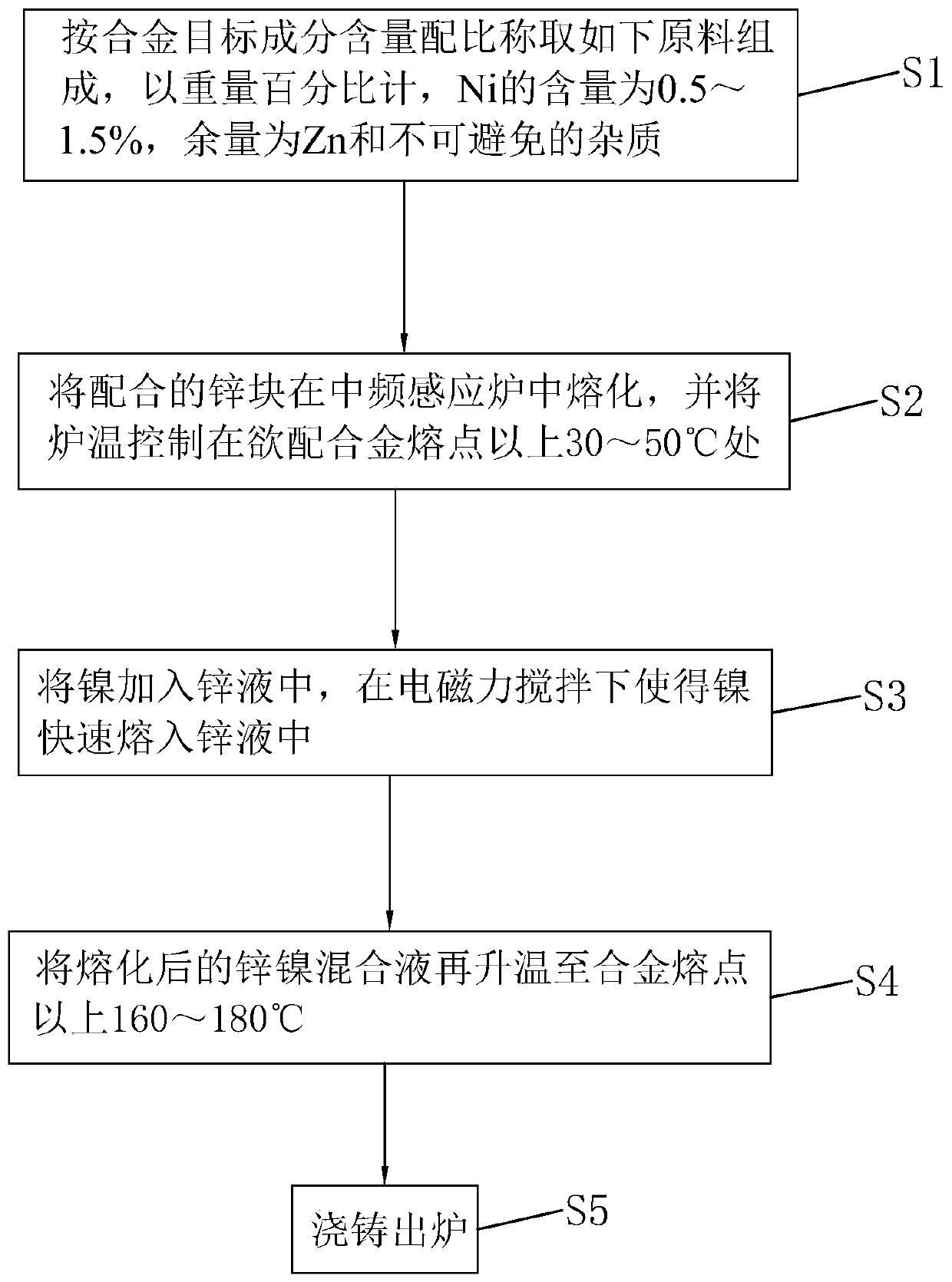

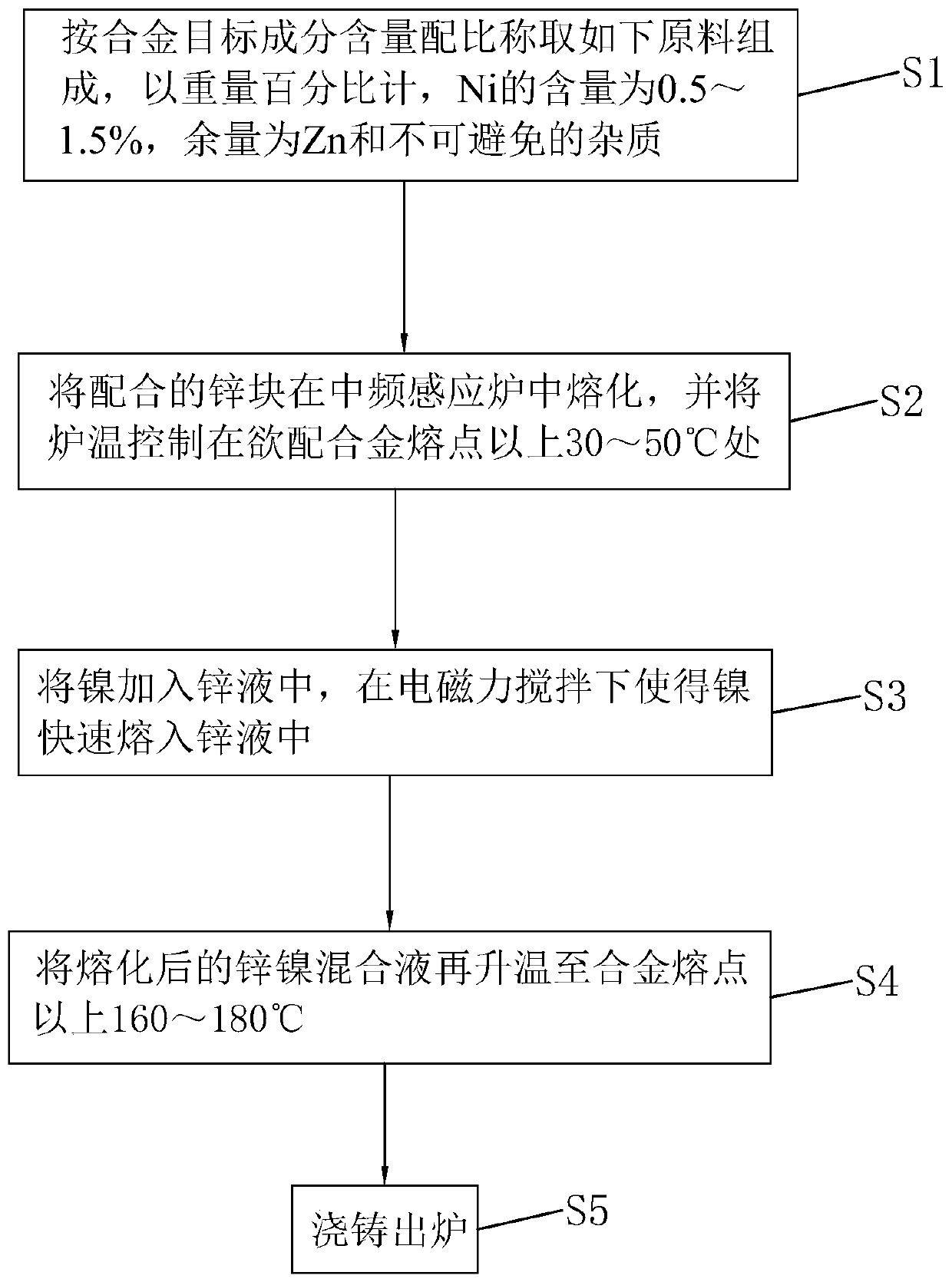

Zinc-nickel alloy and preparation method thereof

InactiveCN111020294AAffects adhesion strengthAffect molding qualityHot-dipping/immersion processesNickel alloyZinc

The invention discloses a zinc-nickel alloy and a preparation method thereof and relates to the technical field of nonferrous metallurgy. The zinc-nickel alloy comprises the components of 0.5-1.5% Niand the balance of Zn and inevitable impurities according to the weight percentage. According to the zinc-nickel alloy and the preparation method thereof, the adhesion strength of a plating can be guaranteed, the molding quality and beauty of the surface of a plated part can be improved, the production capacity of the enterprise can be guaranteed, and the zinc-nickel alloy and the preparation method thereof are also conducive to reducing the enterprise production cost.

Owner:天津市兴生辉锌制品有限公司

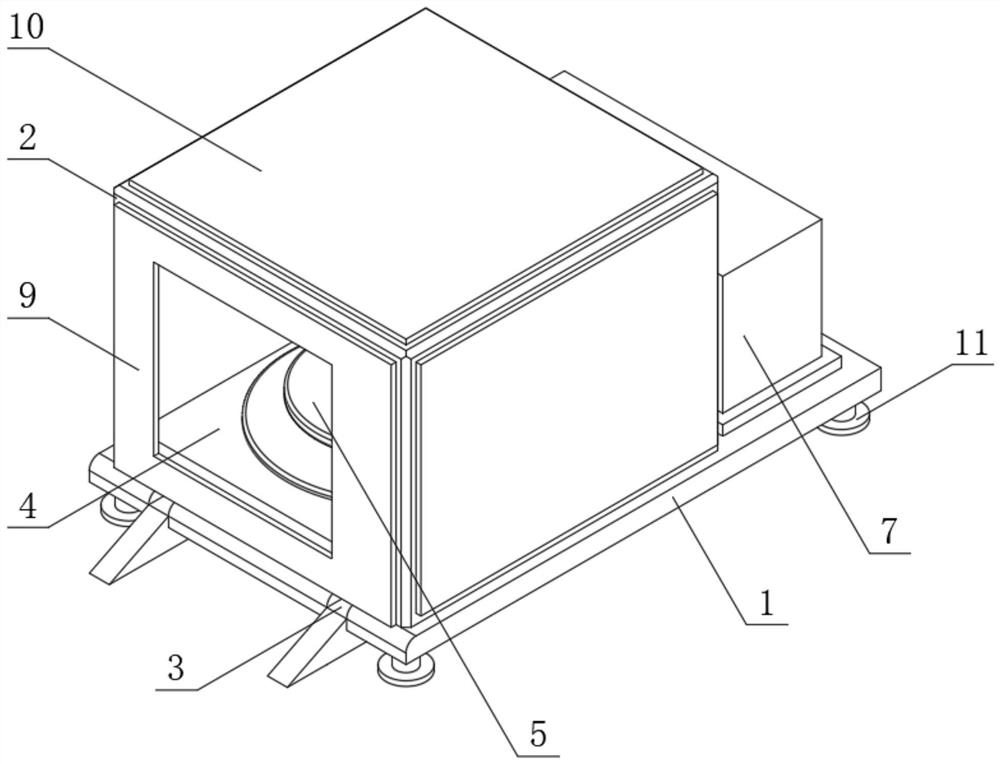

Round spinning machine with dust removing device

InactiveCN106978666AImprove stabilityEasy and stable deliveryCircular loomsAuxillary apparatusYarnEngineering

The invention discloses a circular textile machine with a dust removal device, which comprises a machine body, a yarn guide and a creel. A rotating mechanism, a dust removal mechanism and an air delivery device are arranged above the creel, and the rotating mechanism is rotatably connected to a column. The rotating mechanism includes a triangular bracket, the bottom end of the triangular bracket is connected with a turntable through a fixed shaft, the top circumference of the turntable is connected with the triangular bracket through a supporting mechanism, and dust removal mechanisms are arranged on the triangular brackets. The dust removal mechanism includes a hydraulic cylinder, a booster block, The lifting plate, the dust removal assembly and the locking assembly, the booster block is connected to the hydraulic cylinder through the piston rod, the lifting plate is connected to the booster block through the dust removal assembly and the locking assembly, and the air delivery device is connected to the dust removal mechanism through the air delivery pipe. The invention is simple in structure and strong in practicability. It can not only realize fast dust removal and cleaning of yarn, prevent dust and impurities from adhering to yarn and affect the final forming quality of cloth, but also improve the stability of rotating mechanism and air delivery device. and security.

Owner:嵊州市靖洁纺织机械有限公司

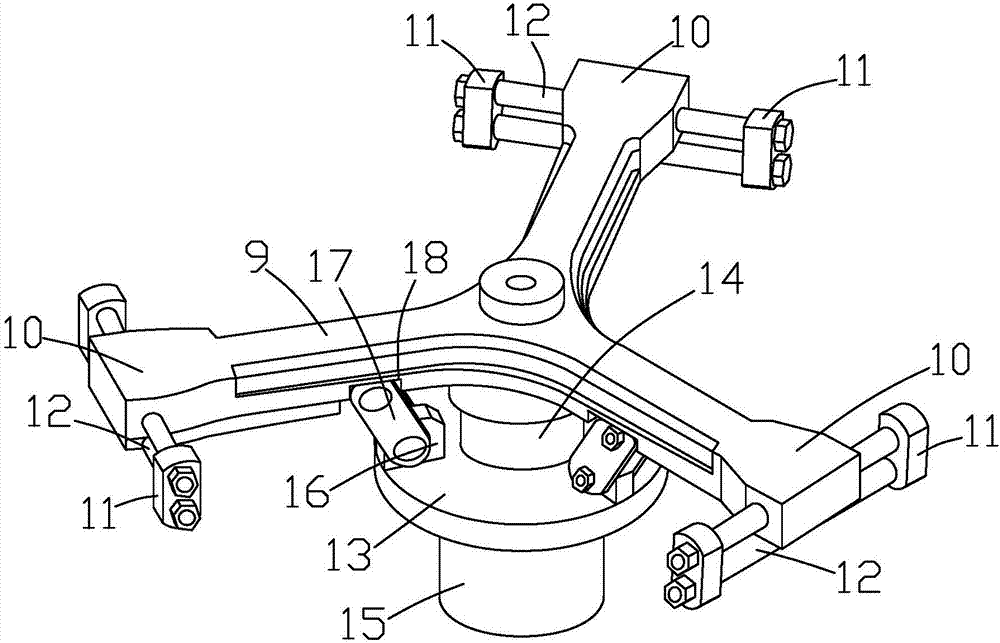

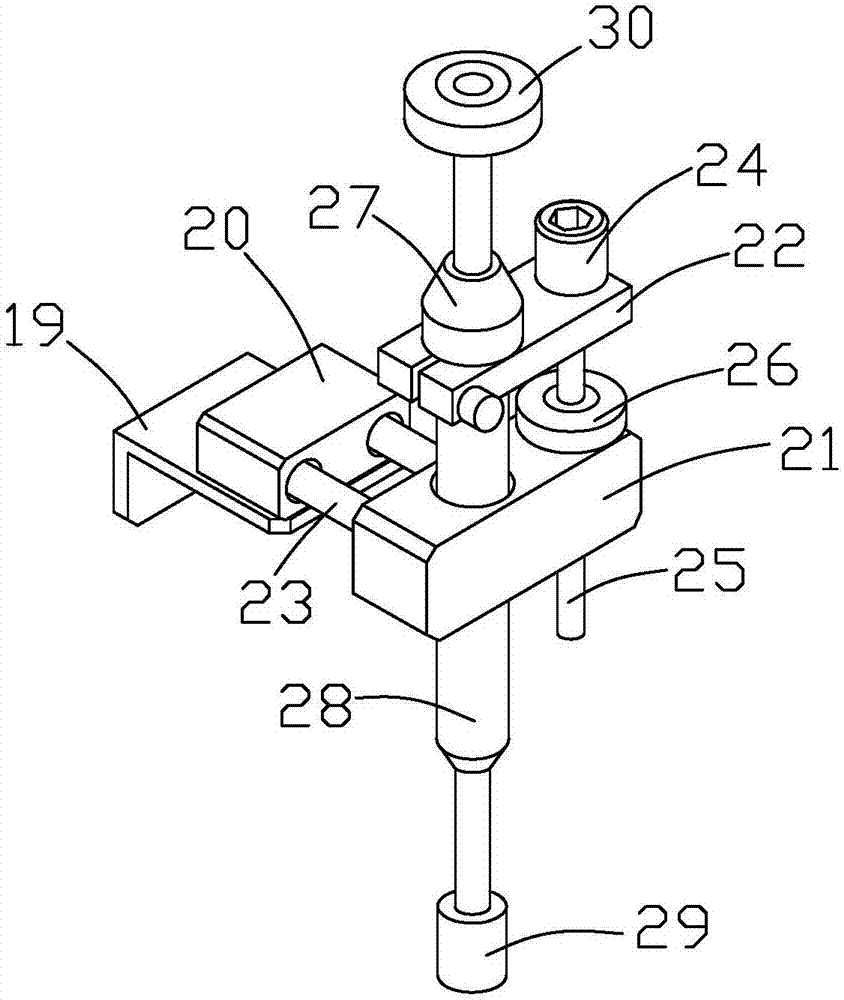

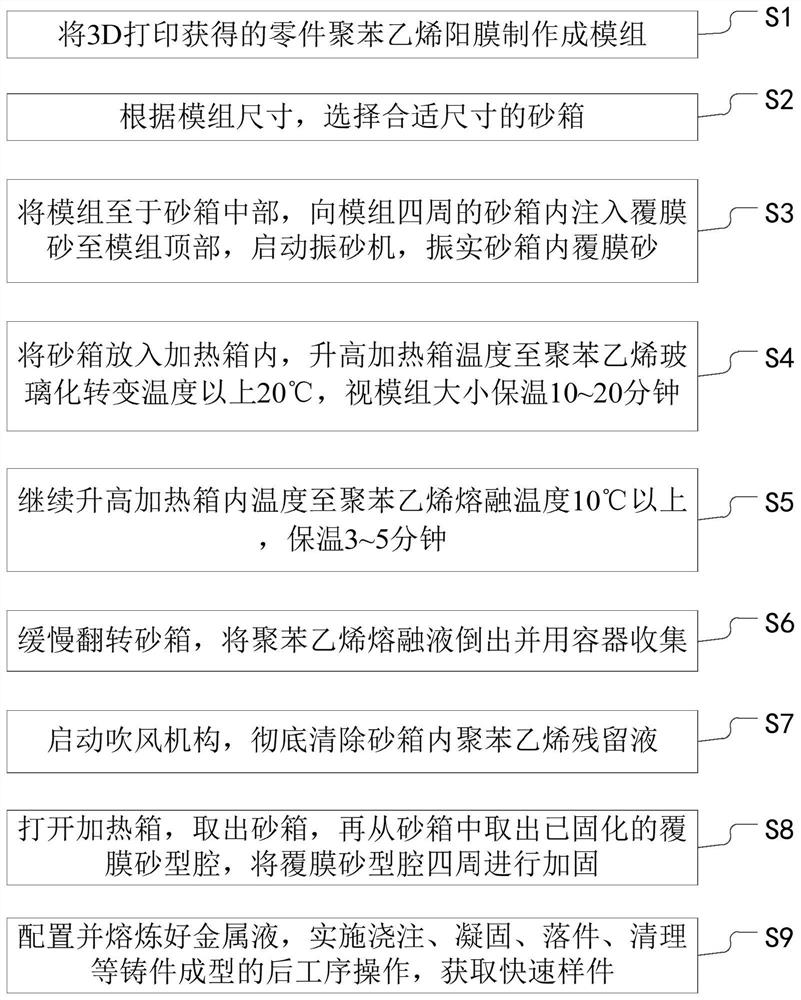

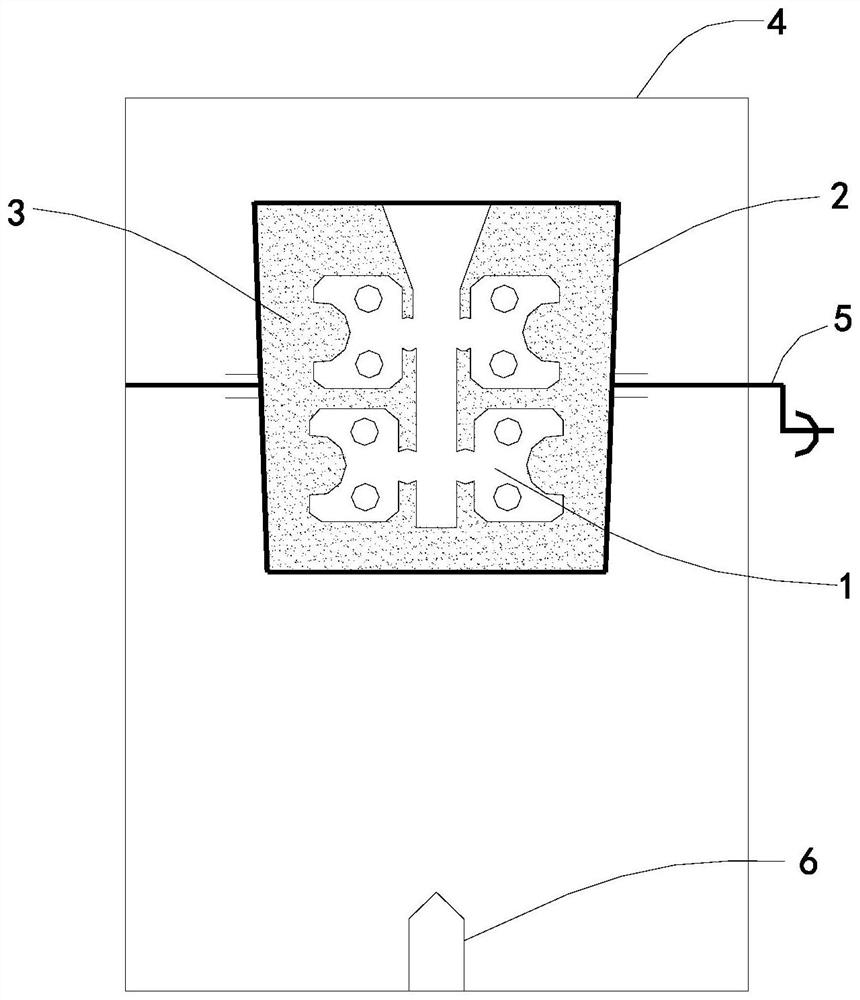

Investment casting quick forming method for polystyrene coated sand mold shell

InactiveCN111804872AShort cycleAffect molding qualityFoundry mouldsFoundry coresInvestment castingEngineering

The invention provides an investment casting quick forming method for a polystyrene coated sand mold shell. The method comprises the following steps of S1, manufacturing a mold set from a polystyreneanode membrane, obtained by 3D printing, of a part; S2, selecting a sand box with an appropriate size; S3, injecting coated sand into the sand box around the mold set to the top of the mold set and compacting the coated sand by vibration in the sand box; S4, placing the sand box in a heating box, and raising the temperature of the heating box to a glass-transition temperature of polystyrene; S5, raising the temperature in the heating box continuously to a melting temperature of polystyrene; S6, overturning the sand box slowly to pour out a polystyrene molten liquid; S7, starting a blowing mechanism to clean up a polystyrene residual liquid in the sand box thoroughly; S8, taking out a cured coated sand cavity and reinforcing the periphery of the coated sand cavity; and S9, implementing post-step operations of casting forming such as pouring, freezing, falling and cleaning to obtain a quick sample piece. The forming method shortens the period of manufacturing the shell by casting greatly, so as to achieve the purposes of quick printing of the anode membrane, quick manufacturing of the mold shell and quick forming of the sample piece.

Owner:DONGFENG PRECISION CASTING CO LTD

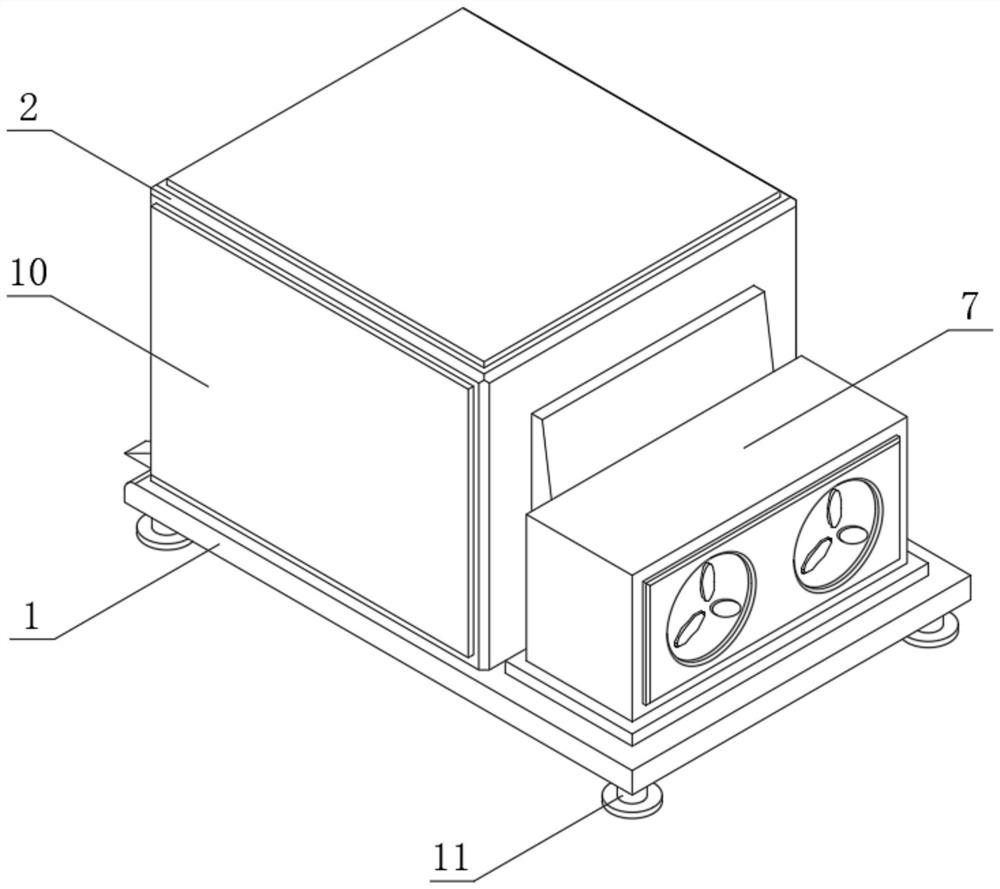

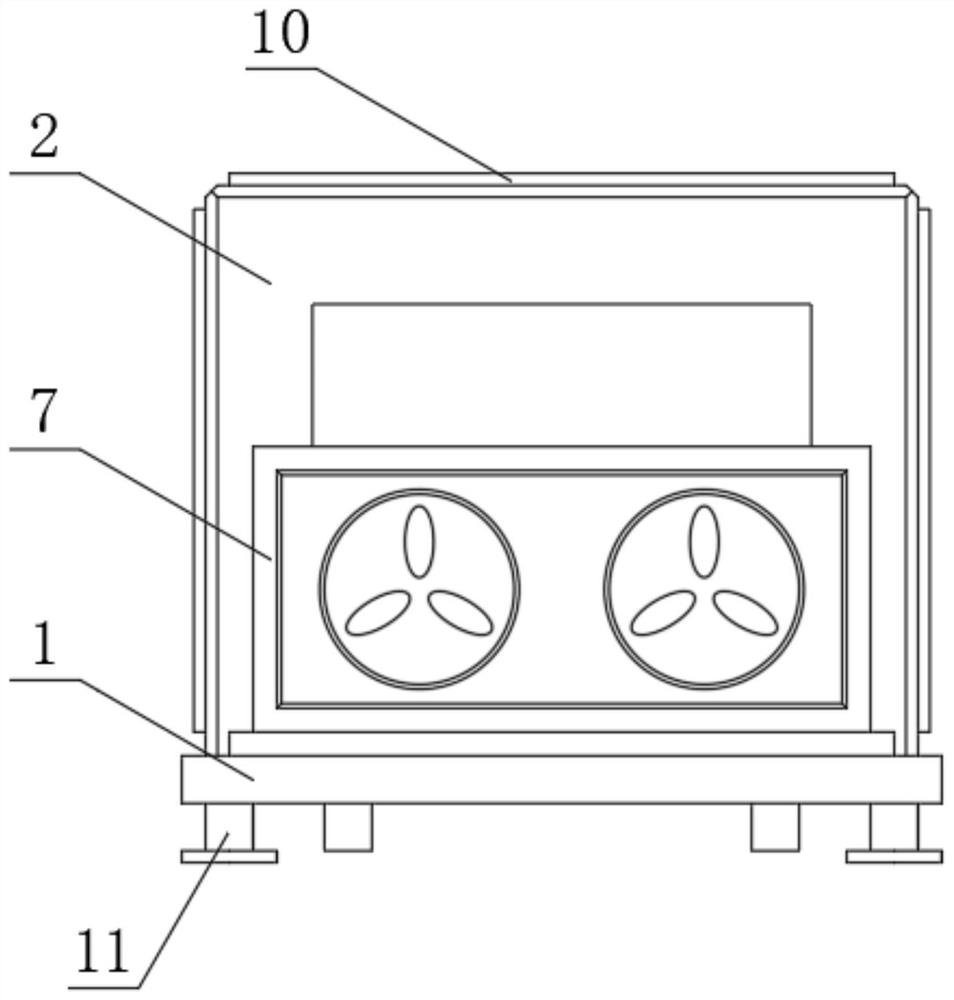

Continuous cooling device for discharged plastic bags

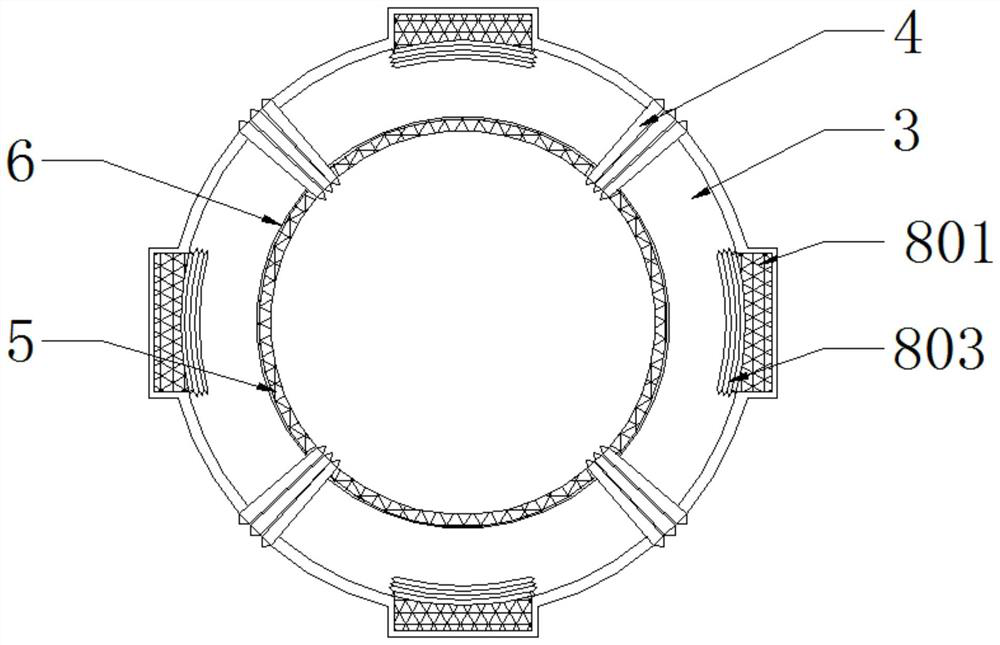

ActiveCN114474521AAchieve coolingScalableDispersed particle filtrationTransportation and packagingVentilation tubeEngineering

The invention discloses a plastic bag discharging continuous cooling device, and relates to the technical field of plastic bag film blowing machine cooling devices.The plastic bag discharging continuous cooling device comprises an outer ring, inner ring pipes and an air cooling assembly, telescopic rods are installed in the outer ring, the inner ring pipes are fixed to the top ends of the telescopic rods, outer corrugated pipes are connected between the inner ring pipes, ventilation openings are formed in the inner sides of the inner ring pipes, and the ventilation openings are communicated with the air cooling assembly. And the air cooling assembly is arranged on the periphery of the interior of the inner ring pipe, the air cooling assembly comprises an installation air chamber, a heat dissipation fan, a corrugated sleeve, a ventilation pipe, an air outlet, a connecting flange and an inner corrugated pipe, the heat dissipation fan is installed in the installation air chamber, and the corrugated sleeve is connected to the inner side of the installation air chamber. According to the continuous cooling device for the discharged plastic bag, the outer ring can be additionally arranged on the periphery of the blown film discharging part, the adjustable blowing device is arranged in the inner ring pipe, the front-back blowing position and the blowing angle can be conveniently adjusted, and therefore the film barrel can be rapidly cooled.

Owner:江苏英普科科技股份有限公司

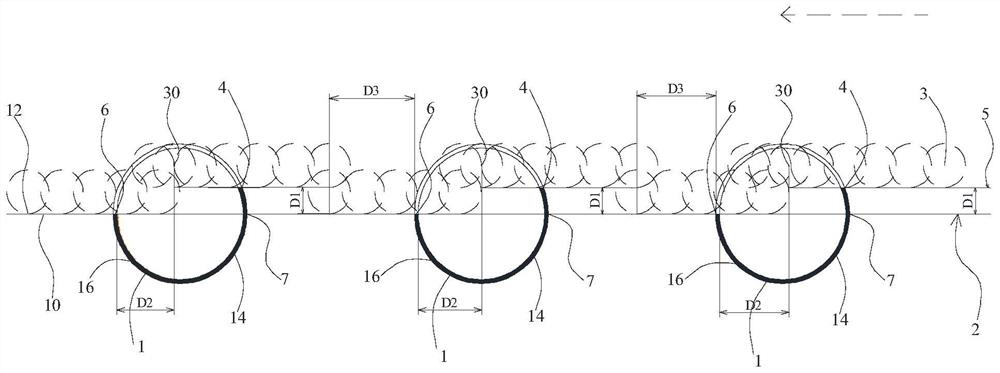

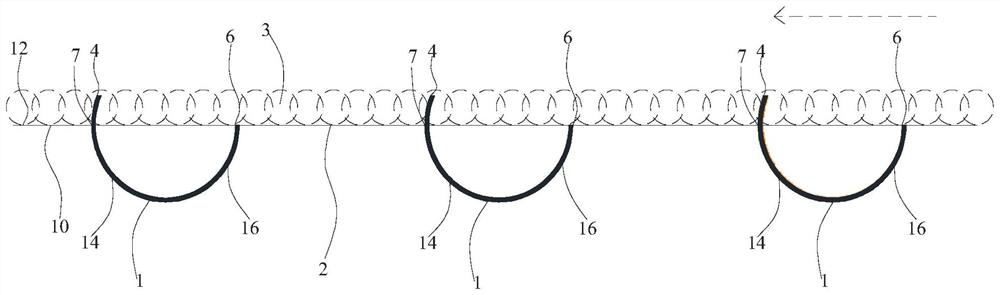

A jet lay-up board system

ActiveCN110004759BImprove reliabilityGuaranteed reliabilityInorganic fibres/flakesPaper-making machinesMolding machineElectric machine

The invention relates to a jet layup board-producing system. The jet layup board-producing system comprises a woolen blanket, a slurry stabilizing filter tank, a plurality of jet-type slurry spreadingmoulding machines, a colorant adding machine, a cloth puncher, a woolen blanket flushing assembly, a vacuum water suction box and a plurality of supporting rolls, wherein the slurry stabilizing filter tank is arranged beside the woolen blanket; each jet-type slurry spreading moulding machine comprises a jetting device and a moulding device; each jetting device comprises a support, a driving motor, a feed pipe, a balancing valve, a stirring propeller, a slurry jetting head, a dispersing component and a flow control assembly; each moulding device comprises a machine frame, a first dewatering assembly, at least one second dewatering assembly, a first cylindrical net cage, a first couch roll, a moulding cloth belt, an upper water receiving tank body, a lower water receiving tank body, a flushing assembly and a plurality of guide rolls; the colorant adding machine comprises a colorant tank, a second cylindrical net cage, a swinging rod, a colorizing roll, colorizing net cloth and a secondcouch roll; and the cloth puncher, the woolen blanket flushing assembly and the vacuum water suction box are arranged beside the woolen blanket. The jet layup board-producing system has the advantagesof a good shaping effect, low production cost, high reliability, high processing quality and the like.

Owner:FOSHAN JINFU PANEL

Fluctuation pressure adjusting system used for thread rib forming

ActiveCN111250636AAffect molding qualityAvoid the problem of overloadingScrew-threads articlesHydraulic cylinderEngineering

The invention discloses a fluctuation pressure adjusting system used for thread rib forming. The fluctuation pressure adjusting system used for thread rib forming is low in forming load, capable of supplementing materials and high in yield. According to the technical scheme, the system comprises a rotating mechanism and a fluctuation propelling system. The fluctuation propelling system comprises apressure supply system, a pressure adjusting system and an output system which are connected in sequence, the output system comprises a hydraulic cylinder, the hydraulic cylinder is in transmission connection with a knife clamp body, the knife clamp body is provided with a knife bit assembly, the rotating mechanism is linked with the knife clamp body to rotate, the pressure adjusting system is provided with a rapid pressurizing stage, a pressurizing forming stage, a pressure relief material supplementing stage and a fluctuation loading stage, the hydraulic cylinder is controlled to be provided with a corresponding path, and the system is applicable to the technical field of mechanical devices.

Owner:聊城市艾智信息科技有限公司

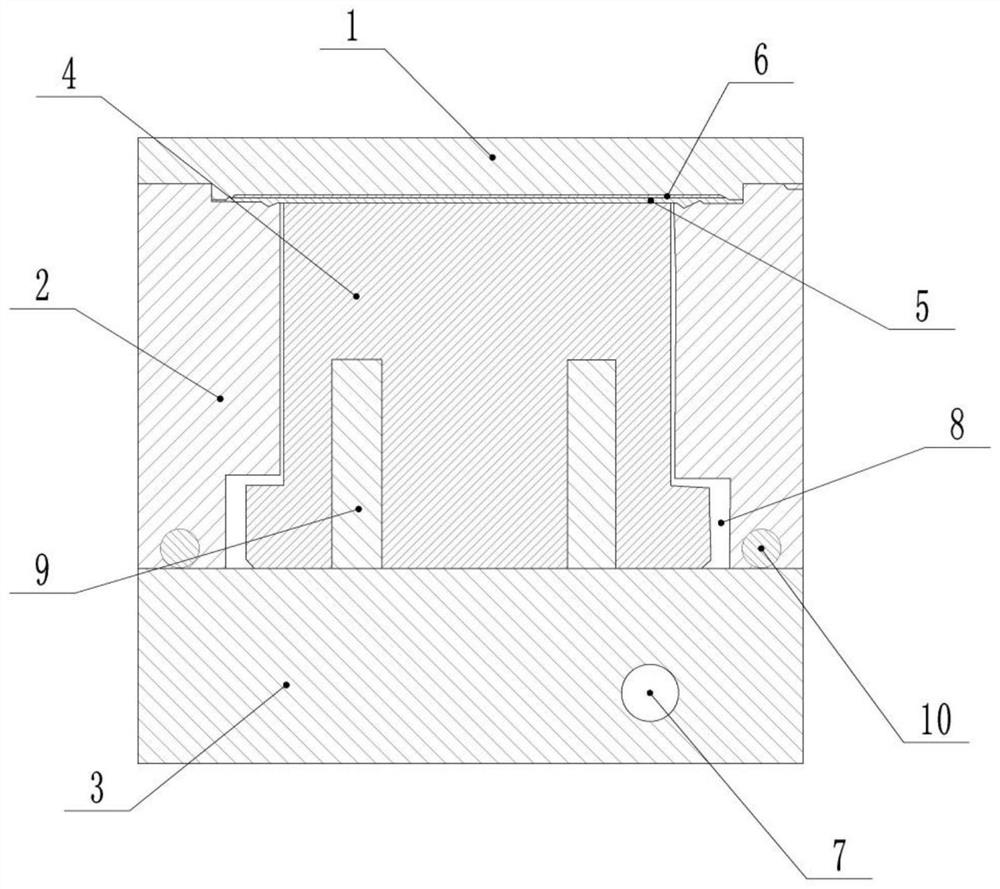

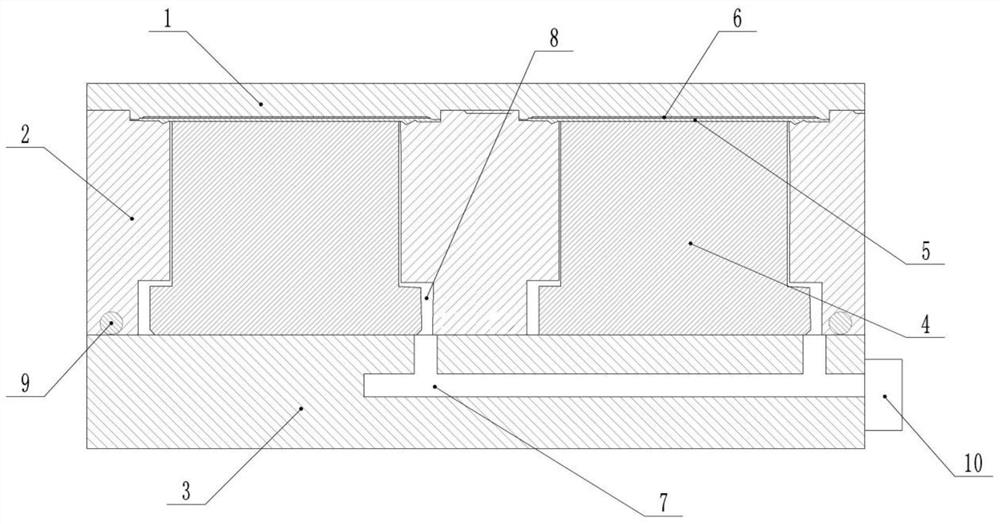

Rubber hot press forming die

The invention belongs to the field of rubber forming, and particularly relates to a rubber hot press forming die which comprises an upper die, a middle die, a lower die and a cylindrical insert. Upper forming cavities are formed in the end, corresponding to the middle die, of the upper die; and lower forming cavities are formed in the end, corresponding to the upper die, of the middle die. Rubber gaskets for sealing the middle die and the lower die is arranged between the lower die and the middle die, a cylindrical insert is fixedly connected with the lower die through a positioning groove and a positioning column, gaps are formed between the cylindrical insert and the middle die and communicate with the lower forming cavities, an air suction channel is formed in the lower die, one end of the air suction channel communicates with the gaps, and the other end of the air suction channel communicates with an air pump. According to the scheme, a plastic model is fixed by negative pressure of the gaps and the air suction channel and is prevented from moving to cause bad products, so that the production efficiency of rubber products is improved; and meanwhile, gas in the forming cavities is reduced, bubbles in the rubber products are reduced, and the rubber forming effect is good.

Owner:重庆富胜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com