Patents

Literature

50results about How to "Easy to move axially" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

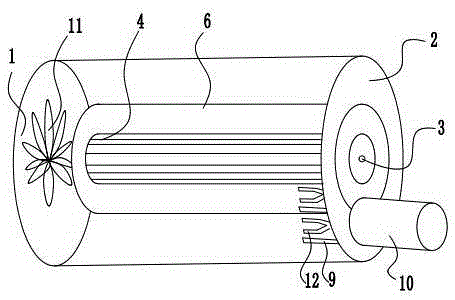

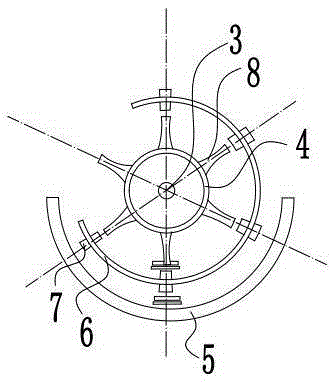

Axial rotational flow stepless regulation low-nitrogen combustor

ActiveCN106871116AAdapt to swirl intensityAdapt to requirementsPulverulent fuel combustion burnersIndirect carbon-dioxide mitigationSet screwThermodynamics

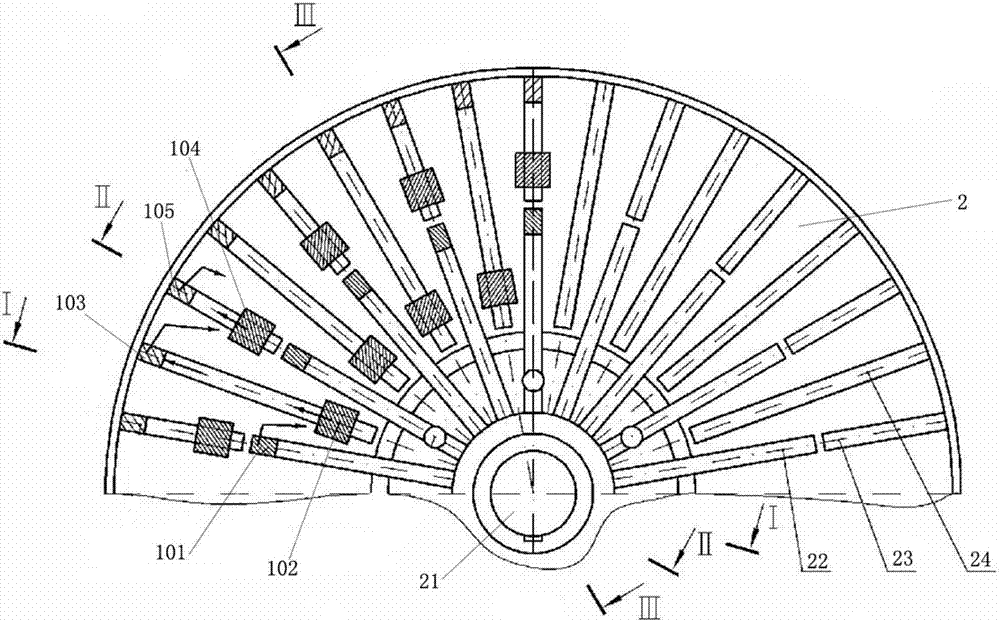

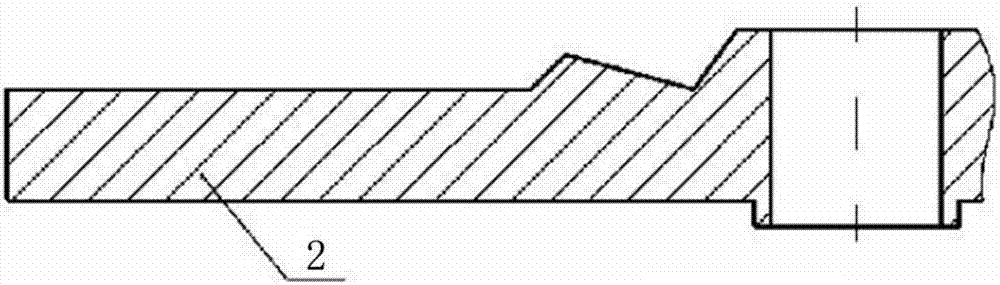

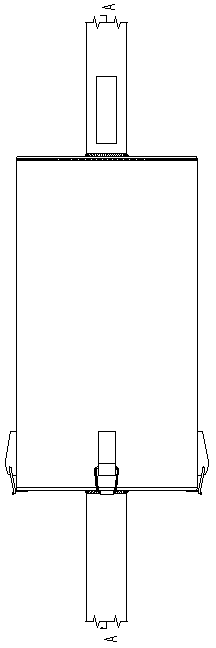

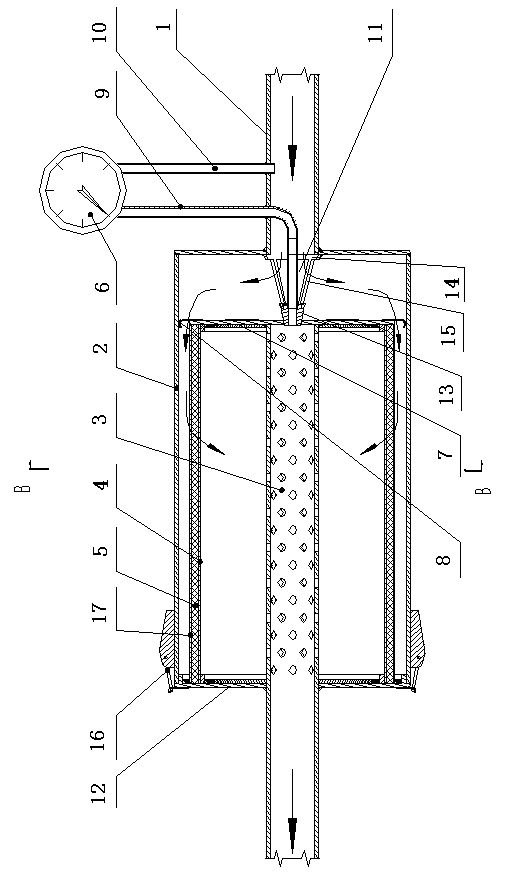

The invention discloses an axial rotational flow stepless regulation low-nitrogen combustor in the field of combustors. The combustor comprises an oil gun, a center air pipe, a gas pipe, a coal air pipe and an axial flow air pipe which are arranged from inside to outside in a sleeved manner; a gas channel is formed between the gas pipe and the center air pipe, a rotational flow air adjusting mechanism is arranged in the gas channel and comprises a plurality of rotational flow air adjusting fan plates evenly arranged on the periphery of the center air pipe, the rotational flow air adjusting fan plates are mounted on the periphery of the center air pipe through positioning screws, and can swing around the positioning screws, the tails of the rotational flow air adjusting fan plates are connected to a rotational flow air adjusting ring through flexible shafts, the rotational flow air adjusting ring is rotatably arranged on the periphery of the center air pipe in a sleeving manner, and the tail of the rotational flow air adjusting ring is connected with a first adjusting rod used for controlling the rotational flow air adjusting ring to rotate. The rotational flow air outlet air speed adjusting and blade angular stepless adjusting are achieved, the combustor meets the requirements of different stations for the rotational flow strength and the rotational flow angle of the combustor, and the combustor can be used for work of combustion of various kinds of industrial furnaces.

Owner:江苏炬烽热能科技有限公司

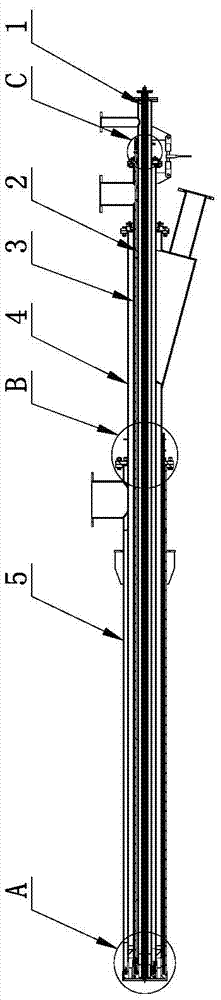

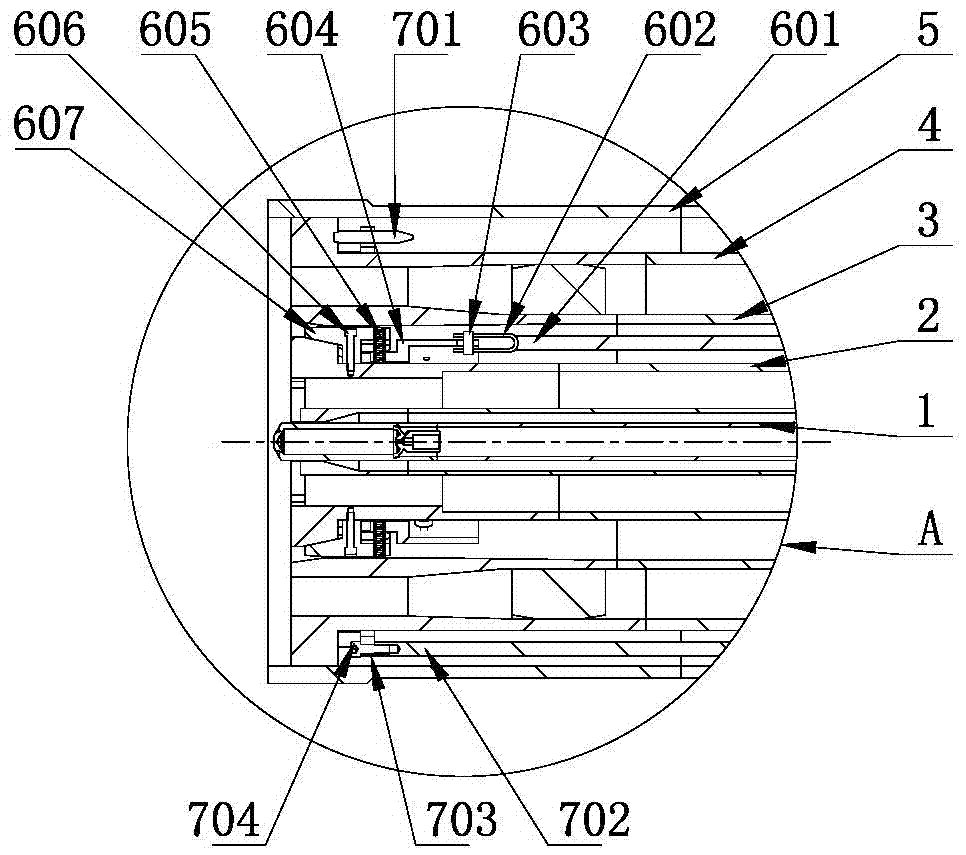

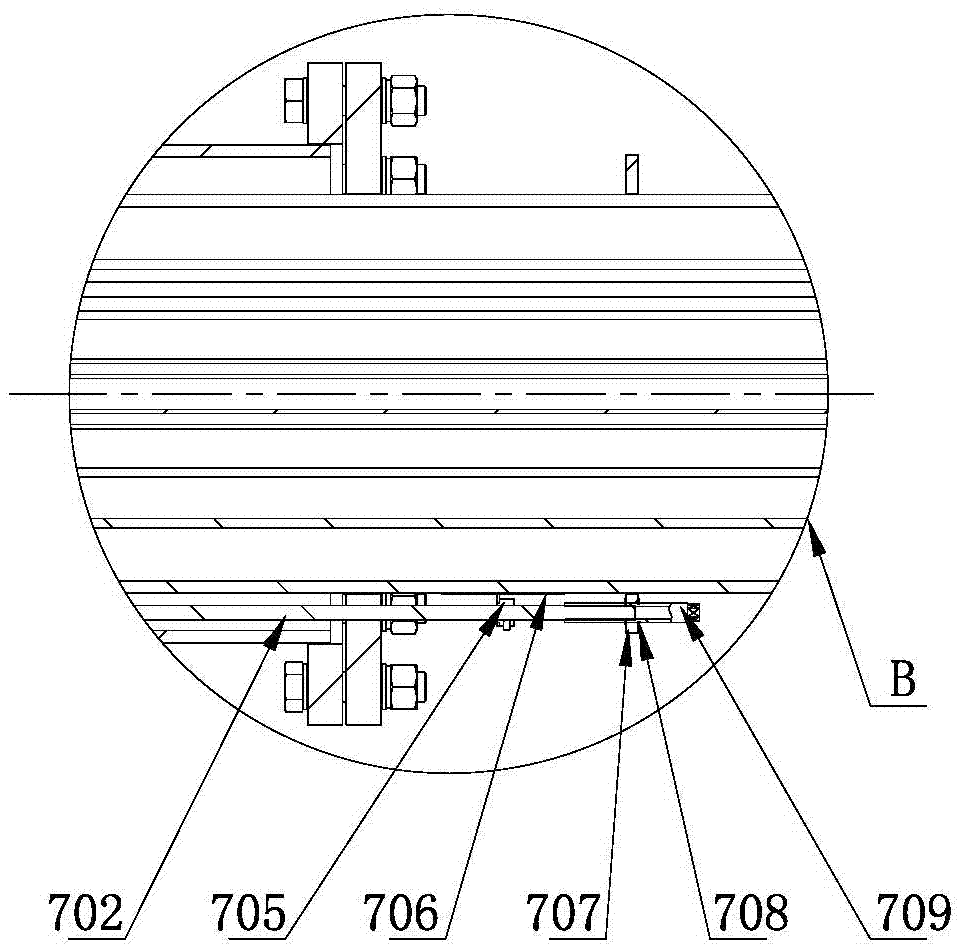

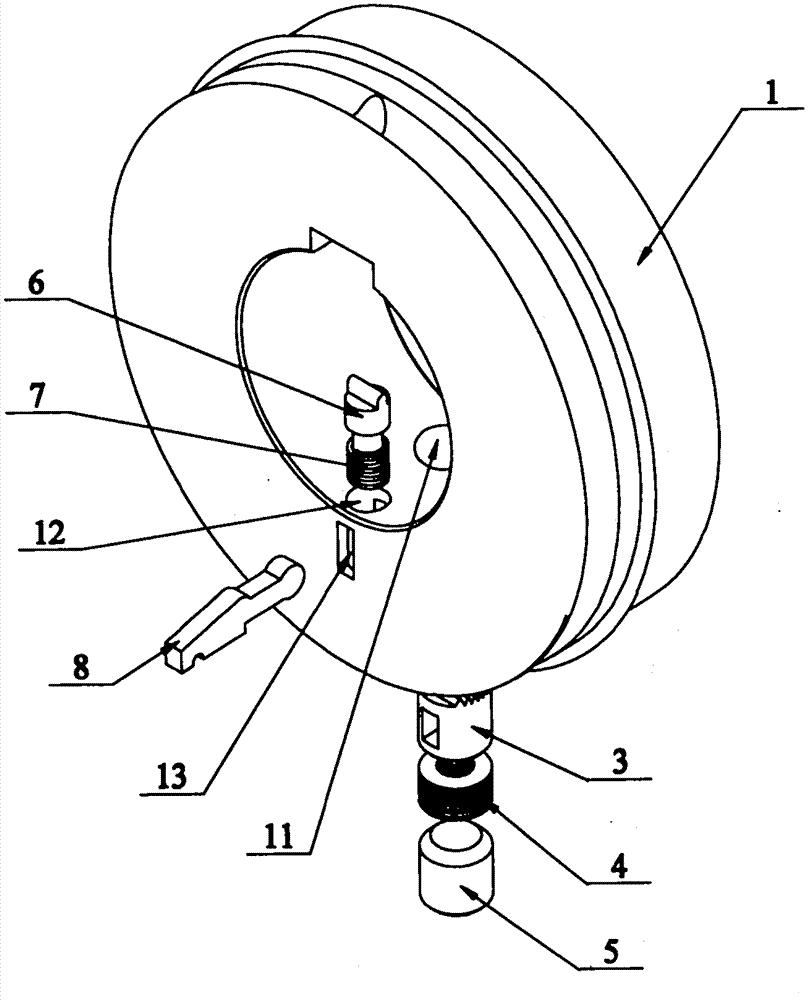

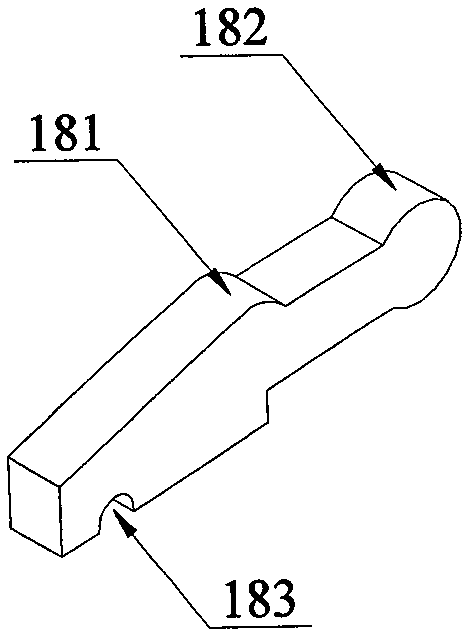

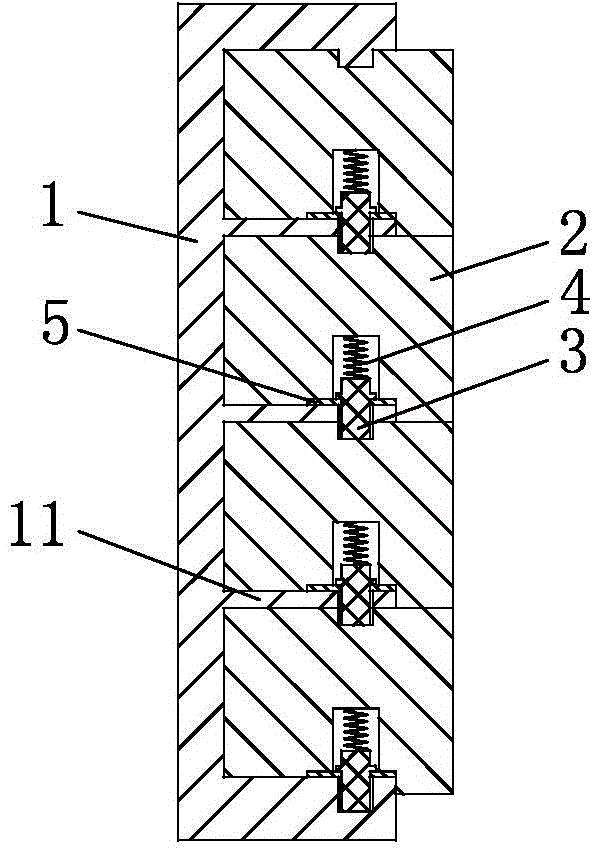

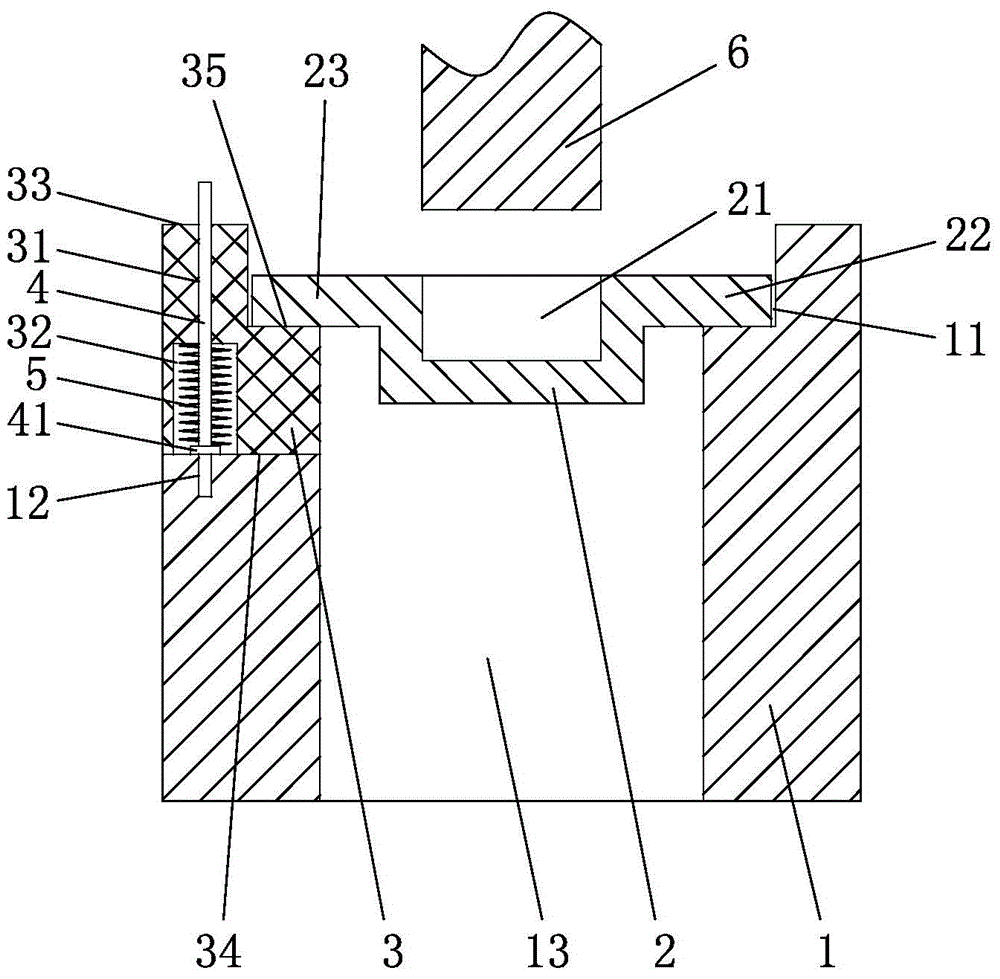

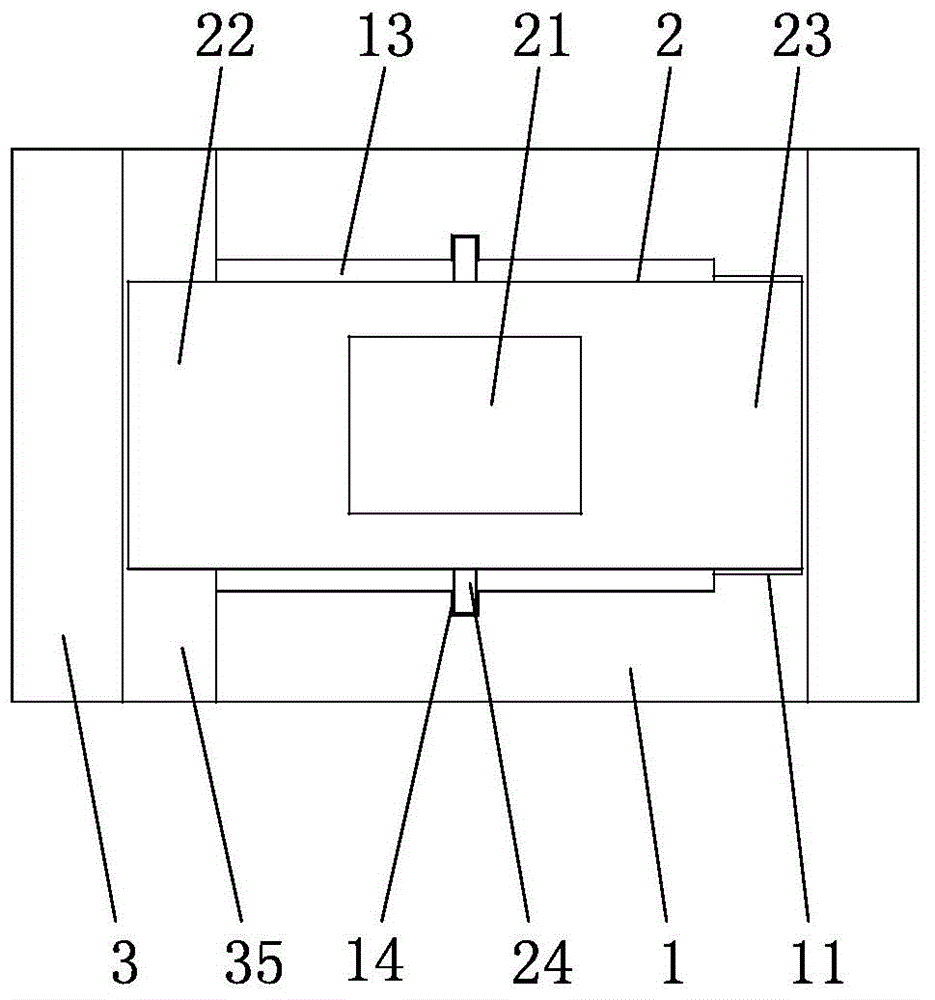

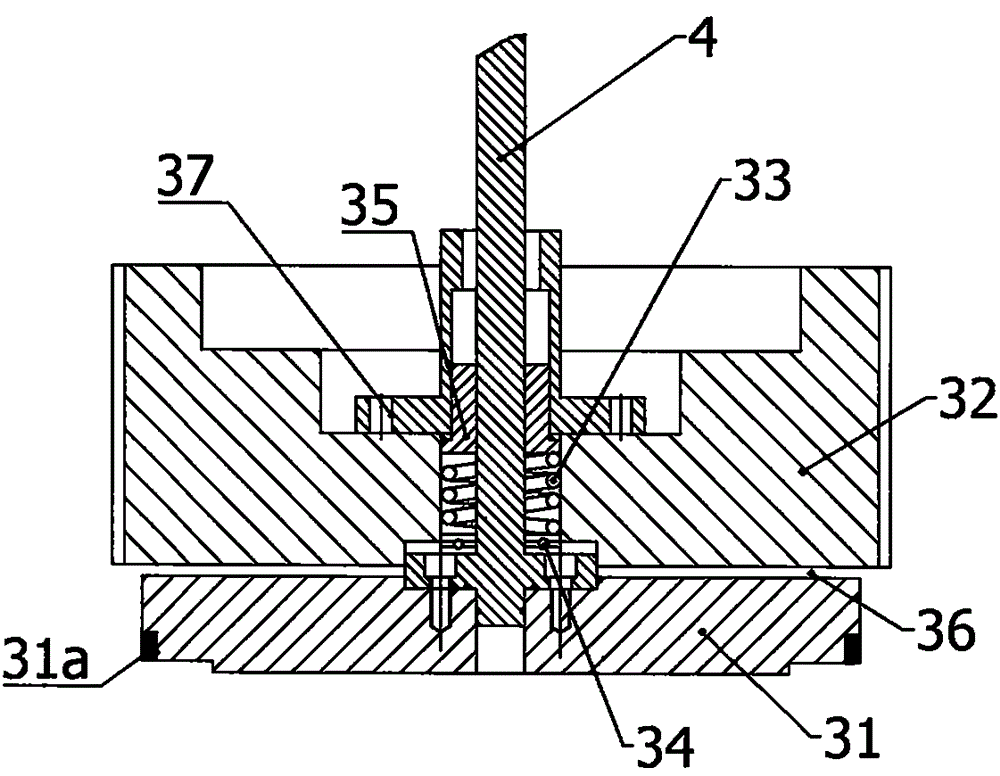

Axial locating self-locking device of creasing wheel

ActiveCN102303424BEasy to move axiallyFast self-locking bitContainer making machinerySet screwEngineering

The invention discloses an axial locating self-locking device of a creasing wheel. The device comprises a creasing wheel arranged on a creasing wheel axle, wherein the creasing wheel axle is axially equipped with a row of rack-shaped clamping grooves; a first radial through hole and a second radial through hole are arranged on the inner wall of an axle hole of the creasing wheel; an axial through hole is arranged on the side face and is perpendicularly crossed with the first radial through hole and the second radial through hole; a tongue pressing block is inserted into the axial through hole; a bulge is arranged on the upper surface of the middle part of the tongue pressing block and props against the upper surface of the inner wall of the axial through hole; a latching block is inserted into the first radial through hole from top to bottom and is connected with the inner end of the tongue pressing block; a spring and a set screw are sequentially inserted into the first radial through hole from bottom to top; and a pressure pin is inserted into the second radial through hole and props against the lower surface of the outer end of the tongue pressing block. According to the invention, the latching block moves up and down through a lever mechanism formed by the tongue pressing block so that the latching block is meshed with or released from the clamping grooves; and therefore, the axial movement of the creasing wheel is convenient, and rapid self-locking localization of the creasing wheel can be realized.

Owner:SHANDONG AHUA PACKAGE PRINTING

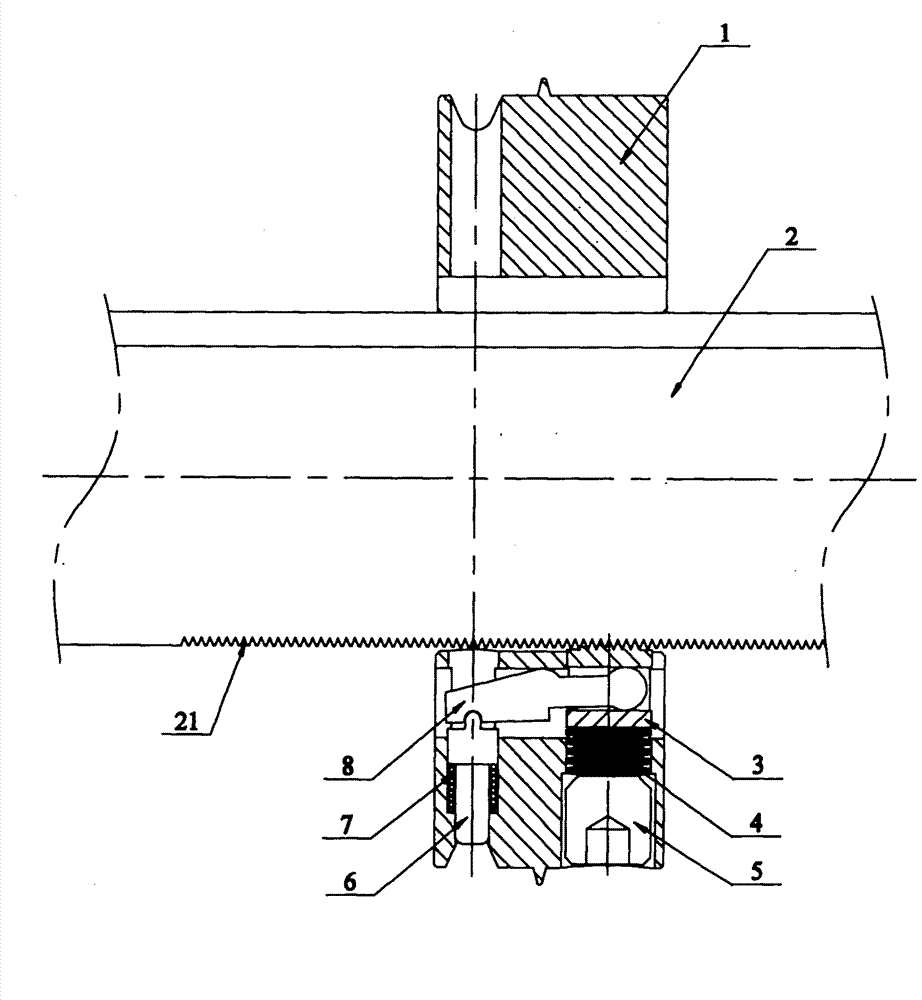

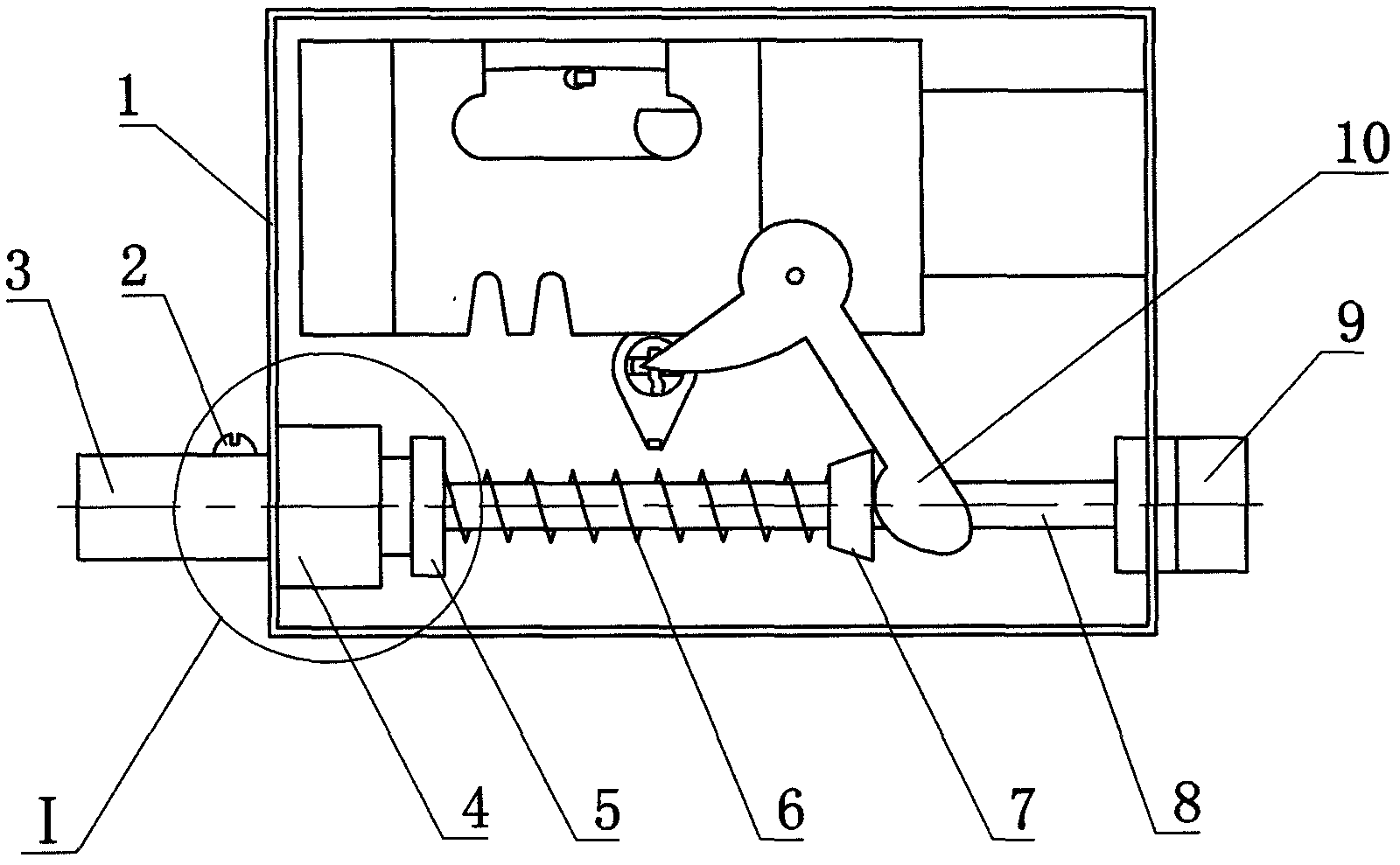

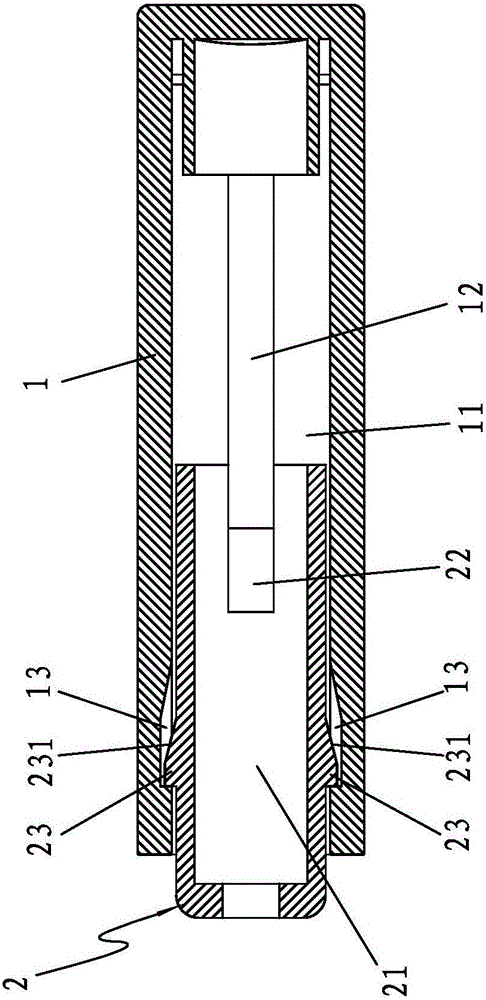

Inward-opening type adjustable anti-theft door locking bolt

The invention discloses an inward-opening type adjustable anti-theft door locking bolt which comprises a screw (2), a handle (3), a compression spring (6), a stopping block (7), a shaft (8) and a door bolt head (9). An adjusting sleeve (5) is sleeved on the shaft (8) and fixedly connected with a fixed sleeve (4) through threads, an inner hole of the adjusting sleeve (5) is in clearance fit with the shaft (8), an external thread is arranged on the adjusting sleeve (5) and is a fine thread, a circular groove (11) is arranged in the inner hole of the adjusting sleeve (5), and the fixed sleeve (4) is provided with an inner hole thread which is a fine thread. The inward-opening type adjustable anti-theft door locking bolt is simple in structure, easy to assemble, adjustable in spring force, reliable to operate, easy to unlock and long in service life.

Owner:HUANGSHI UNIVERSE AUTO EQUIP

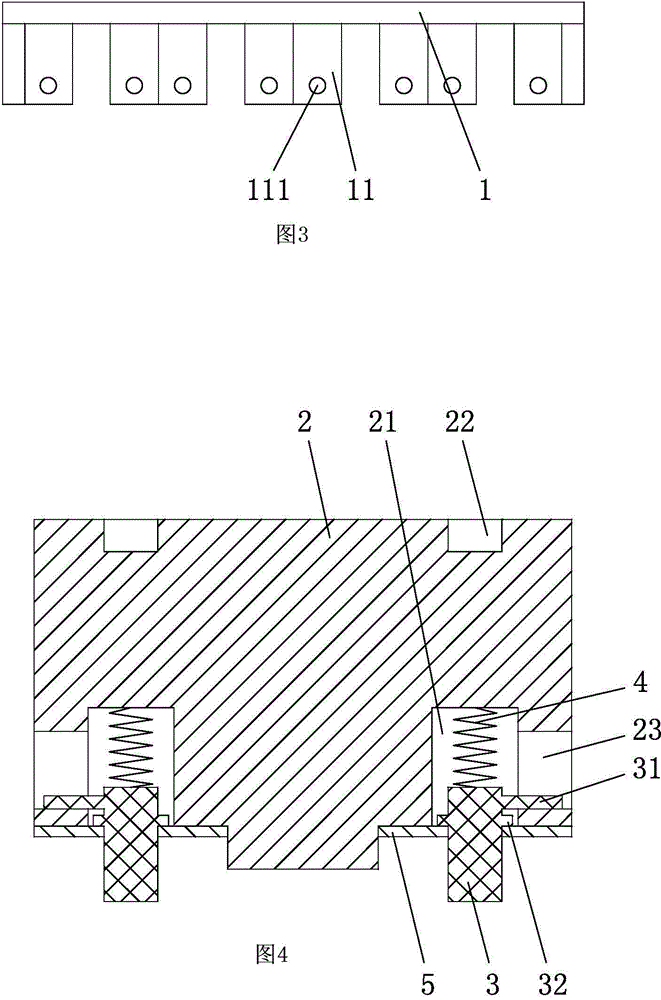

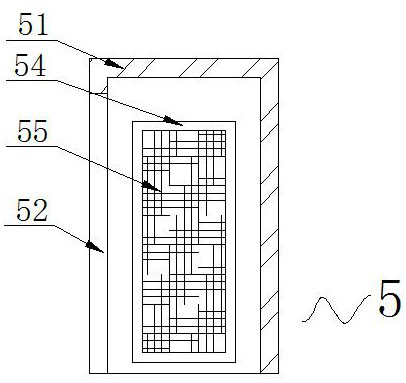

Huge-curtain LED screen

ActiveCN104091534AShorten the timeEasy to move axiallyCasings/cabinets/drawers detailsIdentification meansEngineering

The invention relates to a huge-curtain LED screen and belongs to the field of display screens. The huge-curtain LED screen solves the problem that an LED screen is low in disassembly and assembly speed. According to the technical scheme, the huge-curtain LED screen comprises a frame and a plurality of LED screen bodies arranged on the frame. Locating plates for carrying the LED screen bodies are arranged on the frame. The locating plates are provided with locating holes. The LED screen bodies are provided with mounting grooves, locking grooves and cover plates. A limiting rod capable of moving in the axial direction is arranged in each mounting groove and can be fixed into the mounting groove through the corresponding cover plate. Each limiting rod is provided with an operating rod which extends out of a box body. The limiting rods on the LED screen bodies can move in the axial direction to penetrate through the corresponding locating holes and be inserted into or pulled out of the locking grooves of the adjacent LED screen bodies.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY DONGYANG POWER SUPPLY +3

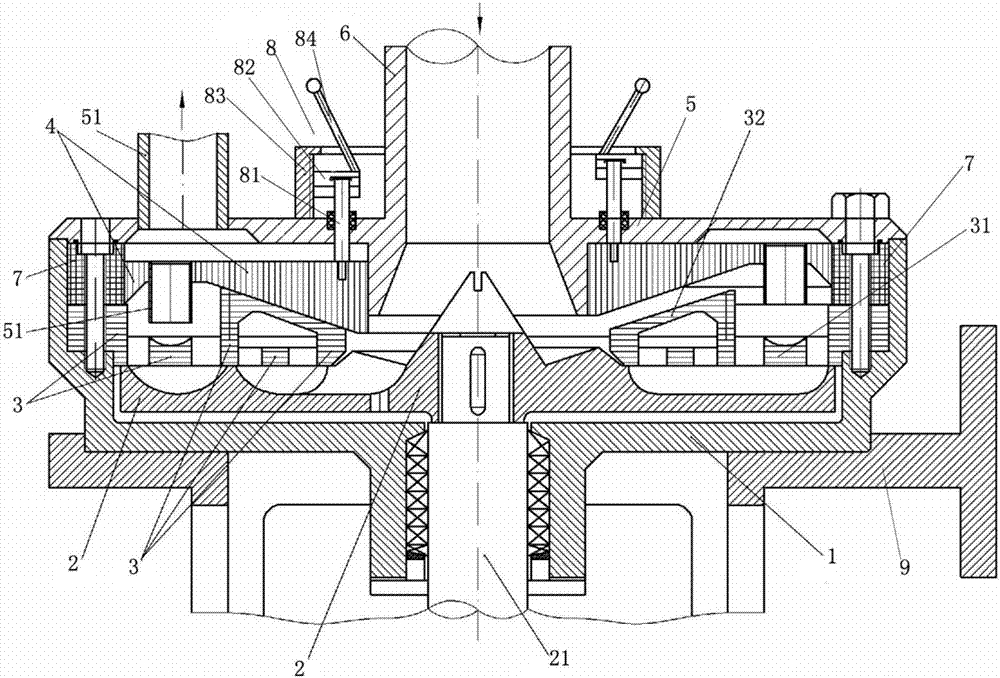

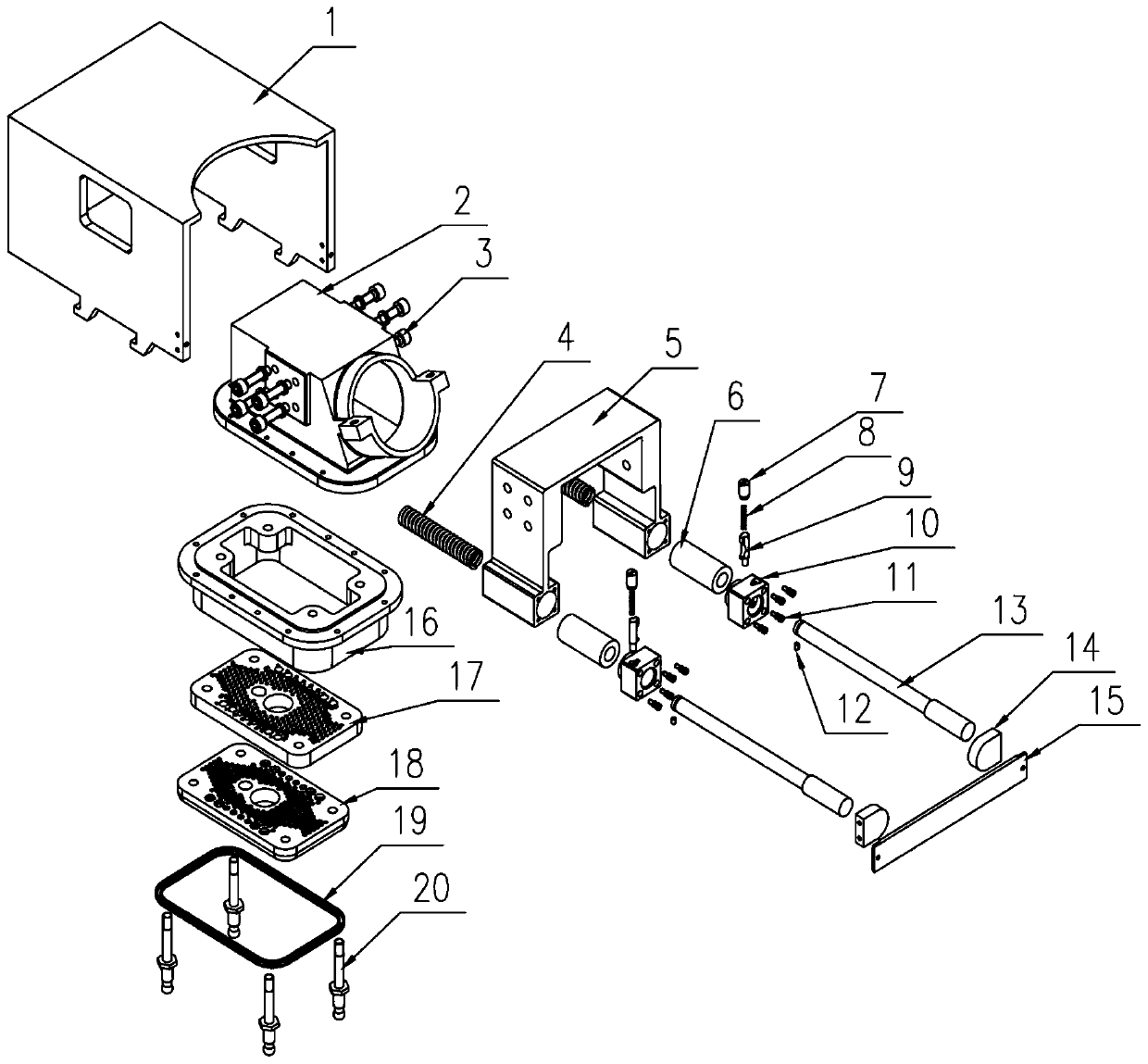

Hydrodynamic force rotor type cavitator

ActiveCN106925147AEnhanced chemical changeGuaranteed Microbial DisinfectionFlow mixersMixing methodsEmulsionCavitation

The invention relates to a hydrodynamic force rotor type cavitator. The hydrodynamic force rotor type cavitator comprises a machine body, a rotor, a stator, an embedded plate with a central hole and a machine cover which are coaxially arranged in turn, wherein a built-in shaft which is vertically fixed at the center of the rotor penetrates through the center of the machine body and is connected with the machine body through a bearing; the built-in shaft is in driving connection with a motor; a peripheral edge of the machine cover is fixedly connected with the peripheral edge of the machine body; the peripheral edge of the stator is fixedly pressed between the machine cover and the rotor; the embedded plate is moveably connected with the machine cover and is located between the machine cover and the stator; the embedded plate can move along an axial direction of the machine cover and a second-level cavitating chamber with adjustable volume is formed between the embedded plate and the stator; a first-level cavitating chamber is arranged in the stator; and the first-level cavitating chamber is communicated with a guiding pipe. In the hydrodynamic force rotor type cavitator provided by the invention, a plurality of cavitating barriers for performing liquid cavitating treatment are arranged between the stator and the rotor, so that the technical efficiency of the cavitation effect is obviously increased, the chemical change of the liquid is intensified, the high-degree microorganism disinfection of the liquid is guaranteed and the quality of microcosmic homogeneous emulsion and suspension is promoted.

Owner:顾履明

Automobile exhaust filtering silencer

InactiveCN103835787AEasy to disassembleEasy to fixInternal combustion piston enginesExhaust apparatusEngineeringExhaust pipe

The invention discloses an automobile exhaust filtering silencer which is provided with an exhaust pipe, an outer barrel body and a core body pipe. The automobile exhaust filtering silencer is characterized in that a filtering element framework, a filtering element, a differential pressure gauge, an inner sealing cover, leaf springs, an outer cavity pressure guide pipe, an inner cavity pressure guide pipe, a locating plug and an outer sealing cover are arranged, one end of the outer barrel body is fixedly connected with the exhaust pipe, the filtering element framework is arranged in the outer barrel body, the wall of the filtering element framework is filled with the filtering element, one end of the filtering element framework is connected with the inner sealing cover, the other end of the filtering element framework is connected with an outer sealing cover, the leaf springs are evenly arranged outside the inner sealing cover, the inner sealing cover is connected with the inner wall of the outer barrel body, the outer sealing cover is connected with the outer barrel body, the core body pipe is arranged at the axis of the filtering element framework, one end of the core body pipe is in sealing connection with the outer sealing cover, the other end of the core body pipe is in sealing connection with the inner sealing cover, one end of the locating plug is in abutting-against connection with a locating hole, the other end of the locating plug is fixedly connected with the exhaust pipe, one connector of the differential pressure gauge is connected with the exhaust pipe, and the other connector of the differential pressure gauge is connected with the locating plug. The automobile exhaust filtering silencer has the advantages of being novel in structure, convenient to maintain, environmentally friendly, free of pollution and the like.

Owner:WEIHAI PLOUMETER

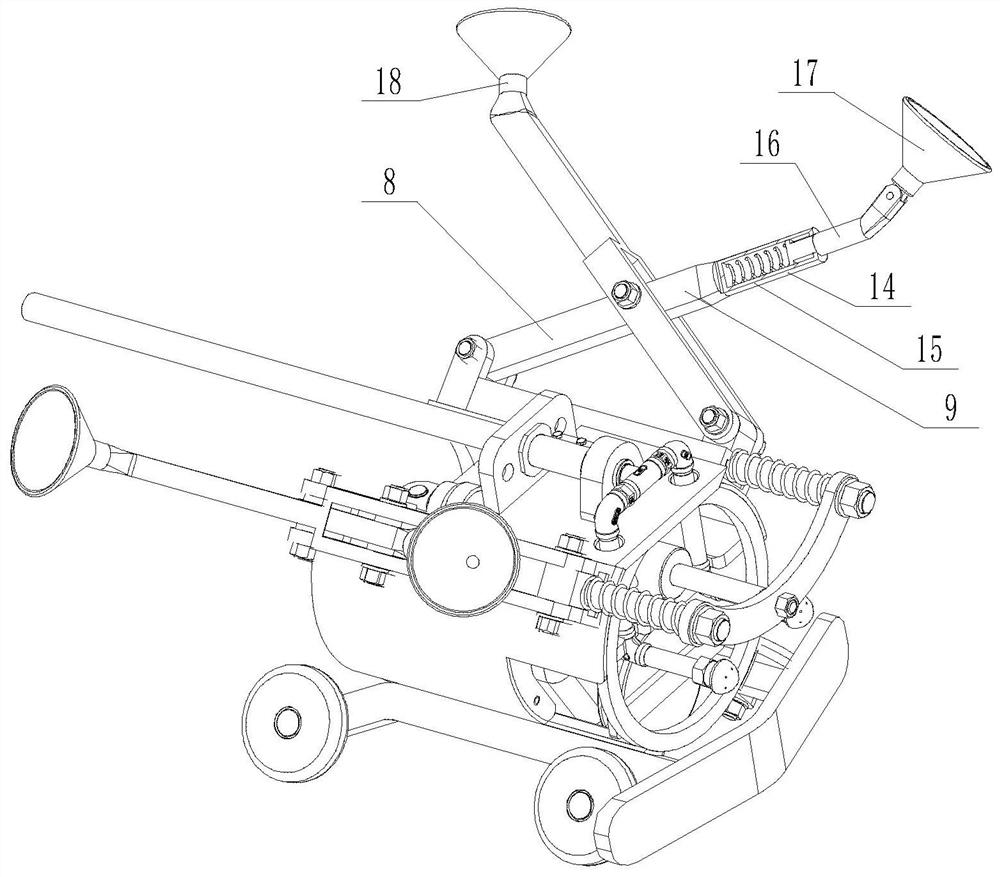

Synthetic adhesive cutting machine

The invention relates to the field of adhesive production devices, in particular to a synthetic adhesive cutting machine. The synthetic adhesive cutting machine comprises an upper shell and a lower shell, wherein the upper shell is arranged above the lower shell. The synthetic adhesive cutting machine is characterized in that the upper end of the upper shell is connected with a feeding hopper, a circular cavity is formed between the upper shell and the lower shell, a rotor is arranged in the circular cavity and is provided with blades, a plurality of fixed cutters are arranged between the upper shell and the lower shell and are provided with mounting holes, the fixed cutters are connected with the lower shell through locating pins, the diameter of each locating pin is smaller than that of each mounting hole, the outer side of each fixed cutter is connected with a regulating screw for regulating each fixed cutter, an annular sieve is arranged at the lower end of the circular cavity and is provided with holes, a discharge hole is formed in the lower end of the lower shell, and the lower ends of the holes are connected with an insulator jetting device. The synthetic adhesive cutting machine has the advantages that the production cost is low, the structure is simple, and the synthetic adhesive is cut uniformly.

Owner:CHANGZHOU CHANGOU METAL PROD

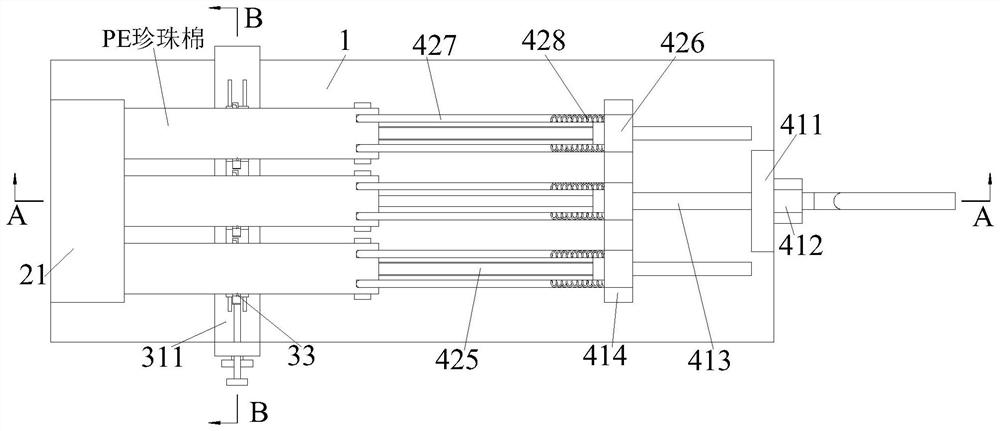

PE pearl wool packaging material structure forming processing technology

InactiveCN111730669AImprove processing efficiencyReduce cumbersomeFlexible coversWrappersMachiningIndustrial engineering

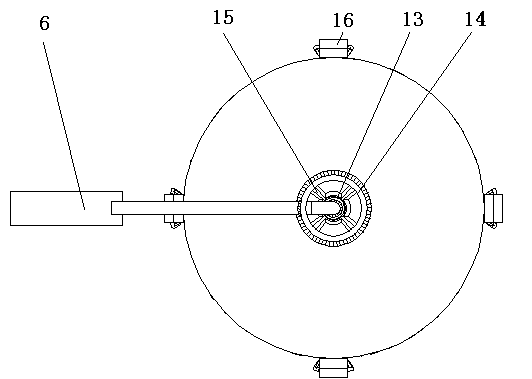

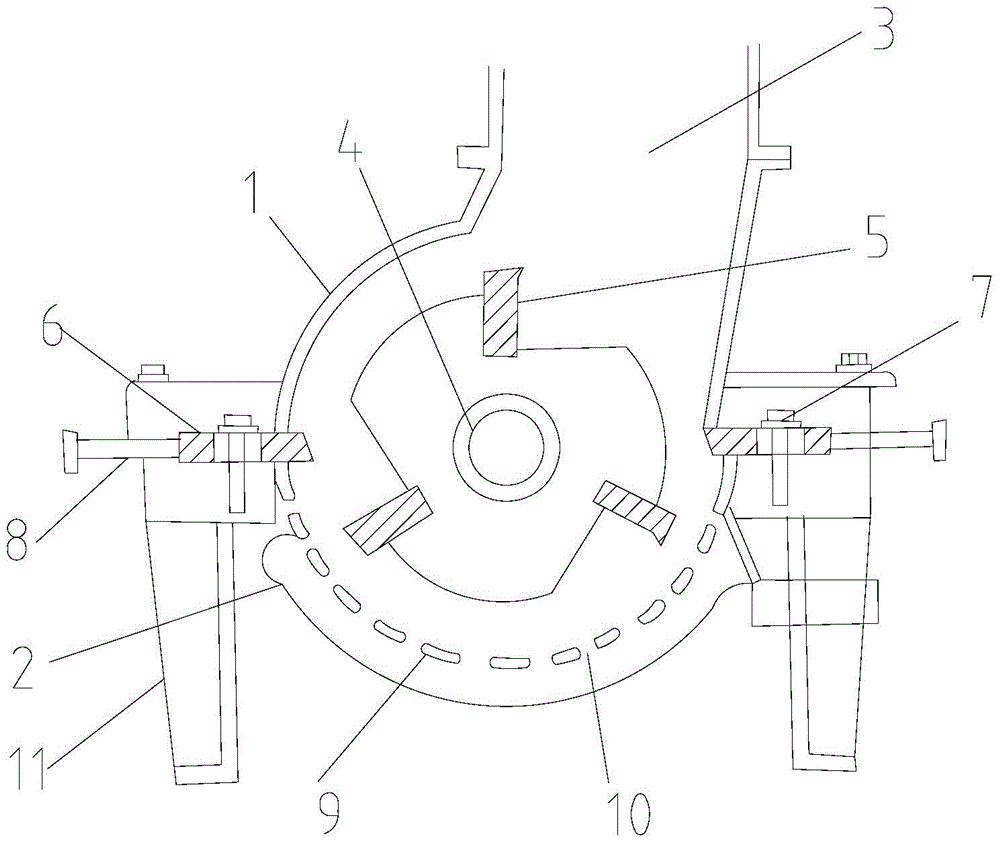

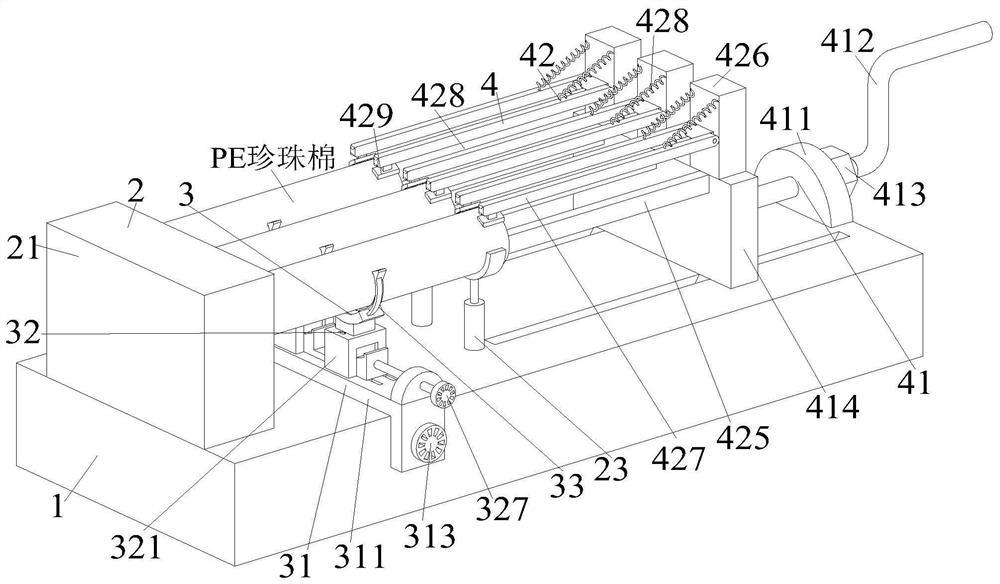

The invention relates to a PE pearl wool packaging material structure forming processing technology which comprises a workbench, a fixing device, a circumferential dividing device and an axial dividing device. The fixing device is installed on the left side of the upper end of the workbench, the circumferential dividing device is arranged on the right side of the fixing device, the circumferentialdividing device is installed at the upper end of the workbench, and the axial dividing device is mounted on the right side of the upper end of the workbench. According to the PE pearl wool packagingmaterial structure forming processing technology, the problems that in the manual processing process, PE pearl wool is locked and fixed firstly, then the PE pearl wool is divided in the circumferential direction and the axial direction, manual cutting easily enables the PE pearl wool dividing position to generate fractures, when existing PE pearl wool manufacturing equipment is used for machining,the PE pearl wool is clamped and fixed firstly and then is divided, the existing PE pearl wool manufacturing equipment can only divide the PE pearl wool in the circumferential direction or the axialdirection, the dividing process is tedious, and consequently, the PE pearl wool dividing and forming efficiency is low are solved.

Owner:黄远明

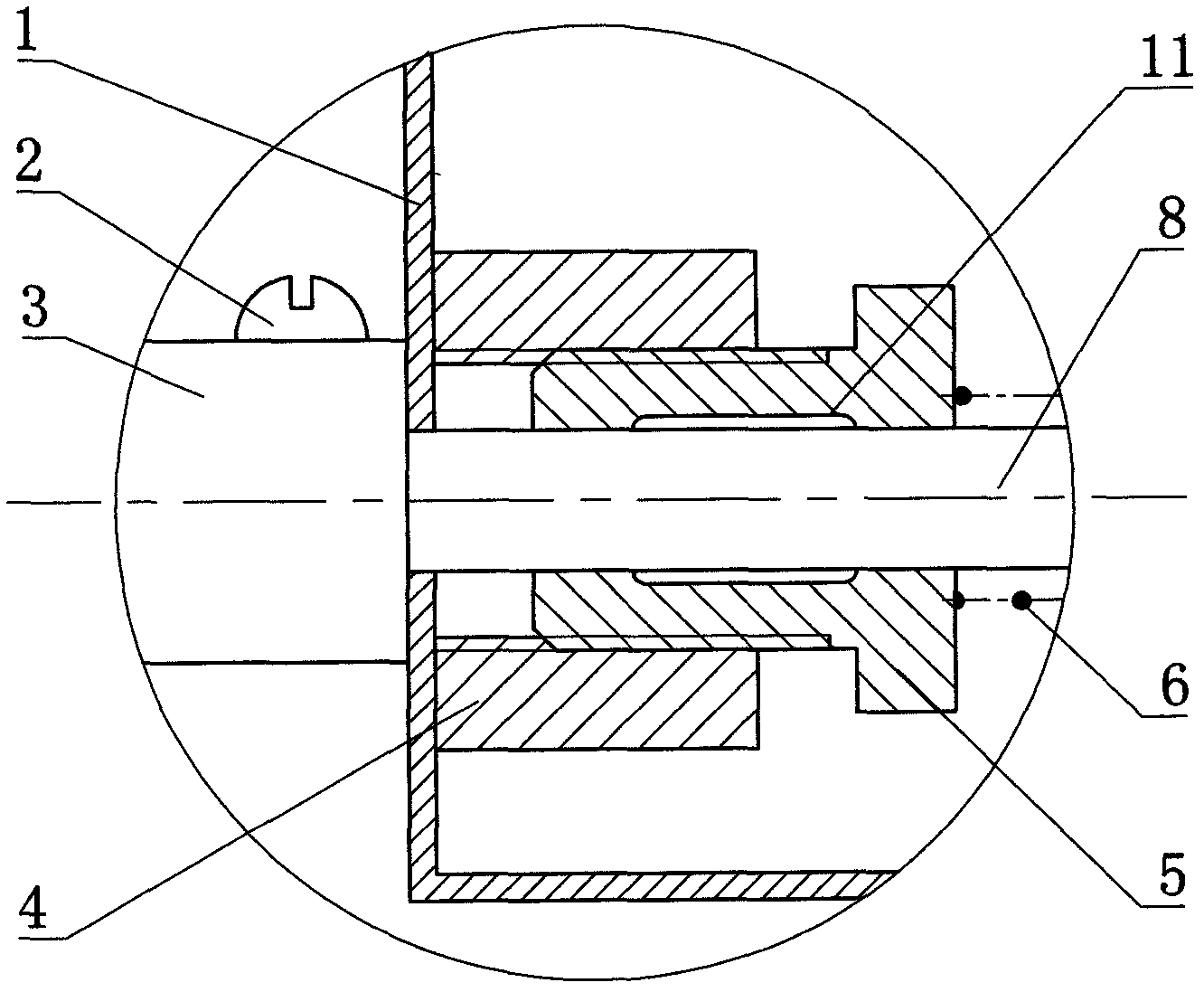

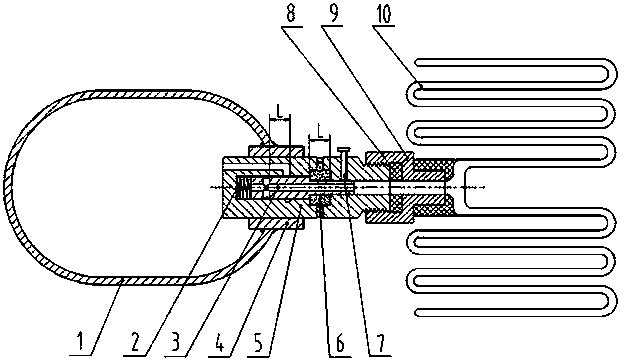

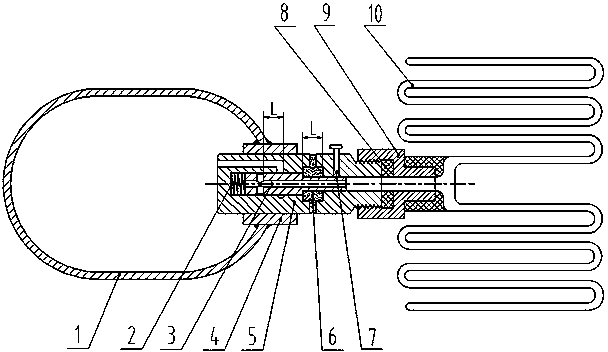

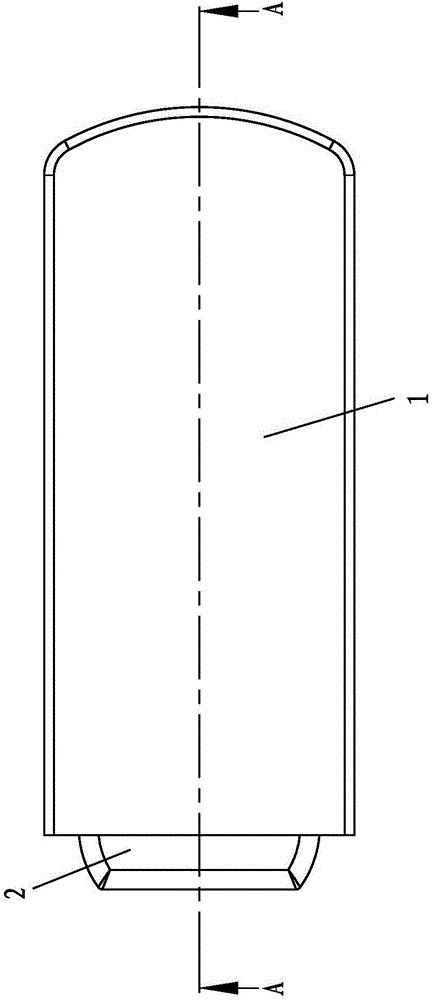

Gas bag capable of autoinflation underwater

InactiveCN103991524ADoes not affect ejectionEasy to move axiallyVessel salvagingUnderwaterGas cylinder

A gas bag capable of autoinflation underwater is designed in the invention. The gas bag comprises a gas cylinder housing (1), a spring (2), a valve inner-nozzle (3), a reinforced sleeve (4), a valve bushing (5), a locating slot (6), a jackscrew (7), a sealing ring (8), a thread sleeve (9) and a gas bag (10). When the gas bag is filled with high pressure gas, the locating slot (6) is filled with a whole piece of edible rock sugar and the outside of the locating slot is sealed up with paraffin. The jackscrew (7) is screwed. Before the gas bag and a gas cylinder are poured underwater to carry out air inflation work, a small hole is poked in the paraffin seal outside the locating slot (6) of the gas cylinder according to the sinking depth underwater. Then, the jackscrew is screwed down, and the gas cylinder and the gas bag are poured into water. After the rock sugar in the locating slot (6) is dissolved underwater, the spring (2) pushes the valve inner-nozzle (3) to move outwards for a distance L. the valve inner-nozzle (3) is communicated with a venthole in the valve bushing (5), and high pressure gas in the gas cylinder is automatically ejected to inflate the gas bag.

Owner:NINGBO CHENGDA MACHINERY RES INST

Airbag capable of autoinflation underwater

ActiveCN103991523ADoes not affect ejectionEasy to move axiallyVessel salvagingGas cylinderUnderwater

An airbag capable of autoinflation underwater is designed in the invention. The airbag comprises a gas cylinder housing (1), a spring (2), a valve inner-nozzle (3), a reinforced sleeve (4), a valve bushing (5), a locating slot (6), a jackscrew (7), a sealing ring (8), a thread sleeve (9) and an airbag (10). When a gas cylinder is filled with high pressure gas, the locating slot (6) is filled with a whole piece of edible rock sugar, and the outside of the locating slot is sealed up with paraffin. The jackscrew (7) is screwed. Before the gas cylinder is poured into water to carry out air inflation work, a small hole is poked in the paraffin seal outside the locating slot (6) according to the sinking depth underwater. Then, the jackscrew is screwed down, and the gas cylinder and the airbag are poured into water. After the rock sugar in the locating slot (6) is dissolved in water, the spring (2) pushes the valve inner-nozzle (3) to move outward for a distance L. The valve inner-nozzle (3) is communicated with a venthole in the valve bushing (5), and high pressure gas in the gas cylinder is automatically ejected to inflate the airbag.

Owner:徐州博创建设发展集团有限公司

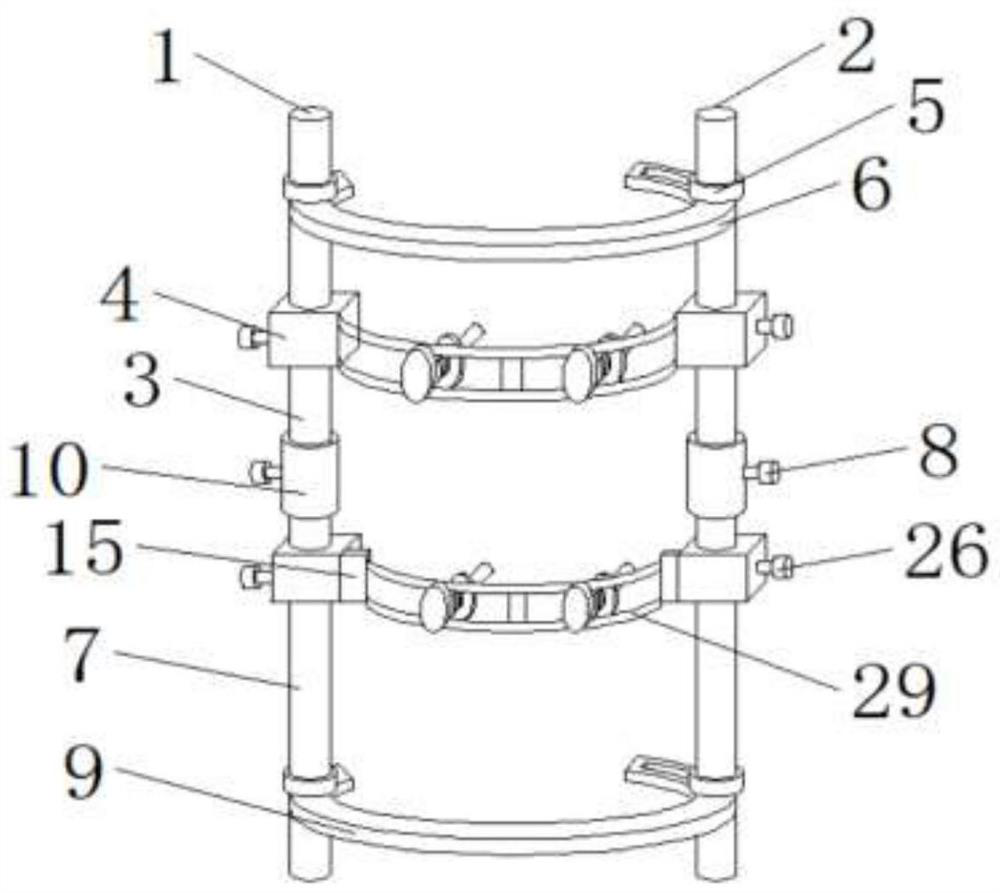

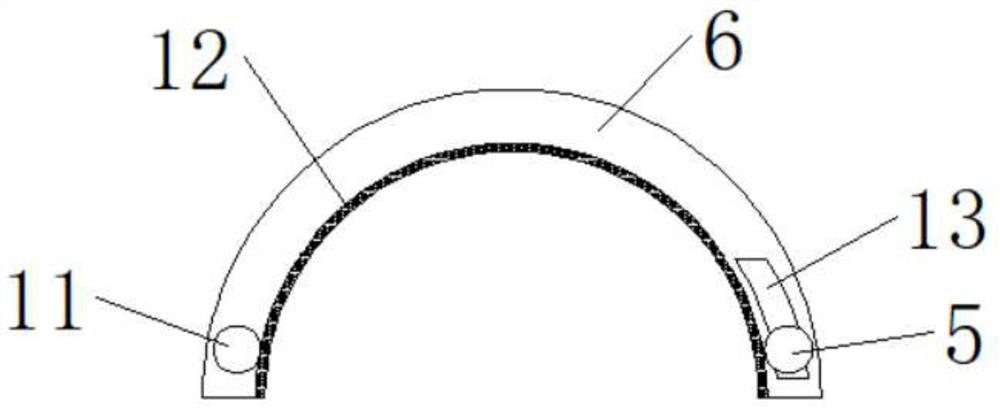

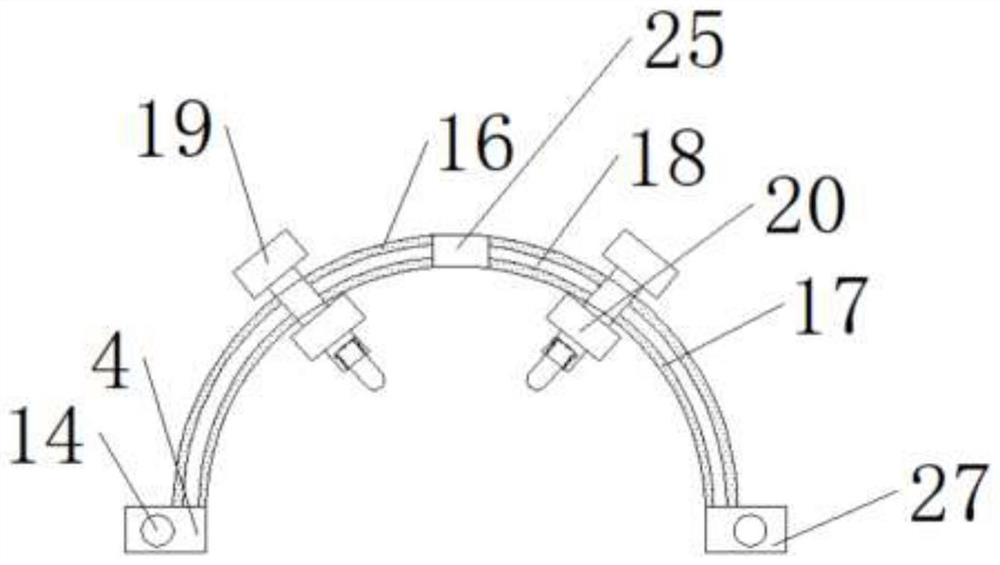

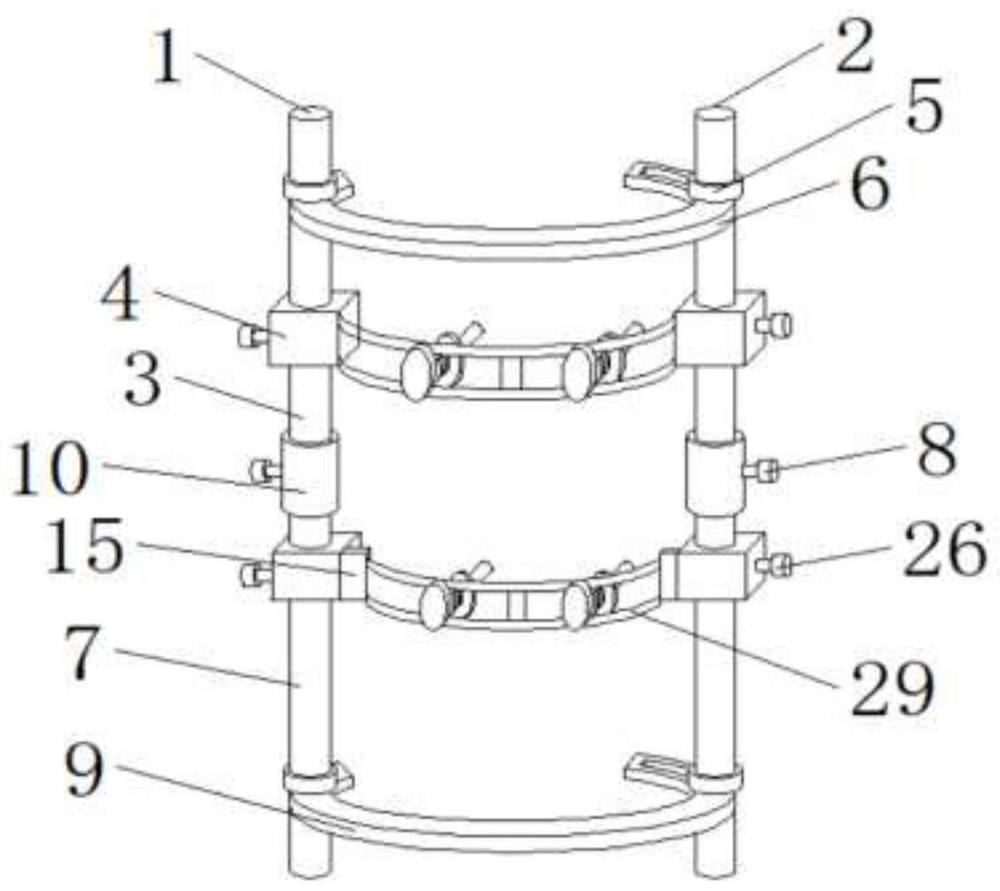

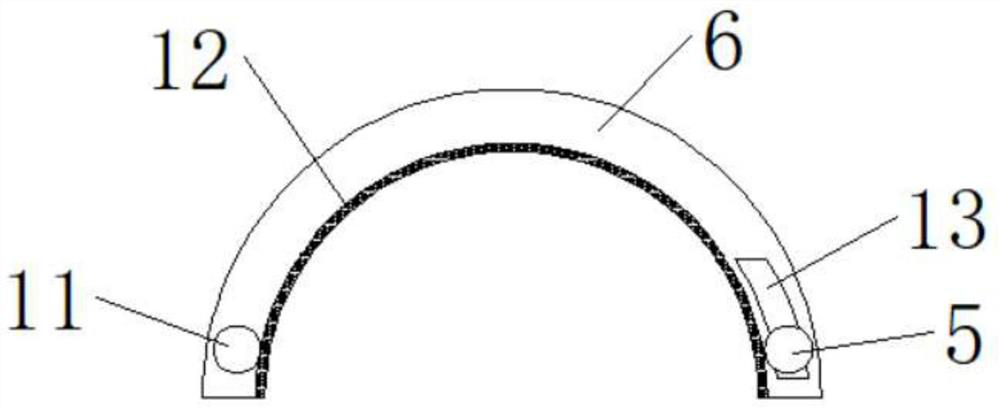

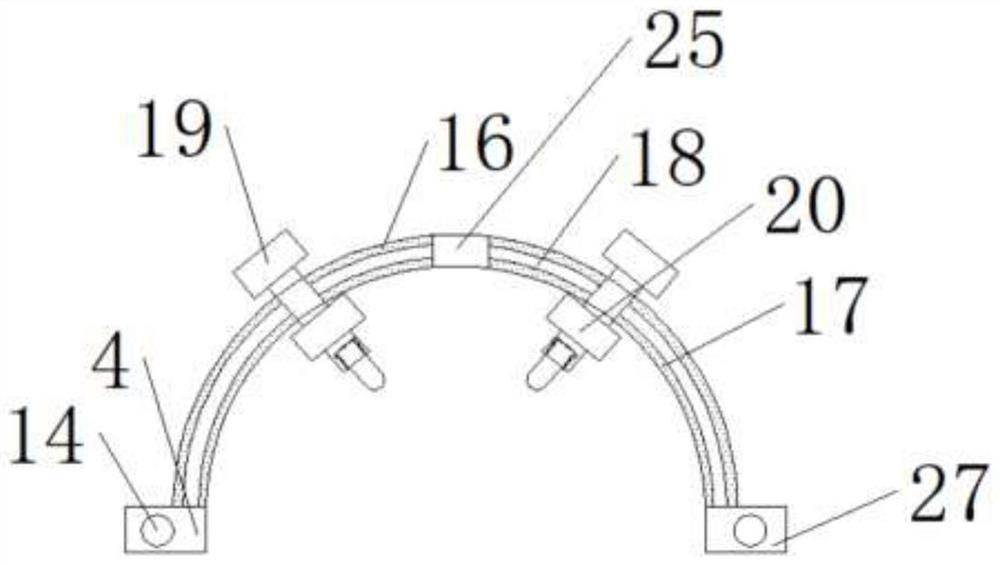

Adjustable fracture repositor

ActiveCN111743613APlay a blocking roleEasy to adjustExternal osteosynthesisClassical mechanicsStructural engineering

The invention discloses an adjustable fracture repository that comprises a first guide rod, a second guide rod and a first semi-ring fixing plate; one side of the first guide rod is movably connectedwith a first semi-ring fixing plate; one side of the first semi-ring fixing plate is movably connected with a second guide rod; the top of the first guide rod is connected with a first semi-annular needle base in a penetrating mode. One side of the bottom of the first guide rod is movably connected with a second semi-ring fixing plate; the top of the second semi-ring fixing plate is fixedly connected with a second semi-ring needle seat; a needle seat sliding groove is formed in the second semi-ring needle seat; a user can rotate the rotary screw cap to loosen the connection between the needleholder and the needle seat sliding groove, the needle holder is manually moved to a fixed position, so that the needle holder moves in the needle seat sliding groove, and the insertion position of theneedle piece is conveniently adjusted; the connecting plate is vertically arranged in the middle of the semi-arc plate, so that a user can conveniently adjust the angle of the needle holder in sequence according to the position of the connecting plate, and the invention is suitable for bone fracture reduction and has a wide development prospect in the future.

Owner:THE AFFILIATED HOSPITAL OF SHANDONG UNIV OF TCM

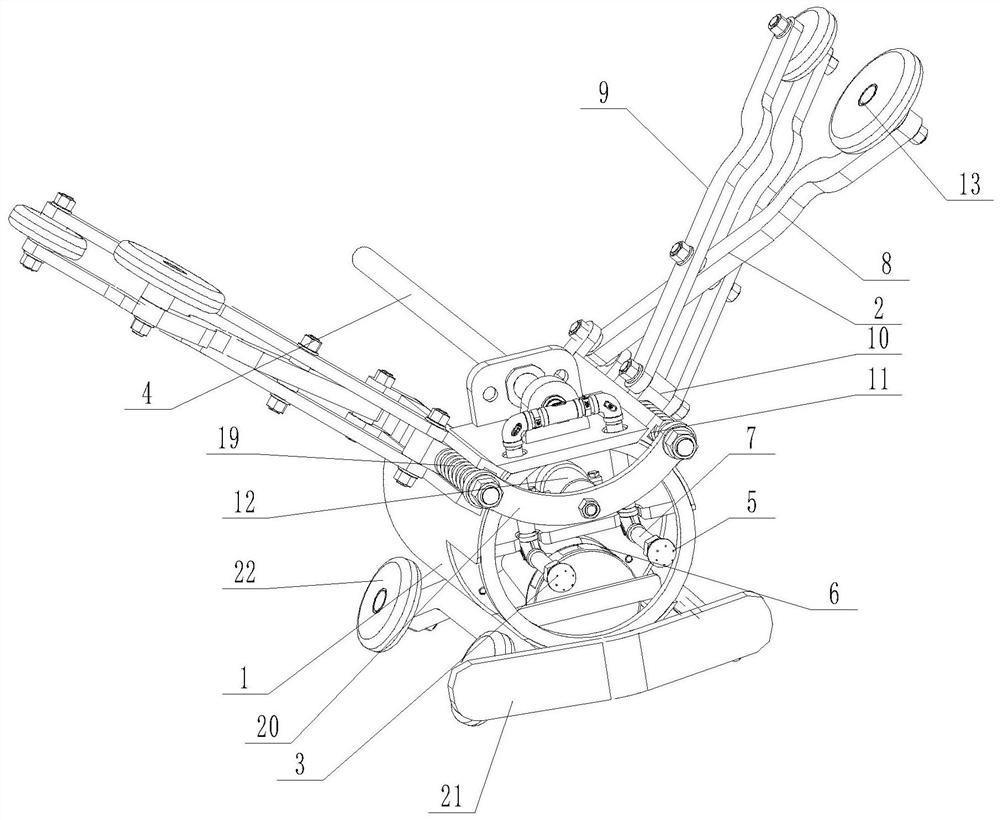

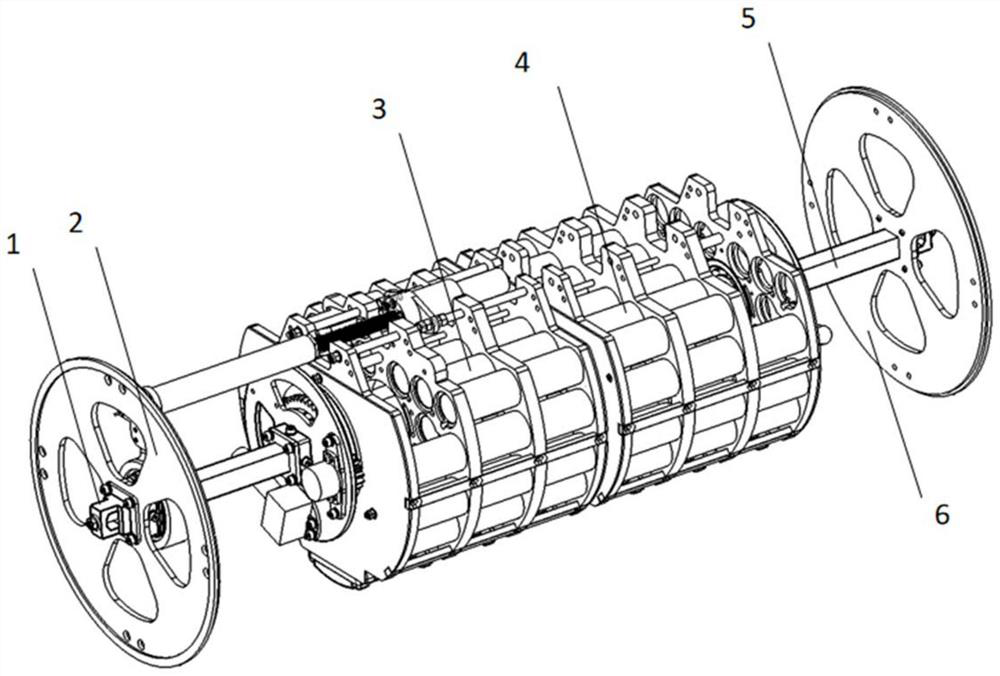

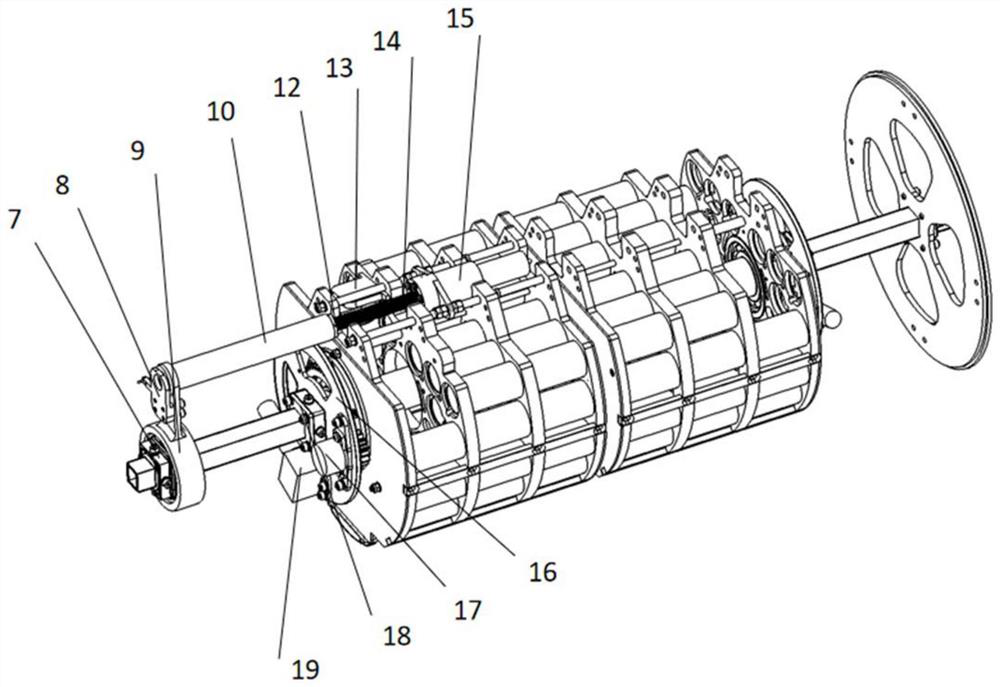

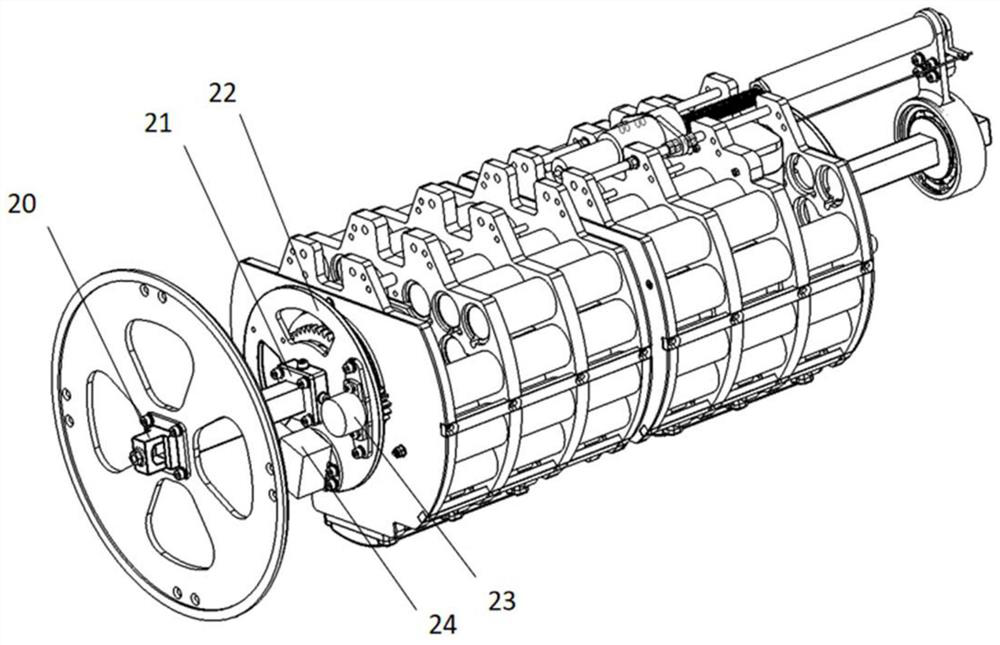

Threshing device

The invention relates to the field of agricultural harvesting machinery, and particularly discloses a threshing device which comprises a left wall plate, a right wall plate and cleaning facilities, wherein the left wall plate and the right wall plate are fixed on the main body of a harvesting machine or a reaping machine; the cleaning facilities are arranged on the left wall plate and the right wall plate; a drum shaft is arranged between the left wall plate and the right wall plate, and sleeved by a spike-tooth drum; a concave plate screen is arranged below the spike-tooth drum; screen holes are formed in the concave plate screen; the concave plate screen is connected between the left wall plate and the right wall plate, and totally covers the spike-tooth drum; the spike-tooth drum is sleeved by a housing; the housing is a hollow cylinder with openings formed in the side surface; radial bulges and leaks are formed on and in both the inner wall and the outer wall on the side surface of the housing; the housing is connected onto the drum shaft, and can rotate around the drum shaft together with the spike-tooth drum.

Owner:CHONGQING XINSHUI MACHINERY MFG

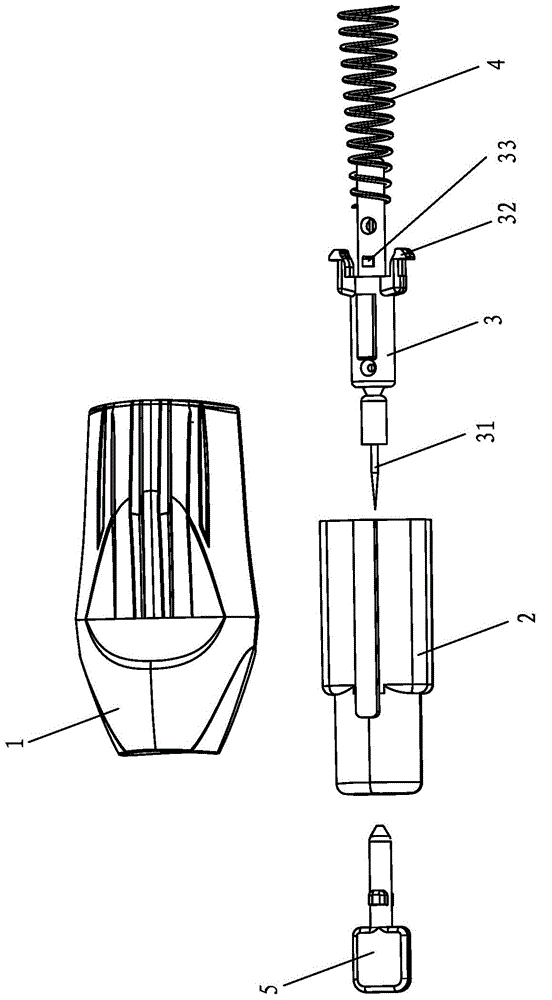

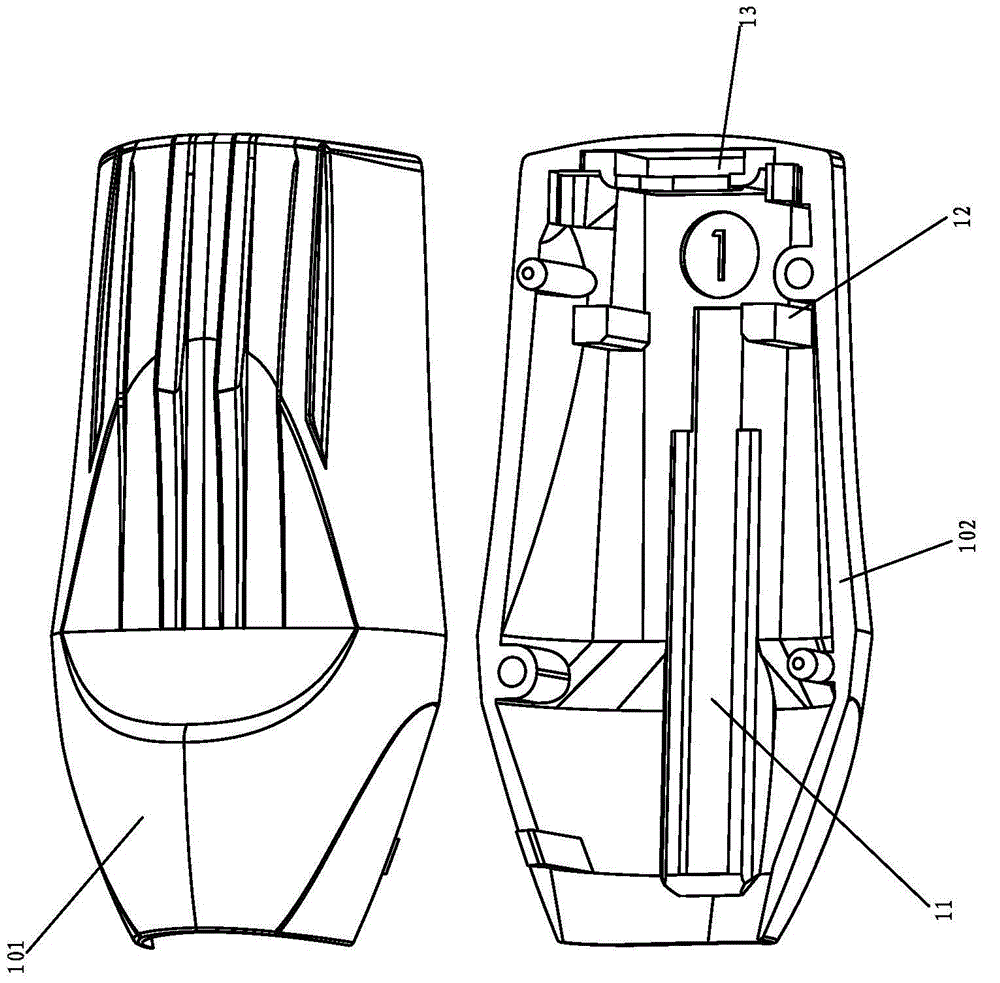

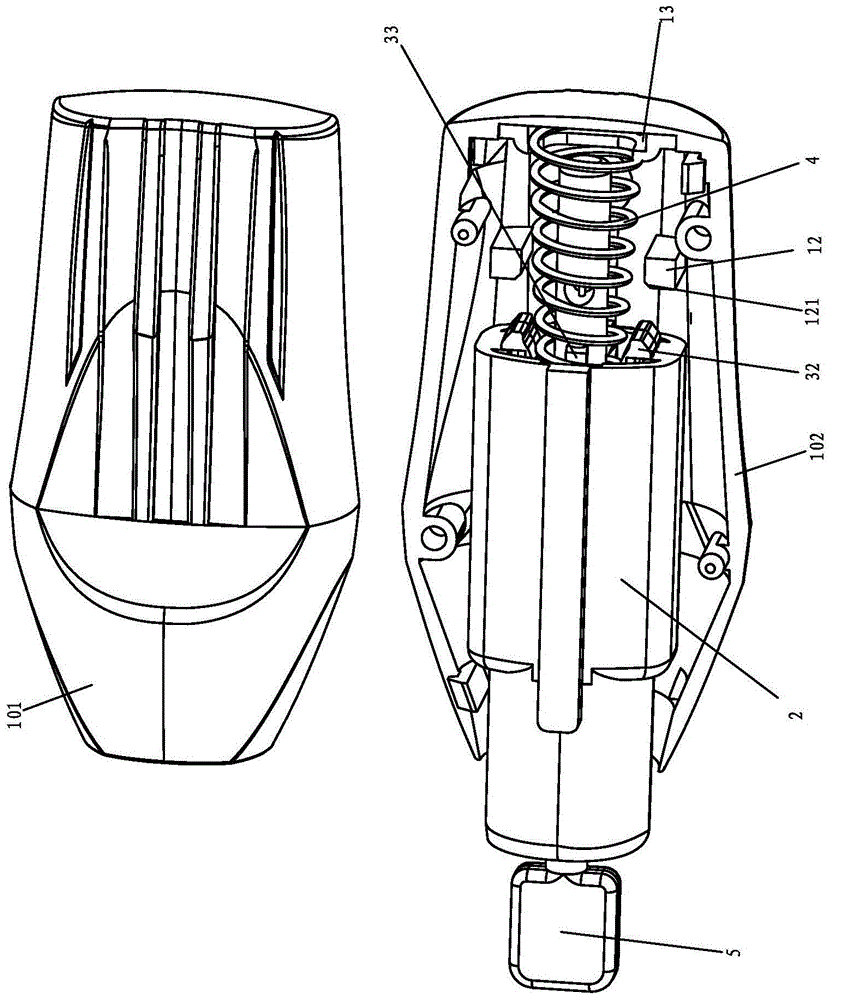

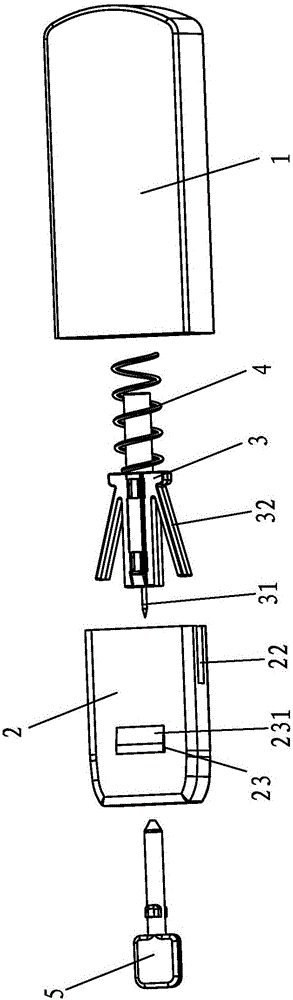

Forward press type blood collection device

InactiveCN104983432AFew componentsEasy to assembleDiagnostic recording/measuringSensorsBlood collectionBiomedical engineering

The invention discloses a forward press type blood collection device which comprises a shell, a sliding sleeve and a needle body. The shell comprises an upper half shell body and a lower half shell body which are buckled. A needle head is arranged at the front end of the needle body. A first guide limiting channel where the sliding sleeve axially moves is arranged in an inner cavity of the shell and enables the front end of the sliding sleeve to stretch out of the shell. A second guide limiting channel where the needle body axially moves is arranged in the sliding sleeve. The needle body is provided with an elastic buckle used for abutting against the rear wall of the sliding sleeve during assembling. A disengagement protrusion which is used for enabling the elastic buckle on the needle body to be disengaged from the rear wall of the sliding sleeve and to enter the sliding sleeve when the front end of the sliding sleeve retracts into the shell is arranged in the shell. A spring used for pushing the needle body to move forwards so as to enable the needle head to pierce out of the shell from the front end of the sliding sleeve is connected between the needle body and the bottom of the inner cavity of the shell. The forward press type blood collection device is simple in structure, easy to obtain, convenient to assemble and safe to use, and is provided with a small number of components.

Owner:中山瑞福医疗器械科技有限公司

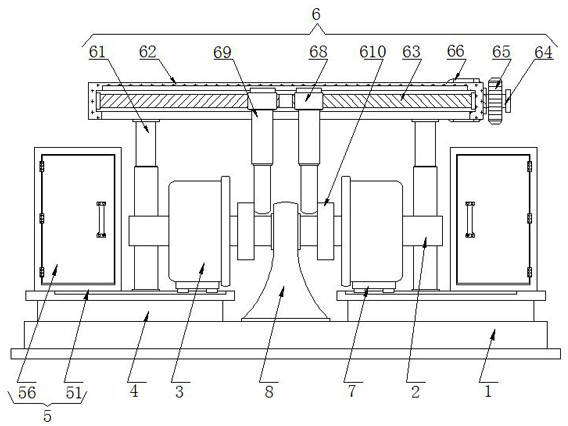

Draught fan rotor and paired wheel disassembly device

InactiveCN111673416AEasy to disassembleNo manual disassemblyMetal working apparatusRotor (electric)Industrial engineering

The invention discloses a draught fan rotor and paired wheel disassembly device and relates to the technical field of draught fans. The draught fan rotor and paired wheel disassembly device comprisesa base, a rotor shaft, a pair of wheels slidably connected to the two sides of the surface of the rotor shaft and fixing tables fixedly connected to the two sides of the top of the base. A storage assembly is arranged on one side of the top of each fixing table. A disassembling assembly is arranged on the other side of the top of each fixing table. Each disassembling assembly comprises a first electric push rod and a fixing frame, and the bottom end of each first electric push rod is fixedly connected with one side of the top of the corresponding fixing table. According to the draught fan rotor and paired wheel disassembly device, the rotor shaft with the pair of wheels is placed on a support frame, and two second electric push rods drive clamping blocks to move away from each other so asto enable the pair of wheels to move on the rotor shaft in the axial direction until the pair of wheels is disengaged from the rotor shaft. By the adoption of the disassembly device, convenient disassembly of the pair of wheels and the rotor shaft is achieved, no manual disassembly is needed, the operation is convenient, the disassembly efficiency is high, and certain potential safety hazards arereduced.

Owner:华电呼图壁能源有限公司热电厂

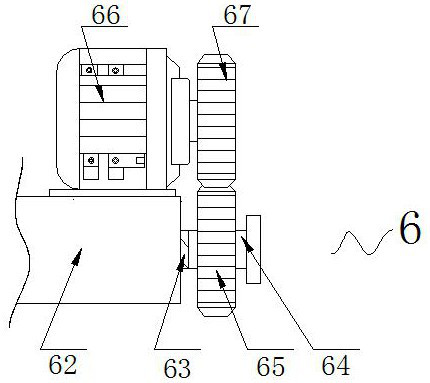

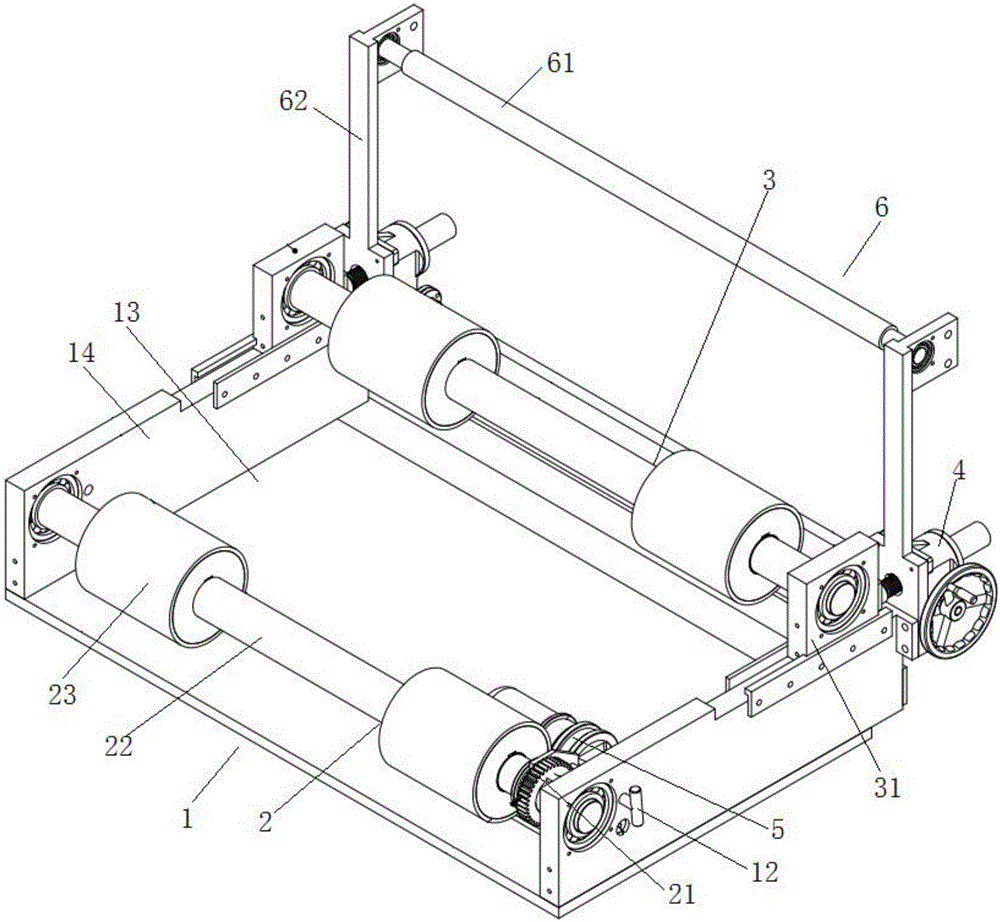

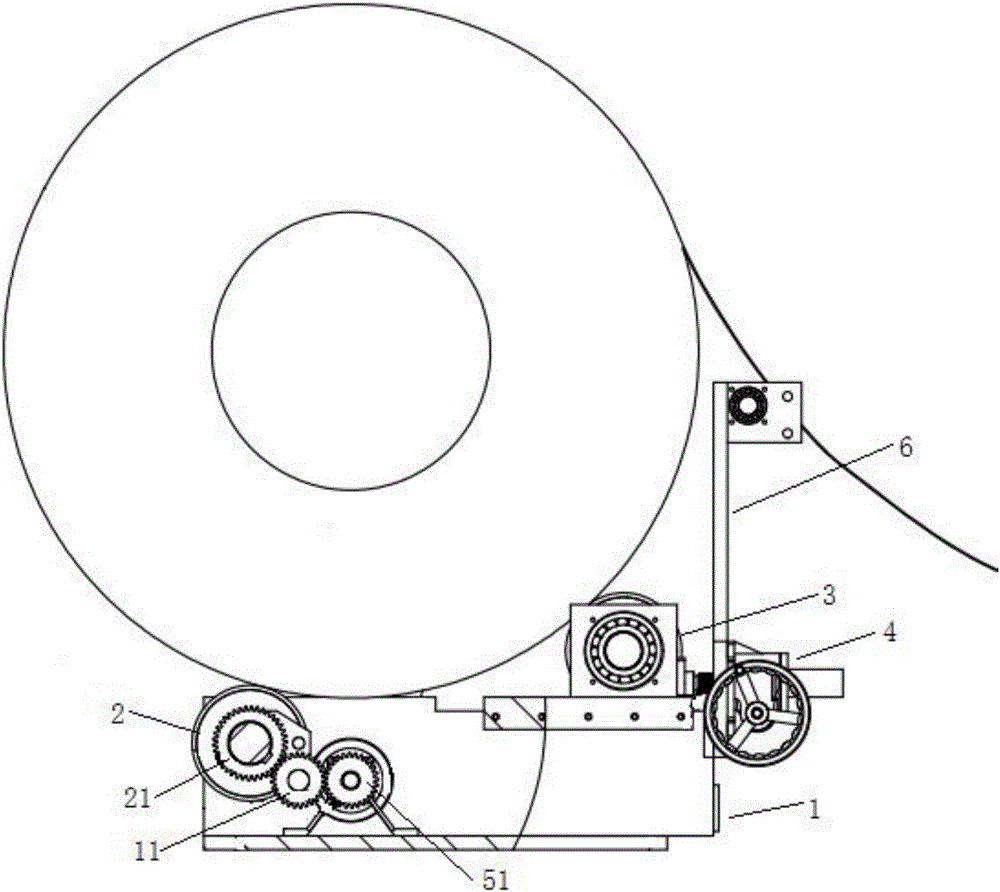

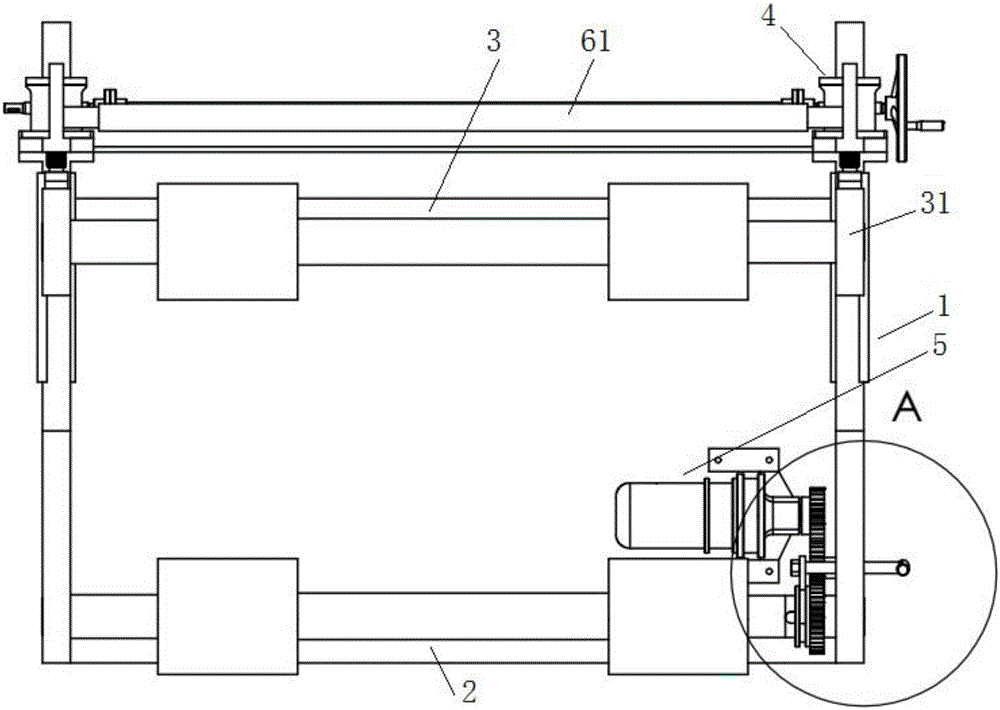

Uncoiling and discharging machine for coiled plates

The invention relates to an uncoiling and discharging machine for coiled plates. A first drum shaft assembly and a second drum shaft assembly are transversely arranged at intervals in parallel; the first drum shaft assembly is rotatably mounted on a mounting support; two ends of the second drum shaft assembly are slidably mounted on the mounting support through bearing blocks; power pushing devices are mounted on the mounting support, and can push the second drum shaft assembly to move horizontally along the mounting support so as to be close to or away from the first drum shaft assembly; a rotation driving device is mounted on the mounting support; a driving gear is arranged at a driving end of the rotation driving device; an intermediate gear is arranged on the mounting support and is engaged with the driving gear; the first drum shaft assembly is provided with a driven gear; and the driven gear can move along the first drum shaft assembly in the axial direction so that the driven gear is engaged with or separated from the intermediate gear. The uncoiling and discharging machine for coiled plates has the advantages that the structure is simple, the first drum shaft assembly is adjusted to actively or passively discharge materials according to usage requirements, the distance between the first drum shaft assembly and the second drum shaft assembly is adjusted, and therefore, the uncoiling and discharging machine for coiled plates is flexible and convenient to use.

Owner:安陆市华誉金属网机制造有限公司

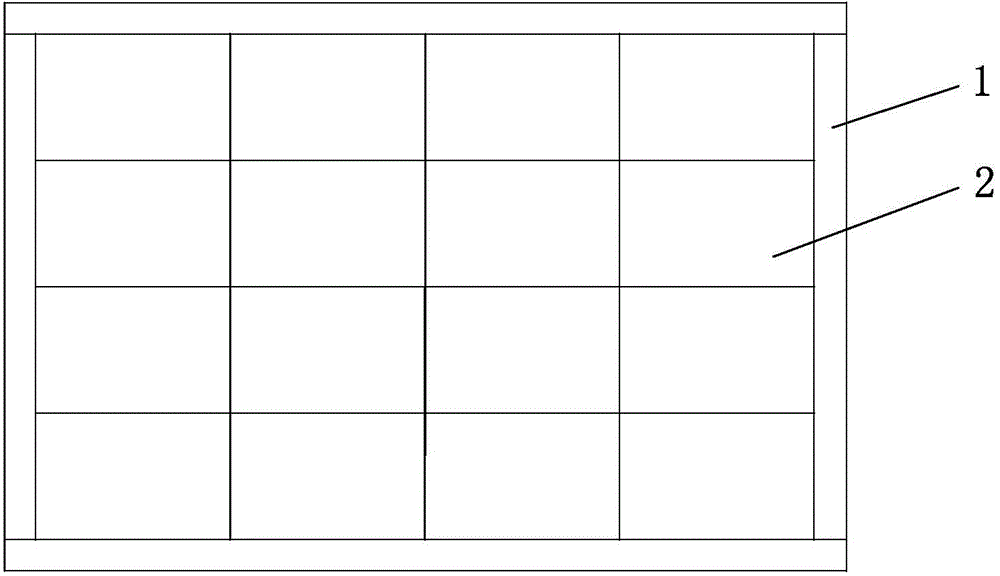

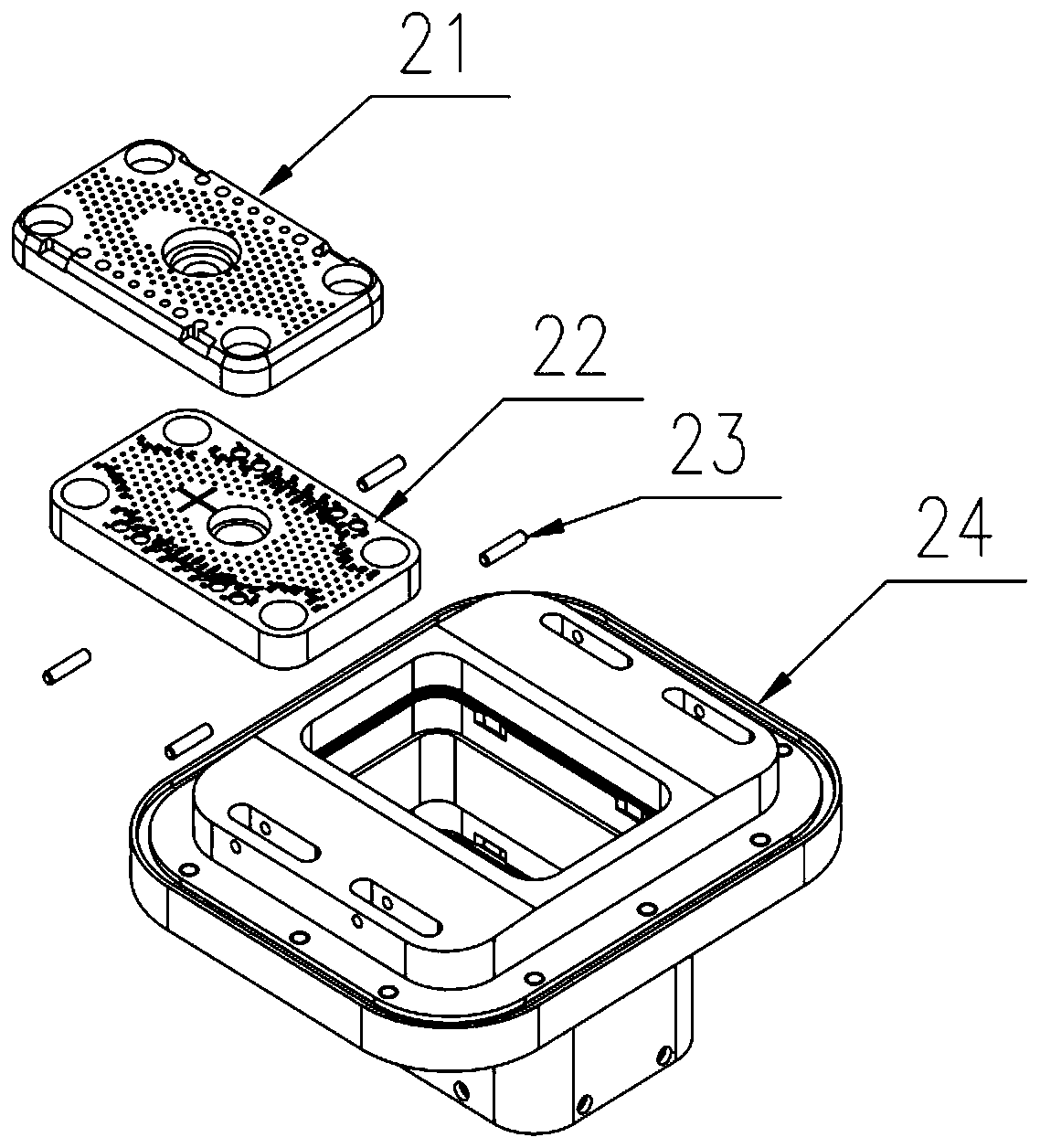

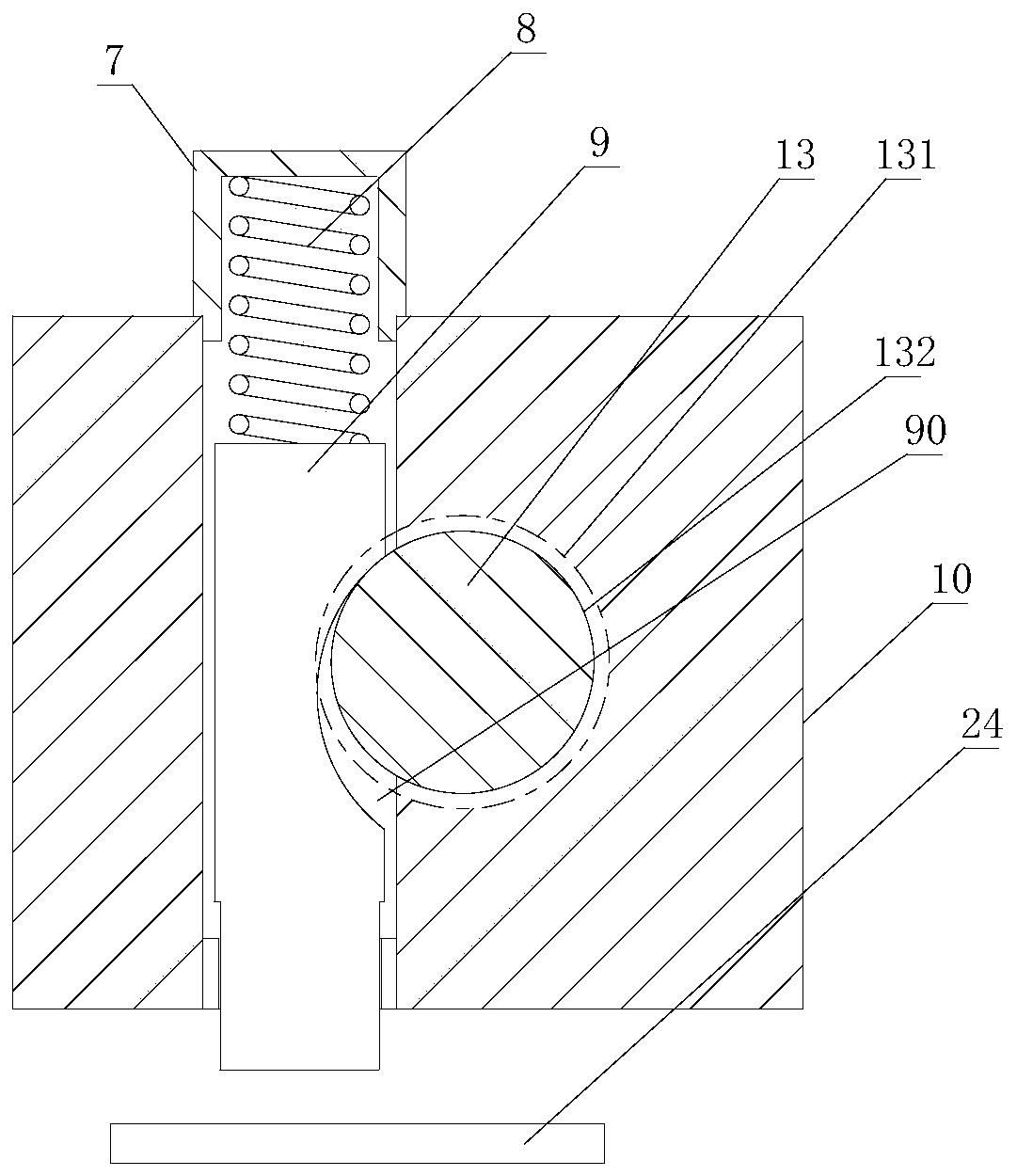

Rotatable pressing mould base

InactiveCN104149174AEasy to move axiallyAvoid breakingMouldsShaping press ramBrickMechanical engineering

The invention belongs to the field of refractory brick pressing moulds and relates to a rotatable pressing mould base. The rotatable pressing mould base comprises a pressing seat and a fixing component, the pressing seat is provided with a forming groove and a rotating shaft and capable of rotating on the fixing component through the rotating shaft, and a first connection block and a second connection block are arranged on the pressing seat. The fixing component comprises a fixing block body and a stepped block, the fixing block body is provided with a clamping groove and a positioning groove matched with the rotating shaft, the first connection block can be inserted into the clamping groove, the second connection block can be placed on the stepped block, the stepped block is fastened onto the fixing block body through an elastic locking device which comprises a lock rod extending outside the stepped block, and the lock rod is capable of axially moving to penetrate through the stepped block to be inserted into the fixing block body. Pressing mould manufacturing cost is reduced, and refractory brick forming quality is improved.

Owner:浙江立鑫高温耐火材料有限公司

Automatic side wall separating mechanism of electric connector

ActiveCN109764767AQuick lockEasy to useVehicular energy storageSelf-propelled projectilesEngineeringMechanical engineering

The invention relates to an automatic side wall separating mechanism of an electric connector. The side wall automatic separating mechanism comprises a plug and a socket, wherein the socket comprisesa socket shell and a locking pin, and the plug comprises an outer shell, a plug cable cover, a fixing frame and a plug shell; the plug cable cover is fixedly connected in the fixing frame, and a clamping hook matched with the locking pin is arranged on the outer shell. The automatic side wall separating mechanism of the electric connector is characterized in that the clamping hook is arranged on the outer shell and the locking pin is arranged on the socket, when the plug and the socket can be plugged, only the downward insertion force needs to be applied to the outer shell, when the plug is incontact with the socket, a locking block is subjected to upward pressure, a pressure spring is compressed, when a groove is matched with a moving end, a guide rod moves leftwards under the acting force of a spring, the outer shell moves leftwards along with the guide rod, and when the clamping hook on the outer shell clamps the locking pin, the plug and the socket can be locked. The automatic side wall separating mechanism has the advantages of being capable of automatically separating along with elasticity, high in reliability and convenient to use.

Owner:杭州航天电子技术有限公司

An adjustable fracture reducer

ActiveCN111743613BPlay a blocking roleEasy to adjustExternal osteosynthesisFracture reductionStructural engineering

The invention discloses an adjustable fracture reducer, which comprises a first guide rod, a second guide rod and a first half-ring fixing plate. One side of the first guide rod is movably connected with a first half-ring fixing plate. One side of the ring fixing plate is movably connected with a second guide rod, the top of the first guide rod is connected with a first semi-circular needle seat, the bottom side of the first guide rod is movably connected with a second half ring fixing plate, and the second The top of the half-ring fixing plate is fixedly connected with the second semi-annular needle seat, and there is a needle seat chute inside the second half-annular needle seat. The user can rotate the nut to loosen the connection between the needle holder and the needle seat chute, and manually Move the needle holder to a fixed position, so that the needle holder moves in the needle seat slide groove, which is convenient for adjusting the insertion position of the needle. The connecting plate is vertically arranged in the middle of the half-arc plate, which is convenient for the user to follow the position of the connecting plate. Adjusting the angle of the needle holder is suitable for the use of fracture reduction, and has broad development prospects in the future.

Owner:THE AFFILIATED HOSPITAL OF SHANDONG UNIV OF TCM

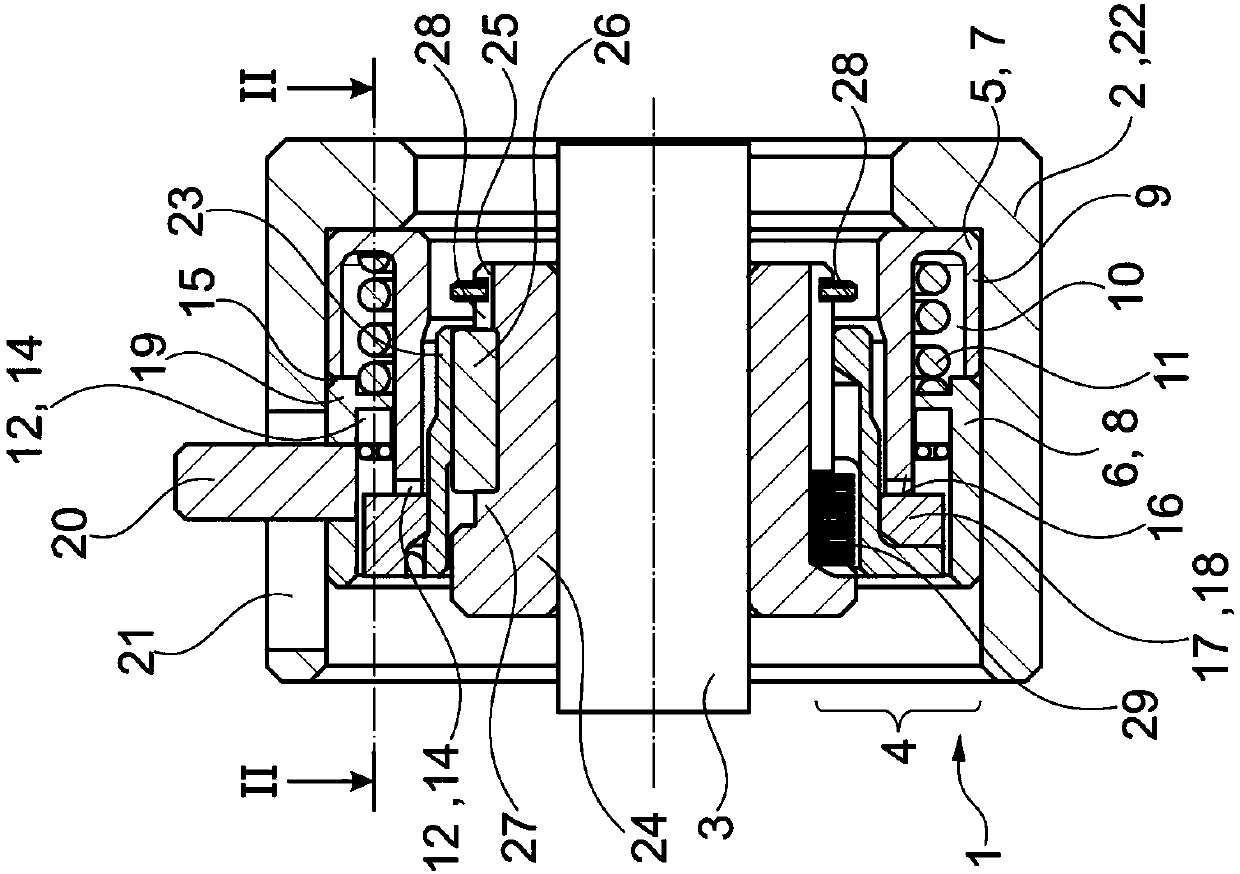

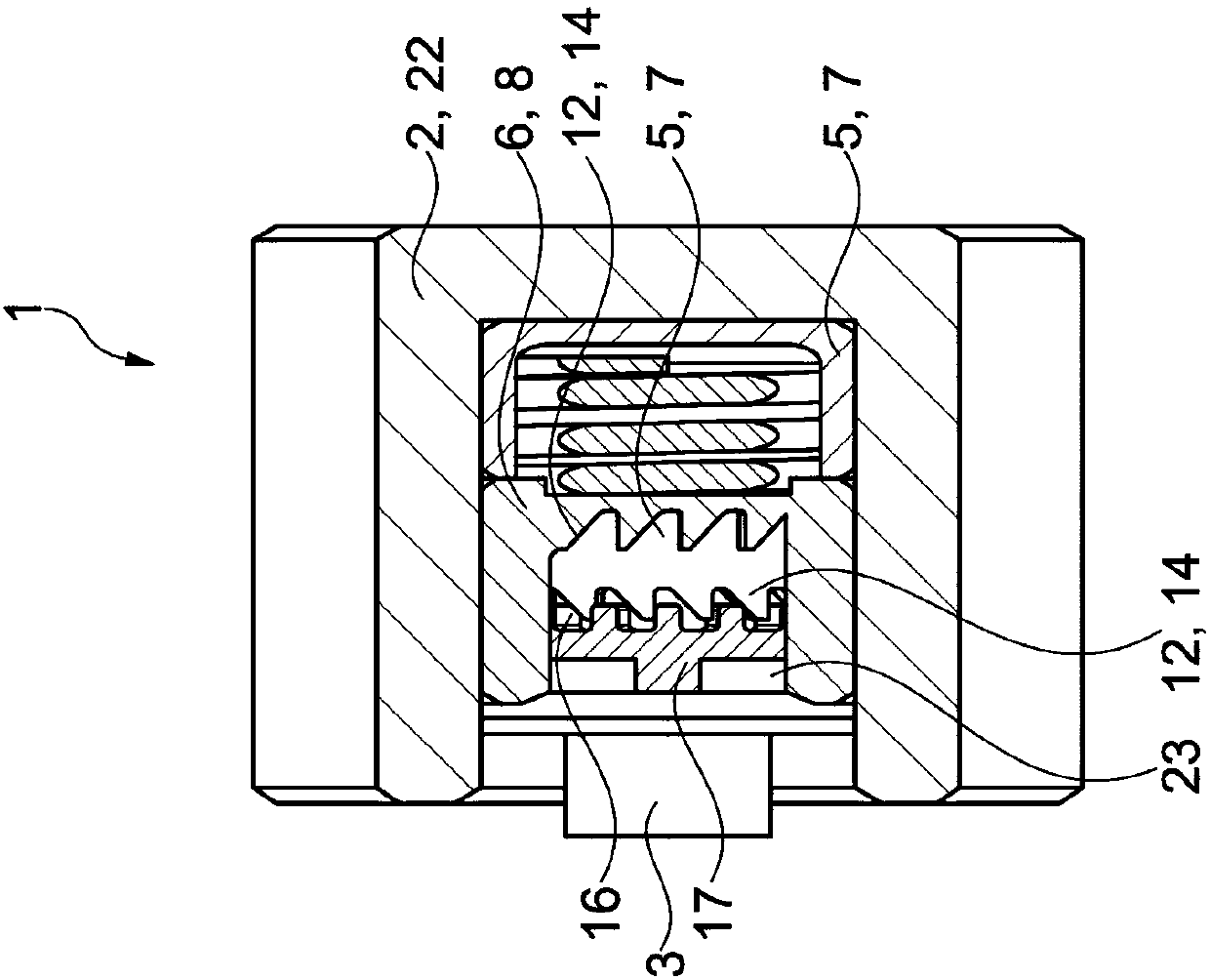

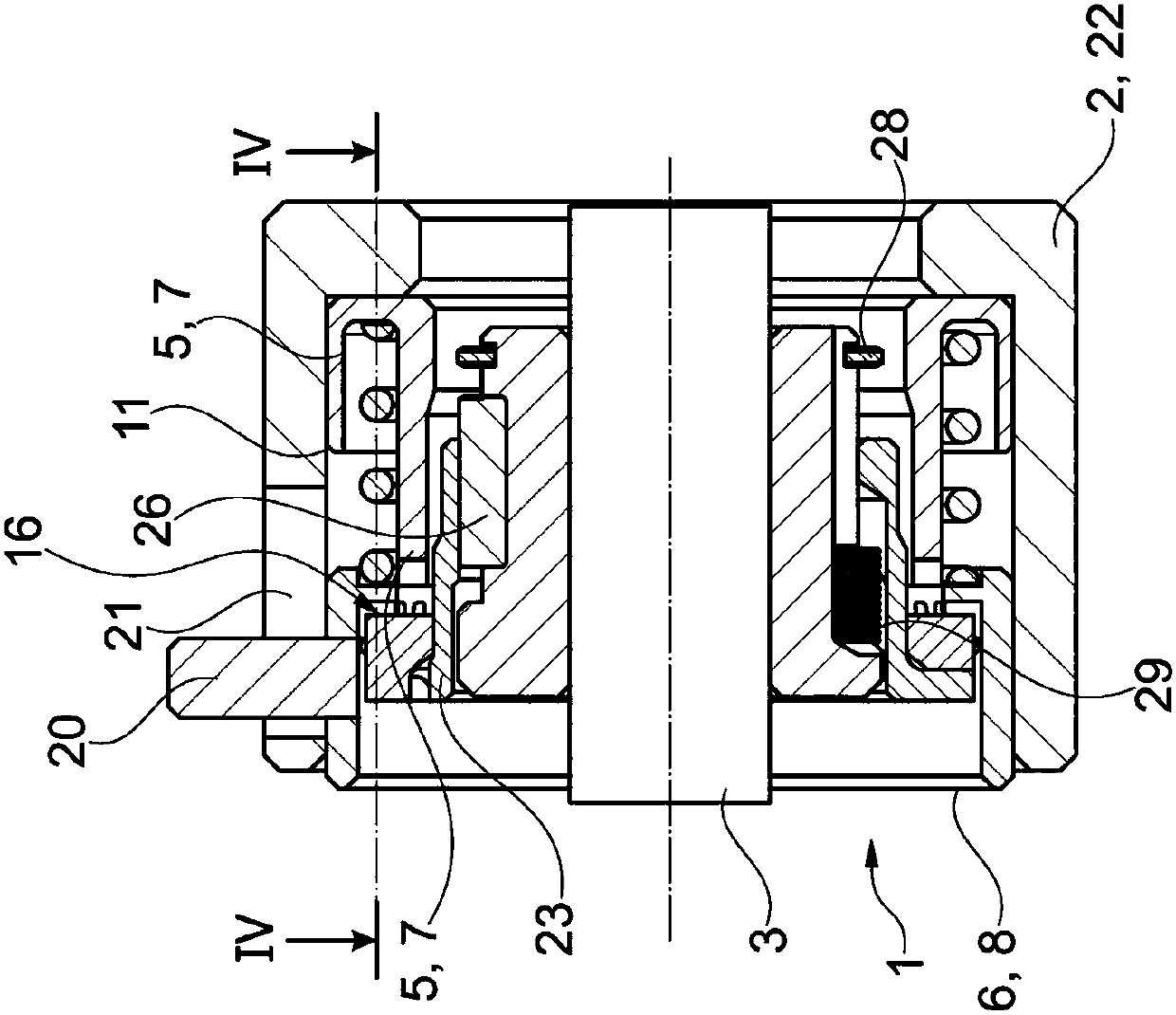

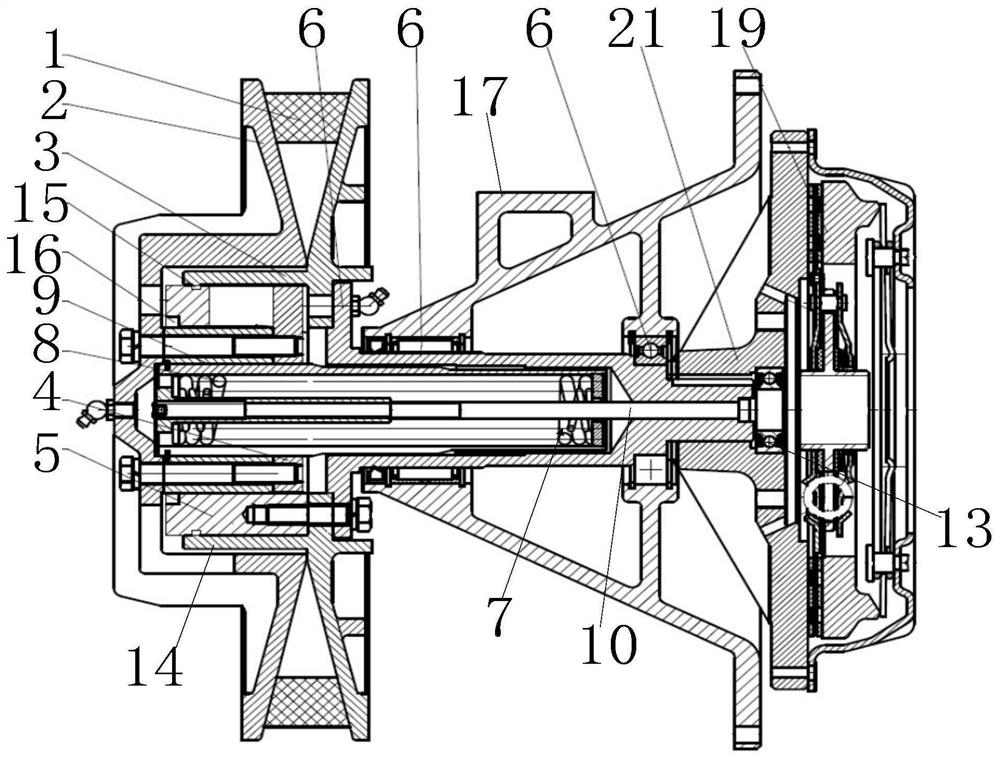

Space-saving ratchet unit with freewheel

The invention relates to a ratchet (1) for a medical device (30), comprising a torque-guiding element (2) and a torque discharging element (3), between which a switchable toothed unit (4) is arrangedso that, in accordance with a switching position of the toothed unit (4), torque from the torque-guiding element (2) is transferred to the torque discharging element, said toothed unit (4) comprises two torque transfer sleeves (5, 6) arranged in a nested manner and which are arranged and produced such that both can be brought into torque-transmitting contact with an intermediate sleeve (17). The invention also relates to a medical device (30) comprising a ratchet of said type (1).

Owner:AESCULAP AG

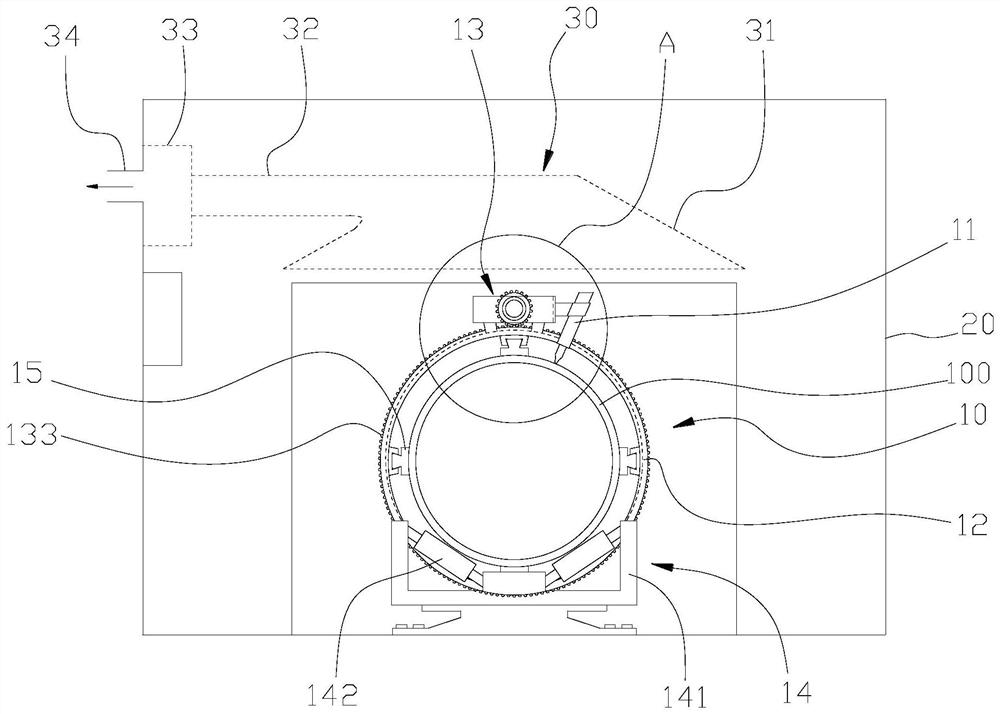

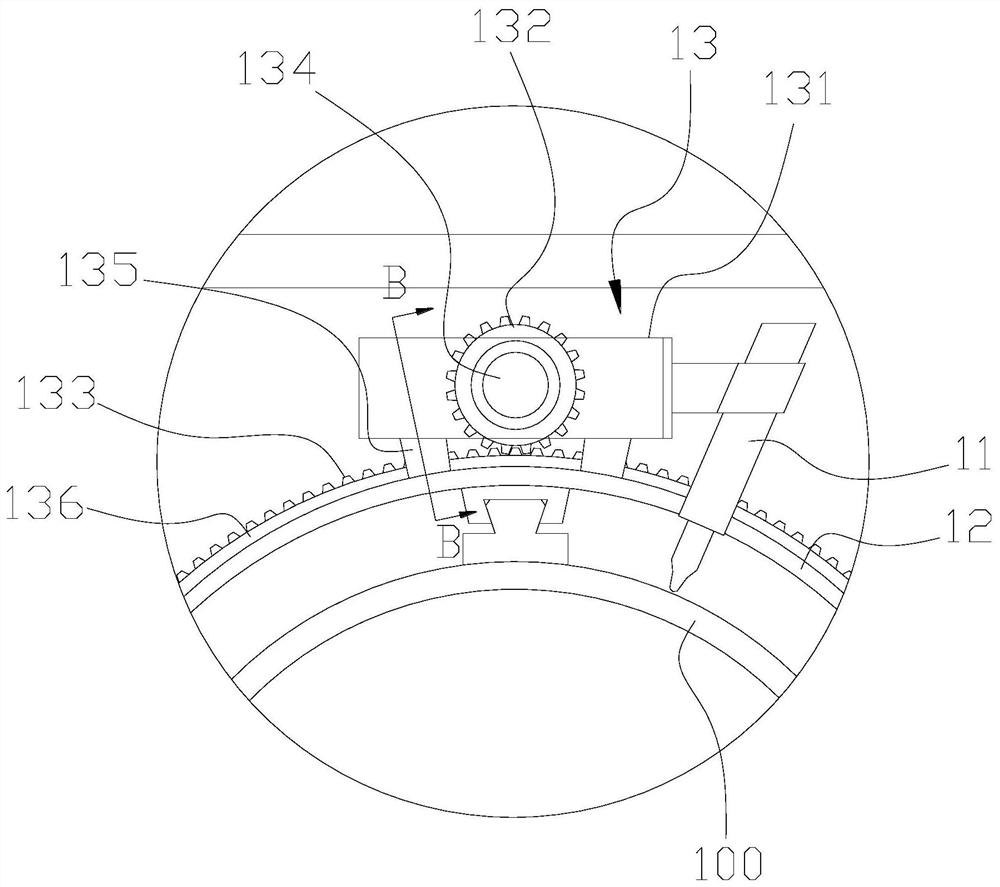

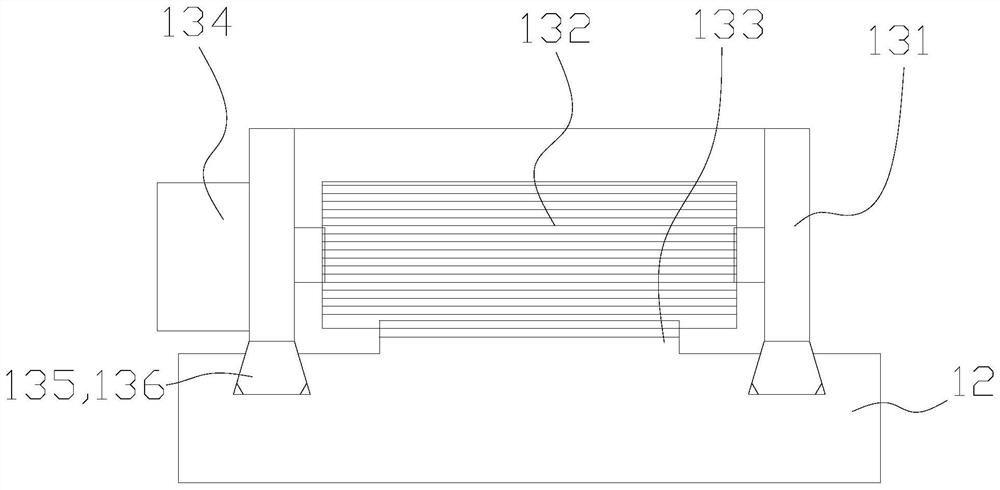

Welding chamber device

PendingCN112570936AAvoid influenceSafe operating spaceWelding/cutting auxillary devicesDirt cleaningStructural engineeringMechanical engineering

The invention discloses a welding chamber device. The welding chamber device comprises a shed chamber and a welding device, wherein the shed chamber is arranged in a channel, and the shed chamber comprises a frame and shed cloth attached to the frame; the welding device is arranged in the shed chamber, and the welding device comprises a ring body allowing a pipeline to penetrate through and a welding gun moving in the circumferential direction of the ring body, wherein the pipeline to be welded is in butt joint with the ring body, and the gun head of the welding gun faces the butt joint position of the pipeline so as to weld the pipeline. According to the welding chamber device, the shed chamber is additionally arranged, so that a safe operation space is provided for welding operation, andthe large influence on the welding operation due to channel collapse can be effectively avoided.

Owner:LANGFANG CNPC KUNLUN PIPELINE ENG

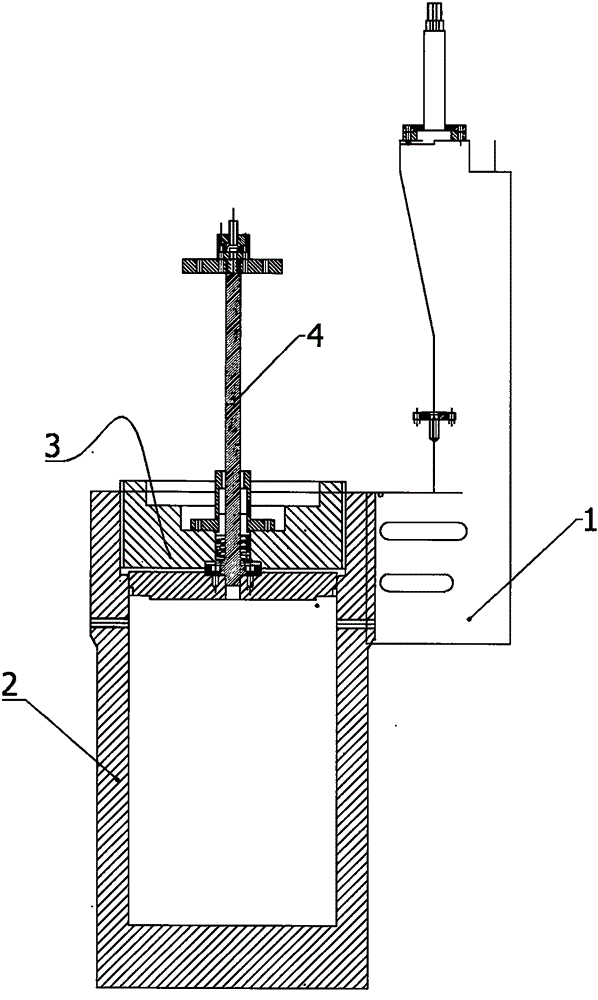

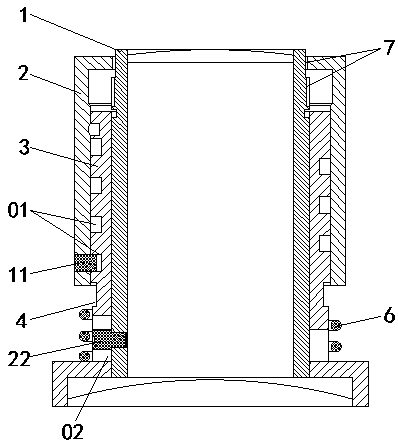

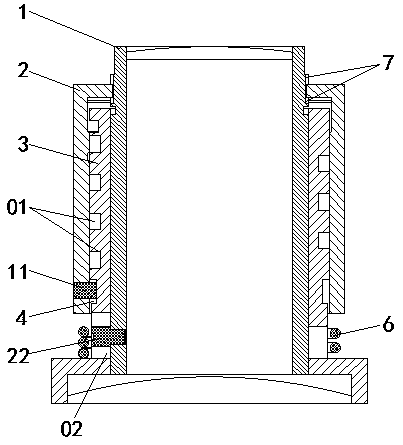

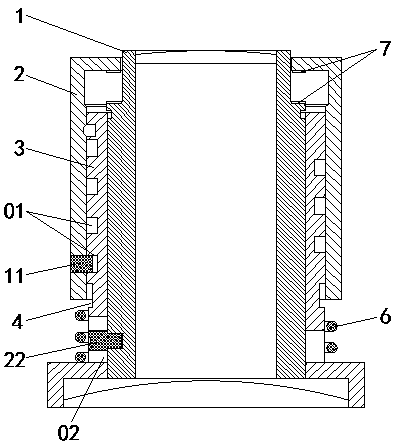

Vertical cold isostatic press

Owner:陈烈

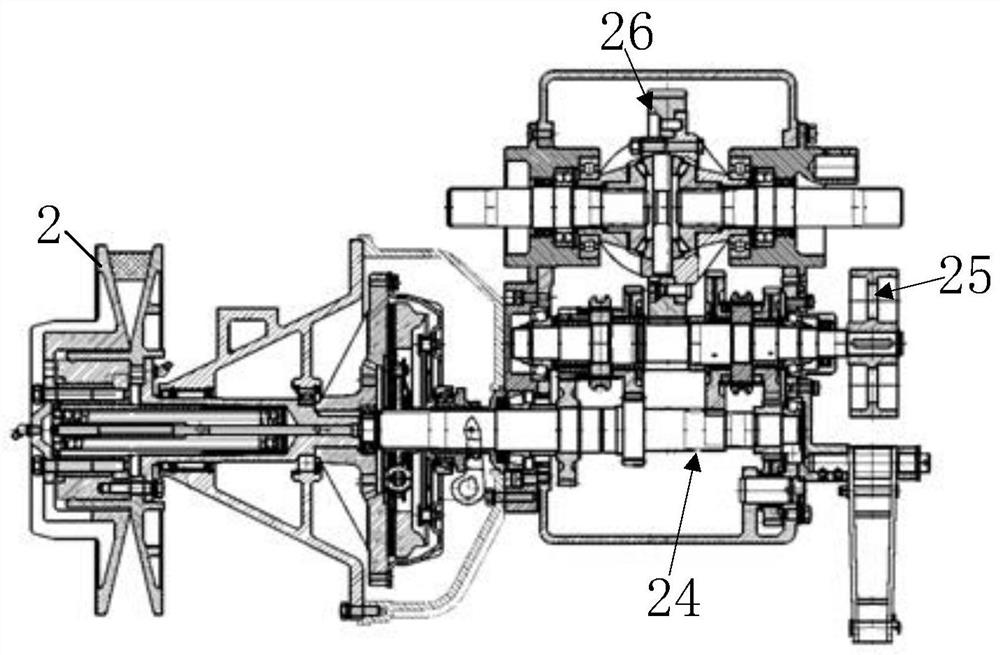

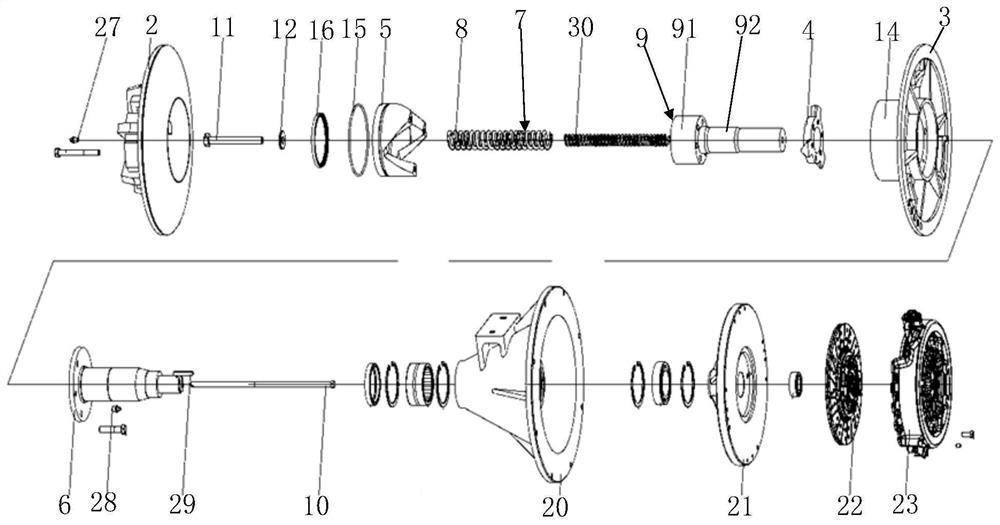

Speed changer and harvester

PendingCN113417981AReduce frequent shifting processEasy to installHarvestersGearingElastic componentEngineering

The invention provides a speed changer and a harvester. The speed changer comprises a movable disc, a fixed disc, a sliding cam, a fixed cam, an elastic part used for resetting the relative position of the movable disc and the fixed disc, a support and an input shaft assembly, the movable disc is arranged on the fixed disc in an axial moving mode through the elastic part, so that the movable disc axially moves in the direction close to the fixed disc. The movable disc is fixedly connected with the sliding cam, the fixed disc is connected with the fixed cam, the sliding cam is meshed with the fixed cam and has the stroke of sliding relative to the axial direction, the input shaft assembly is rotatably arranged on the support, and one end of the input shaft assembly is connected with the fixed disc. The movable disc can move axially relative to the fixed disc, the distance between the movable disc and the fixed disc is adjusted in a self-adaptive mode, and the adaptability of the harvesting machine to different working conditions is improved.

Owner:山东潍柴雷沃传动有限公司

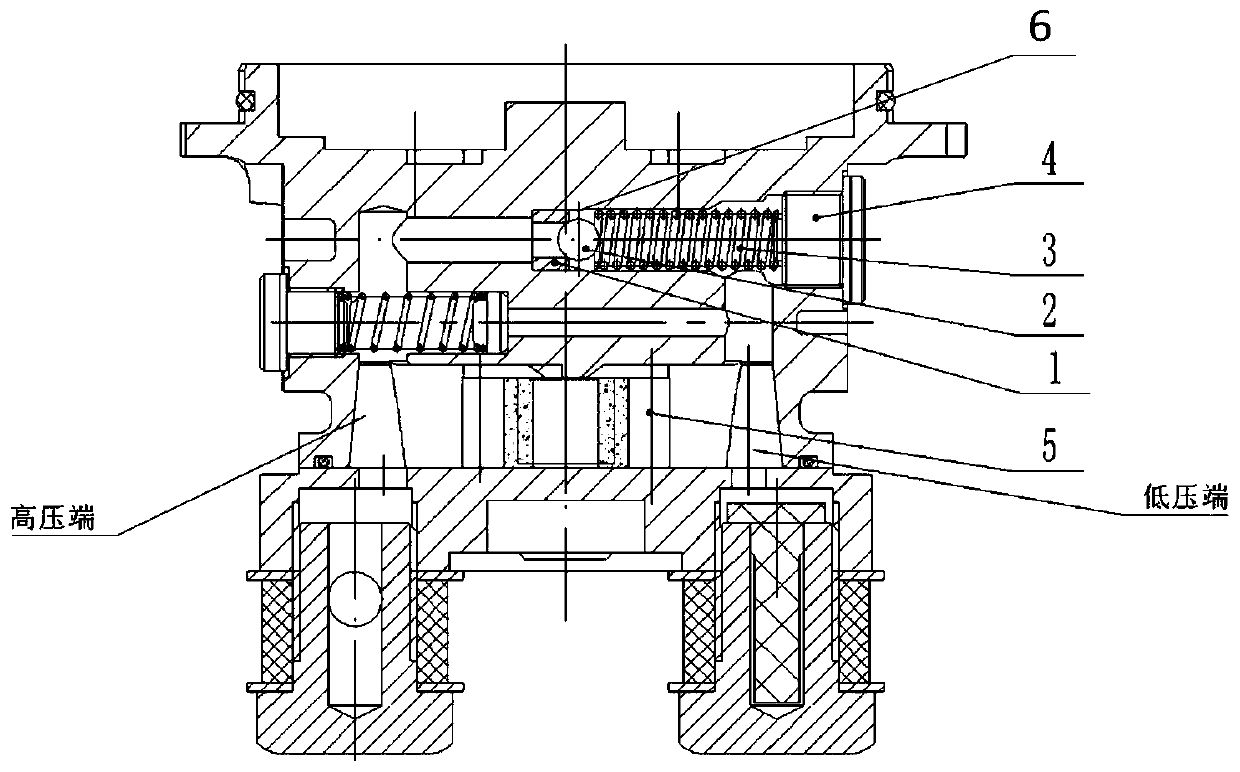

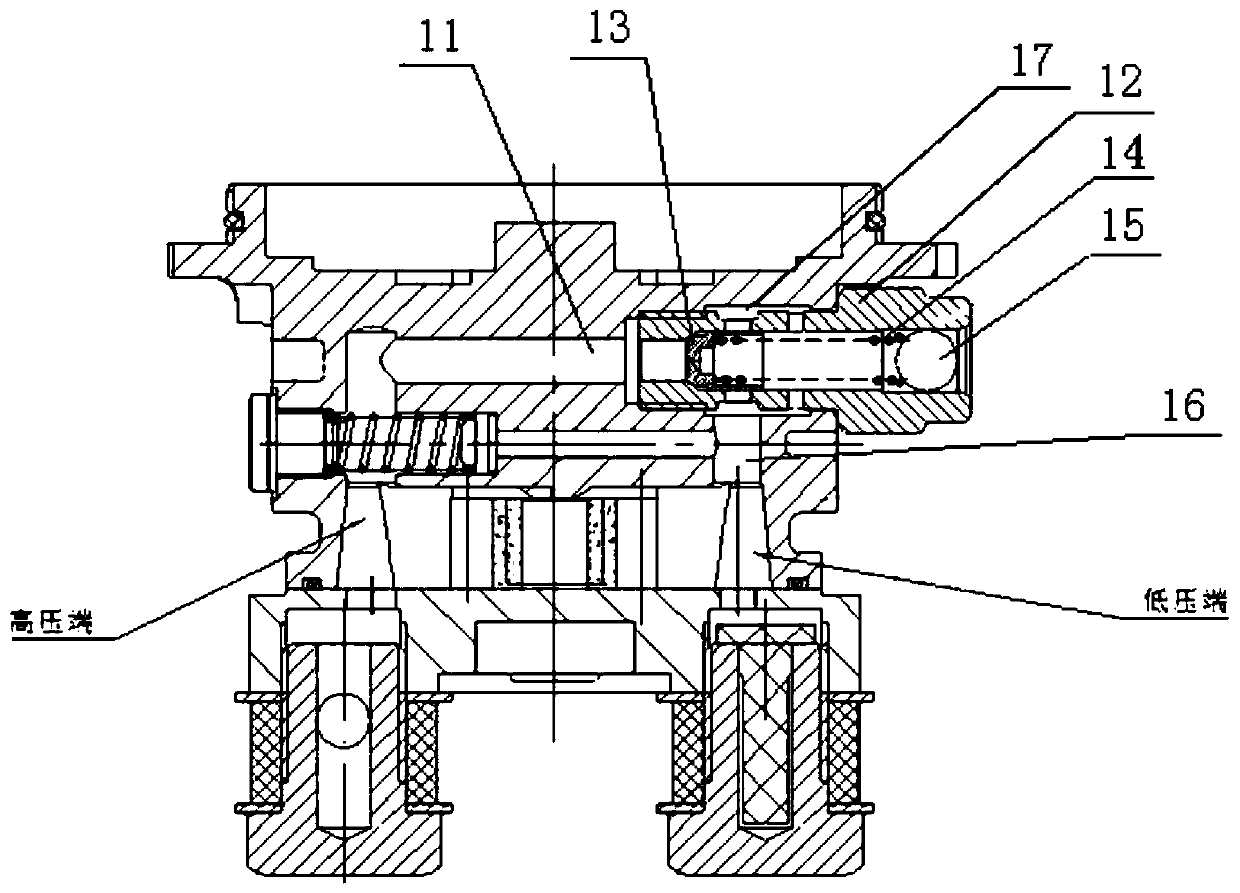

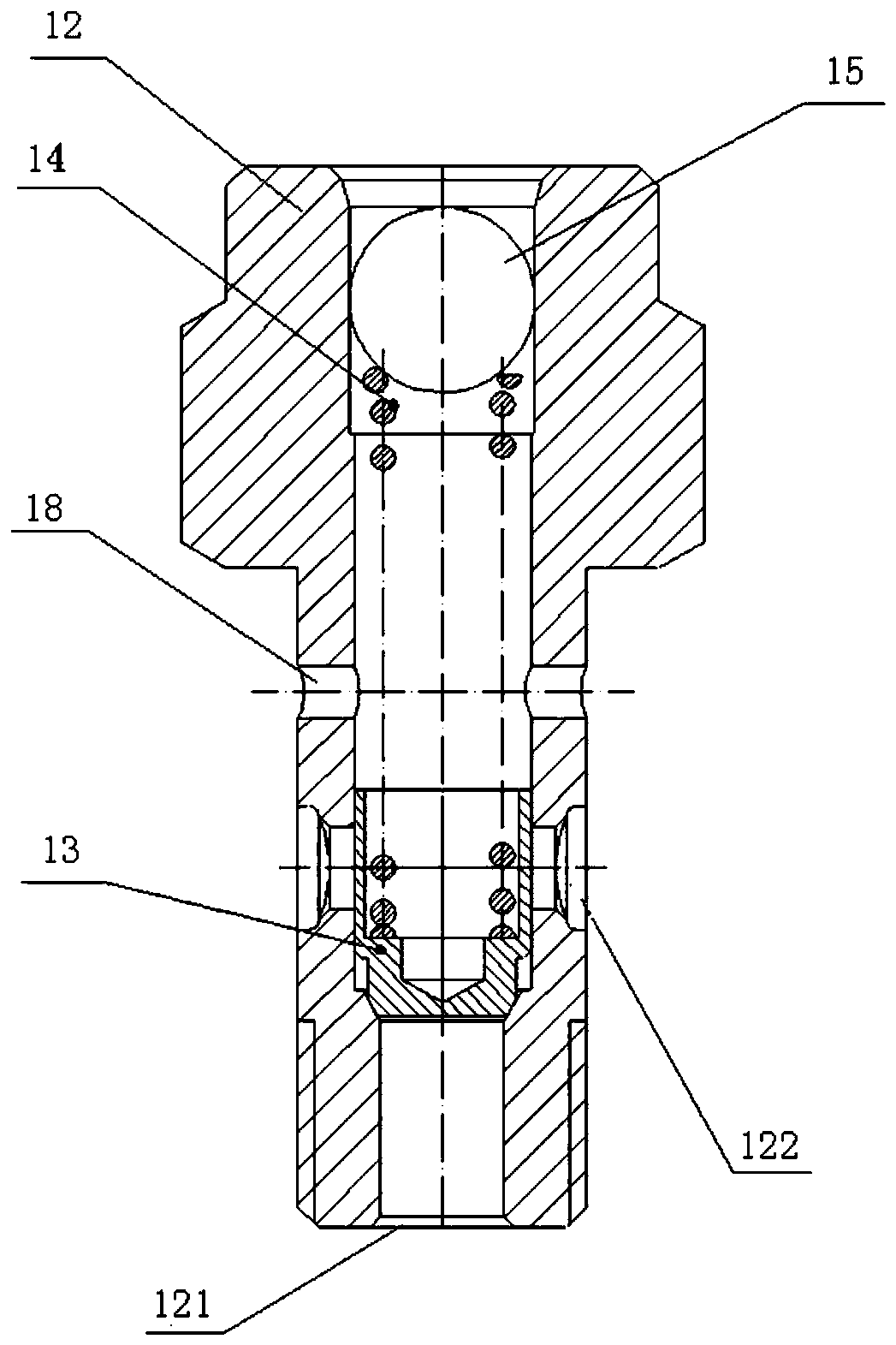

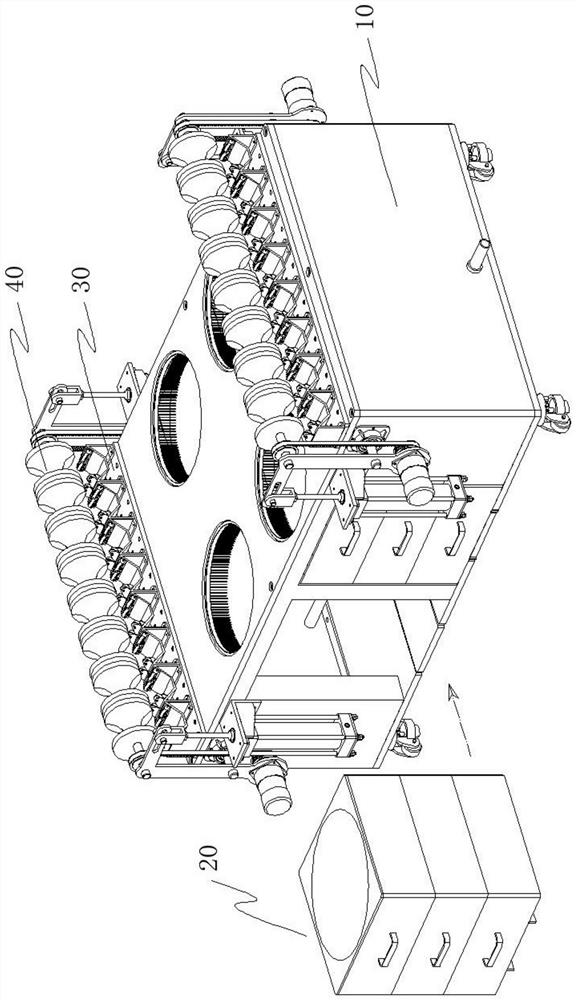

High pressure common rail fuel delivery pump with adjustable pressure and flow rate

PendingCN111396222ARealize regulationEasy to controlMachines/enginesFuel injecting pumpsSpool valveCommon rail

The invention discloses a high pressure common rail fuel delivery pump with the adjustable pressure and flow rate. The pump comprises a regulating slide valve arranged on a high pressure end fuel channel in a pump body. The regulating slide valve comprises a slide valve body, a slide valve element, an overflow spring and a retaining plug. The slide valve body is fixed to the high pressure end fuelchannel and is a hollow pipe, wherein one open end of the hollow pipe communicates with the high pressure end fuel channel, and an oil draining hole is formed in the pipe wall of the hollow pipe andcommunicates with a low pressure end fuel input channel in the pump body. The slide valve element, the overflow spring and the retaining plug are sequentially arranged inside the hollow pipe. The slide valve element is a cylindrical piston. The slide valve element moves axially along the hollow pipe under the double effects of fuel pressure and the overflow spring, the opening and closing action of the oil draining hole and the opening section area of the oil draining hole are controlled, and the fuel pressure and flow rate are adjusted. According to the high pressure common rail fuel deliverypump provided by the invention, by arranging the regulating slide valve on the high pressure end fuel channel of the pump body, the high pressure end fuel pressure and flow rate are adjusted and controlled, a traditional ball valve structure is successfully replaced, and the energy consumption is reduced.

Owner:北油电控燃油喷射系统(天津)有限公司

Cutting platform for glass fiber reinforced plastic products

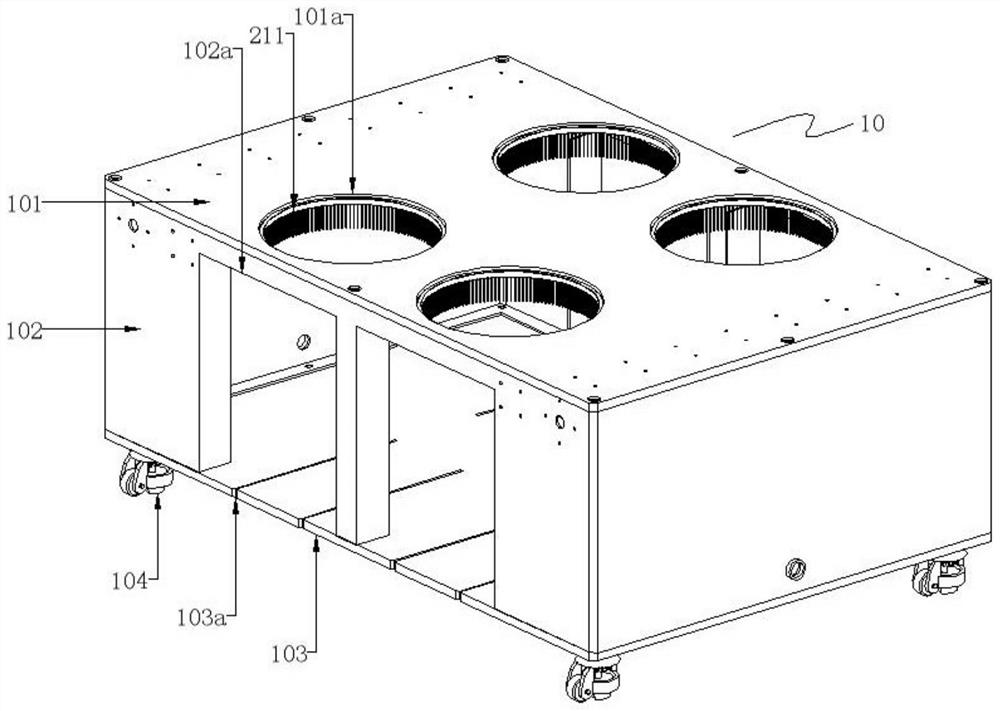

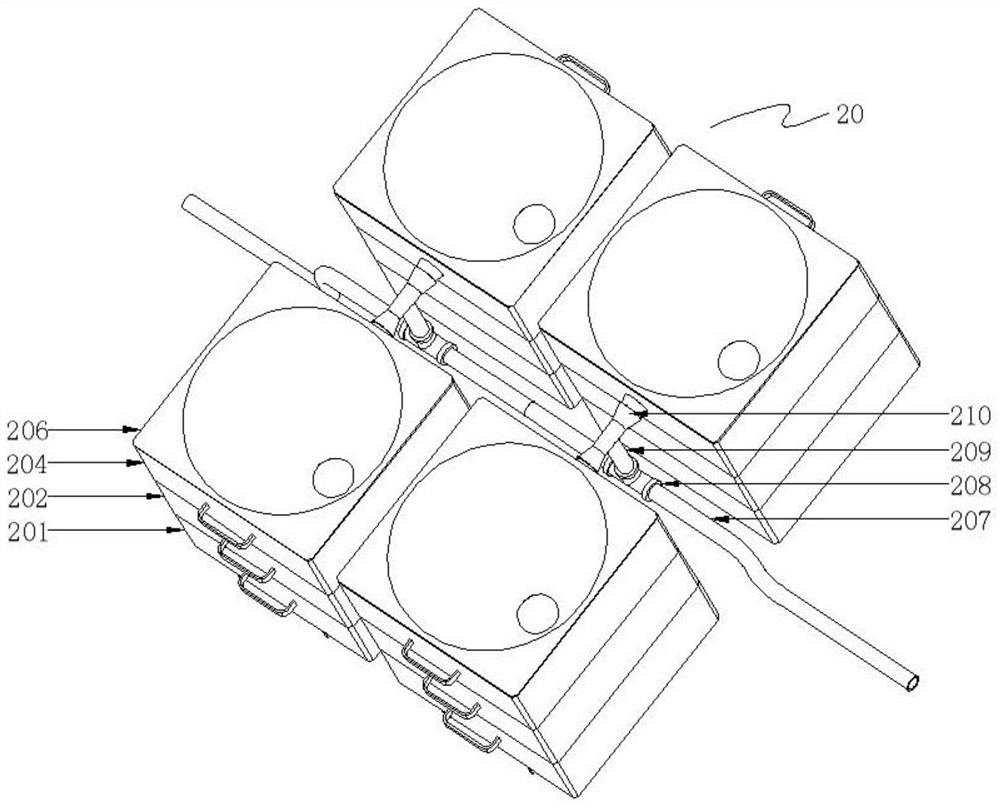

InactiveCN113547570ARapid positioningEasy to move axiallyMetal working apparatusGlass fiberEngineering

The invention discloses a cutting platform for glass fiber reinforced plastic products, and relates to the technical field of glass fiber reinforced plastic machining. The cutting platform comprises a supporting assembly, a scrap collecting assembly, positioning assemblies and clamping assemblies, wherein the supporting assembly specifically comprises a supporting top plate, a supporting cabinet body, a supporting bottom plate and footmaster wheels; and the scrap collecting assembly is centrally located on the inner side of the supporting cabinet body and used for collecting dust and scraps generated by cutting during cutting of the glass fiber reinforced plastic products, the positioning assemblies are symmetrically located on the left side and the right side of the supporting top plate and used for positioning the glass fiber reinforced plastic products during cutting of the glass fiber reinforced plastic products, and the clamping assemblies are symmetrically located on the left side and the right side of the supporting cabinet body and used for clamping the glass fiber reinforced plastic products when the glass fiber reinforced plastic products are cut. The cutting platform for the glass fiber reinforced plastic products has the advantages of being ingenious in design, reasonable in structure and convenient to use, the glass fiber reinforced plastic products can be rapidly positioned and rapidly clamped when cut, dust and scraps generated during cutting can be effectively collected, and manual participation is avoided.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Telescope diopter focusing structure

PendingCN111413776AEasy to move axiallyConvenient card connectionTelescopesMountingsEyepieceEngineering

The invention discloses a telescope diopter focusing structure, which comprises a fixedly-arranged eyepiece seat. A movable eyeshade which axially moves relative to the eyepiece seat is coaxially arranged on the outer side of the eyepiece seat, and an eyepiece frame which axially moves relative to the eyepiece seat is coaxially arranged on the inner side of the eyepiece seat. An avoiding annular groove for limiting the axial movement of the movable eyeshade is formed between the eyepiece seat and the movable eyeshade; a movable clamping part connected or disconnected along with the axial movement of the movable eyeshade is arranged between the movable eyeshade and the eyepiece frame. On the premise that a hand wheel and a connecting structure of the hand wheel are not arranged, the focusing structure is simpler and more compact, meanwhile, convenient and rapid focusing is achieved, and meanwhile focusing misoperation caused by touch is effectively avoided.

Owner:成都赛诺特光学有限公司

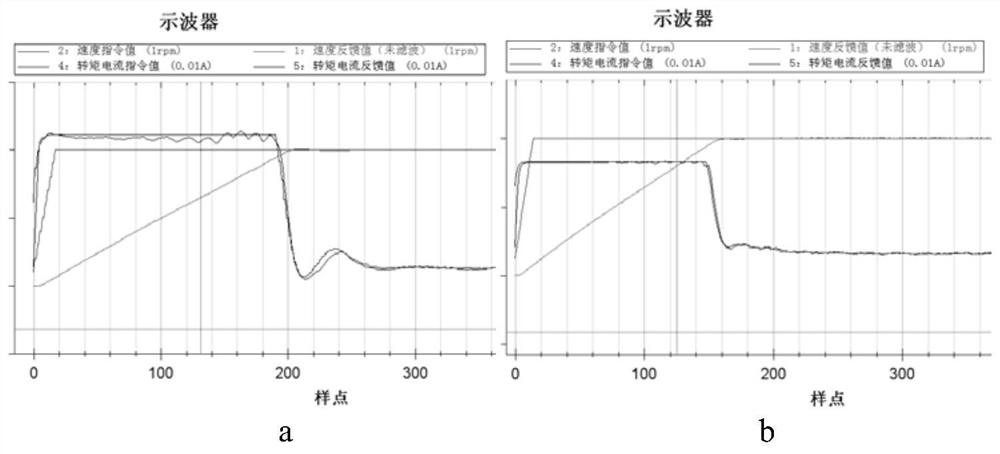

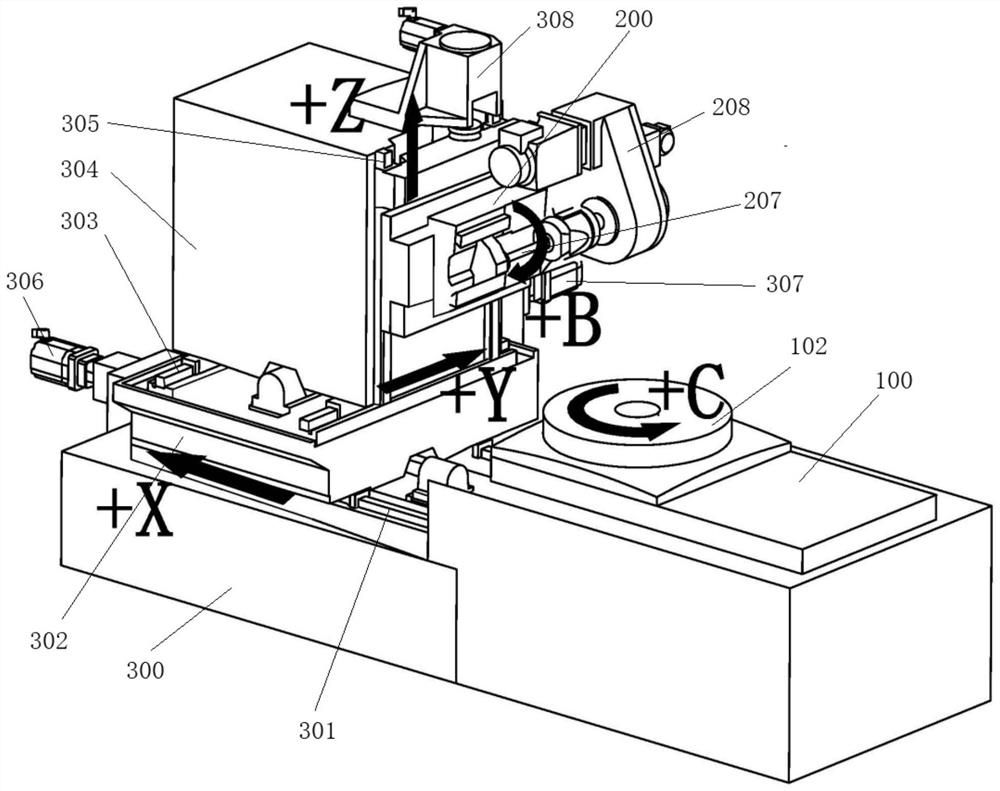

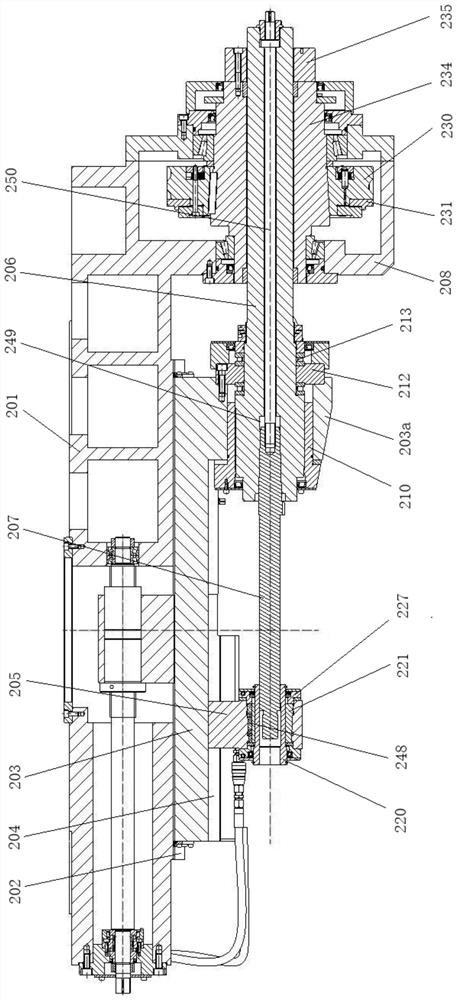

Worm gear machine tool

PendingCN112975469AAchieve replacementEasy to move axiallyFeeding apparatusPositioning apparatusMachine toolWorkbench

The invention discloses a worm gear machine tool. The worm gear machine tool comprises a workbench used for clamping a worm gear workpiece, a tool rest used for clamping a tool and a tool rest adjusting system used for adjusting the position of the tool rest relative to the workbench; the tool rest comprises a large bracket, a first sliding rail is arranged on the large bracket, a sliding seat in sliding fit with the first sliding rail is arranged on the first sliding rail, a second sliding rail is arranged on the sliding seat, a small bracket in sliding fit with the second sliding rail is arranged on the second sliding rail, and the first sliding rail is parallel to the second sliding rail; a tool rest main shaft is arranged between the large bracket and the sliding seat, a knife bar synchronously rotating with the tool rest main shaft is arranged between one end, facing the small bracket, of the tool rest main shaft and the small bracket, and a gear box used for driving the tool rest main shaft to rotate is arranged in the large bracket; and a first hydrostatic bearing mechanism is arranged between the sliding seat and the tool rest main shaft, and a second hydrostatic bearing mechanism is arranged between the tool bar and the small bracket.

Owner:CHONGQING UNIV

Press type blood collection needle device

InactiveCN104983431AEasy to move axiallyLess componentsDiagnostic recording/measuringSensorsBiomedical engineeringBlood collection

The invention discloses a press type blood collection needle device which comprises a shell, a sliding sleeve and a needle body. A needle head is arranged at the front end of the needle body. A first guide limiting channel where the sliding sleeve axially moves is arranged in an inner cavity of the shell and enables the front end of the sliding sleeve to stretch out of the shell. A second guide limiting channel where the needle body axially moves is arranged in the sliding sleeve and enables the needle head to stretch out of the front end of the sliding sleeve. The needle body is provided with an elastic expanding arm which expands towards the front end of the inner cavity of the shell. The rear wall of the sliding sleeve is provided with a notch groove used for limiting the end of the elastic expanding arm during assembling. A disengagement rod which is used for enabling the elastic expanding arm on the needle body to be disengaged from the notch groove and to enter the second guide limiting channel when the front end of the sliding sleeve retracts into the shell is arranged in the shell. A spring used for pushing the needle body to move forwards so as to enable the needle head to pierce out of the shell from the front end of the sliding sleeve is arranged between the needle body and the bottom of the inner cavity of the shell. The press type blood collection needle device is simple in structure, easy to obtain, convenient to assemble and safe to use, and is provided with a small number of components.

Owner:中山瑞福医疗器械科技有限公司

A pipeline crawling device

ActiveCN112452971BSimplify dredging operationsImprove dredging effectHollow article cleaningDirt cleaningHigh pressure waterSewage

The invention provides a pipeline crawling device, which includes a pipeline support frame, a pipeline support mechanism for supporting the inner wall of the pipeline is fixedly arranged on the outer wall of the pipeline support framework, and a flushing mechanism is also arranged on the pipeline support framework, and the flushing mechanism Including the steel pipe, the steel pipe is fixedly connected to the pipeline support frame, the end of the steel pipe is provided with a high-pressure water flushing port, the axial direction of the steel pipe is the same as the traveling direction of the pipeline support frame, and a sewage suction pipe is also arranged in the pipe support frame. device, the sewage suction port of the sewage suction device is located on the same side as the high-pressure water flushing port. The invention provides a pipeline crawling device which can perform pipeline flushing and dirt suction at the same time, crawls in the pipeline with high stability, has strong pipeline support, and prevents the device from turning over.

Owner:HUBEI PETROKH MACHINE MFG

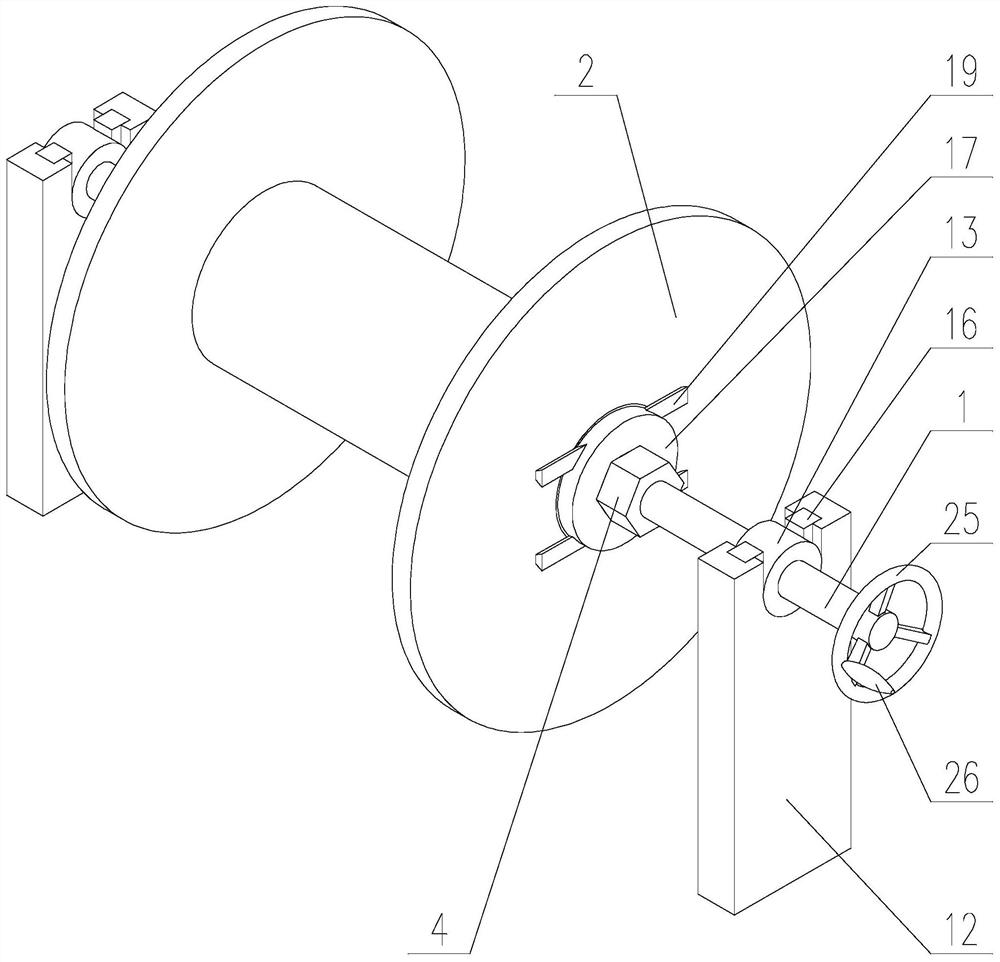

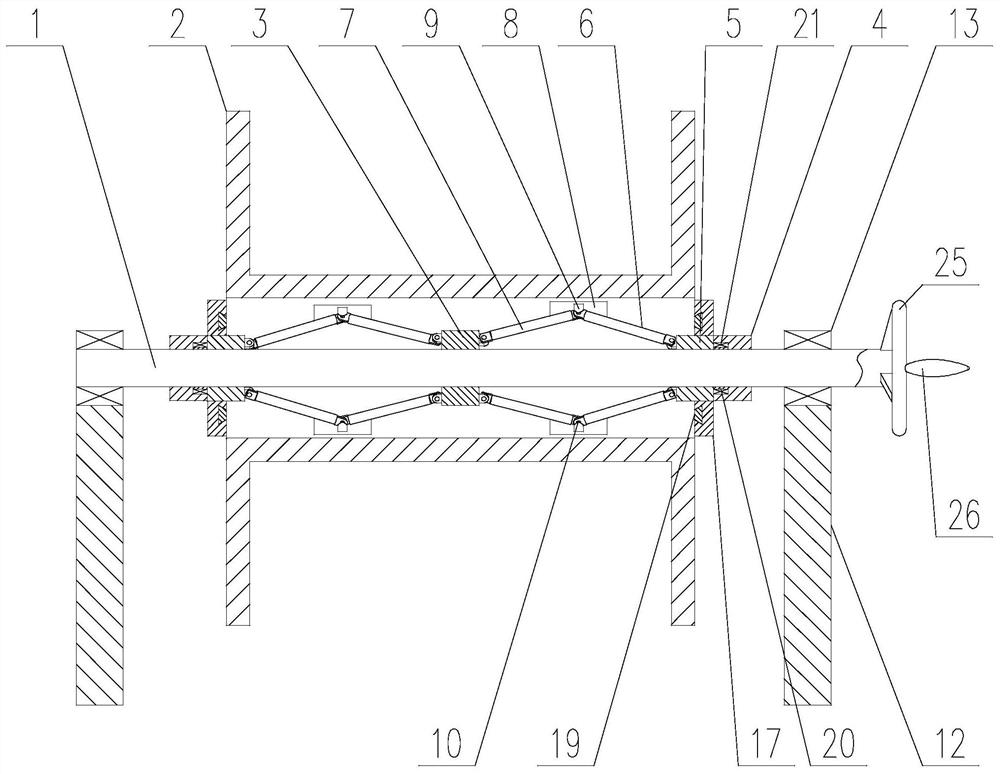

A mechanism real gold color steel plate production line

ActiveCN110014303BIncrease productivityImprove convenienceOther manufacturing equipments/toolsMetal working apparatusPolystyreneStructural engineering

The invention discloses a machine-made thermosetting polystyrene foamed plastic color steel plate production line, comprising a composite board all-in-one machine and a machine-made thermosetting polystyrene foamed plastic color steel plate cutting machine; a steel coil feeding device is arranged on the composite board all-in-one machine; the steel coil feeding device comprises a rotary shaft, supporting assemblies and a reel; a middle ring sleeves the middle part of the rotary shaft; pushing assemblies are arranged on two sides of the middle ring; each pushing assembly comprises a pushing nut, a movable ring and a pushing assembly; the pushing nuts sleeve the rotary shaft and are in threaded connection with the rotary shaft; the movable rings sleeve the rotary shaft; each pushing assemblycomprises a first connection rod, a second connection rod and a contacting mechanism; one end of each first connection rod is hinged with one end of the corresponding second connection rod by a hingepin, and the other end of the first connection rod and the other end of the second connection rod are respectively hinged with the movable ring and the middle ring; each contacting mechanism comprises a contacting shaft, a spring and a U-shaped plate which are sequentially connected. The production efficiency and convenience of the machine-made thermosetting polystyrene foamed plastic color steelplate production line are improved.

Owner:成都市医净净化设备科技有限公司

An underwater glider attitude adjustment mechanism with full-angle pitch angle adjustment

ActiveCN113581427BRich adjustment positionEasy to achieve a wide range of pitch angle adjustmentUnderwater vesselsUnderwater equipmentBall bearingGear wheel

The invention discloses an underwater glider attitude adjustment mechanism for full-angle pitch angle adjustment, which includes a fixed seat, a support plate, a pitch limit plate, a swing rod, a swing rod fixing part, a lead screw fixing cover, a lead screw nut, and hexagonal fine teeth. Nut, trapezoidal screw, pitch motor, eccentric mass, self-lubricating bearing, supporting square tube, rolling motor, fixed slider, fixed plate, gear bearing end cover, cable sensor, angle sensor, swing rod self-aligning ball bearing, Self-aligning ball bearings, circular bushings, tension rods; the attitude adjustment mechanism is set inside the cabin of the underwater glider, and the front eccentric mass and the rear eccentric mass are driven by the pitch motor to move forward and backward along the axis or the front eccentric is driven by the roll motor The mass block and the rear eccentric mass block rotate circumferentially to change the position of the center of gravity of the underwater glider body, and cooperate with the buoyancy control system to return and discharge oil to realize the attitude adjustment of the underwater glider.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com