Patents

Literature

97results about How to "Good anti-looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

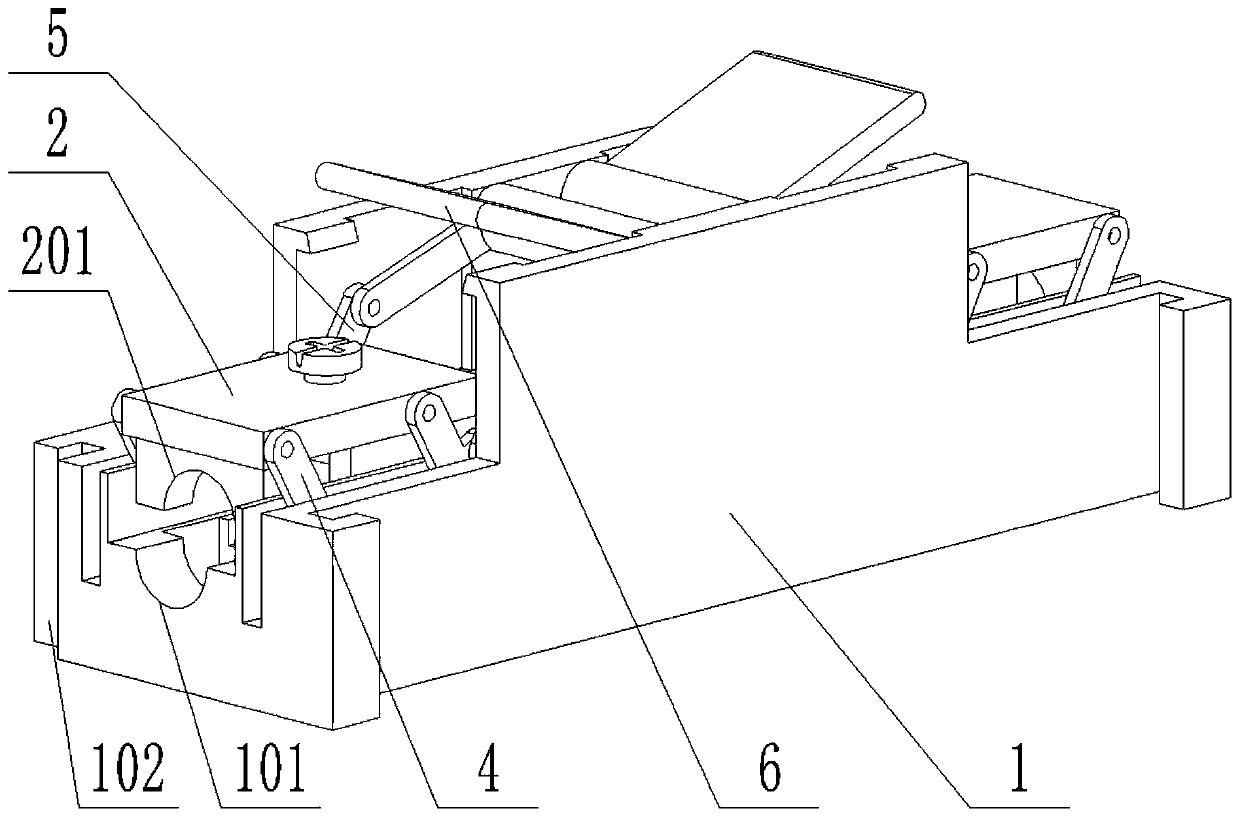

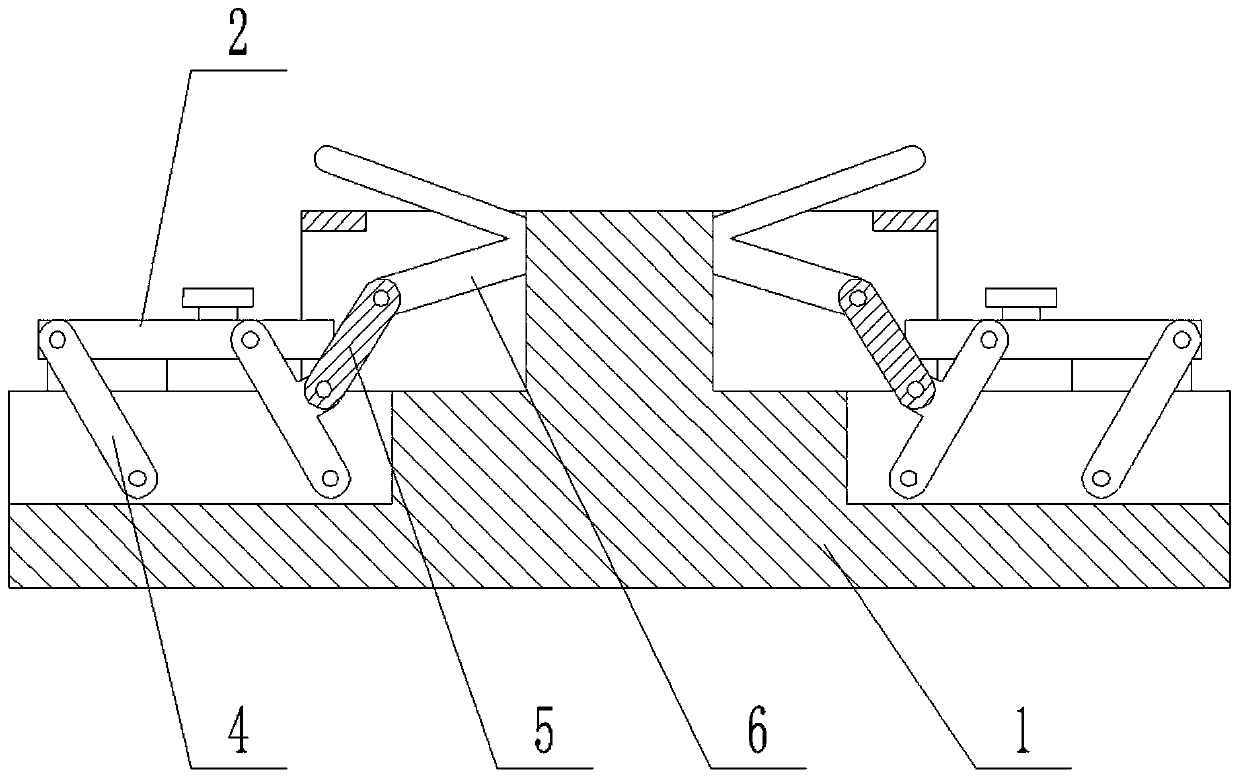

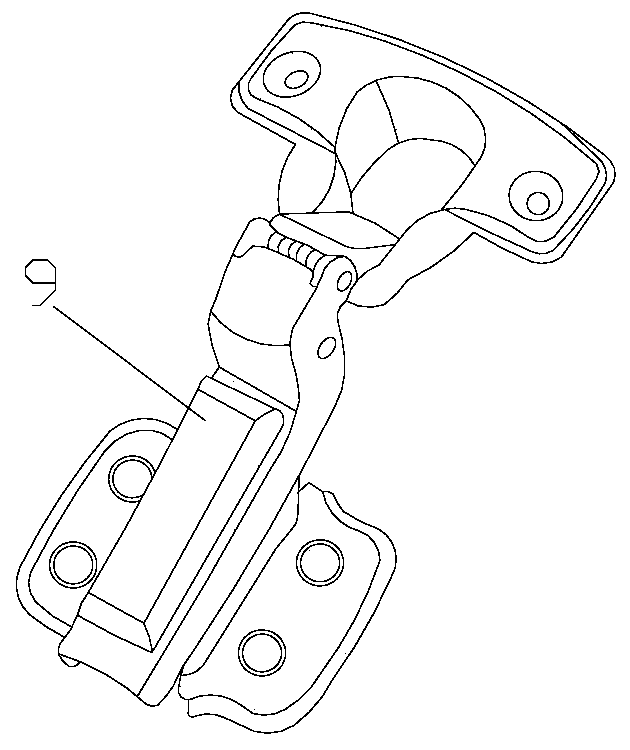

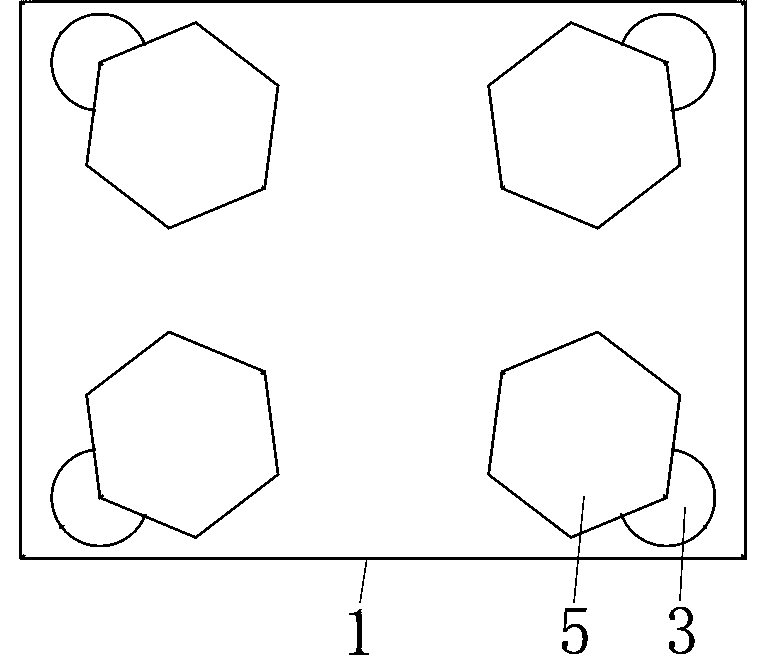

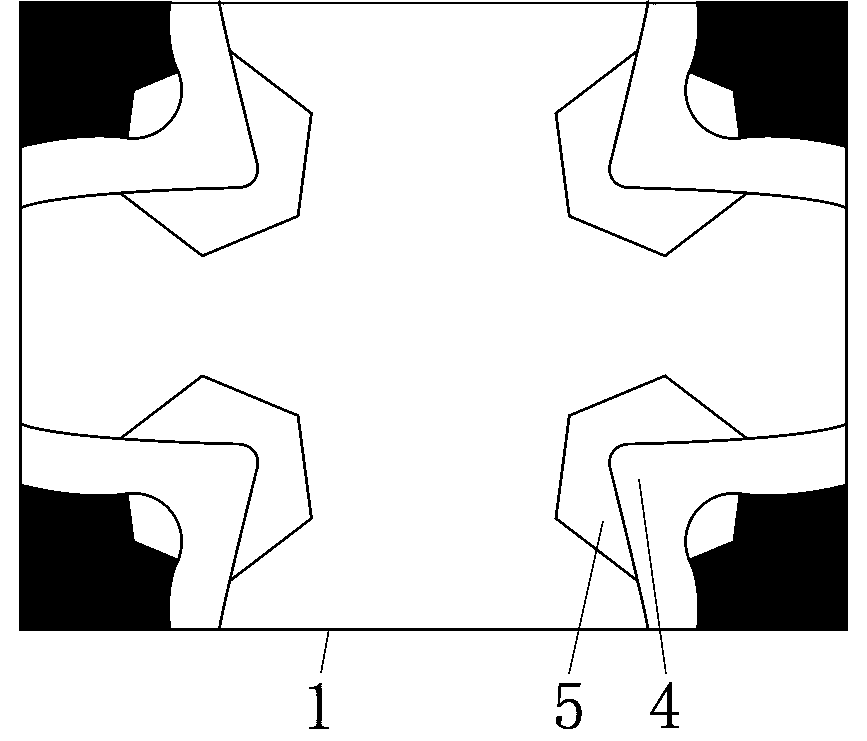

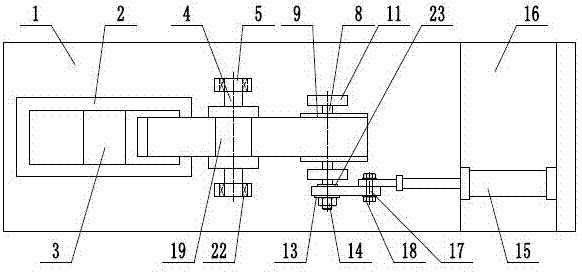

Elastic clamping device used for fragile objects

InactiveCN107225522AReduce wearExtended service lifeWork holdersWorking accessoriesHinge angleLocknut

Owner:张明强

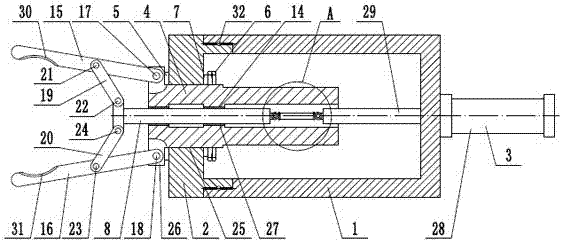

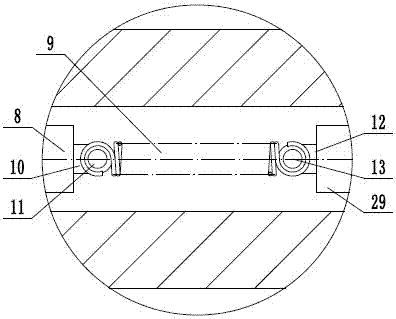

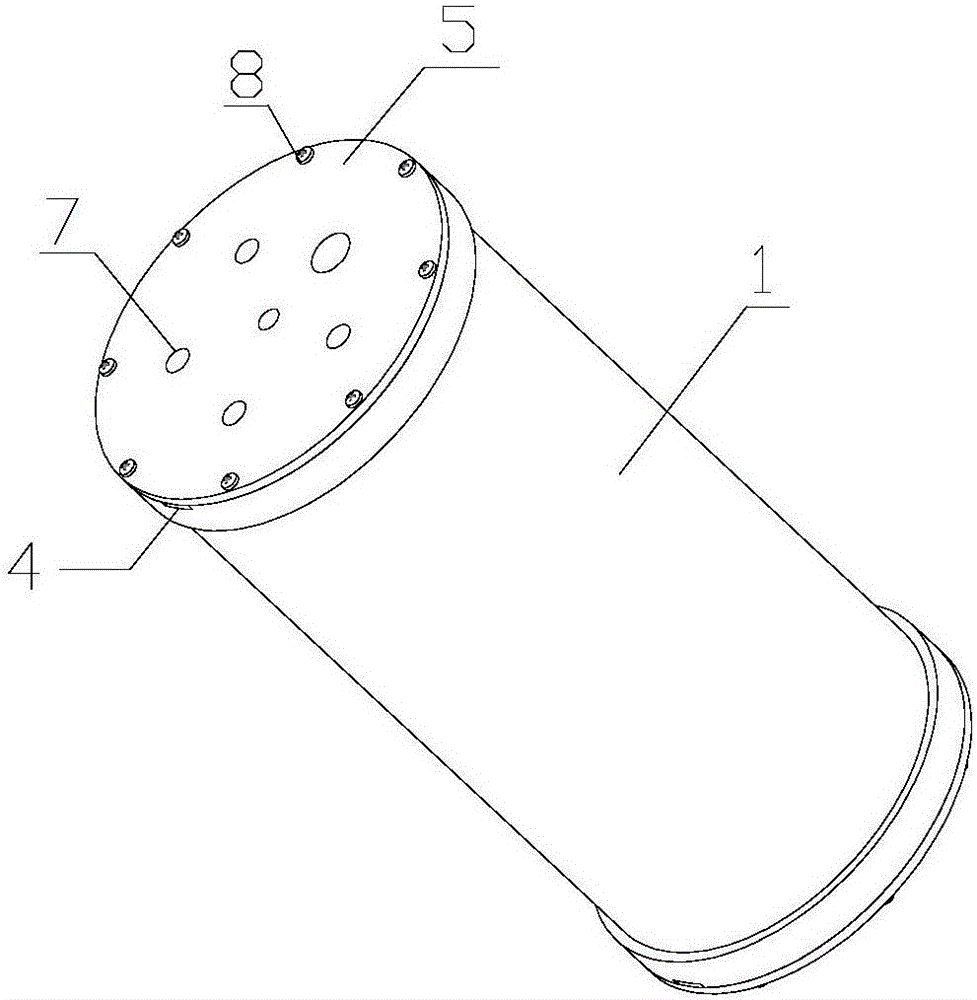

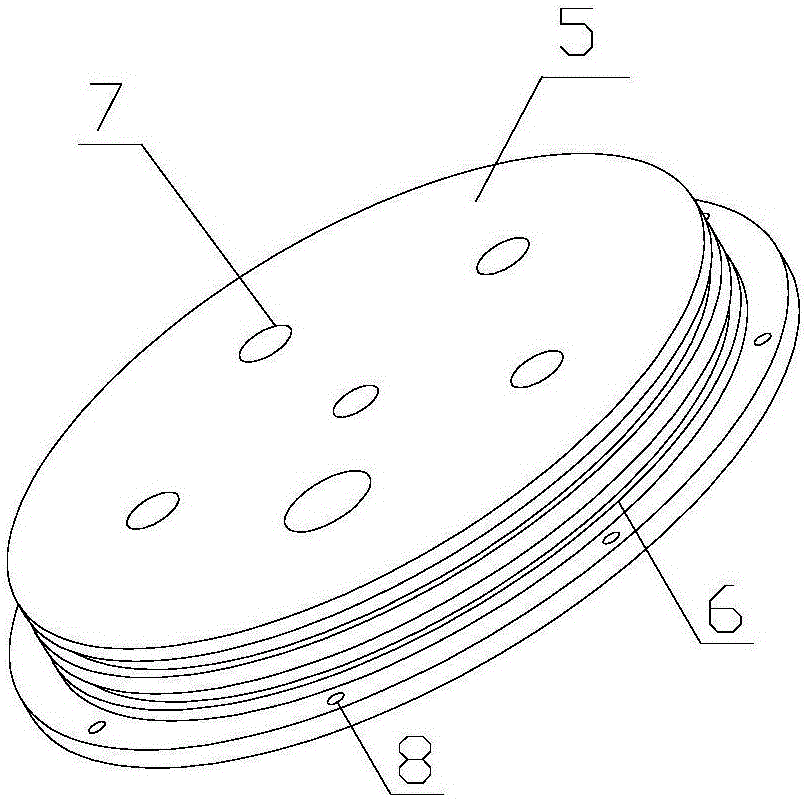

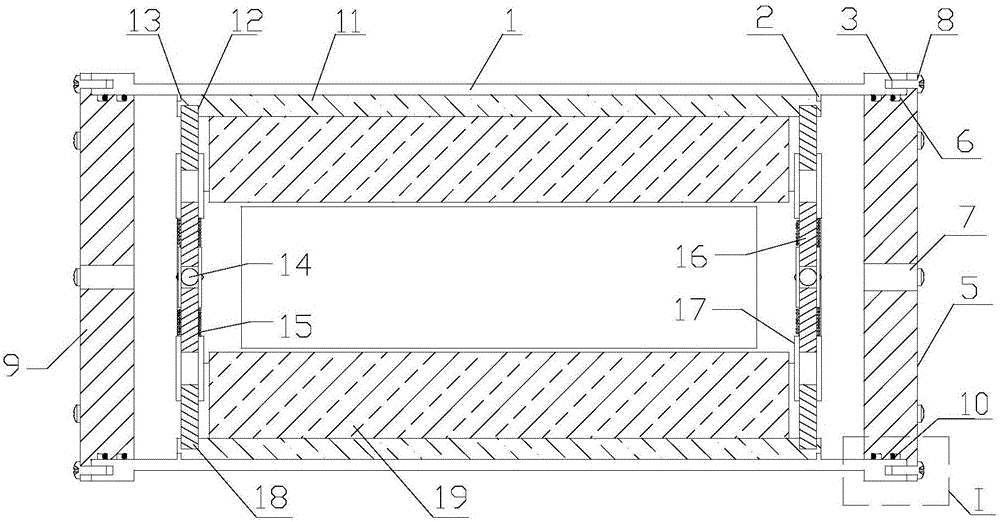

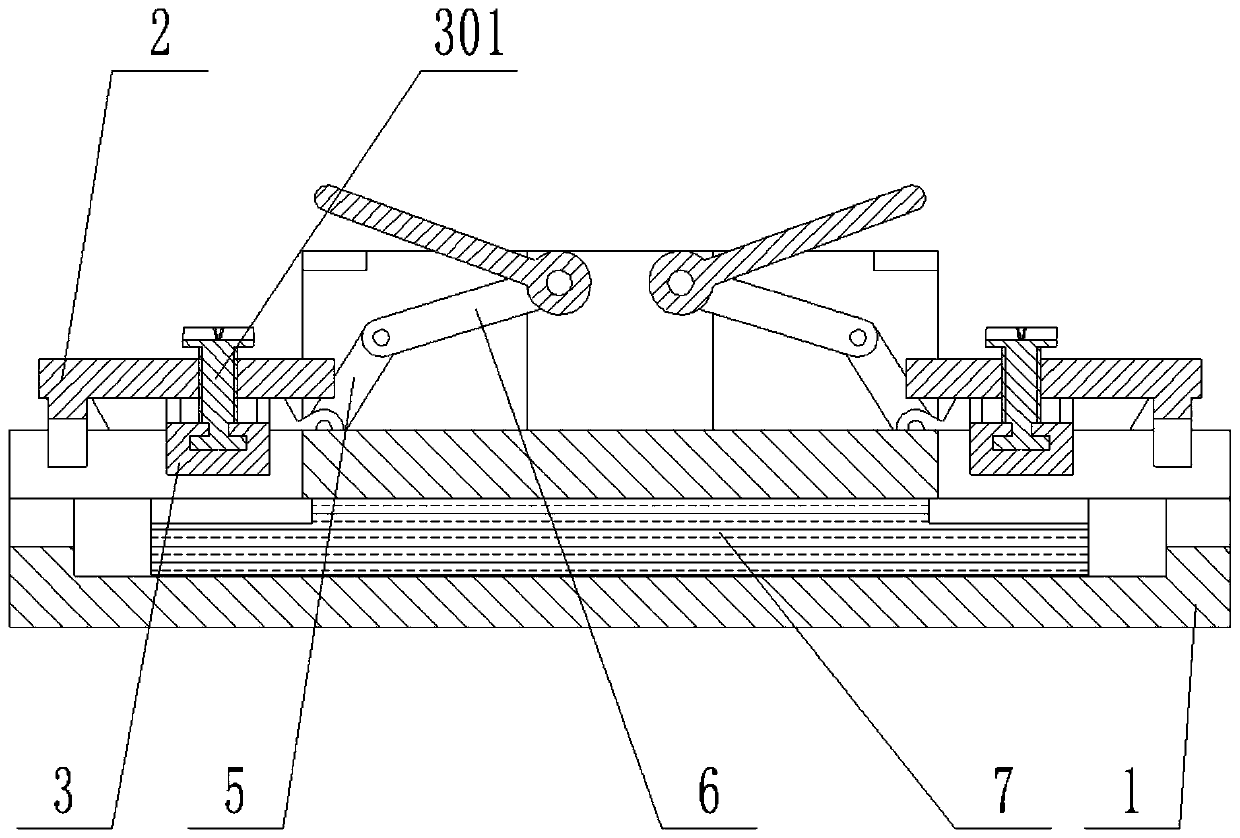

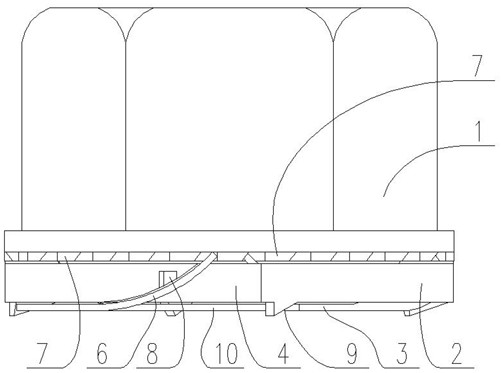

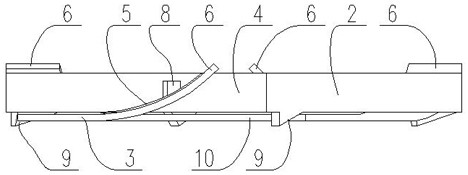

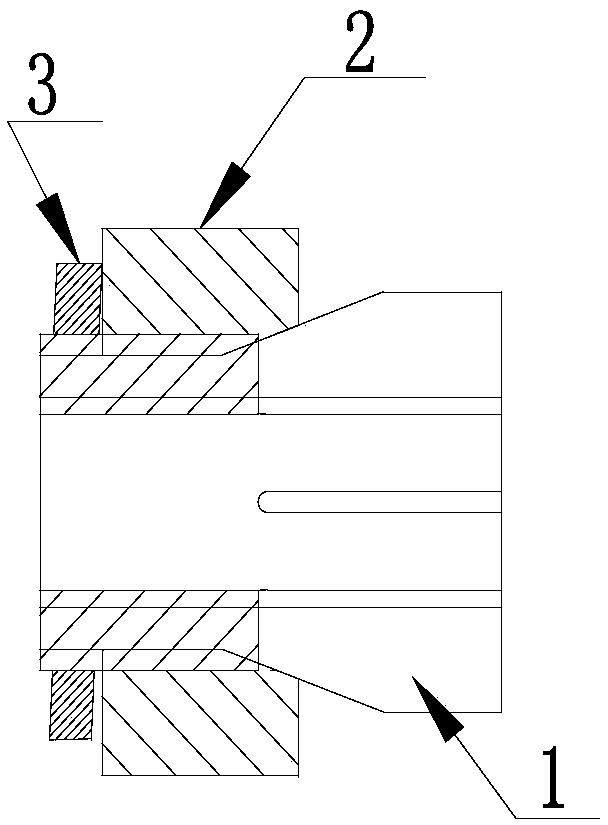

Water-cooled heat dissipation type pressure-resistant electronic cabin

ActiveCN106413351AEasy to installImprove the convenience of loading and unloading and post-maintenanceModifications by conduction heat transferUnderwater vesselsHeat sinkWhole systems

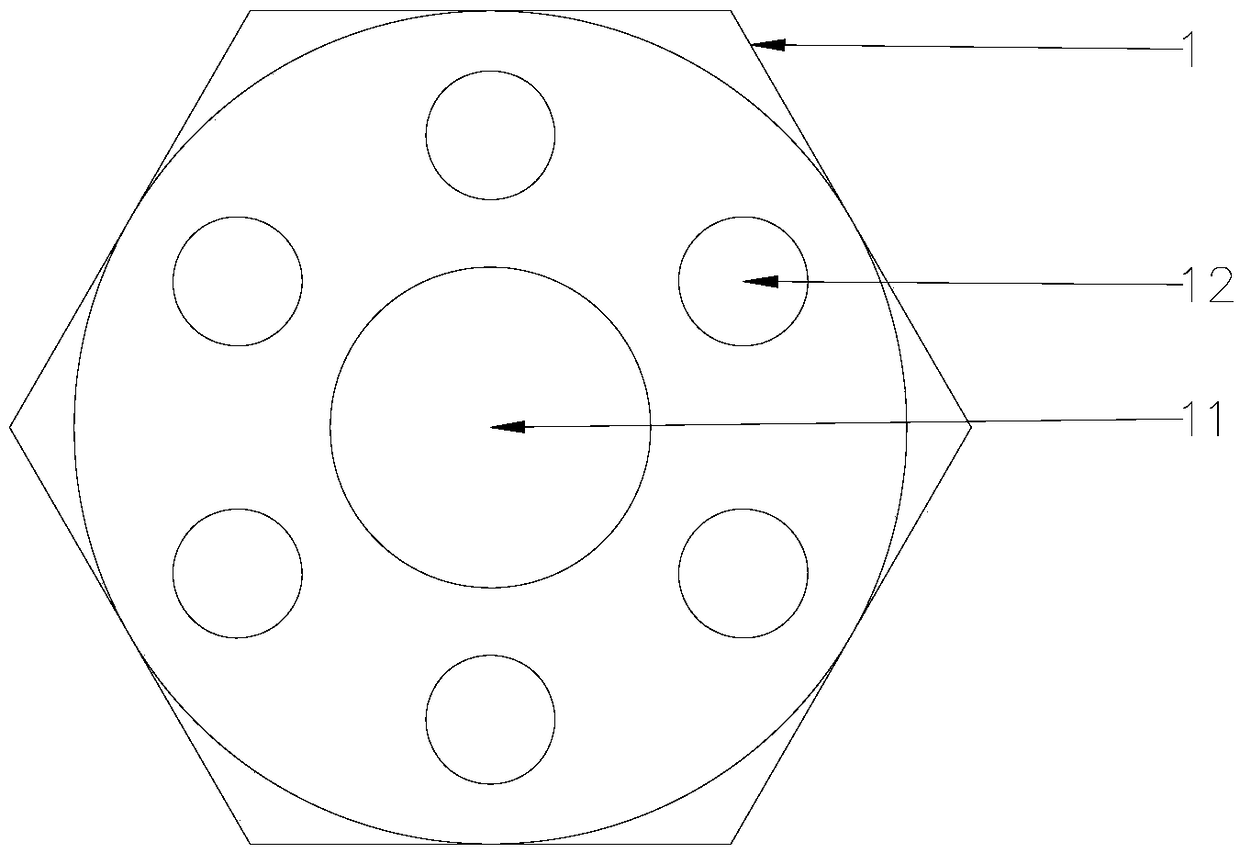

The invention discloses a water-cooled heat dissipation type pressure-resistant electronic cabin which comprises a main cabin body. A front end cover and a rear end cover are respectively arranged on both ends of the main cabin body. The main cabin body is sealed into a cavity by the front end cover and the rear end cover. A heat dissipation device is arranged in the cavity. The heat dissipation device comprises four heat sinks which are supported by cross-shaped telescopic brackets on both ends and are arranged on the inner wall of the cavity through the cross-shaped telescopic brackets. The heat sinks are arranged on electrical components. According to the water-cooled heat dissipation type pressure-resistant electronic cabin, the pressure-resistant cabin casing and the internal electrical device are respectively two separate systems, and can be completely separated; the convenience of assembling and debugging is improved; the electrical device is arranged on a separate heat dissipation bracket; the heat dissipation bracket can transfer heat of the electrical components to the wall of the pressure-resistant cabin and water outside the cabin; heat dissipation of the electrical device in the cabin body is realized; and in addition, the support effect of the heat dissipation bracket on the cabin wall enhances the pressure-resistant ability of the pressure-resistant cabin casing and improves the reliability of the whole system.

Owner:JIANGSU UNIV OF SCI & TECH

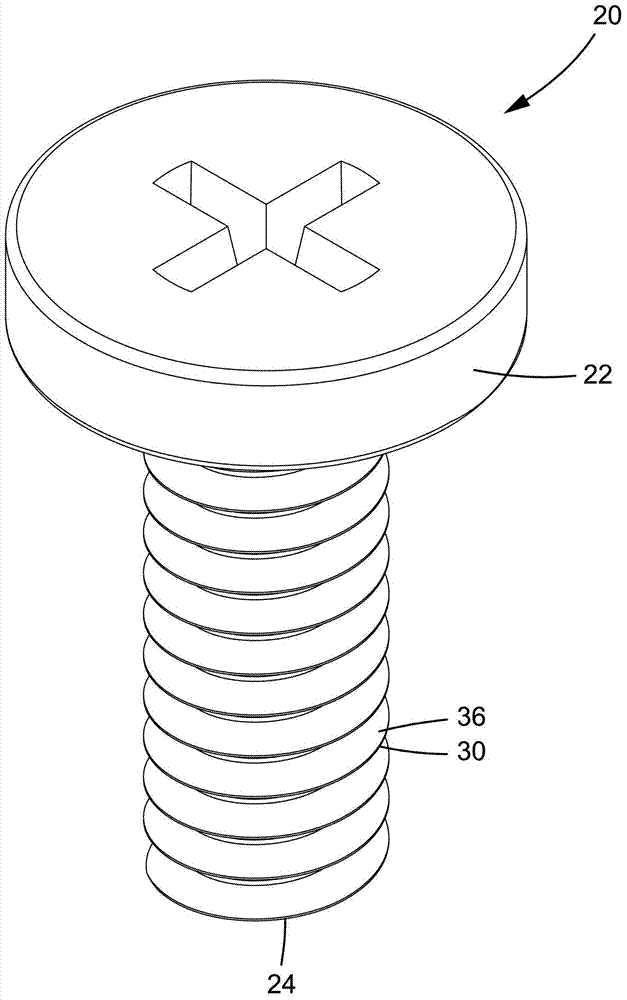

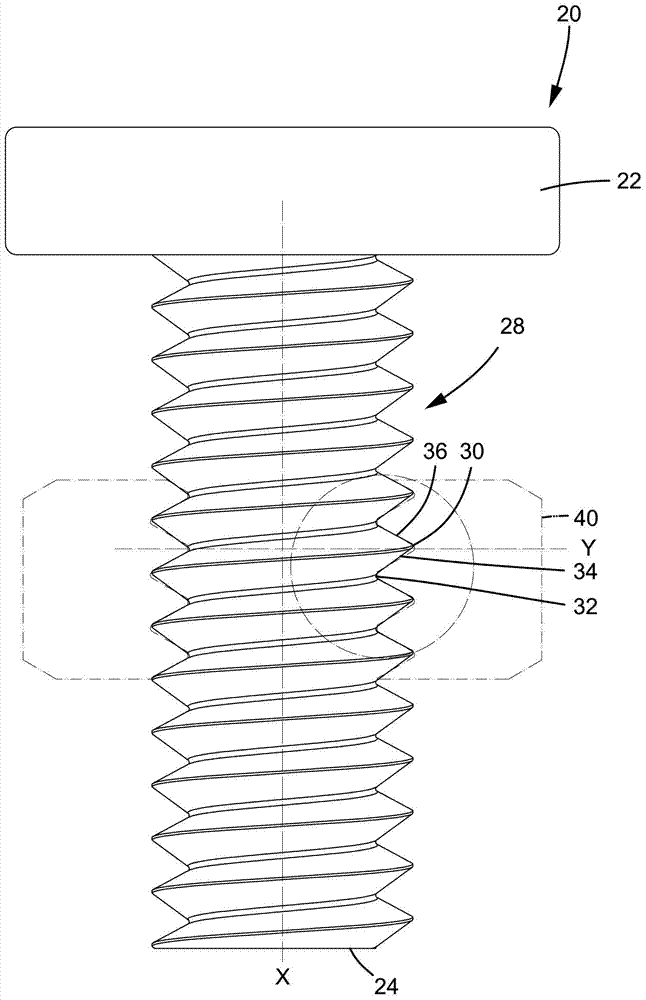

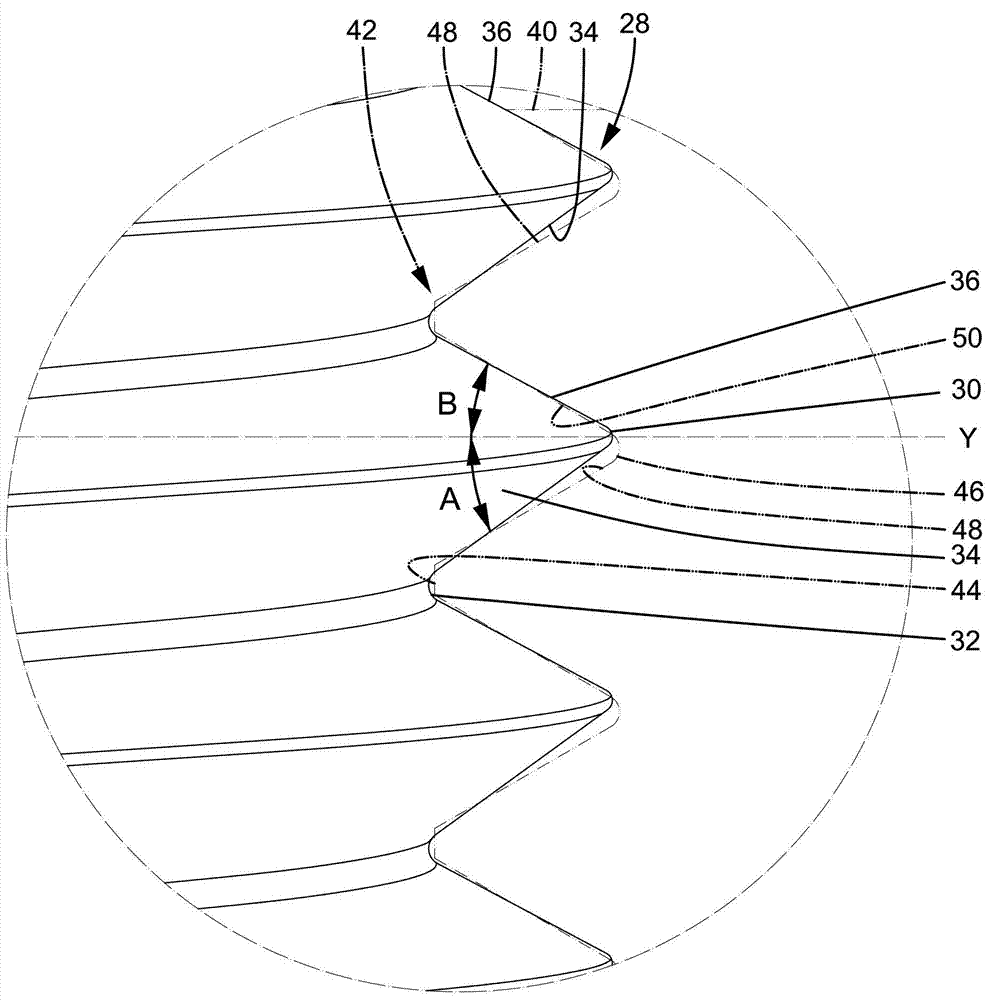

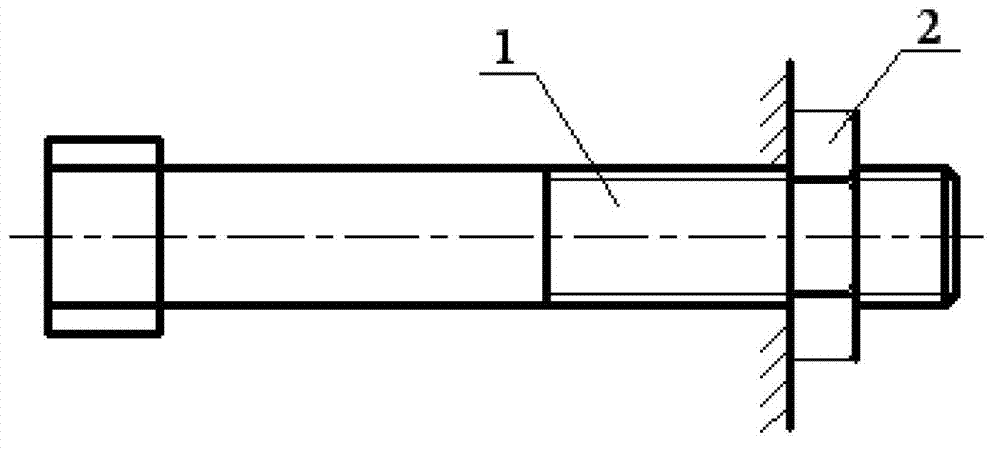

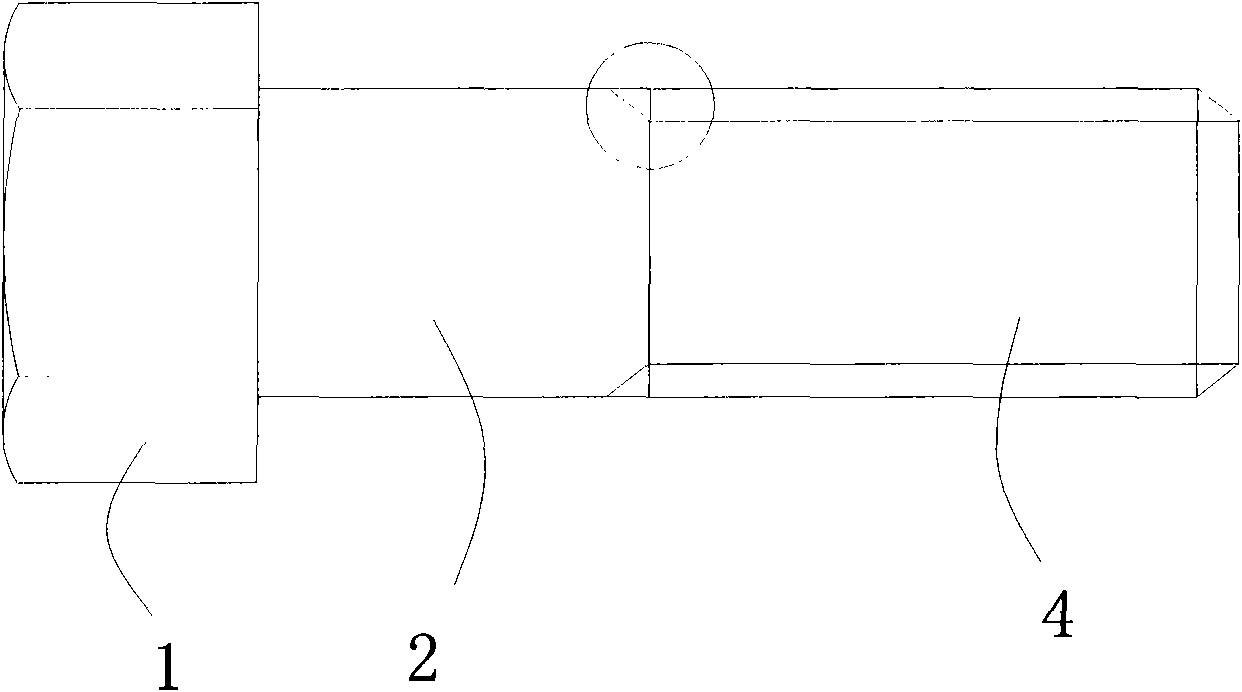

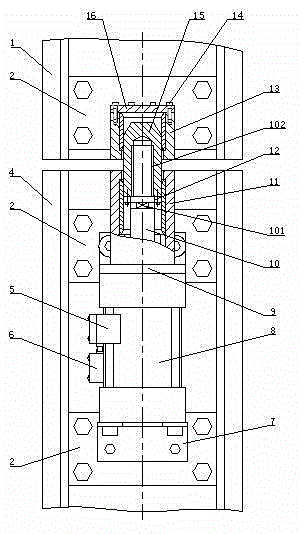

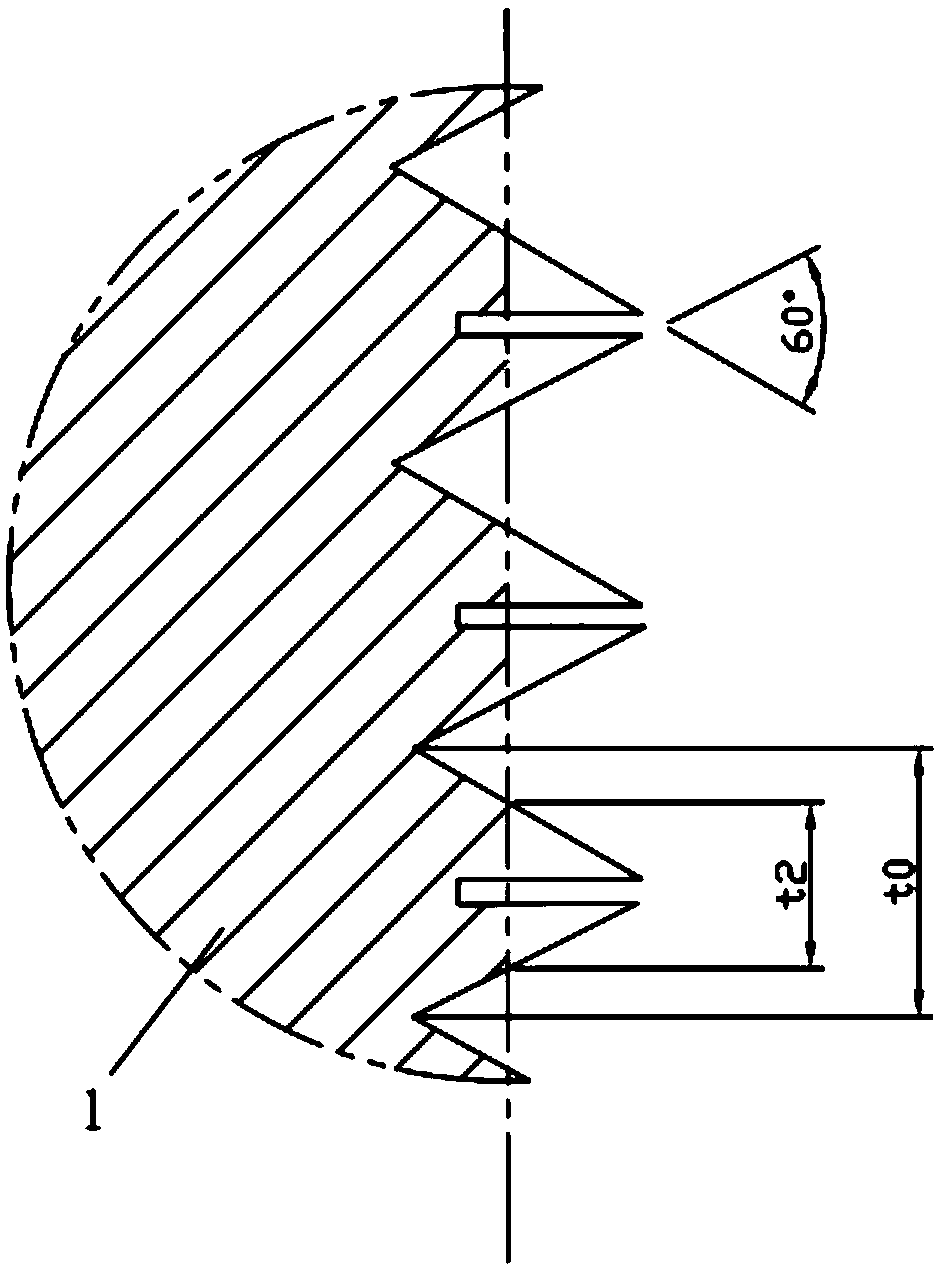

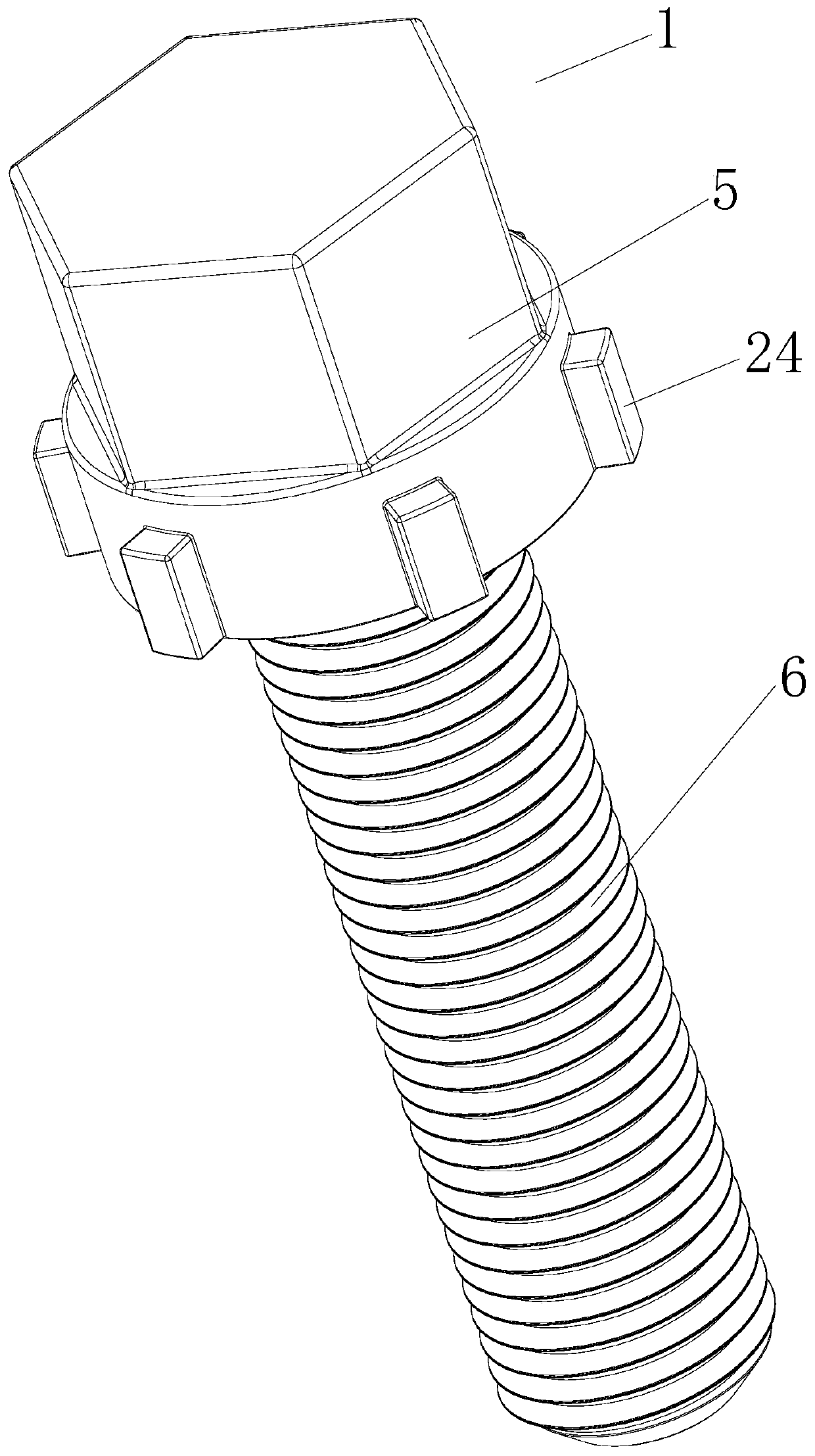

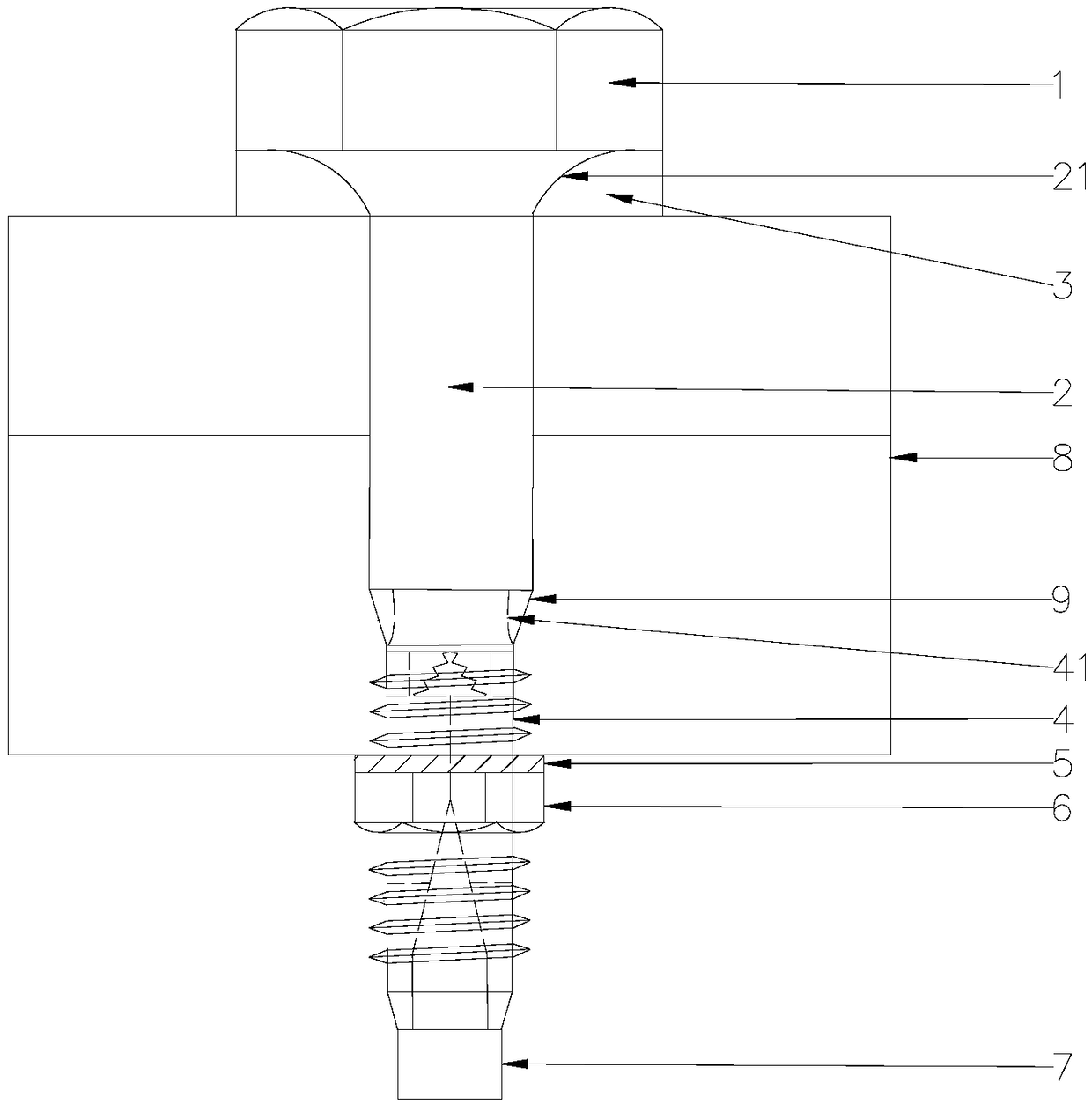

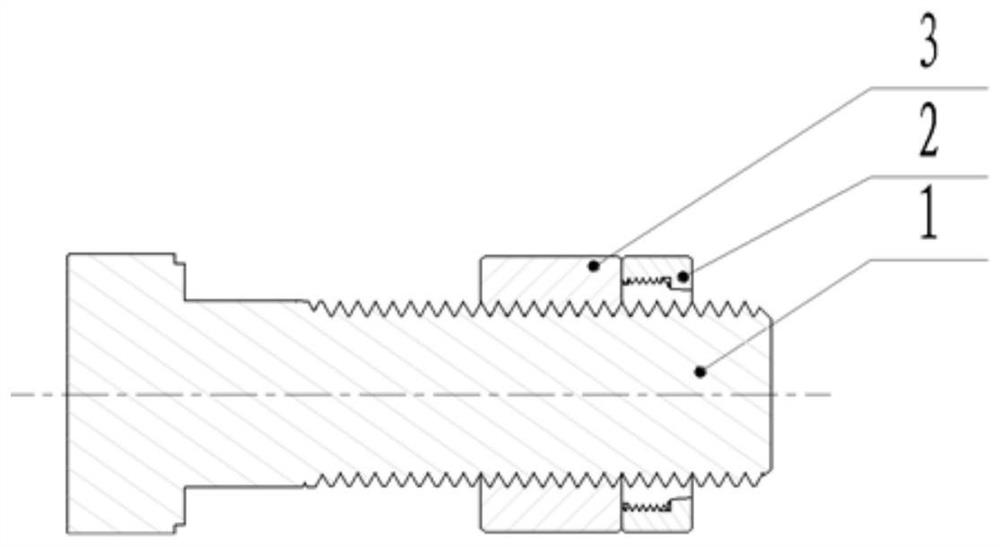

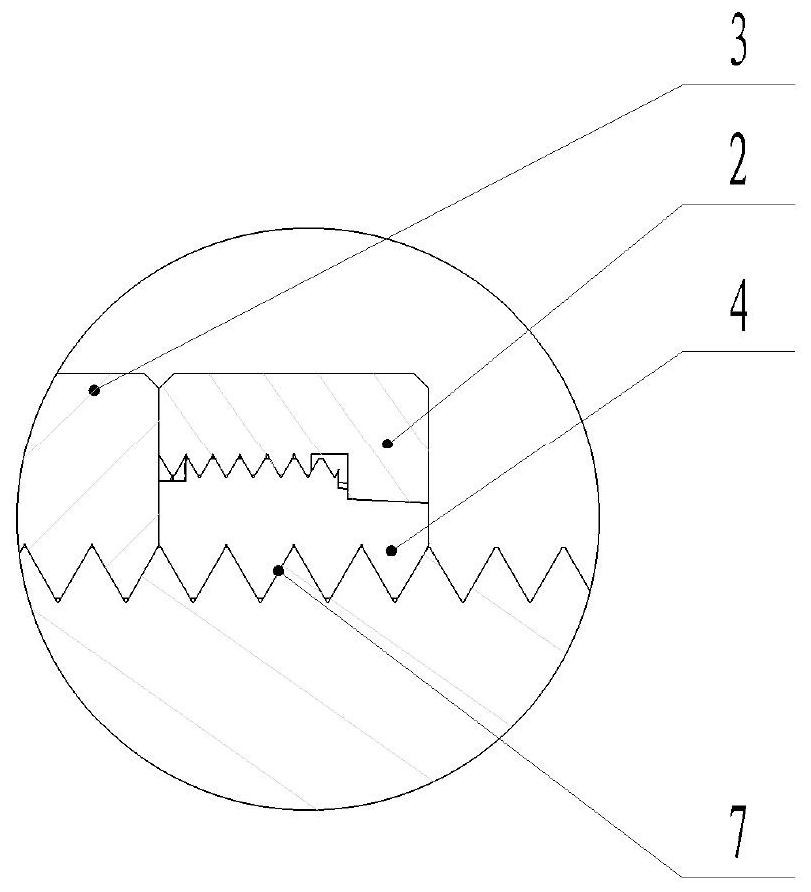

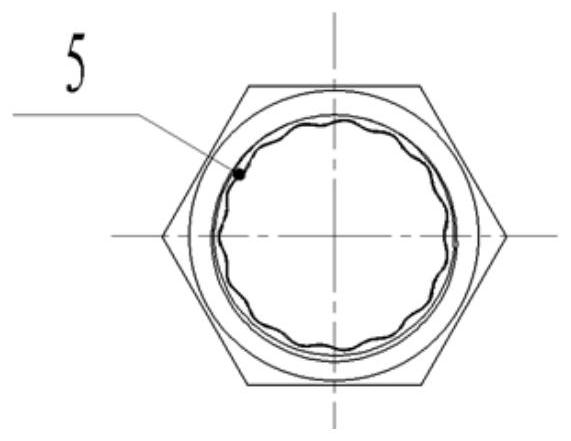

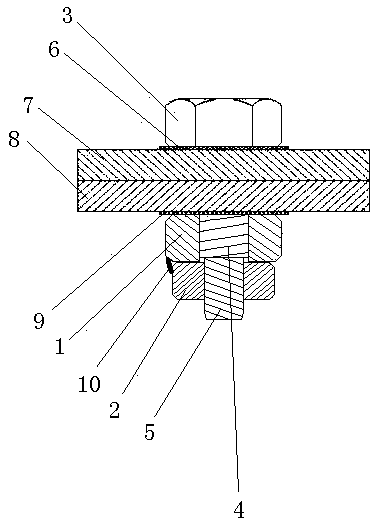

Locking screw

InactiveCN104235162AIncrease positive forceIncrease frictionNutsBoltsInterference fitAngular degrees

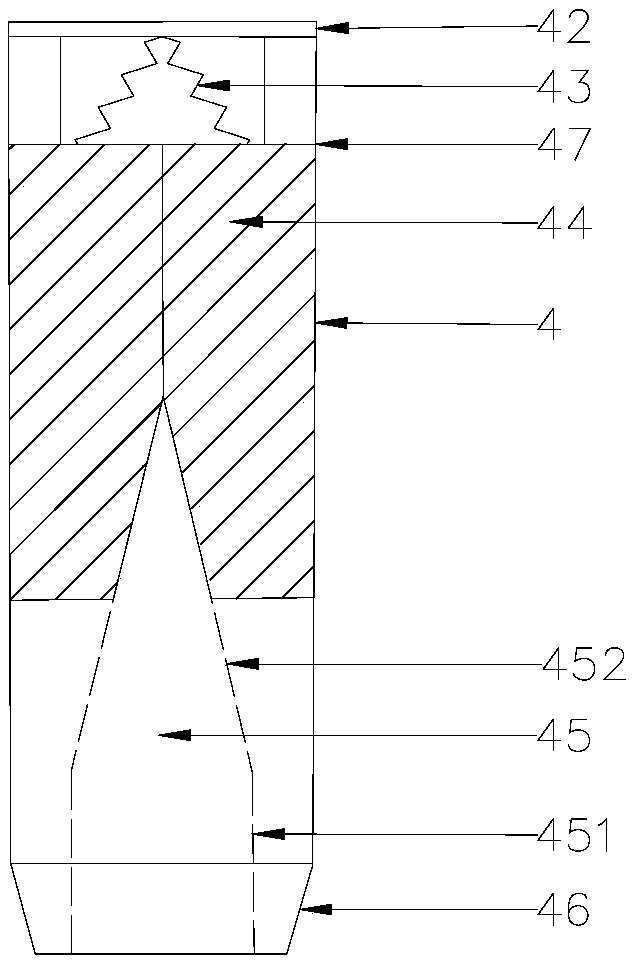

The invention relates to a locking screw comprising a head and a shank extending from one side of the head. The peripheral surface of the shank is provided with an external thread; two sides of a crest of the external thread incline to a vertical line perpendicular to the center axis of the shank, at different angles including a first inclination angle and a second inclination angle; an angle of thread of the locking screw ranges from 61 degrees to 67 degrees; the first inclination angle of the angle of thread ranges from 32 degrees to 40 degrees; the second inclination angle of the angle of thread ranges from 25 degrees to 29 degrees; therefore, the external thread of the locking screw and an internal thread of an object form a standard 60-degree angle of thread for screwing use, and the upper and lower edges of two flanks of the external thread are in interference fit with the internal thread so that good locking effect is achieved.

Owner:卢小璇

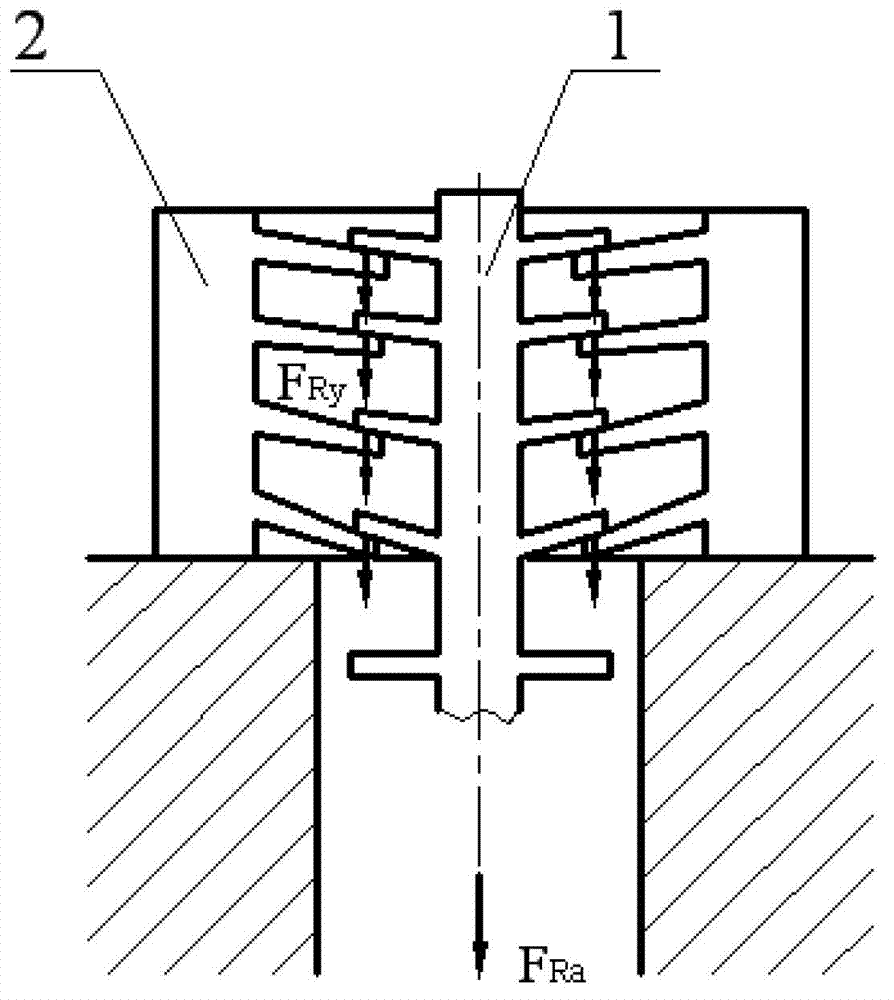

Iron-based shape memory alloy locking bolt as well as production and application method thereof

InactiveCN103194694AGood anti-loosenessHigh tensile strengthNutsBoltsMartensite transformationAviation

The invention relates to an iron-based shape memory alloy locking bolt as well as a production and application method thereof. The iron-based shape memory alloy locking bolt is characterized by comprising 16.8-17.23% of Mn, 4.50-4.7% of Si, 2.23-10.30% of Cr, 2.26-5.29% of Ni, C equal to or less than 0.08% and Fe beside the impurities in mass percent. The production and application method comprises the steps of: treating a turned bolt bar which is made of an iron-based shape memory alloy at 1100DEG C for 60 minutes and then carrying out uniaxial tension; and combining the bolt bar with a common nut to form a screw thread pair through precisely controlling the pre-tightening force and then carrying out heating, heat preservation and cooling: the stage is the realization stage of shape memory effect of the bolt: through radial, axial and martensitic phase transformation and restoration, radial and axial restoration force is produced to realize locking. The iron-based shape memory alloy locking bolt is applicable to the occasions with dismounting difficulty, high-velocity motion and check difficulty in machines and capable of effectively solving the loose failure cracks of key thread connection in chain transmission, bridges and space flight and aviation equipment.

Owner:DALIAN JIAOTONG UNIVERSITY

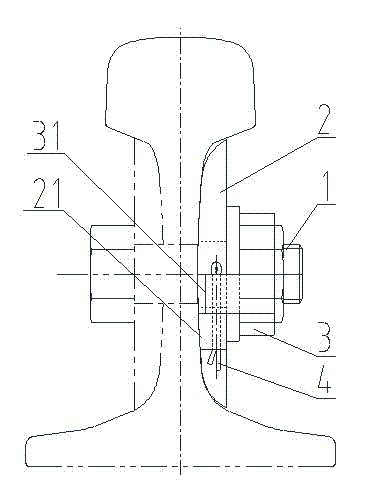

Nut anti-loosening mechanism special for railway turnout

The invention relates to a nut anti-loosening mechanism special for a railway turnout. A steel rail gasket is fixedly installed at a steel rail web through a bolt and a nut, and an anti-rotating gasket which is installed on the bolt and the nut in a sleeved mode is connected with the steel rail gasket through a split pin, so that the nut is prevented from rotating in the loosening direction to achieve a self-locking function. The nut anti-loosening mechanism has the advantages that the mechanical type bolt and nut anti-loosening mechanism is simple in structure and convenient to operate, the problem that bolts and nuts are prone to loosening, which troubles a turnout work maintenance department for a long time is effectively solved, in the maintenance or after disassembling adjusting, the bolts and nuts can be continuously used, and turnout cost is greatly reduced; contributions are made to durability, safety and few maintenance of the railway turnout; the mechanism is obvious in anti-loosening effect, the maintenance load of the turnout work maintenance department can be reduced substantially, and the mechanism is adaptive to needs of railway rapid development.

Owner:CHINA RAILWAY BAOQIAO (NANJING) CO LTD

Bolt combiner with thread pitch difference between bolt and nut

InactiveCN101576113AAvoid stress concentrationImprove fatigue strengthLoad modified fastenersNutsEngineeringMachine parts

The invention relates to a bolt combiner with thread pitch difference between a bolt and a nut, which belongs to the technical field of machine parts. The bolt combiner comprises the bolt and the nut, wherein the bolt comprises a bolt head, a bolt cylindrical part and a threaded part; the threaded part consists of an incomplete threaded part, a thread tooth removing part and a complete threaded part; and the thread pitch Pn of the nut is slightly larger than the thread pitch Pb of the bolt, and the following relational expression is satisfied: (Pn-Pb) / Pb is more than or equal to 2*10 and is less than or equal to 2*10. By adjusting the thread pitch difference between the bolt and the nut in a humidity range, the bolt combiner has obvious locking effect, cannot cause loosening and fatigue damages by applying repeated varying stresses under a connection state, can surely maintain the connection state, has good anti-flaccid property and fatigue resistance, can be applicable to occasions with repeated stresses, and has extra-high industrial applicability.

Owner:孙中强

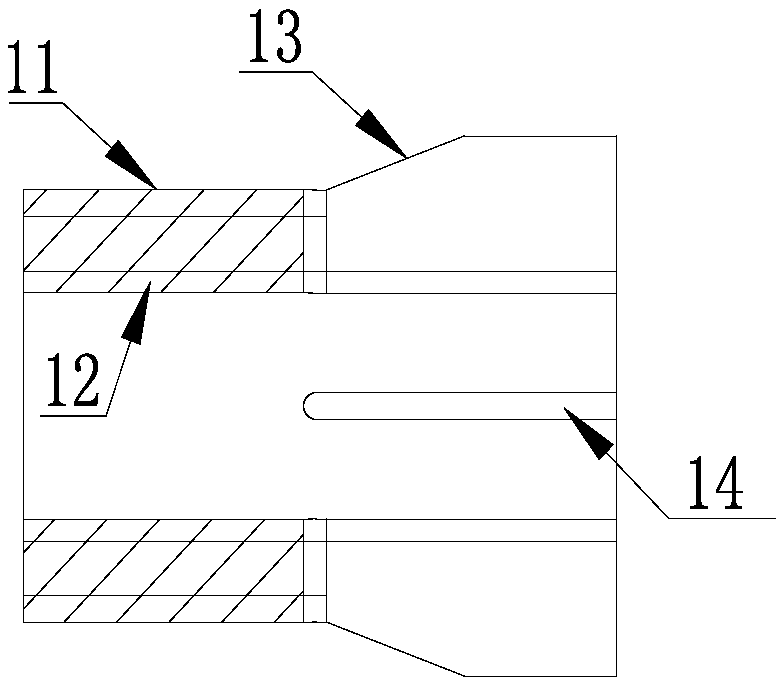

Inward-opening type adjustable anti-theft door locking bolt

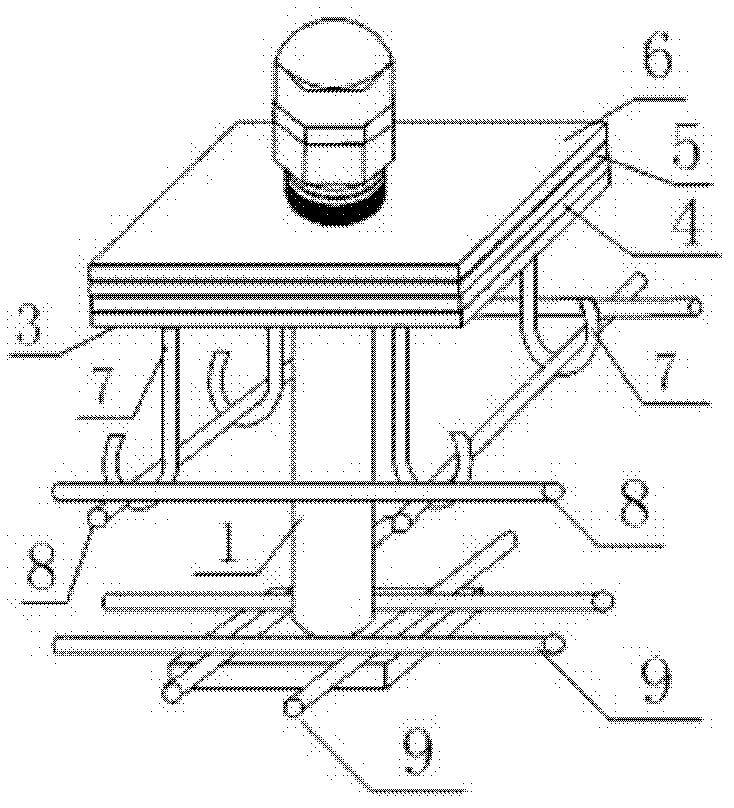

The invention discloses an inward-opening type adjustable anti-theft door locking bolt which comprises a screw (2), a handle (3), a compression spring (6), a stopping block (7), a shaft (8) and a door bolt head (9). An adjusting sleeve (5) is sleeved on the shaft (8) and fixedly connected with a fixed sleeve (4) through threads, an inner hole of the adjusting sleeve (5) is in clearance fit with the shaft (8), an external thread is arranged on the adjusting sleeve (5) and is a fine thread, a circular groove (11) is arranged in the inner hole of the adjusting sleeve (5), and the fixed sleeve (4) is provided with an inner hole thread which is a fine thread. The inward-opening type adjustable anti-theft door locking bolt is simple in structure, easy to assemble, adjustable in spring force, reliable to operate, easy to unlock and long in service life.

Owner:HUANGSHI UNIVERSE AUTO EQUIP

Tapping screw

ActiveUS8985926B2Improve anti-loosening performanceGood anti-loosenessNutsBoltsEngineeringSoft materials

Owner:NITTO SEIKO KO

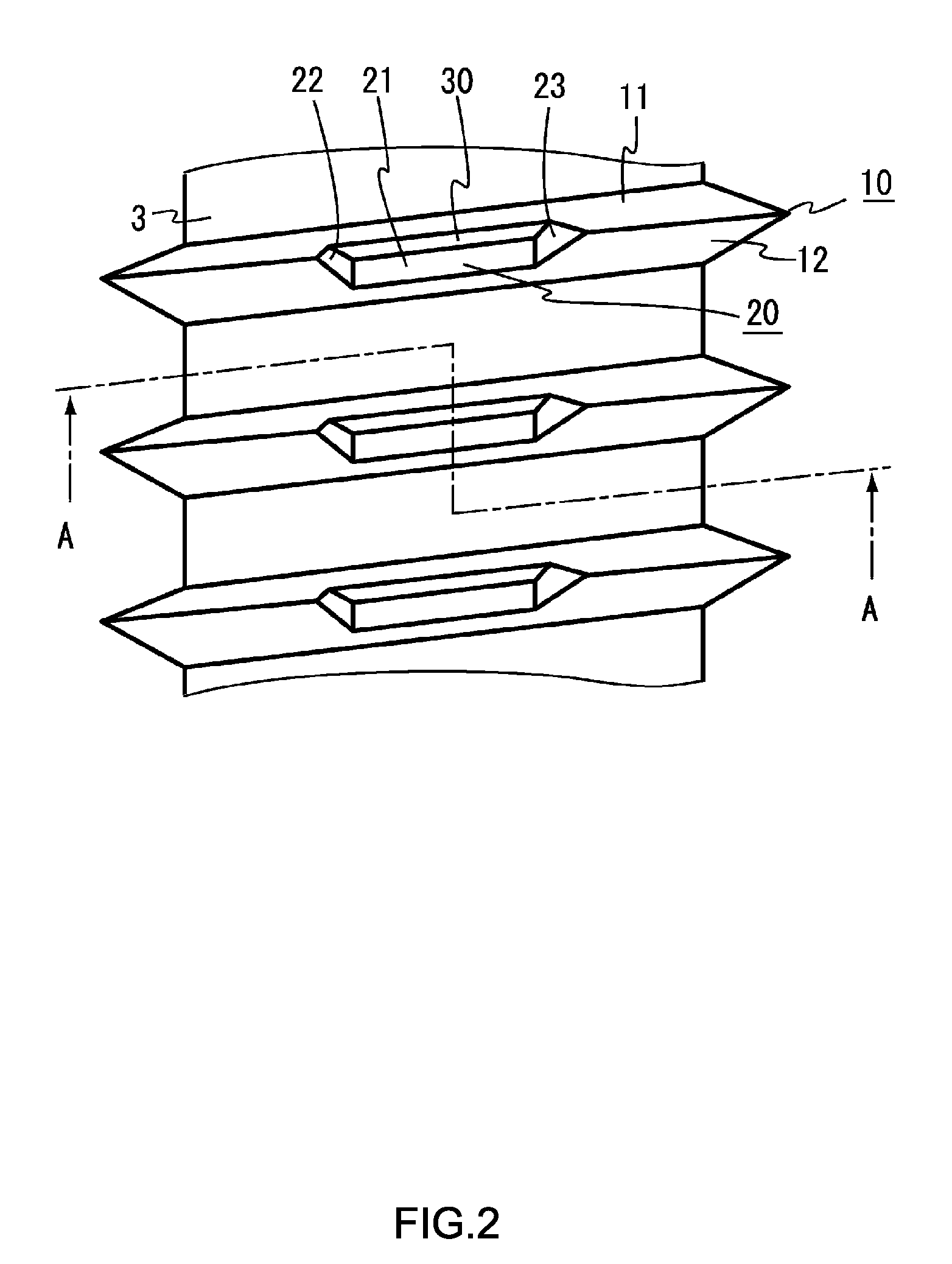

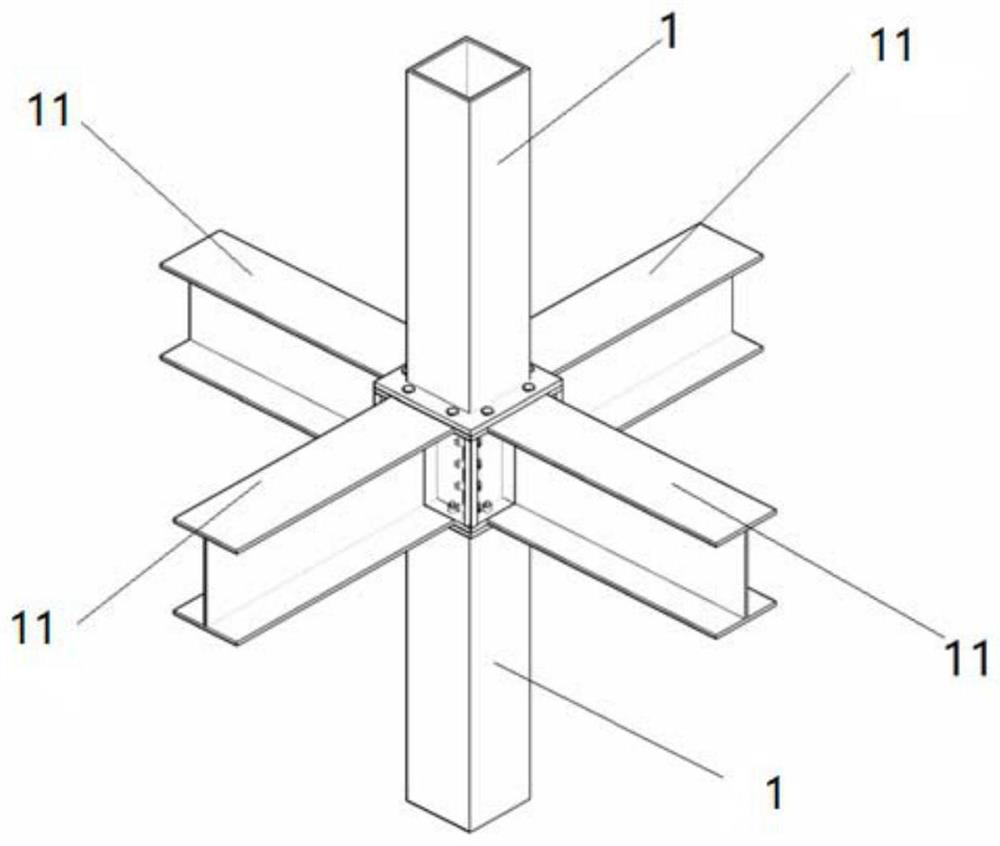

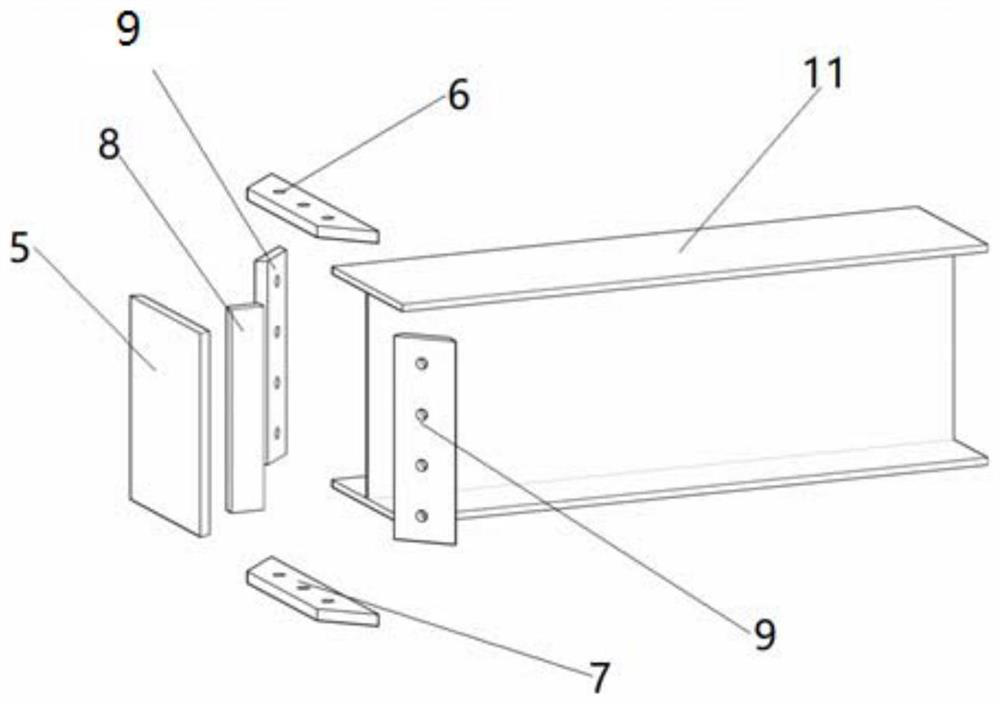

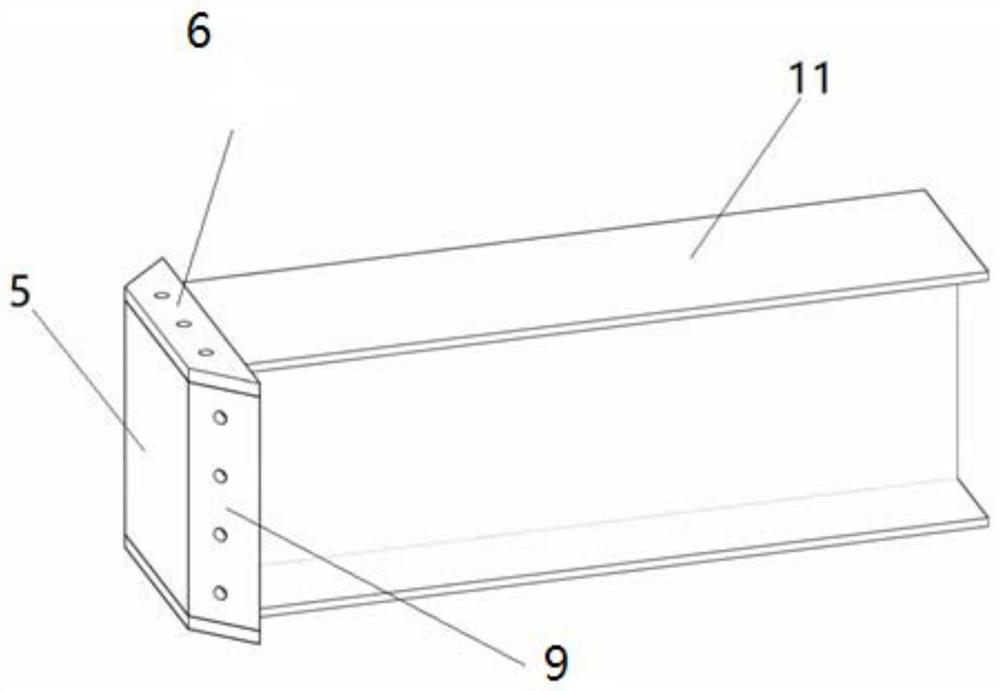

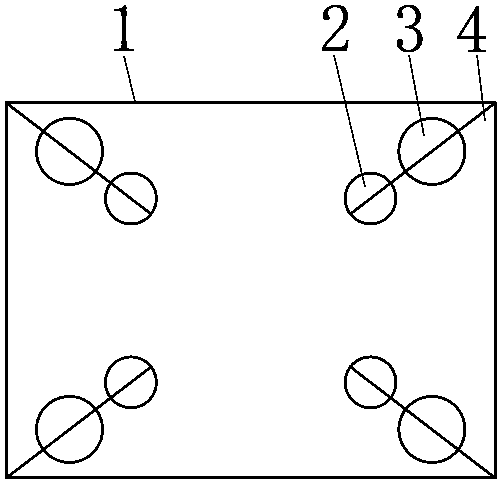

Assembled node employing rivet connection

InactiveCN111809746AAvoid destructionHigh strengthBuilding constructionsUltimate tensile strengthIndustrial engineering

The invention provides an assembled node employing rivet connection. The assembled node comprises stand columns, cross beams, beam end heads and stand column end plates; the end portions of the four cross beams are fixedly provided with the beam end heads, the end portions of the four cross beams are oppositely arranged to form a cross-shaped structure, and the adjacent beam end heads are fixedlyconnected; the stand column end plates are arranged at the ends of the stand columns, the two stand columns with the stand column end plates are respectively arranged on the upper side and the lower side of the cross-shaped structure, and each stand column end plate is fixedly connected with all the beam ends on the cross-shaped structure. According to the assembled node, by strengthening the columns in the junction region, the strength and rigidity of node parts are improved, and large damage to the columns at the node under the earthquake action is avoided. The structure is prefabricated ata factory, so that site welding and column connection are avoided, the welding quality is not high; and meanwhile, the situations that due to a large welding area, large residual deformation is easilygenerated, the stress performance of the node is affected, the node ductility is poor, and the construction speed and quality are affected are avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High-strength cable connecting plate structure with waterproof performance

InactiveCN110380243AGood compression effectEasy to operateElectric connection structural associationsAgricultural engineeringHigh intensity

The invention provides a high-strength cable connecting plate structure with waterproof performance, which comprises an outer shell, a protective sleeve compression lower bayonet and a middle connecting copper wore, wherein the top of the outer shell is axially connected with two sets of operating handles; both the left and right sides of the outer shell are hinged with a set of sealing compression plate through four sets of compression connecting rods; the bottom of each sealing compression plate is slidably connected with a set of wire core compression plate; and the middle part of the outershell is fixedly connected with a set of intermediate connecting copper cores. The device is good in compression effect, simple and efficient to operate and high in compression strength, has a good anti-loose effect, and can well fix the cable. Meanwhile, device has a good sealing effect, prevents moisture from entering to cause the corrosion between wire cores and the intermediate connecting copper cores and result in poor contact, prolongs the service life, improves the safety in use and has good waterproof performance. In addition, the device is simple and efficient to operate, can be spliced and combined to use and has high flexibility.

Owner:INNER MONGOLIA DATANG INT TUOKETUO POWER GENERATION

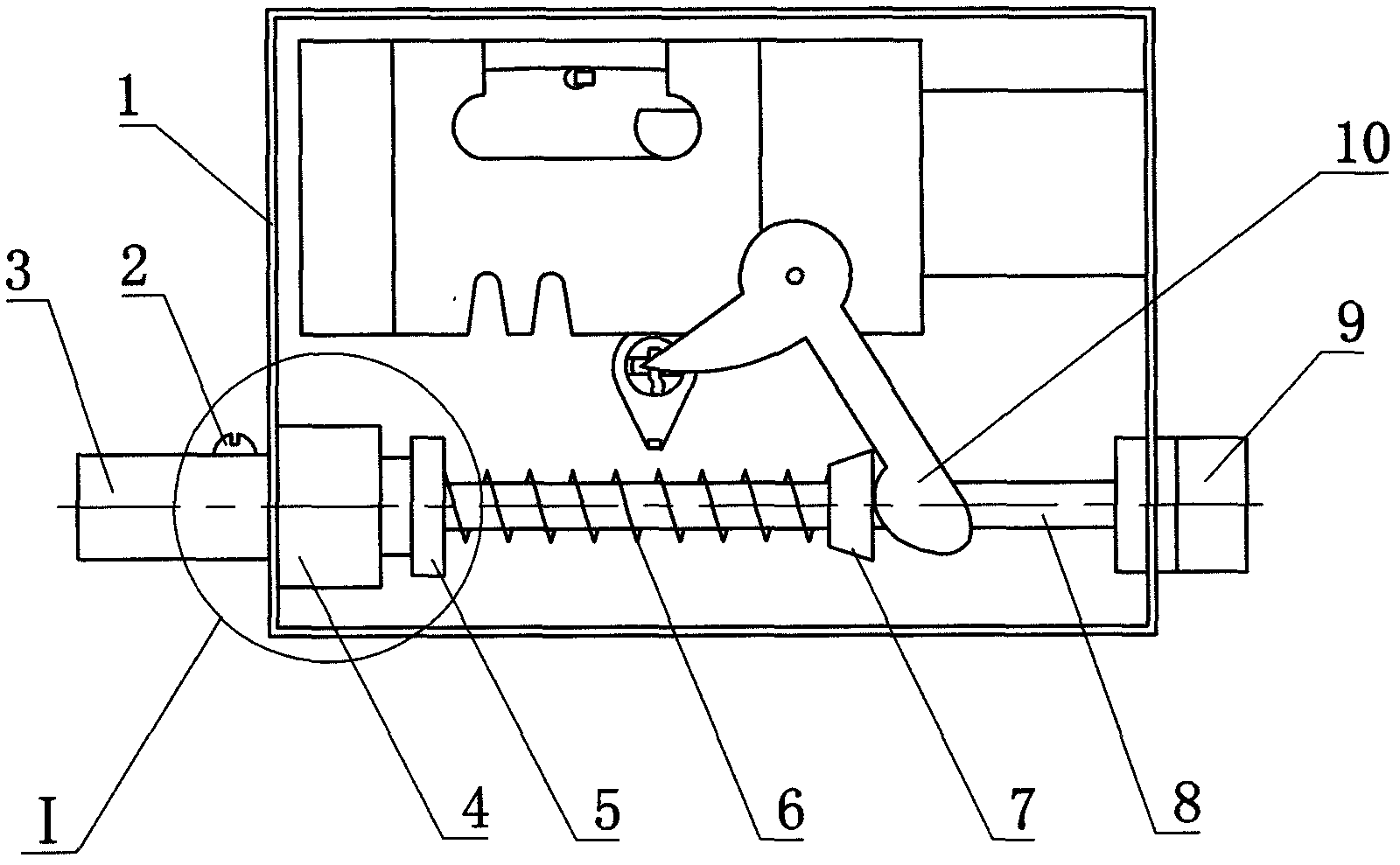

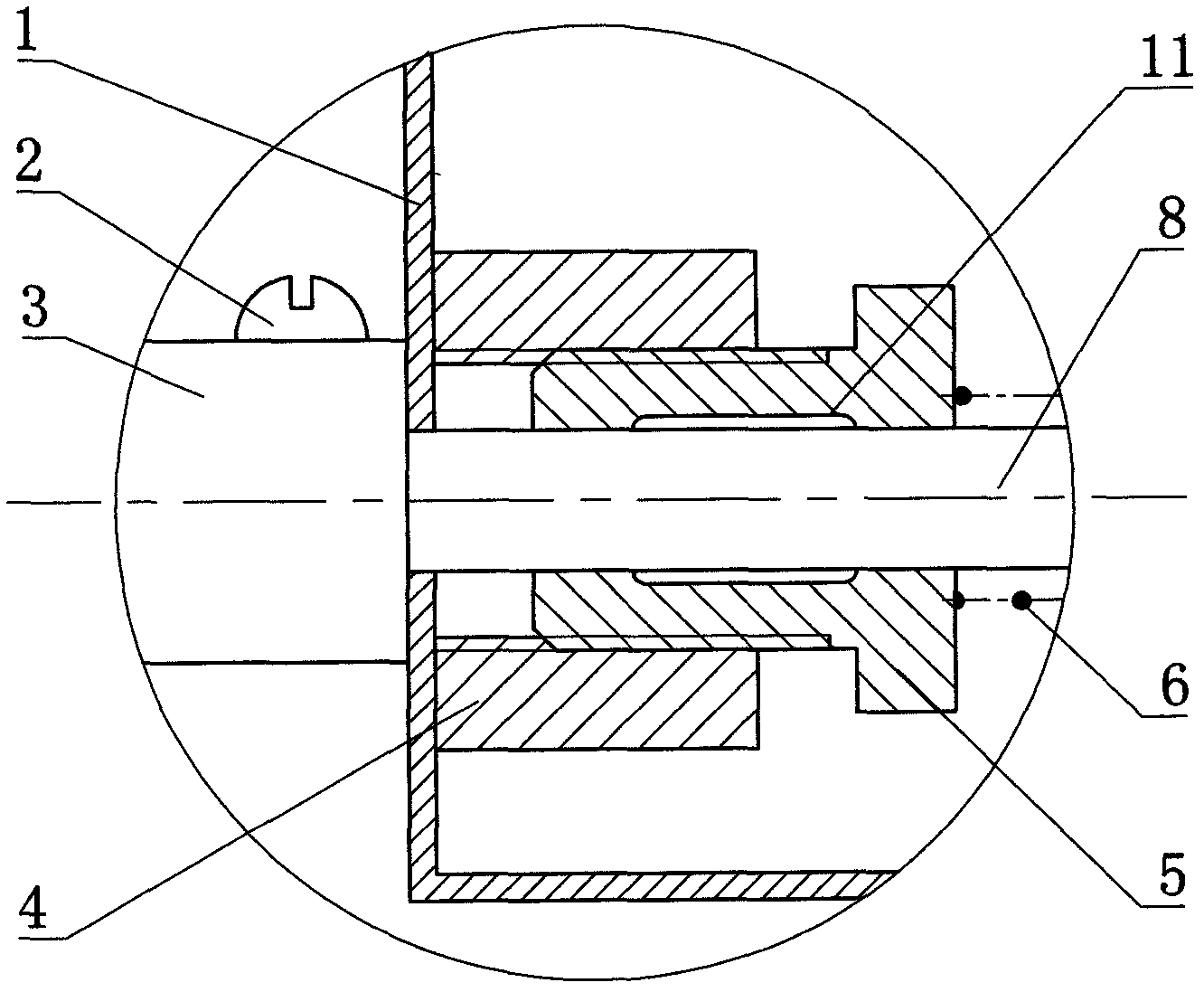

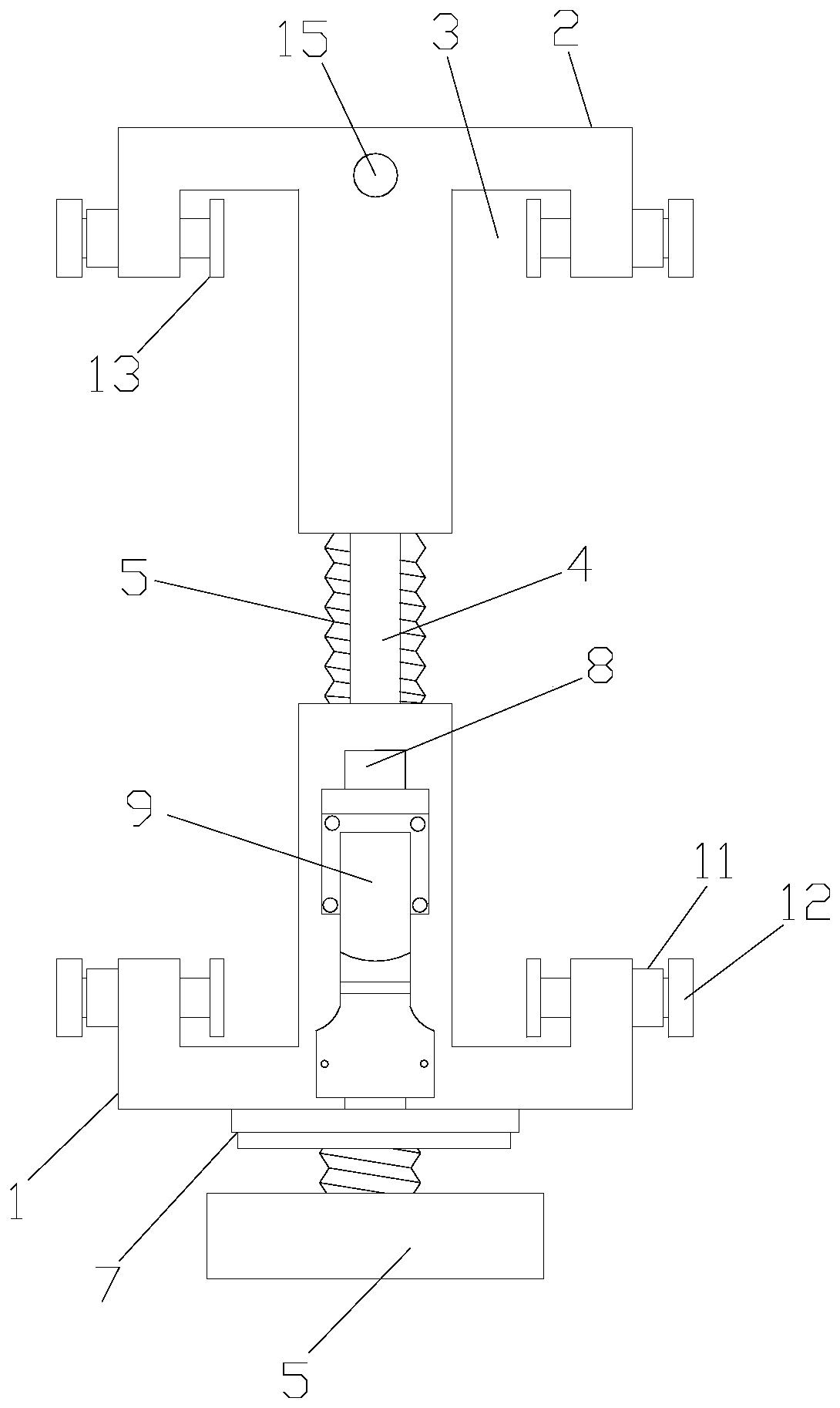

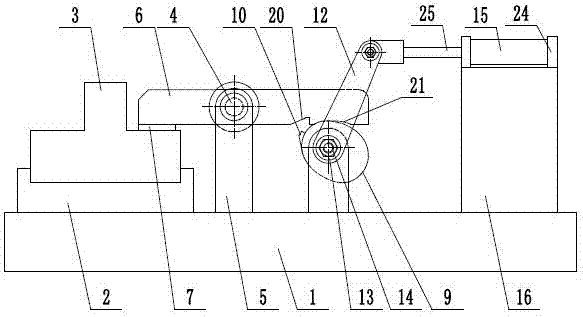

Precise rail docking device of self-walking trolley conveying machine

InactiveCN104150174ALimited axial freedomRestricted circumferential degrees of freedomMechanical conveyorsEngineeringMechanical engineering

The invention discloses a precise rail docking device of a self-walking trolley conveying machine. The precise rail docking device of the self-walking trolley conveying machine comprises a movable rail, a fixed rail and a rail docking rod and further comprises an air cylinder fixing base, an air cylinder, an air cylinder end base, a fixed-end positioning composite base, an anti-loosening plate, a movable-end positioning composite base, an end cover and three positioning bases. An upper limiting switch and a lower limiting switch are arranged on the air cylinder, a tenon and outer threads are arranged on an air cylinder stretching shaft, the air cylinder stretching shaft and the rail docking rod are connected in a threaded mode, a hole matched with the tenon in size on the air cylinder stretching shaft is formed in the anti-loosening plate, and the anti-loosening plate is arranged on the lower end face of the rail docking rod through bolts and arranged on the tenon of the air cylinder stretching plate in a sleeved mode. The precise rail docking device of the self-walking trolley conveying machine is simple in structure, good in anti-loosening performance, high in rail docking accuracy, safe and reliable and long in service life.

Owner:HUANGSHI HUATIAN AUTOMATION EQUIP

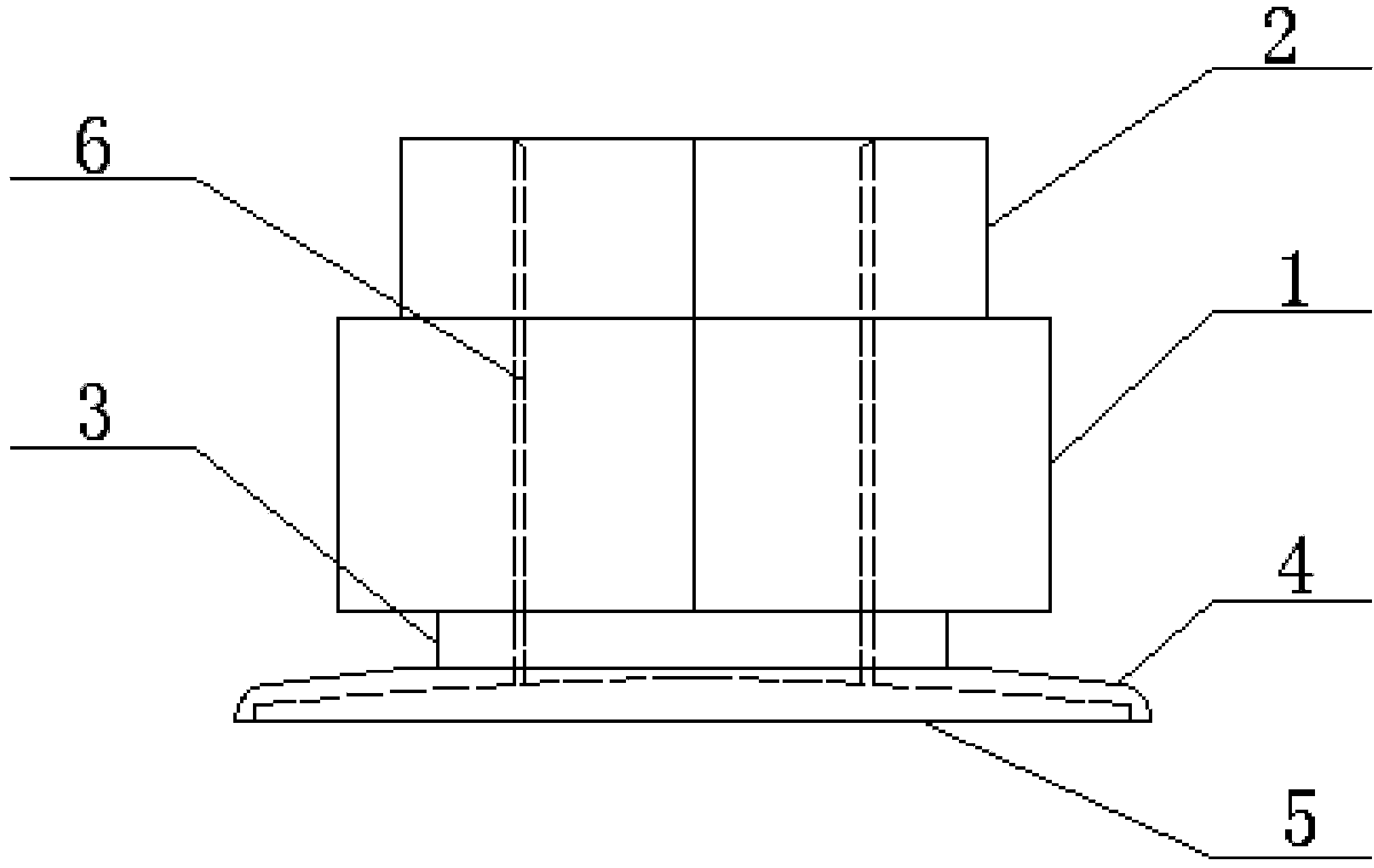

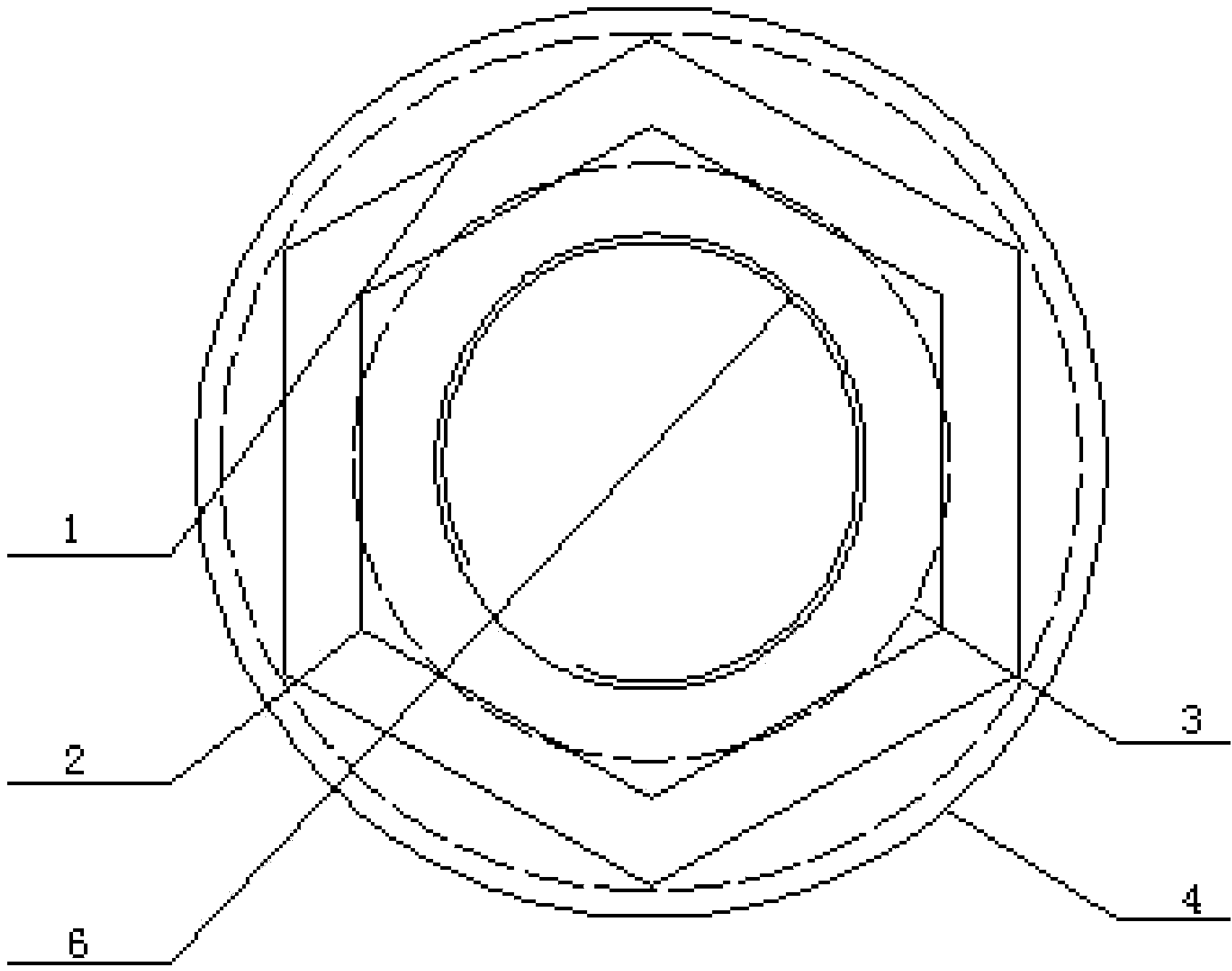

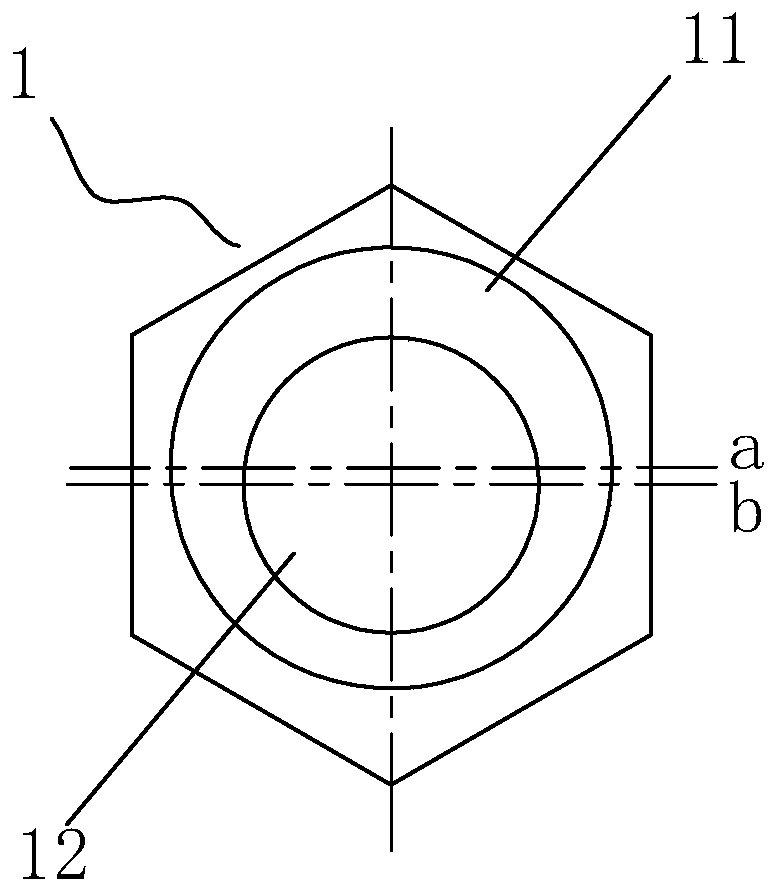

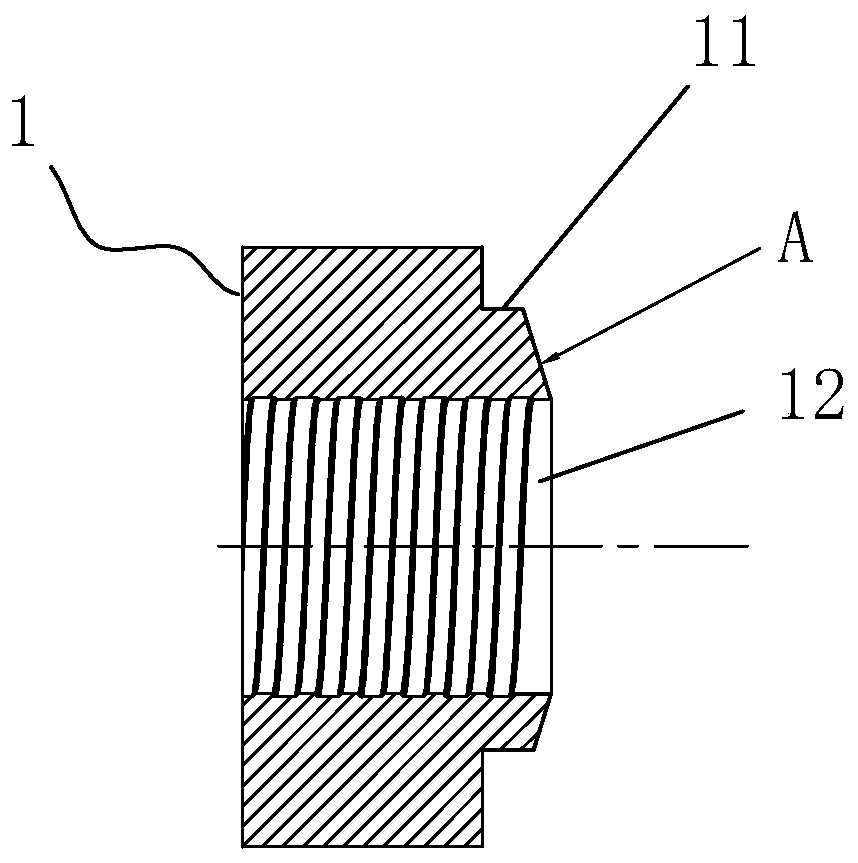

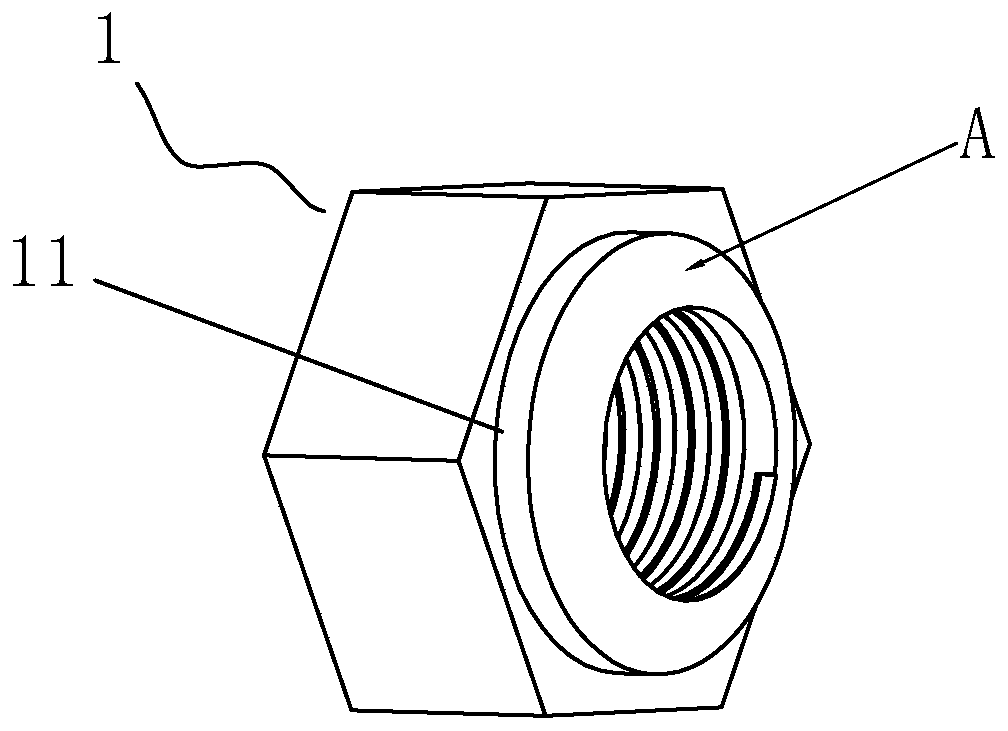

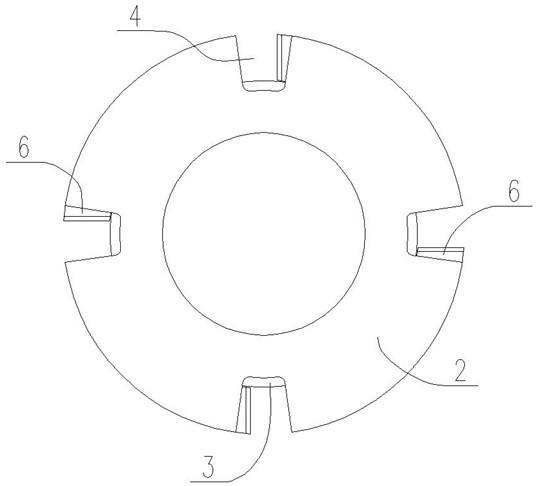

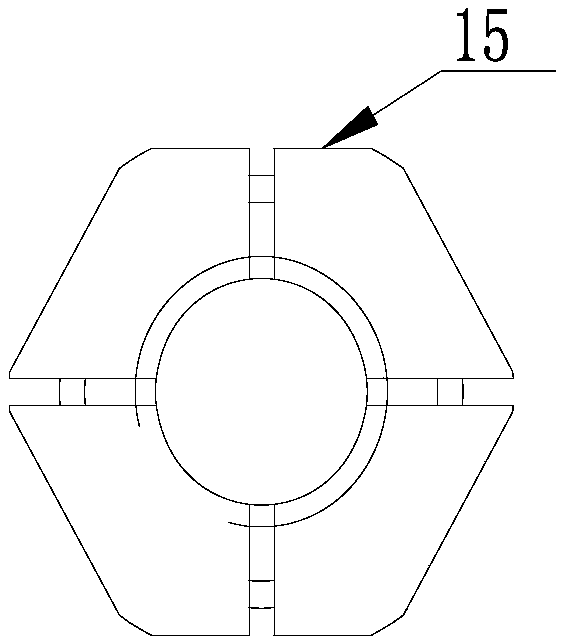

Nut

The invention discloses a nut. The nut comprises nut bodies comprising the first nut body and the second nut body located above the first nut body, wherein the external diameter of the second nut body is smaller than that of the first nut body, the lower portion of the first nut body is provided with a transition cylinder with the external diameter being smaller than the diameter of the inscribed circle of the first nut body, the bottom of the transition cylinder is provided with an installation piece extending outwards, the lower bottom surface of the installation piece is an arch-shaped surface concaved inwards, and a threaded through hole of an oval structure is arranged in the nut bodies. As the threaded through hole is an oval hole, the nut is difficult to screw up or unscrew in screwing up and unscrewing processes, the nut falls off from a stud hardly after being screwed up because of inconformity of the hole diameters under the condition that vibration is serious, and use safe performance of a machine is improved. The nut is good in looseness preventing performance and long in service life and has good use value and economical value.

Owner:费小芳

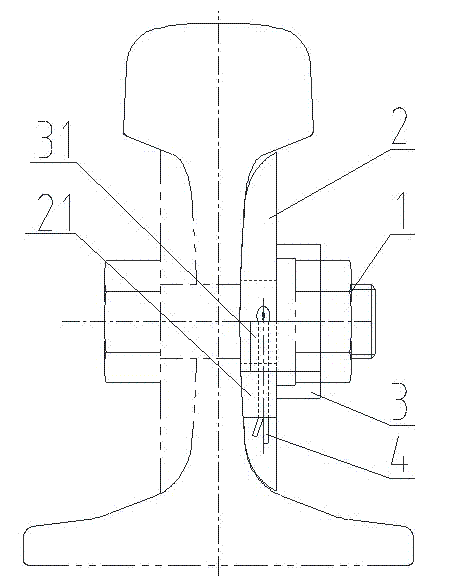

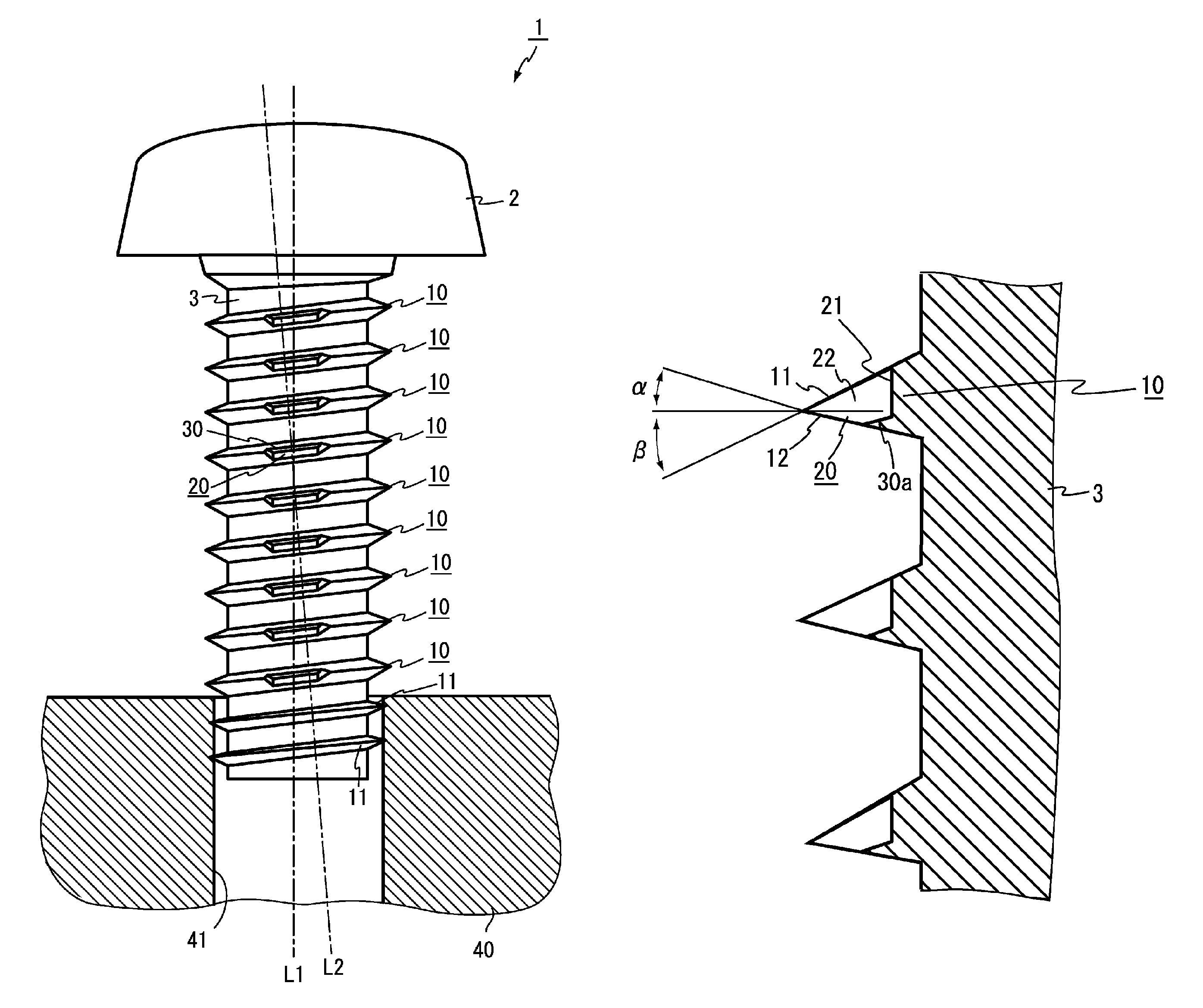

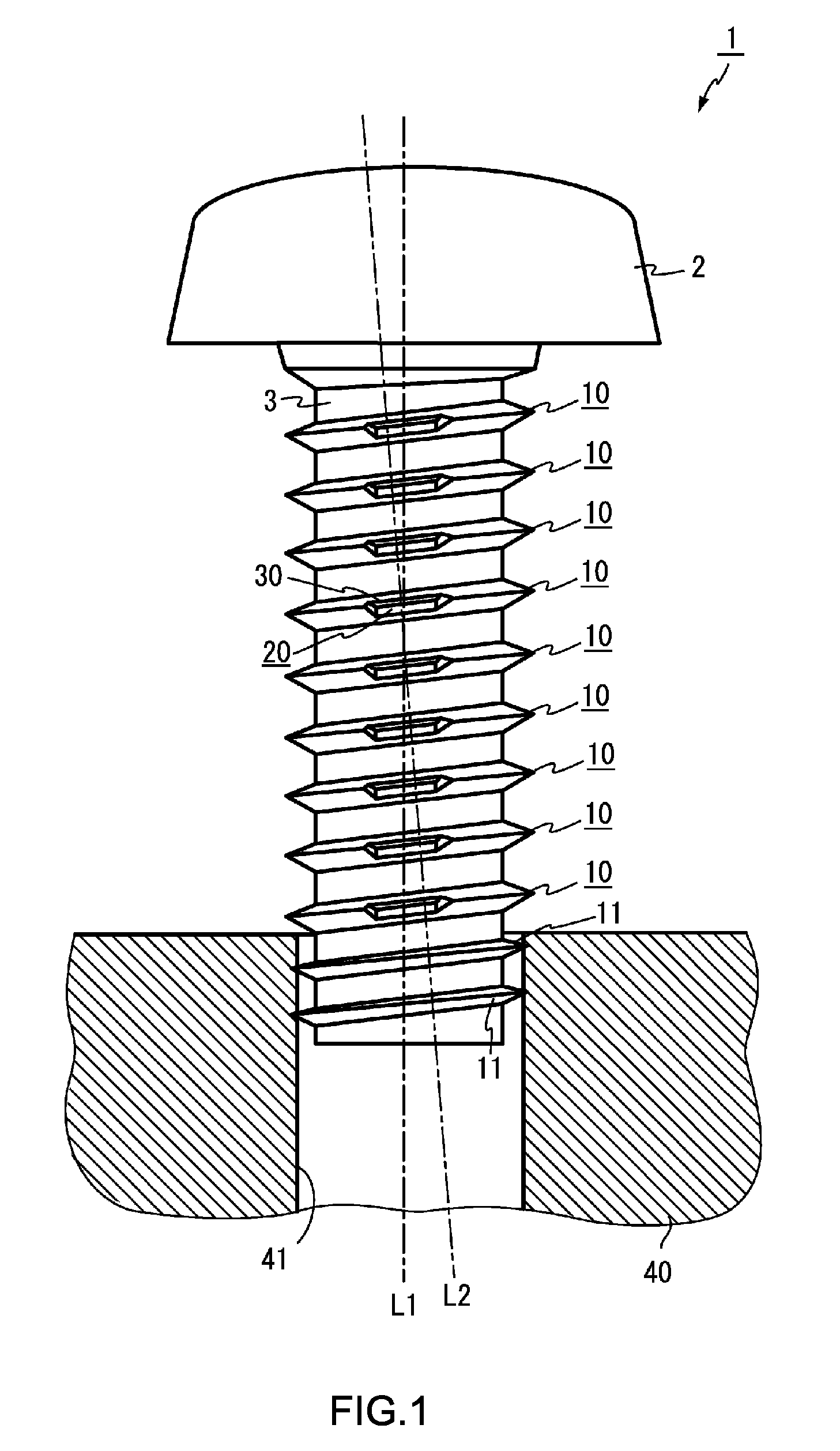

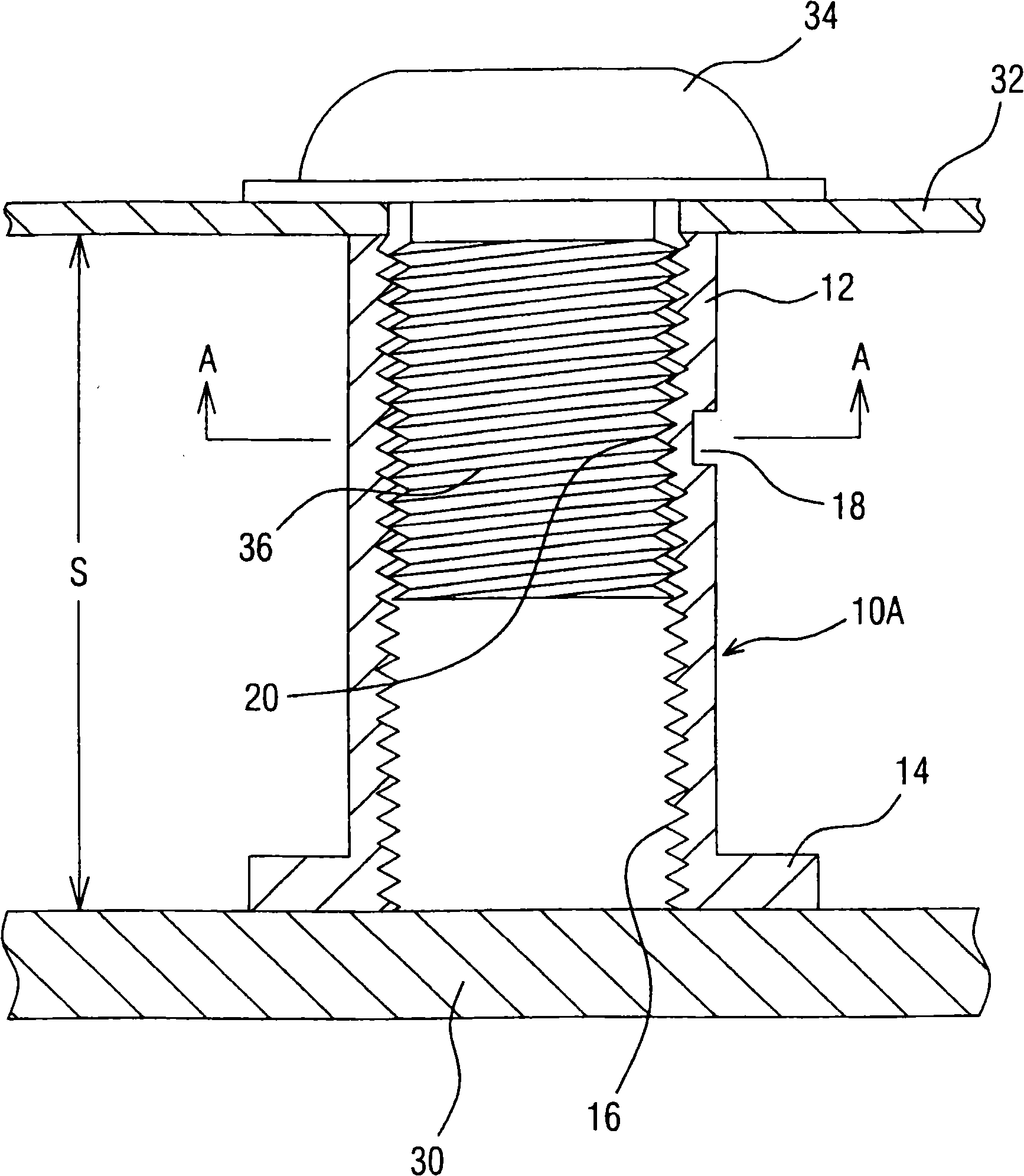

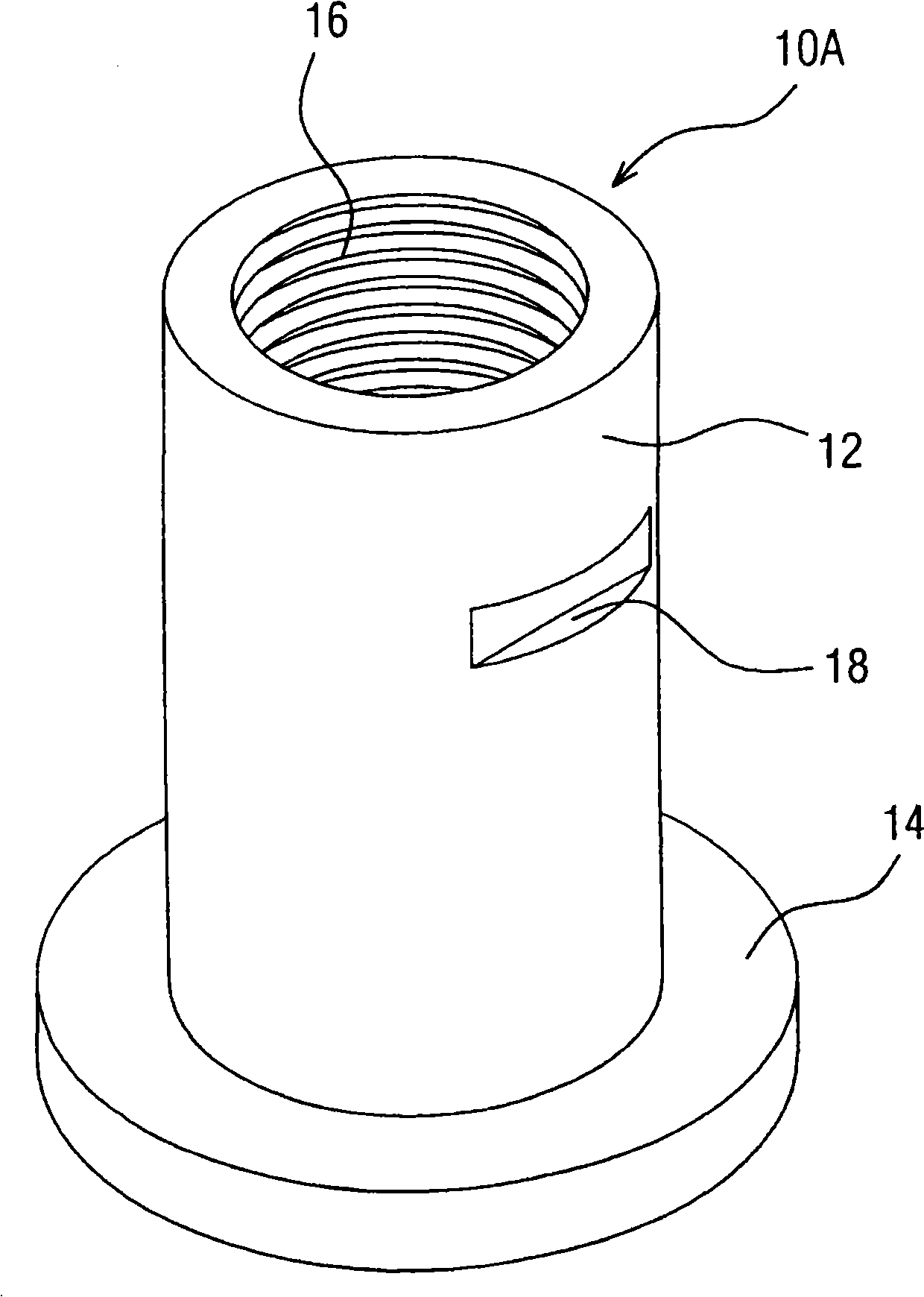

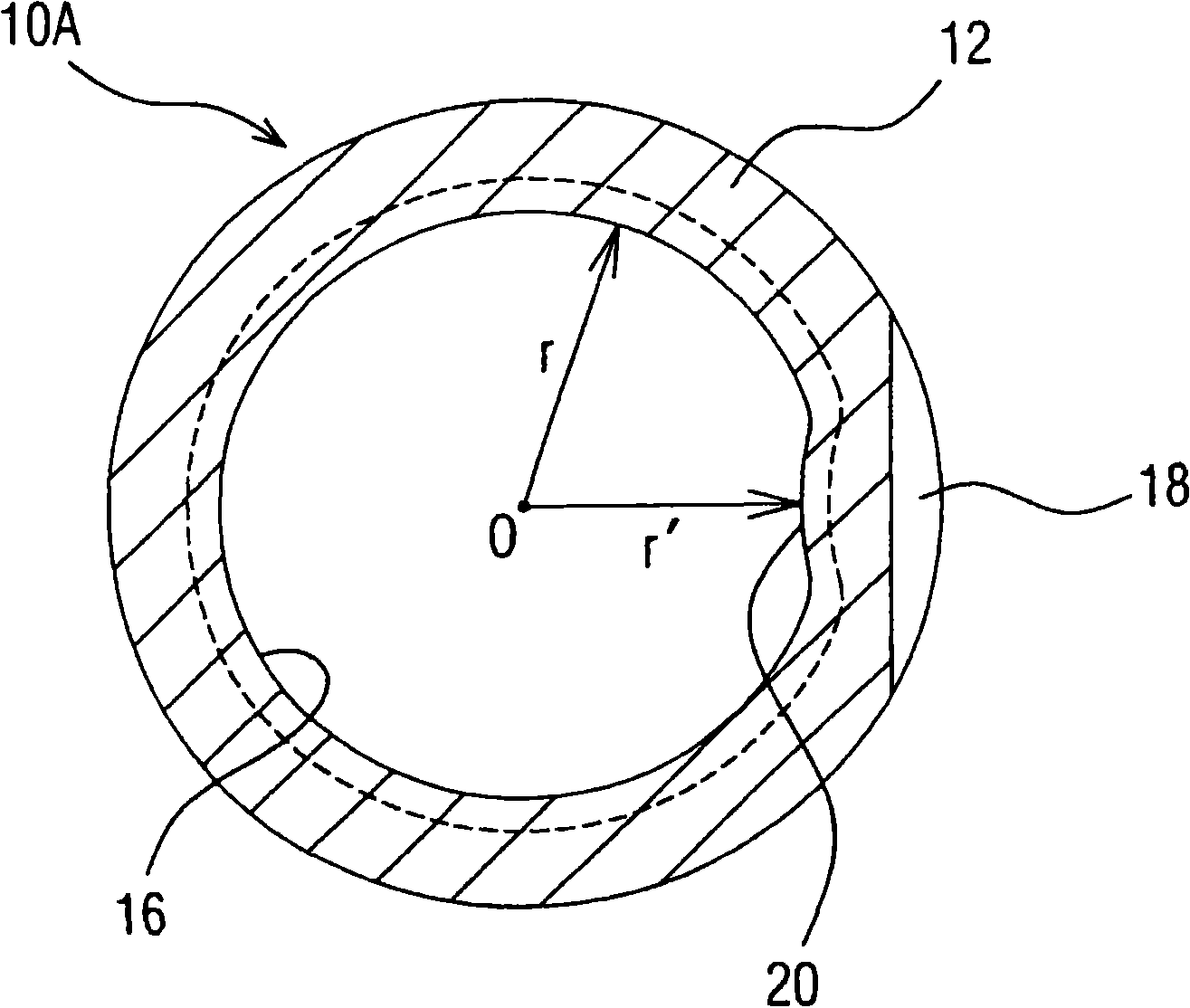

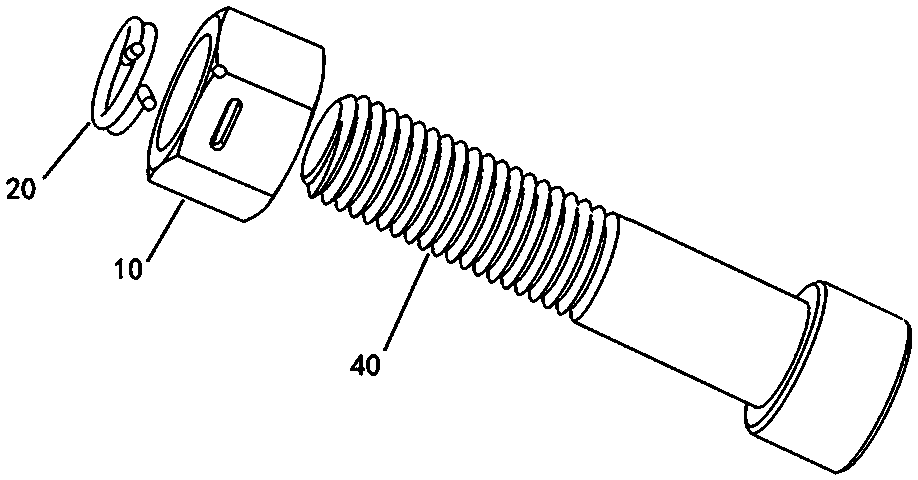

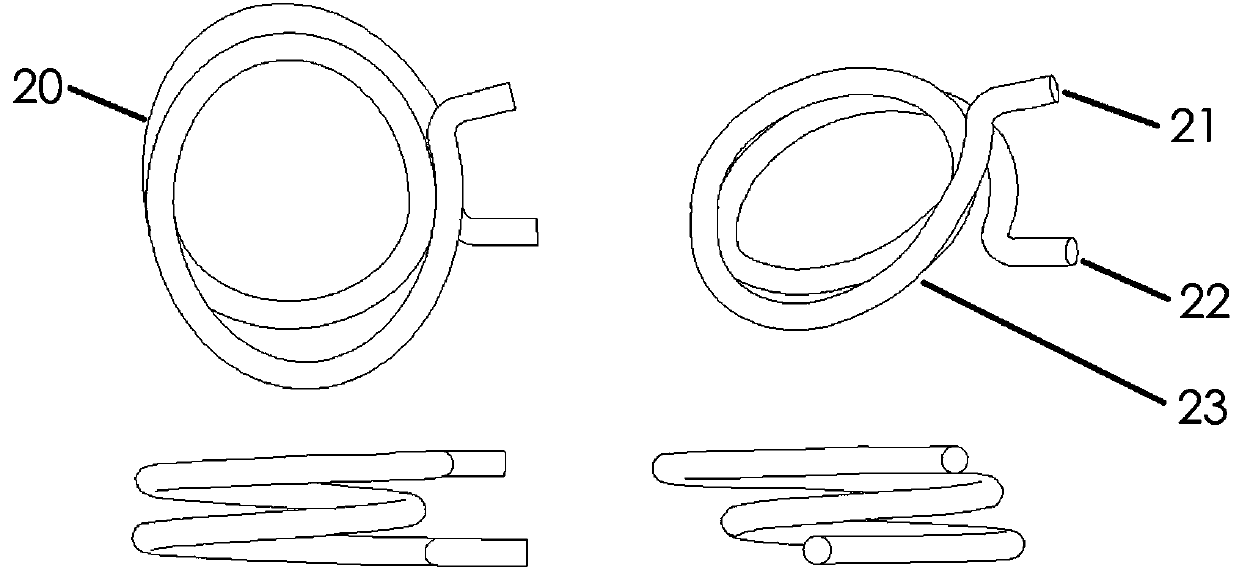

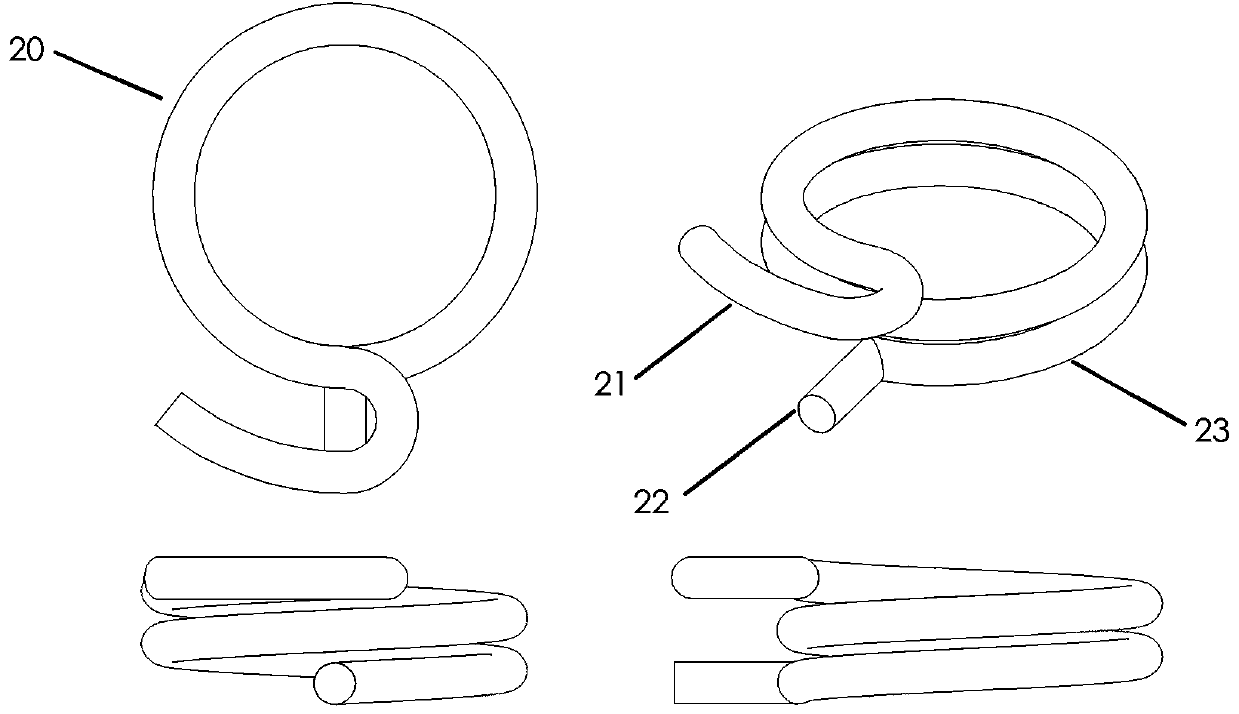

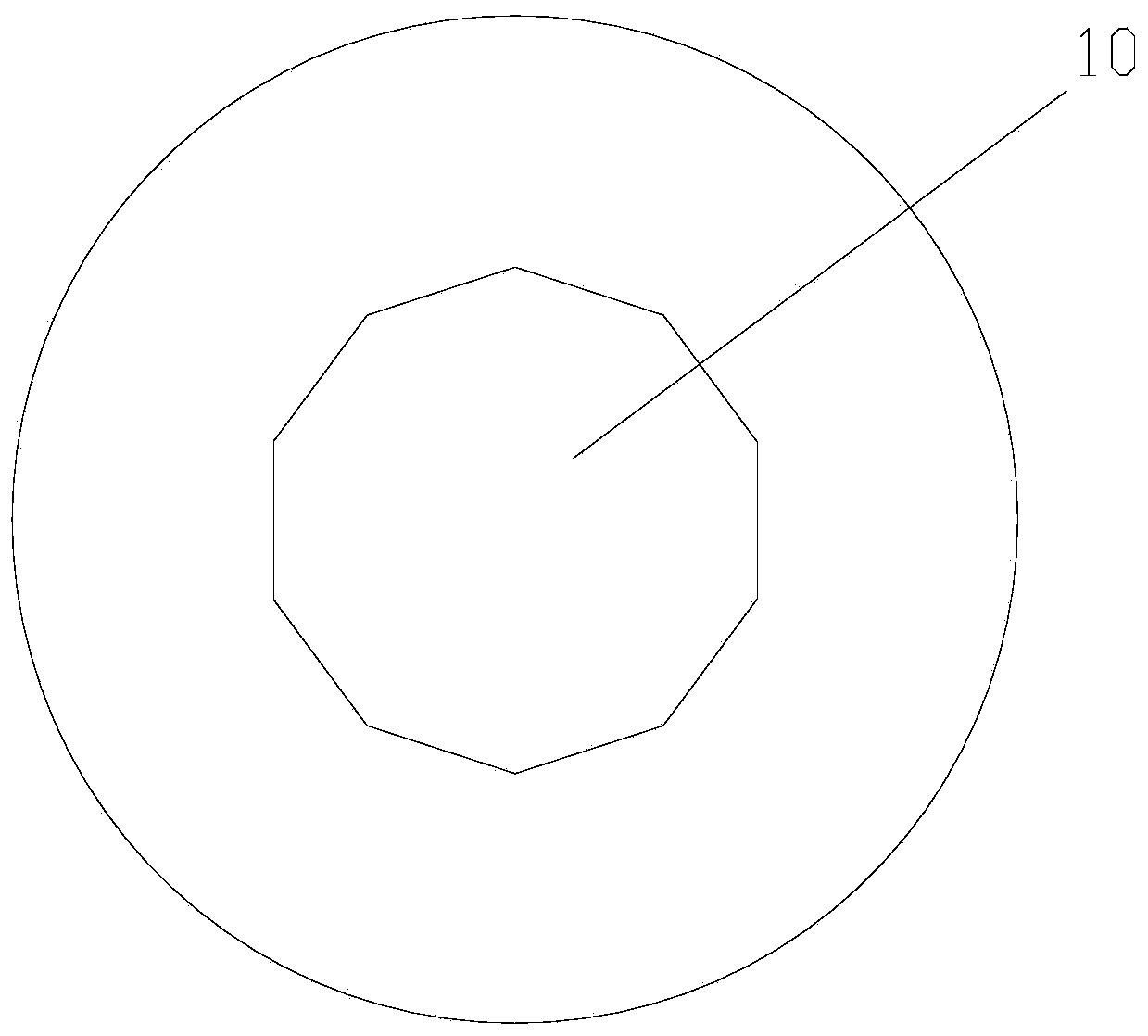

Slack preventive fastener for screw tool, and method and device for manufacturing the same

The present invention provides a slack preventive fastener for a screw tool formed in a relatively simple structure, easily manufacturable at low cost by mass production, and capable of easily and securely preventing a screw tool from being loosened as a fastener for a screw tool miniaturized or refined by precise processing for assembling various types of small-sized products; and a method and a device for manufacturing the fastener. The fastener comprises a fastening device (10) such as a nut, an insert, etc. to be fastened with the screw device such as a screw, a bolt, etc. A recessed part (18) formed by press-molding from the outside is provided in a part of the outer peripheral wall of the fastening device to form a diameter-reduced deformation part (20) where the diameter of the crest or bottom of a female thread is partially reduced in the inner peripheral wall of the fastening device.

Owner:户津胜行

Anti-vibration anti-loose spring nut structure

The invention discloses an anti-vibration anti-loose spring nut structure. The anti-vibration anti-loose spring nut structure comprises a nut main body and an anti-loose spring, wherein a partial internal thread is arranged at the rear end part of the inner wall of the nut main body, the front end part of the inner wall of the nut main body is further provided with a step part without the internalthread, the anti-loose spring is provided with a head end, a coil and a tail end, a clamping part and a transverse I-shaped opening groove are formed in the inner wall of the step part, the clampingpart is used for fixing the head end of the anti-loose spring, the tail end part of the anti-loose spring is clamped in the transverse I-shaped opening groove, the tail end part extends out or does not extend out of the outer wall of the nut main body, a circle of anti-loose teeth is arranged at the rear end of the nut main body, the anti-loose teeth can increase friction force between the anti-loose teeth and a contacted workpiece, a bolt is prevented from being loosened due to the action of an external force through the overall elastic clamping force of the anti-loose spring, so that the defect that a traditional nut is easy to loose from a bolt is effectively overcome, production process is simple, multiple times of repeated use can be realized, and a safe and lasting anti-loose effectcan be fully realized.

Owner:SHENZHEN YIJINGGONG HARDWARE SPRING

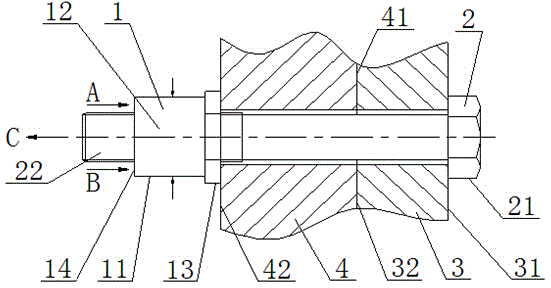

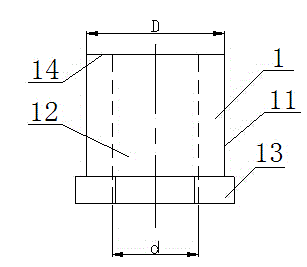

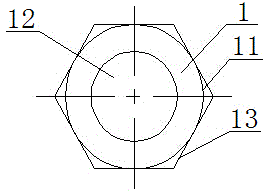

End surface taper centering and interlocking lock nut suite

The invention discloses an end surface taper centering and interlocking lock nut suite which comprises an upper nut with an axial threaded through hole I and a lower nut with an axial threaded throughhole II; one end surface of the upper nut is configured to be a boss; the end surface of the boss is tapered; one end surface of the lower nut is provided with a cylindrical groove adapted to the boss in a sunken forming manner; a taper adapted to the end surface of the boss is made at a contact plane of the bottom of the groove and the end surface of the boss; and in an assembly state, the end surface of the boss is arranged at the bottom of the groove, the central axis of the threaded through hole I coincides with the central axis of the threaded through hole II, and the boss of the upper nut is in clearance fit with the cylindrical groove of the lower nut. For the nut suite provided by the invention, by adopting a novel end surface taper centering and interlocking lock nut suite whichadopts end surface taper centering to avoid the situation that lateral force is additionally applied to a screw rod by eccentricity, the thread lateral stress caused by matching with side surface of an eccentric cone is avoided, and the safety and the anti-seismic performance of the novel end surface taper centering and interlocking lock nut suite are both superior to an existing shockproof nut inthe market.

Owner:周峰

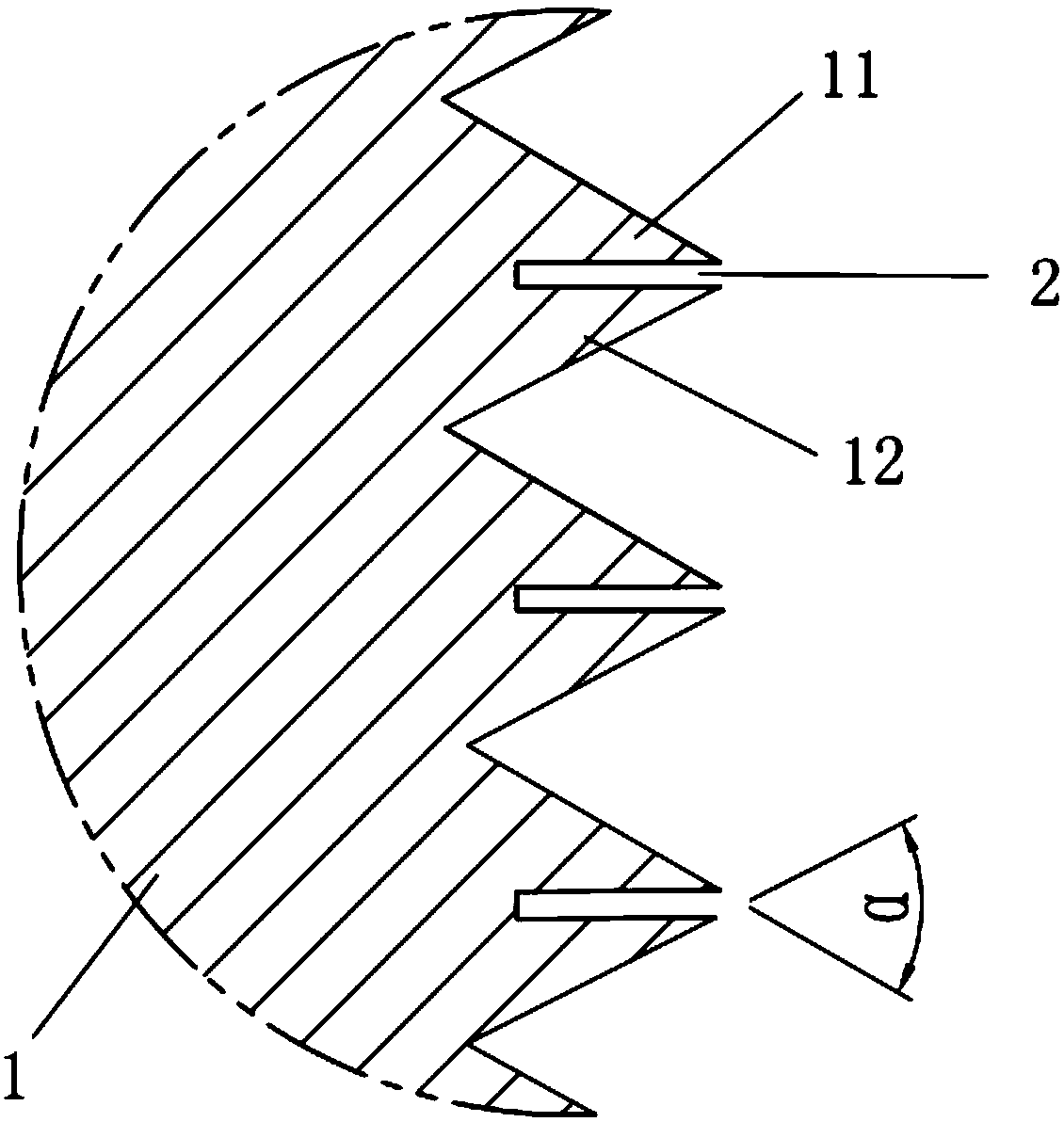

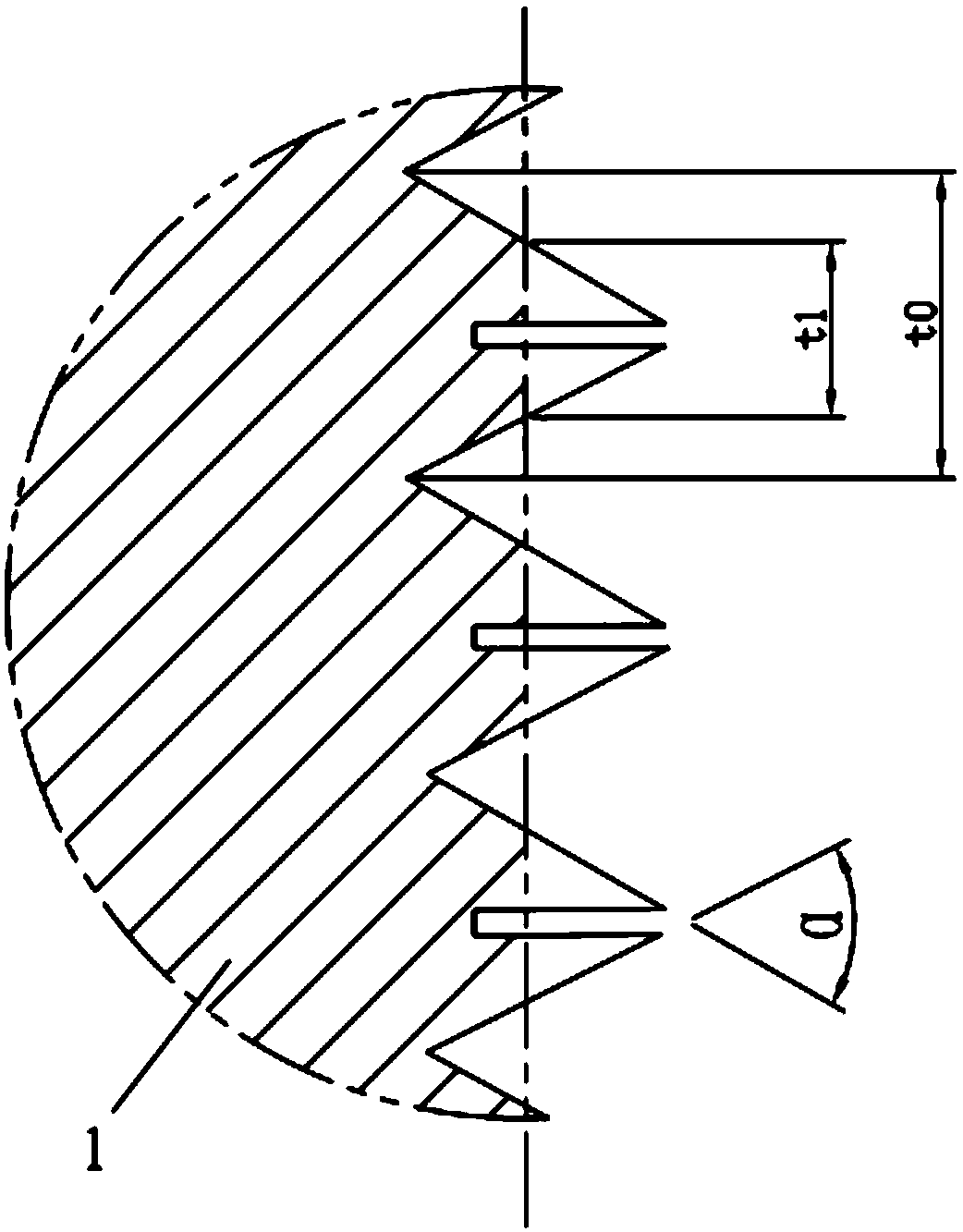

Lock thread

ActiveCN109372880APrevents threaded connections from looseningGood anti-loose performanceNutsBoltsGreek letter alphaEngineering

The invention relates to the technical field of mechanical connection, in particular to a lock thread. The lock thread comprises a thread tooth, and the thread angle of the lock thread is alpha. The top of the thread tooth is concaved downwards to form a groove, and the thread tooth is divided by the groove into a first auxiliary tooth and a second auxiliary tooth, wherein the first auxiliary tooth and the second auxiliary tooth can generate elastic deformation towards the groove when being extruded. After the structure is adopted, the tooth middle diameter of the lock thread is larger than the tooth middle diameter of a standard thread, due to the fact that the thread tooth of the lock thread is divided by the groove into the first auxiliary tooth and the second auxiliary tooth, when thestandard thread and the lock thread are used for threaded connection, the first auxiliary tooth and the second auxiliary tooth of the lock thread are extruded by a standard thread tooth and are elastically deformed towards the groove, elastic force generated by elastic deformation of the first auxiliary tooth and the second auxiliary tooth presses the standard thread tooth from two contact faces,thread connection loosening is effectively prevented, the lock performance is good, and reliability is high.

Owner:GUANGDONG IND TECHN COLLEGE

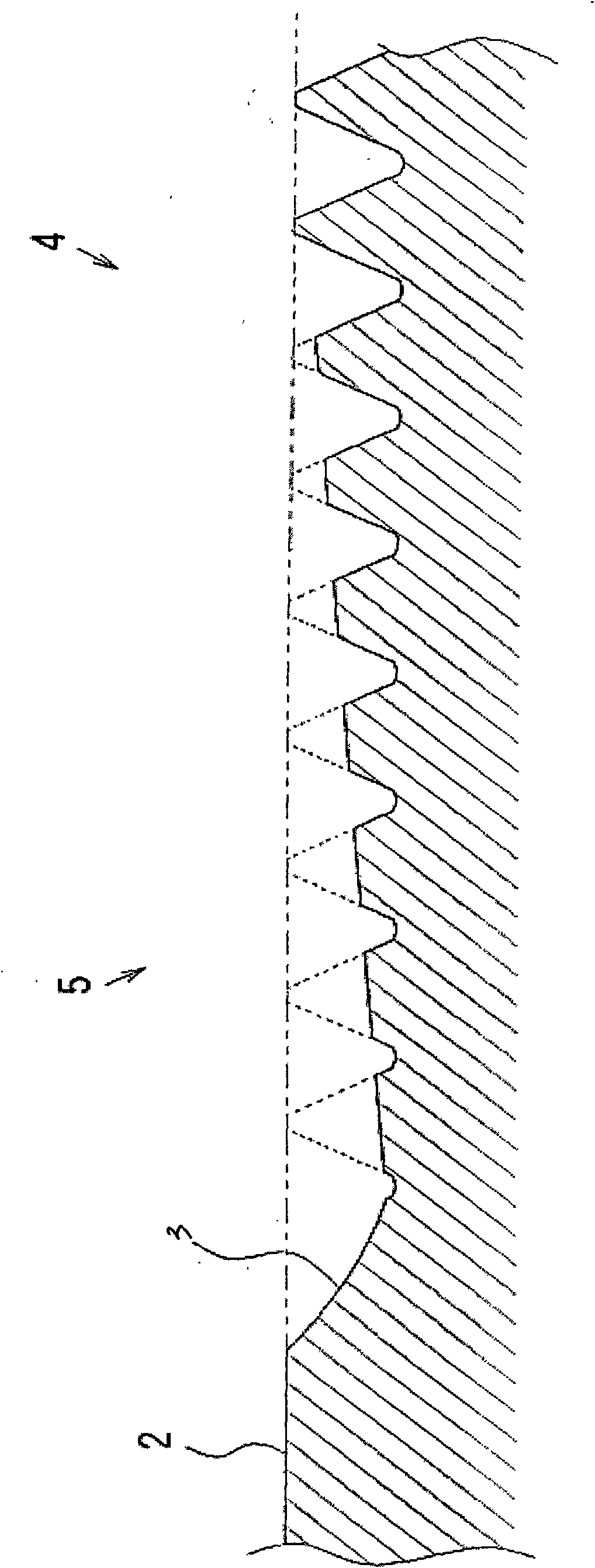

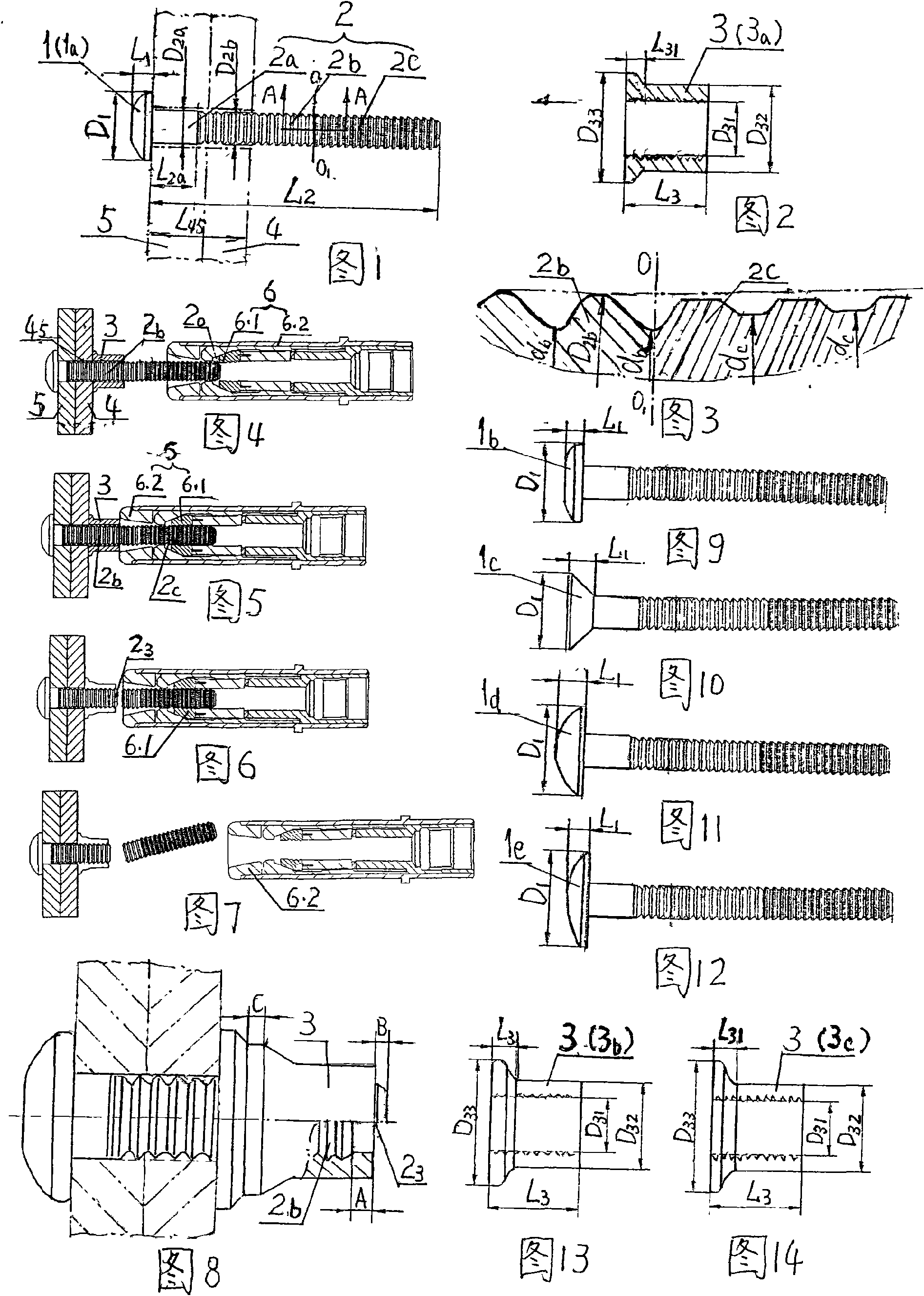

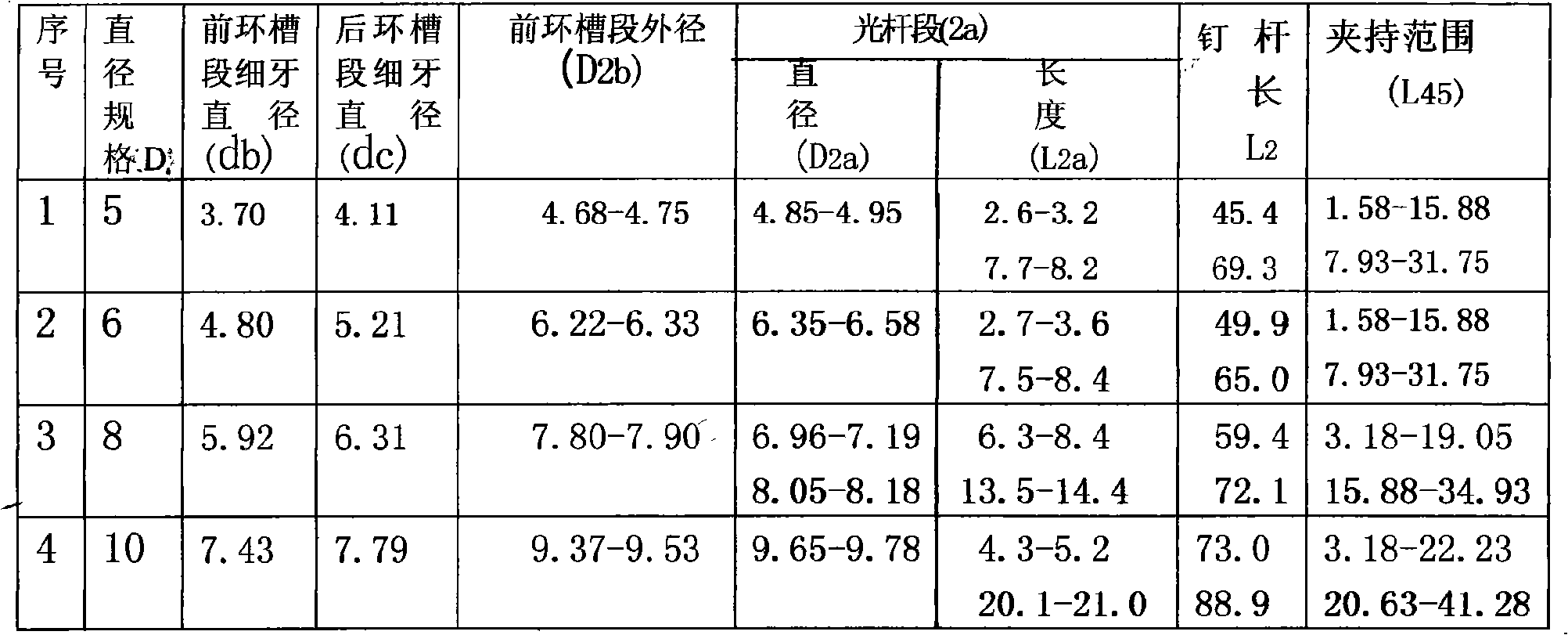

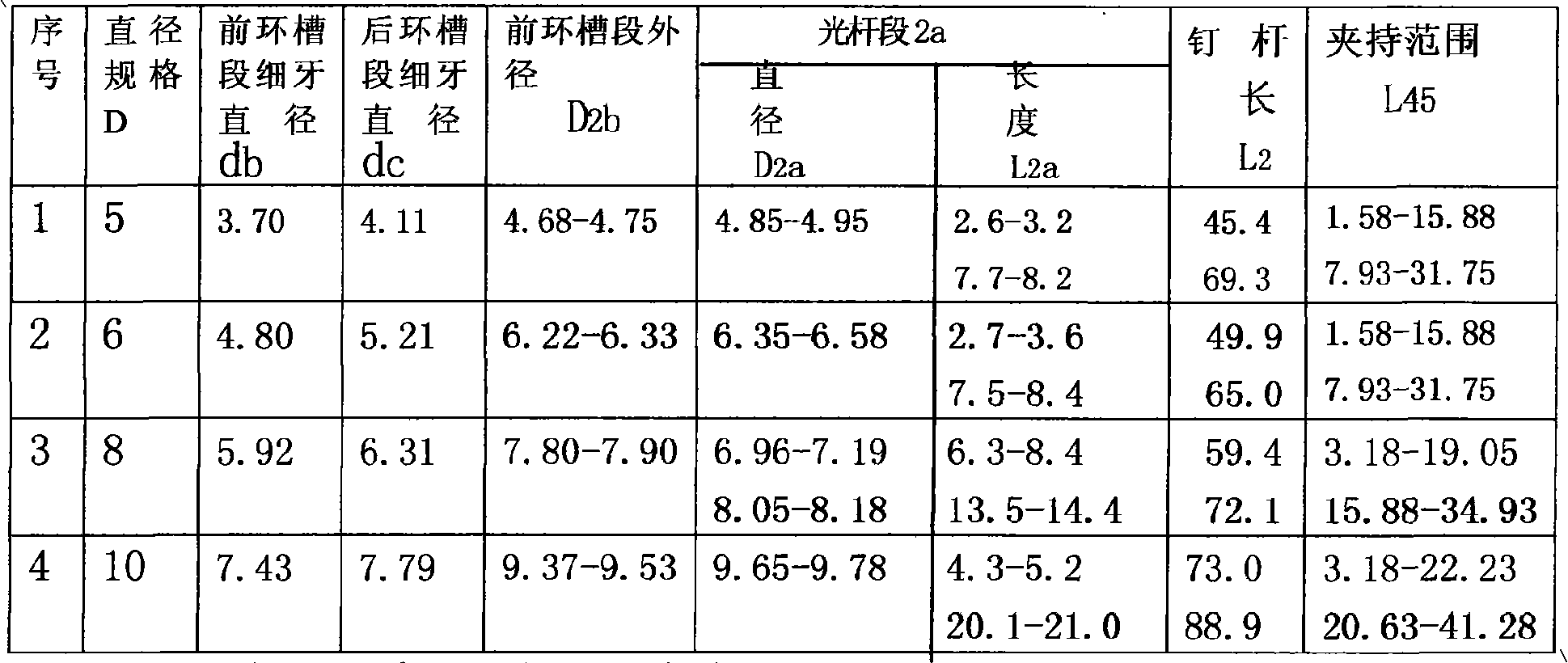

Small ring-grooved rivet with wide range and riveting method

The invention relates to a small ring-grooved rivet with wide range and a riveting method; the small ring-grooved rivet is composed of a rivet head, a rivet pole and a lantern ring, the rivet pole is composed of a polished rod section at the front end, a front ring-grooved section matched with the lantern ring in an extruding way and a rear ring-grooved section riveted with a riveting device at the rear end; the diameter of the fin thread of the front ring-grooved section is less than that of the rear ring-grooved section, and the length of the front ring-grooved section is matched with the maximum holding thickness; the advantages of high intensity, good locking performance and high corrosion resistance of the ring-grooved rivet are kept, and the holding range is increased to five times of common small ring-grooved rivet with the same diameter; in addition, the rivet is snapped at the end of the lantern ring, therefore, the rivet is artistic and tidy after being installed. The ring-grooved rivet solves the problems that the existing rivet has complex kinds caused by small holding range about 3mm, the installation field needs a plurality of kinds of the rivets to be used alternatively, and the trouble caused by storage of a plurality of kinds of the rivets or hundreds of kinds of the rivets occurs, the installation is wrong and the re-installation is needed. The invention provides various rivet heads with the diameter of 5, 6, 8 and 10mm and optimized size range and test results of the lantern ring type rivets, and is particularly suitable for the occasions which need rivets with small specification such as steel structures of railroad wagons, automobiles and bridge girders and the like.

Owner:CRRC MEISHAN

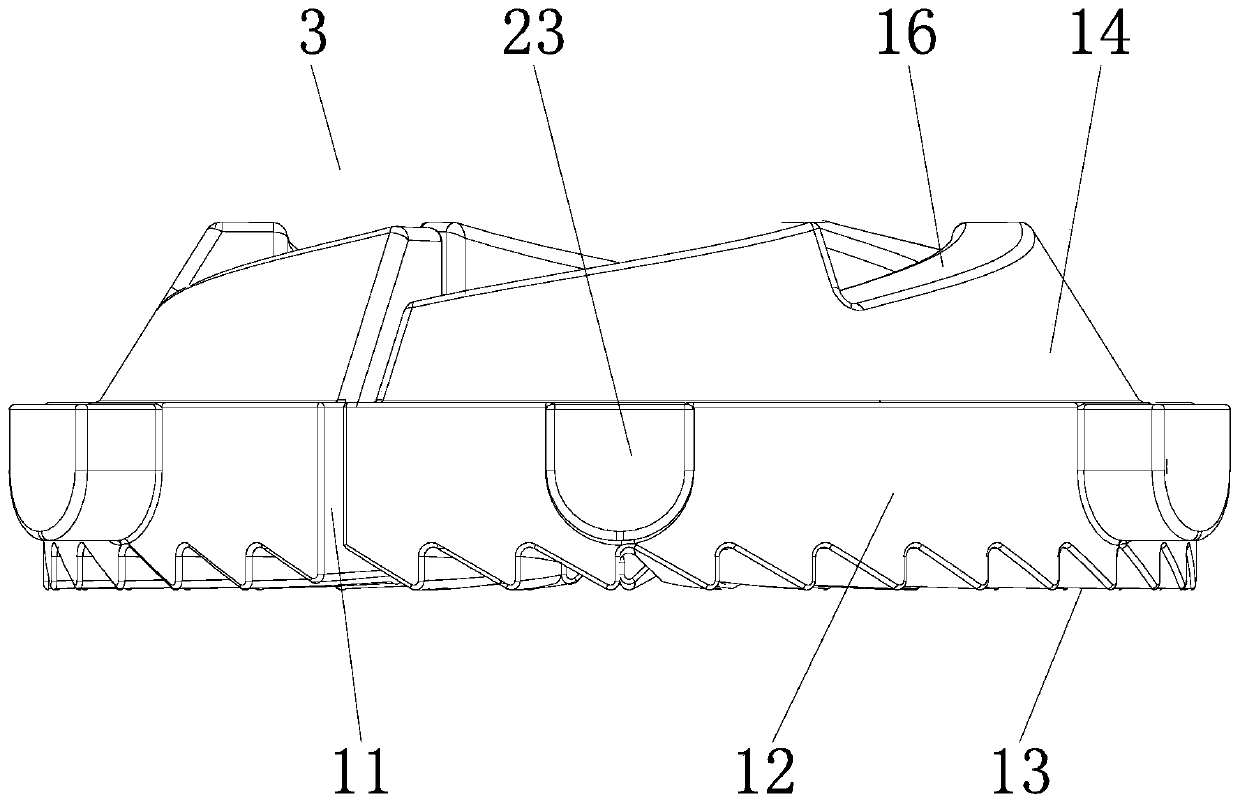

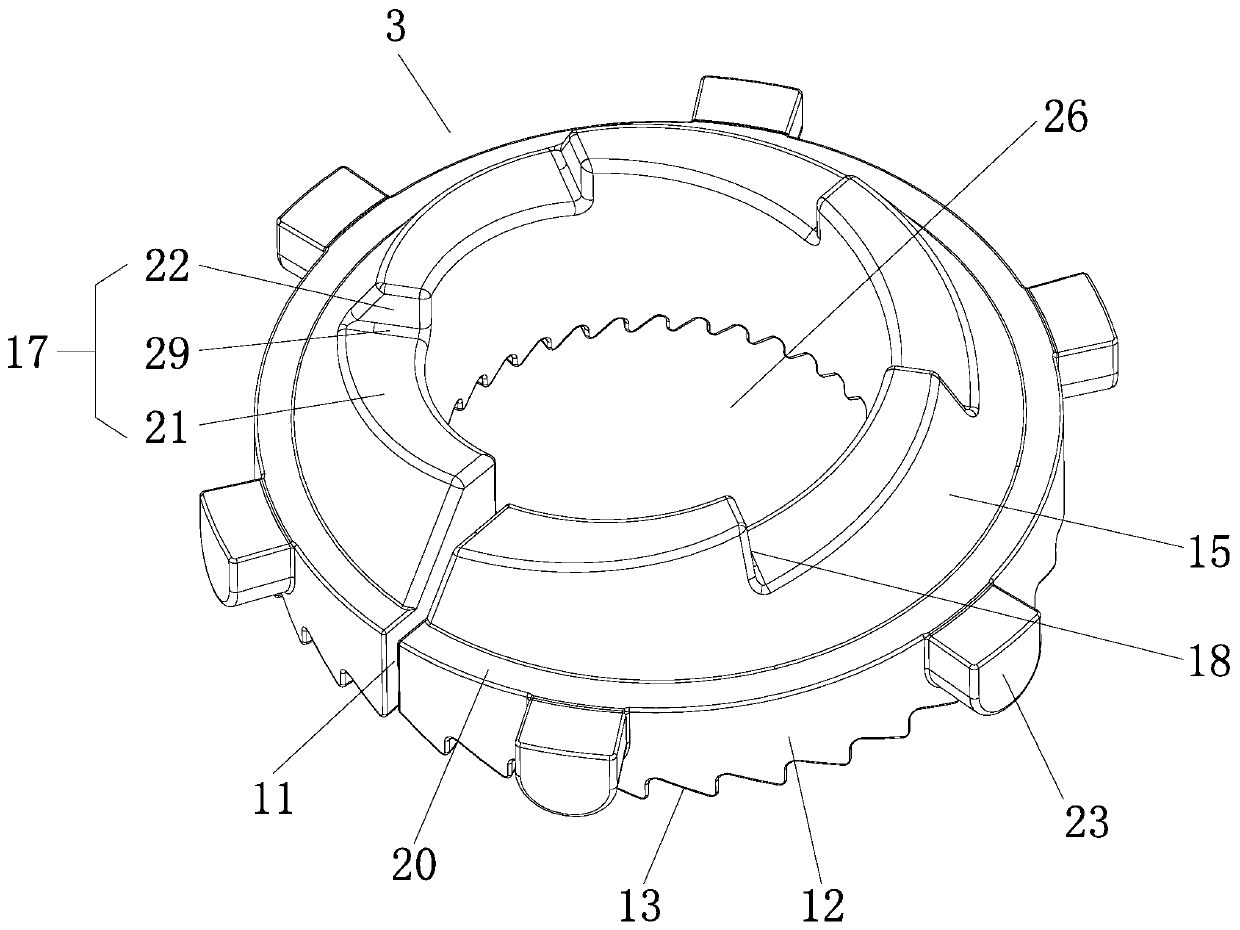

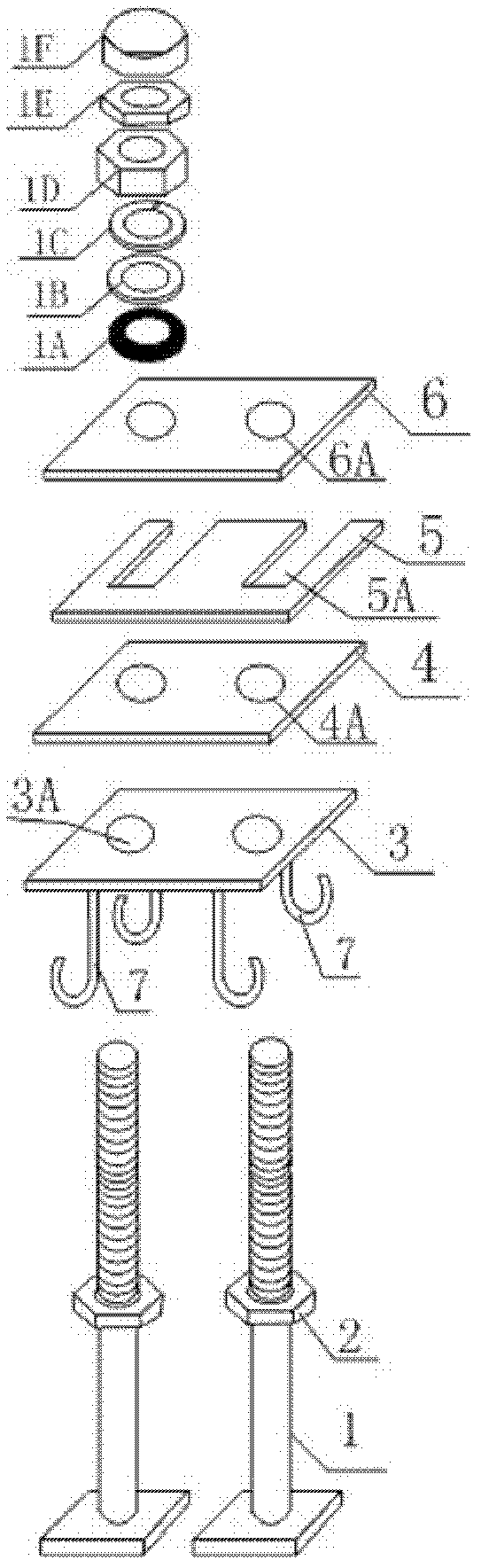

Elastic gasket, screw assembly and nut assembly of anti-loose screw combined structure

The invention discloses an elastic gasket of an anti-loose screw combined structure. The elastic gasket comprises a ring body with a port, anti-slip ratchets are arranged on the bottom surface of thering body, the top surface of the ring body extends upwards to form an anti-loose ring, the anti-loose ring is tapered, so that an outer inclined surface is formed on the outer side surface of the anti-loose ring, a plurality of notches are uniformly distributed in the periphery of the top surface of the anti-loose ring, and the top surface of the anti-loose ring is enabled to form a plurality offirst one-way teeth by the plurality of notches . According to the anti-loose screw combined structure, the elastic gasket, screws and unts are simple in structure, the structure has the functions ofanti-theft, anti-loosening and the like, and solves a series of problems caused by the fact that the screws in existing mechanical equipment cannot ensure to be absolutely anti-loosened and cause loosening of the equipment during running; the structure is stable, the machining is convenient, the batch production is facilitated, the manufacturing cost is low, and the marketization can be conveniently realized; and the invention further discloses a screw assembly of the anti-loose screw combined structure and a nut assembly of the anti-loose screw combined structure.

Owner:杨小华

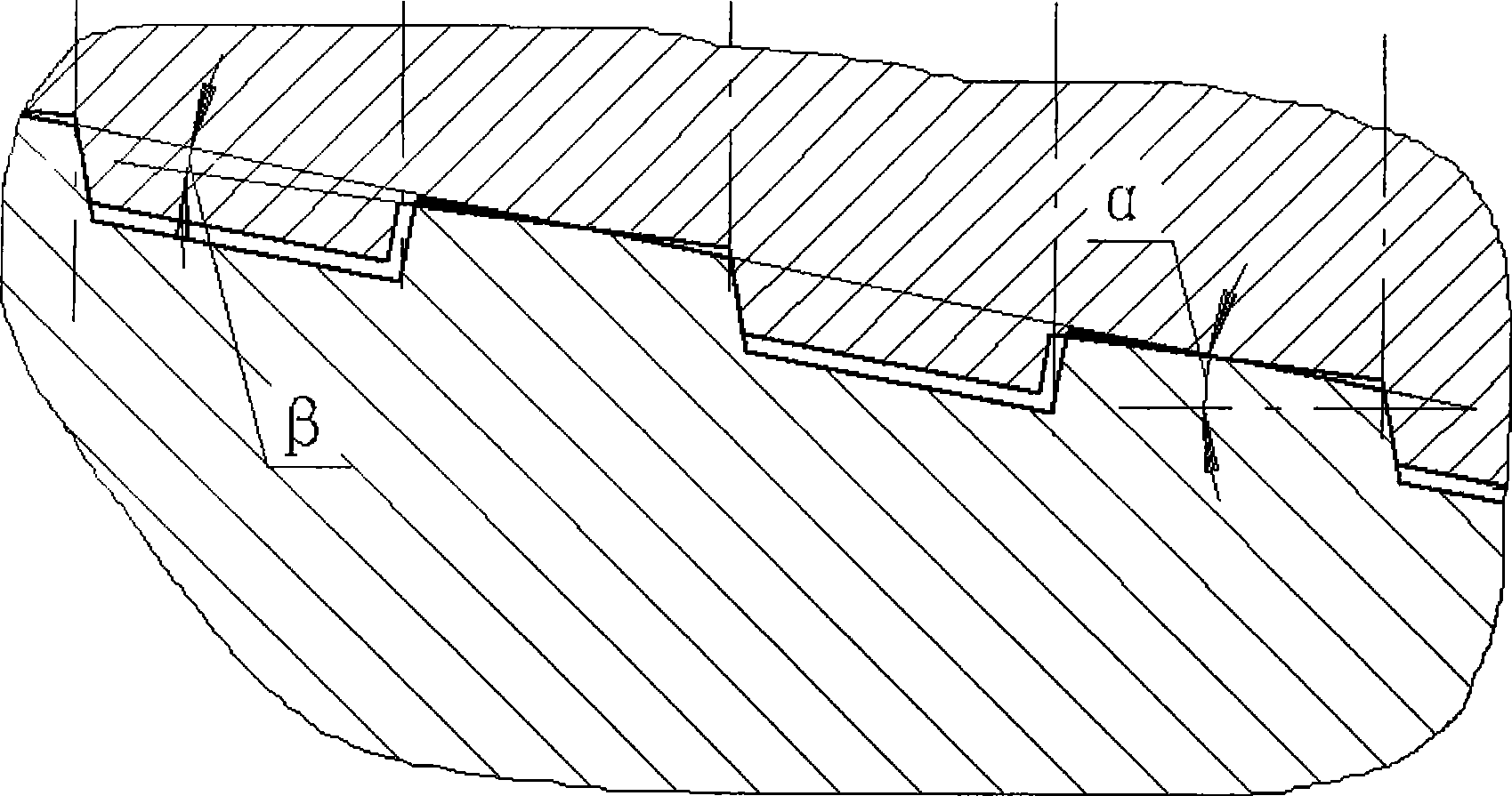

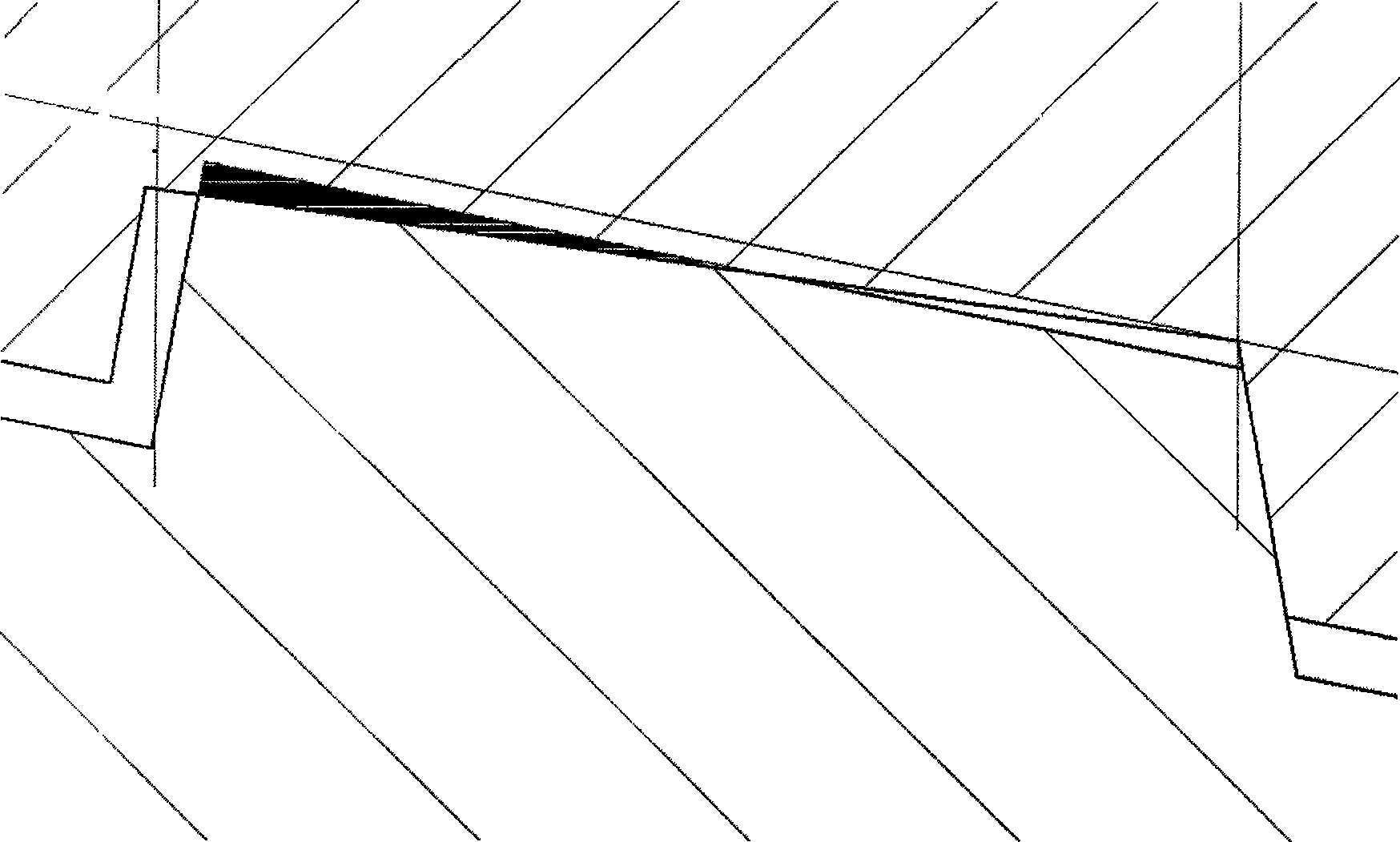

Conical internal thread

The invention relates to a tapered inside thread. The root part between teeth is a centering sloping surface, the large diameter end on the upper part of the centering sloping surface is a centering surface in interference fit with the crest of an outside tapered thread, and the included angle beta between the centering sloping surface and a main conical surface is more than 0 and less than alpha which is the inclination angle of the main conical surface. The root part between the teeth of the tapered inside thread adopts a structure with two conical surfaces of the centering sloping surface to form a full thread helical interference surface of which the size can be adjusted by adjusting the stand-off so as to accord with an operating condition requirement, and the generation of the full thread helical interference surface makes loads be evenly distributed on the full length of the thread, a self-locking helical surface is formed and has superior anti-looseness performance; and the tapered inside thread has excellent capability to resist transverse vibration for dealing with frequent vibration and alternating load, is not easy to cause abrasion and fatigue fracture, is suitable for frequent disassemblies, and can interchange with the prior product by only changing the inside thread.

Owner:河北省地矿局第一地质大队

Steel structure fastening equipment

ActiveCN110820944AEasy to recycleEasy to twistBuilding constructionsPilot holeIndustrial engineering

The invention discloses steel structure fastening equipment. A first T-shaped connecting piece and a second T-shaped connecting piece are included, are horizontally oppositely arranged and are provided with clamp grooves matched with joist steel. A joist steel matched left clamping area and a joist steel matched right clamping area are formed between the first T-shaped connecting piece and the second T-shaped connecting piece. The first T-shaped connecting piece is provided with a guiding column. The first T-shaped connecting piece and the guiding column are integrally arranged. The second T-shaped connecting piece is provided with a guiding hole matched with the guiding column. The guiding column is inserted in the guiding hole. The first T-shaped connecting piece and the second T-shapedconnecting piece are provided with locking screw holes, and a screwing handle is arranged at the tail end of a locking screw. By means of the steel structure fastening equipment, two pieces of joist steel can be detachably connected together.

Owner:隆恩建设工程有限公司

Detachable lock nut

The invention discloses a detachable lock nut which comprises a nut body, a gasket and a spacer. A receding groove is formed in the gasket, the spacer is located below the gasket, an elastic piece is arranged on the spacer, the elastic piece is located in the receding groove of the gasket, the upper end of the elastic piece extends to the position above the gasket, the nut body is located above the gasket, and a ratchet corresponding to the upper end of the elastic piece is arranged on the bottom face of the nut body. The detachable lock nut has the advantages that a good anti-loosening effect is guaranteed, meanwhile, the nut further has a detachable function, and the detachable lock nut can be conveniently and repeatedly used.

Owner:吴天宏

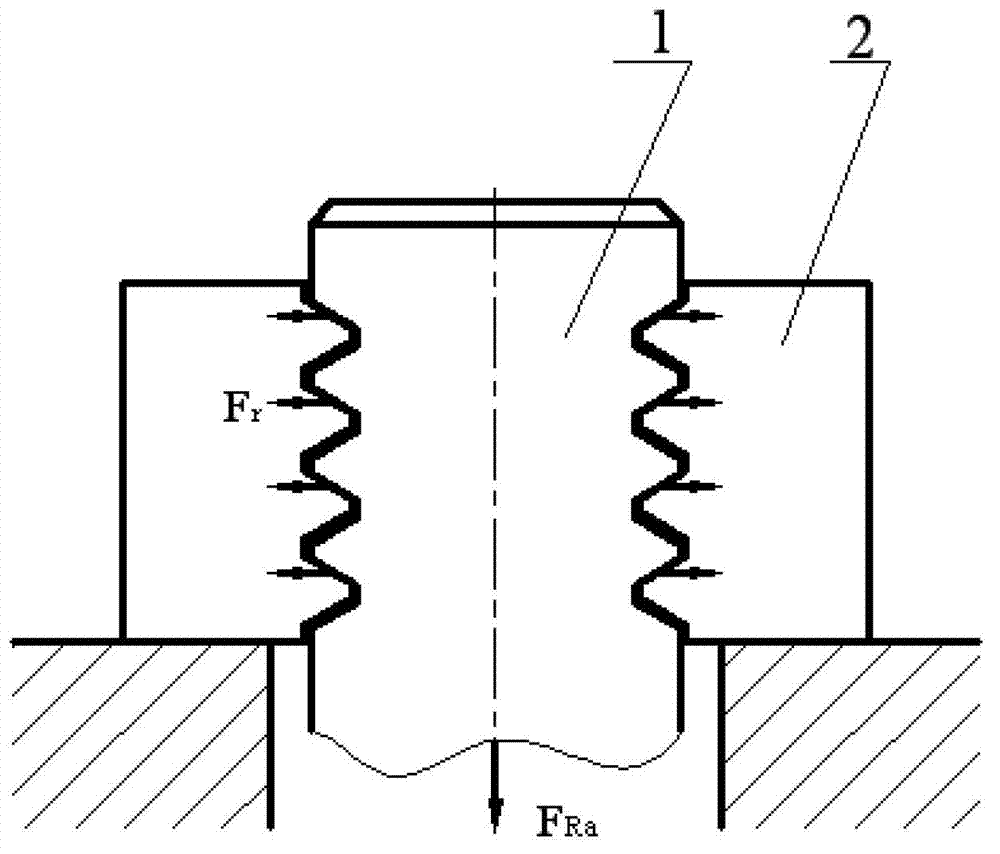

Extrusion assembly nut connection pair and assembly method thereof

InactiveCN104912897AImprove anti-loosening performanceGood anti-loosenessNutsBoltsEngineeringScrew thread

An extrusion assembly nut connection pair comprises an extrusion assembly nut and an external thread fastener, wherein the extrusion assembly nut comprises a nut body which is a cylinder, and a through hole is formed in the center of the nut body. The inner surface of the through hole is a smooth face, the diameter of the through hole is larger than the large diameter of external threads of the matched external thread fastener, and one end of the attached face of the nut body is provided with a flange face with a pulling and screwing structure. During assembly, firstly, the external thread fastener penetrates into an inner hole of a connecting piece, then, the tail of the external thread fastener is sleeved with the extrusion assembly nut, the extrusion assembly nut supports the outer end face of the nut body, the tail of the external thread fastener is pulled till designed clamping force is achieved, meanwhile, the outer circle face of the nut body is extruded and made to generate overall plastic deformation inwards, and the inner surface of the through hole of the nut and the external threads of the external thread fastener are totally meshed in shape so that internal threads can be formed. The extrusion assembly nut connection pair is good in anti-loosening performance, simple in structure, low in cost, easy to assemble and detach and capable of being reused.

Owner:DONGFENG COMML VEHICLE CO LTD

Bolt stopping part and stopping method

The invention discloses a bolt stopping part and a stopping method, and relates to the technical field of fastening parts. The stopping part comprises a stopping gasket with bolt holes, the stopping gasket is further provided with stopping holes used for allowing the corners of bolt heads to be arranged in a sleeved mode, the stopping holes are located between the bolt holes and the gasket corners, close to the bolt holes, of the stopping gasket, the gasket corners are folded upwards, the hole edges of the stopping holes are closely attached to the bolt heads, the gasket corners are pressed onthe upper end faces of the bolt heads, and then stopping is achieved. According to the bolt stopping part and the stopping method, the problem that the bolt loosening preventing effect of an existingbolt stopping part is poor is solved.

Owner:LIUZHOU IRON & STEEL

Nut assembly with reliable locking performance

InactiveCN109139663ASimple structureEasy to manufacture and installNutsBoltsContact positionScrew thread

The invention provides a nut assembly. The nut assembly comprises a locking nut, a driving nut and an elastic washer. The locking nut comprises an outer thread and an inner thread which are coaxial but different in rotating direction. The locking nut is provided with an external reducing part. The outer diameter of the reducing part is increased progressively from the side of the outer thread to the other side, and at least one slot is formed inward from the end surface of the tail of the locking nut; the driving nut is provided with a driving thread engaged to the outer thread of the lockingnut, a reducing structure is also arranged on the inner wall of the driving nut, the slope or the slope progressive increase rate of the reducing structure is not greater than the slope or the slope progressive increase rate of the reducing part, and the slots of the locking nut can stretch inward to cross a contact position of the reducing structure and the reducing part; and the elastic washer can be mounted on an equal diameter part of the outer thread of the locking nut in a sleeved manner, and can be limited by the driving nut. The nut assembly provided by the invention has a good anti-loosening effect.

Owner:AEROSPACE PRECISION PROD INC LTD

Convex plate clamping device

InactiveCN106881610AAchieve clampingAchieve releasePositioning apparatusMetal-working holdersTransverse groovePulp and paper industry

The invention provides a boss clamping device, which belongs to the technical field of mechanical processing. It includes a pressure plate, a cam, a claw, and a rocker. The fulcrum is a stepped shaft. The diameter of the middle end of the fulcrum is larger than the diameter of both ends. On the support, the pressure plate passes through the rectangular groove at the middle end of the support shaft, the pressure head is set at the lower left end of the pressure plate, and the lower side of the right end of the pressure plate is also provided with a transverse groove and a cam support groove, and the cam is fixedly installed on the camshaft, and the cam and the cam of the pressure plate The supporting groove fits together, and the side of the cam is also equipped with a claw that matches the shape of the transverse groove. The lower end of the rocker is installed on the camshaft through a lock nut, and the left end of the piston rod that drives the cylinder and the upper end of the rocker pass through the support pin. Shaft hinged. The present invention sequentially realizes that the pressing plate advances, then clamps the hem, then lifts and releases, and finally completes the retreat action, which is beneficial to the feeding, processing and unloading of the boss, and has reasonable structure, low cost and good reliability.

Owner:ZHEJIANG HONGFENG WARP & WEFT KNITTING

Petrochemical flexible anti-falling bolt

The invention discloses a petrochemical flexible anti-falling bolt. The petrochemical flexible anti-falling bolt comprises a hexagonal screw head, a first screw, a rubber spacer, a second screw, a nutspacer, a nut, a supporting rotary bolt, a fixed object and a reinforcing spacer, wherein a first screw arc is arranged at the top end of the first screw; the side face of the first screw arc is concave toward the direction of the axle wire; the rubber spacer is arranged on the outer side of the first screw arc; the top end and the bottom end of the first screw are separately connected to the hexagonal screw head and the second screw; a thread is arranged on the outer side of the second screw; a second screw arc is arranged at the top end of the second screw; the side face of the second screwarc is concave toward the direction of the axle wire; and the reinforcing spacer is arranged on the outer side of the second screw arc. The petrochemical flexible anti-falling bolt is good in integral reusability, simple in structure, great in strength and excellent in anti-loosening effect.

Owner:浙江长瑞精密零部件制造有限公司

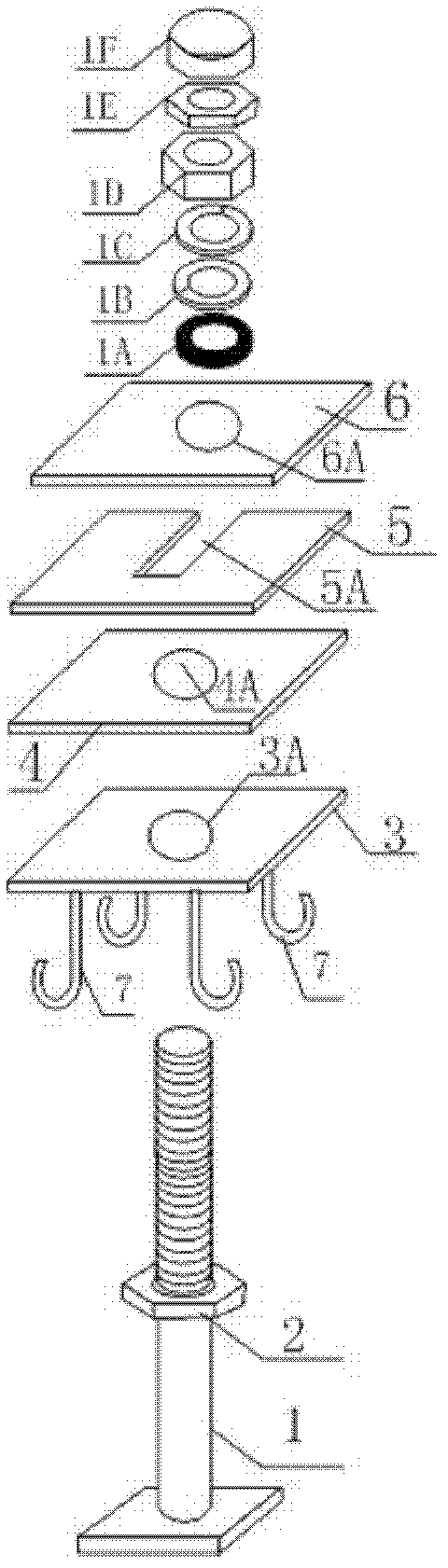

Anti-loosing strong-anchoring fastener high in height adjustment

The invention relates to a fastener for assembly of track panels, in particular to an anti-loosing, double-layer and strong-anchoring fastener for assembly of track panels of a low- and medium-speed maglev track, which is provided with a fastening nut, a lock nut, a heavy spring and a rubber gasket for joint action. The anti-loosing, double-layer and strong-anchoring fastener is capable of meeting various requirements of track sleepers on one to four strong-anchoring bolts in assembly and design, the track is more stable and safer, and the height of the fastener can be adjusted from -20mm to +60mm. The anti-loosing strong-anchoring fastener has the advantages of simple structure, easiness in assembly, high adjusting precision, high height adjustment and the like, and the problems of operational hazards and the like of a maglev train due to loosing of the fasteners and the like can be solved effectively.

Owner:莱芜美澳冶金科技有限公司

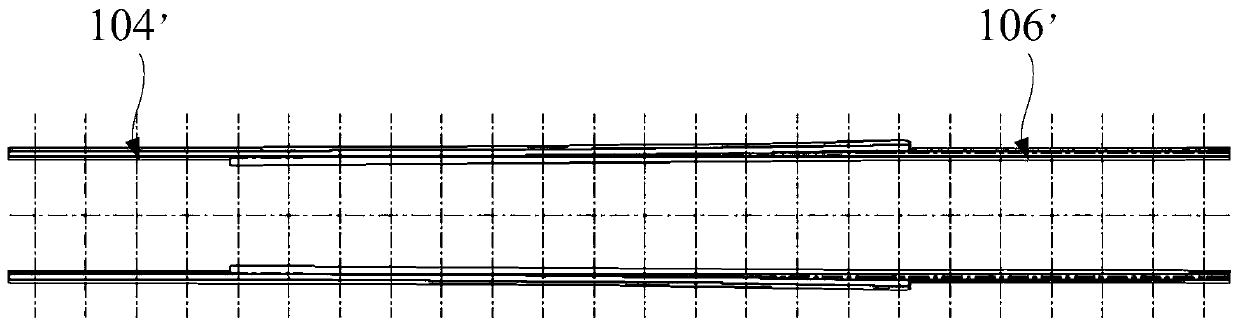

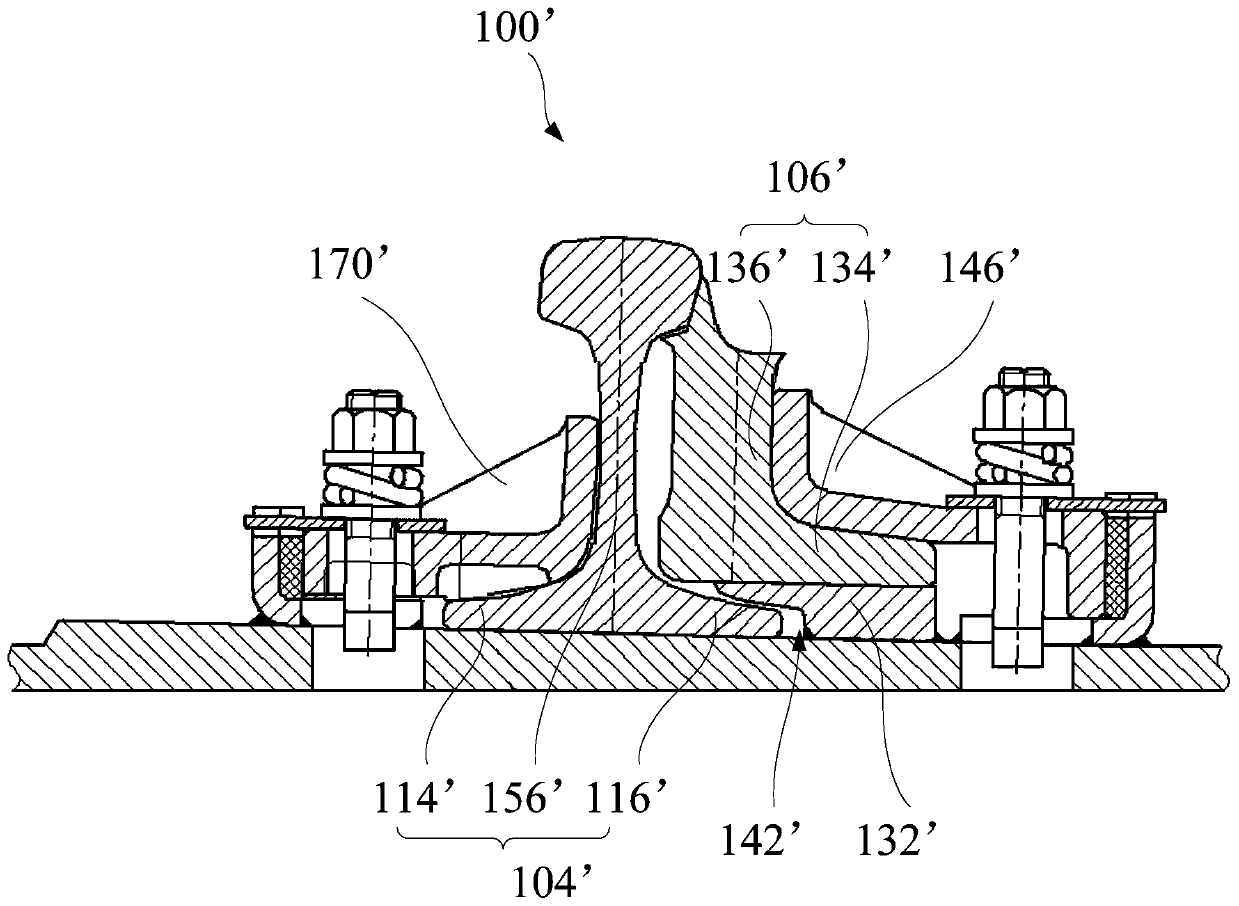

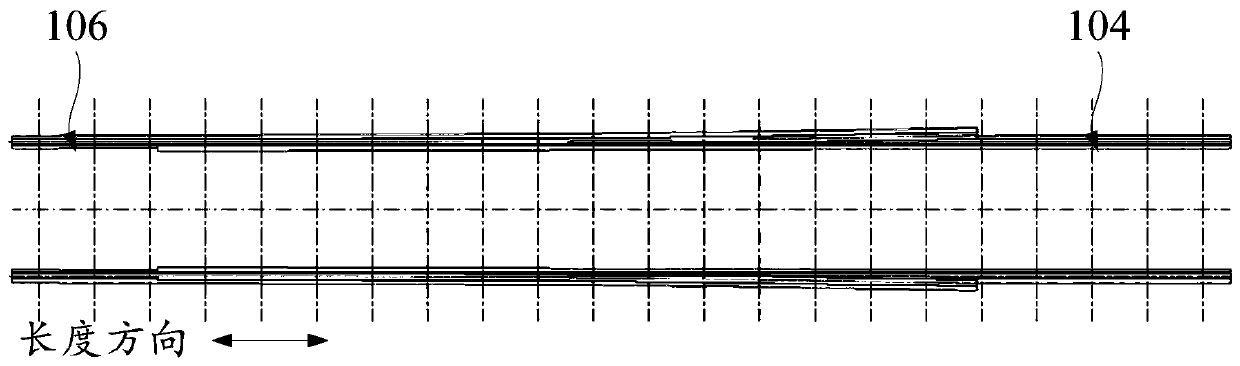

Steel rail telescopic regulator

InactiveCN111441197AHigh standardization rateReduce manufacturing costRail switchesRail fastenersEngineeringStructural engineering

The invention provides a steel rail telescopic regulator. The steel rail telescopic regulator comprises: a base plate, wherein the base plate comprises a bottom plate and a first table plate, and theupper surface of the bottom plate is obliquely arranged; a stock rail fixed on the bottom plate, wherein at least part of the areas of a plurality of cross sections, perpendicular to the length direction of the stock rail, of the stock rail are unequal; a switch rail arranged on the first table plate, wherein at least part of the switch rail is located on the outer side of the stock rail, the areas of multiple cross sections, perpendicular to the length direction of the switch rail, of at least part of the switch rail are unequal, and the switch rail can telescopically move in the direction perpendicular to the length direction of the switch rail; and a telescopic assembly arranged on the first table plate, wherein the telescopic assembly is configured to be suitable for stretching out anddrawing back of the switch rail and enable at least part of the switch rail head to abut against the stock rail head. According to the steel rail telescopic regulator, the problems that an existing steel rail telescopic regulator is unstable in overall structure, and the stock rail is prone to turning outwards are solved, the assembling, maintaining and repairing difficulty is lowered, and the steel rail telescopic regulator is suitable for application and popularization.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Anti-loosening double-nut connecting structure

The invention discloses an anti-loosening double-nut connecting structure. The anti-loosening double-nut connecting structure comprises a nut assembly and a bolt. The nut assembly comprises a main nut, an auxiliary nut and an elastic non-return screw ring. The main nut is connected with the bolt through a thread structure; in the axis direction, the elastic non-return screw ring is coaxially and fixedly connected with the main nut; the outer wall of the elastic non-return screw ring is provided with an external thread and an external conical surface, and the inner wall of the elastic non-return screw ring is provided with a thread structure connected with the bolt; a plurality of partition holes are formed in the elastic non-return screw ring in the circumferential direction, and a petal-shaped locking part is formed between every two adjacent partition holes; an inner cavity of the auxiliary nut is provided with an inner thread used for being matched with the outer thread of the elastic non-return screw ring and an inner conical face used for being in interference fit with the outer conical face of the elastic non-return screw ring. According to the anti-loosening double-nut connecting structure, the auxiliary nut is prevented from rotating through the elastic non-return structure, connection is reliable, installation is easy, the fastener can be repeatedly used, the machining cost is proper, and the anti-loosening effect is good.

Owner:GUANGDONG IND TECHN COLLEGE

Composite double-nut lock bolt

The invention discloses a composite double-nut lock bolt. The composite double-nut lock bolt comprises an upper gasket, a lower gasket, an upper nut, a lower nut and a screw, and is characterized in that the screw comprises three integrally manufactured and formed parts, including an nut, an upper bolt rod and a lower bolt rod; the thread rotation direction of the upper bolt rod is exactly opposite to that of the lower bolt rod; the diameter of the upper bolt rod is a little larger than that of the lower bolt rod; the upper nut can be screwed on the thread of the upper bolt rod after directlypenetrating through the lower bolt rod; the lower nut is screwed on the thread of the lower bolt rod; the ratio of the upper and lower parts of the screw bolt rod follows the following principles: after the screw bolt rod is inserted into the upper gasket, an upper connecting part, a lower connecting part and the lower gasket in sequence, the upper nut is twisted, and at the moment the rearrest part of the tail of the upper nut is not screwed on the thread of the upper bolt rod but sleeves the thread of the lower bolt rod in a suspension manner; the lower nut is directly screwed on the upper nut; and finally a high-frequency cold welding machine is used for implementing spot welding at 1-2 positions so that the upper nut and the lower nut are connected as a whole.

Owner:邬惠林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com