Bolt combiner with thread pitch difference between bolt and nut

A technology of combination and pitch difference, applied in the field of mechanical parts, can solve problems such as pitch difference, and achieve the effect of improving fatigue strength, good relaxation resistance and fatigue resistance, and high availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

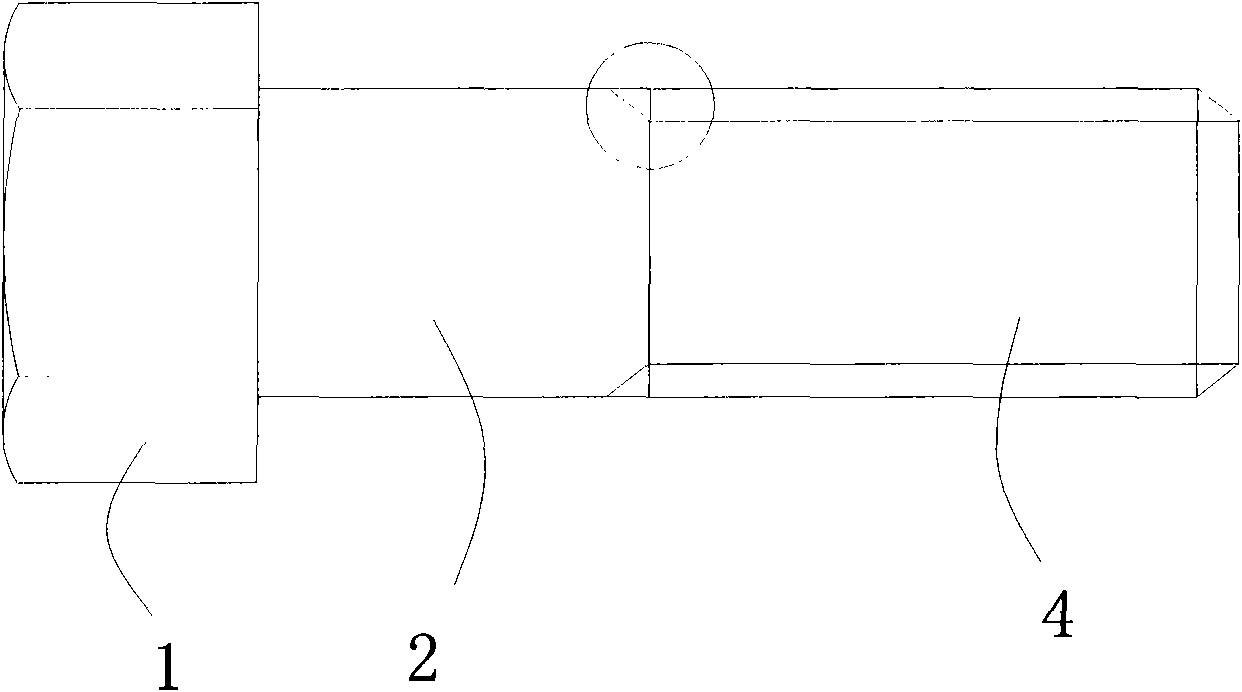

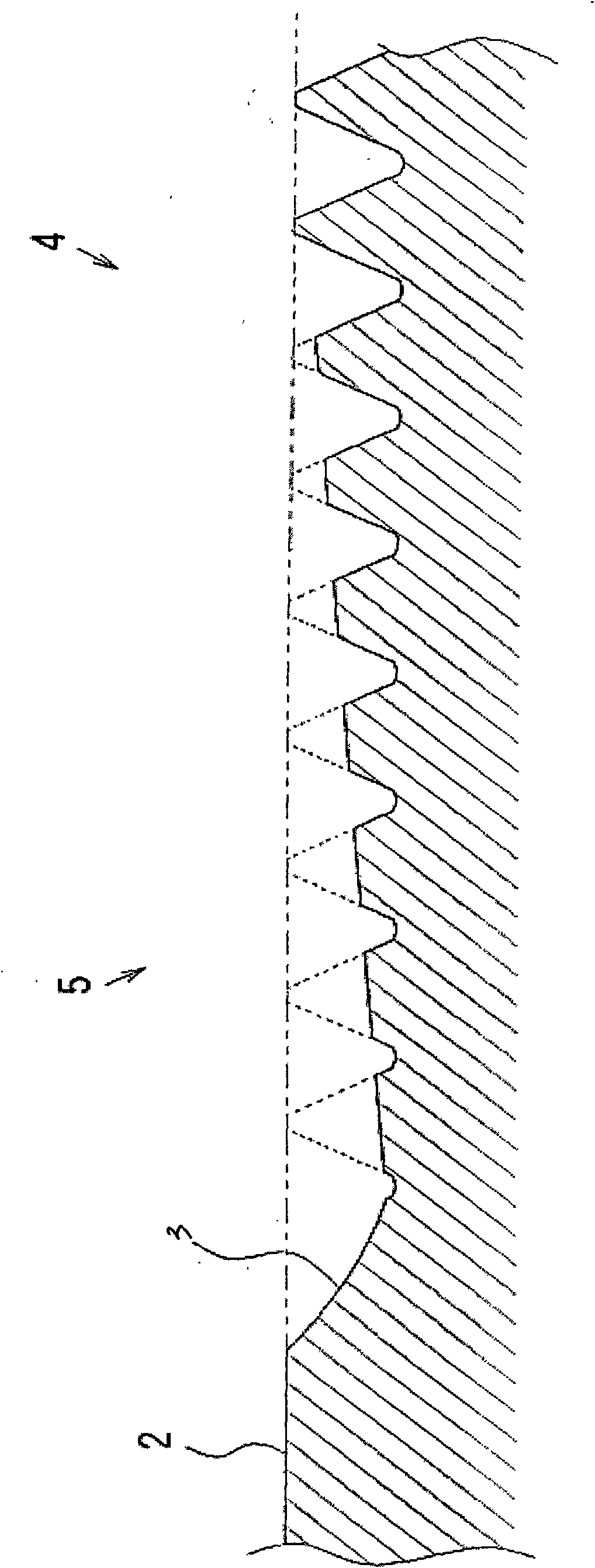

[0014] Example 1: Such as figure 1 , 2 Shown, is a schematic diagram of the bolt structure, using a bolt with M16 specified by ISO. The bolt includes a bolt head 1, a bolt cylindrical part 2 and a threaded part 4. The threaded part 4 consists of a threaded part 3, a threaded removal part 5 and a complete Thread composition, bolt pitch P b 2mm, the thread part is obliquely removed from the thread root to form a frustum-shaped thread tooth removal part 5. The angle between the line of each tooth crest of the thread tooth removal part 5 and the bolt axis is 7% ± 1%, the longer the screw The smaller the included angle is; the smallest diameter of the frustum-shaped thread removal part 5 is gradually expanded in an arc shape to the bolt cylindrical part 2 to form a full thread part 3; the pitch of the bolt union nut P n It is 2.007mm. Due to the difference in the pitch of the bolt and the nut, when the two are rotated together, the part is easy to loosen. In the screwed state, the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com