Steel rail telescopic regulator

A regulator and rail technology, which is applied to rail joints, rails, switches, etc., can solve the problems of unstable overall structure and easy eversion of the rail telescopic regulator 100', so as to reduce the difficulty of assembly, maintenance and repair. Expand the scope of use and expand the optional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

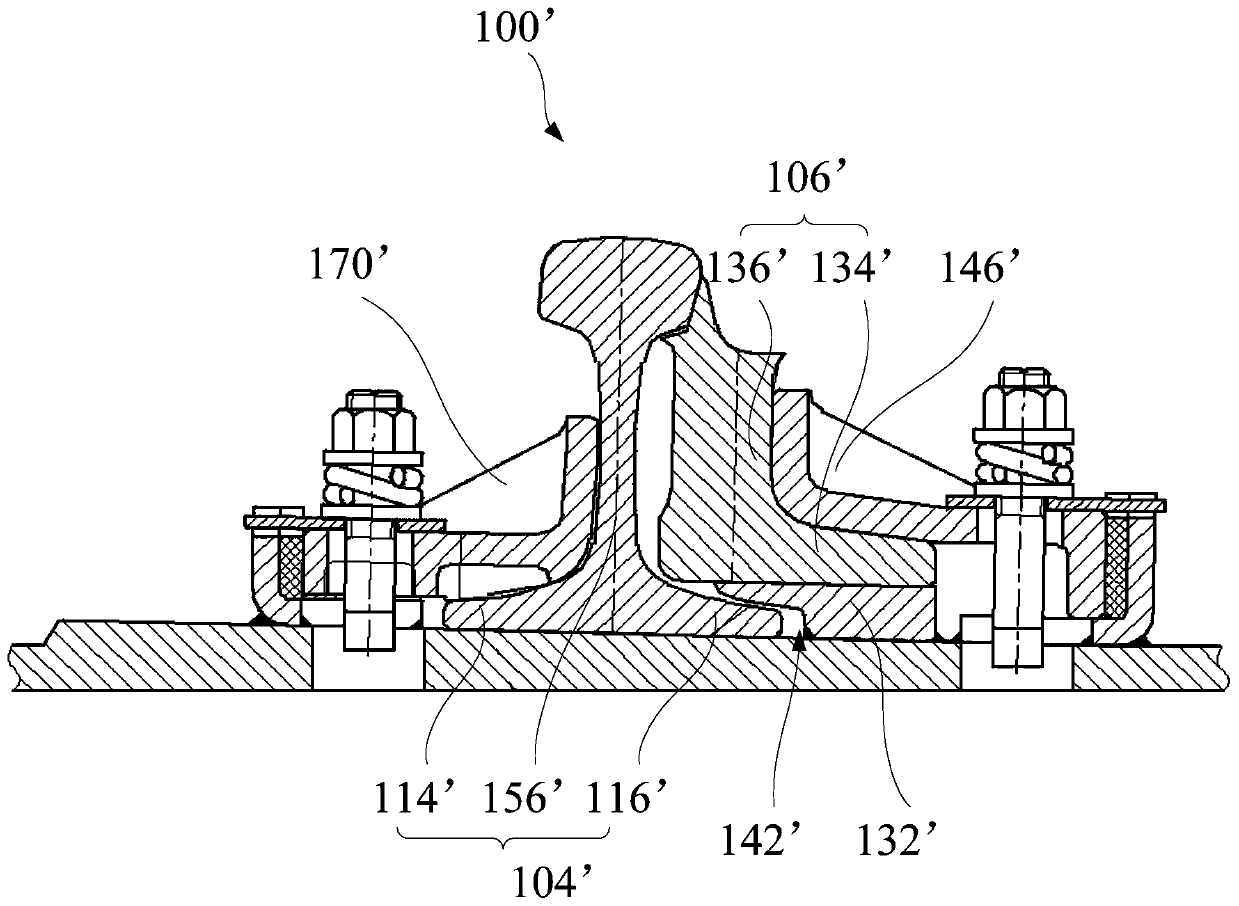

[0056] Such as image 3 and Figure 4 As shown, the embodiment of one aspect of the present invention proposes a rail telescopic adjuster 100, including: a backing plate 166, a base plate 102, a basic rail 104, a switch rail 106 and a telescopic assembly, wherein the backing plate 166 includes a bottom plate 102 and a second A platform 132, the first platform 132 is arranged above the bottom plate 102, the upper surface of the bottom plate 102 is inclined, the basic rail 104 is fixed on the bottom plate 102, at least part of the basic rail 104 is in a plurality of cross-sections perpendicular to the length direction of the basic rail The areas are not equal, the basic rail 104 includes the basic rail rail head; the switch rail 106 is arranged on the first platform 132, at least part of the switch rail 106 is located outside the basic rail 104, at least part of the switch rail 106 is perpendicular to the length direction of the switch rail The areas of the multiple cross-secti...

Embodiment 2

[0060] Such as Figure 3 to Figure 14 As shown, in one embodiment of the present invention, the rail telescopic adjuster 100 includes: a backing plate 166, a basic rail 104, a point rail 106, a telescopic assembly, a first limiting assembly 110 and a second limiting assembly 112, and the basic rail 104 It also includes a first basic rail leg 114 and a second basic rail leg 116 in contact with the bottom plate 102, the basic rail head includes a first basic rail head 118 disposed towards the switch rail, and the first basic rail leg 114 deviates from The switch rail 106 is set; wherein, the first limit assembly 110 abuts against the first basic rail limb 114 to limit the movement of the first basic rail limb 114 relative to the backing plate 166, and the second limit assembly 112 and the second basic rail The rail legs 116 abut against each other to limit the movement of the second basic rail leg 116 relative to the backing plate 166 .

[0061] In this example, if Figure 4 a...

Embodiment 3

[0067] Such as Figure 3 to Figure 14 As shown, the rail telescopic adjuster 100 provided by an embodiment of the present invention, on the basis of the above-mentioned embodiment 2, further, the first platform 132 is higher than the second basic rail limb 116, and the second limit assembly 112 Including: an elastic clip 140, the first plate 132 is provided with a mounting groove toward the side of the bottom plate 102, and the mounting groove is provided with an opening toward the side of the second basic rail leg 116, and one end of the elastic clip 140 passes through the opening and the second The basic rail rail limb 116 abuts, and the other end of the elastic clip 140 is connected with the first platform 132 on the side away from the opening; or the second limiting member is the first platform 132, and the first platform 132 faces the second basic One side of the rail limb 116 is provided with a platen bayonet 142 , and the platen bayonet 142 is adapted to the second basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com