Patents

Literature

39results about How to "Reduce copper usage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

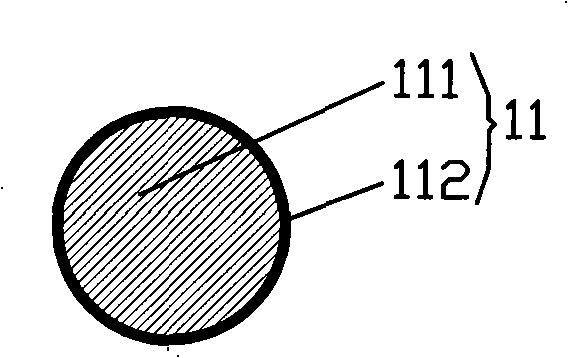

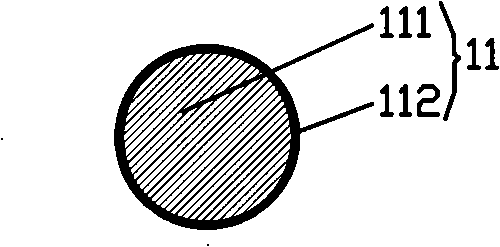

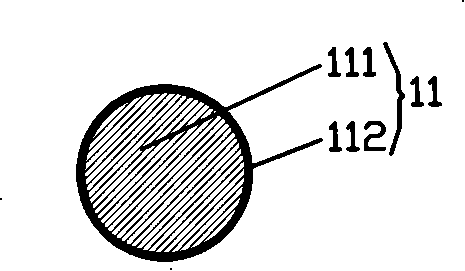

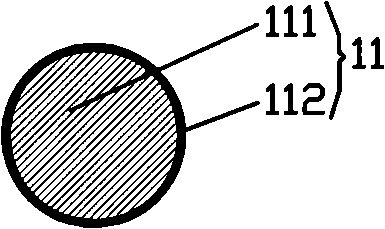

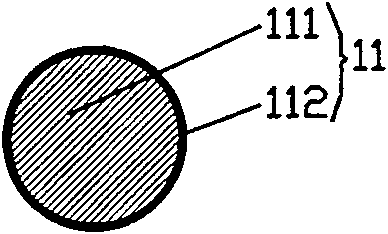

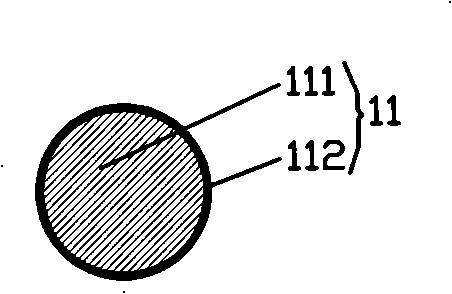

Aluminum core cable and line covered by copper

InactiveCN101086906AGood electrical conductivityHigh strengthRubber insulatorsPlastic/resin/waxes insulatorsCross-linked polyethyleneCopper-clad aluminium wire

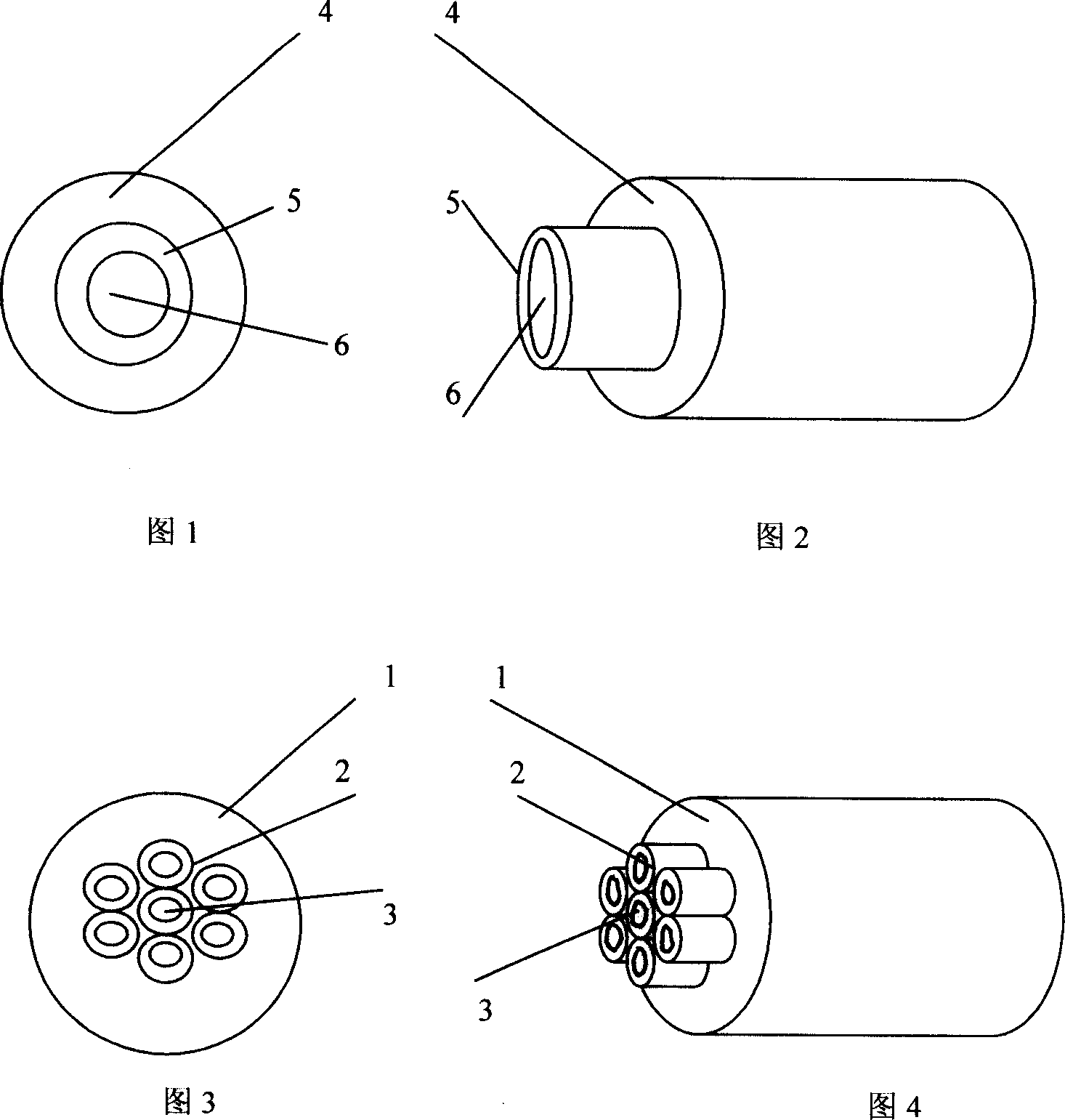

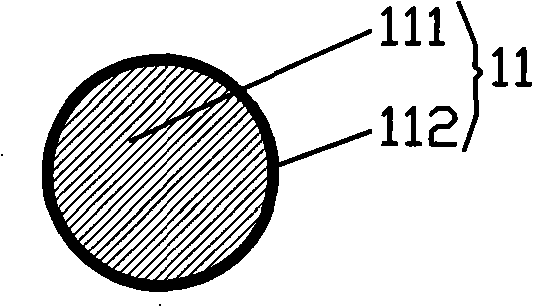

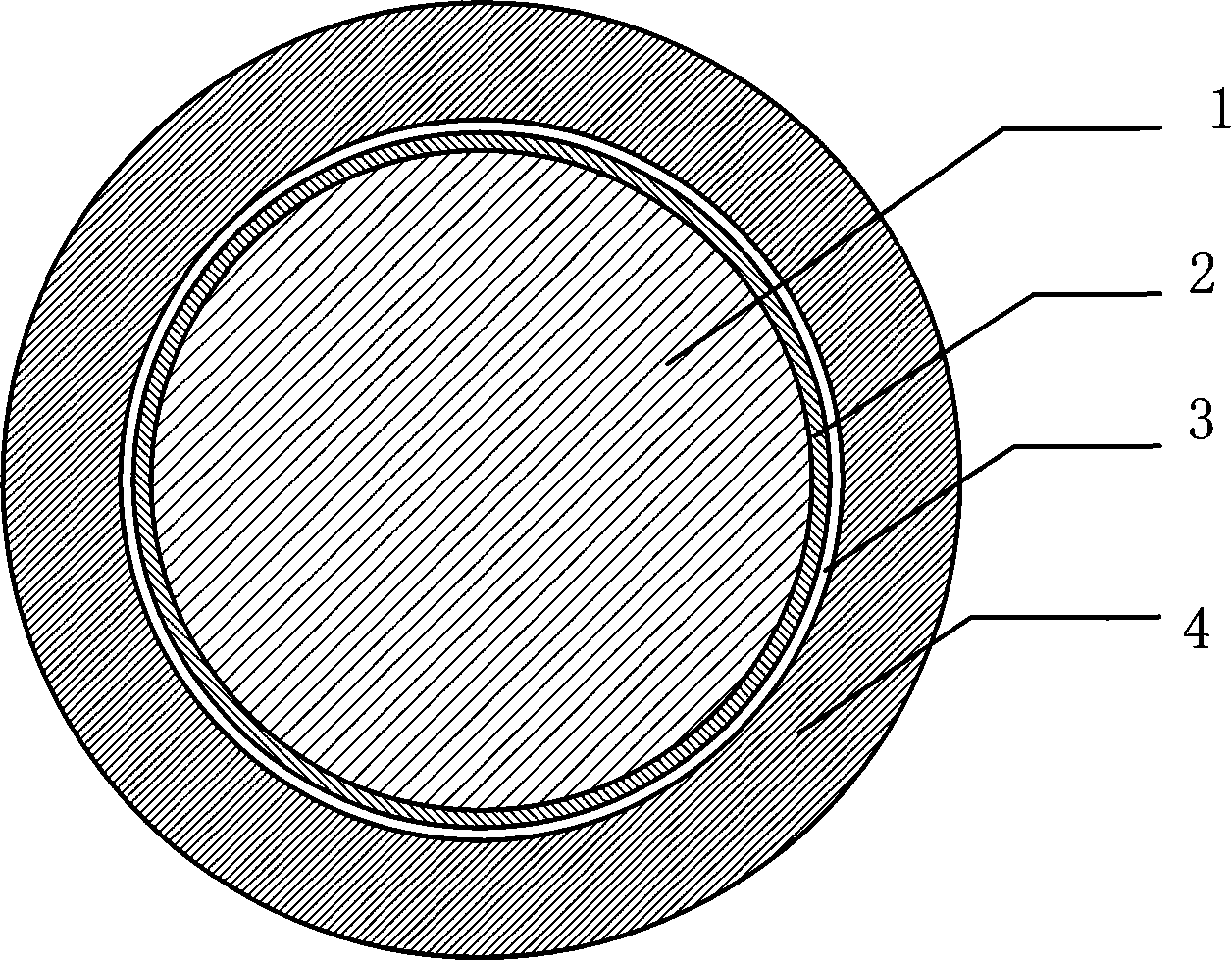

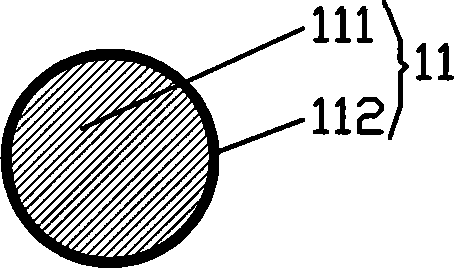

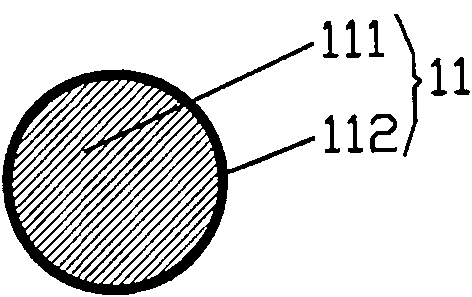

The invention uses copper-clad aluminium conductor as conductive wire core whose inner core is aluminium wire and outer is cylinder copper roofing, the conductive wire also can be at least two conductive wire cores of copper-clad aluminium conductor which are parallel or winding with each other, the outer of conductive wire core is covered with insulated layer of PVC or polyethylene or cross-link polyethylene or rubber. The insulated material such as PVC, polyethylene, cross-link polyethylene or rubber is covered around the conductive wire core to produce copper-clad aluminium wire cable. The copper-clad aluminium wire cable possesses the same conductivity as copper core cable with the same specification, weight is light, easy to process, usage is convenient, and copper can be saved for 80% or above, cost of product can be decreased effectively, defects that the surface of aluminium cable is easy to be oxidized, resistance is big, corrosion resistance and machine performance are poor can be avoided.

Owner:大连极速金属复合材料有限公司

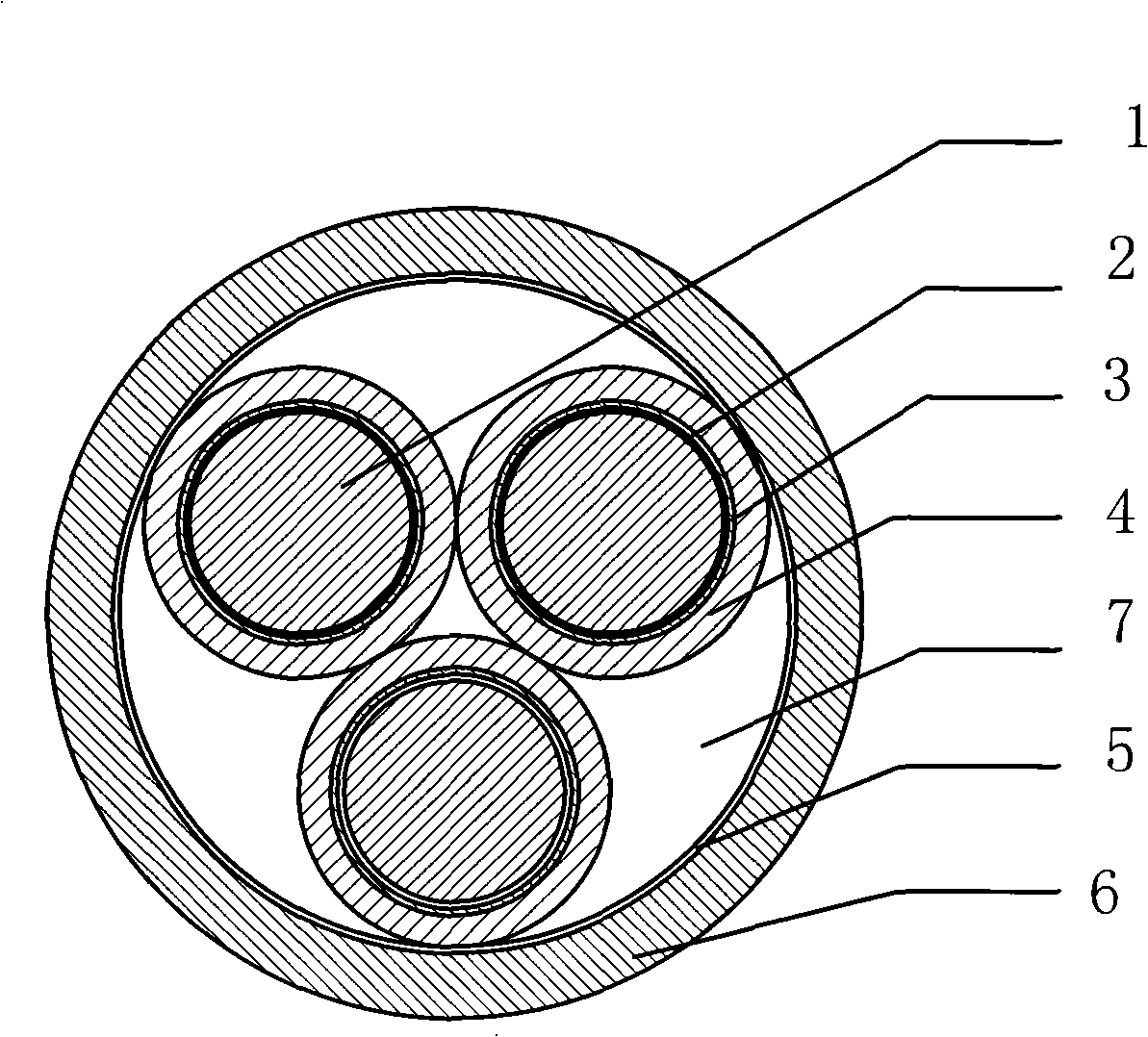

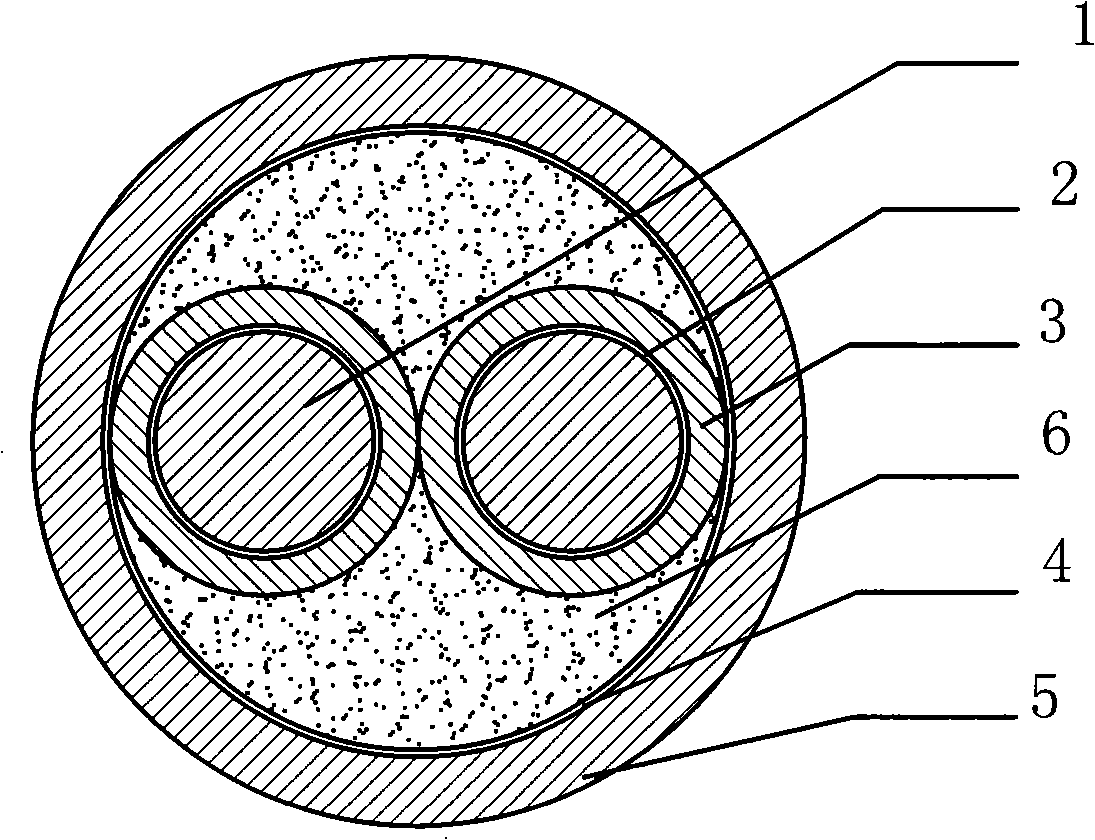

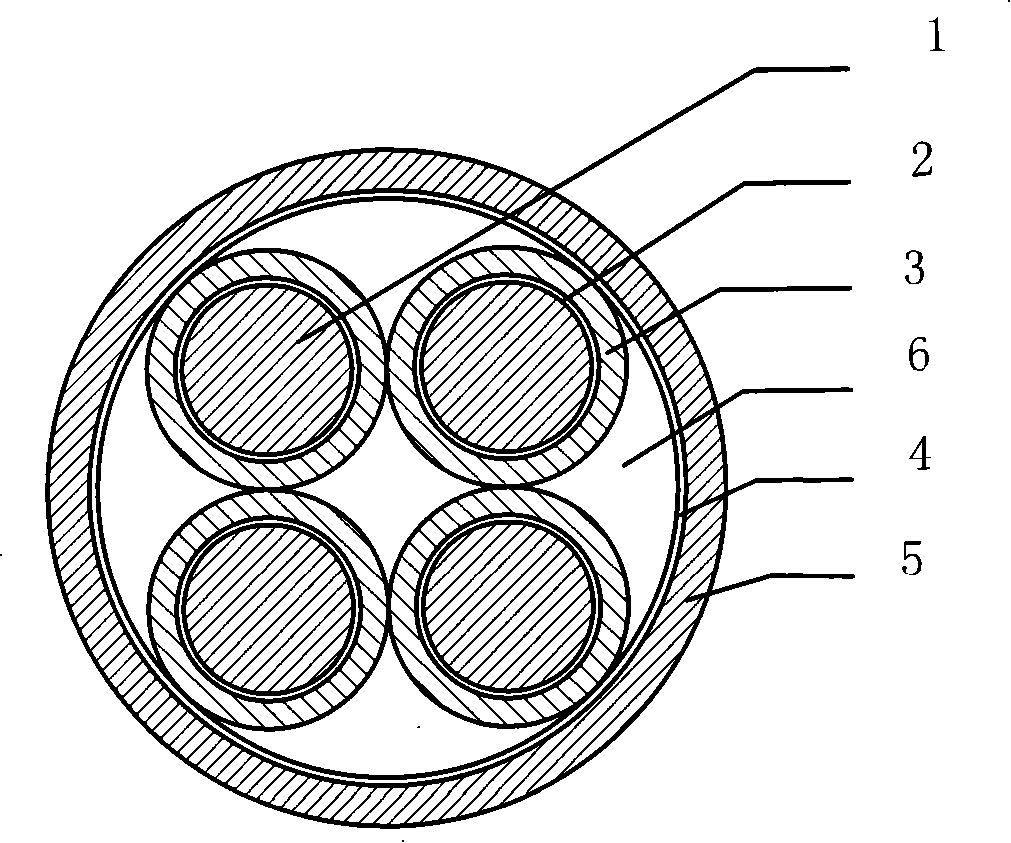

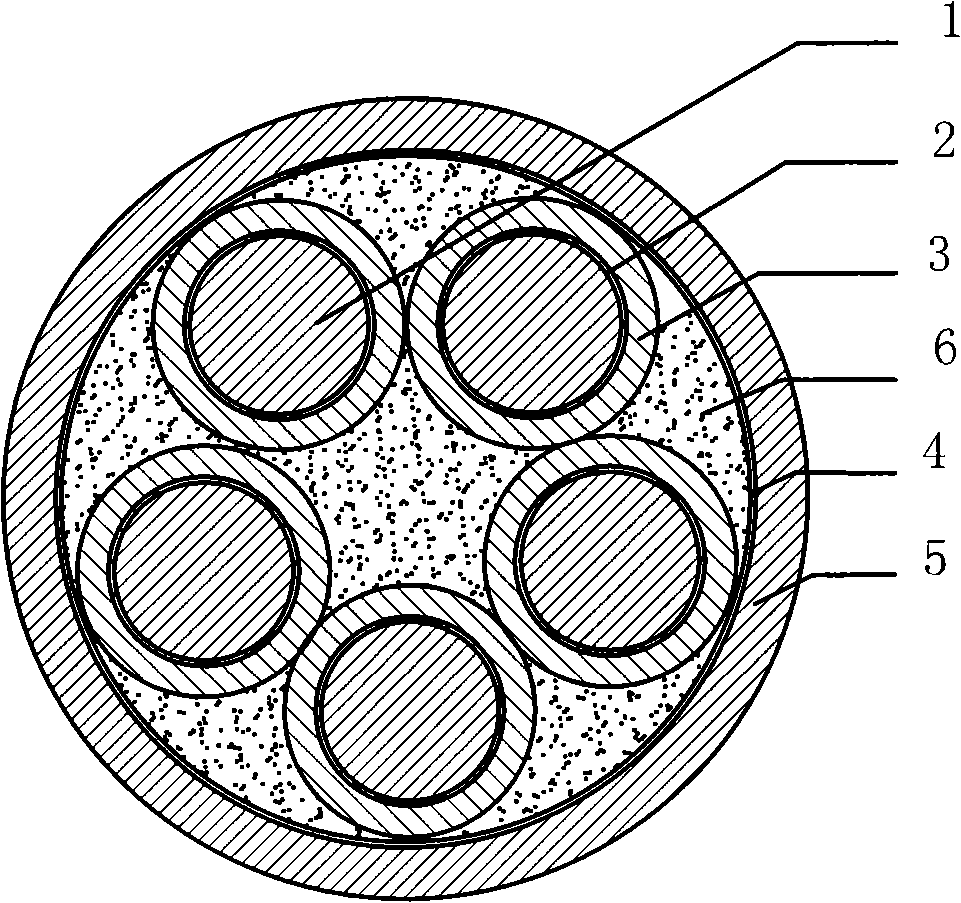

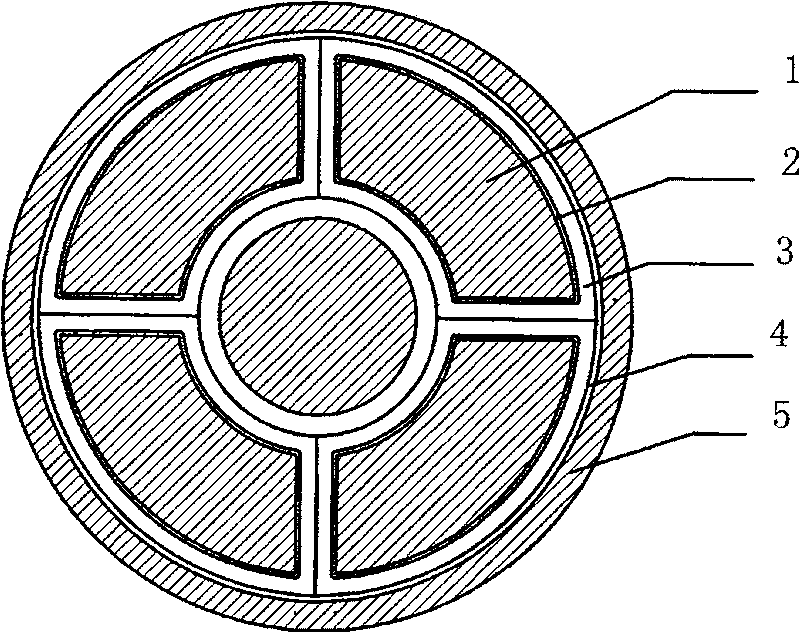

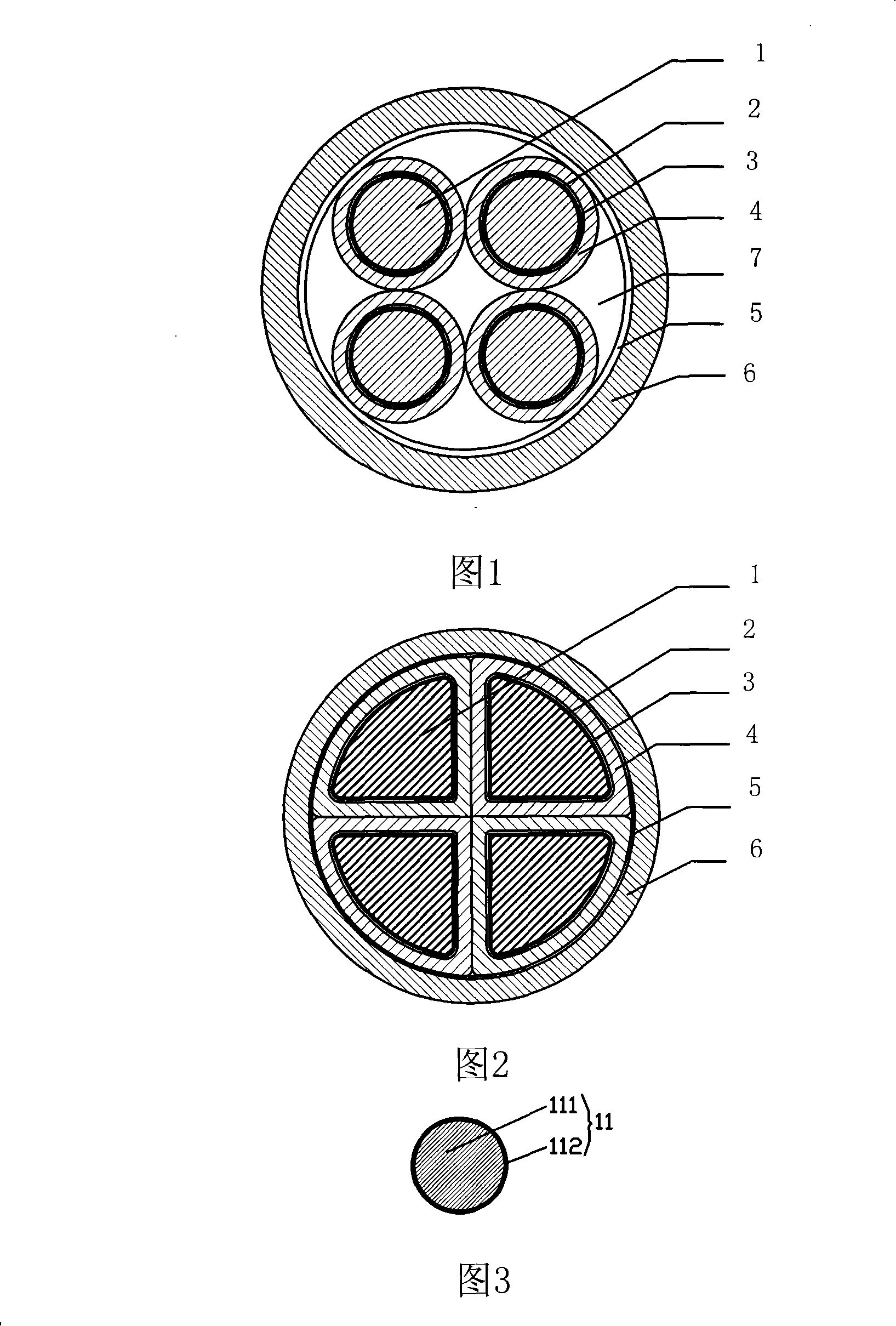

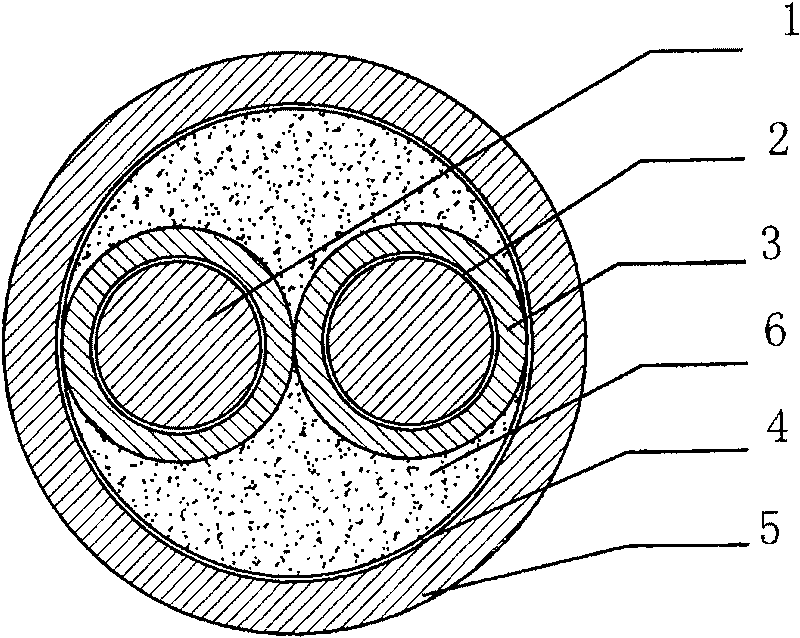

Copper coated aluminum dual-core flame-retardant refractory flexible electric cable and manufacturing method thereof

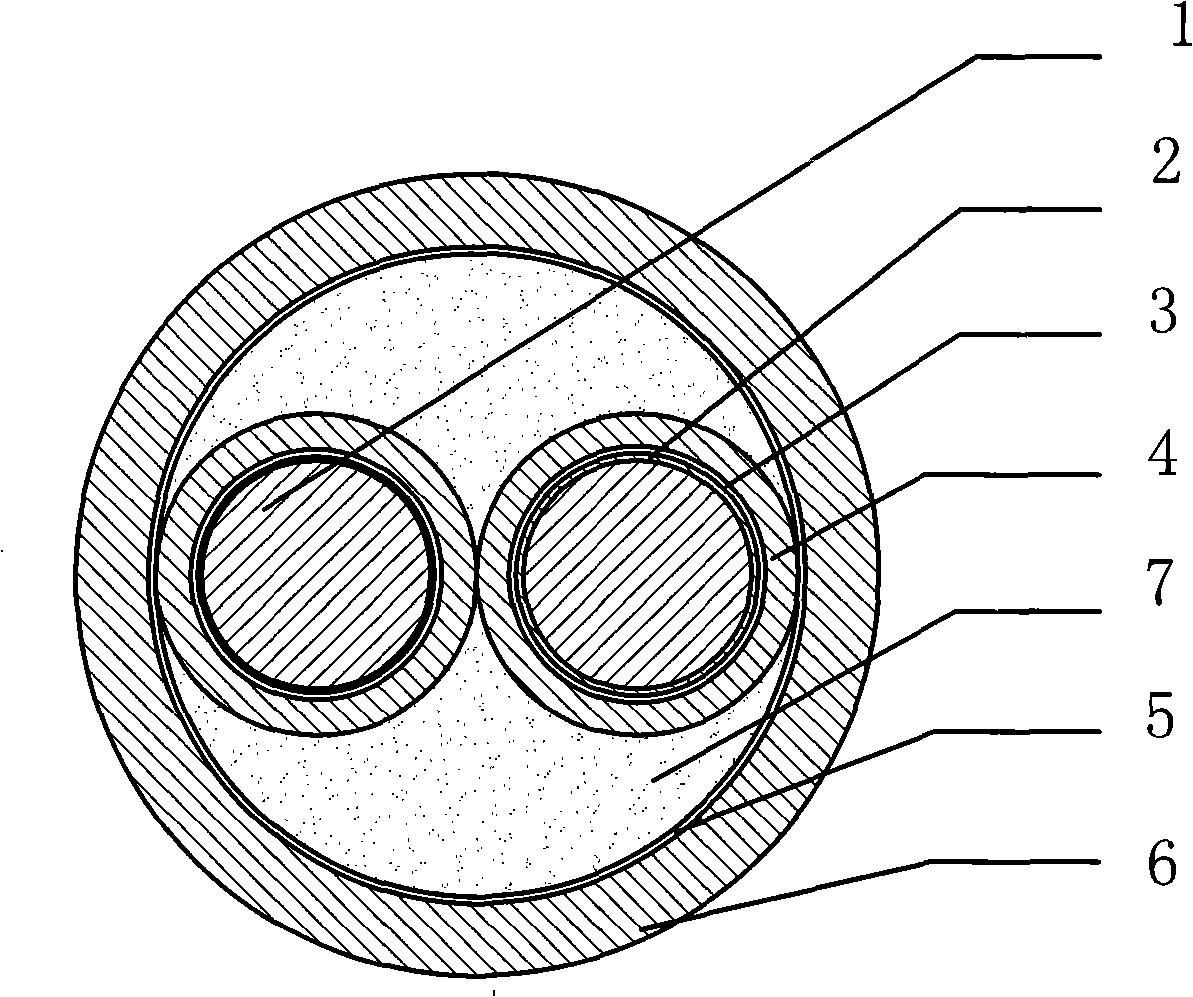

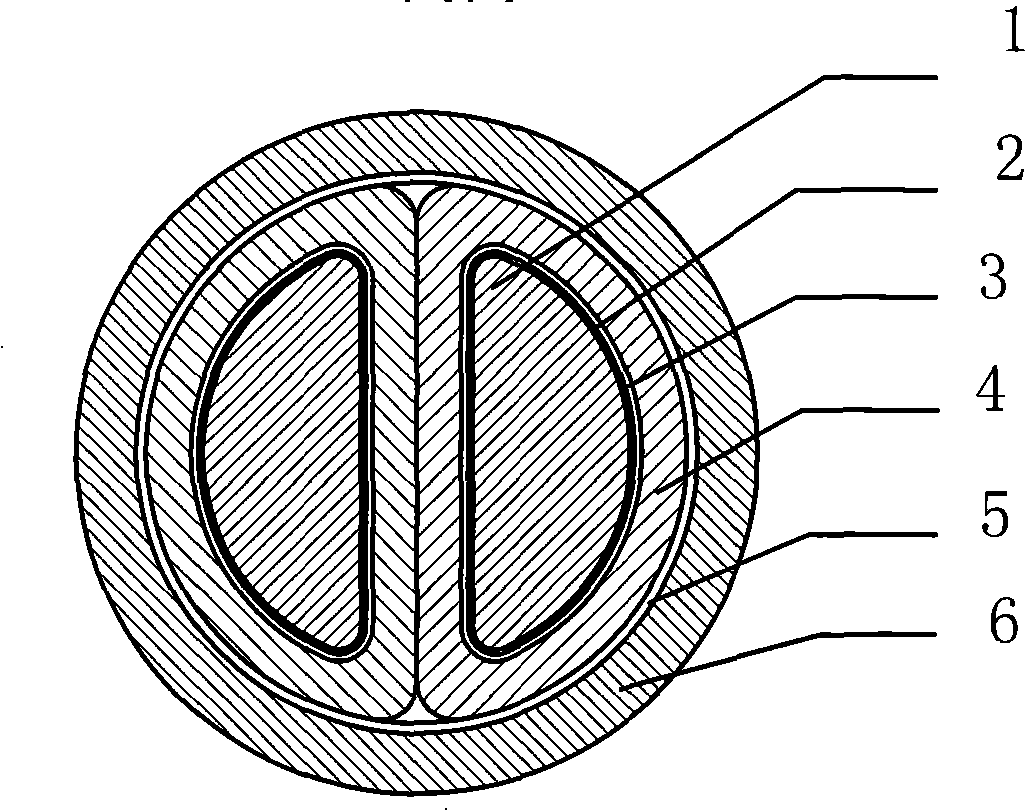

ActiveCN101335114AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

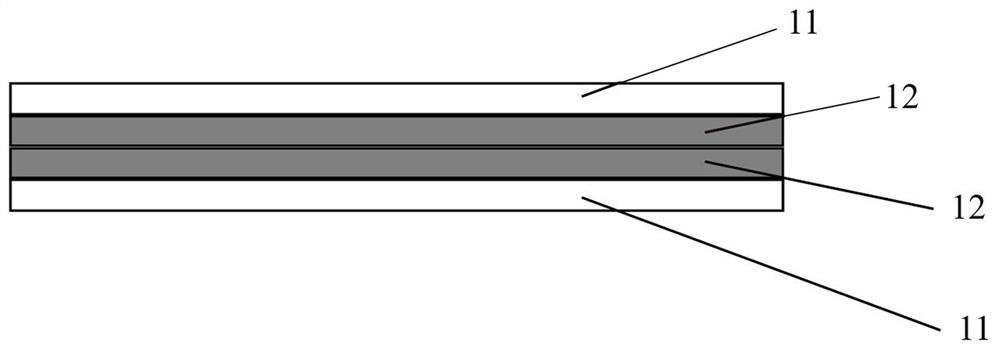

The invention discloses a copper-clad aluminum two-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a semi-round section; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with a semi-round section; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to two insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

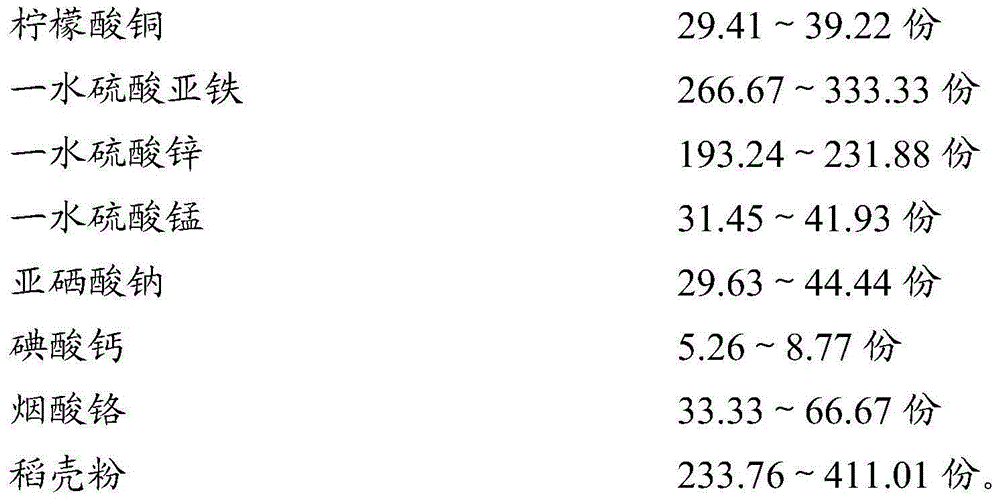

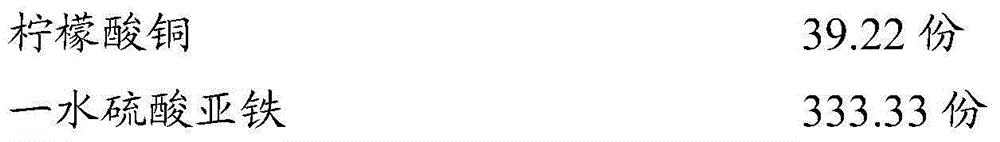

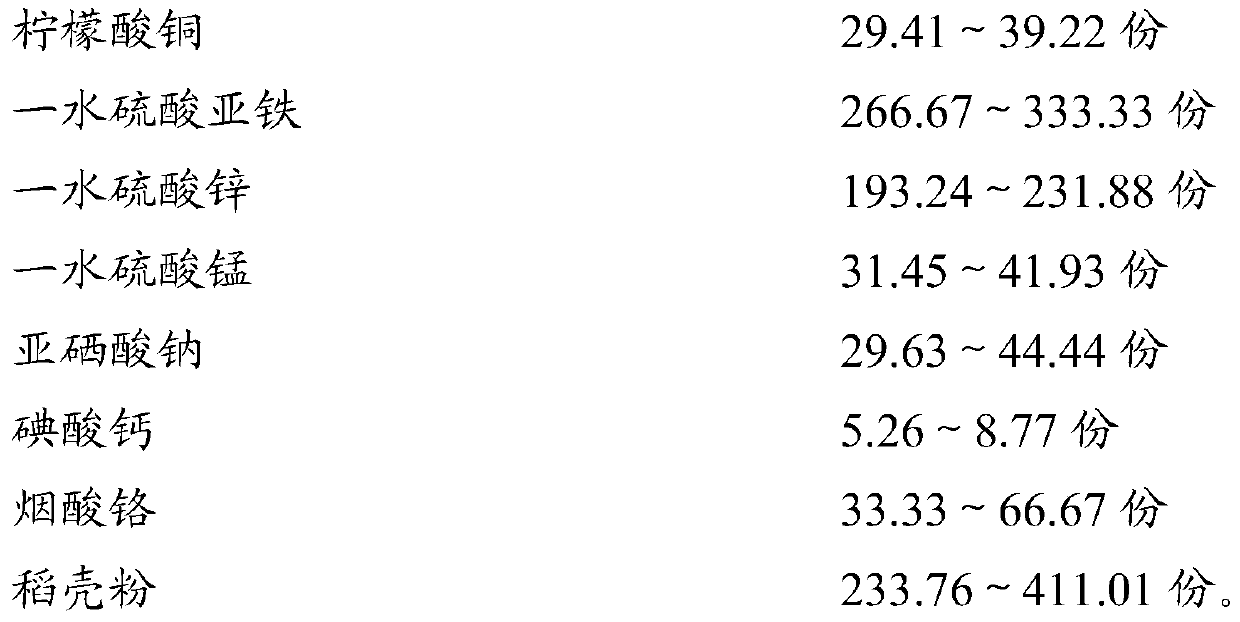

Weaned piglet trace element premix feed and compound feed

ActiveCN105053590AStable chemical structureHigh biological potencyFood processingAnimal feeding stuffTrace elementHigh doses

The present invention relates to the field of animal nutrition, and particularly relates to a trace element premix feed and weaned piglet compound feed. The trace element premix feed does not contain copper sulfate, but contains copper citrate. The compound feed can decrease the amount of copper used in the feed by more than 88%, improve average daily gain (ADG), average daily feed intake (ADFI) and feed to gain ratio (F / G) of piglets compared with high dose copper sulfate, increase lysozyme concentration of serum by more than 50.62%, reduce diarrhea rate of piglets by more than 66.67%, and decrease fecal copper content by more than 88.76%; the above data has highly significant differences (P<0.01) compared with the control group.

Owner:SICHUAN ANIMAL SCI ACAD

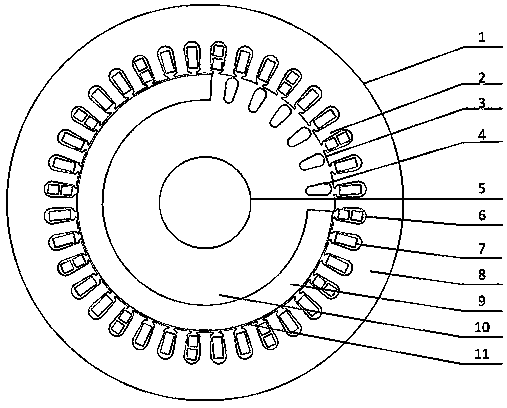

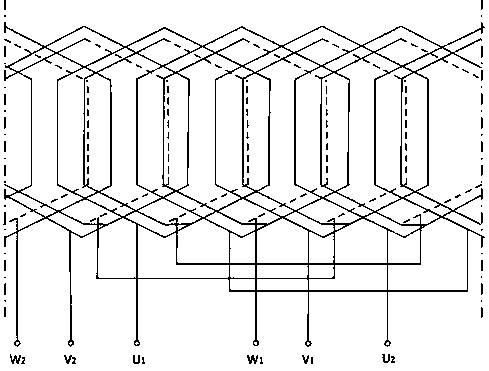

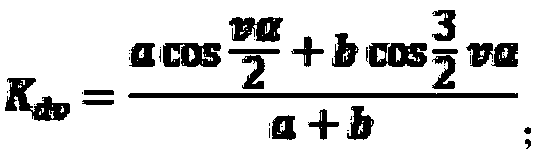

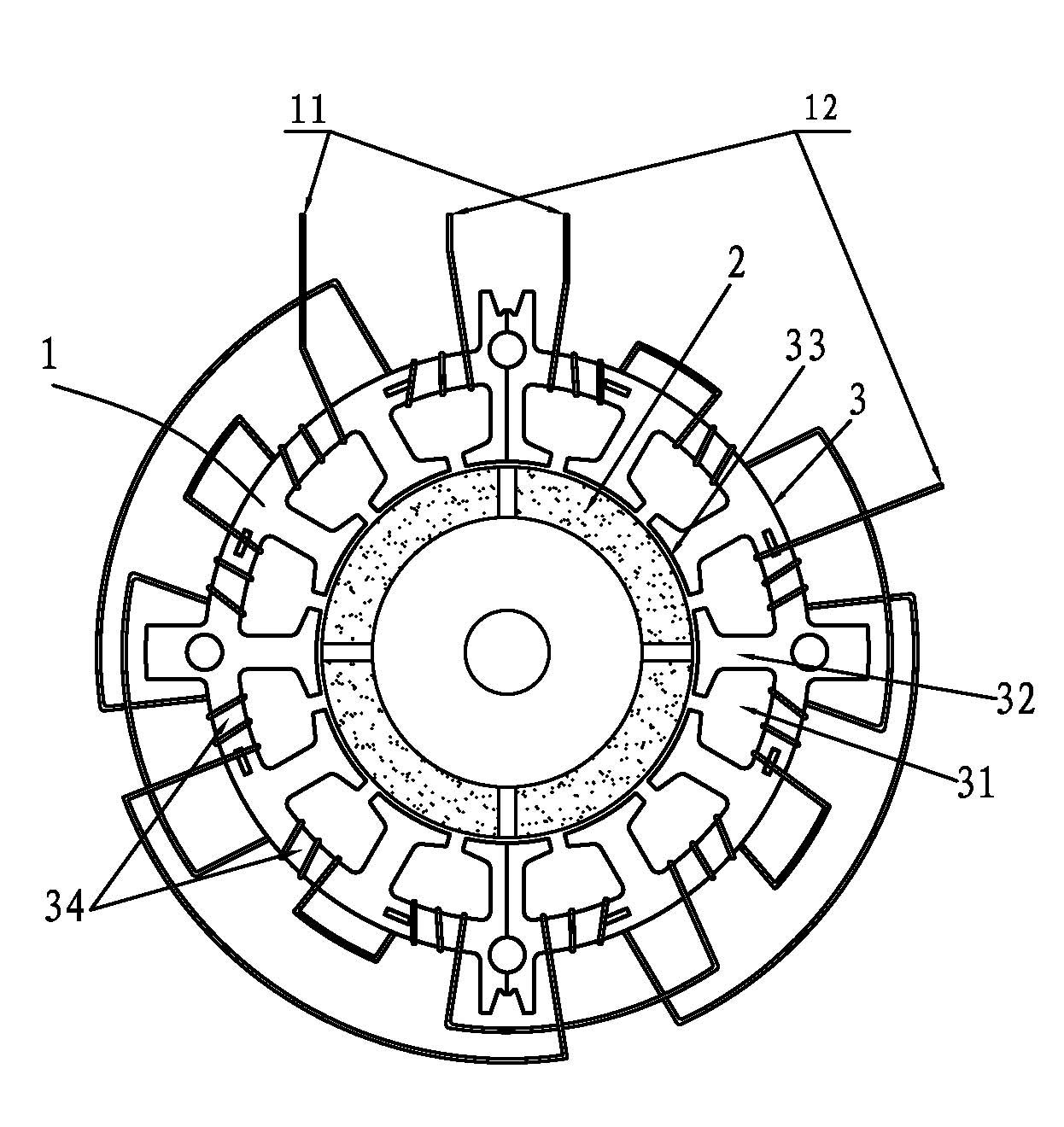

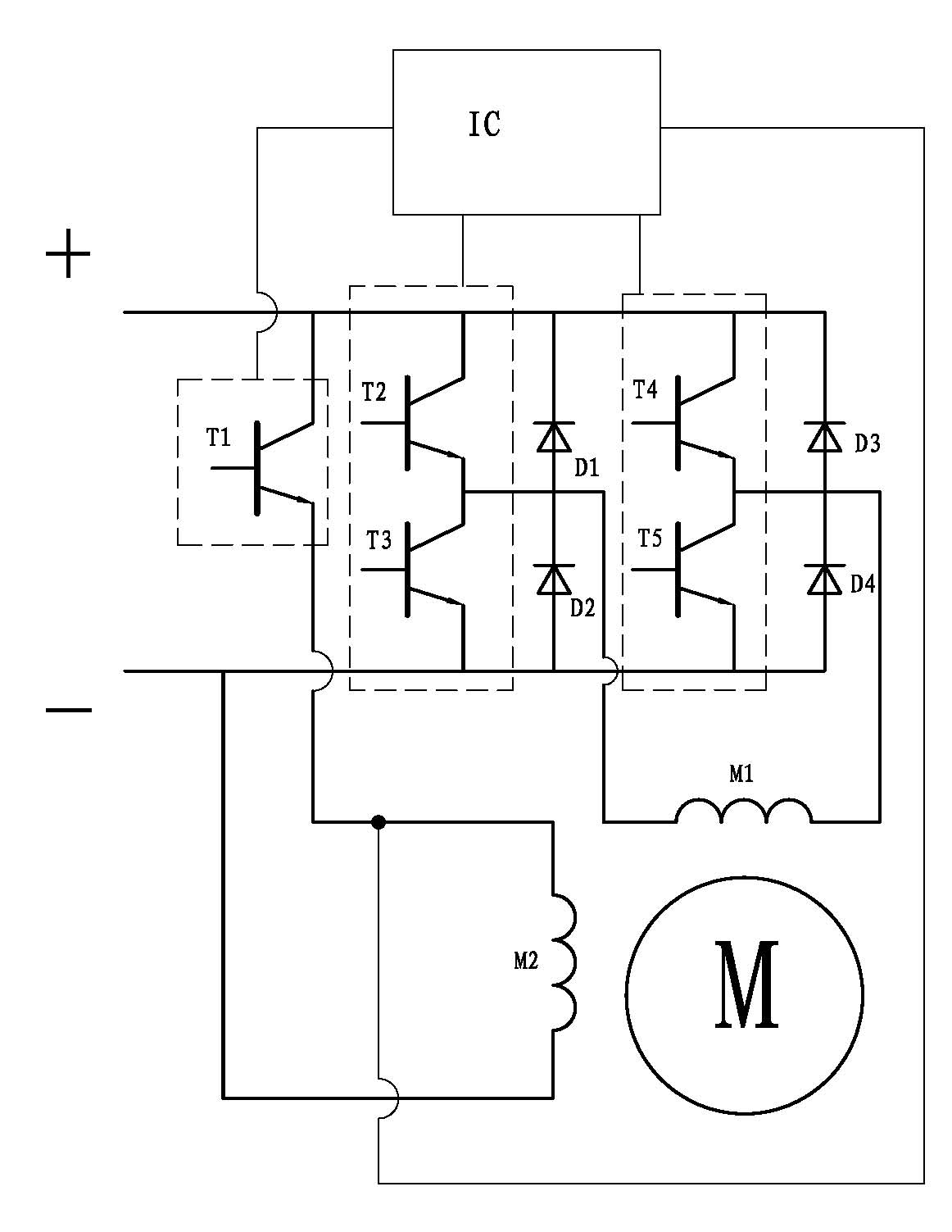

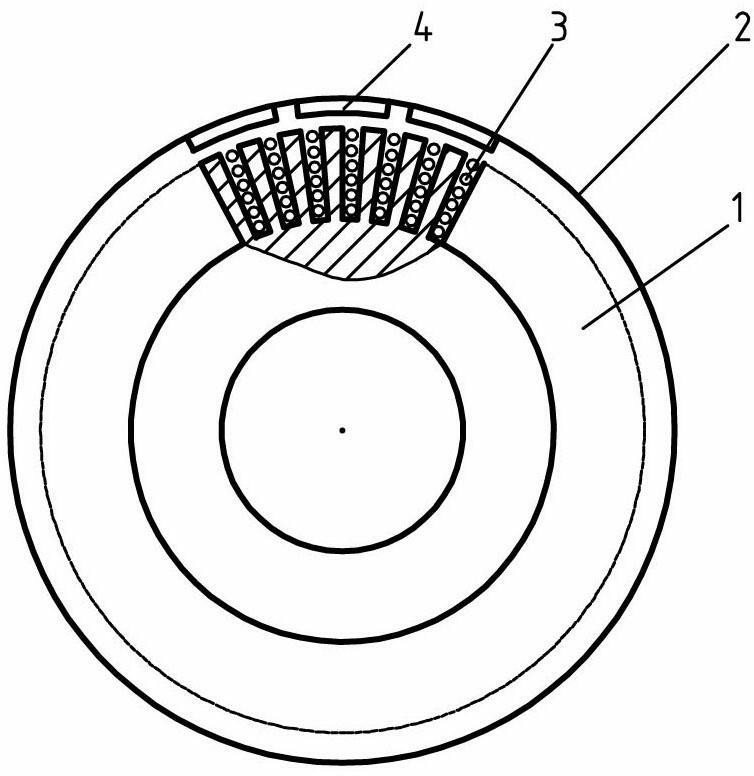

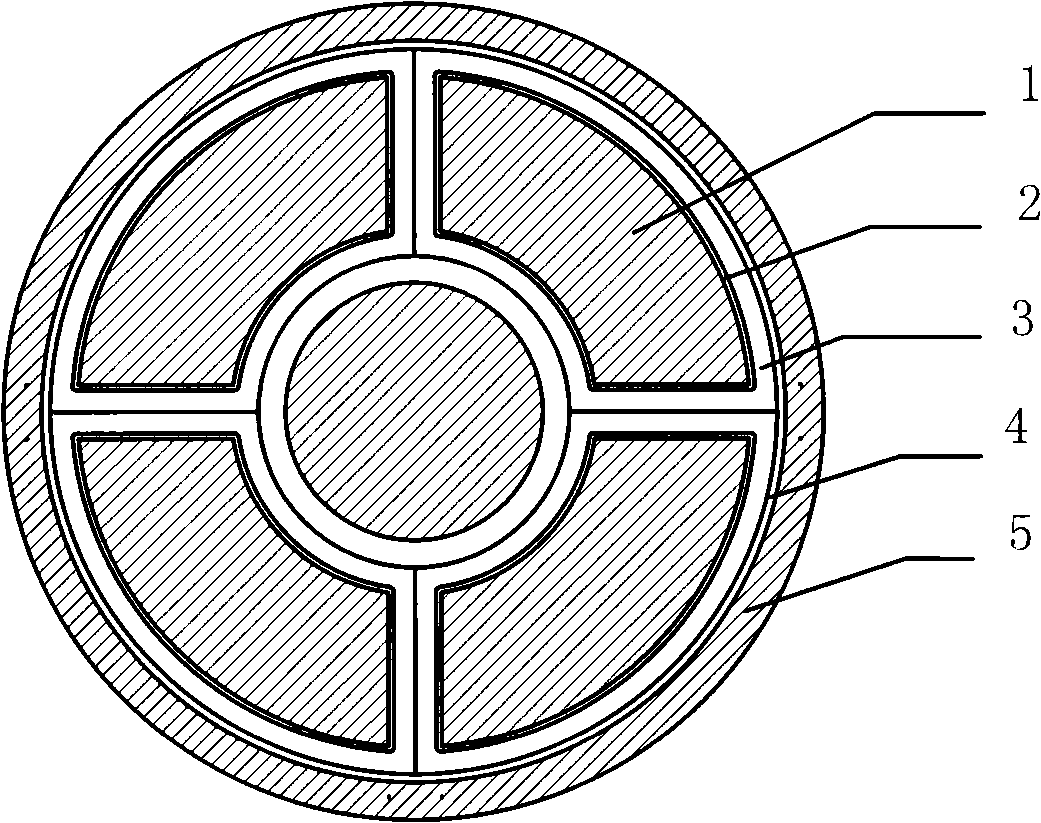

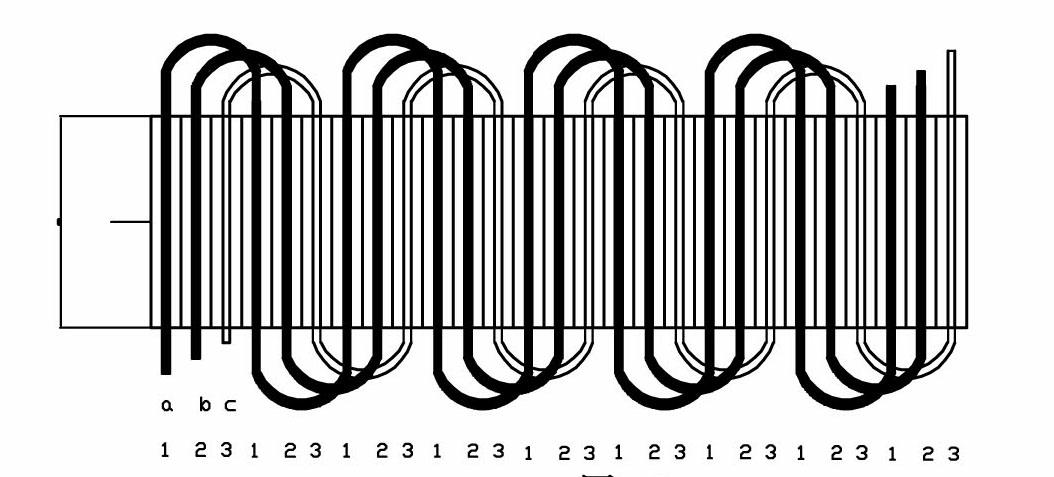

Unequal turn single-double-winding cast copper rotor induction motor

InactiveCN108336878AImprove efficiencyReduce temperature riseMagnetic circuit rotating partsAsynchronous induction motorsHarmonicThree-phase

The invention relates to an unequal turn single-double-winding cast copper rotor induction motor. The motor comprises a stator, a rotor and a rotating shaft, the rotor is located in the stator, an airgap is formed between the stator and the rotor, the stator comprises a stator tooth, a stator slot, an armature winding and a stator yoke, and the rotor comprises a rotor core, a guiding bar and an end ring; the motor is characterized in that the armature winding adopts a winding type of single-layer winding, the layout of each phase double-layer component s and a single-layer component d is s-d-d-s, the corresponding effective turn ratio is approximately 1:1.4:1.4:1 or 1:2.5:2.5:1, each phase winding adopts concentric connection, and three phases form delta connection. The rotor and the guiding bar adopt a pear-shaped closed groove structure with a narrow inner and a wide outer and are of straight groove structures. The motor can save copper for stator winding, weaken 5, 13, 23 or 7 and11 sub-harmonics, reduce motor temperature rising, and improve motor efficiency.

Owner:SOUTHEAST UNIV

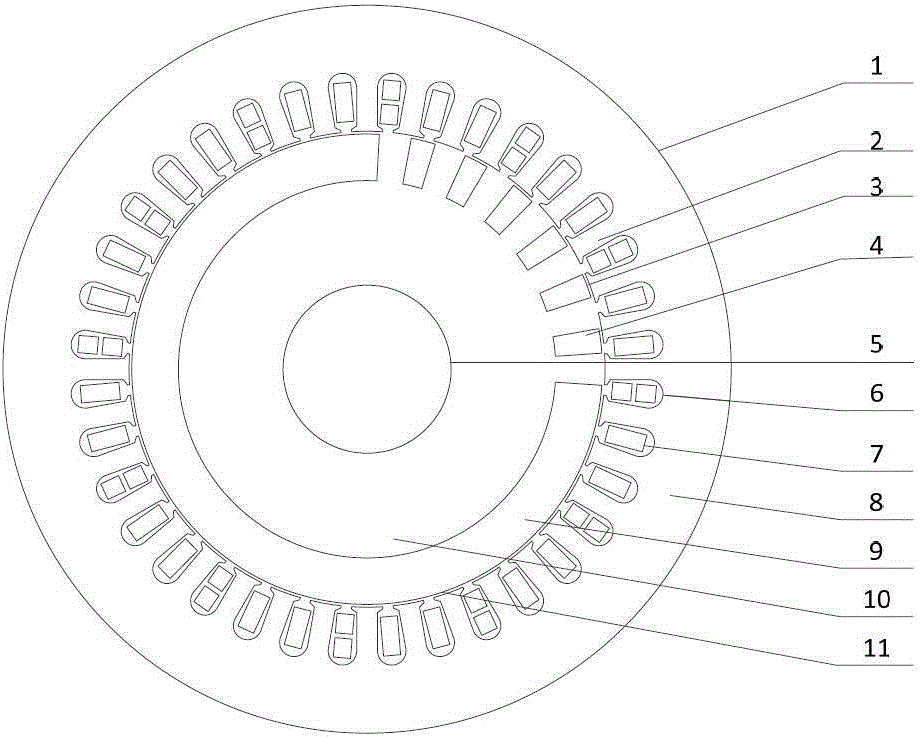

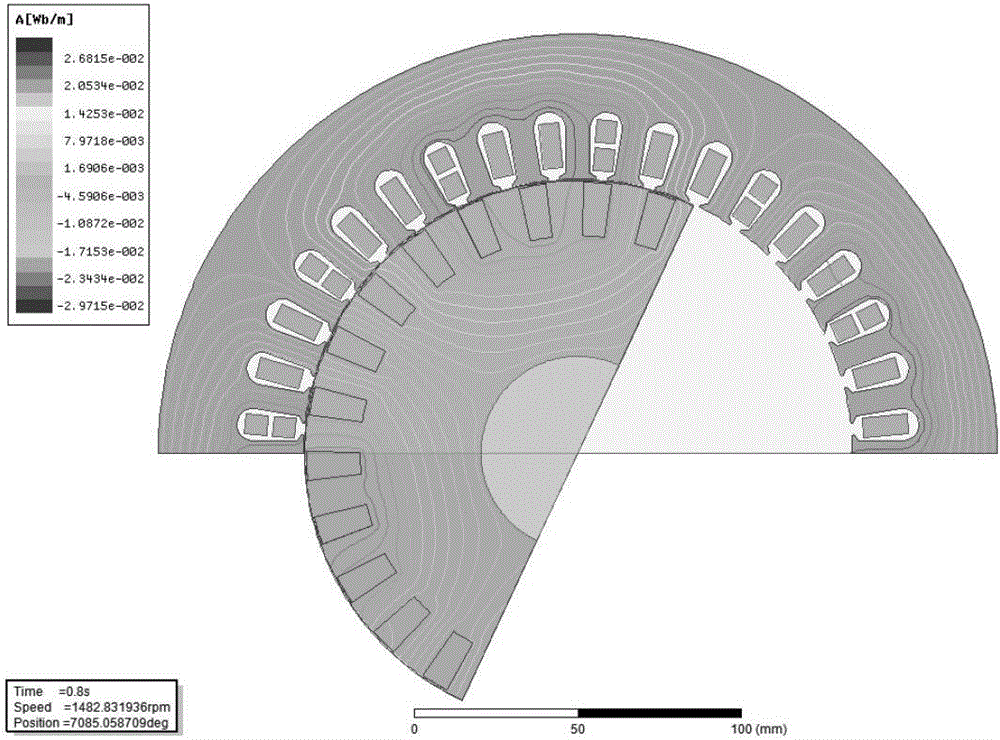

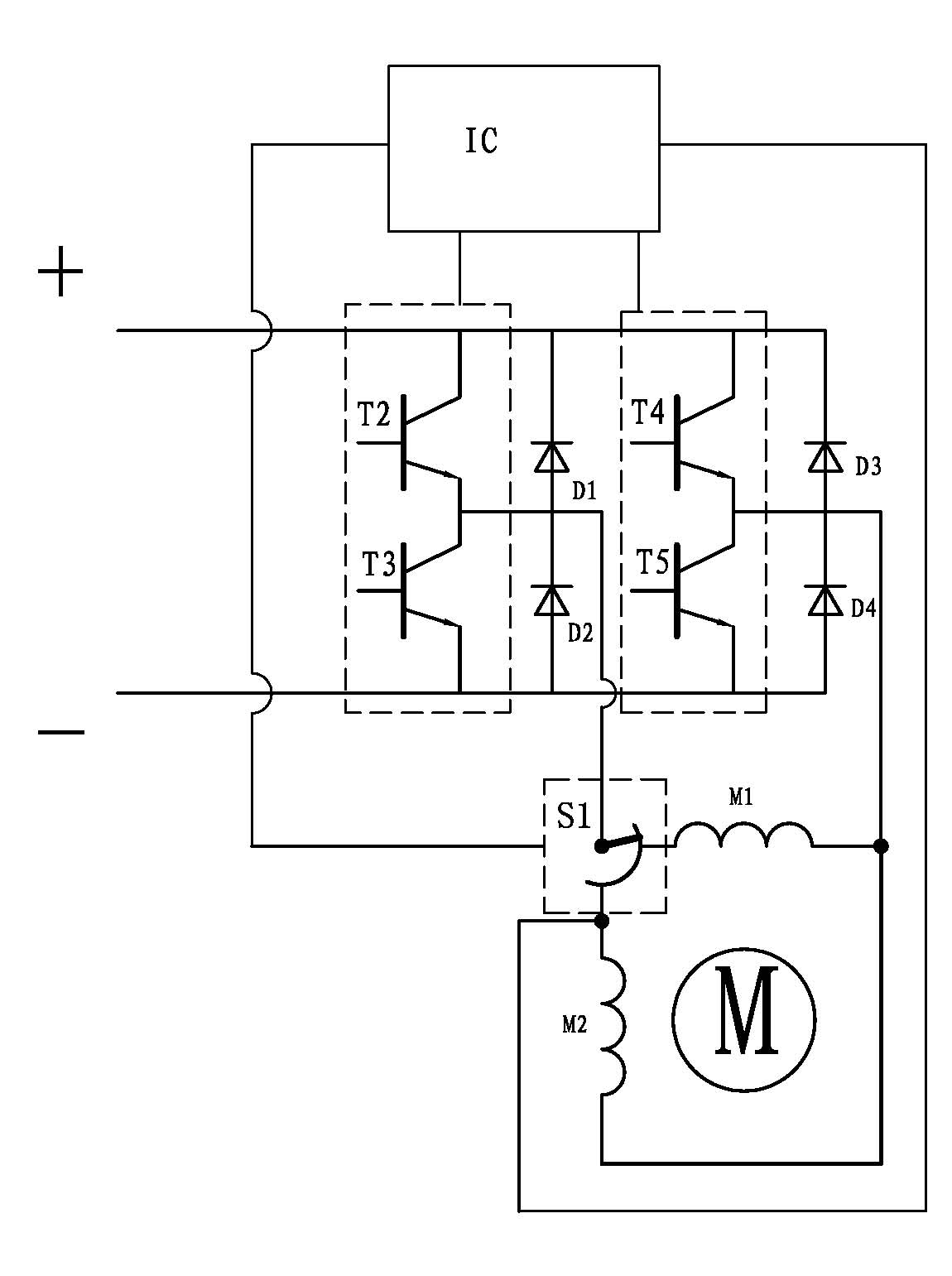

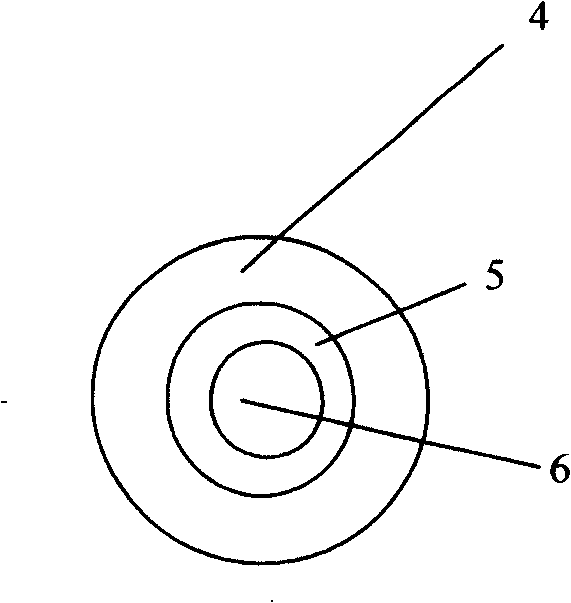

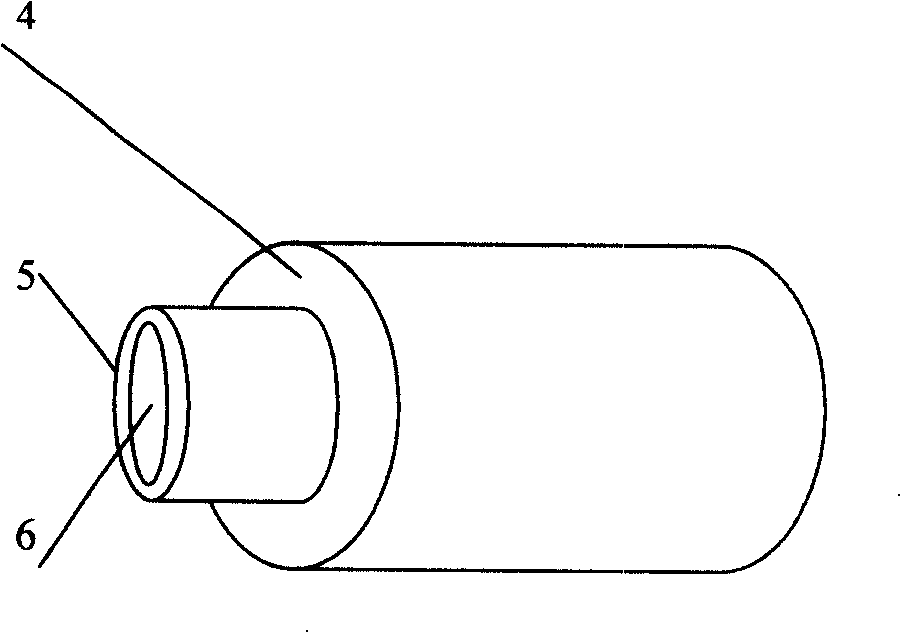

Induction motor provided with cast copper rotor

InactiveCN106787552AGood air gap magnetic field waveformGood starting performanceAsynchronous induction motorsWindings conductor shape/form/constructionPhysicsMotor efficiency

The invention relates to an induction motor provided with a cast copper rotor. The induction motor comprises a stator, a rotor and a rotating shaft, wherein the rotor is located in the stator, an air gap is reserved between the stator and the rotor, the stator comprises stator teeth, stator slots, armature windings and a stator yoke, and the rotor comprises a rotor iron core, guide bars and an end ring. The induction motor is innovatively characterized in that the armature windings adopt a single and double layer winding, upper and lower conductors of the same phase in a short-pitch winding are combined to form a single-layer winding, upper and lower conductors of different phases form a double-layer winding, end parts of the conductors are connected together in a shape of end parts of the concentric double-layer winding, and the single and double layer winding is formed; each guide bar of the rotor adopts a novel concentric arc structure with wide top and narrow bottom, and upper and lower bottoms of each guide bar take the axis of a rotating shaft as circle centers. The starting performance can be improved, copper for stator winding and rotor mouse cages is saved, the motor temperature rise is reduced, and the motor efficiency is improved.

Owner:CHANGZHOU YUCHENG FUTONG MOTOR CO LTD +1

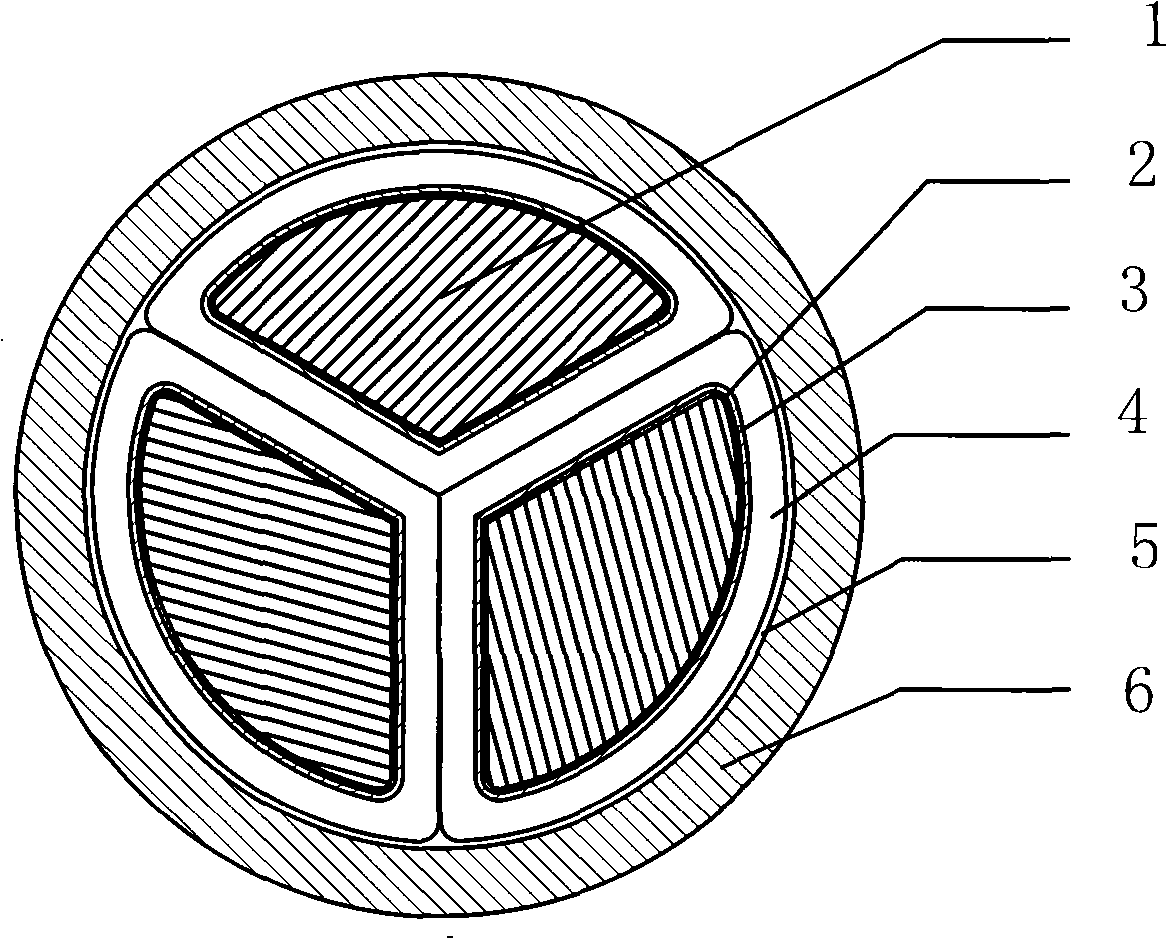

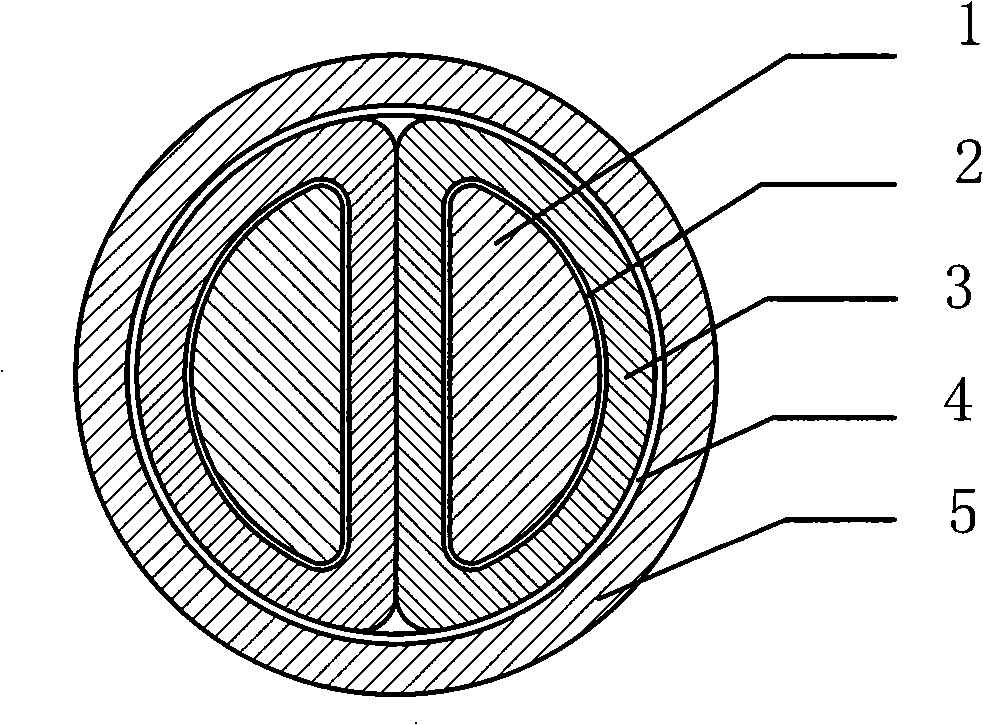

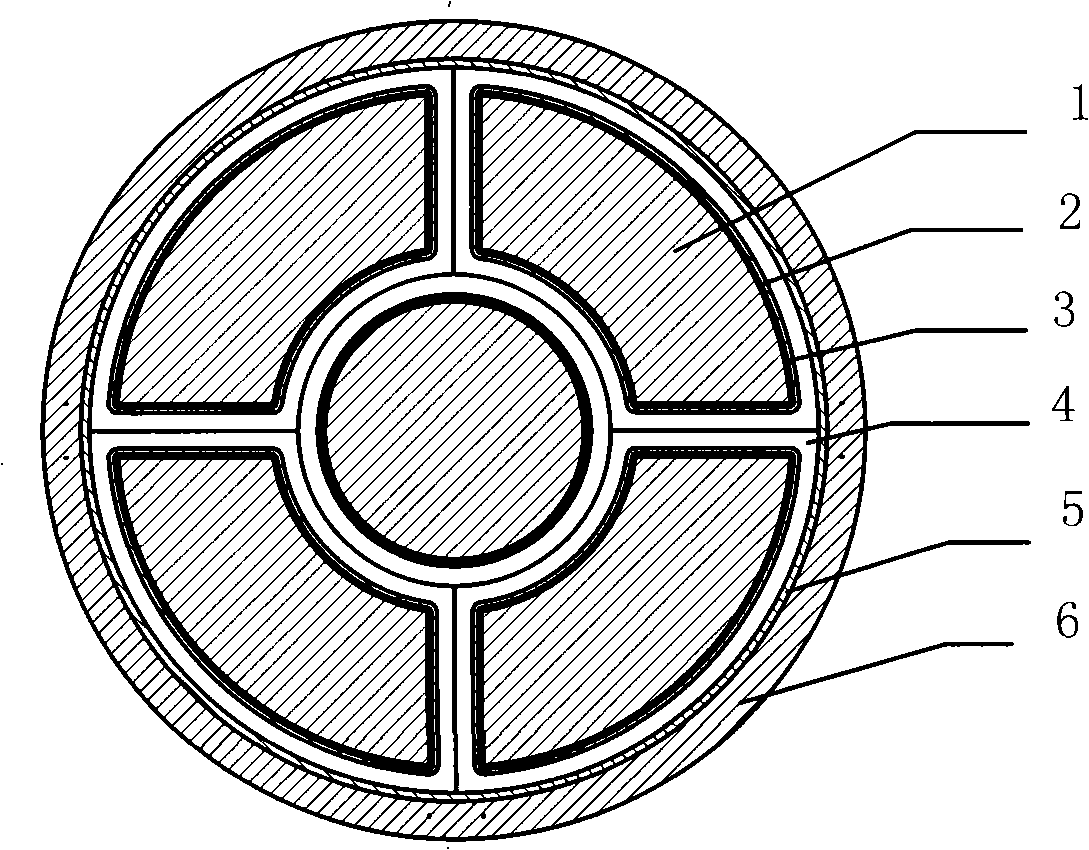

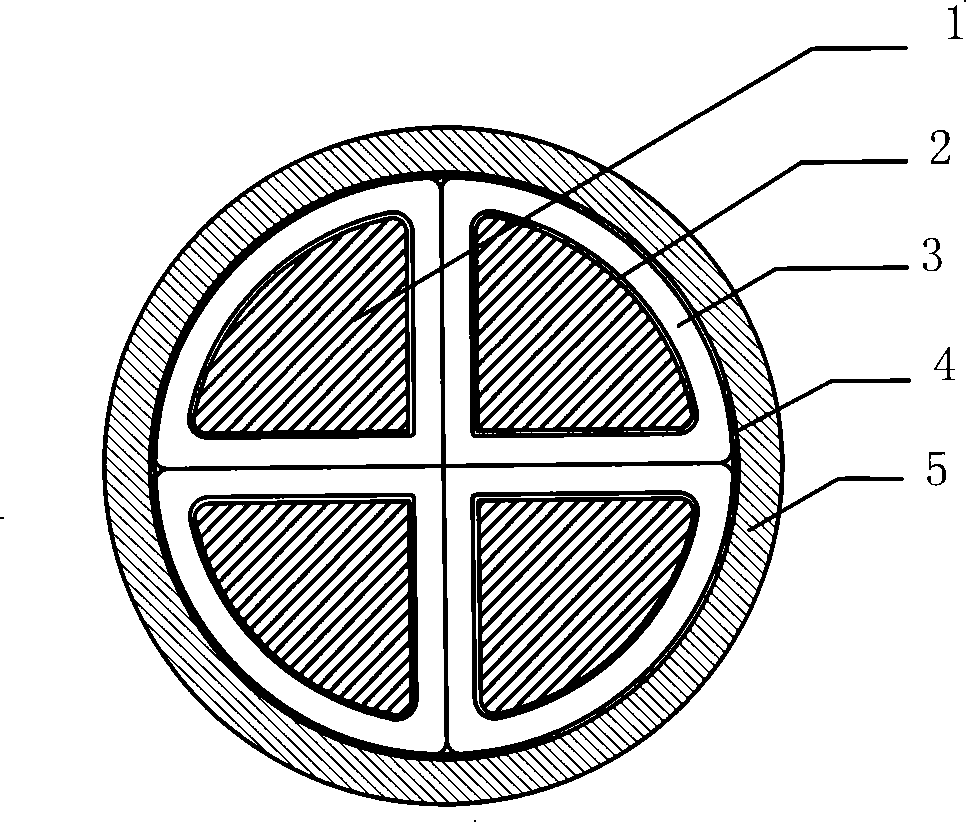

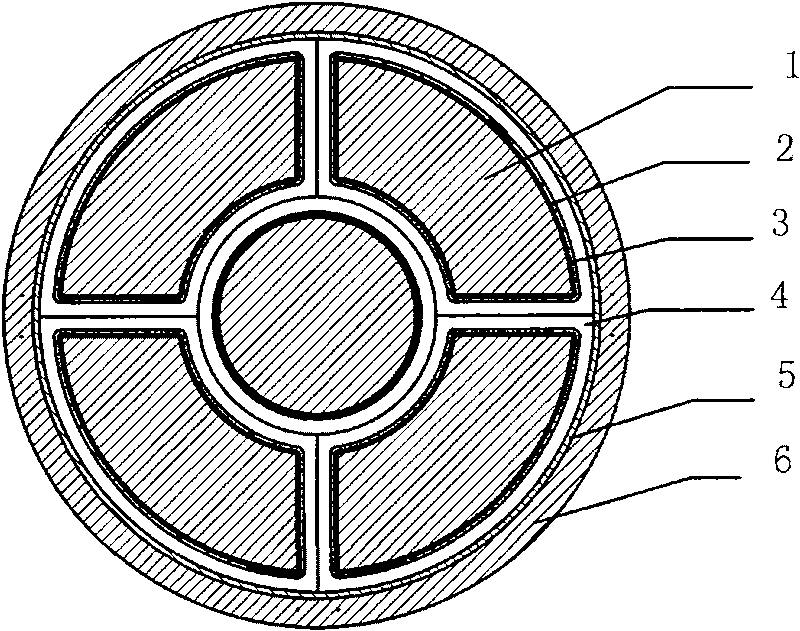

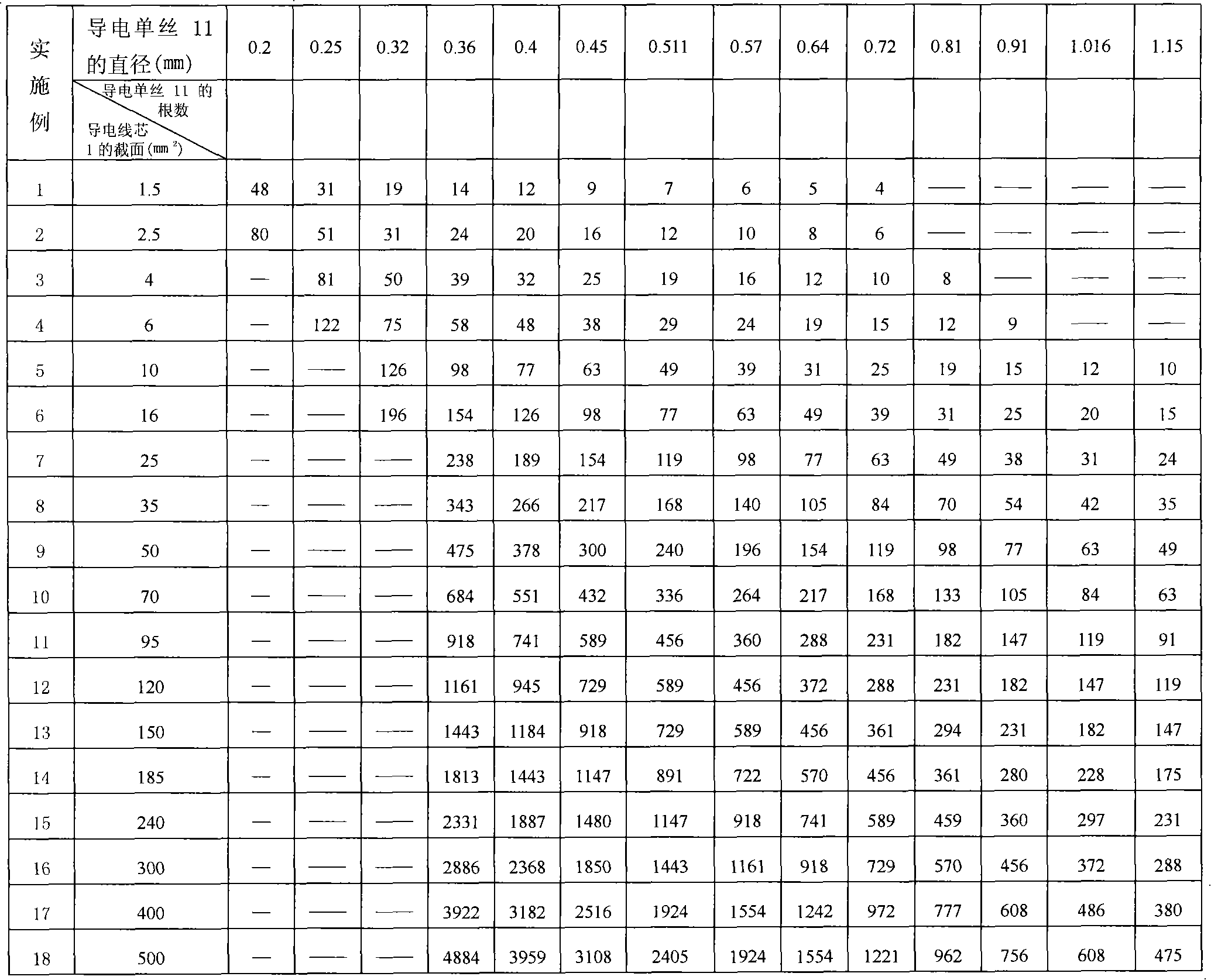

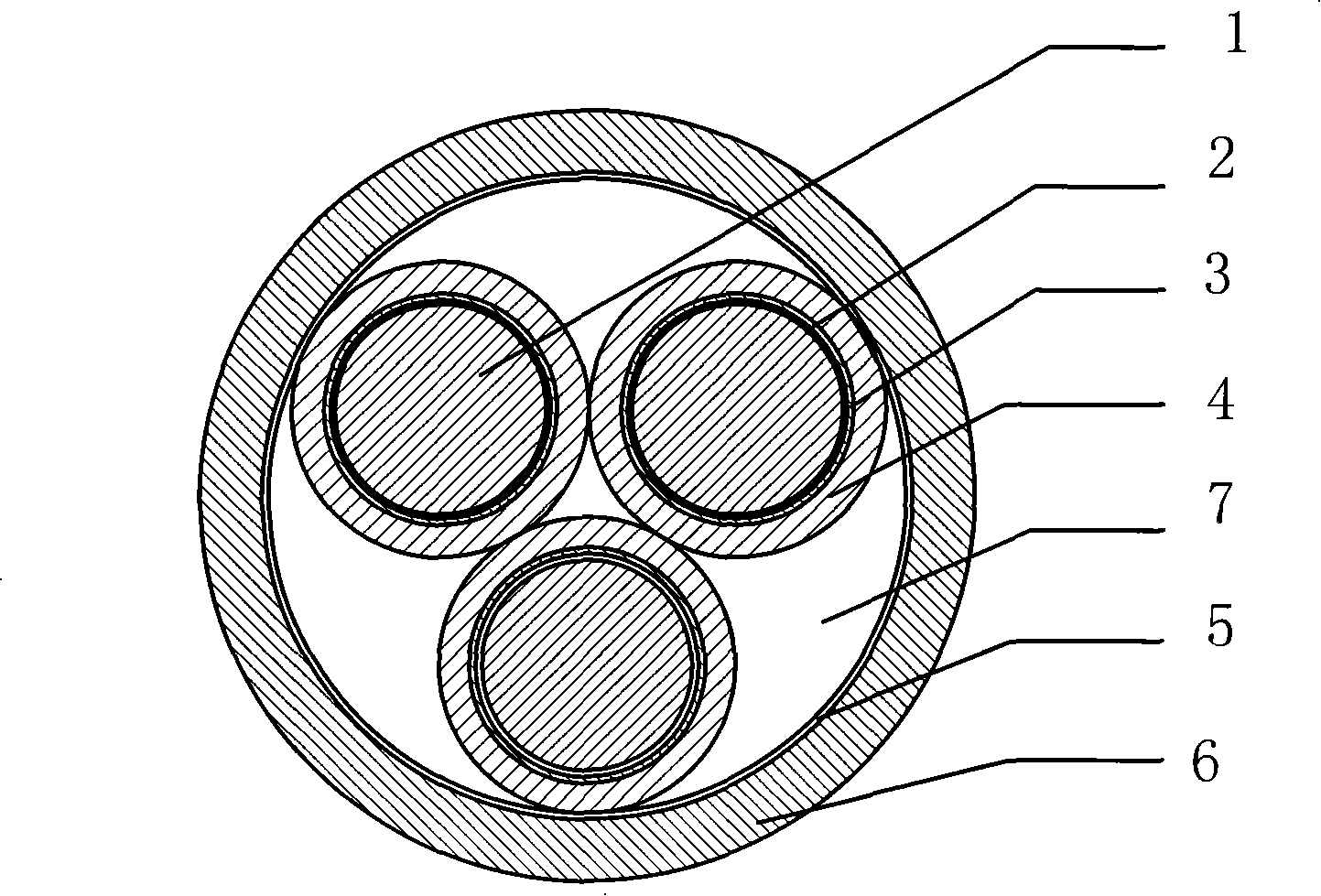

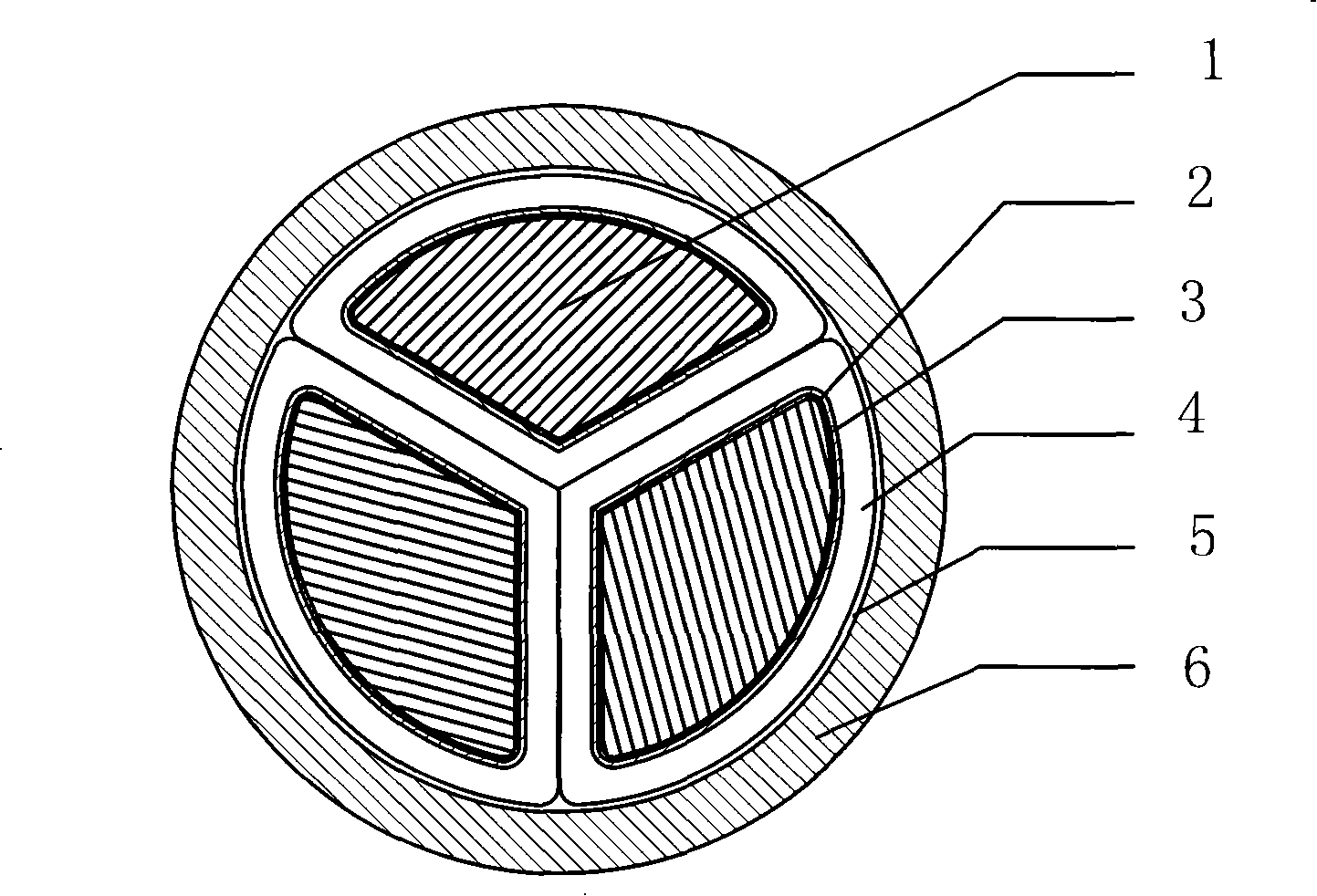

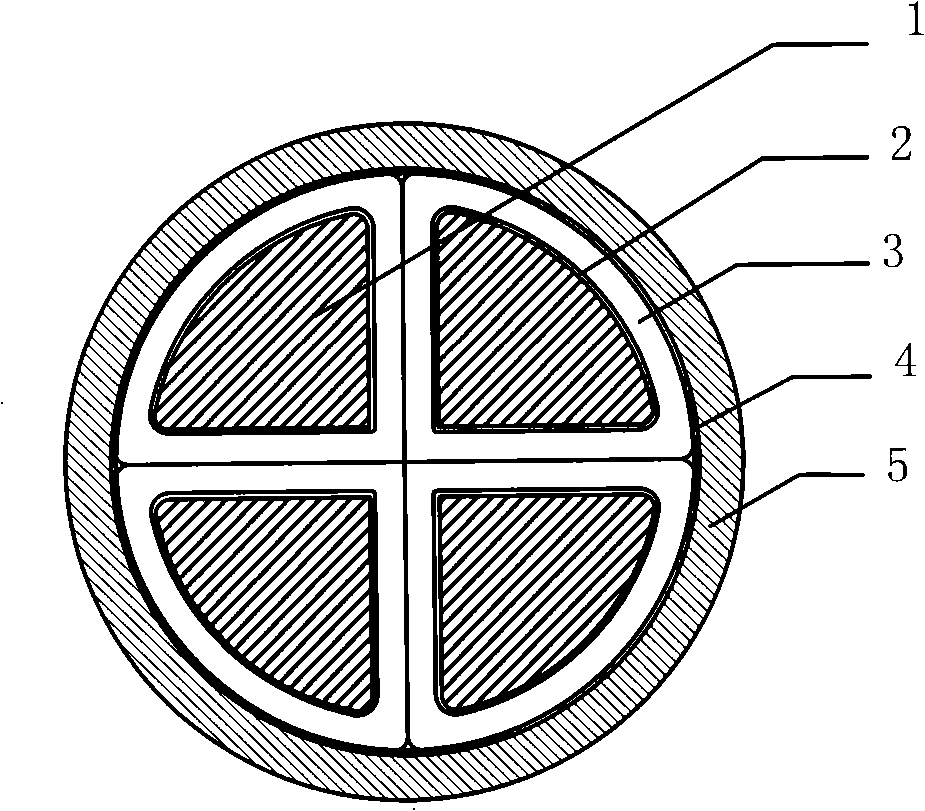

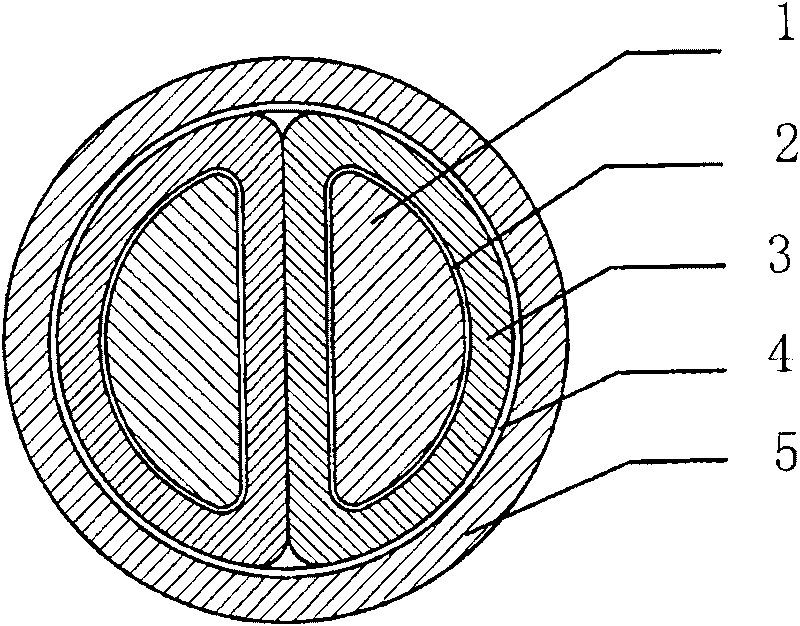

Copper coated aluminum three-core flame-retardant refractory flexible electric cable

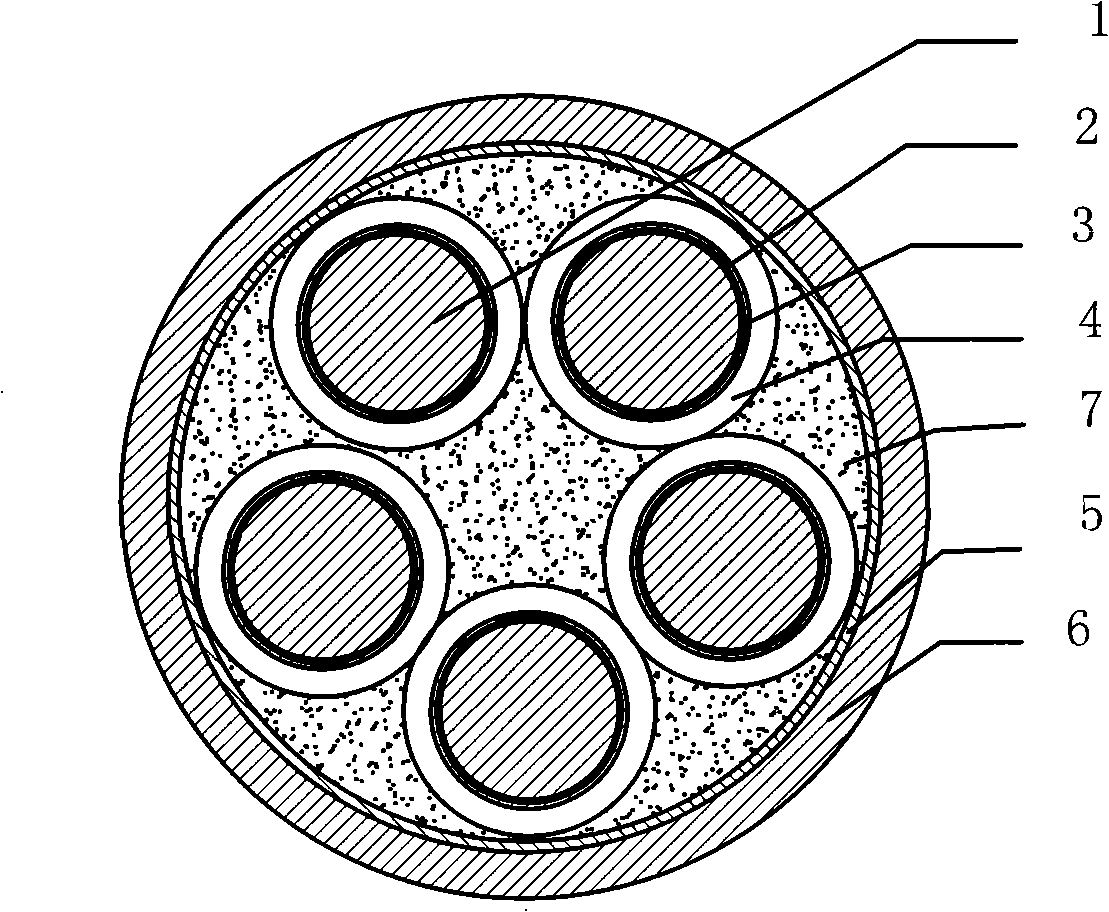

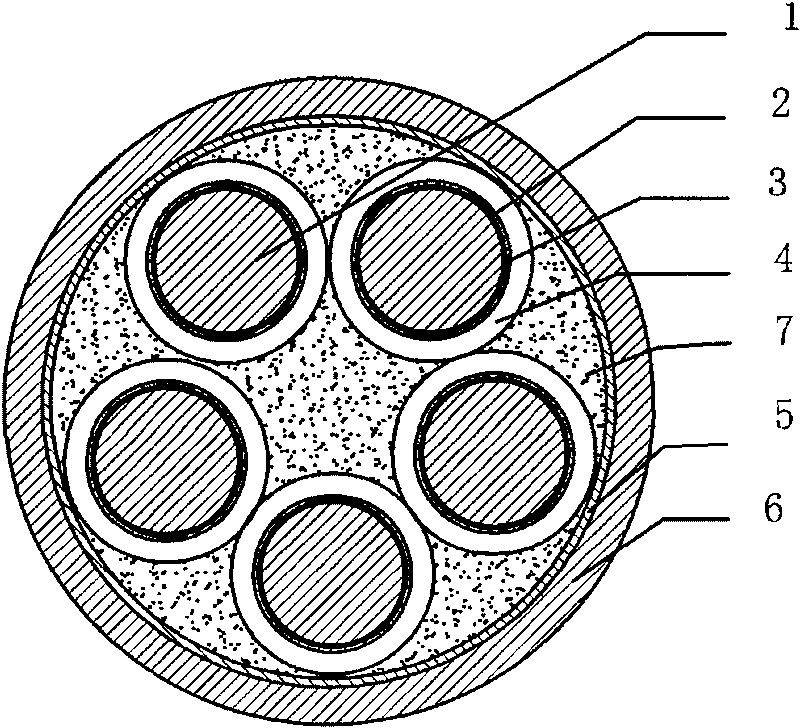

ActiveCN101335111AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum three-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with the section of the fan shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to three insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

A permanent magnet two-phase brushless divided stator motor

InactiveCN102299597AHigh speedOvercome vibrationWindingsStarter arrangementsWinding machinePermanent magnet rotor

The invention relates to a permanent magnet two-phase brushless sub-stator motor, which comprises a stator, a main winding, an auxiliary winding, a permanent magnet rotor and a starting device, and is characterized in that: the stator consists of at least two sub-stators; the slot number of the sub-stators is the multiple of 3; the total slot number of the stator is the multiple of 6; and an eccentric gap is not formed between a stator tooth and the permanent magnet rotor. The motor has the advantages that: 1, the defect of vibration and noise generated by magnetic flux distortion due to the eccentric gap in the prior art is overcome; and 2, the eccentric gap is not formed, so the motor can rotate clockwise and anticlockwise, and the application field of a product is expanded. In addition, due to a sub-stator structure, a winding machine special for the sub-stators has a high speed, a few copper or aluminum wires are used, and working hour and materials are saved.

Owner:佛山市天秤电器有限公司

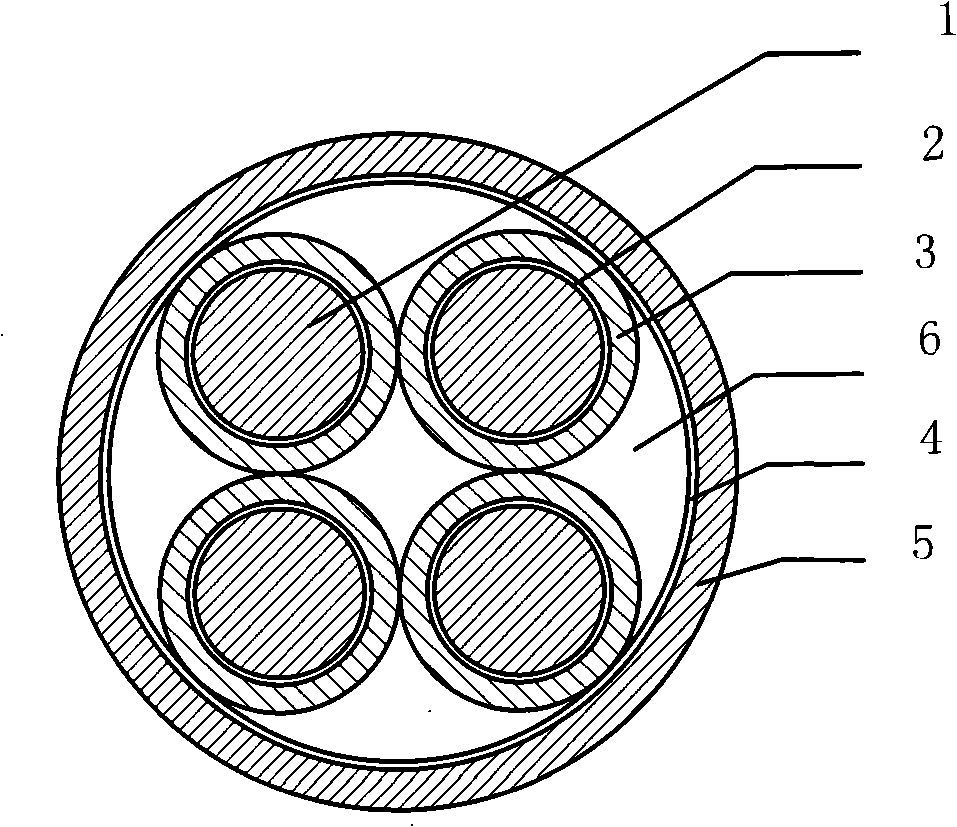

Copper coated aluminum four-core flame-retardant refractory flexible electric cable and manufacturing method thereof

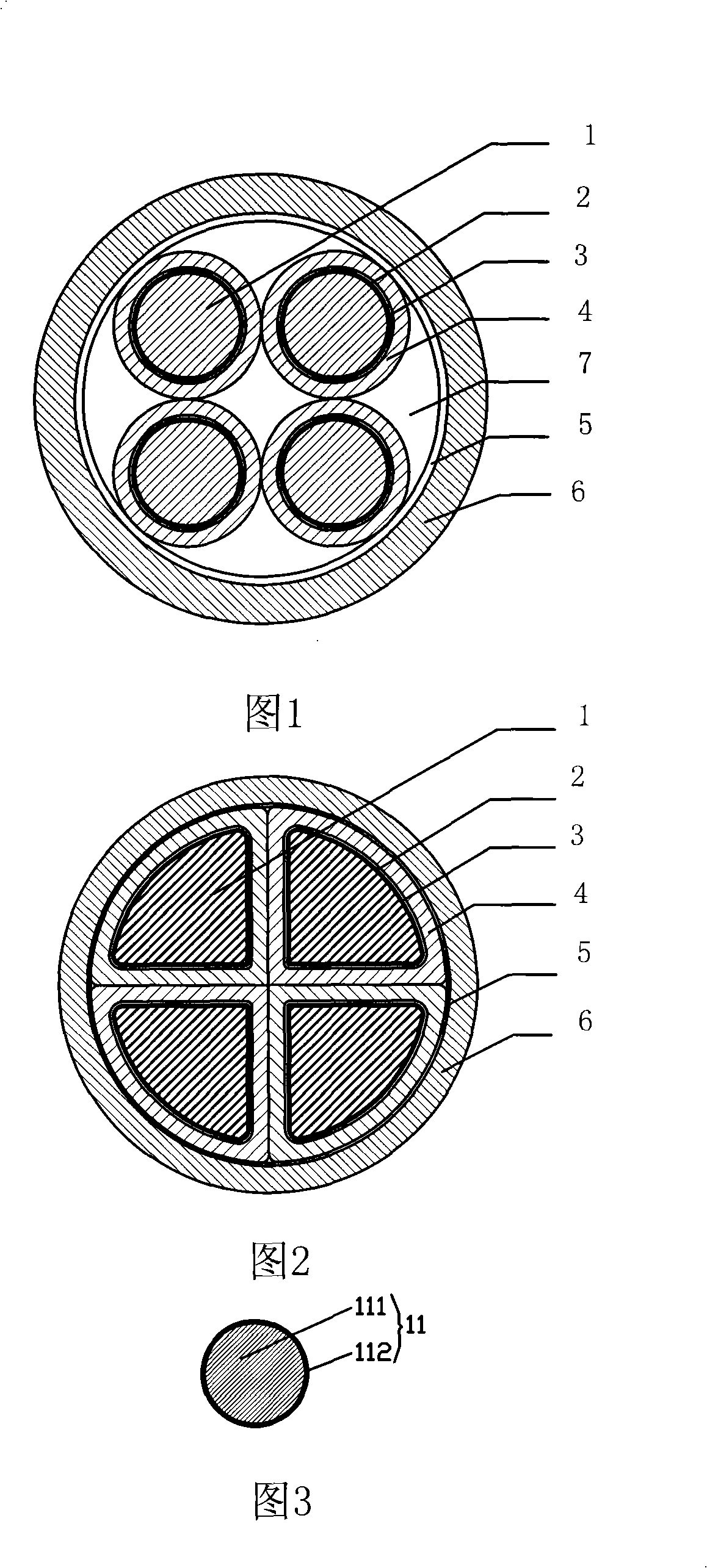

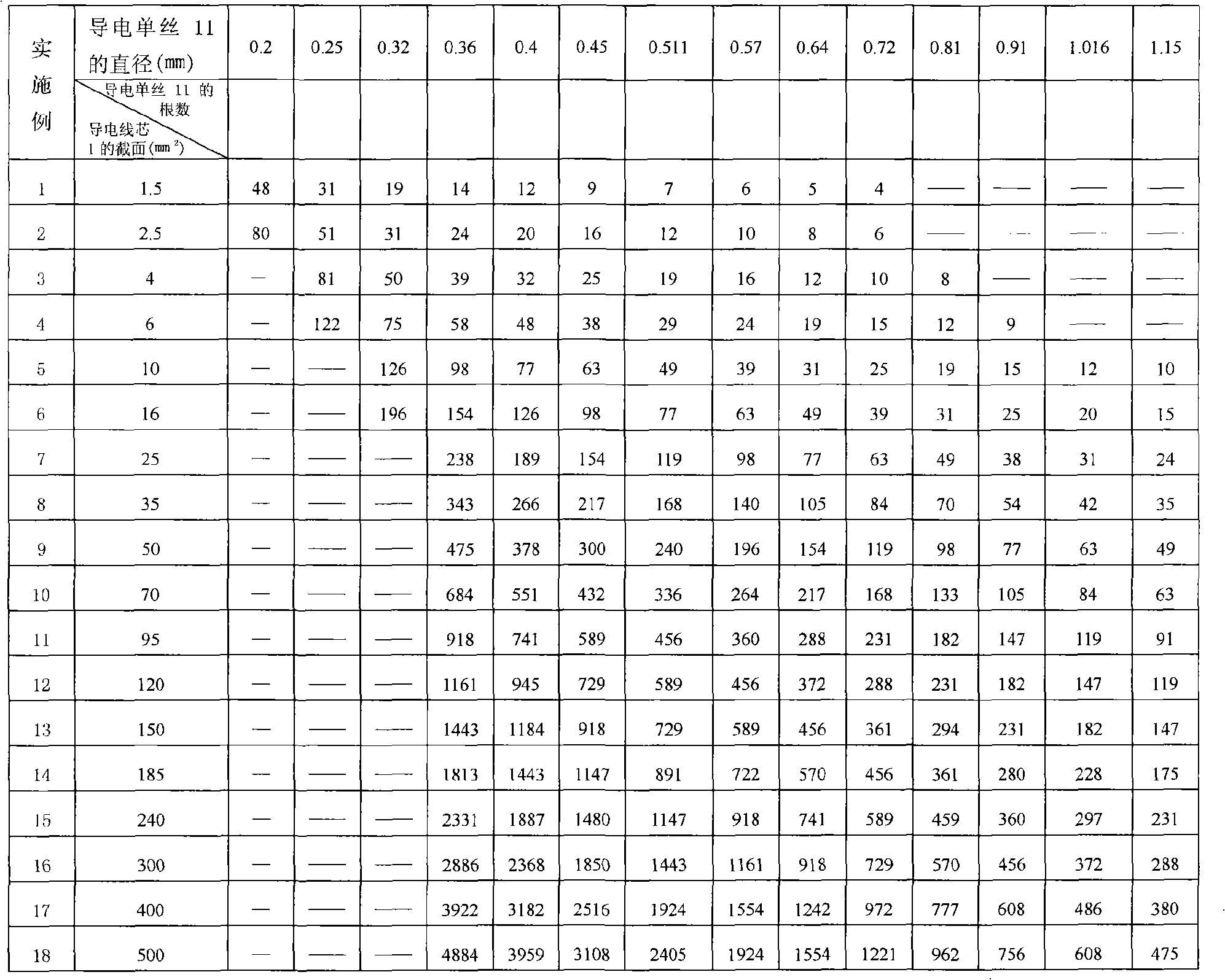

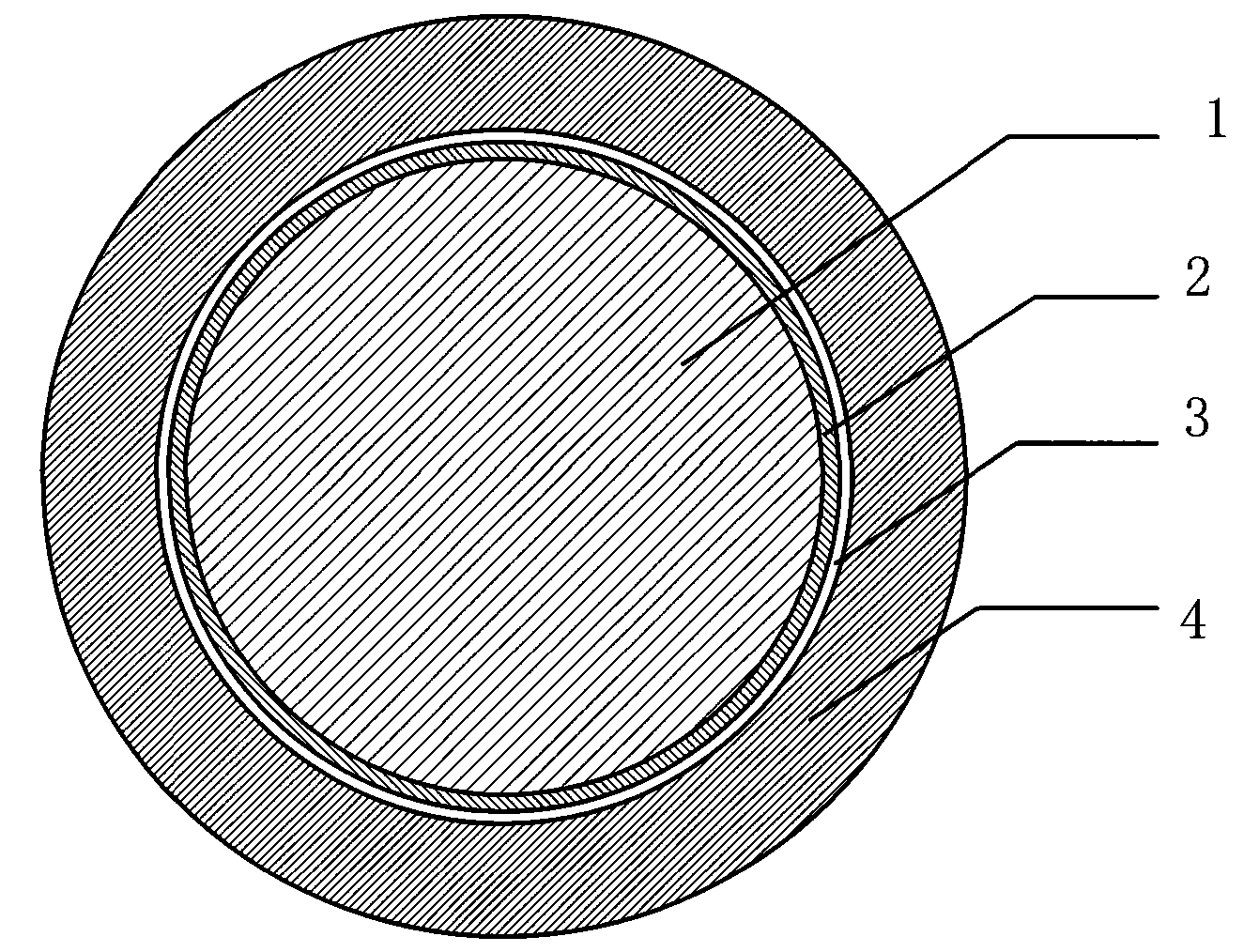

ActiveCN101335113AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum four-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a section of a fan shape; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with the section of the fan shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to four insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

Copper coated aluminum dual-core flame-retardant flexible electric cable and manufacturing method thereof

ActiveCN101335115AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

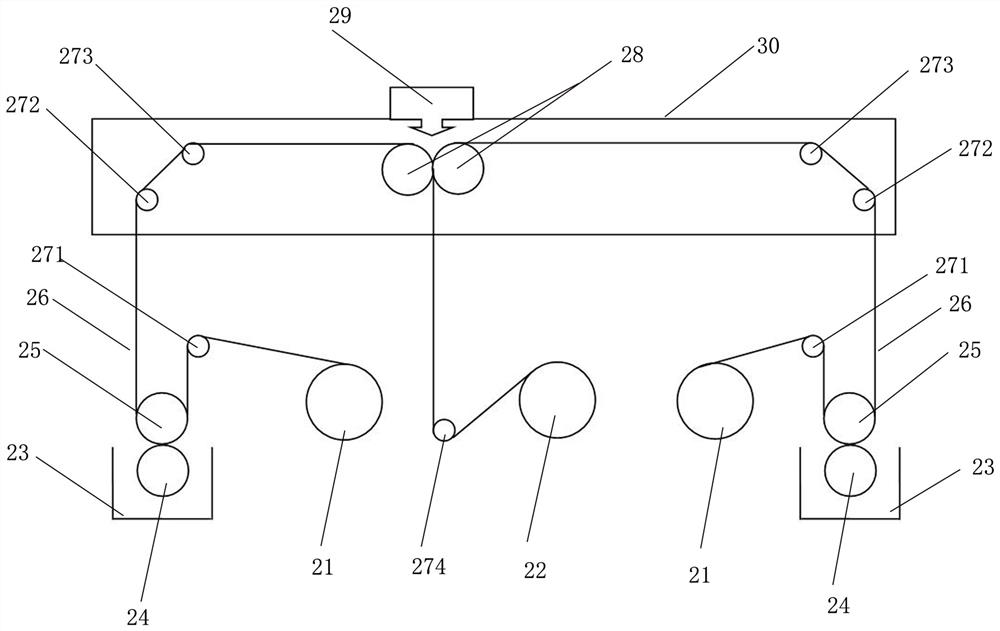

The invention discloses a copper-clad aluminum two-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a semi-round section; an insulation process is carried out to the conductive wire core provided with the semi-round section, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to two insulation wire cores provided with insulation layers, thereby forming a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

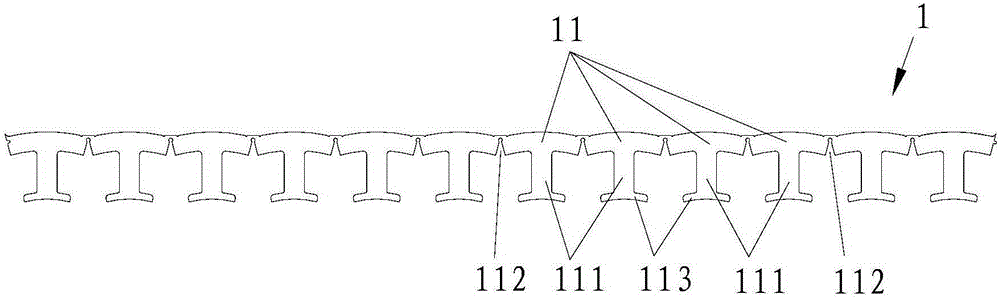

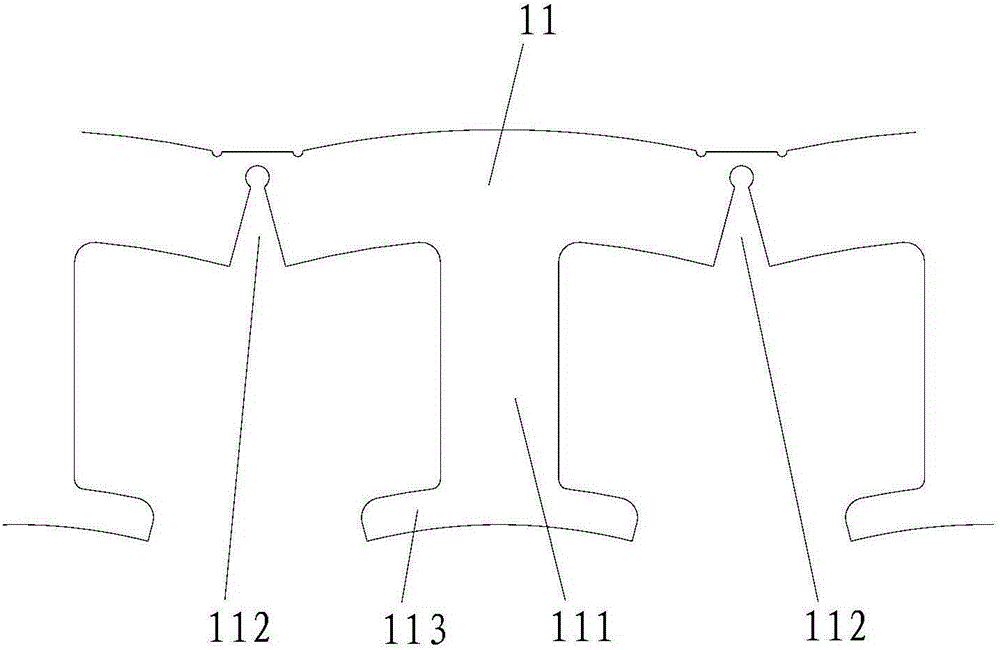

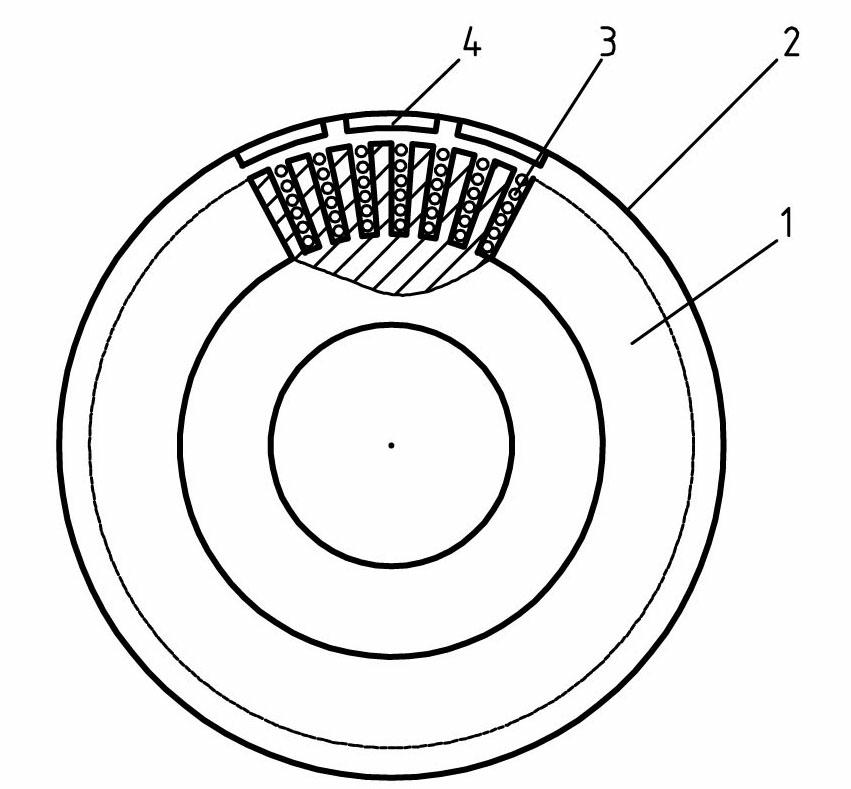

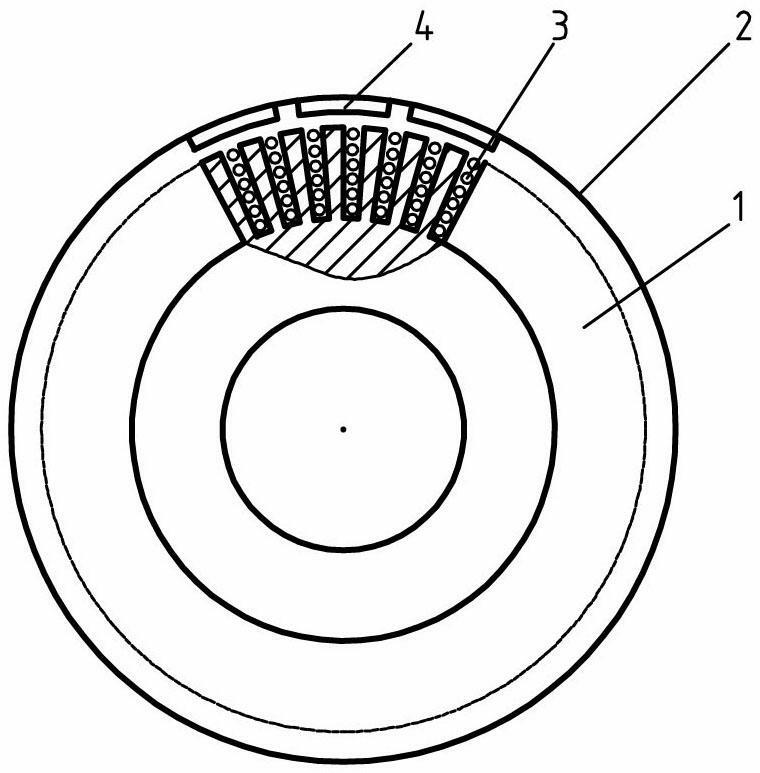

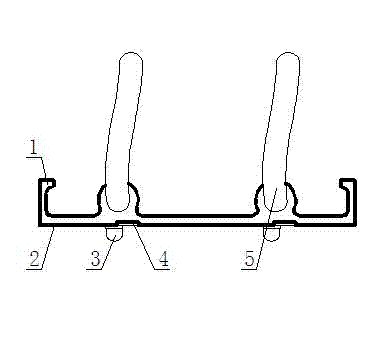

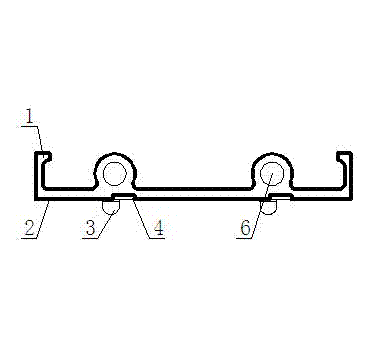

Winding stator used for air-conditioning outdoor fan motor and manufacturing method thereof

InactiveCN105226853AReduce lossReduce copper usageWindings insulation shape/form/constructionMagnetic circuit stationary partsPunchingCopper

The present invention relates to the motor technology field, in particular to a winding stator used for an air-conditioning outdoor fan motor and a manufacturing method thereof. The winding stator comprises a stator punching and windings, the stator punching is characterized in that a plurality of punching blocks are connected orderly and mutually to form a straight bar structure, and the inner sides of the punching blocks protrude the groove-shaped teeth parts integrally and inwards. The insulating frames are fixed on the front and back end faces of the stator punching respectively, the wires of the windings are wound on the groove-shaped teeth parts of the punching blocks orderly to bend the punching blocks inwards orderly along the connection positions, so that the stator punching forms a circular structure, and the two ends of the stator punching are welded and fixed mutually. According to the present invention, a bar-shaped stator centralized winding structure is adopted, the end part loss of the windings and the copper consumption are little, the manufacturing cost is reduced directly, the end part heights of the windings of the motor can be reduced effectively, the end part leakage reactance, the motor loss and the technology difficulty are reduced, a production technology is simplified, the automatic production is easy to realize, and the production efficiency is improved.

Owner:珠海市通得电气设备有限公司

Single-line multi-pole outer rotor single-phase generator

InactiveCN102306994AReduce dosageReduce manufacturing costMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsSingle-phase generatorSingle phase

The invention relates to a generator, in particular to a single-line multi-pole outer rotor single-phase generator. The generator comprises a shell, wherein a stator is arranged in the shell; a plurality of permanent magnetic steels are arranged on the inner wall of the shell; the polarity of the same ends of two adjacent permanent magnetic steels is opposite; the stator is formed by mutual superposition of a plurality of silicon steel sheets; a plurality of wire slots are radially arranged on the stator; and generator windings are arranged in the wire slots. The generator is characterized in that the wire slots are radially and uniformly distributed on the outer edge of the stator; the outer ends of the wire slots are communicated with the outer edge of the stator; the number of the wire slots is integral multiple of 6; the generator windings comprise enamelled wires a, enamelled wires b and enamelled wires c; the enamelled wires a, b and c are respectively put at the bottoms of three wire slots 1, 2, 3 and are wound continuously in the wire slot order of 1-6-1-6, 2-5-2-5 and 3-4-3-4; and after being wound, the enamelled wires a, b and c are connected as one in a cross manner to serve as the output end of the single-phase generator. As fewer enamelled wires and fewer copper materials are consumed for the stator windings, not only is the manufacturing cost of the generator low but also the weight of the generator can be greatly reduced.

Owner:无锡市风驰风电科技有限公司

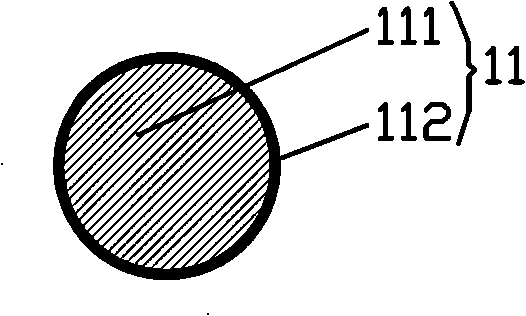

Copper-coated aluminum electromagnetic wire

InactiveCN101246762AHigh strengthLow densityRubber insulatorsPlastic/resin/waxes insulatorsHigh resistanceElectrical conductor

The invention is a copper-clad aluminum conductor magnetic wire, the inner core is aluminum wire clad with a layer of cylinder copper sheet, the magnetic wire can also be a magnetic wire having two or more parallel or winding copper-clad aluminum conductors, the magnetic wire is covered with an insulting layer. Or insulating materials such as paper, insulating paint or fiberglass are covered outside the conductor to form a magnetic wire with an insulating layer. The copper-clad aluminum core magnetic wire has same conductivity as that of same-sized copper-core magnetic wire having same size, light weight, processing simplicity and usage convenience, saves more than 80% copper, effectively lowers cost, and overcomes the following drawbacks: easy oxidability, high resistance, poor corrosion resistance and mechanical property of the aluminum-core magnetic wire.

Owner:大连极速金属复合材料有限公司

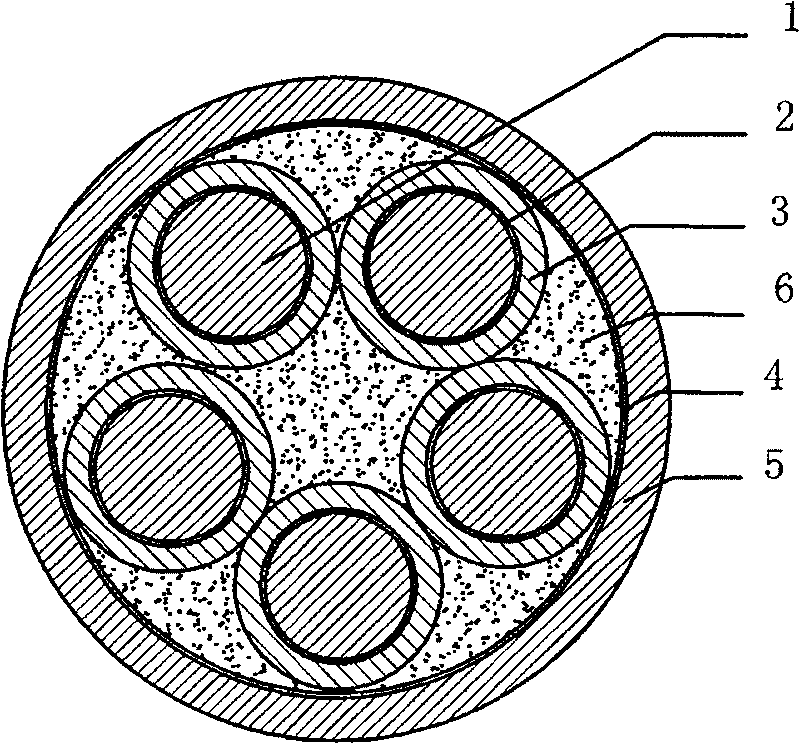

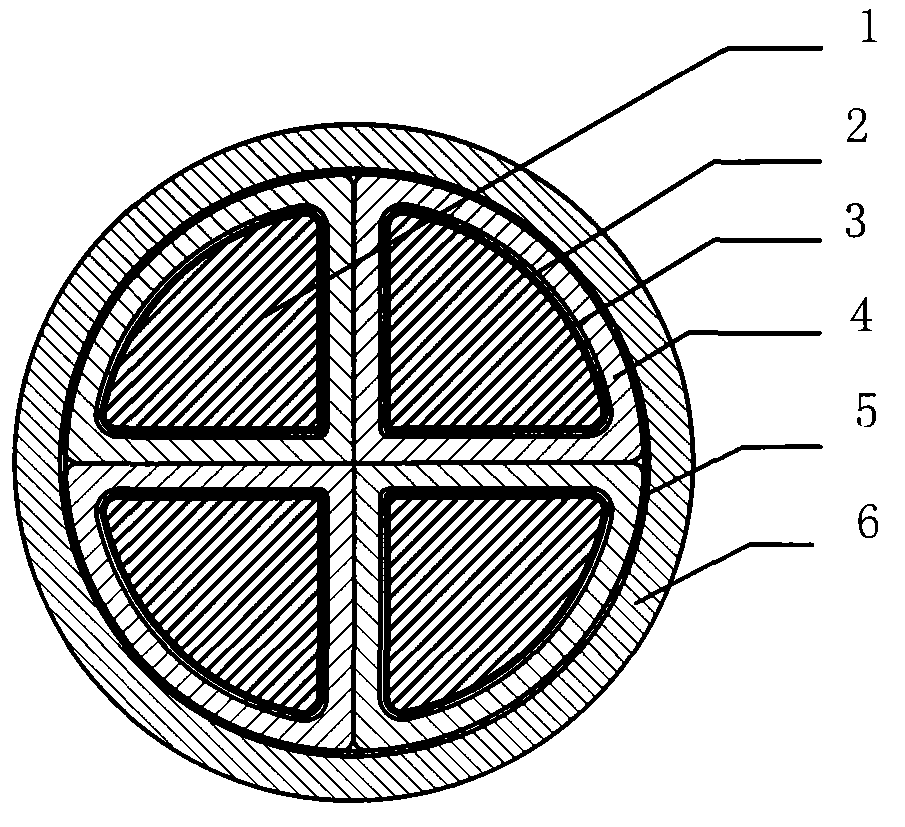

Copper coated aluminum five-core flame-retardant refractory flexible electric cable and manufacturing method thereof

InactiveCN101335108AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum five-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a tile shape; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with the section of the tile shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-forming process is carried out to five insulation wire cores provided with the insulation layers so as to form a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:GUANGDONG ZHONGDE CABLE

Copper coated aluminum four-core flame-retardant flexible electric cable manufacturing method

ActiveCN101335112BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum four-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; an insulation process is carried out to the conductive wire core provided with the section of the fan shape, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to four insulation wire cores provided with insulation layers, thereby forming a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into a single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

Copper coated aluminum five-core flame-retardant flexible electric cable and manufacturing method thereof

ActiveCN101335109AReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum five-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a section of a tile shape; an insulation process is carried out to the conductive wire core provided with the section of the tile shape, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-forming process is carried out to five insulation wire cores with the insulation layers so as to form a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

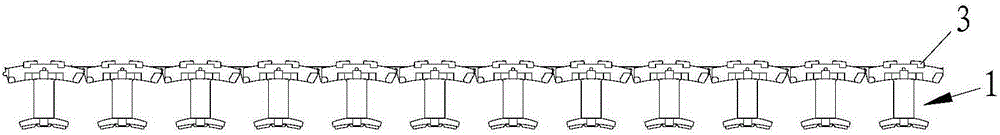

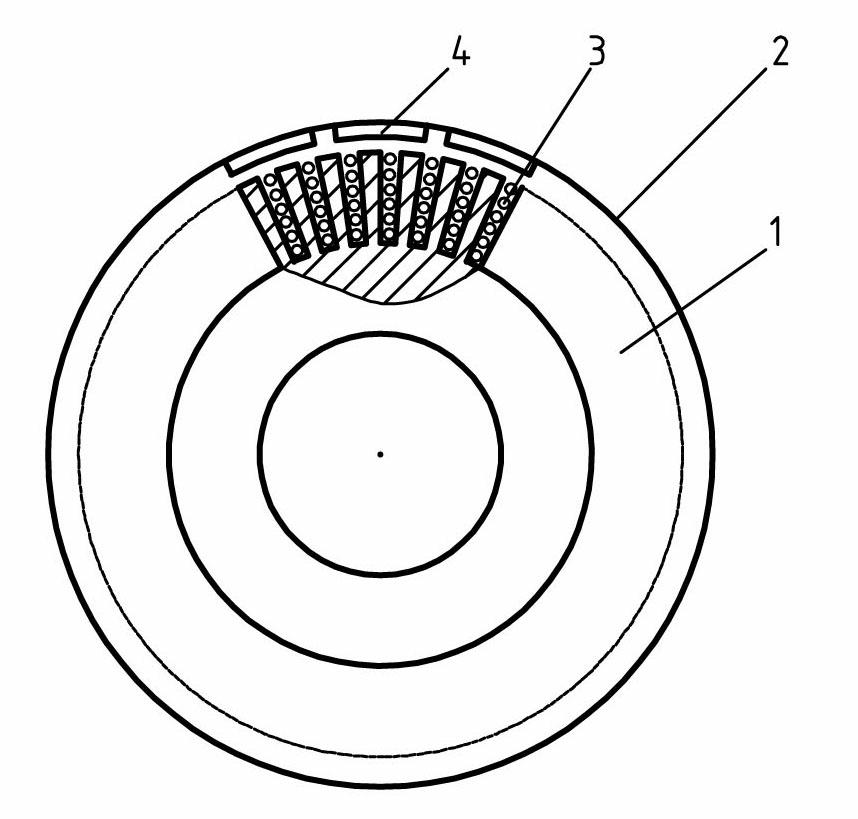

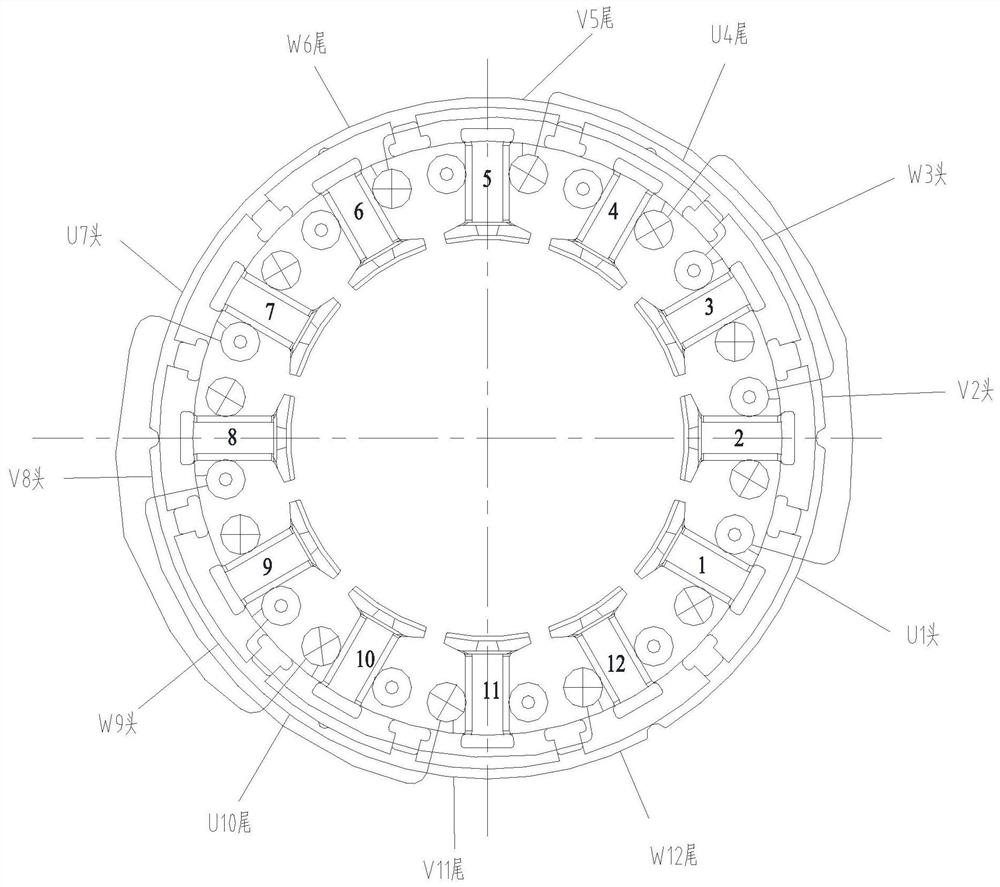

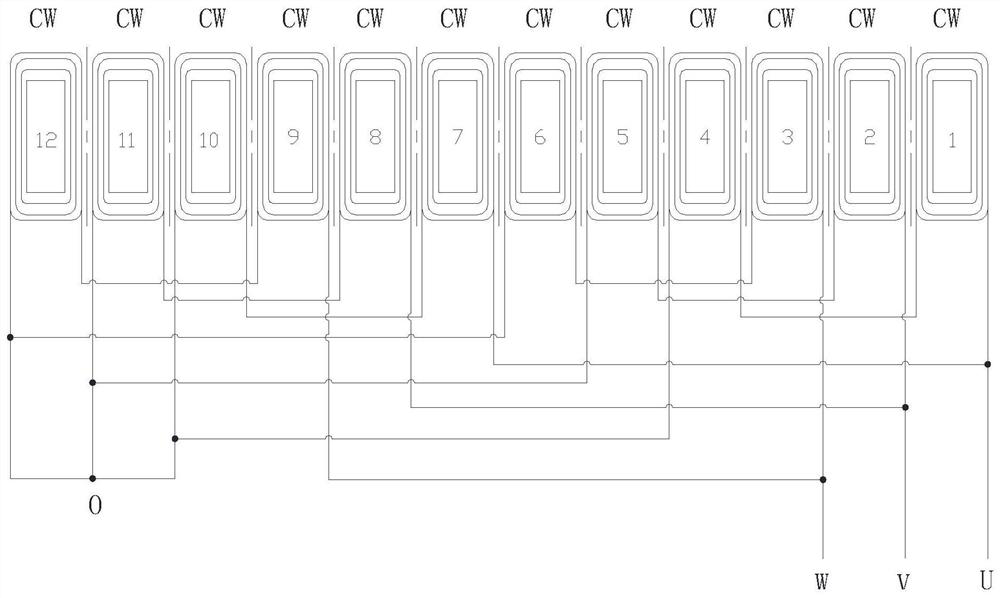

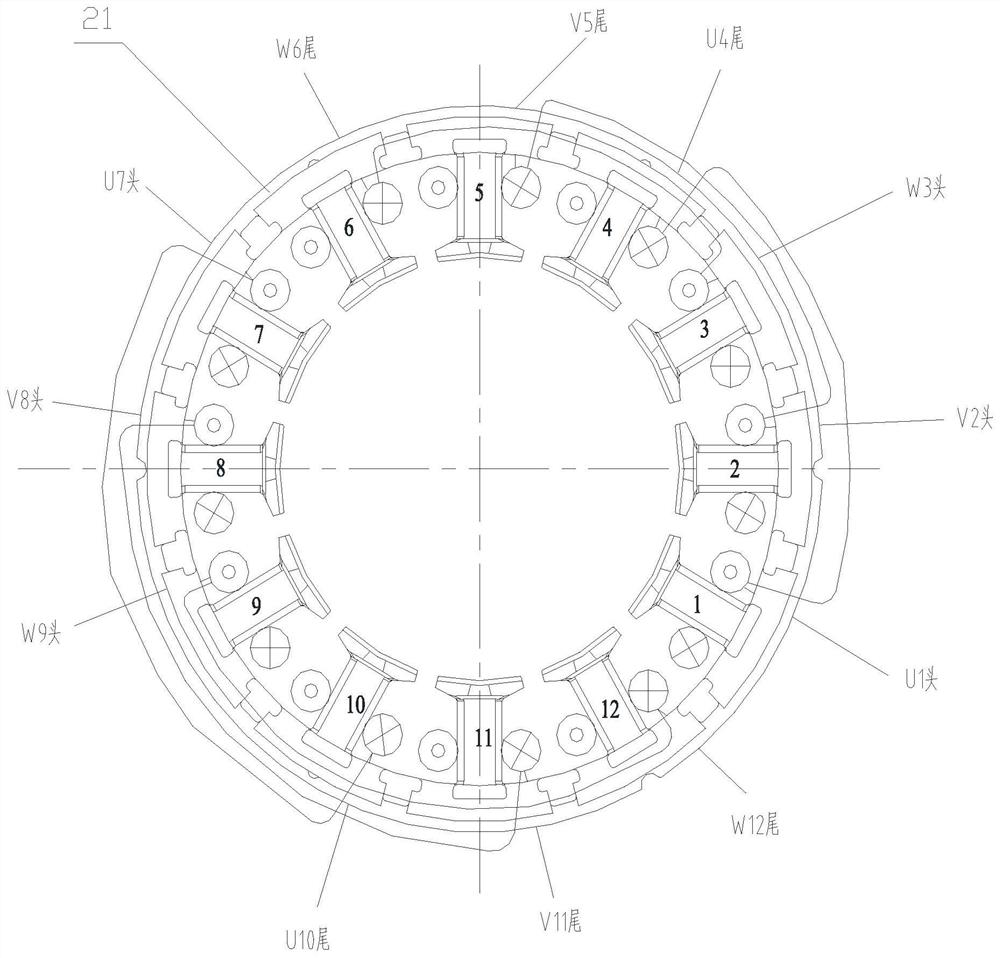

Winding assembly, stator assembly and motor

InactiveCN113489205AReduced number of spansReduce copper usageMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineControl theory

The invention provides a winding assembly, a stator assembly and a motor. The winding assembly comprises a plurality of in-phase windings, wherein all the in-phase windings are divided into a first group of windings and a second group of windings; each of the first group of windings and the second group of windings comprises at least two adjacent in-phase windings; all the in-phase windings in the first group of windings are formed by winding first winding wires in sequence, and all the in-phase windings in the second group of windings are formed by winding second winding wires in sequence; and the first winding sequence and the second winding sequence are opposite in winding direction. According to the winding assembly, the in-phase windings are grouped, and the winding directions of each group are set oppositely, so that the winding mode of the in-phase windings is changed, and the number of cross slots of the bridging wires of the in-phase windings is greatly reduced, so that the bridging wires can be shortened, the copper consumption at the bridging wires is reduced, the wiring operation is simpler, and the working efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC +1

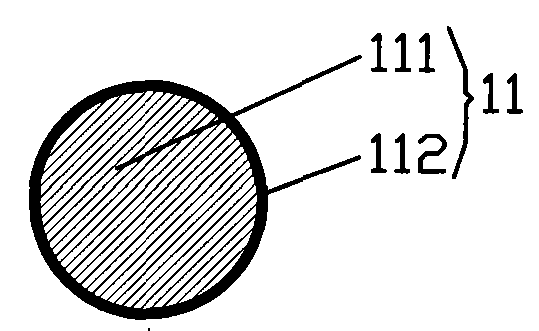

Copper coated aluminum uni-core flame-retardant refractory flexible electric cable manufacturing method

InactiveCN101335117BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsInsulation layerSingle-core

The invention discloses a copper-clad aluminum single-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The manufacturing method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; a fire resisting layer is formed on the outer surface of the single conductive wire core; the step of the insulation process is that a flame retardant is extruded on the fire resisting layer so as to form an insulation layer. wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost. As a single filament structure with multiple filaments and small diameter and a multi-strand twisting technology are adopted, the cable is particularly flexible and can be bended randomly.

Owner:LIAONING ZHONGDE CABLE CO LTD +1

Method for manufacturing copper coated aluminum five-core flame-retardant refractory flexible electric cable

InactiveCN101335108BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum five-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a tile shape; a wire core fire resistinglayer is formed on the outer surface of the conductive wire core provided with the section of the tile shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-forming process is carried out to five insulation wire cores provided with the insulation layersso as to form a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:GUANGDONG ZHONGDE CABLE

Method for manufacturing copper coated aluminum five-core flame-retardant flexible electric cable

ActiveCN101335109BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum five-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a section of a tile shape; an insulation process is carried out to the conductive wire core provided with the section of the tile shape, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-forming process iscarried out to five insulation wire cores with the insulation layers so as to form a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor intoa single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed singleconductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

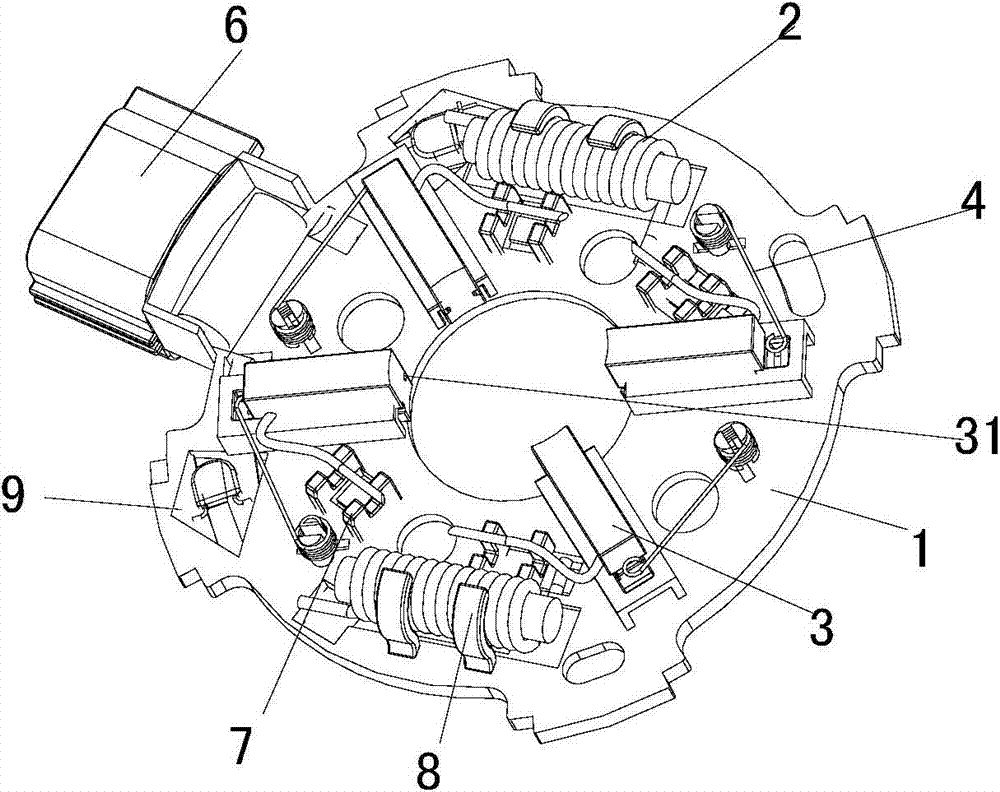

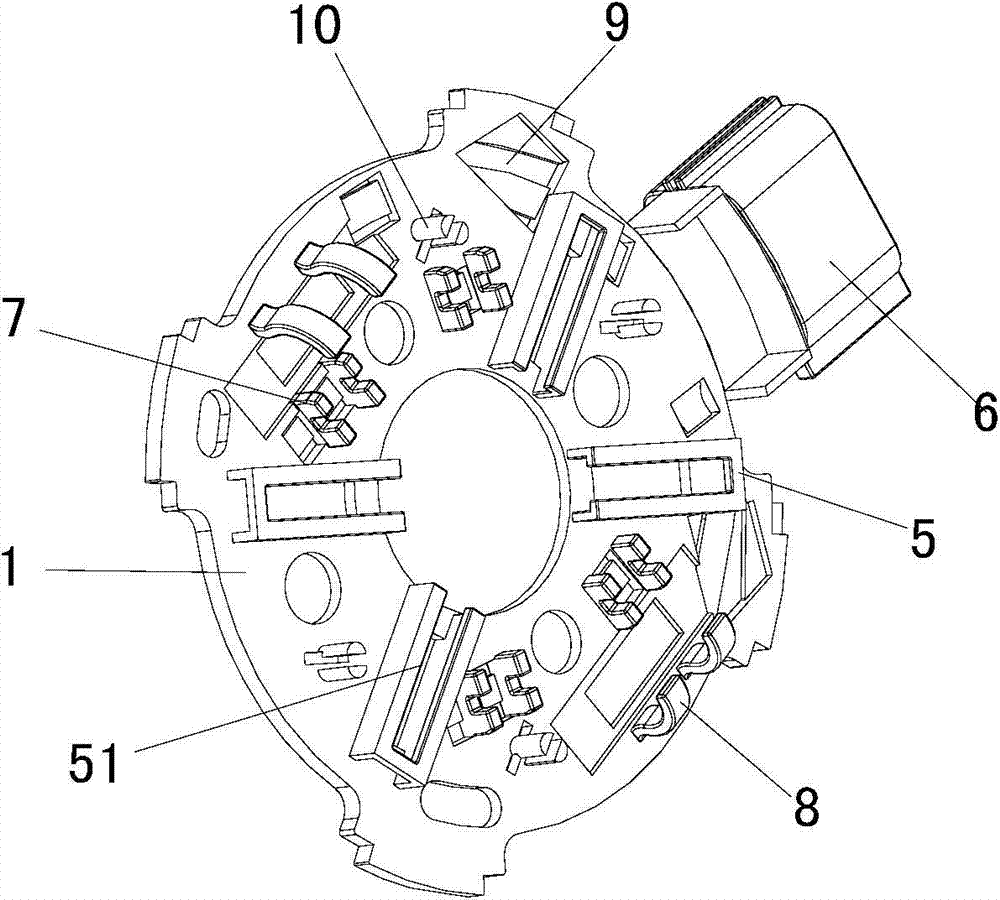

Electrical connecting part

An electrical connecting part comprises a brush pot, an inductor assembly, an electric brush and an electric brush spring, wherein the inductance assembly, the electric brush and the electric brush spring are installed on the brush pot. A guide rail, an electrical seat, a positioning block, an inductor clamp, a conductive connecting piece and an open column are arranged on the brush pot and are integrally formed with a brush pot body, the inductor assembly is installed on the inductor clamp, the electric brush is embedded in the guide rail, and the electric brush spring is connected between the electric brush and the open column. The electrical connecting part has the advantages of having few parts, saving materials, having few manufacturing procedures and being good in electric brush heat radiation performance, high in size accuracy, even in electric brush stress, small in electric brush spark and the like.

Owner:SHANGHAI MALU RI YONG JEA GATE ELECTRIC +2

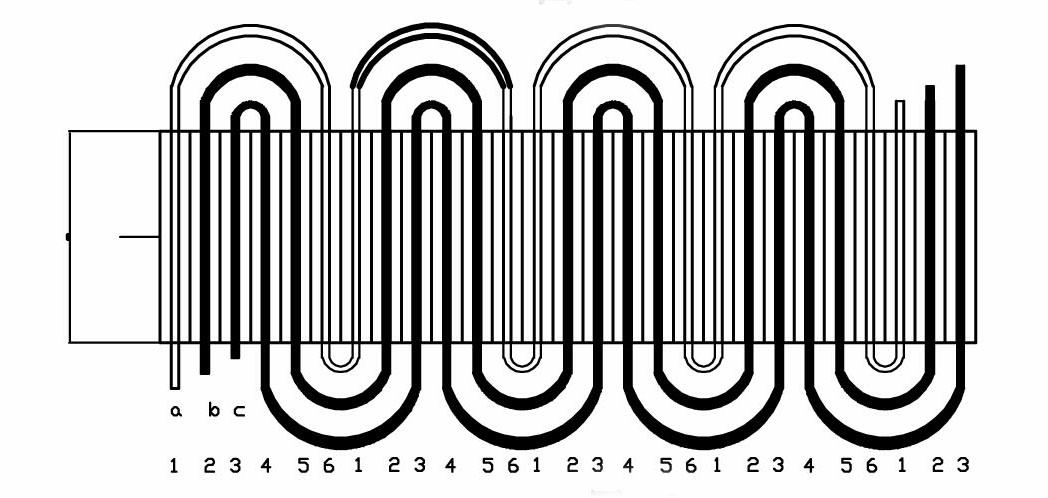

Single-line multi-pole outer rotor three-phase generator

InactiveCN102306993AReduce dosageReduce manufacturing costMagnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsEngineeringThree-phase

The invention relates to a generator, in particular to a single-line multi-pole outer rotor three-phase generator. The generator comprises a shell, wherein a stator is arranged in the shell; a plurality of permanent magnetic steels are arranged on the inner wall of the shell; the polarity of the same ends of two adjacent permanent magnetic steels is opposite; the stator is formed by mutual superposition of a plurality of silicon steel sheets; a plurality of wire slots are radially arranged on the stator; and generator windings are arranged in the wire slots. The generator is characterized in that the wire slots are radially and uniformly distributed on the outer edge of the stator; the outer ends of the wire slots are communicated with the outer edge of the stator; the number of the wire slots is integral multiple of 3; the generator windings comprise enamelled wires a, enamelled wires b and enamelled wires c; the three kinds of enamelled wires are respectively put at the bottoms of three wire slots 1, 2, 3 and are wound continuously in the wire slot order of 1-1, 2-2 and 3-3; and after being wound, the enamelled wires a, b and c serve as the three-phase output ends of the generator. The single-line multi-pole outer rotor three-phase generator has low manufacturing cost and light weight.

Owner:无锡市风驰风电科技有限公司

Material for heat radiation of electrical apparatus

The invention discloses a material for dissipating heat of appliances, which consists of copper, manganese, molybdenum and aluminum. The material has less amount of copper and is superior to pure copper material in both heat dissipation effect and strength.

Owner:JIANGSU DONGYUAN ELECTRIC APPLIANCEGROUP

Copper coated aluminum four-core flame-retardant refractory flexible electric cable and manufacturing method thereof

ActiveCN101335113BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum four-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a section of a fan shape; a wire core fire resisting layer is formed on the outer surface of the conductive wire core provided with the section of the fan shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to four insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

Method for manufacturing copper coated aluminum three-core flame-retardant refractory flexible electric cable

ActiveCN101335111BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum three-core flame retardant and fire resisting flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; a wire core fire resistinglayer is formed on the outer surface of the conductive wire core provided with the section of the fan shape; an insulation material is extruded on the wire core fire resisting layer, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to three insulation wire cores provided with insulation layers, thereby forming a cable yarn; flame retardant plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD

Trace element premixed feed and compound feed for weaned piglets

ActiveCN105053590BReduce copper usageIncrease daily weight gainFood processingAnimal feeding stuffCITRATE ESTERTrace element

The present invention relates to the field of animal nutrition, and particularly relates to a trace element premix feed and weaned piglet compound feed. The trace element premix feed does not contain copper sulfate, but contains copper citrate. The compound feed can decrease the amount of copper used in the feed by more than 88%, improve average daily gain (ADG), average daily feed intake (ADFI) and feed to gain ratio (F / G) of piglets compared with high dose copper sulfate, increase lysozyme concentration of serum by more than 50.62%, reduce diarrhea rate of piglets by more than 66.67%, and decrease fecal copper content by more than 88.76%; the above data has highly significant differences (P<0.01) compared with the control group.

Owner:SICHUAN ANIMAL SCI ACAD

Copper coated aluminum four-core flame-retardant flexible electric cable and manufacturing method thereof

ActiveCN101335112AUse less copperReduce weightInsulated cablesMetal/alloy conductorsCopper-clad aluminium wireElectrically conductive

The invention discloses a copper-clad aluminum four-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is made into a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with the section of a fan shape; an insulation process is carried out to the conductive wire core provided with the section of the fan shape, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried out to four insulation wire cores provided with insulation layers, thereby forming a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the step that the copper-clad aluminum conductor is made into a single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copper consumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +1

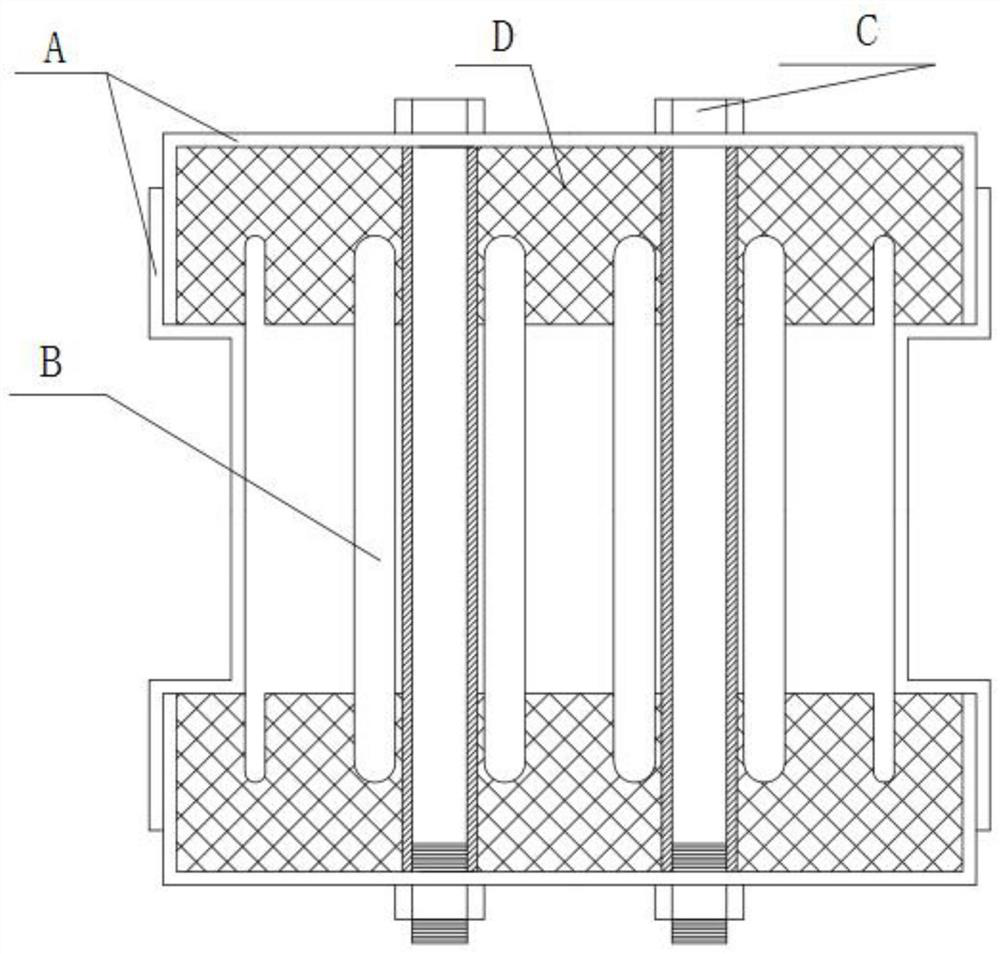

LED (light emitting diode) lighting module with thermoelectricity separation function

InactiveCN102313175ASolve the problem of heat dissipation bottleneckImprove cooling efficiencyPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The invention relates to an LED (light emitting diode) lighting module with a thermoelectricity separation function, and the LED light module is used for fundamentally solving the problems of the existing LED lamp that the heat dissipation effect is bad, and the service life is reduced; and the LED lighting module comprises a baseplate and LEDs. The technical scheme of the invention is as follows: one side, on which the LEDs are arranged, of the baseplate is provided with a plurality of stripped grooves, and each stripped groove is internally provided with an insulated circuit strip of which the thickness is 0.4-0.8mm; and each insulated circuit strip is provided with a plurality of LEDs, the positive and negative poles of each LED are respectively connected to each insulated circuit strip, and a heat transfer end of each LED is connected to the baseplate. The LED lighting module provided by the invention has the advantages of prolonging the service life and achieving the energy-saving purpose on the premise of guaranteeing the superior lighting effect of the LED lamp, and is suitable for manufacturing LED lamps for different occasions.

Owner:沈阳立晶光电有限公司 +2

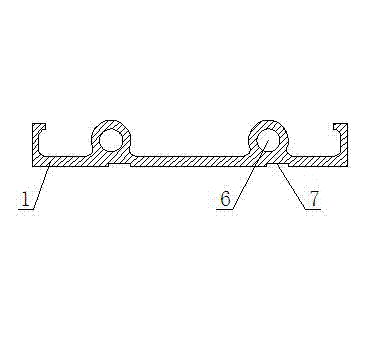

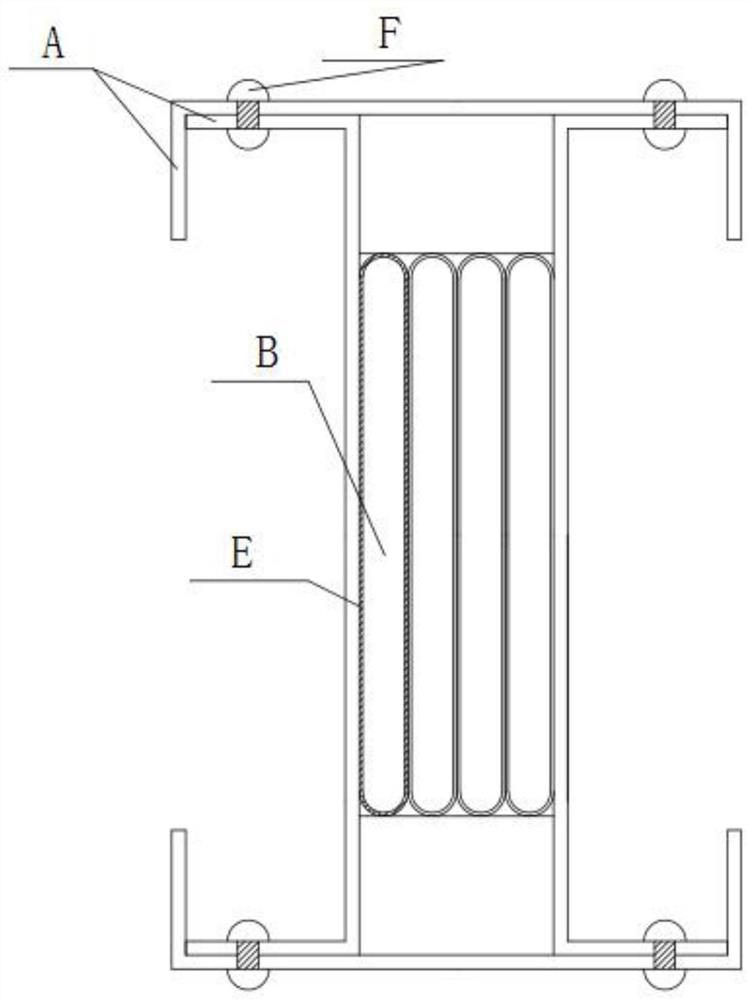

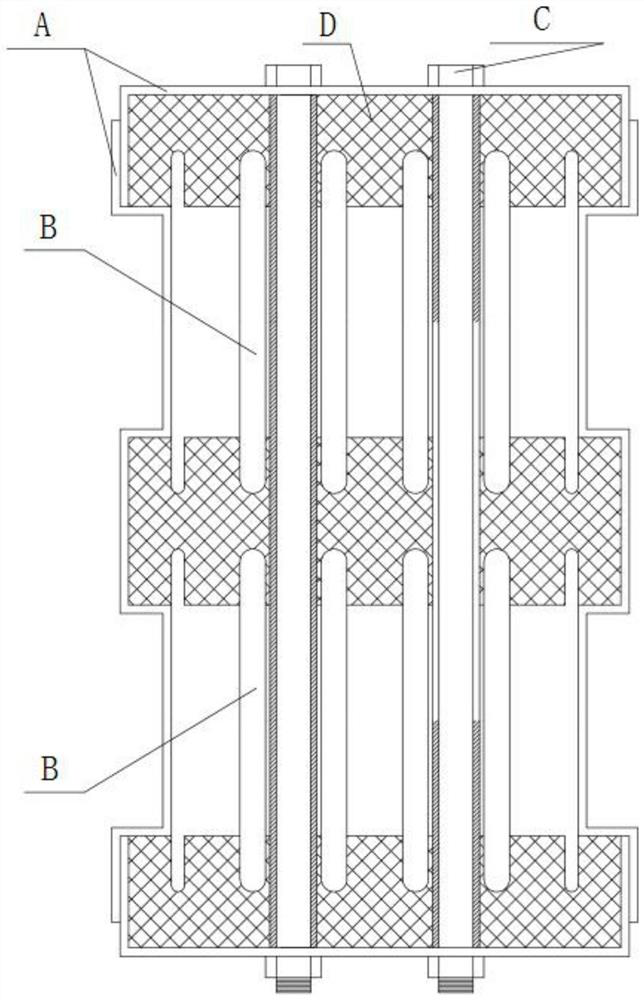

Small busbar combined all-insulated enclosed bus

ActiveCN112003219ALow costReduce copper usageTotally enclosed bus-bar installationsButt joining bus-barsBusbarBus interface

The invention discloses a small busbar combined all-insulated enclosed bus, and belongs to the technical field of buses and branch buses for low-voltage electrical transmission and distribution. The small busbar combined all-insulated enclosed bus comprises a bus, bus interfaces, cable crimping outgoing line devices, bus vertical tees and bus vertical elbows, wherein the bus adopts a small copperbar combined structure design, the heat dissipation area of a single-phase small copper bar is several times that of an existing bus, the copper consumption can be properly reduced, and the product material cost can be obviously reduced. The bus has four phases and each phase has independent insulation and high mechanical strength. A bus interface adopts a non-insulating bolt connection scheme, and therefore the material cost is obviously reduced. The standardization rate is extremely high, the bus production process is simple, the production cost is low, the production efficiency is high, andthe stock fund utilization rate is greatly improved. The bus provided by the invention has the core concepts of independent innovation, cost reduction, benefit increase, safety and first in key scheme design of a bus structure, a wire outlet mode, an interface, a vertical tee joint, a vertical elbow and the like, and can truly realize enterprise commitment of maintenance-free and lifelong qualityguarantee of a product.

Owner:JILIN AOQI MECHANICAL & ELECTRICAL GRP

Method for manufacturing copper coated aluminum dual-core flame-retardant flexible electric cable

ActiveCN101335115BReduce copper usageReduce weightInsulated cablesMetal/alloy conductorsYarnInsulation layer

The invention discloses a copper-clad aluminum two-core flame retardant flexible cable and a manufacturing method thereof. The method comprises the steps that: a copper-clad aluminum conductor is madeinto a single conductive wire core; the single conductive wire core is processed into a conductive wire core provided with a semi-round section; an insulation process is carried out to the conductivewire core provided with the semi-round section, and an insulation process for forming an insulation wire core provided with an insulation layer is carried out; a cable-froming process is carried outto two insulation wire cores provided with insulation layers, thereby forming a cable yarn; plastic is extruded on the cable yarn so as to form a flame retardant restrictive coating, wherein, the stepthat the copper-clad aluminum conductor is made into the single conductive wire core comprises the steps that: a wire-drawing machine is utilized to draw the copper-clad aluminum conductor into a single conductive filament; an annealer is utilized to carry out an annealing process to the single conductive filament; a wire-bunching machine is utilized to bunch a plurality of annealed single conductive filaments into braided wires; a wire twisting machine is utilized to twist a plurality of braided wires into the conductive wire core. The cable of the invention has the advantages of low copperconsumption, light weight and low cost.

Owner:JIANGSU ZHONGLI GRP CO LTD +2

Normal-temperature pi electron high conductor in zero magnetic vector field and preparation method thereof

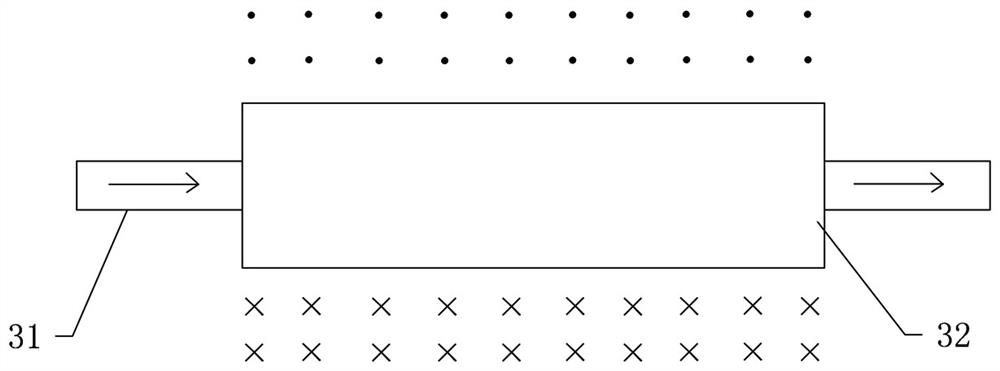

ActiveCN113380441AIncreased conductivity at room temperatureImprove conductivitySingle bars/rods/wires/strips conductorsCable/conductor manufactureElectrical conductorElectric machine

The invention discloses a normal-temperature Pi electron high conductor in a zero magnetic vector field. The normal-temperature Pi electron high conductor comprises two flat normal-temperature Pi electron high conduction elements which are identical in structure and are stacked. The flat normal-temperature Pi electron high-conductivity element is formed by stacking a flat conductive excitation body and a Pi electron plane excitation network; the flat conductive excitation body adopts a flat conductor; the Pi electron plane excitation network is of a net structure which takes an insulating resin adhesive as a continuous phase and takes a material with Pi electron elements as a dispersed phase, and Pi electrons are arranged in order under the constraint of Lorentz force and Coulomb force in a standard field of the Pi electrons and are cured on the flat conductive excitation body. The invention further discloses a preparation method of the normal-temperature pi electron high conductor in the zero magnetic vector field. The high conductor provided by the invention is high in normal-temperature conductivity, can be used for preparing a power-on bar, a motor winding and a transformer winding for low-voltage power distribution below 35000V, can replace copper with aluminum to save copper, realizes cost reduction and efficiency improvement, and is wide in market prospect and huge in economic value.

Owner:澳门听澜康诚新能源技术有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com