Copper coated aluminum uni-core flame-retardant refractory flexible electric cable manufacturing method

A flame-retardant, fire-resistant, manufacturing method technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of cable rigidity, low strength, and low tensile force of aluminum materials, and achieve low cost, light weight, and copper use. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

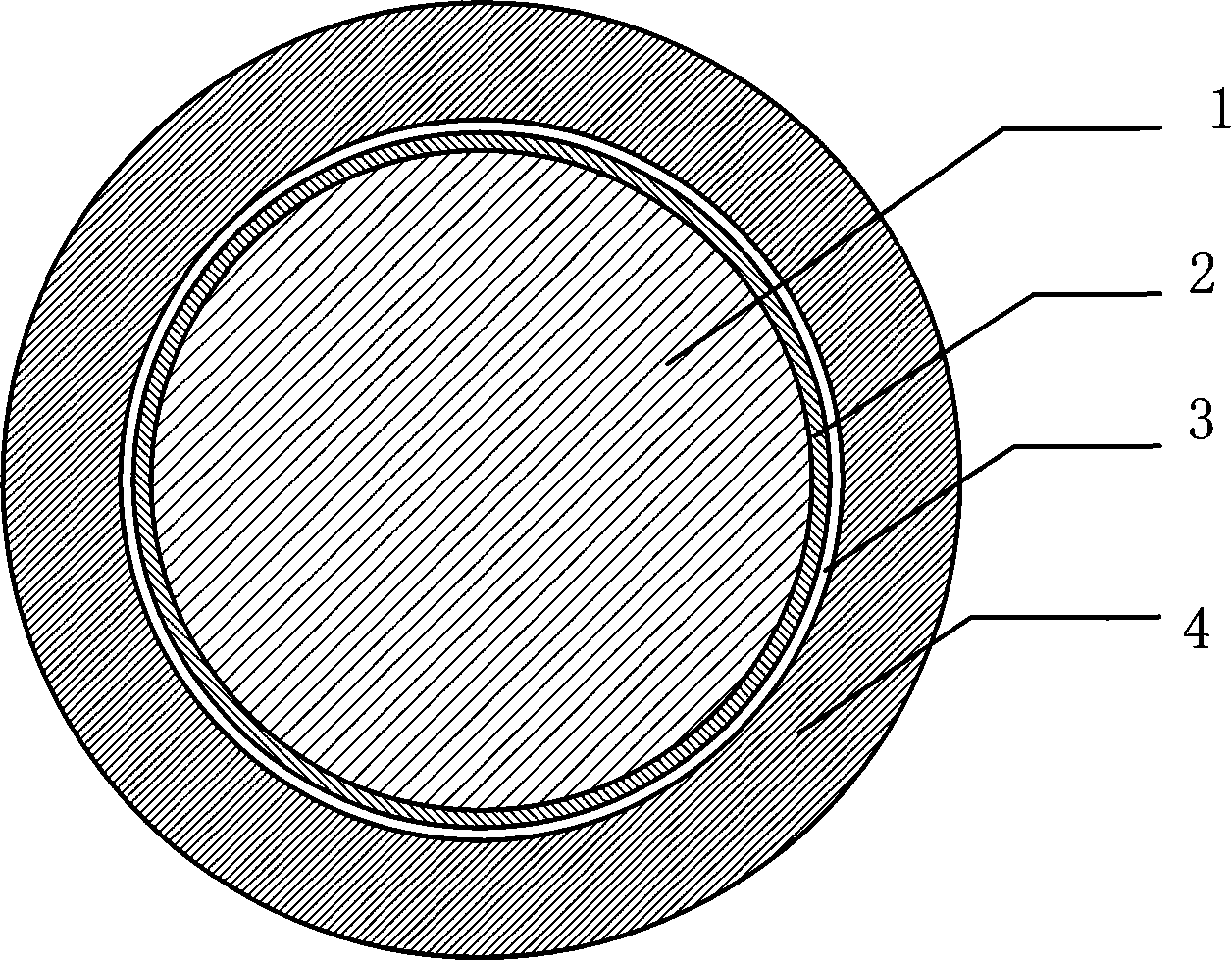

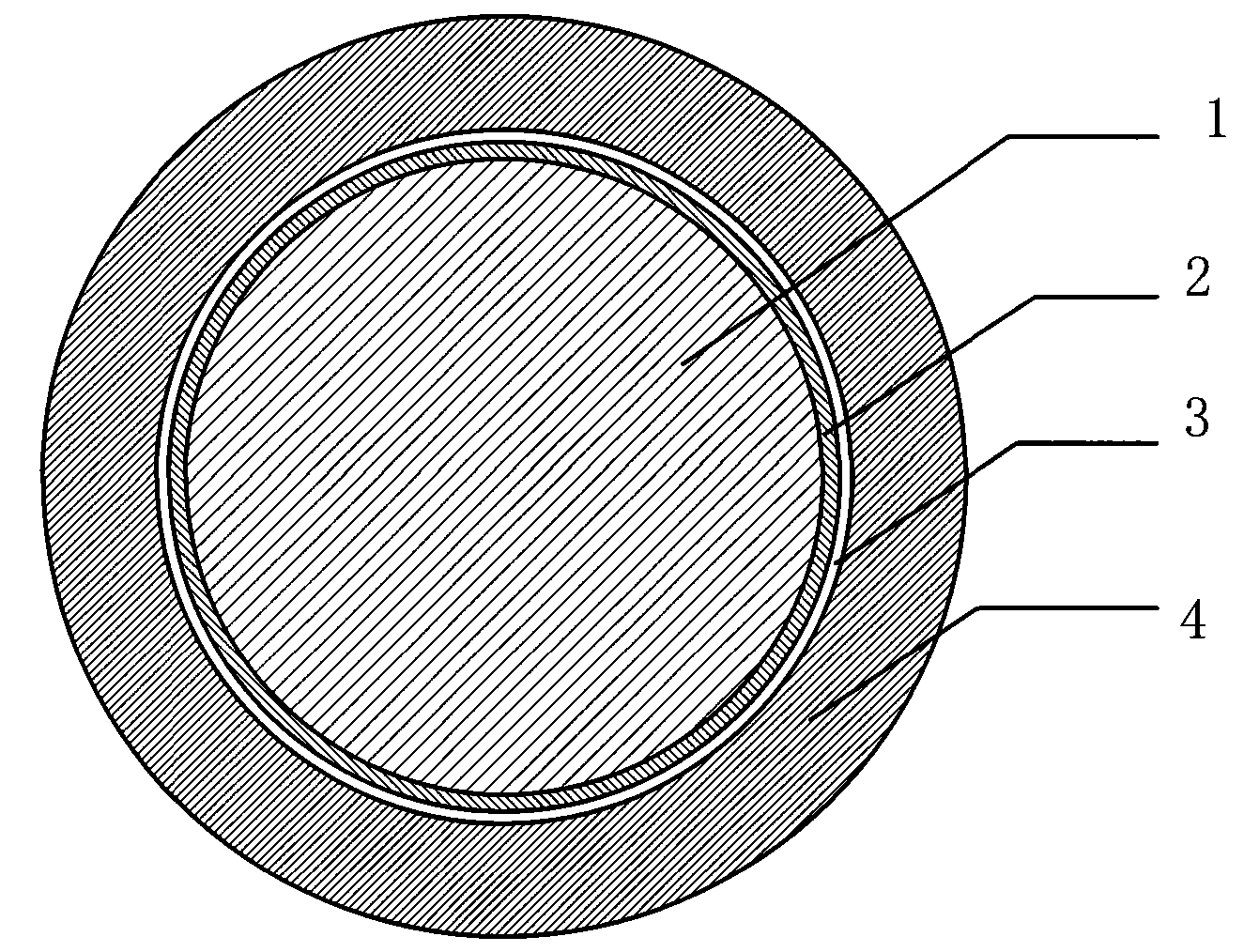

[0030] The manufacturing method of the copper-clad aluminum single-core flame-retardant and fire-resistant flexible cable of the present invention comprises: the step of making the copper-clad aluminum wire into a single conductive wire core 1; forming a fire-resistant layer on the outer surface of the single conductive wire core 1 (2 , 3) and an insulating treatment step of extruding flame-retardant plastic on the fire-resistant layers (2, 3) to form a flame-resistant insulating layer 4.

[0031] The above step of forming a refractory layer (2, 3) on the outer surface of a single conductive core 1 includes: wrapping a mica layer (tape) 2 on the outer surface of the single conductive core 1; The outer surface is wrapped with a glass fiber layer (band) 3.

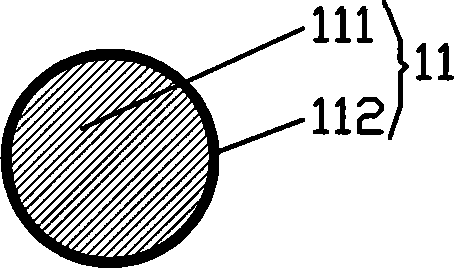

[0032] The step of making the copper-clad aluminum wire into a single conductive wire core 1 of the present invention comprises: drawing the copper-clad aluminum wire into a single conductive monofilament 11 by using a wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com