Small busbar combined all-insulated enclosed bus

A closed busbar, fully insulated technology, applied in the direction of fully enclosed busbar device, butt busbar, busbar installation, etc., can solve problems such as poor contact of busbar outlet pins, poor welding of vertical busbars, unreasonable busbar structure, etc., to increase inventory. The effect of capital utilization, material cost reduction, firm and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

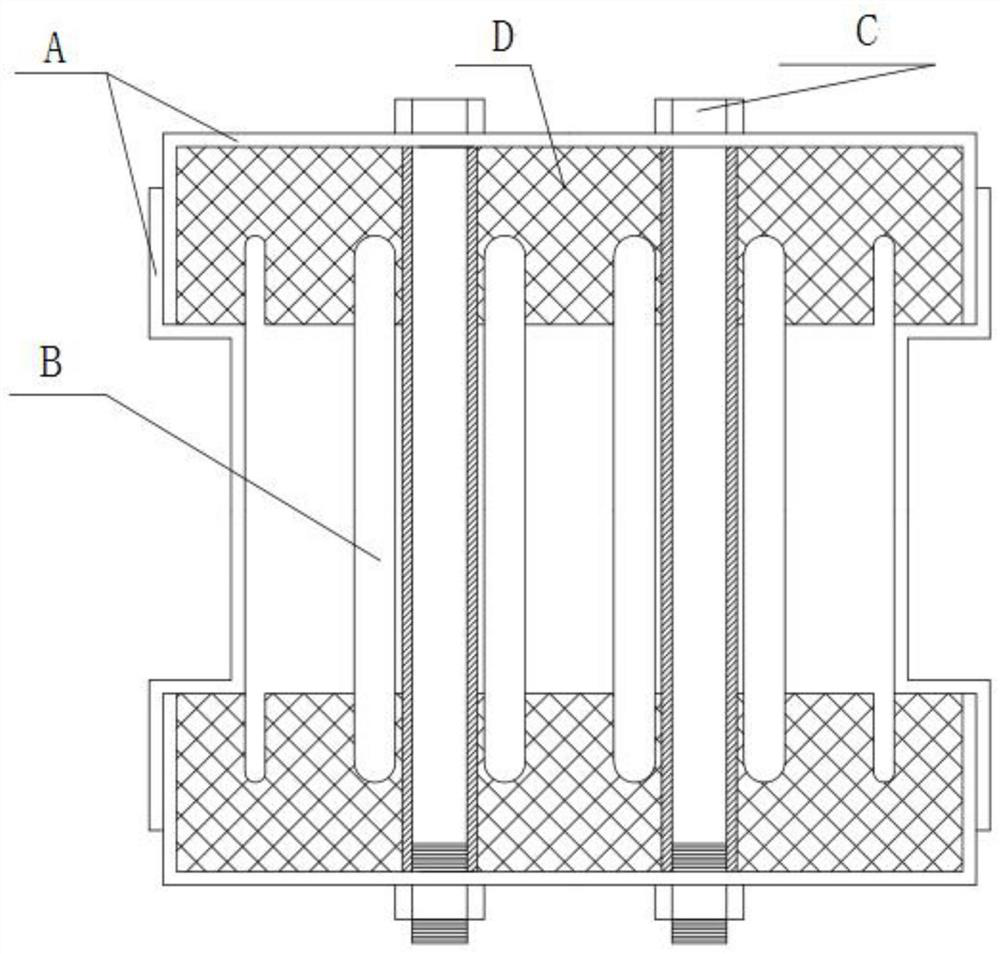

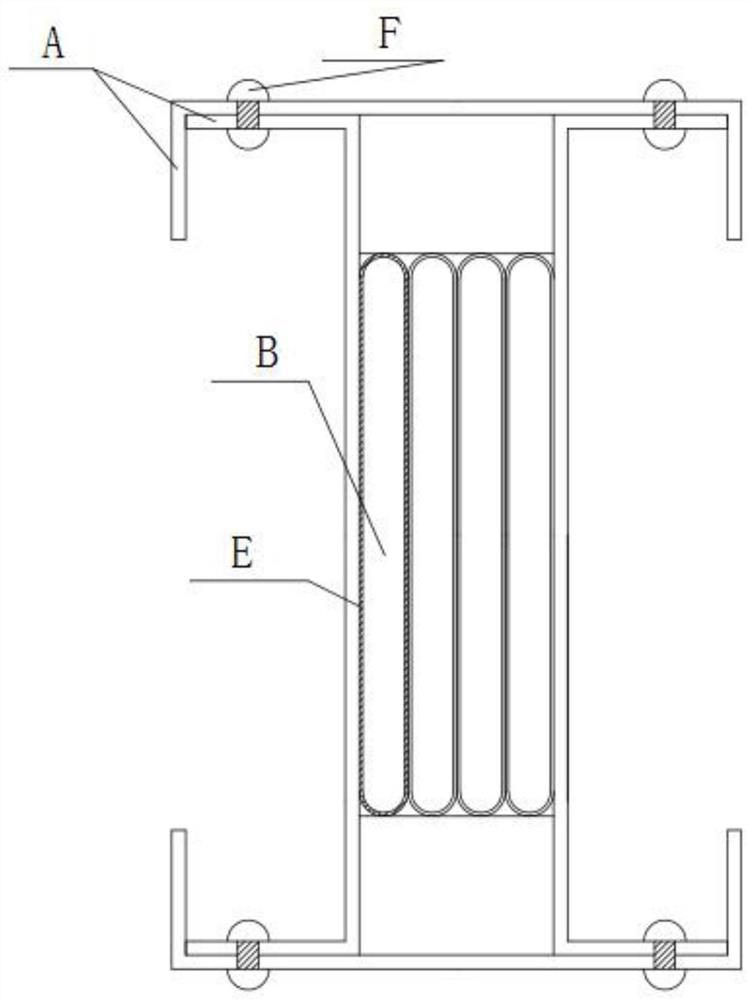

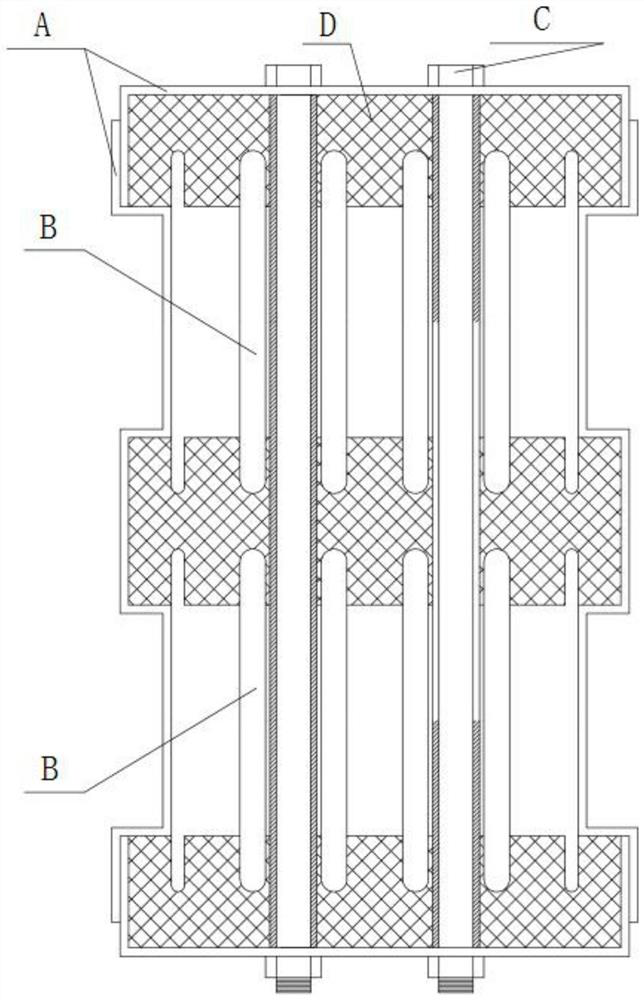

[0046] At present, there are two main products of low-voltage busbars in my country. 1: Air-type busbars. As the name implies, the insulating medium between copper bars is air, that is to say, it is insulated by air. The main structure is composed of: metal shell A, (cold-rolled thin steel plate , aluminum alloy profiles), insulating bracket D (DMC unsaturated resin glass fiber reinforced plastic), copper bar B, etc., copper bar B and metal shell A are isolated by insulating bracket D, and there are copper bars B between each phase A certain space distance, solid and called the air bus, the structure see figure 1 . 2: Intensive busbar, the insulation medium between copper bars B is organic insulating film or heat shrinkable sleeve E, the main structure is composed of: metal shell A (cold-rolled thin steel plate, aluminum alloy profile), polyethylene film or heat shrinkable sleeve Tubes, assembly rivets F, etc., each phase copper bar B is individually covered by polyethylene fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com