Single-line multi-pole outer rotor single-phase generator

A single-phase generator and outer rotor technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problem of heavy generator weight and manufacturing Problems such as high cost and high copper consumption achieve the effect of reducing weight, consuming less copper and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

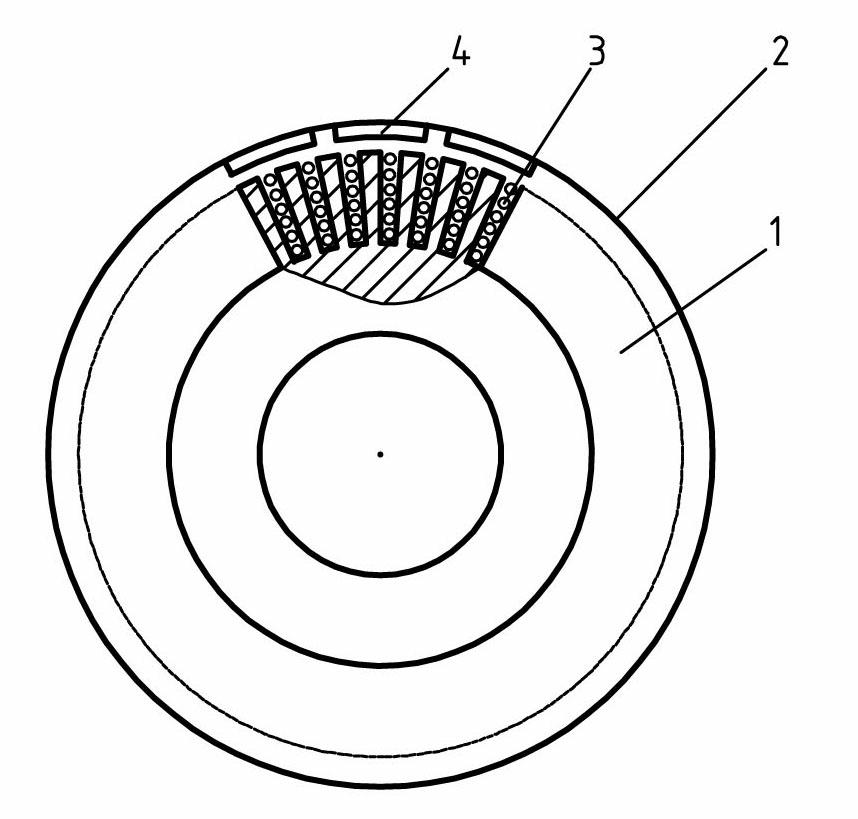

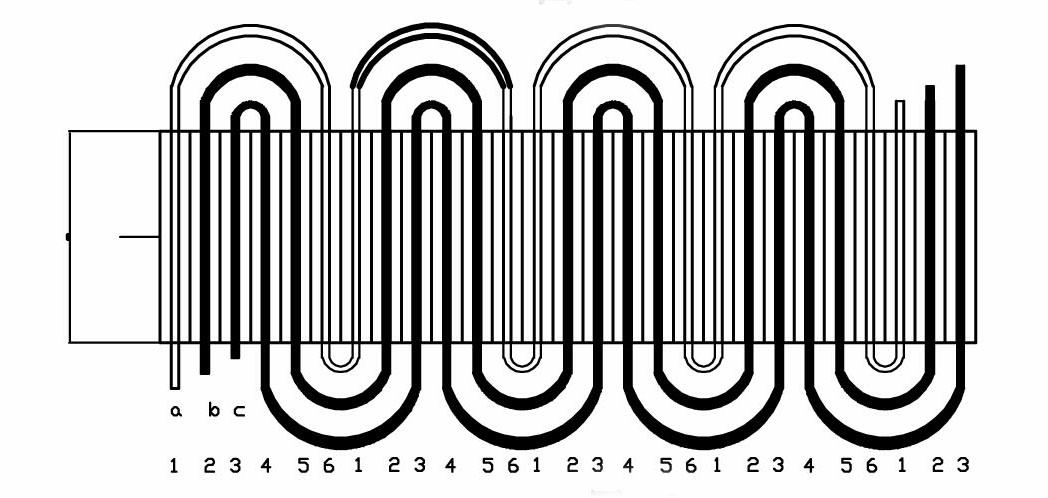

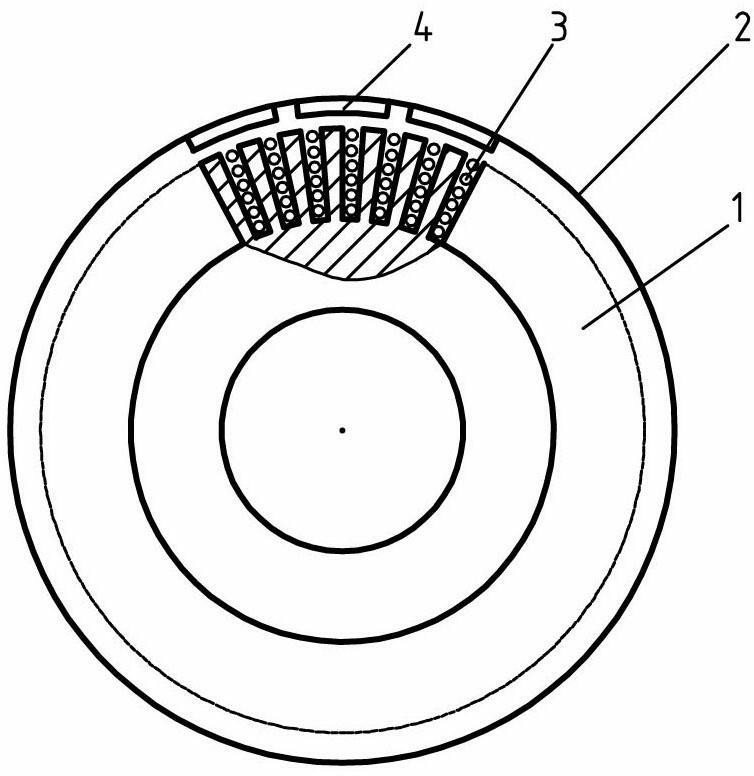

[0012] Such as figure 1 As shown, the single-wire multi-pole outer rotor single-phase generator of the present invention includes a casing 2, and a stator 1 is arranged inside the casing 2. Several pieces of permanent magnets 4 are installed on the inner wall of the housing 2, and the quantity of the permanent magnets 4 depends on the specifications of the generator. The permanent magnets 4 are arranged according to the polarity of N—S—N—S······, so that the polarities of the same ends of two adjacent permanent magnets 4 are opposite. The stator 1 is formed by welding several silicon steel sheets stacked on top of each other, and the stacking direction of the silicon steel sheets is parallel to the axis of the casing 2 . The stator 1 is processed with several radially arranged wire slots, and the generator winding 3 is wound in the wire slots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com