Winding assembly, stator assembly and motor

A technology of windings and components, applied in the shape/style/structure of windings, electric components, winding conductors, etc., can solve the problems of long bridge line, many input terminals and center points spanning slots, and large amount of copper in the bridge line. , to achieve the effect of reducing the number of cross-slots, saving copper consumption, and shortening the bridge line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

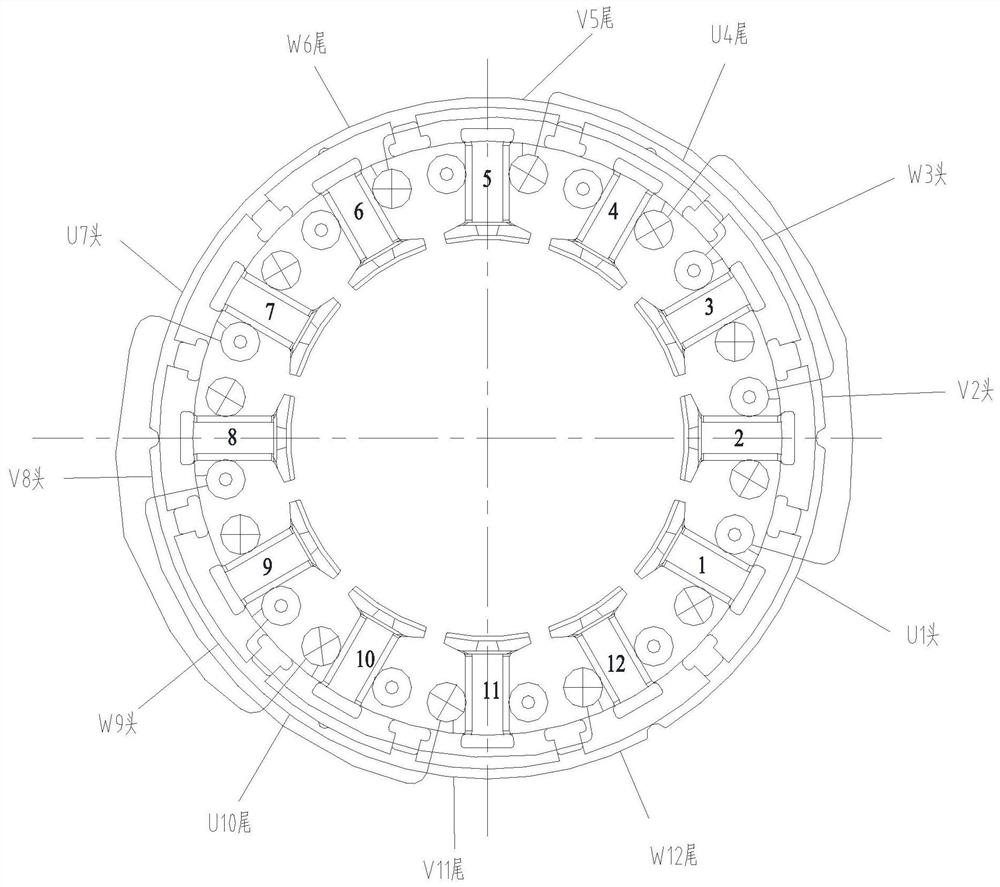

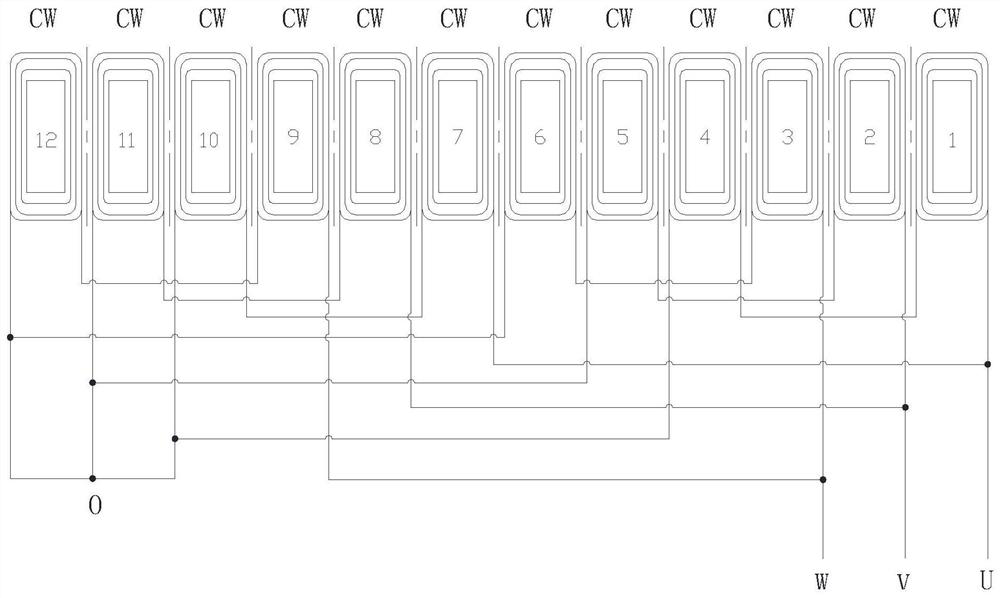

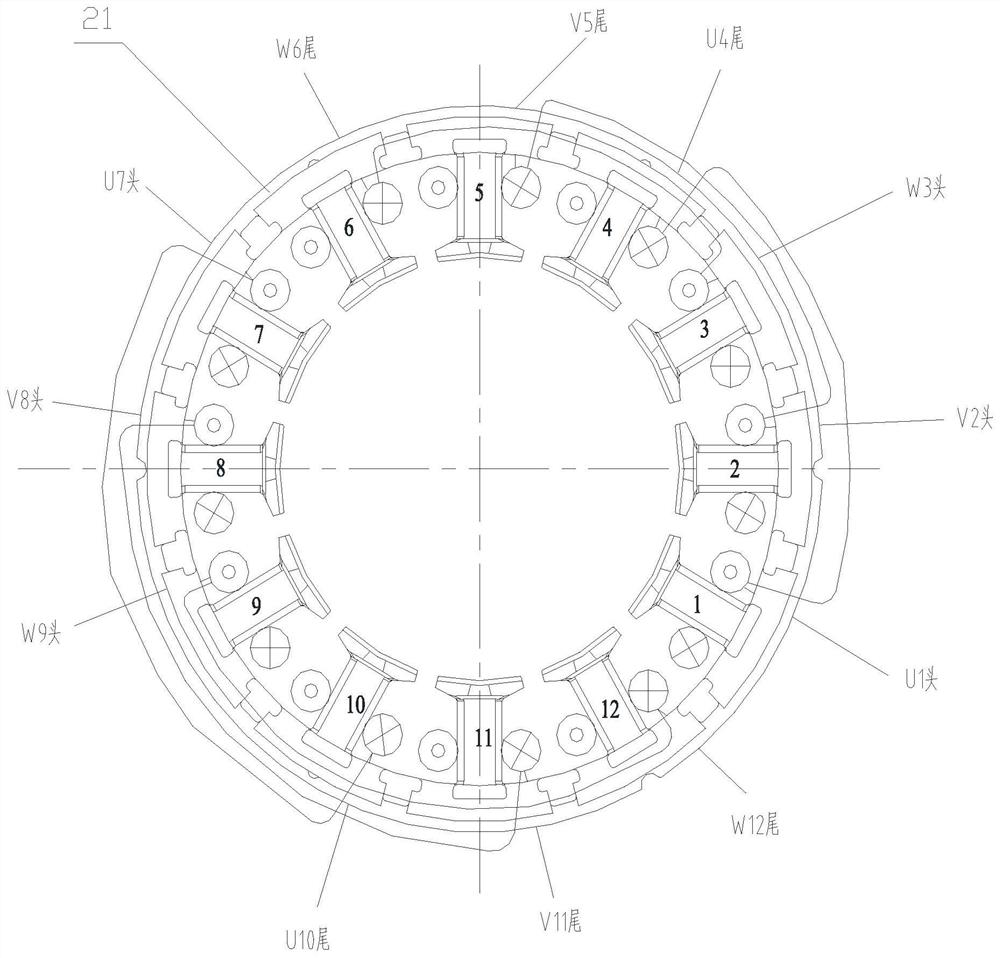

[0026] see in conjunction Figure 3 to Figure 5 As shown, according to an embodiment of the present application, a winding assembly includes:

[0027] There are multiple in-phase windings; all the in-phase winding groups are provided with a first set of windings and a second set of windings;

[0028] Both the first group of windings and the second group of windings include at least two adjacent same-phase windings;

[0029] All the same-phase windings in the first group of windings are wound by the first winding sequence, and all the same-phase windings in the second group of windings are wound by the second winding sequence; The first winding sequence and the second winding sequence are opposite winding directions.

[0030] The same-phase winding in this application refers to the winding formed by winding enameled wires of the same phase. In a stator or motor, the enameled wires of the same phase will be wound on multiple stator teeth at intervals. The windings wound in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com