Series excited machine with improved rotor assembly

A series excitation motor and rotor technology, applied in the field of series excitation, can solve the problems of high motor height of the whole motor, commutator cannot be pressed down for installation, and commutator distance is far away, so as to achieve the effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

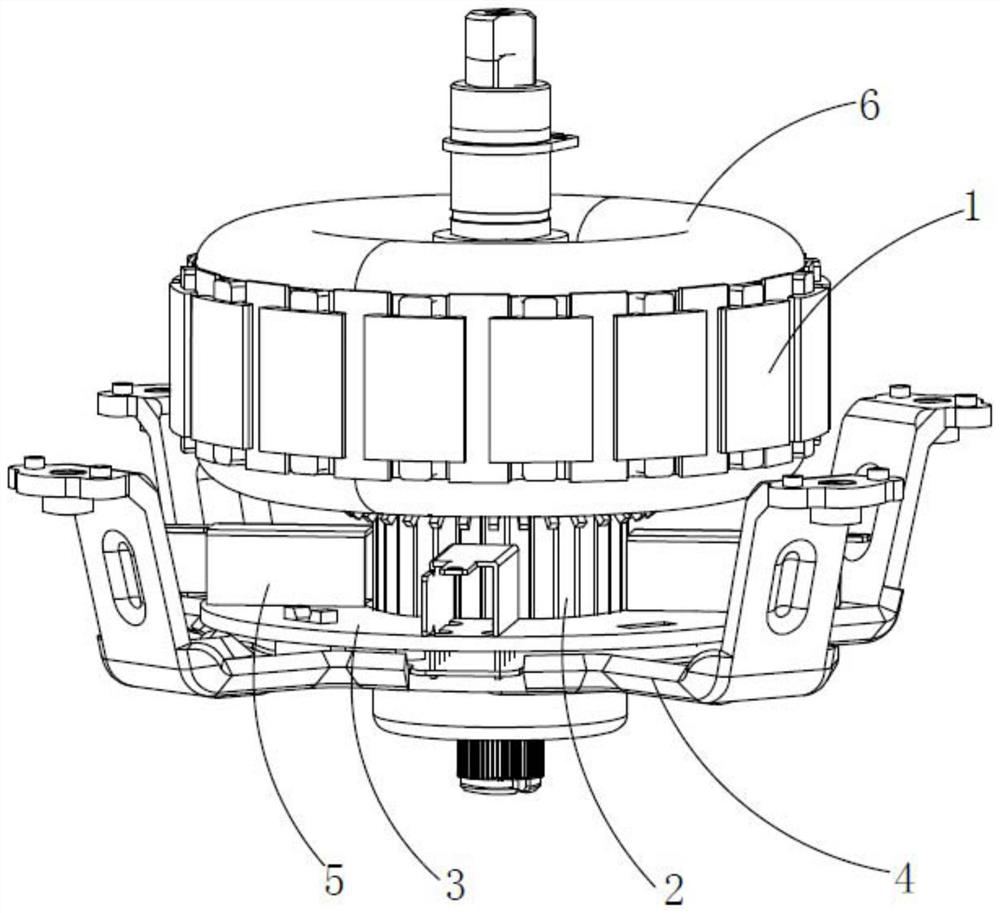

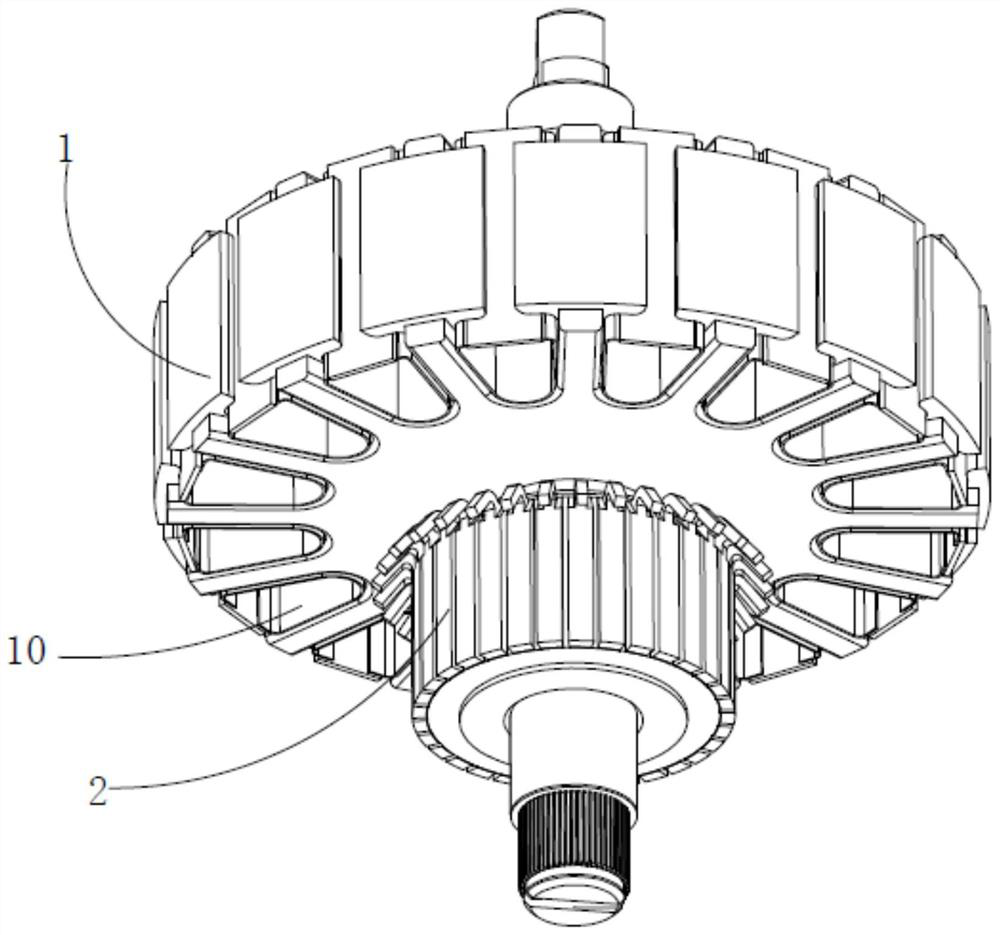

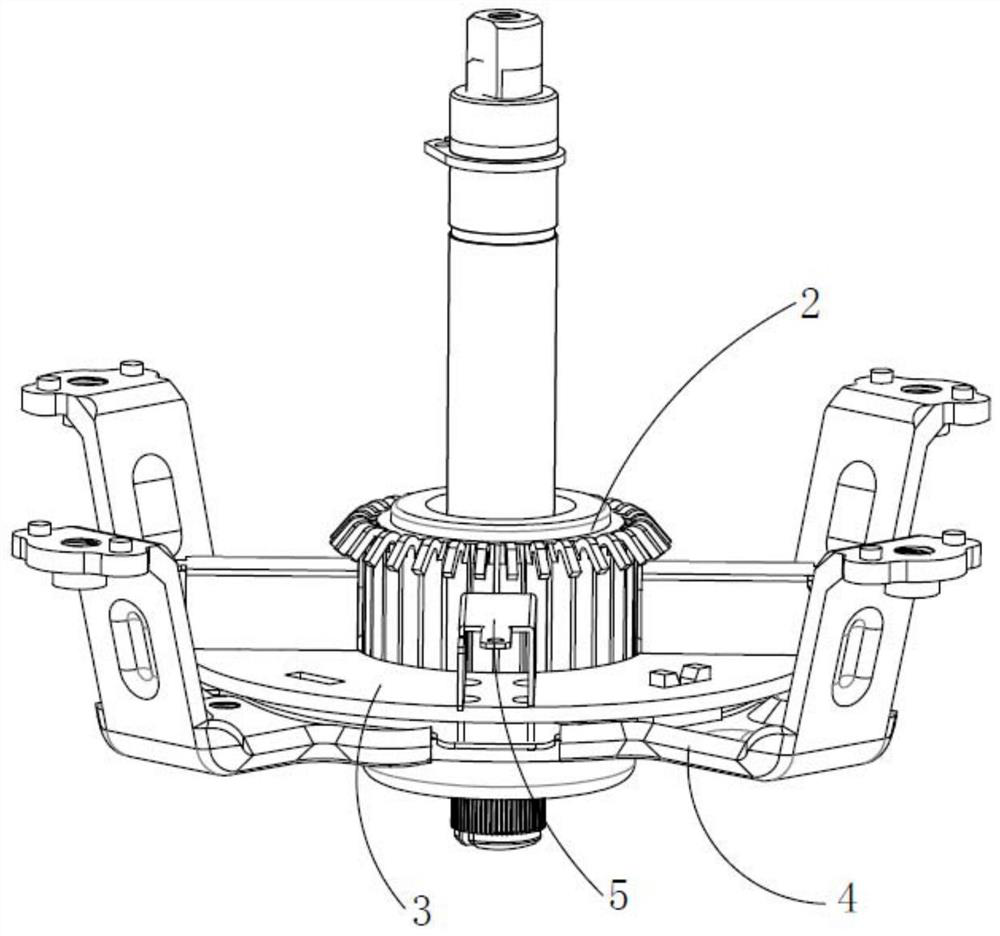

[0046] Such as Figures 1 to 17 As shown, the present invention provides a series motor with an improved rotor assembly, including a stator assembly and a rotor assembly, and the rotor assembly rotates with the stator assembly. It is characterized in that: the rotor assembly includes rotor cores 1 sequentially arranged , commutator 2, brush mounting plate 3 and motor rear bracket 4, the middle part of rotor core 1 and brush mounting plate 3 are all formed with a shaft hole for commutator 2 to pass through, and the upper part of commutator 2 passes through Set in the shaft hole of the rotor core 1, the lower part of the commutator 2 is pierced through the shaft hole of the brush mounting plate 3, and the brush mounting plate 3 is equipped with a plurality of brushes distributed in an axis array, and each brush is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com