Patents

Literature

298 results about "Commutator (electric)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A commutator is a rotary electrical switch in certain types of electric motors and electrical generators that periodically reverses the current direction between the rotor and the external circuit. It consists of a cylinder composed of multiple metal contact segments on the rotating armature of the machine. Two or more electrical contacts called "brushes" made of a soft conductive material like carbon press against the commutator, making sliding contact with successive segments of the commutator as it rotates. The windings (coils of wire) on the armature are connected to the commutator segments.

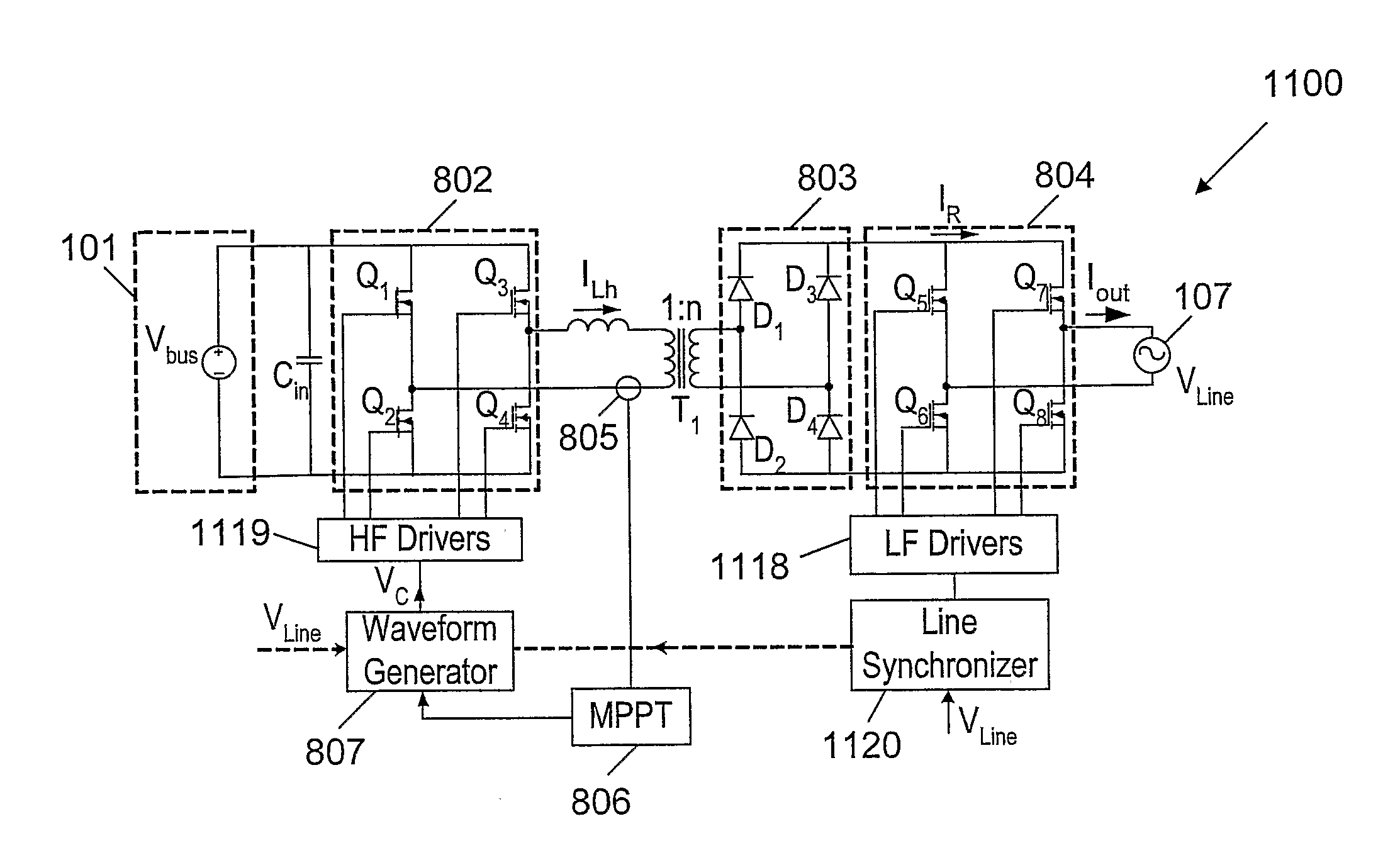

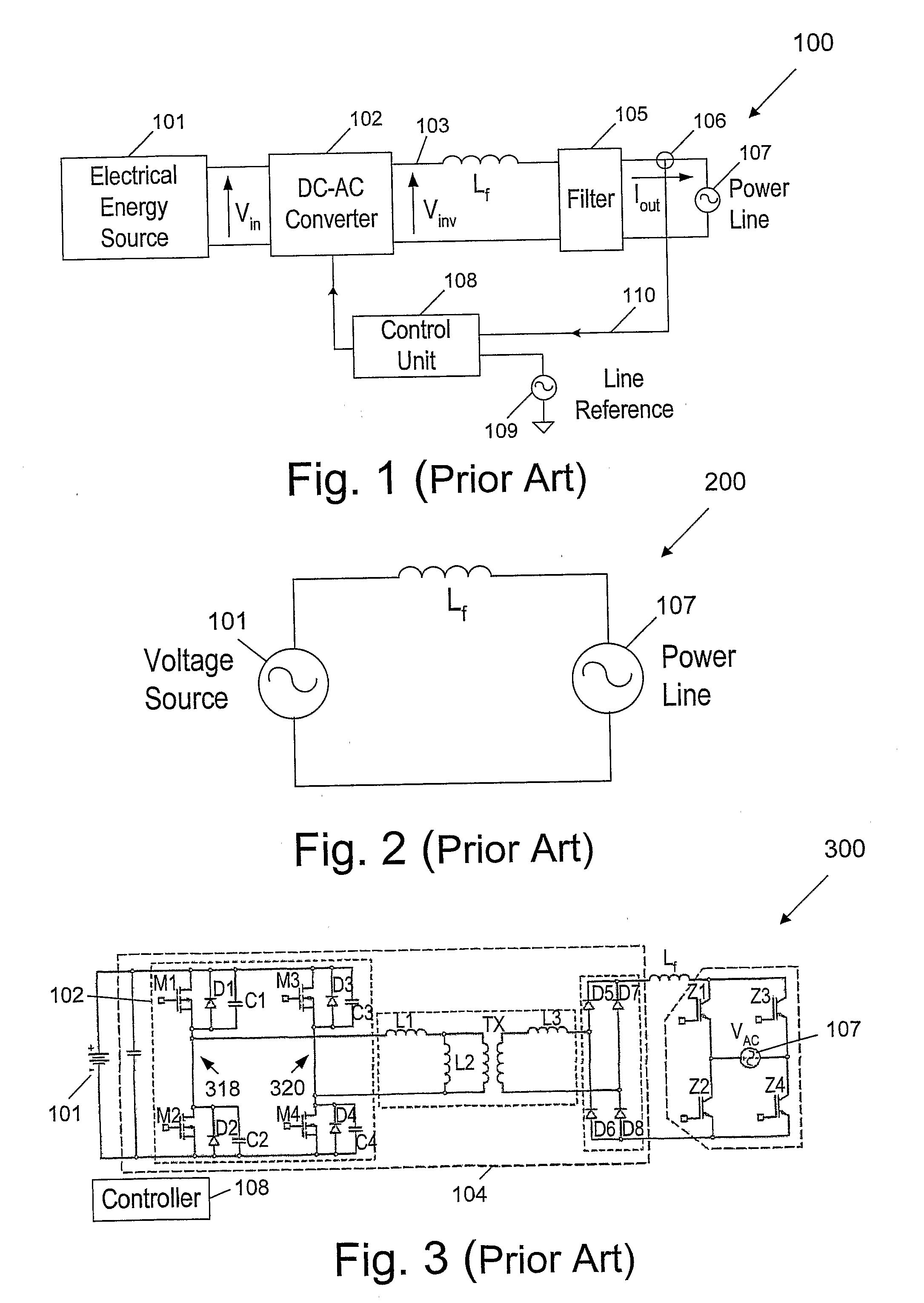

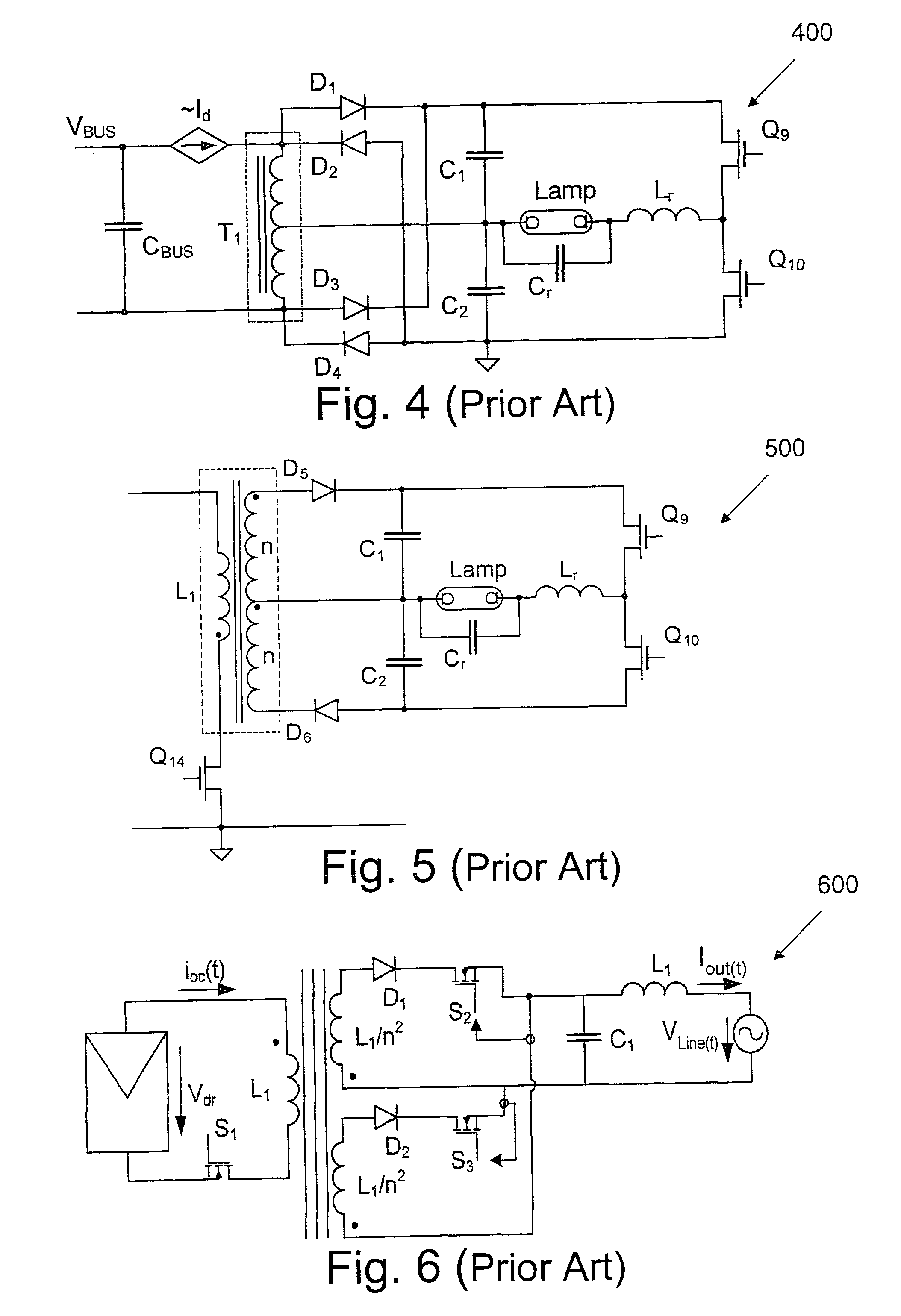

Method And Circuitry for Improving the Magnitude and Shape of the Output Current of Switching Power Converters

InactiveUS20100097827A1Not to damageReduce total powerAc-dc conversionElectric lighting sourcesControl signalEngineering

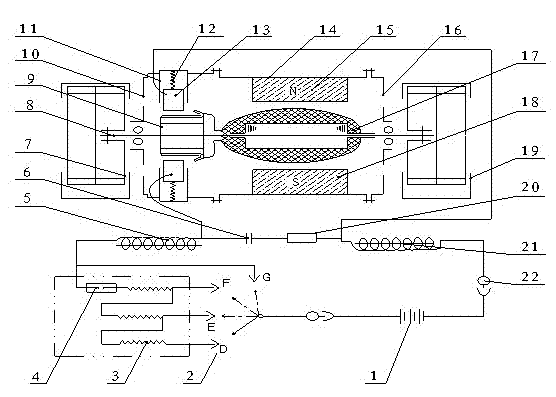

Apparatus of a grid-connected switching inverter for injecting it current into a power line comprises: (a) an electrical energy source for providing the substantially DC voltage to the apparatus; (b) a switching inverter connected to the electrical energy source for converting the substantially DC voltage of the electrical energy source to a high frequency alternating voltage; (c) a waveform generator for controlling the magnitude and shape of the alternating high frequency voltage outputted from the switching inverter by means of a control signal fed into the switching inverter; (d) an inductor connected to an output of the switching inverter for generating an alternating current from the alternating high frequency voltage, wherein the magnitude of the alternating current depends on a frequency of the alternating high frequency voltage: (e) a rectifier connected in series with the inductor for rectifying the alternating current and for outputting a rectified unipolar alternating current, wherein the rectified average value of the alternating current is proportional to the absolute magnitude of the power line voltage; and (t) a polarity commutator connected to an output of the rectifier for converting the rectified unipolar alternating current into a bipolar alternating current, and for injecting the bipolar alternating current into a power line, wherein the bipolar alternating current is substantially in phase with and of shape of the power line voltage of the power line.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

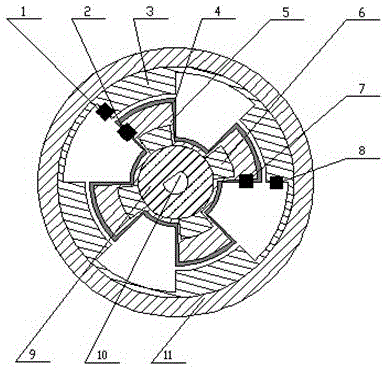

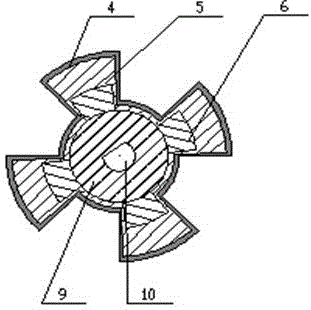

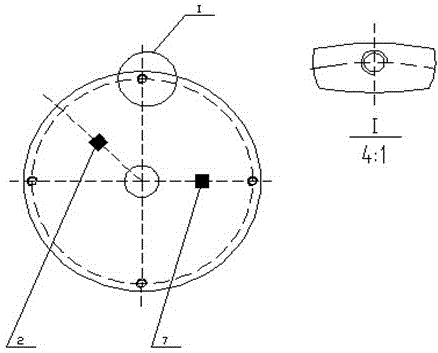

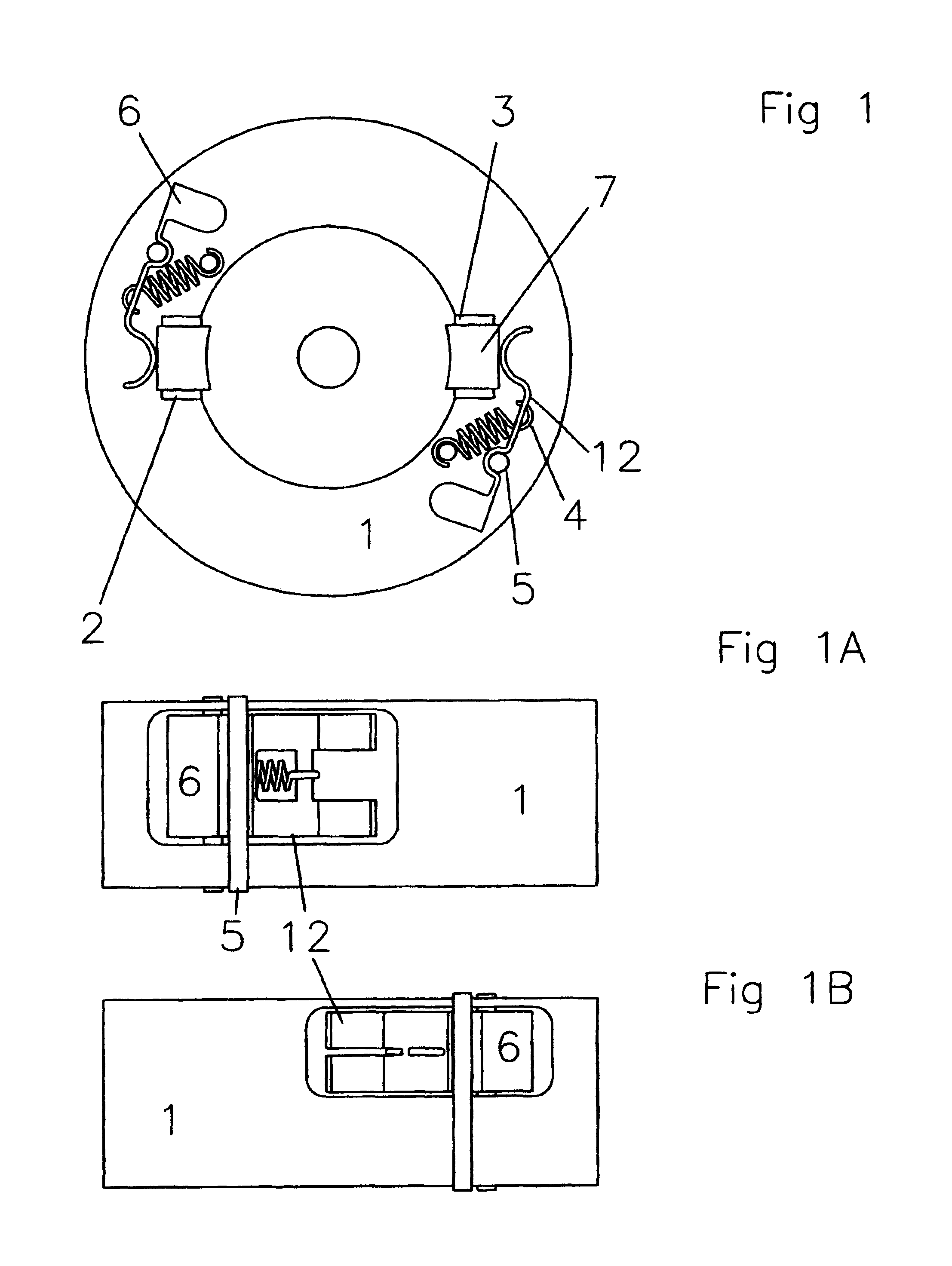

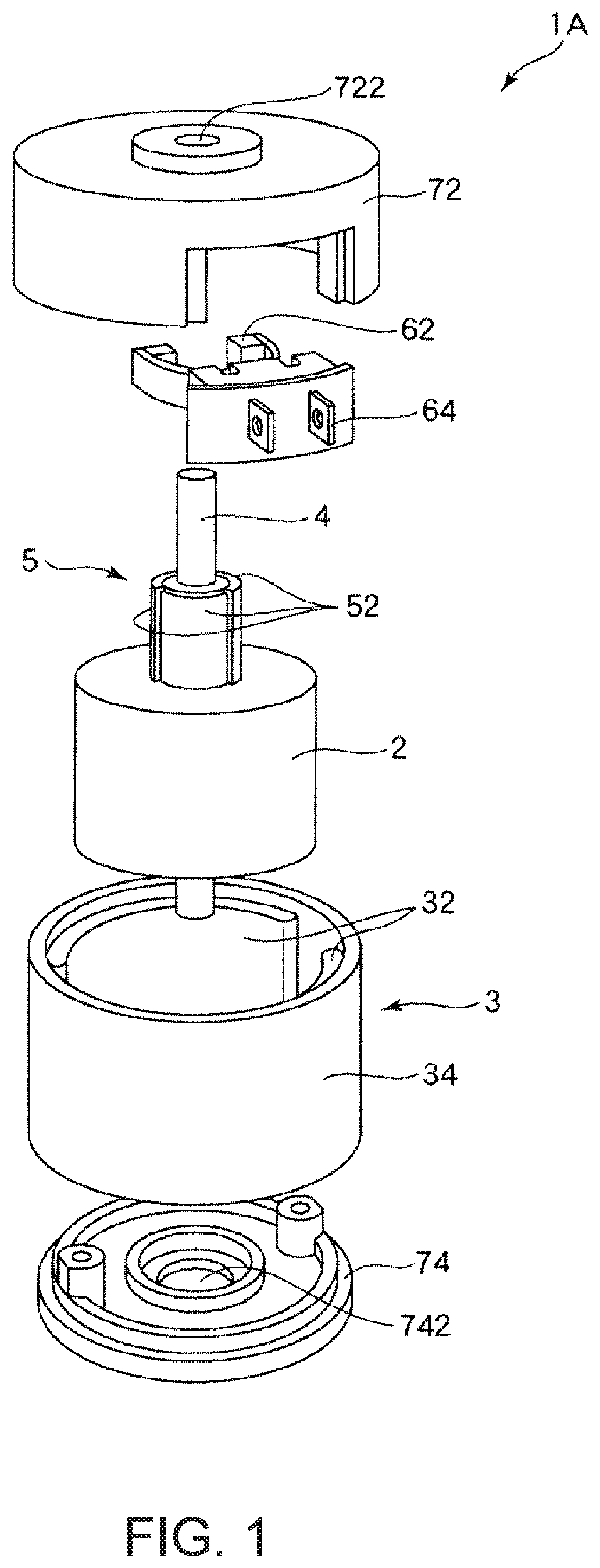

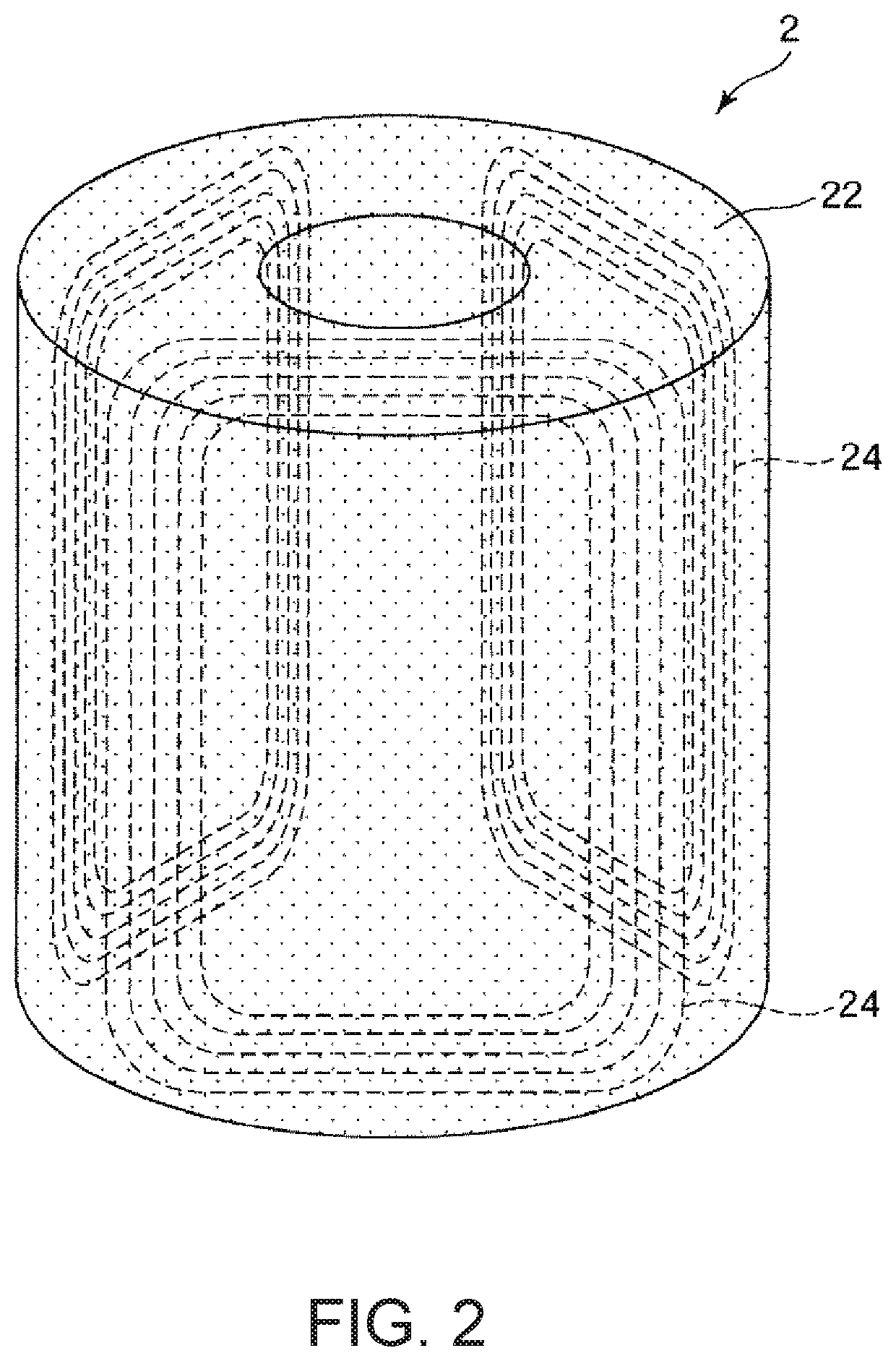

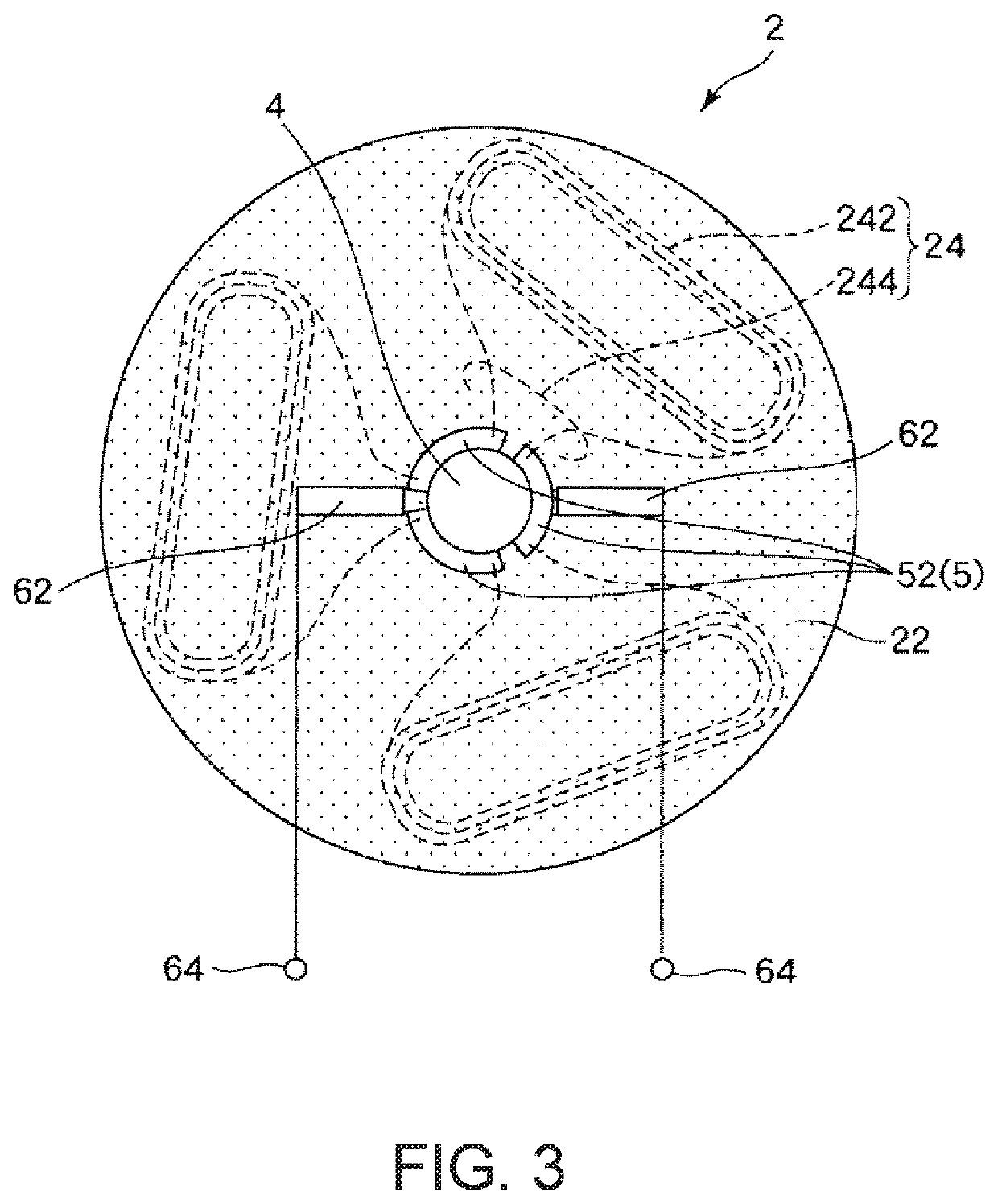

Generation device for generating DC triboelectricity

InactiveCN105048860ASimple structureEasy to implementFriction generatorsElectron flowEconomic benefits

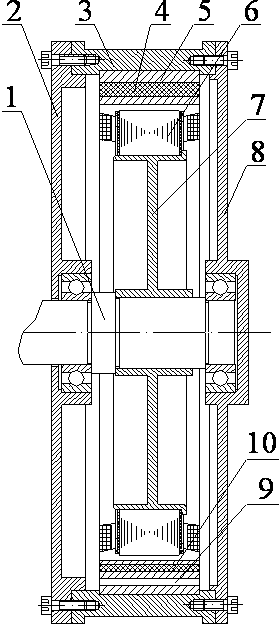

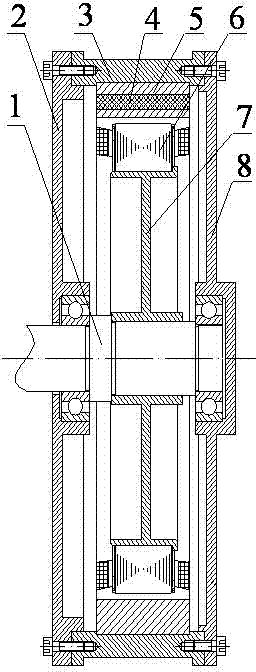

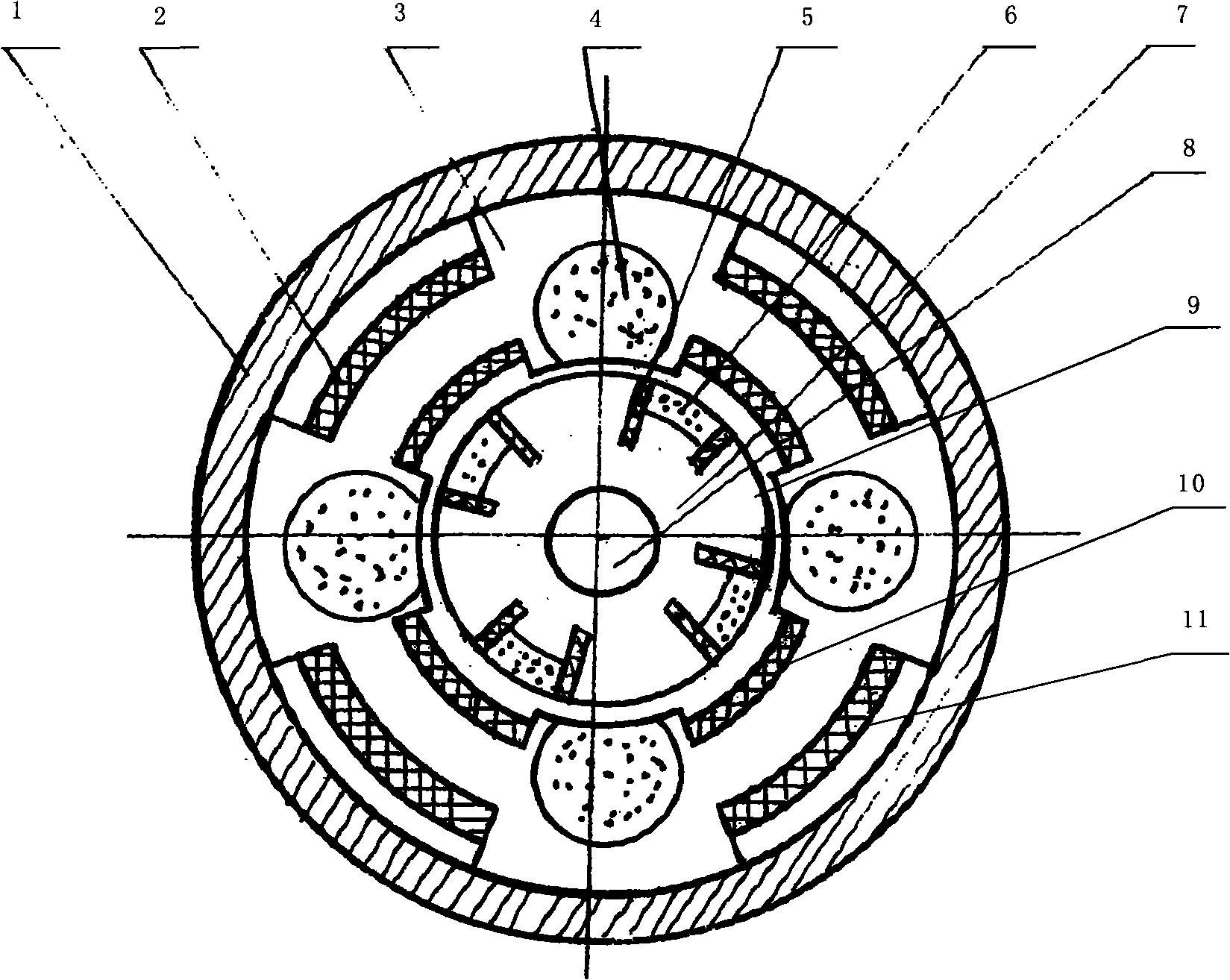

The invention discloses a generation device for generating DC triboelectricity, including a stator, a rotor, an outer casing, a conductive component, a V-shaped support, and a front end cap and a rear end cap. The generation device uses the phenomenon of electrification by friction to generate electricity. A stator friction piece on the inner wall of the outer casing and a rotor friction piece on the outer wall of the rotor are in tight contact and conduct rotational friction therebetween via the rotation of the rotor, and thus generating current. According to the invention, the two friction pieces maintain contact friction therebetween from beginning to end via the uniform circular motion so as to generate inductive charges, and electrons flow through an external circuit and constant direct current is output with the conductive component as a reverse commutator. The generation device is simple in structure and low in cost, and can directly and constantly supply electricity to electronic components without extra rectifying devices, and has excellent social and economic benefits.

Owner:JIANGSU UNIV

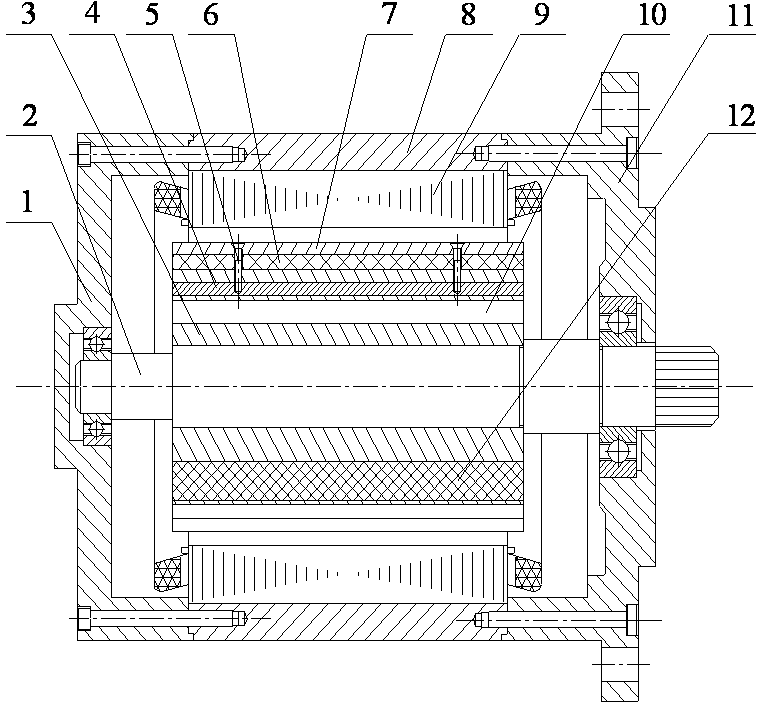

Permanent-magnet hybrid magnetic circuit drive motor of electric vehicle

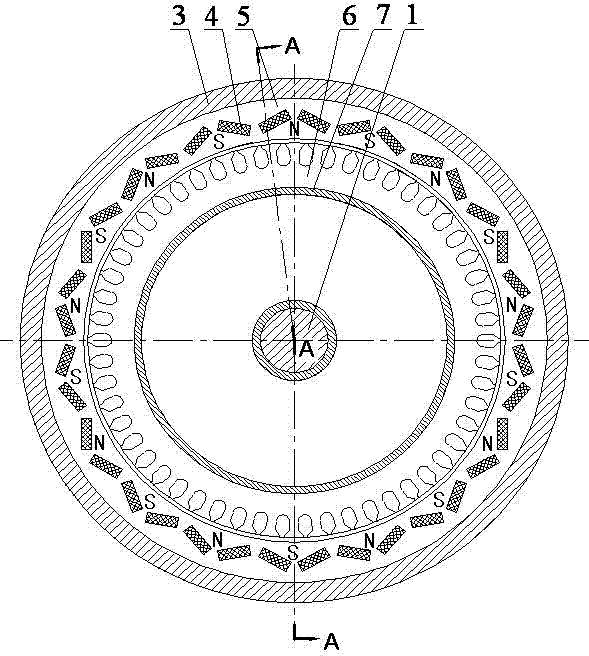

InactiveCN103762766AReduce consumptionIncrease the magnetic field strengthMagnetic circuit rotating partsElectric machinesElectric machineElectrical energy consumption

The invention provides a permanent-magnet hybrid magnetic circuit drive motor of an electric vehicle, and belongs to the technical field of vehicle motor electric appliances. The permanent-magnet hybrid magnetic circuit drive motor of the electric vehicle is composed of a front end cover, a rear end cover, a motor case, a rotor and a stator. Tile permanent magnet steel is fixed to a rotor iron core through a screw via a pole shoe, and rectangular permanent magnet steel is embedded into the rotor iron core, so that a rotor magnetic bypass structure is achieved, the permanent magnet steel is effectively prevented from generating irreversible demagnetization under over-high temperature or under the armature reaction action of impact currents, and the permanent magnet steel does not lose magnetism. A rotor magnetic field of the drive motor is provided by a radial magnetic field and a tangential magnetic field together, the intensity of the magnetic field is large, the output power is high, no electro-magnetic winding is needed, power consumption is little, no carbon brush or mechanical commutator is provided, the failure rate is low, and the permanent-magnet hybrid magnetic circuit drive motor has the advantages of being high in efficiency, high in power density, compact in structure, reliable in working and the like.

Owner:SHANDONG UNIV OF TECH

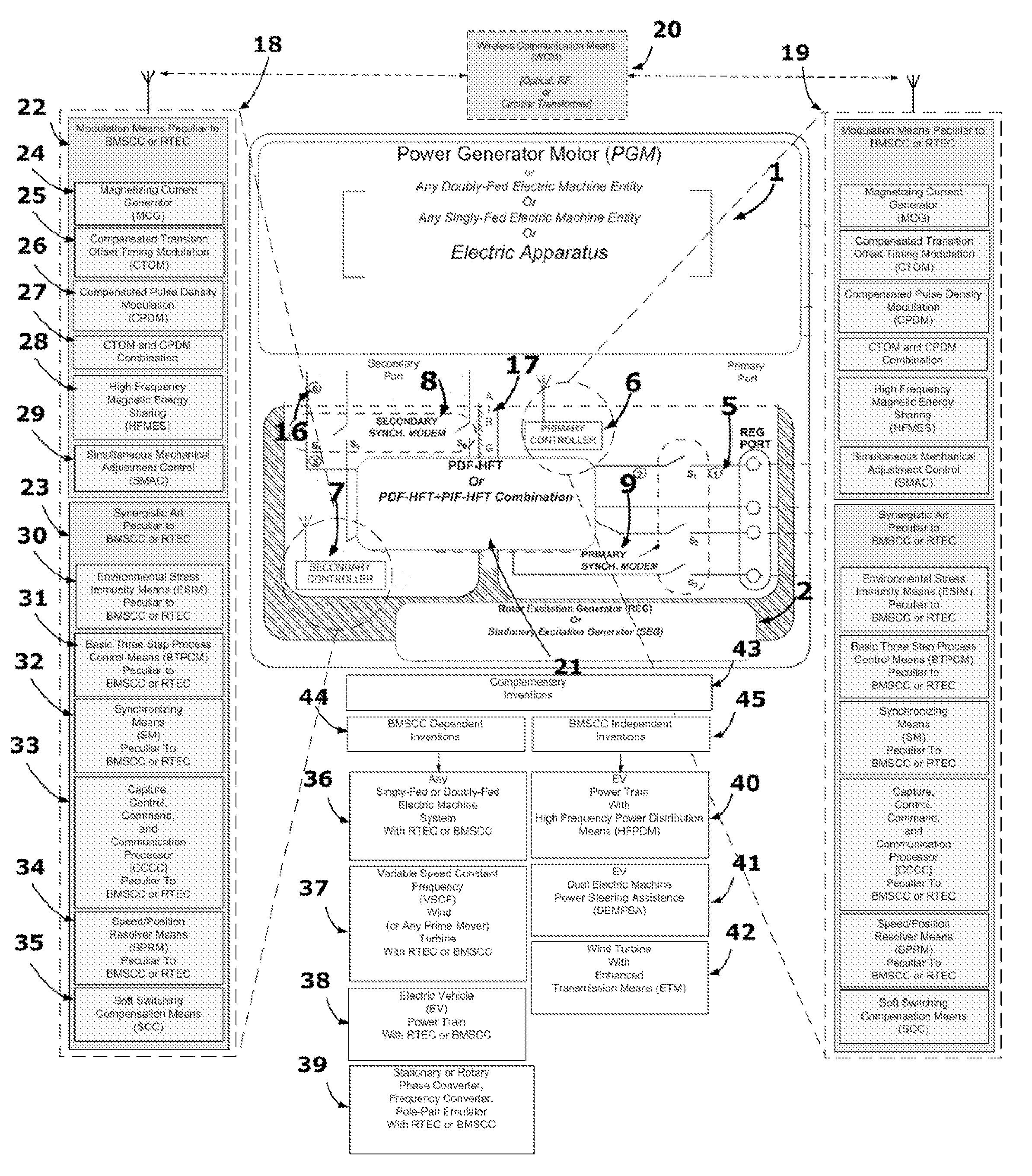

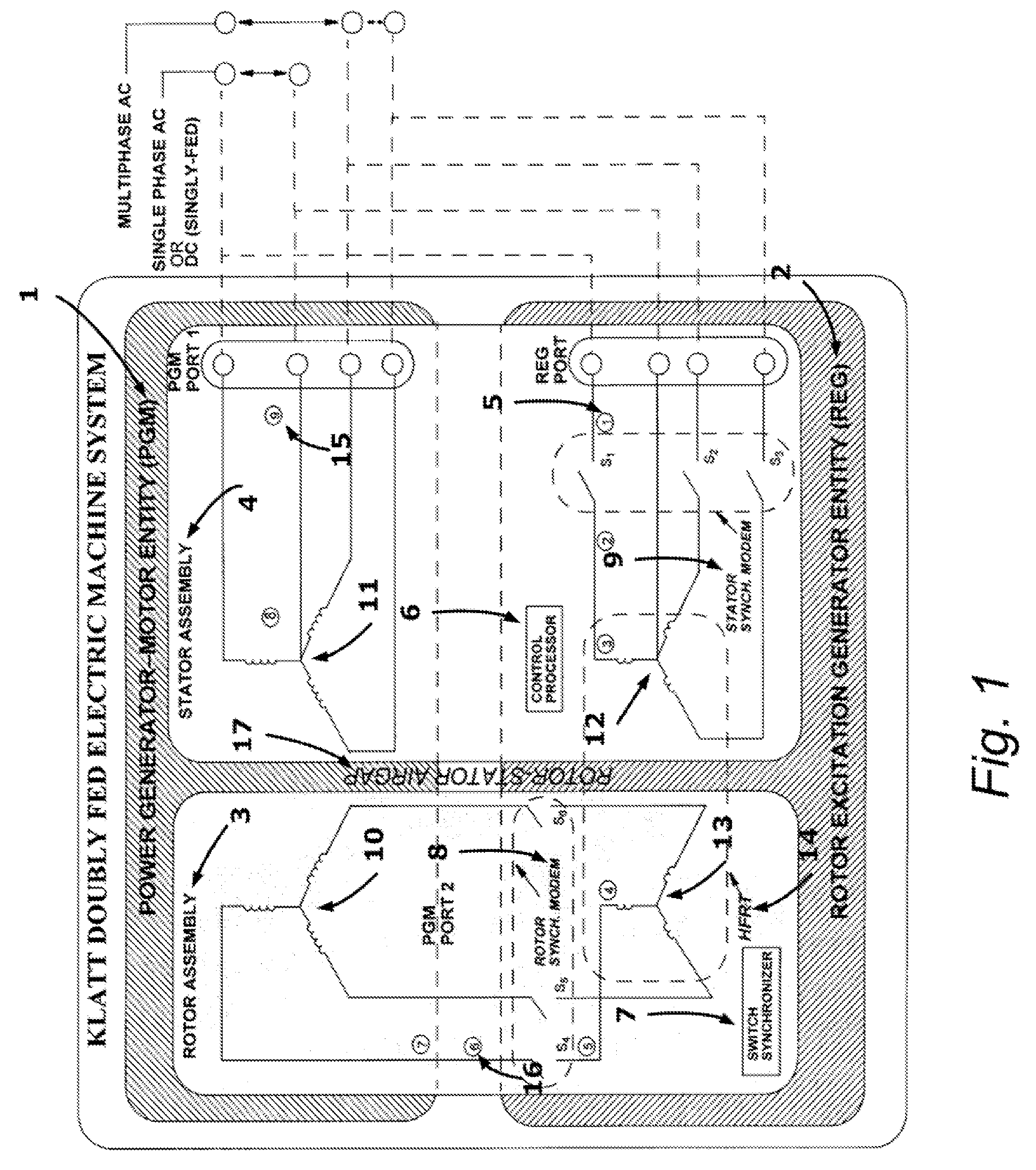

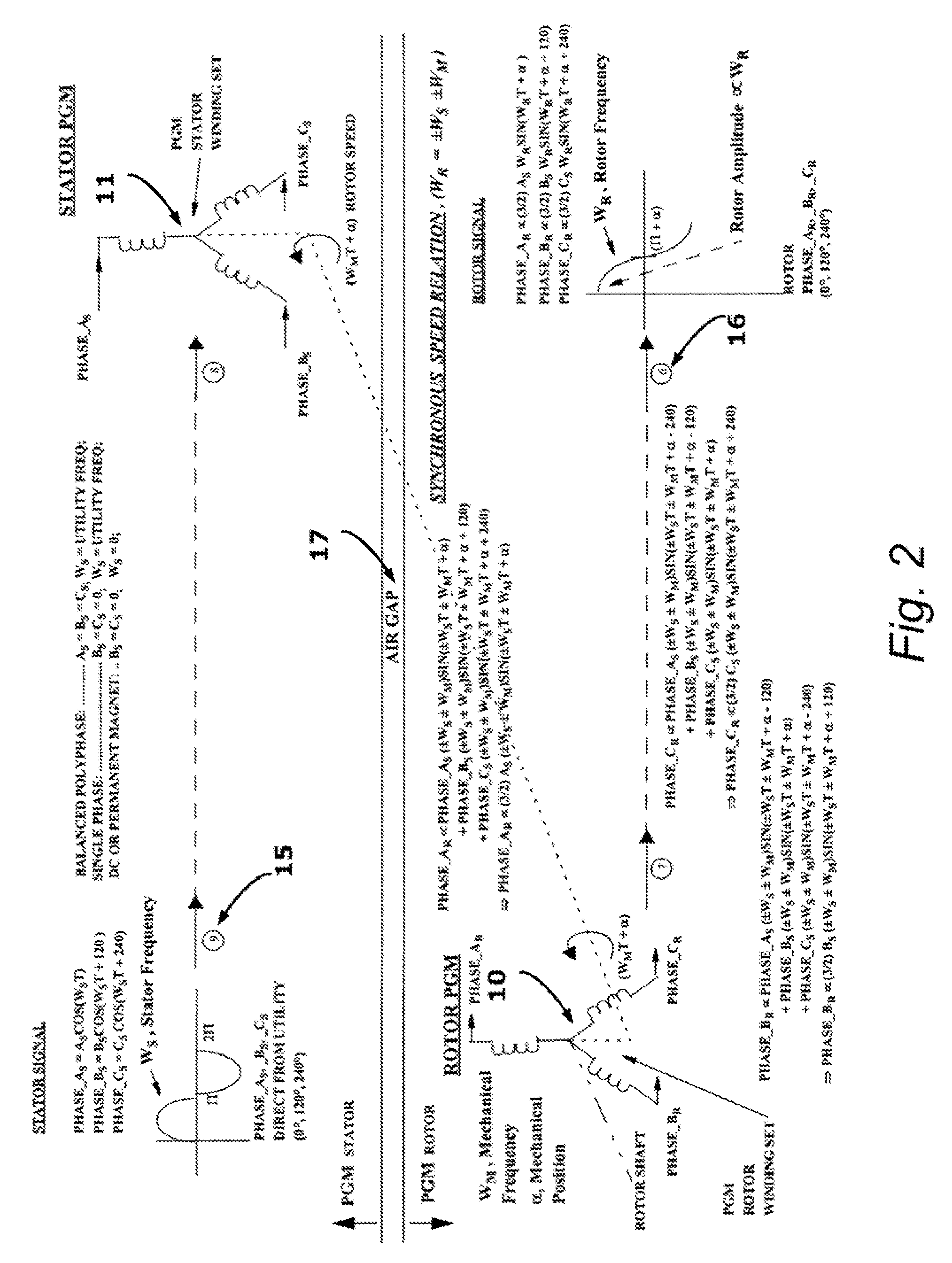

Brushless Multiphase Self-Commutation (or BMSCC) And Related Invention

ActiveUS20100148712A1Provide immunityAC motor controlSynchronous motors startersElectricityElectrical devices

Owner:KLATT FREDERICK WILLIAM

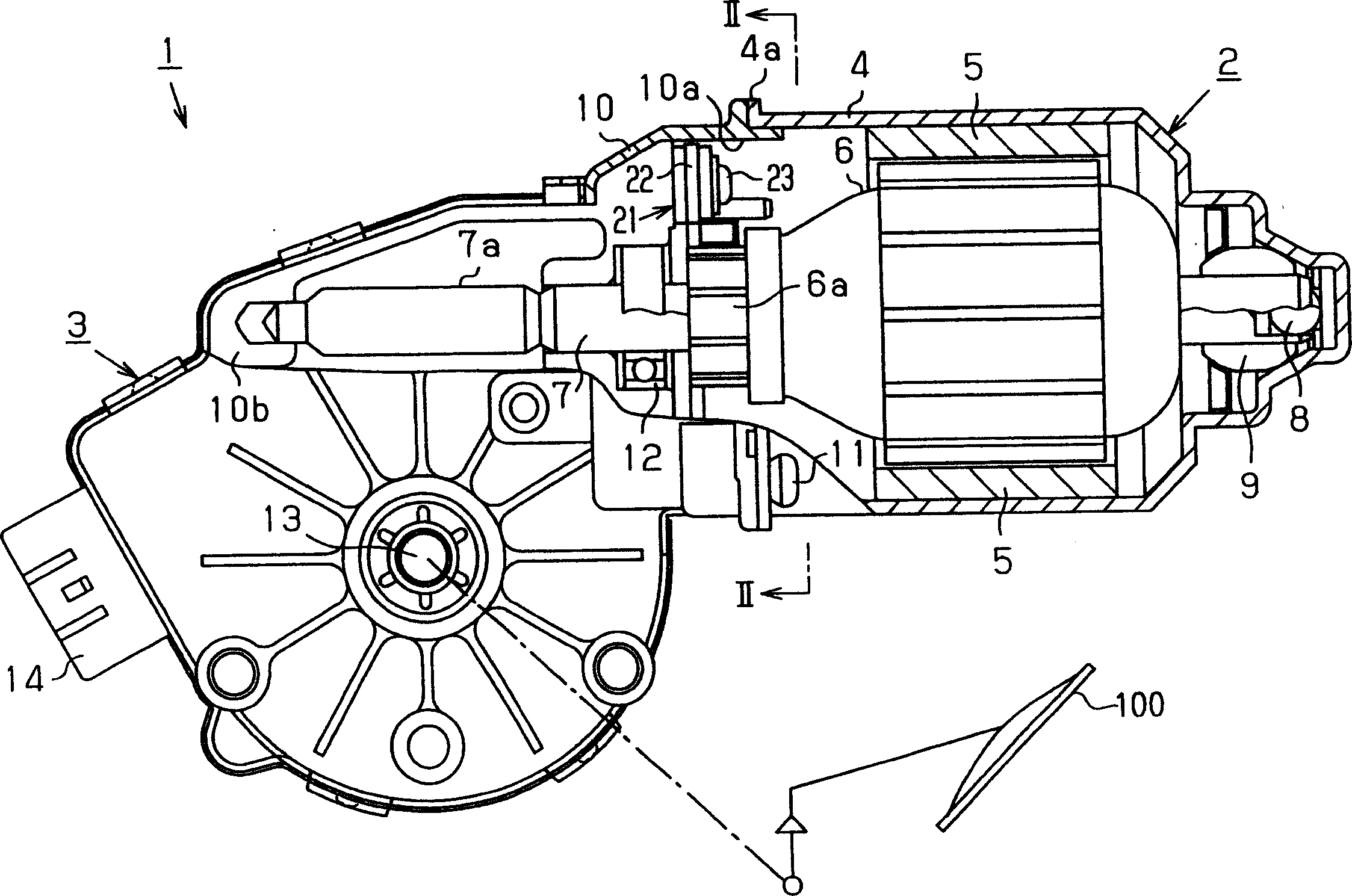

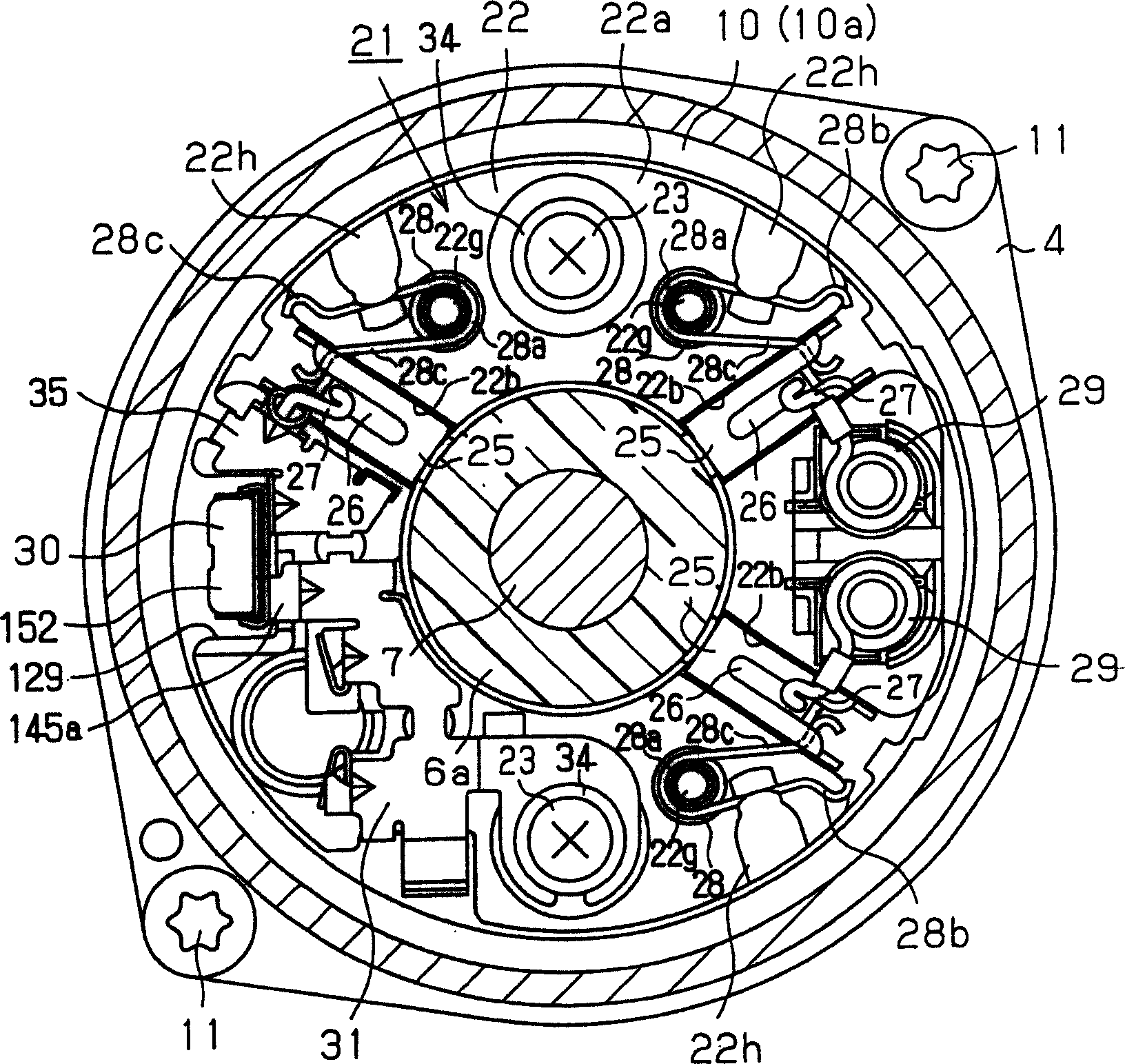

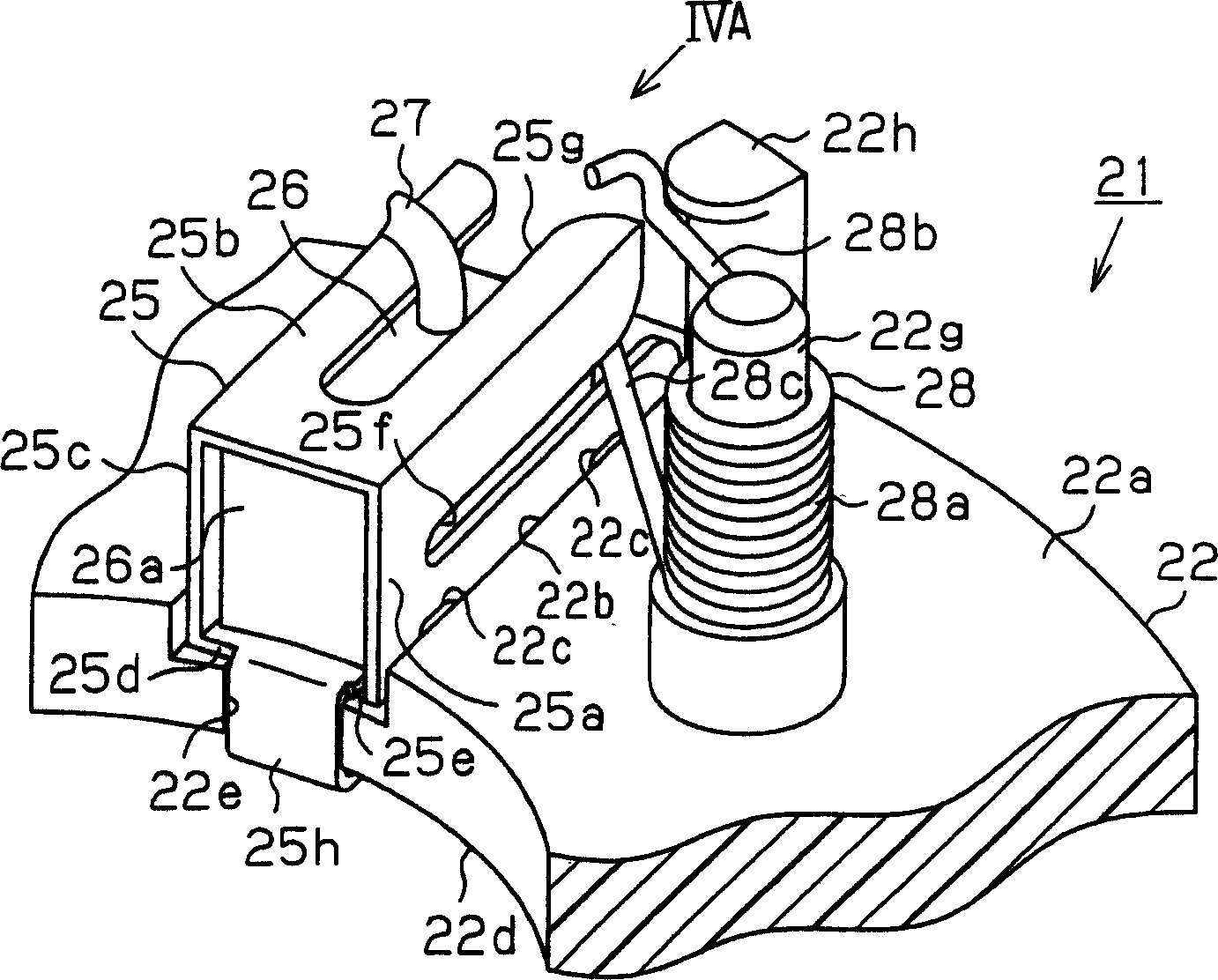

Brush holder device for dynamoelectric machine

ActiveCN1574562AReduce manufacturing costLimit thermal deformationRotary current collectorMechanical energy handlingEngineeringBrush

Brush holder device for dynamoelectric machine. Each brush holder is formed by bending a holder material made of a metal plate, so that the brush holder is shaped into a generally rectangular tubular body, which includes opposed first and second lateral walls, a top wall and a base wall. A base plate includes holder limiting grooves. Each brush holder is received in a corresponding one of the limiting grooves. The limiting groove limits an increase in a space between the first lateral wall and the second lateral wall of the corresponding brush holder. Furthermore, each brush is received in a corresponding one of the brush holders in a slidable manner in a sliding direction toward and away from a commutator of a motor.

Owner:DENSO CORP

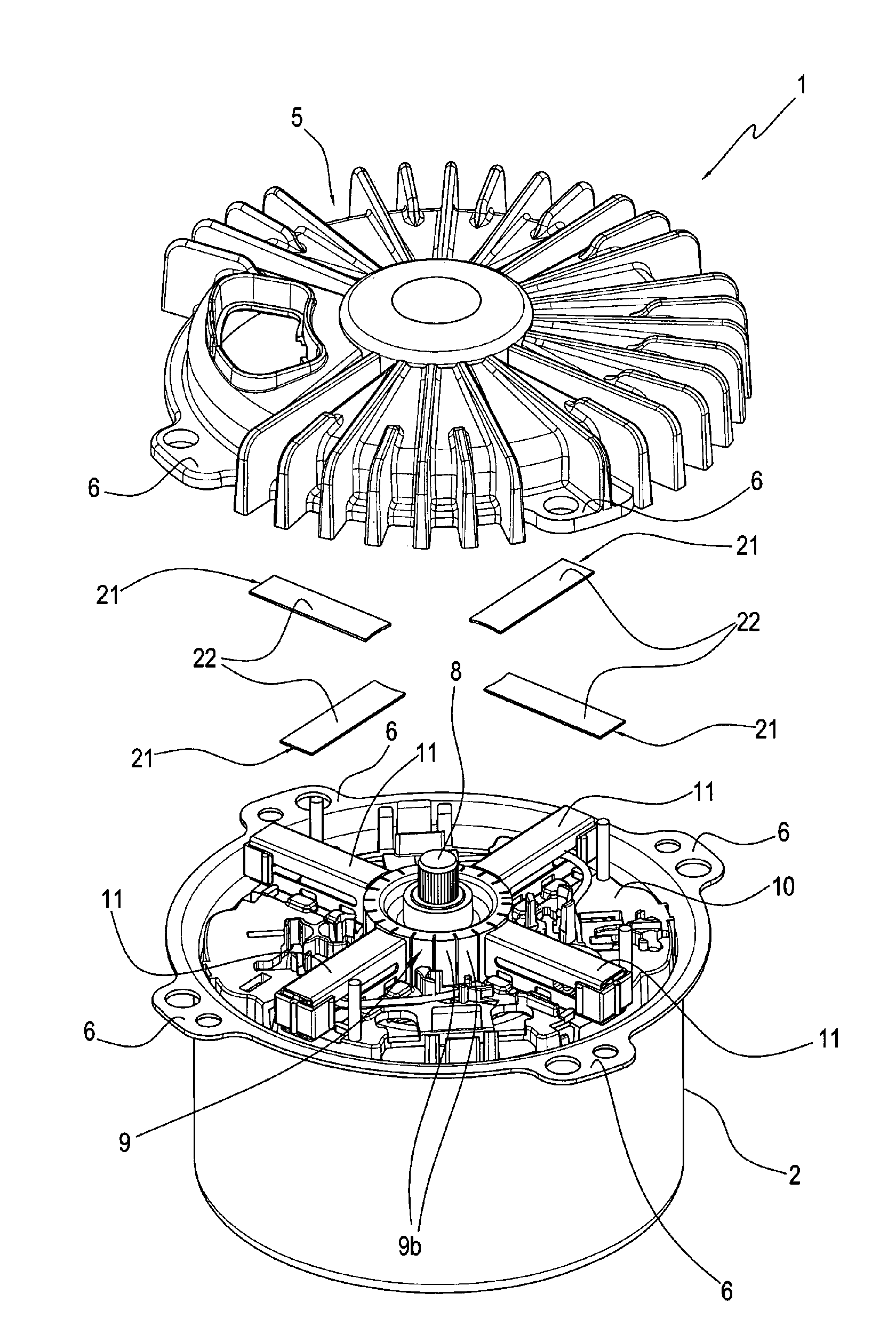

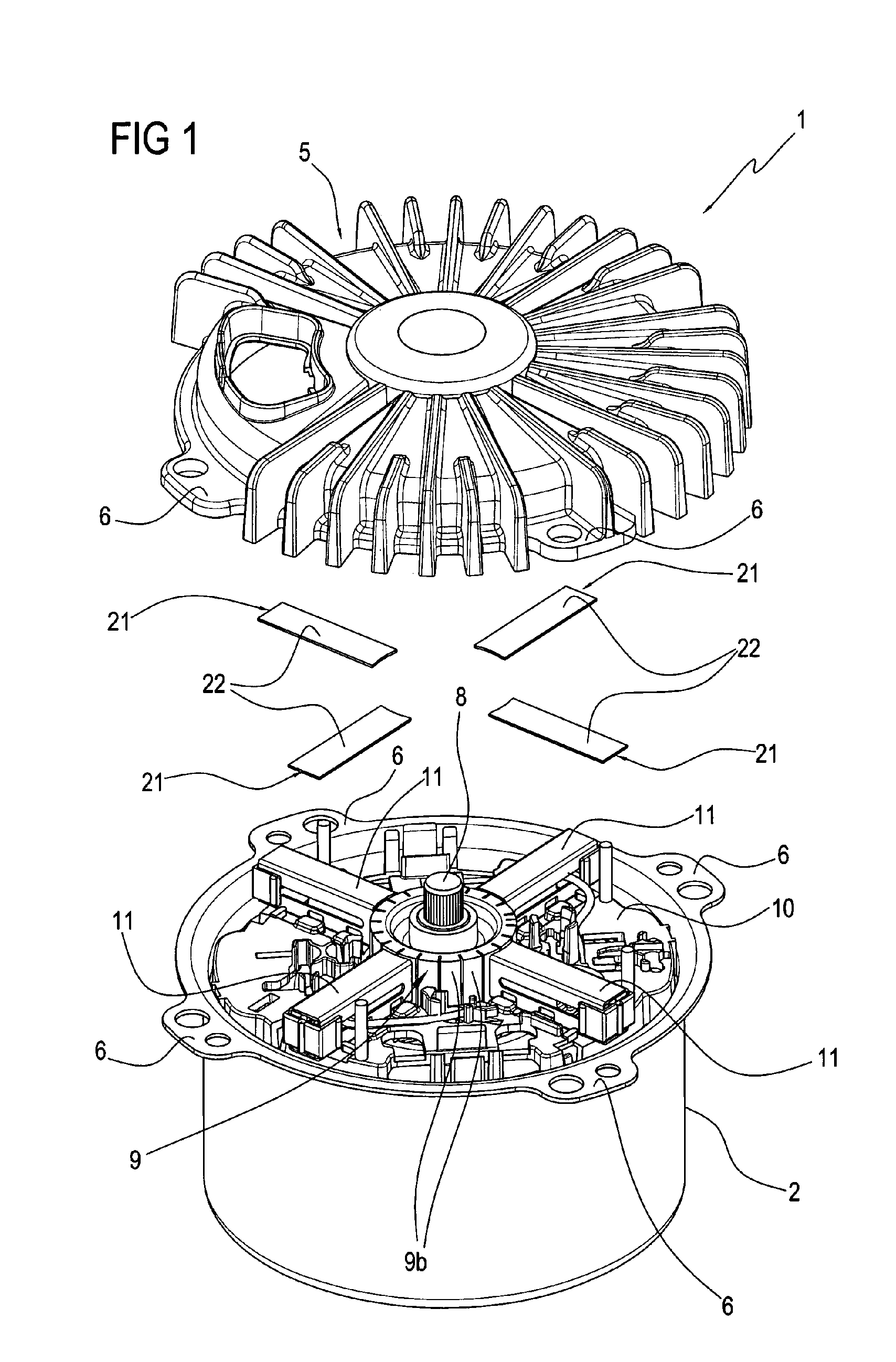

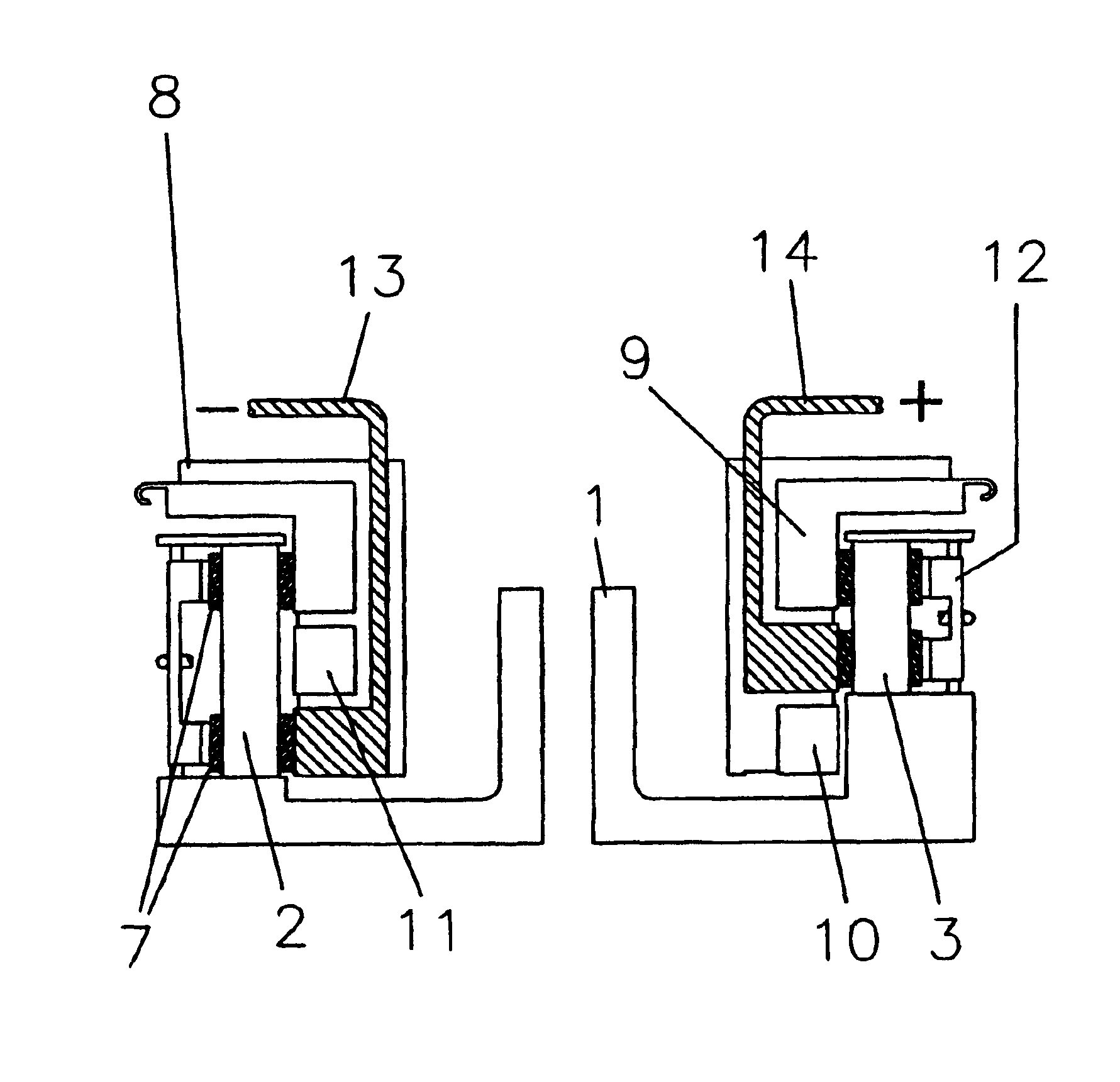

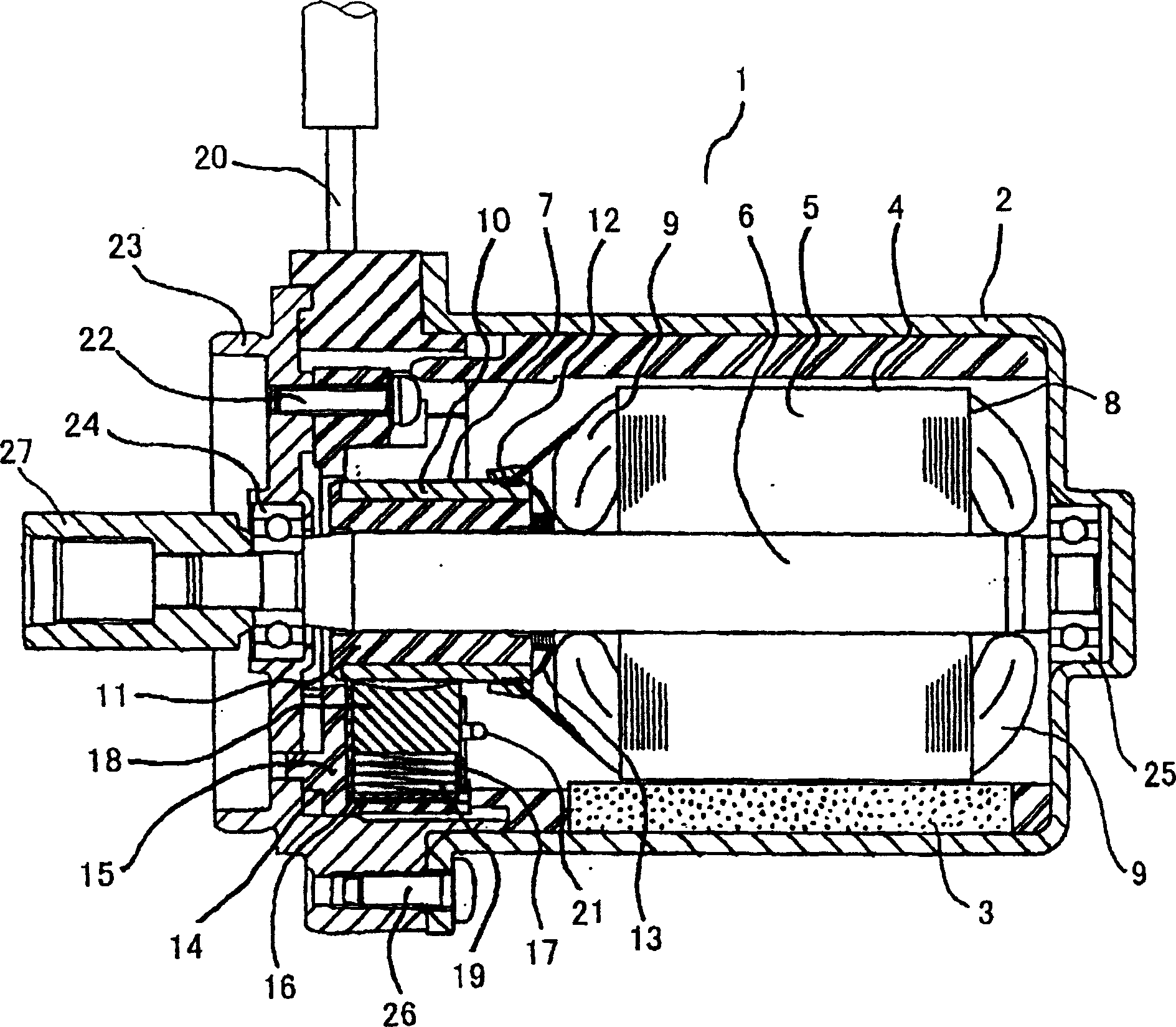

Brush apparatus for an electric machine and electric machine

ActiveCN102460909AIncrease temperatureReduce external temperatureVehicle connectorsPower operated startersBusbarElectric machine

The invention relates to an electric machine (1), especially a starter for an internal combustion engine, comprising a commutator (4) and a brush apparatus (2), brushes (3) being arranged on the commutator (4) in such a manner that at least one pair of brushes can rotate off-set from each other, every brush (3) being held in a brush holder (5), every brush holder (5) being fastened to an axial face on a brush plate (6), every brush (3) being alternately switchable in series either with a negative pole or a positive pole by a current conducting device (18, 19) to give a pair of brushes, and the brush plate (6) with connecting leads (24, 25, 26) leading to brushes (3) on the negative pole side and a busbar (10) with connecting leads (21, 22, 23) leading to brushes (3) on the positive pole side forming a respective current conducting device (18, 19). In order to protect the brush apparatus (2) from thermal overloads in an easy manner, at least one current conducting device (18, 19) is designed to have a unit for reducing heat dissipation.

Owner:SEG AUTOMOTIVE GERMANY GMBH

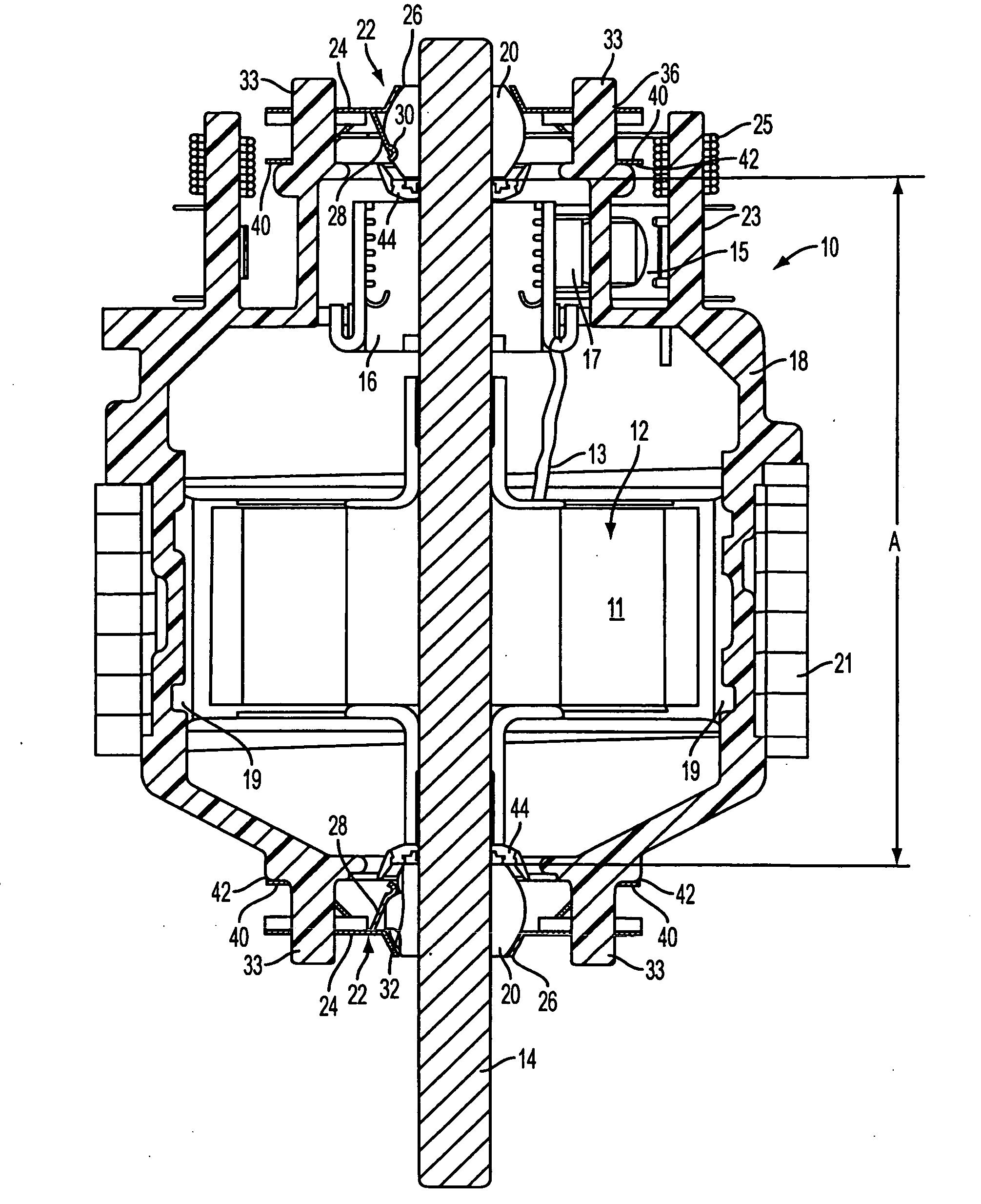

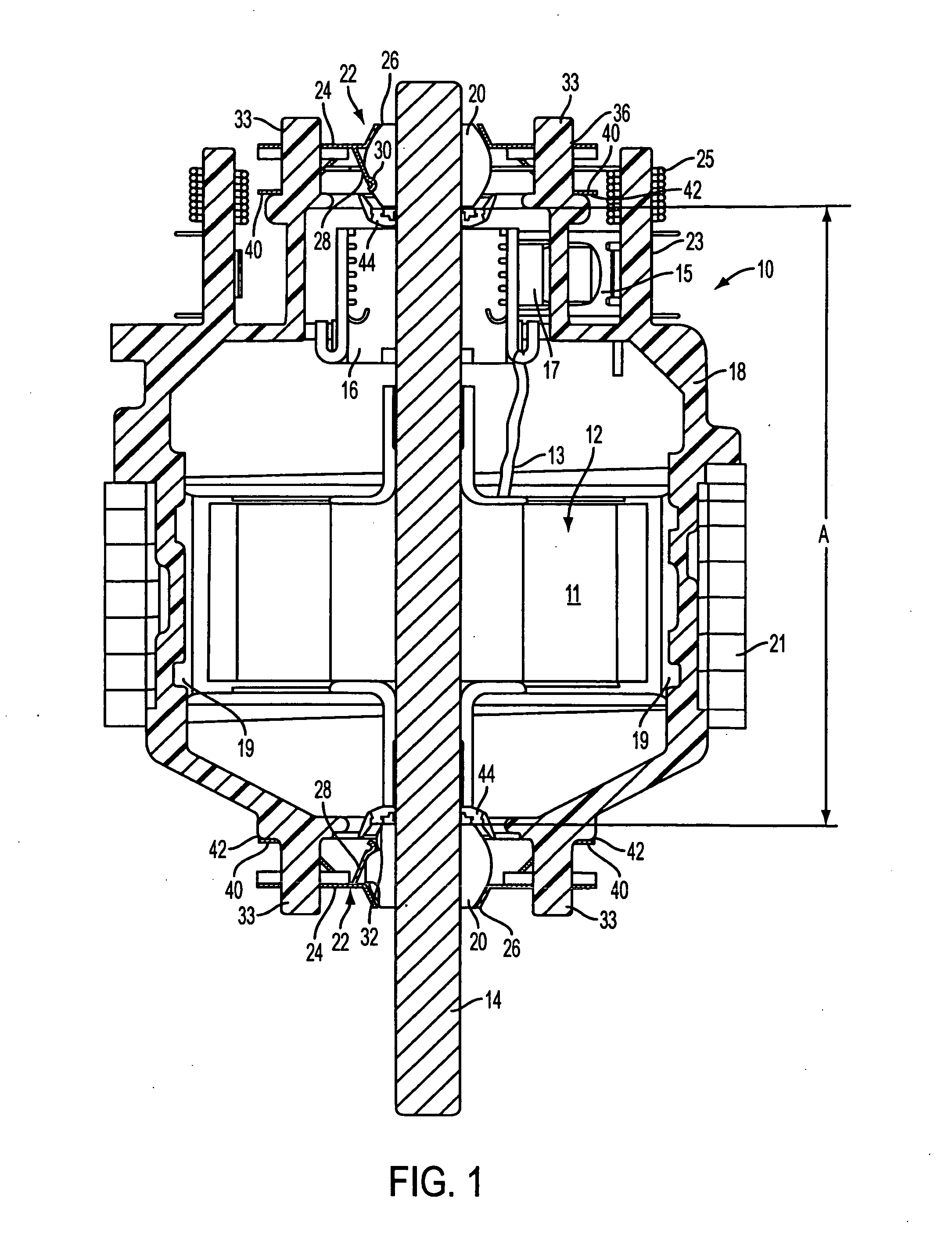

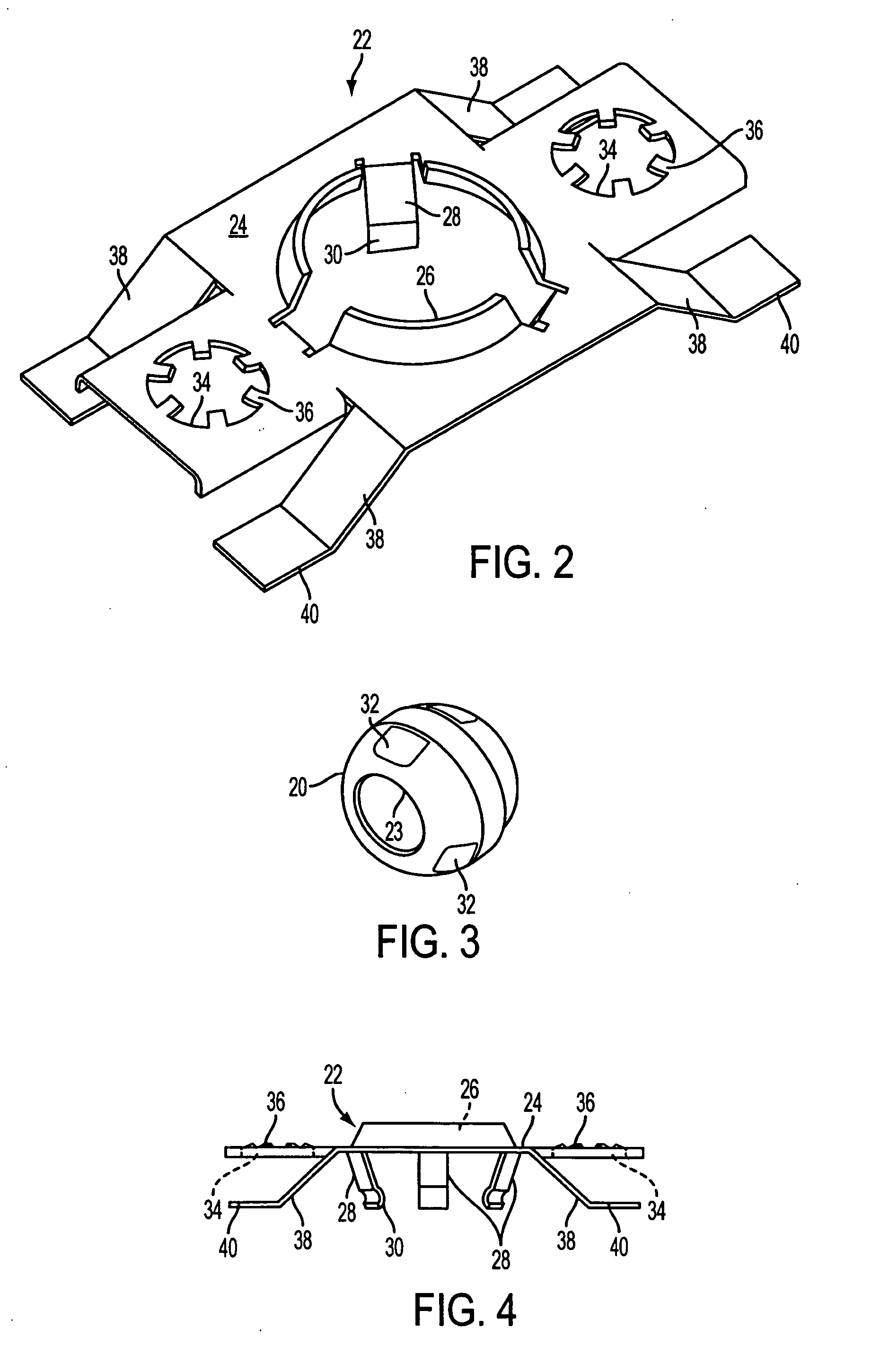

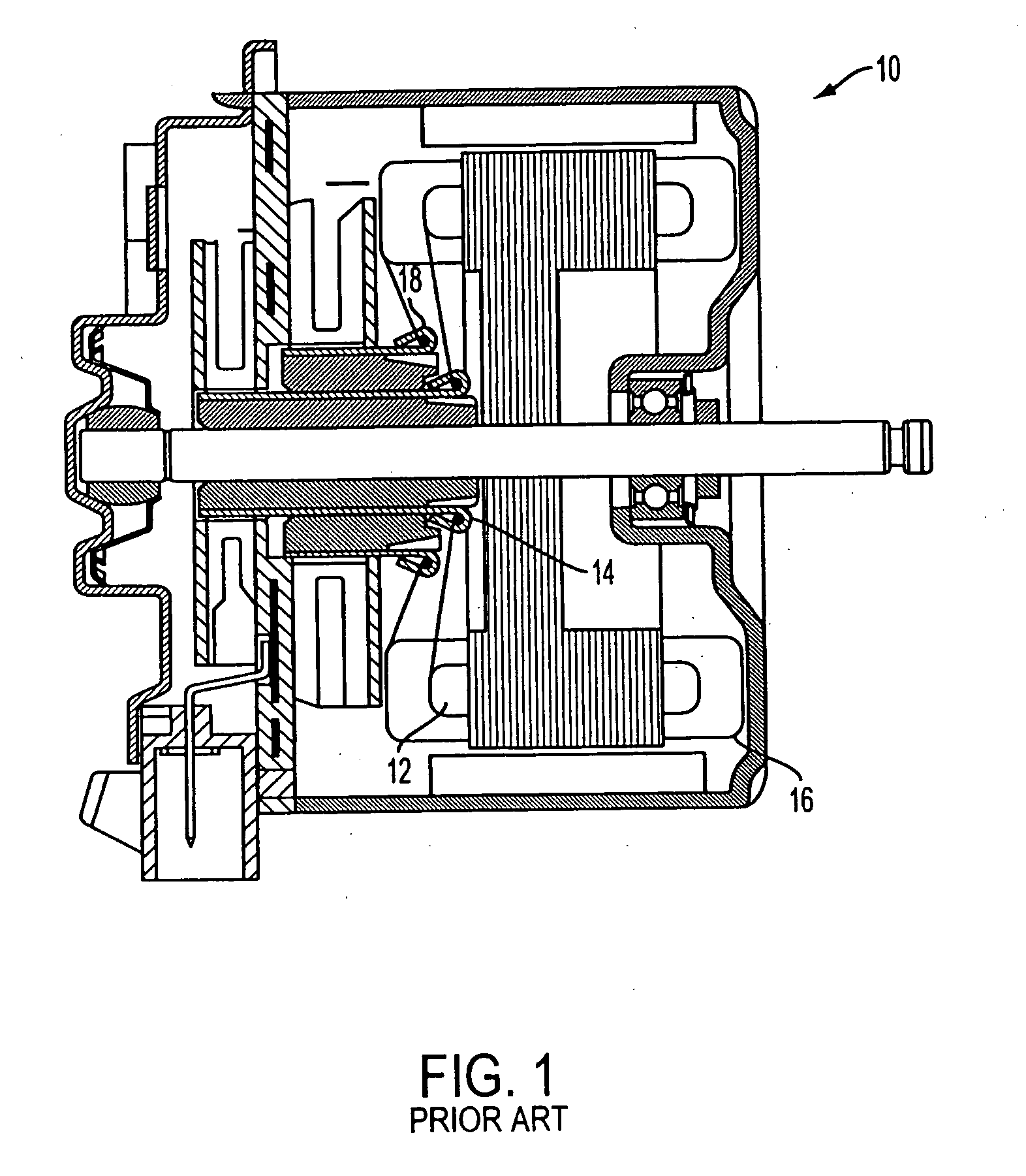

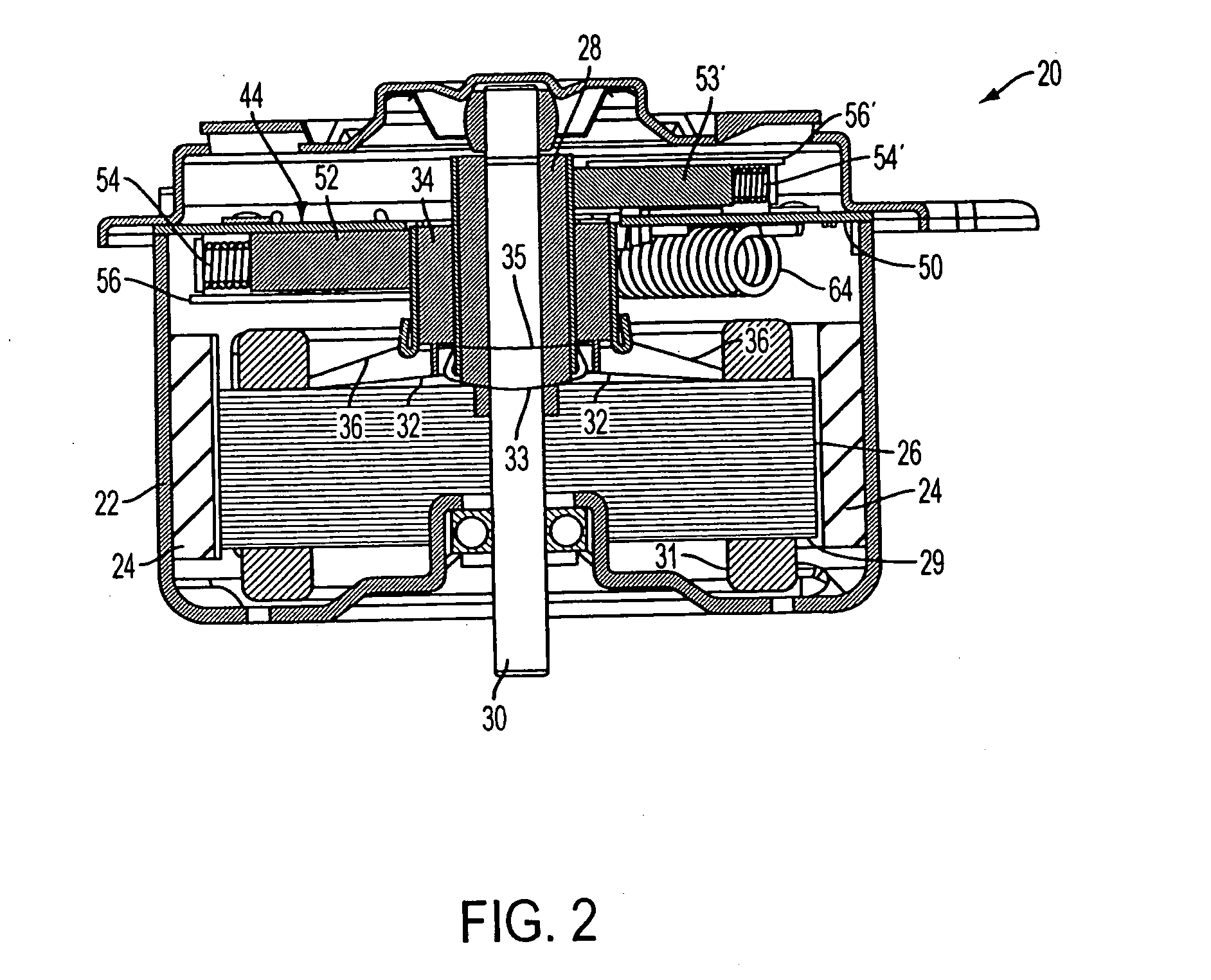

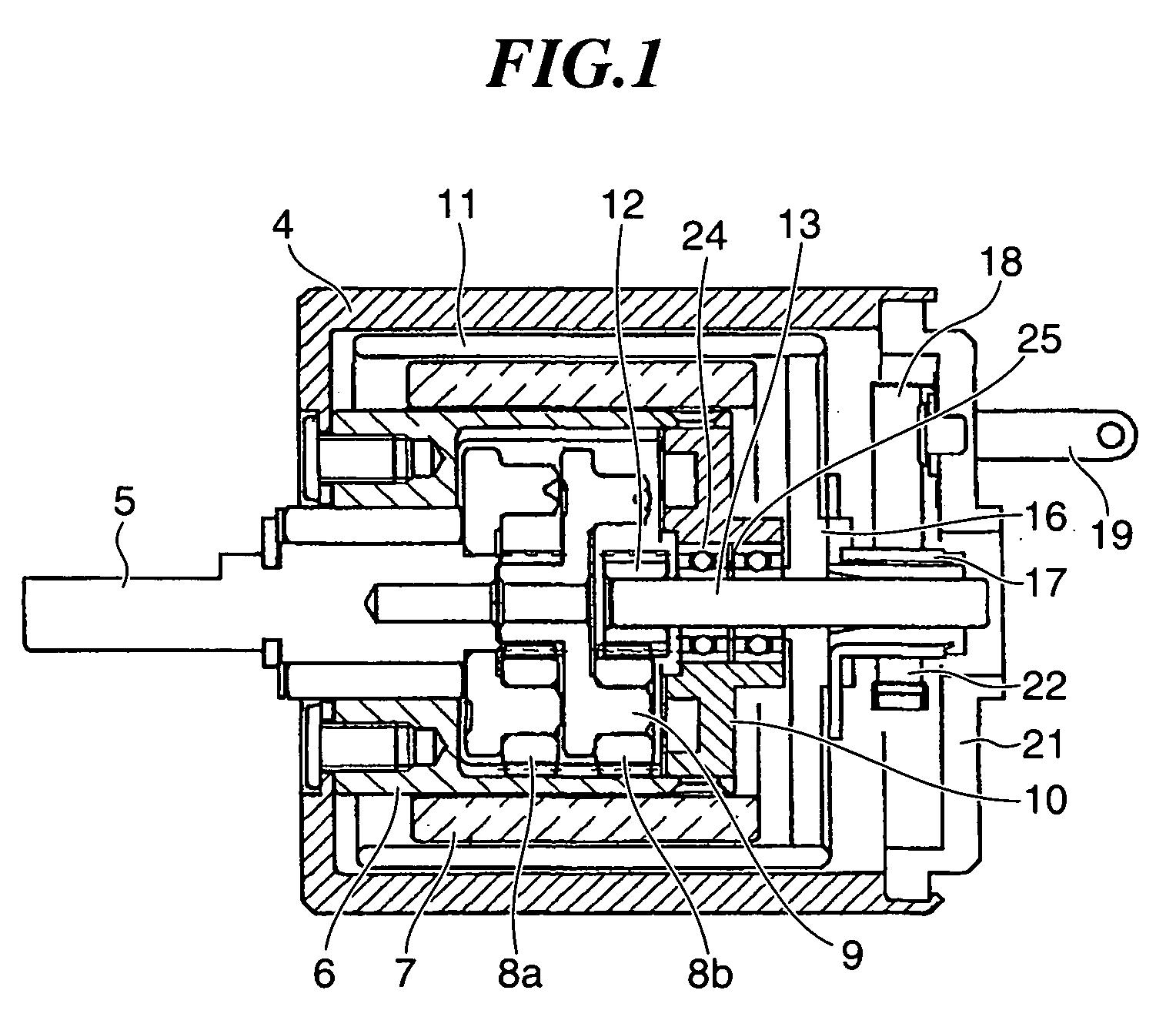

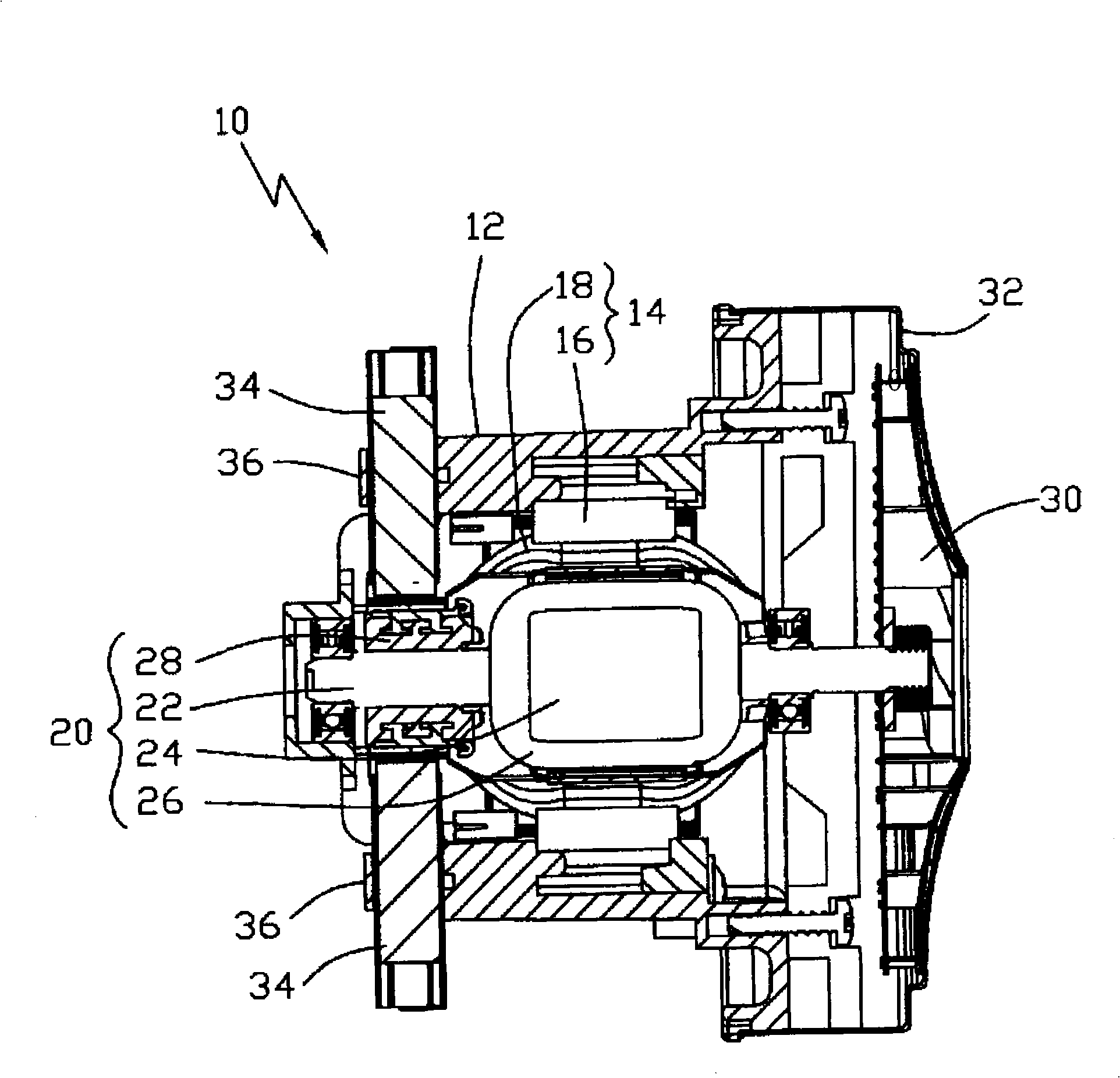

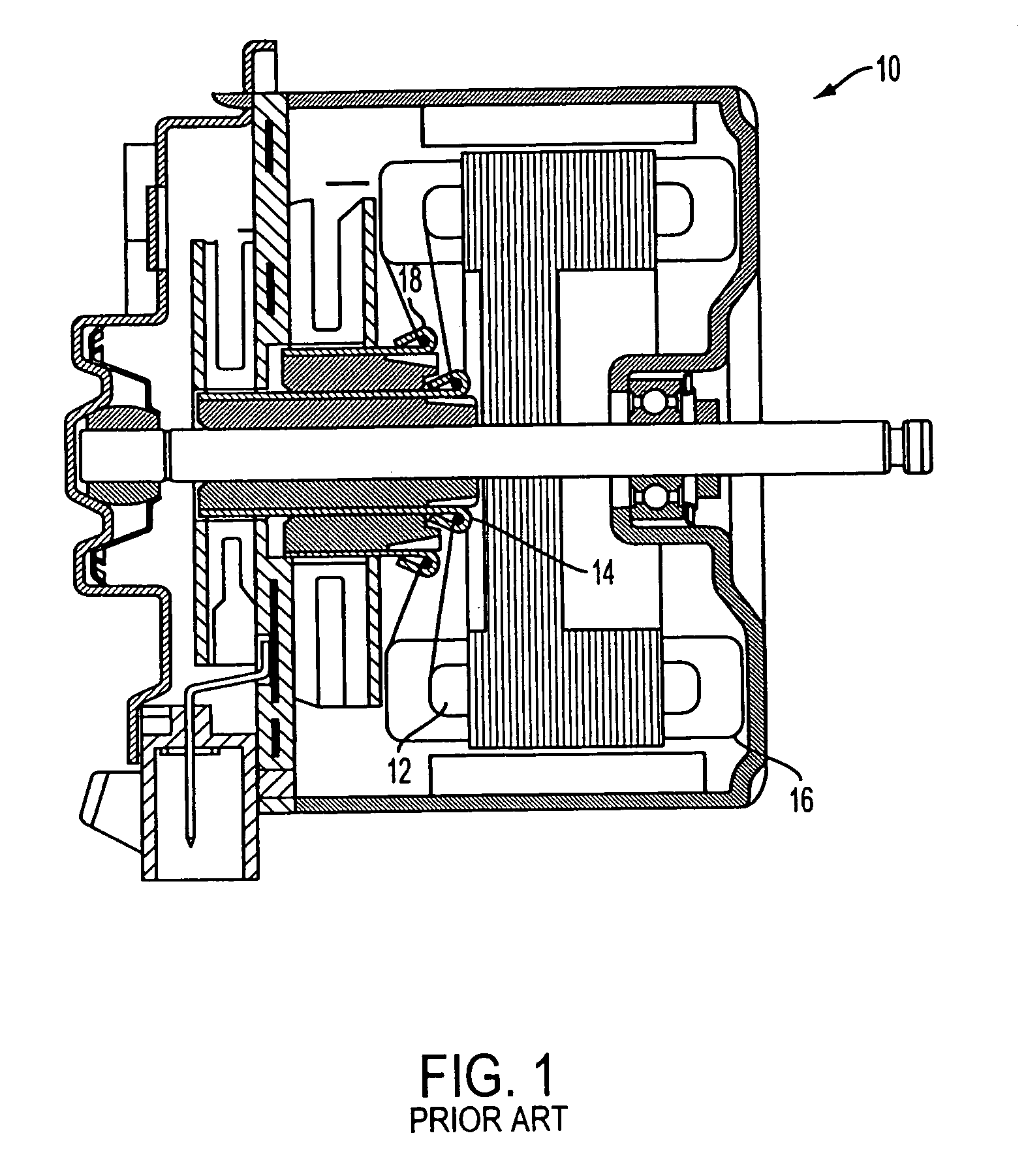

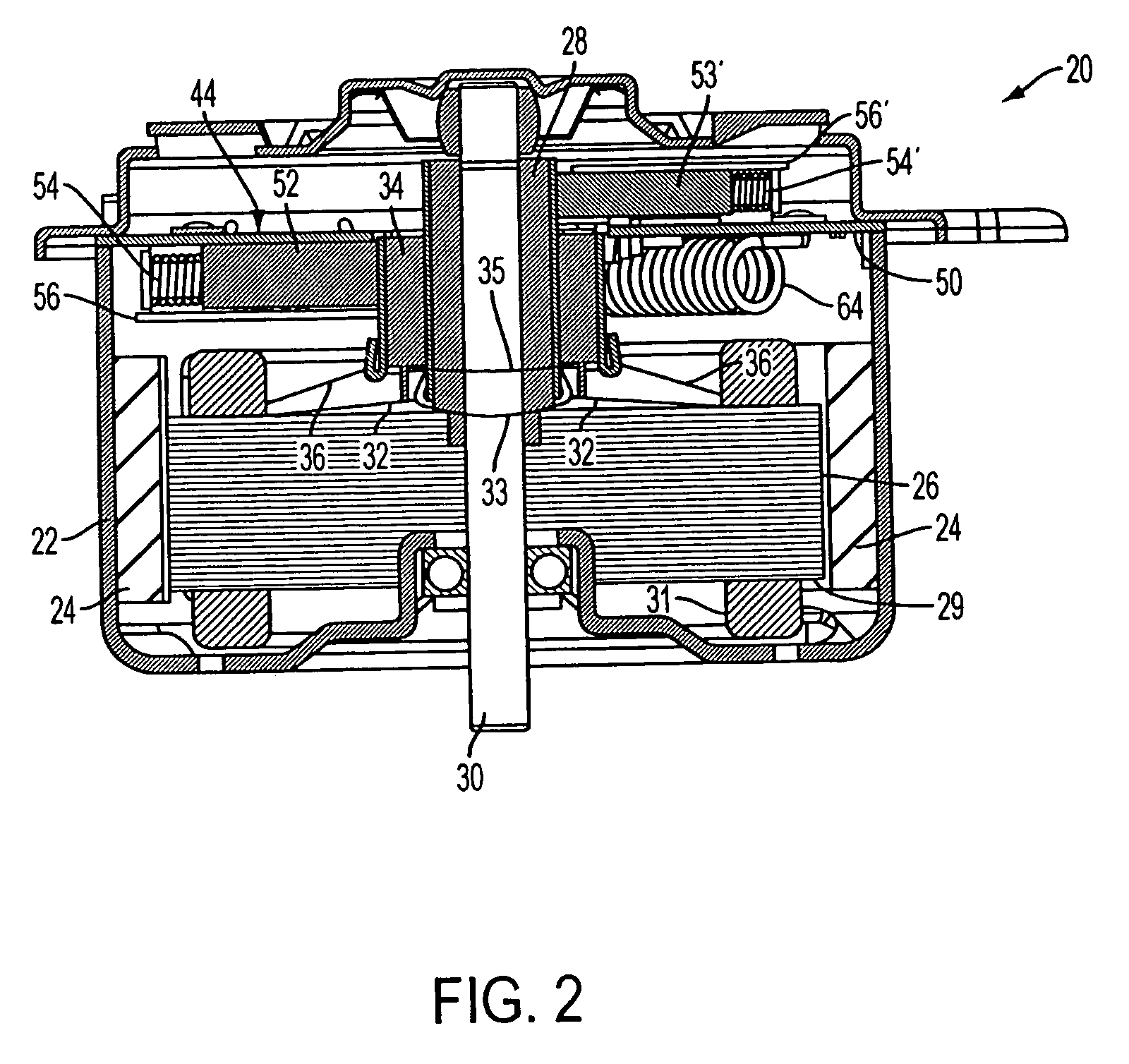

Endplay adjustment and bearing decoupling in an electric motor

InactiveUS20050018935A1Prevent movementRolling contact bearingsBearing componentsSpring forceEngineering

An electric motor 10 has an armature structure 12 including a shaft 14, a lamination stack 11 coupled with the shaft, a commutator 16 coupled with the shaft, and windings 13 carried by the lamination stack and connected to the commutator. Brushes 17 engage the commutator to deliver electric current to the windings. The motor includes a frame structure 18 carrying permanent magnets 19, at least one sleeve bearing 20 operatively associated with an end of the shaft to support the shaft for rotation, and a unitary bearing retainer structure 22 coupled with the frame structure and holding the at least one sleeve bearing. The retainer structure is constructed and arranged 1) to prevent movement of the retainer structure in a direction towards the end of the shaft, 2) to provide a spring force against the frame structure to prevent the retainer structure from moving in a direction away from the end of the shaft, and 3) to control endplay of the armature structure by controlling engagement of the retainer structure with the frame structure.

Owner:SIEMENS VDO AUTOMOTIVE INC

Electric machine

InactiveUS20100277032A1Improve reliabilityReduce manufacturing costRotary current collectorMagnetic circuit rotating partsElectric machineConductor Coil

An electric machine comprises: a casing (2); a stator (3) and a rotor (4) supported by the casing (2), the rotor (4) having at least one rotor winding (7); a commutator (9) connected permanently to the rotor (4) and electrically connected to the rotor winding (7); a pair of brushes (12), each having a first end (12a) maintained in a sliding position with the commutator (9) and electrically connected to respective terminals which may be connected to an electricity mains supply; a pair of brush holder elements (11) supported by the casing (2), each brush holder element (11) being associated with a respective brush (12) to keep it pressed on the commutator (9). Each brush holder element (11) has at least one lateral surface (18) to face a respective butting position (17) of the casing (2), and which may be joined to the butting portion (17) to transmit a thermal power to the butting portion. The lateral surface (18) of each brush holder element (11) is electrically isolated from the respective butting portion (17).

Owner:SPAL AUTOMOTIVE

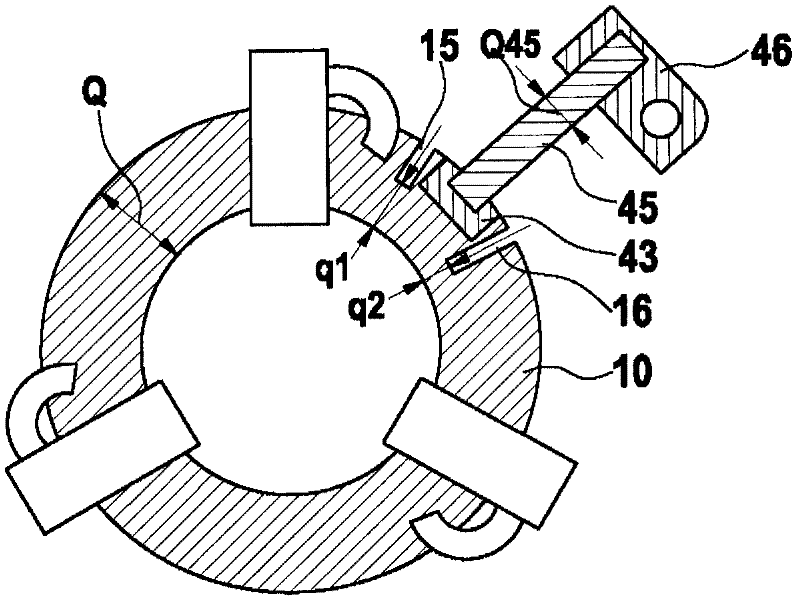

Motor with brush and commutator, and electric apparatus using the same motor

InactiveUS6841914B2Minimize the numberReduce weightRotary current collectorMagnetic circuitEngineeringPower tool

An arc length in contact with a commutator of two brushes in a rotational direction of a motor is defined as not more than 5% of an outer rim length or circumference of the commutator, i.e., not more than πA / 2O, where A is an outside diameter of the commutator. A number of shorted segments of the commutator, which short is caused by the brush, can be minimized so that reduction in output of the motor can be prevented. As a result, the motor employed in a car product or an electric tool can be downsized and made lighter.

Owner:PANASONIC CORP

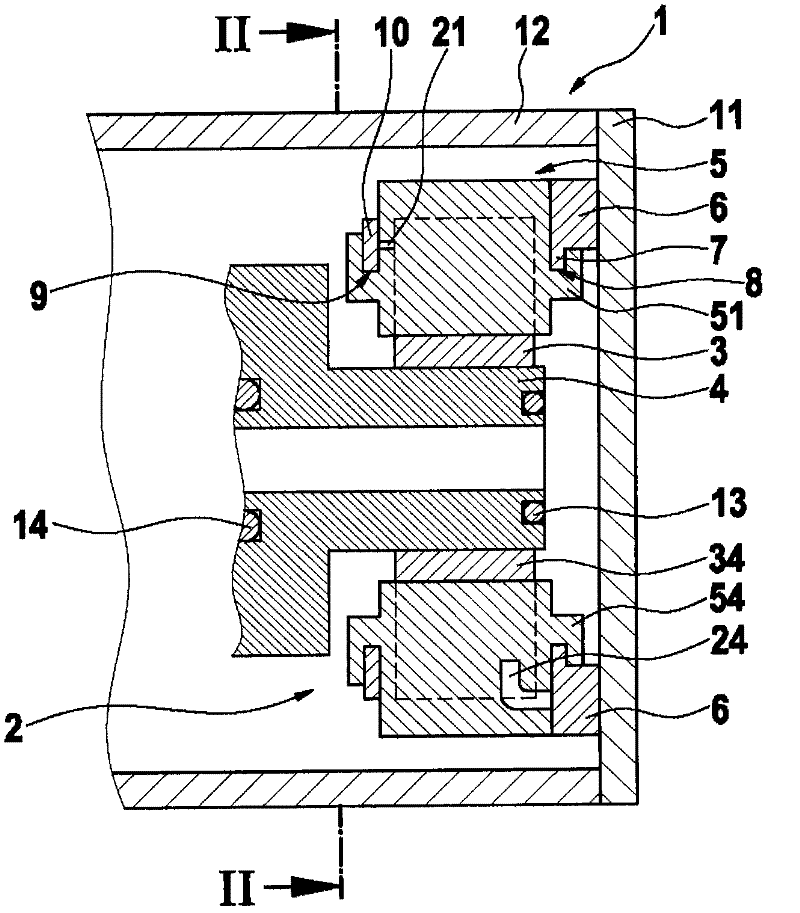

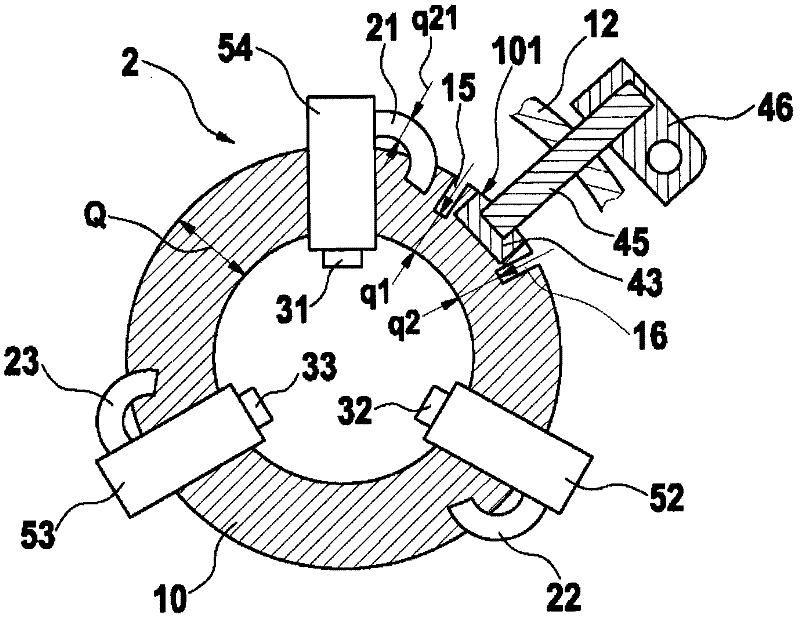

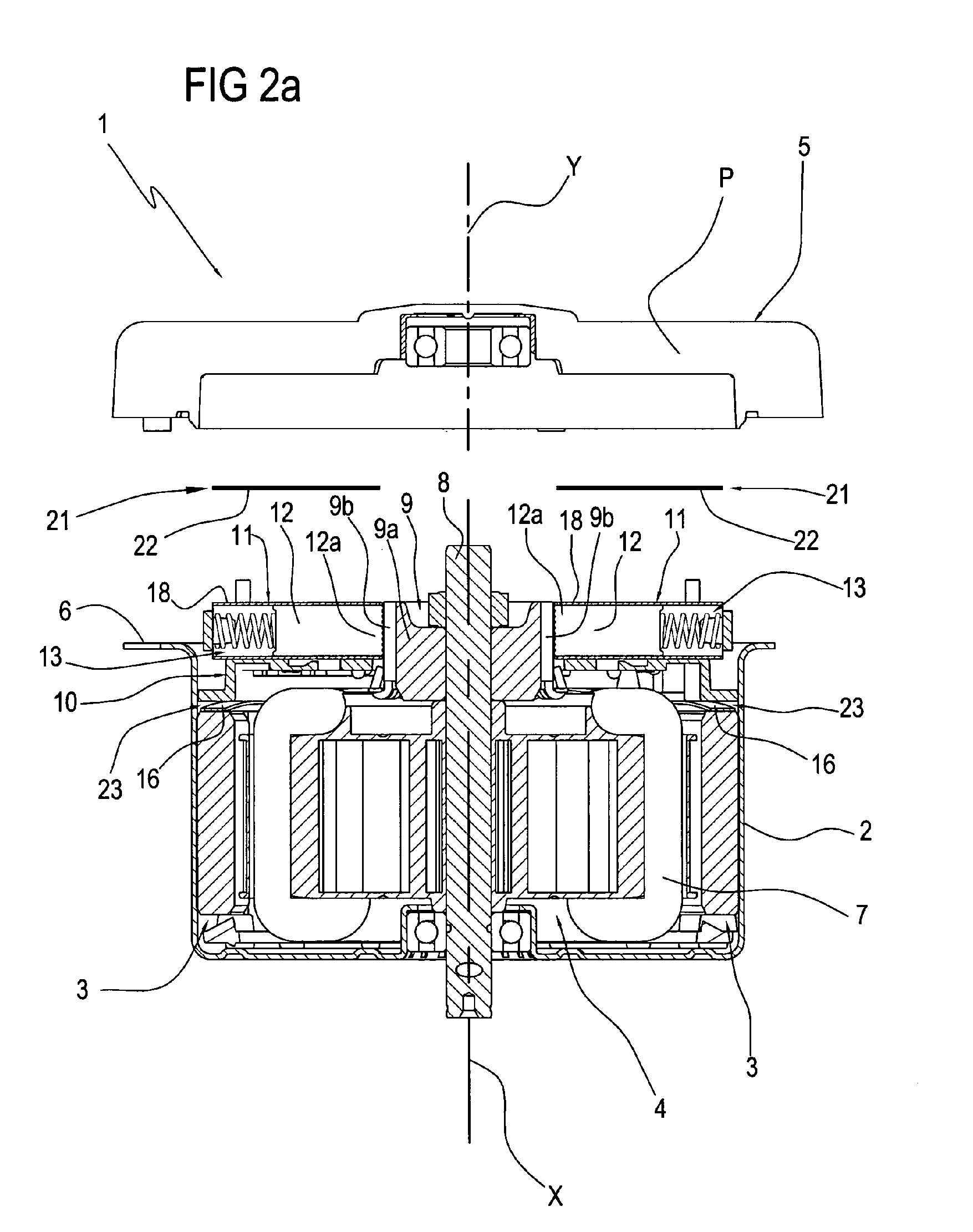

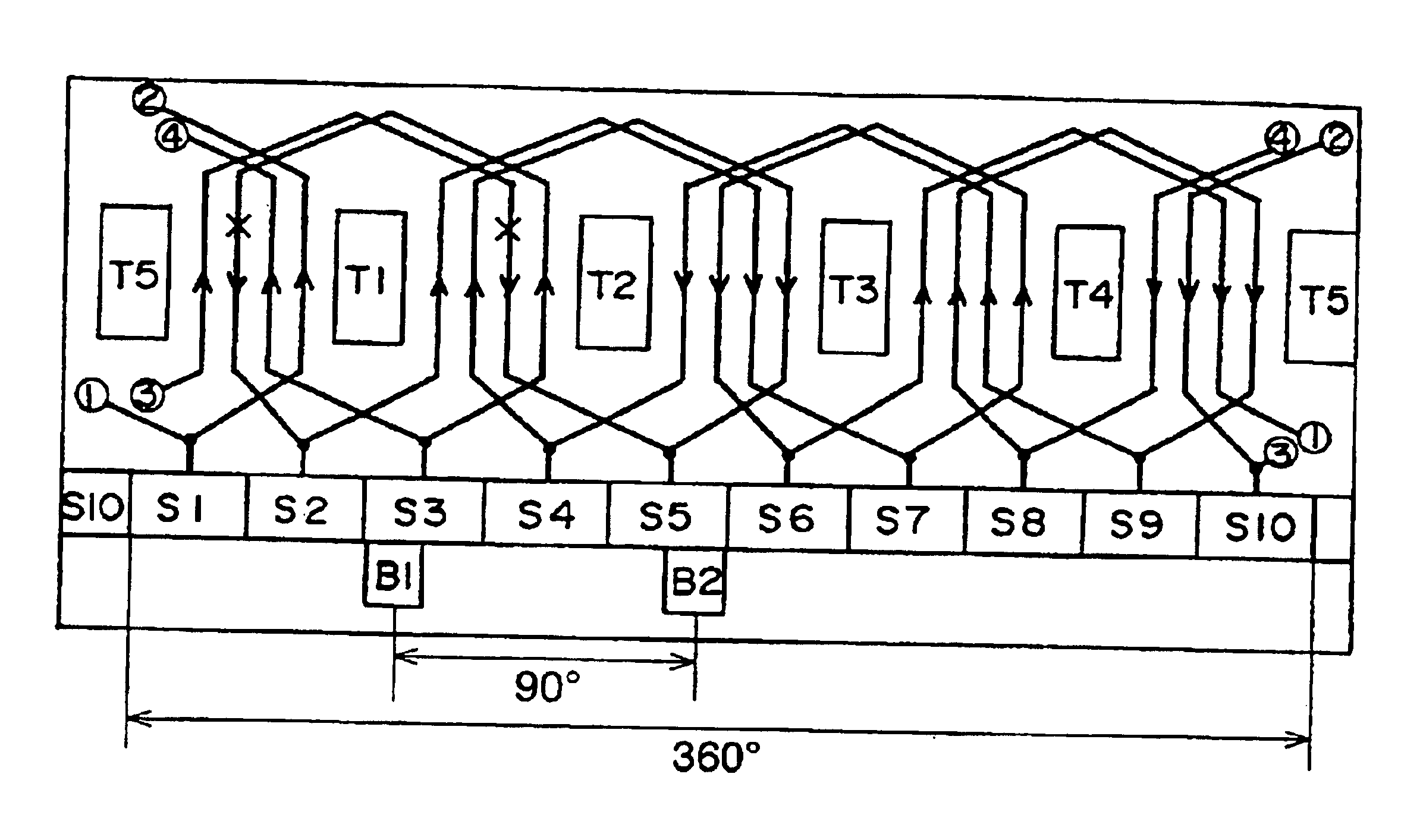

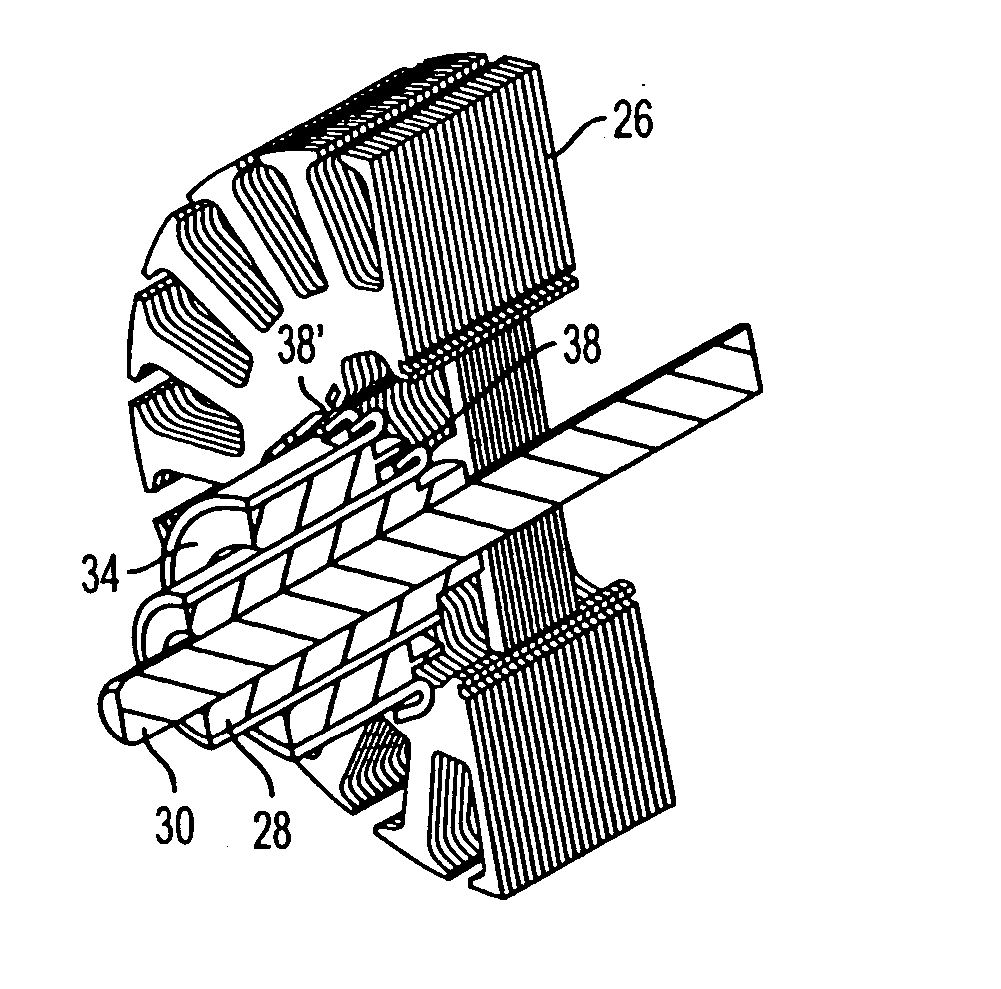

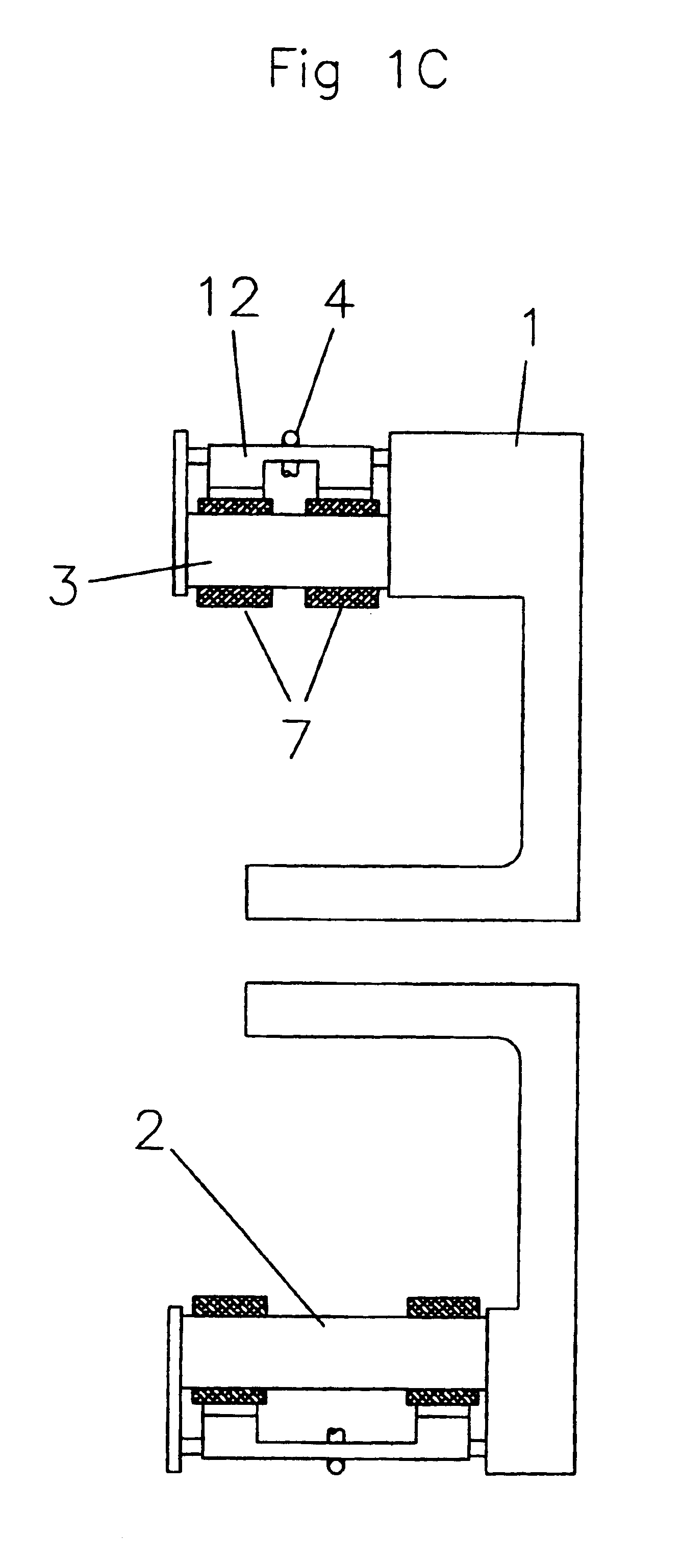

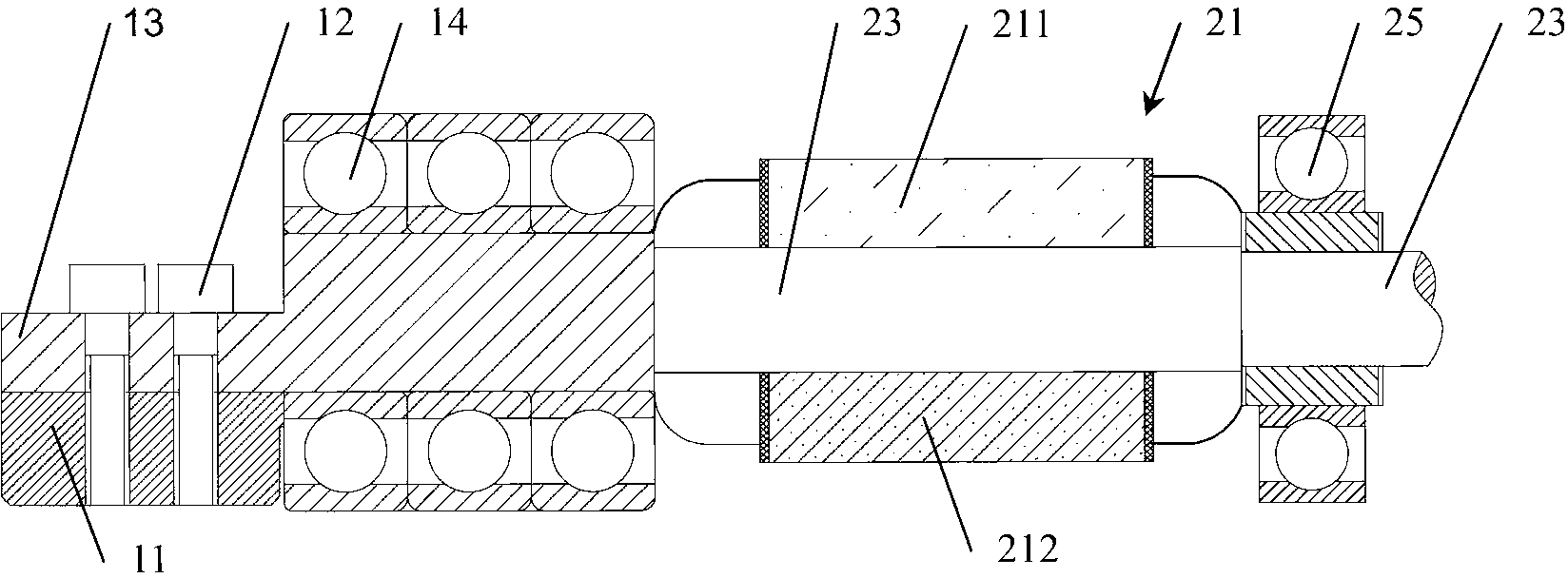

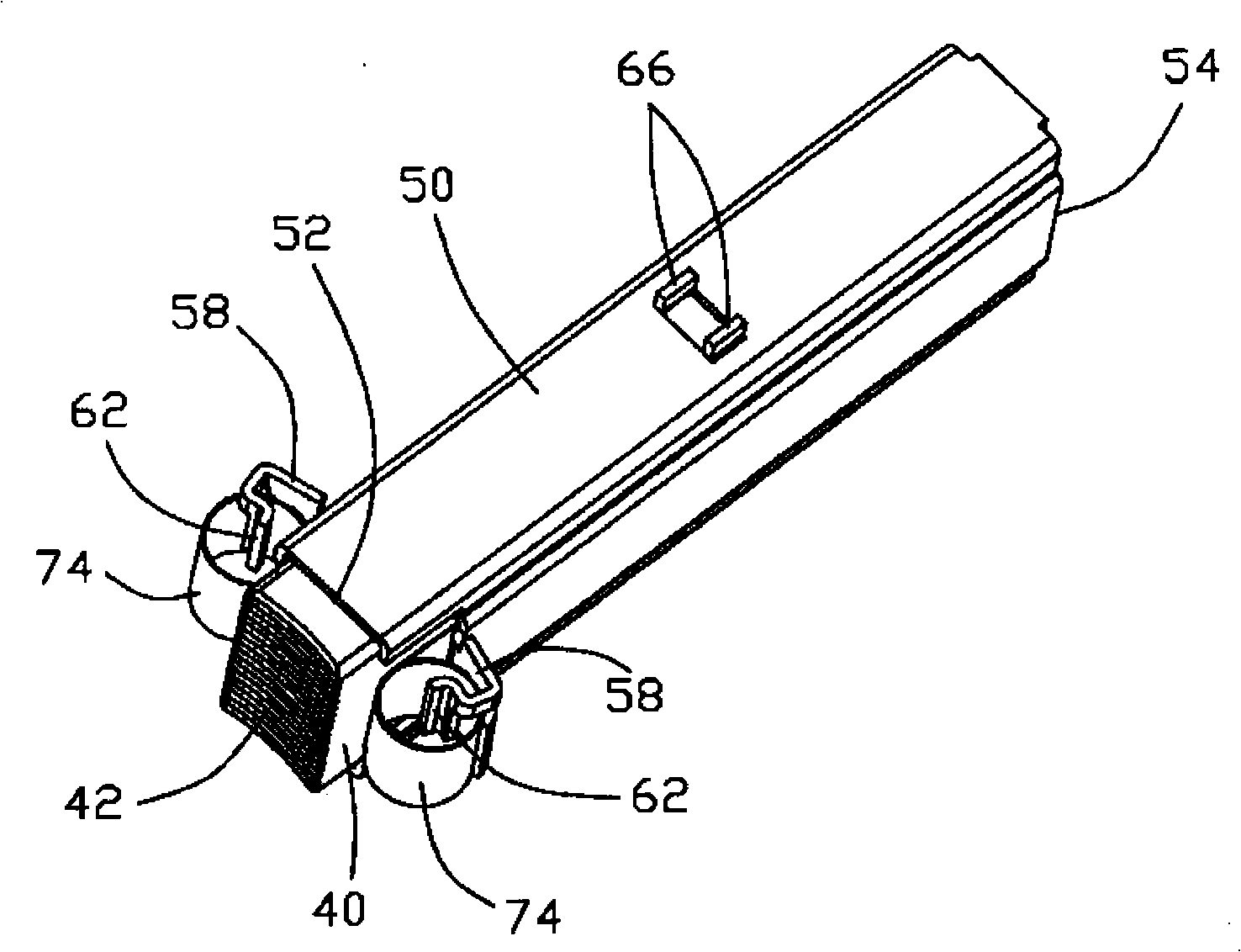

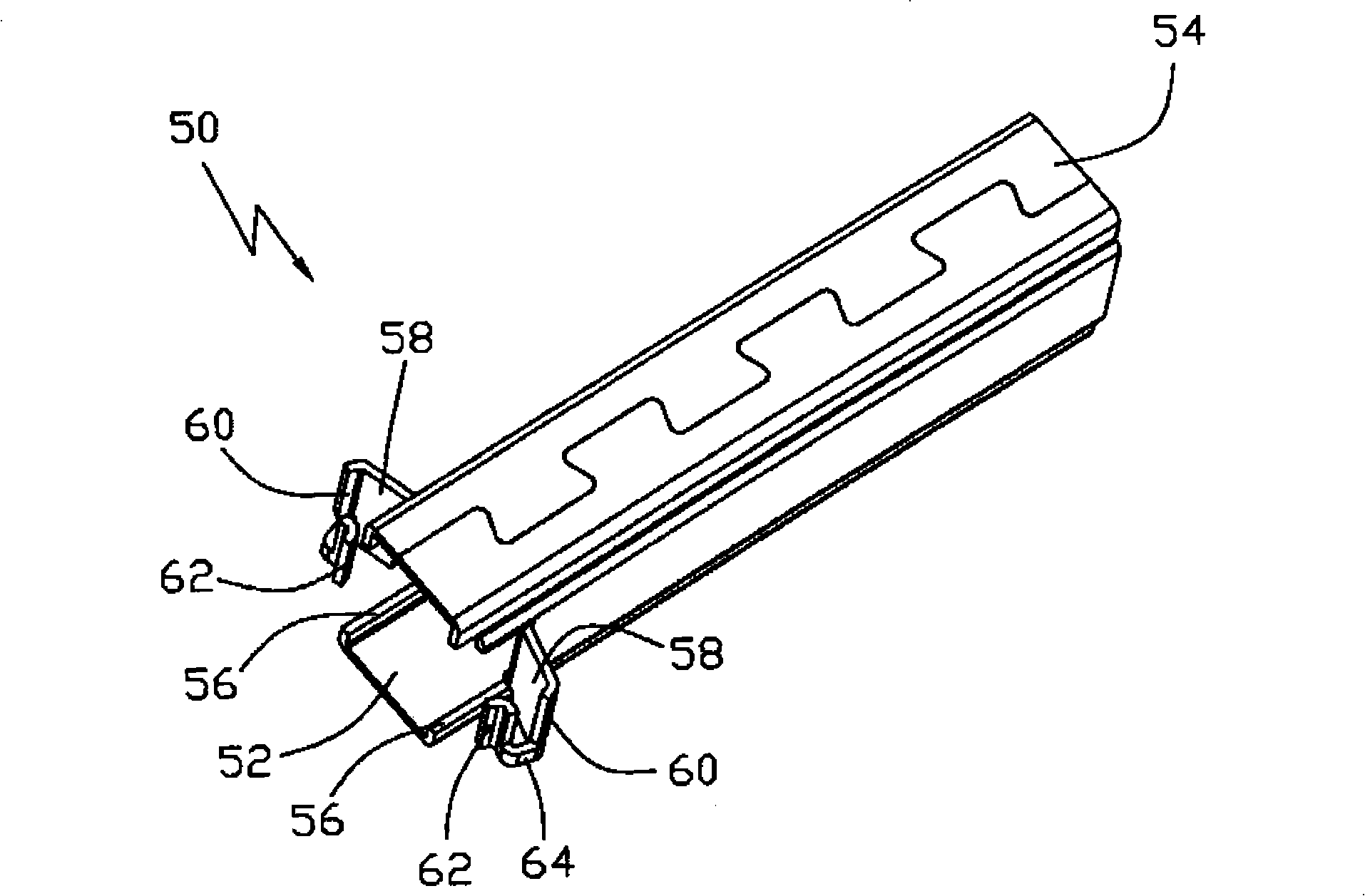

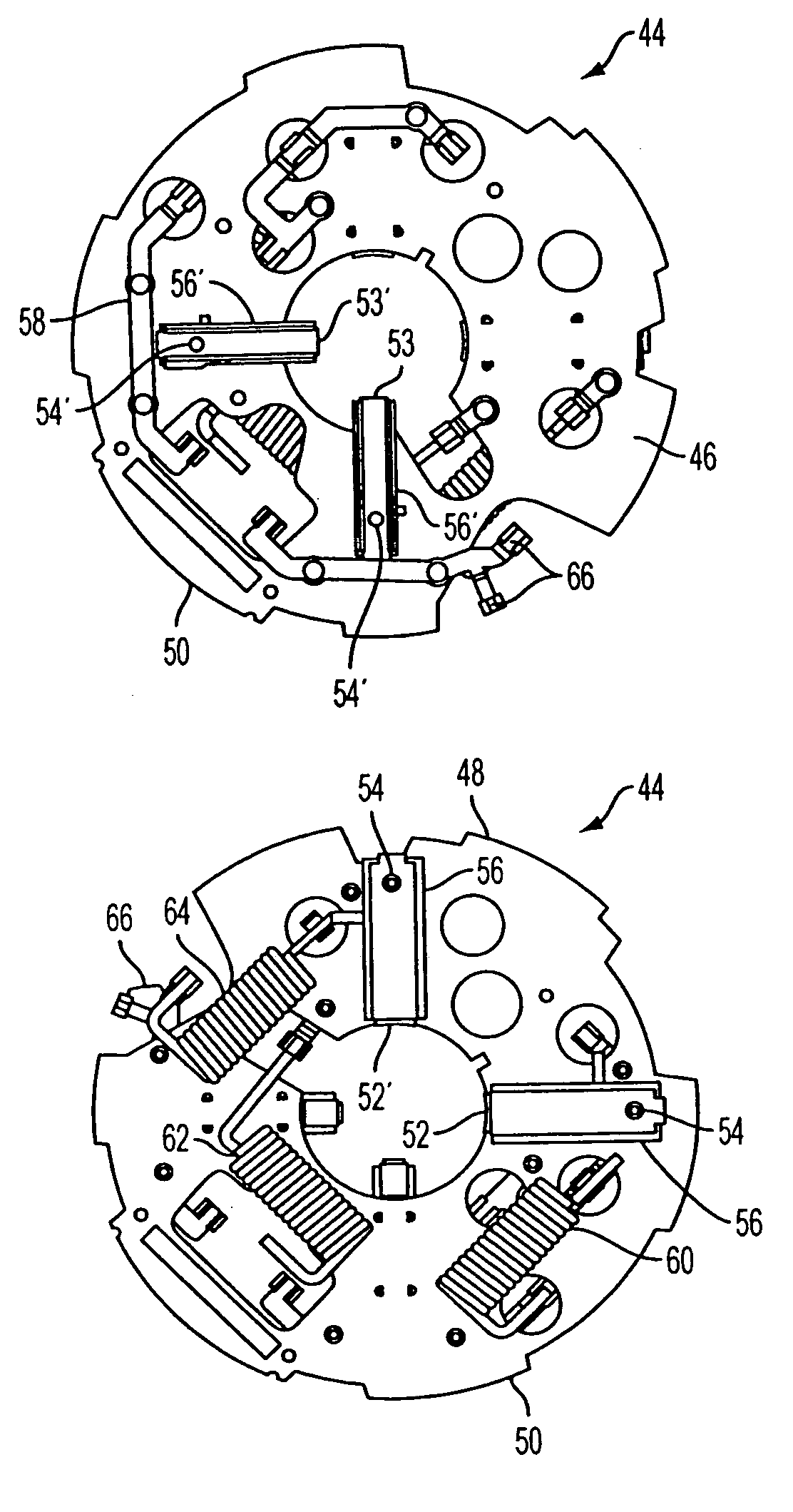

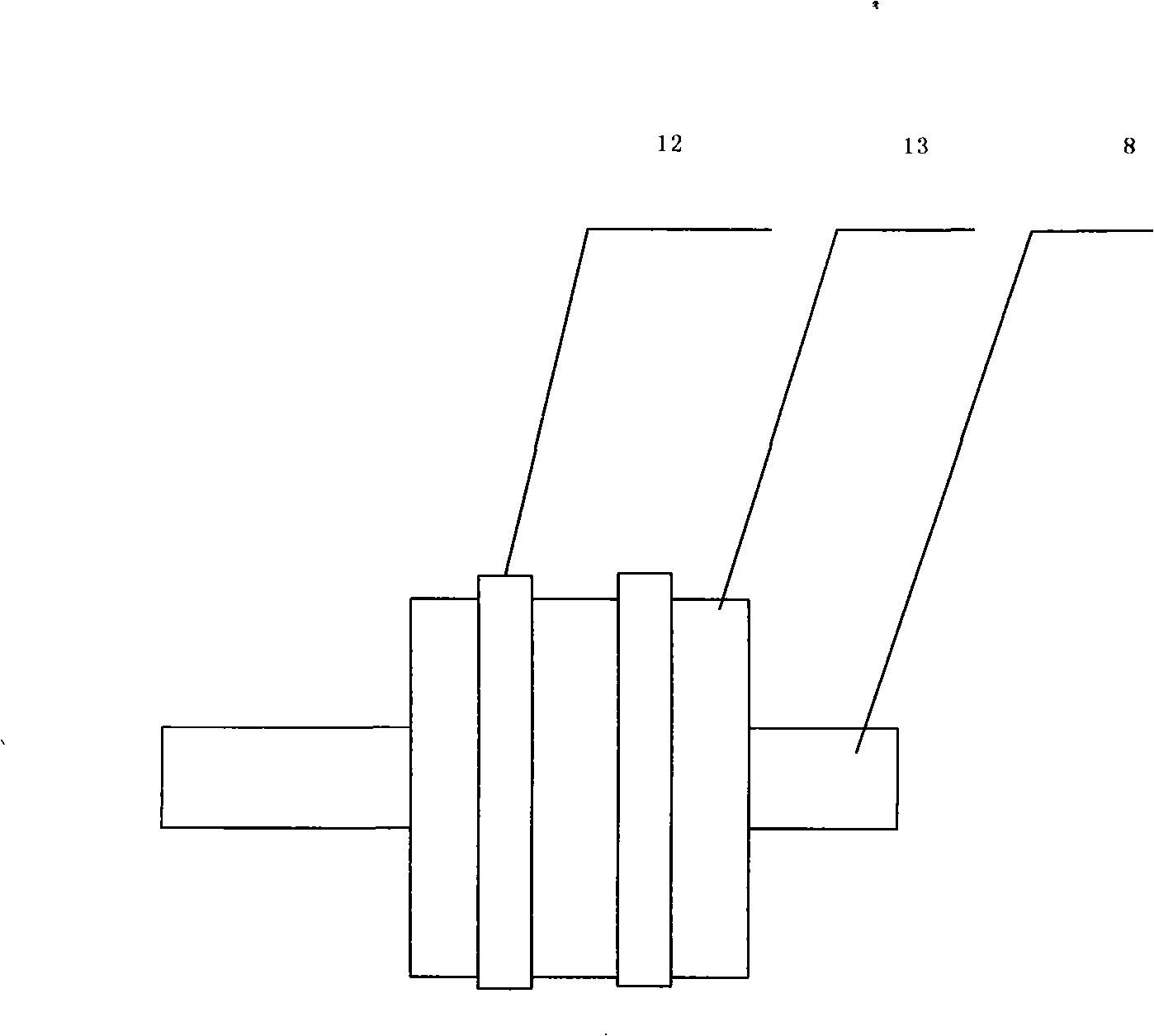

Two speed electric motor with link wound dual-commutator and dual-armature winding

InactiveUS20050225198A1Rotary current collectorMagnetic circuit rotating partsLow speedElectric machine

A permanent magnet D.C. electric motor includes a stator housing, permanent magnet structure, and an armature assembly. The armature assembly includes a shaft rotatably mounted in the stator housing, lamination structure, first and second coil windings associated with the lamination structure, a first commutator electrically connected with the first coil windings, and second commutator electrically connected with the second coil windings, each of the first and second commutators being generally cylindrical and having a plurality of commutator segments. Certain segments of the first commutator and certain segments of the second commutator are electrically connected. The motor also includes a brush card assembly including a high speed side having first brush structure associated with the first commutator, and a low speed side having a second brush structure associated with the second commutator, and switches for selectively connecting a D.C. voltage in such a way as to cause the armature assembly to rotate at a first speed and a second speed.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Stationary armature machine

The Stationary Armature Machine (SAM) comprised of a stationary armature, a stationary commutator affixed to the frame or housing and a rotating field and brushes affixed to a common shaft as a means for mechanical commutation of electrical currents based on Lorentz' force law. SAM's unique stationary armature increases current carrying capacity and heat abatement at low voltages and high rotating speeds without increasing overall physical size relative to BLDC motors. SAM's armature and field structure are arranged in reverse having the armature in a stationary position with a commutation assembly affixed to the machine's housing while said field structure (and brush assembly) rotate at the center of the machine. By making the armature and commutator assembly stationary, the current carrying conductors can be made much larger without being subjected to extreme centrifugal forces at high rotating velocities. SAM is ideally suited for applications that require high torque and power at high rotational speeds in a small inexpensive package.

Owner:RICHARD DOUGLAS ODELL

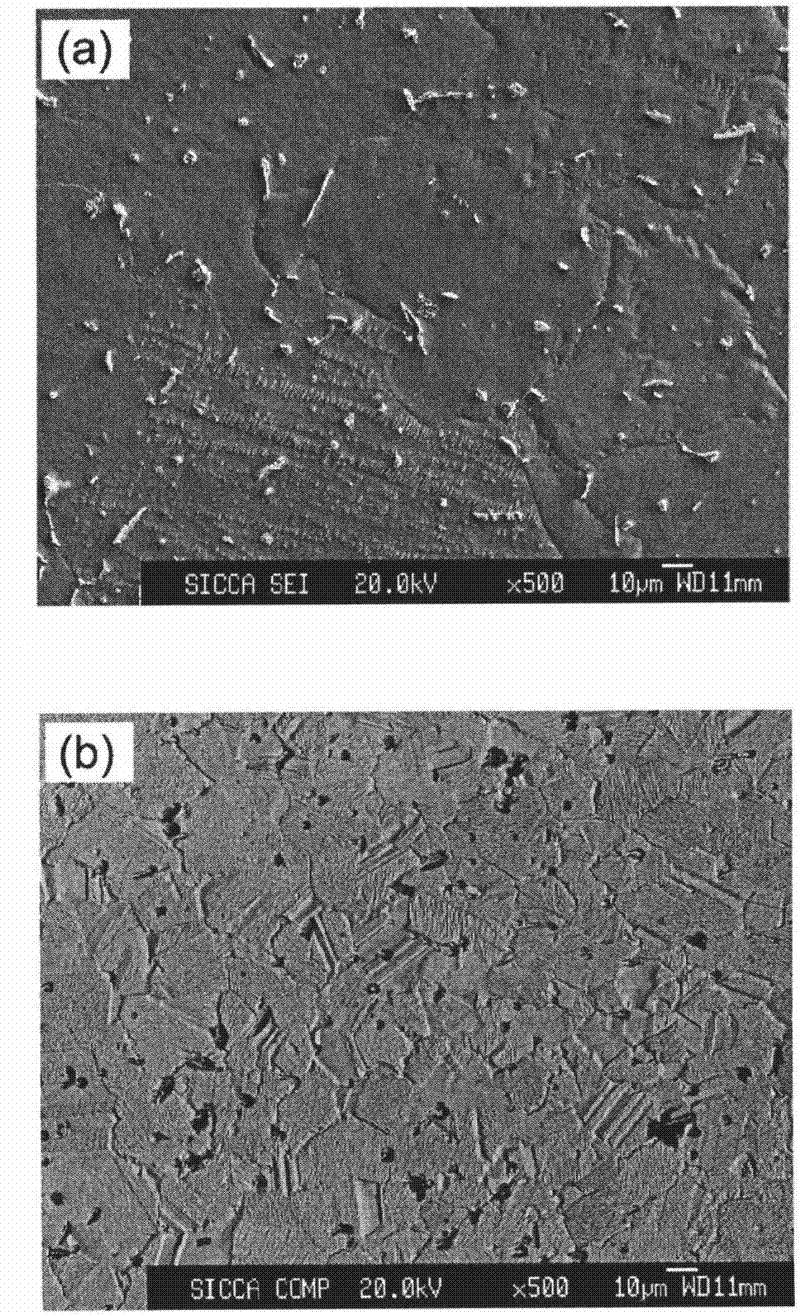

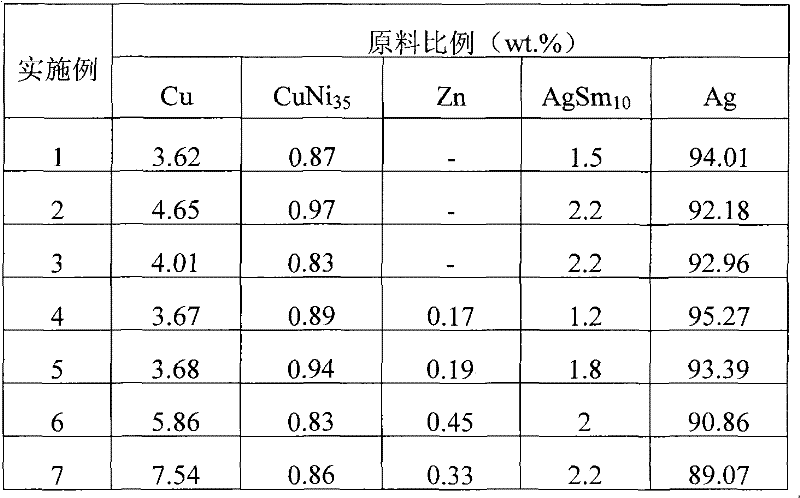

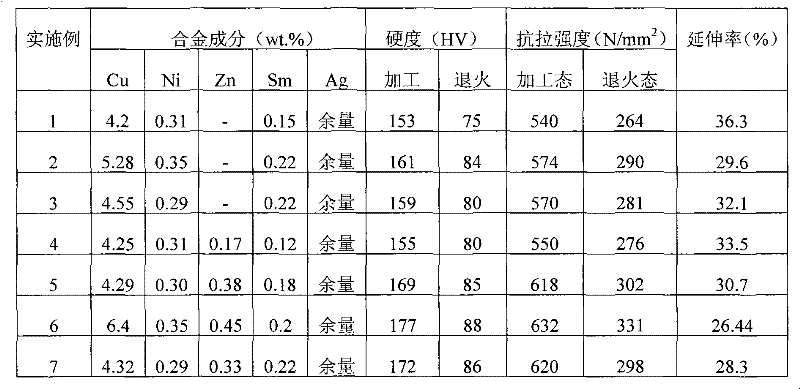

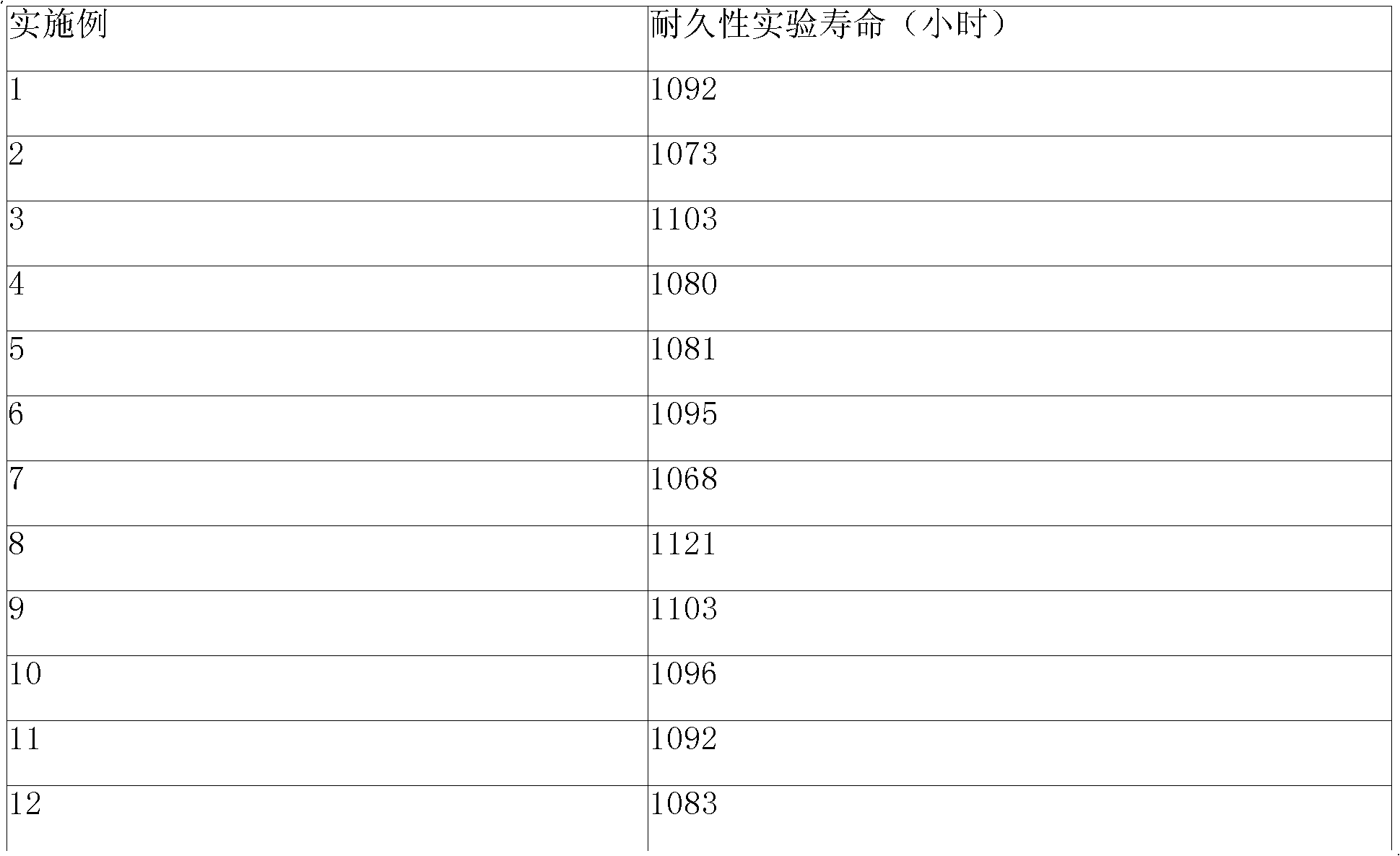

Silver-base rare-earth alloy material and preparation method and application thereof

ActiveCN102304640ASolve problems such as unstable contact resistance and reduced contact reliabilityImprove wear resistanceRare-earth elementMicro motor

The invention provides a silver-base rare-earth alloy material, which is characterized by comprising the following components in percentage by mass: 0.1 to 8 percent of Cu, 0.01 to 0.5 percent of Ni, 0.01 and 0.3 percent of Sm and the balance of Ag. By the silver-base rare-earth alloy material, the defect that the service life of the conventional silver-base composite material is reduced greatly due to unsuitability for high-temperature environment of a micro motor, the defect that materials are difficult to process due to substantial reduction of elongation of the materials caused by the addition of rare-earth elements in the silver-base composite material which is suitable for the micro motor and the like are overcome, so the invention provides a new silver-base rare-earth alloy material and a preparation method and application thereof. The silver-base rare-earth alloy material has the characteristics of high elongation, high recrystallization temperature, high hardness at high temperature, high abrasive resistance and the like, is suitable to be used as a sliding electric contact material, can be particularly used for manufacturing parts of a commutator of the micro motor and the like, and has the advantages of high quality and long service life at the high temperature of 70 DEG C.

Owner:深圳市深汕特别合作区中金岭南新材料有限公司

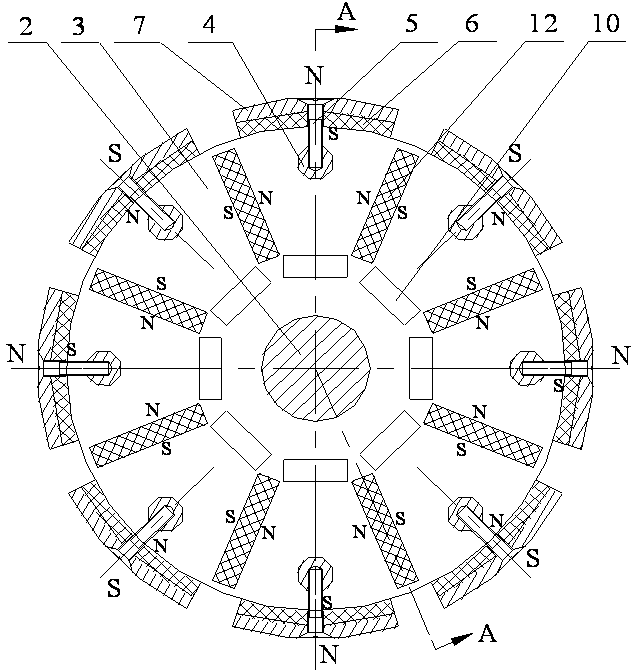

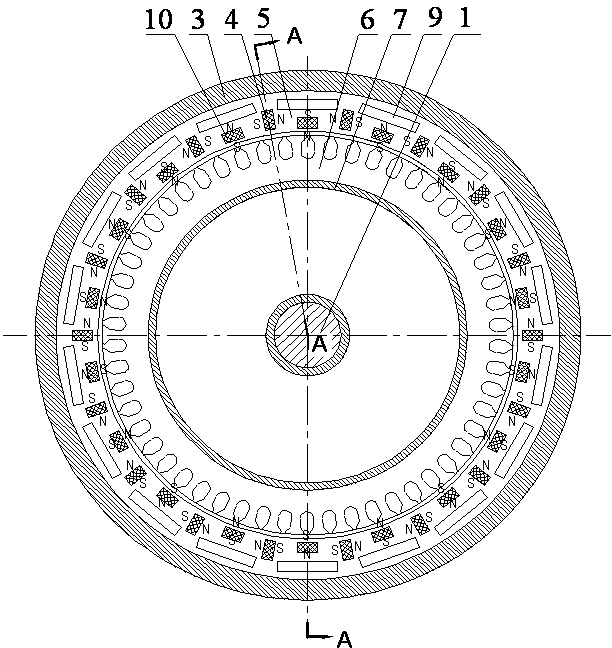

Hub drive motor with radial and tangential permanent magnet steel embedded in rotor

InactiveCN103944336AIncrease the magnetic field strengthIncrease output powerSynchronous machines with stationary armatures and rotating magnetsElectric machineDrive motor

The invention provides a hub drive motor with radial and tangential permanent magnet steel embedded in a rotor, and belongs to the technical field of automobile motor electric appliances. The hub drive motor with the radial and tangential permanent magnet steel embedded in the rotor is composed of a shaft, a front end cover, a rear end cover, a hub type motor shell, the rotor, a stator and a stator support. The rectangular permanent magnet steel is embedded in tangential rectangular grooves and radial rectangular grooves of a rotor iron core respectively, rotor fields of the hub drive motor are formed by tangential magnetic fields and radial magnetic fields jointly, the magnetic field intensity is large, output power is high, electric exciting windings are not needed, power consumption is little, carbon brushes and mechanical commutators do not exist, the fault rate is low, and the hub drive motor with the radial and tangential permanent magnet steel embedded in the rotor has the advantages of being high in efficiency, high in power density, compact in structure, reliable in work and the like.

Owner:SHANDONG UNIV OF TECH

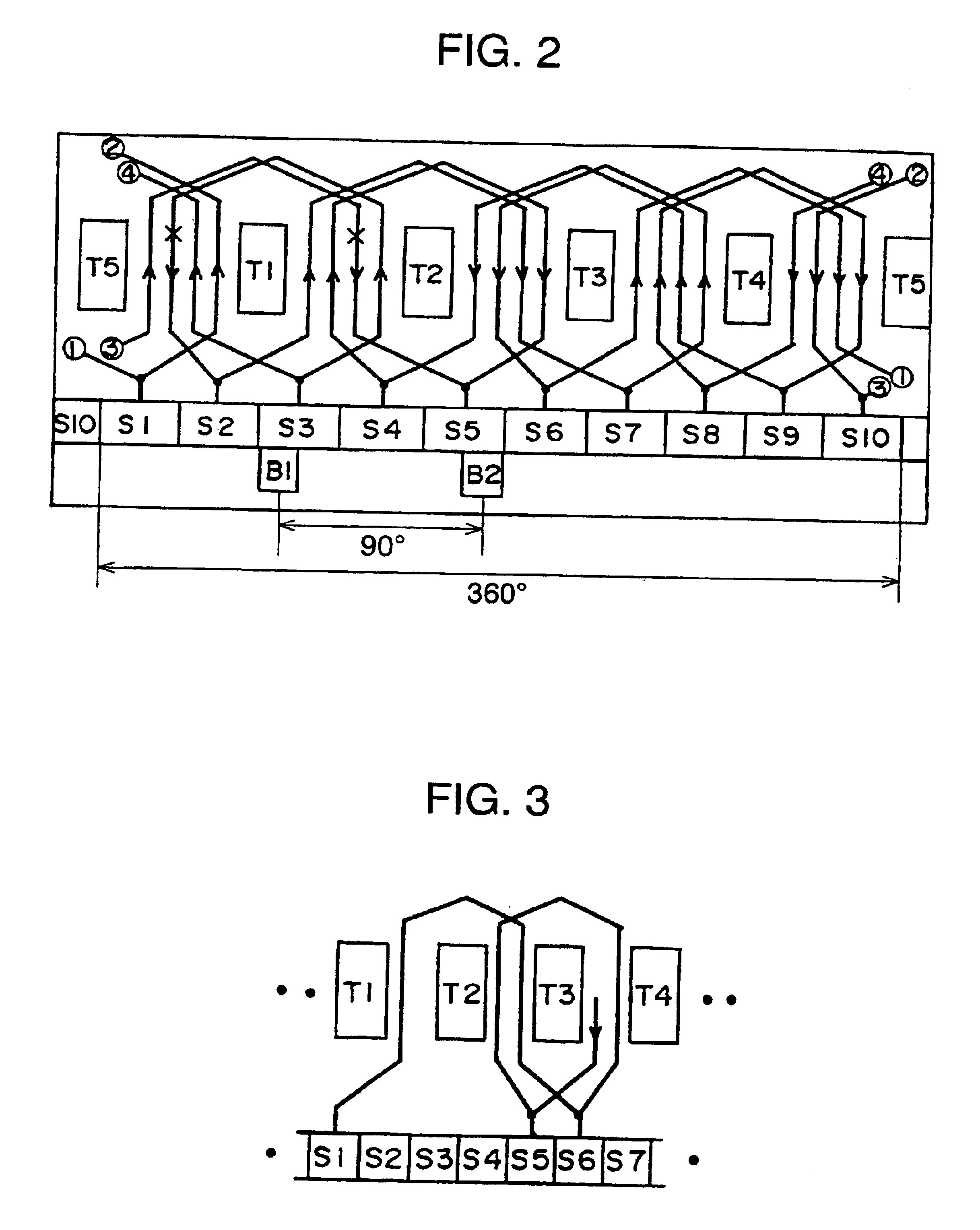

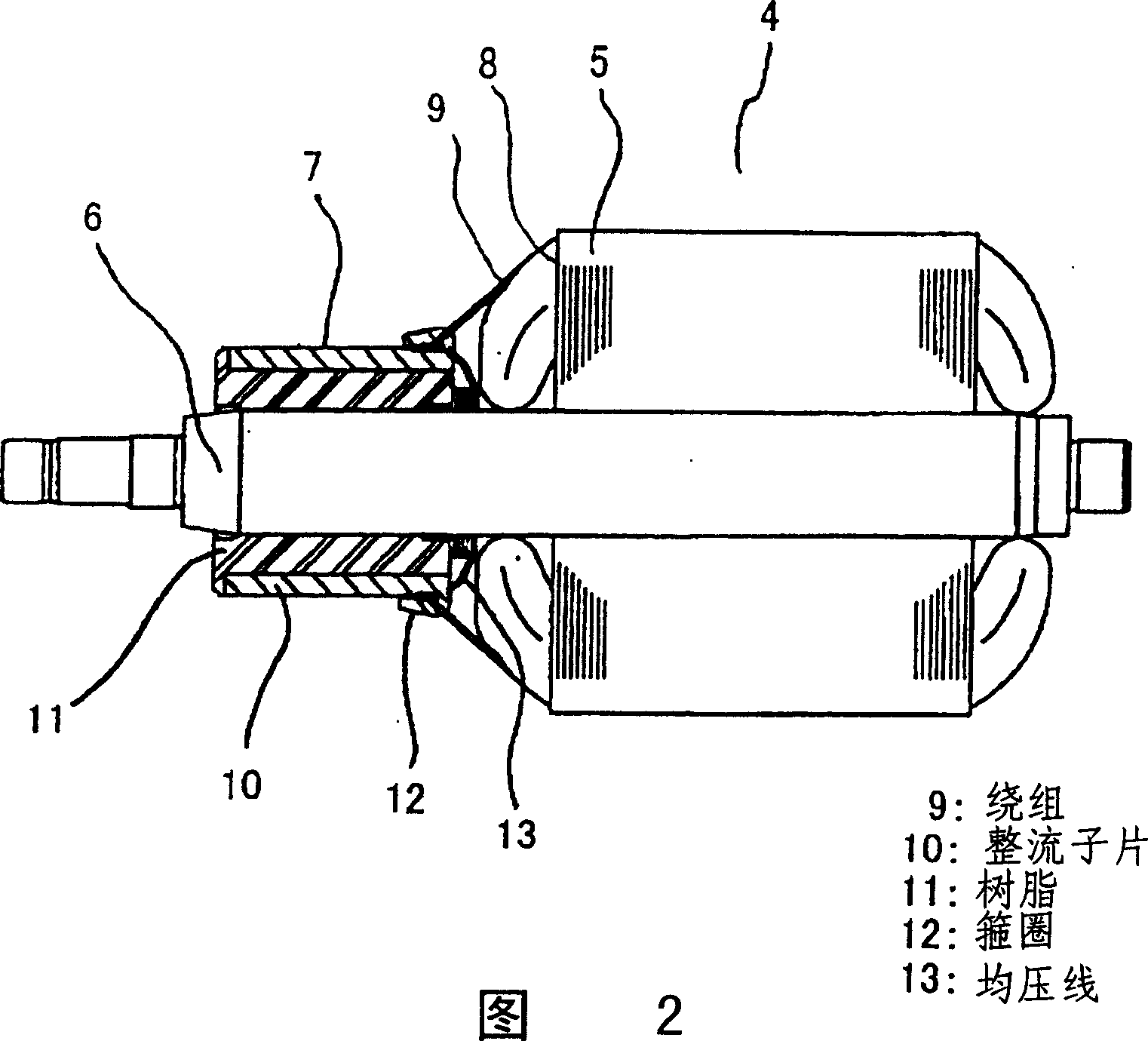

Electric brush motor for electric power turning device

A brush motor for an electric power steering system comprises a four-pole field portion 3, an armature 4 having windings 9 wound around a core 5 with 22 slots 8 to constitute a lap winding, hooks 12 which are formed on one ends of 22 commutator segments 10 respectively and on which the windings 9 are hooked, and a cylindrical commutator 7 constructed by molding integrally the commutator segments 10 with a resin, and four brushes 18 which contact slidably to outer peripheral surfaces of the commutator segments 10, wherein, when the commutator 7 to which a sliding contact portion of the brush 18 contacts is sectioned perpendicularly to an axial direction, a relationship of 0.18<=(AxN) / (DxD)<=0.23 is satisfied,where A is a sectional area of one commutator segment, N is a number of the commutator segments, and D is a diameter of outer peripheral surfaces of the commutator segments.

Owner:MITSUBISHI ELECTRIC CORP

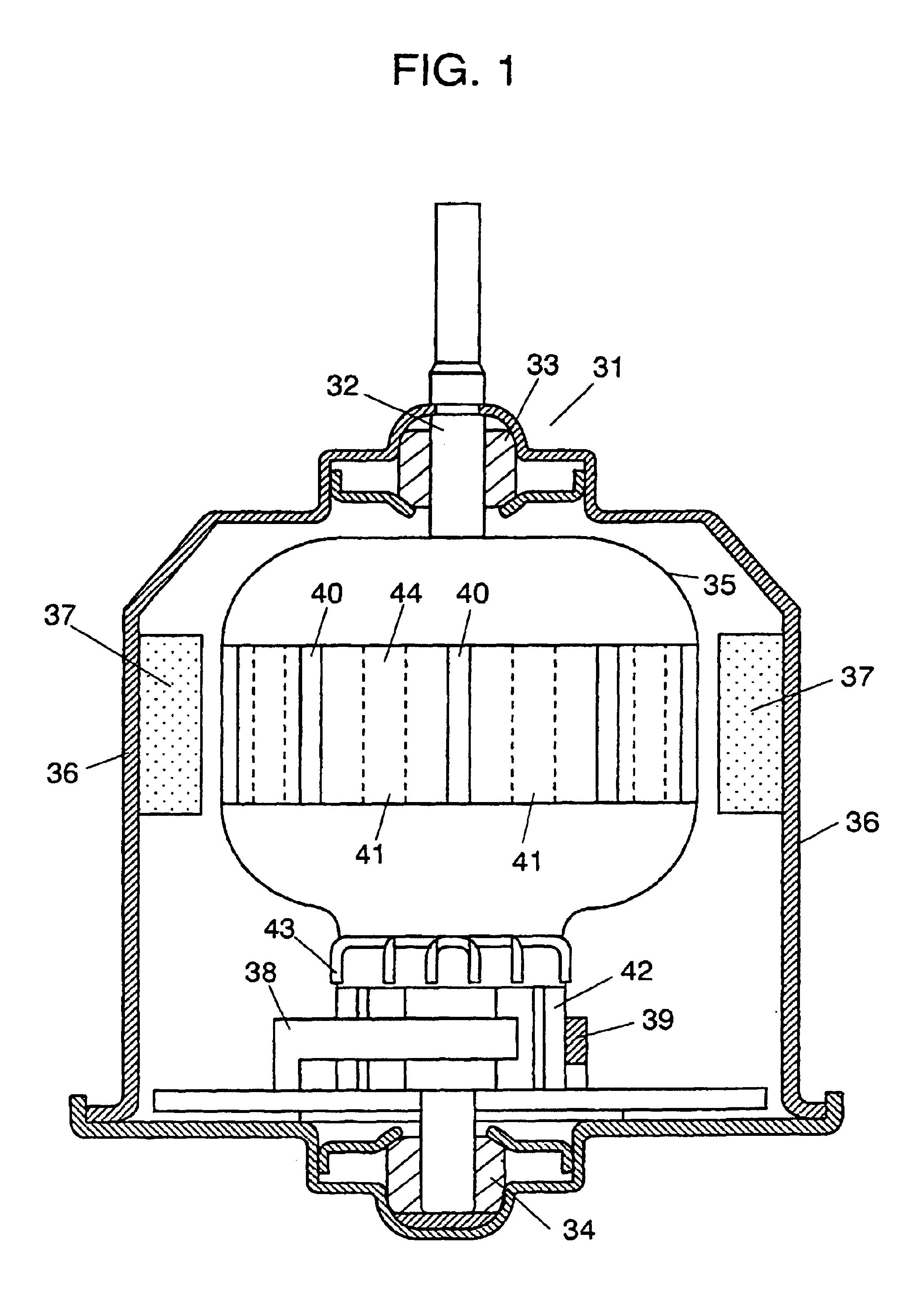

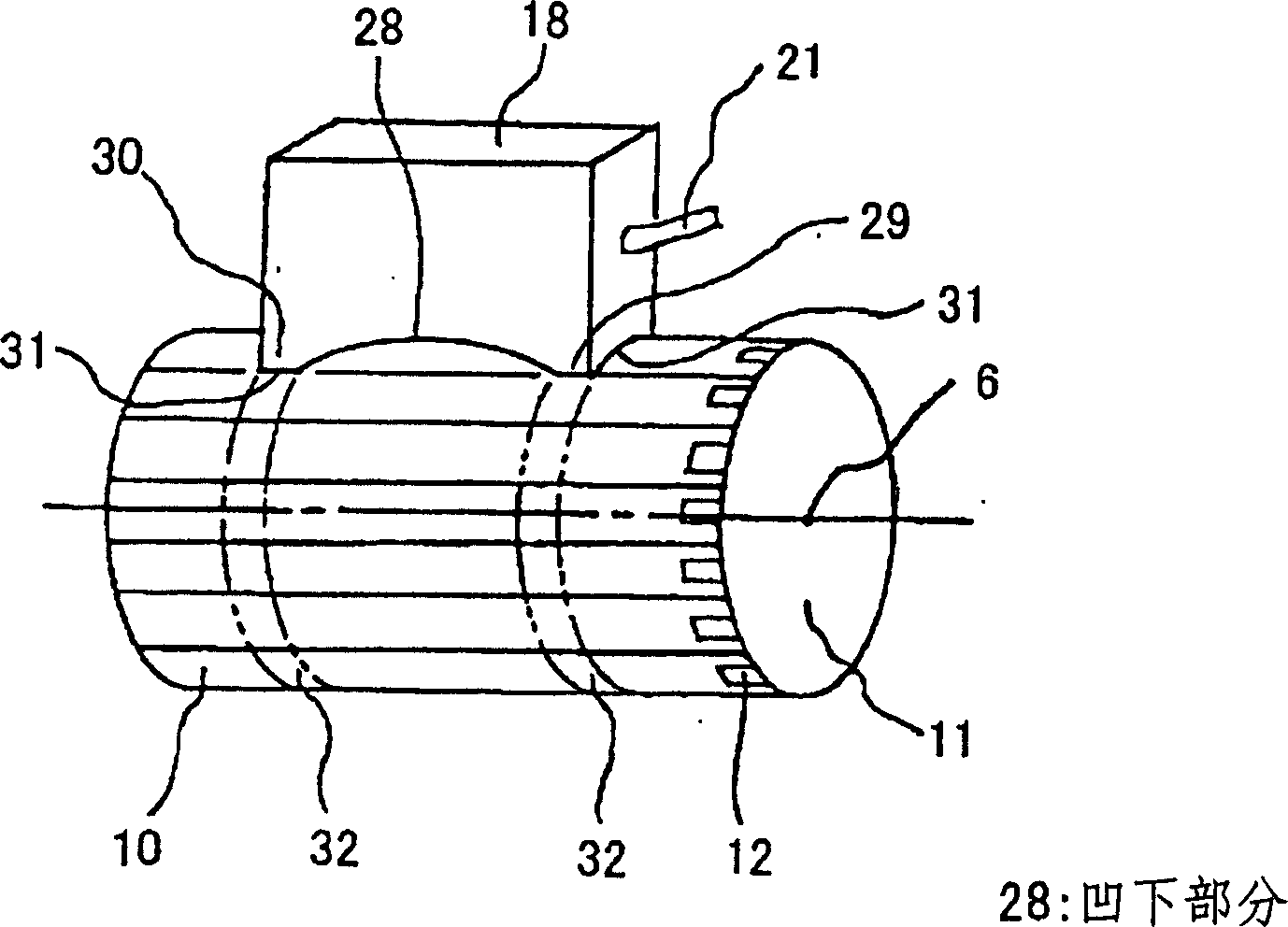

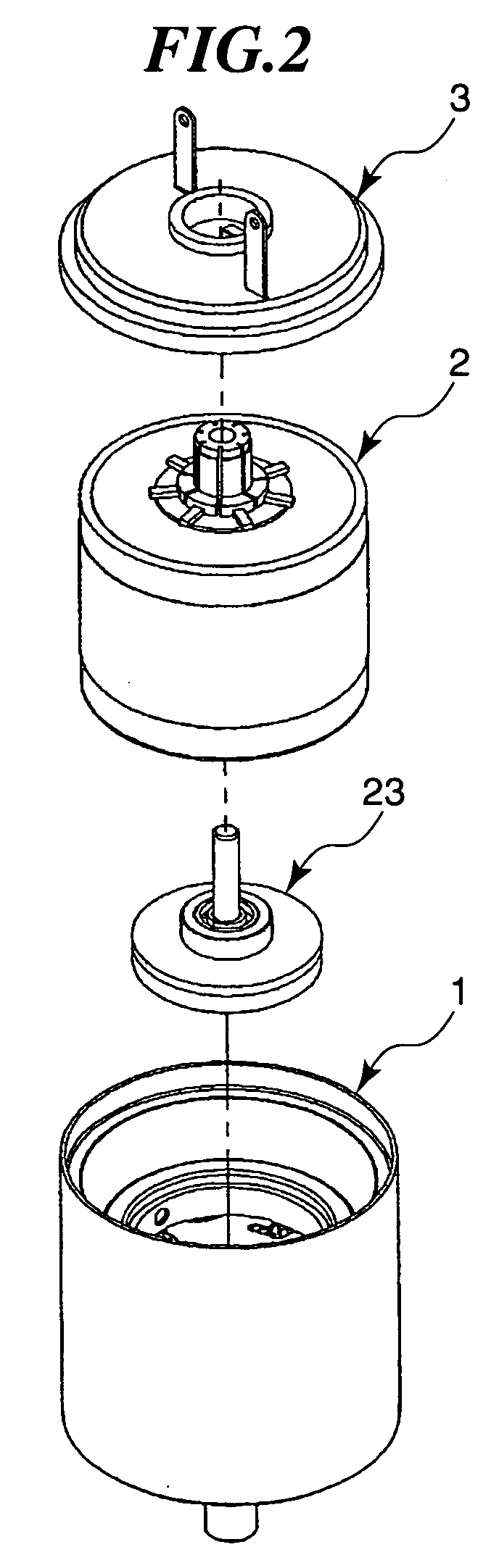

Coreless motor

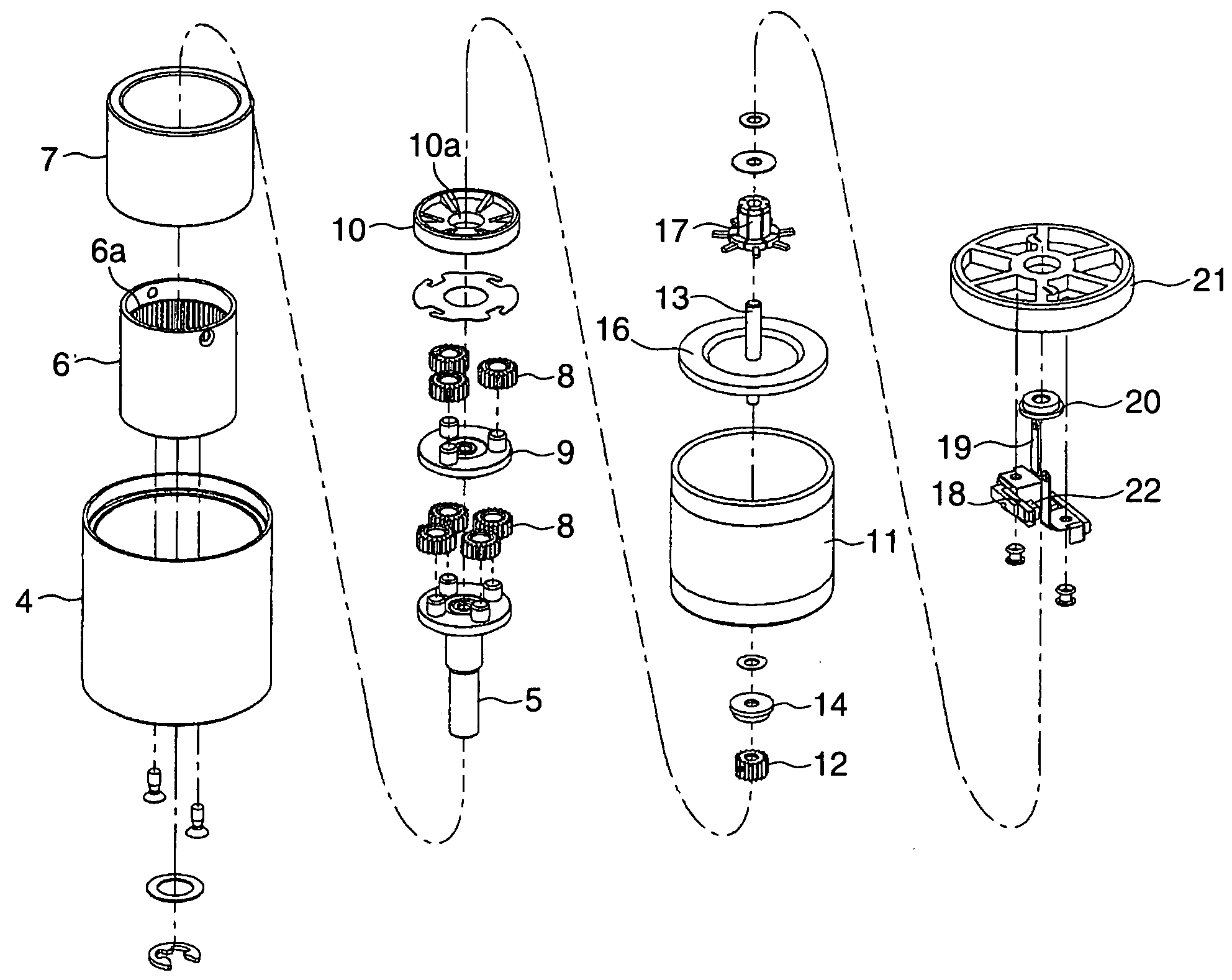

ActiveUS20090289514A1Easy to assembleEasy to guaranteeDC commutatorMechanical energy handlingBall bearingReduction drive

A coreless motor able to be downsized and easy to be assembled and to ensure the concentricity between a motor shaft, a magnet, and an outer cylinder. The coreless motor includes an outer cylinder gear unit having an output shaft and a speed-reducer mechanism incorporated into a field assembly having a magnet fitted on an inner yoke and an outer cylinder fitted on an outer periphery of the magnet, a motor shaft unit having an inner lid rotatably supporting a motor shaft via ball bearings, a rotor unit having a circular plate attached with a commutator electrically connected to a coil, an outer lid unit having an outer lid mounted with brushes. The inner lid is incorporated in the inner yoke, the coil is incorporated in between the outer cylinder and the magnet, and the outer lid unit is attached to the rotor unit and the outer cylinder.

Owner:CANON KK +1

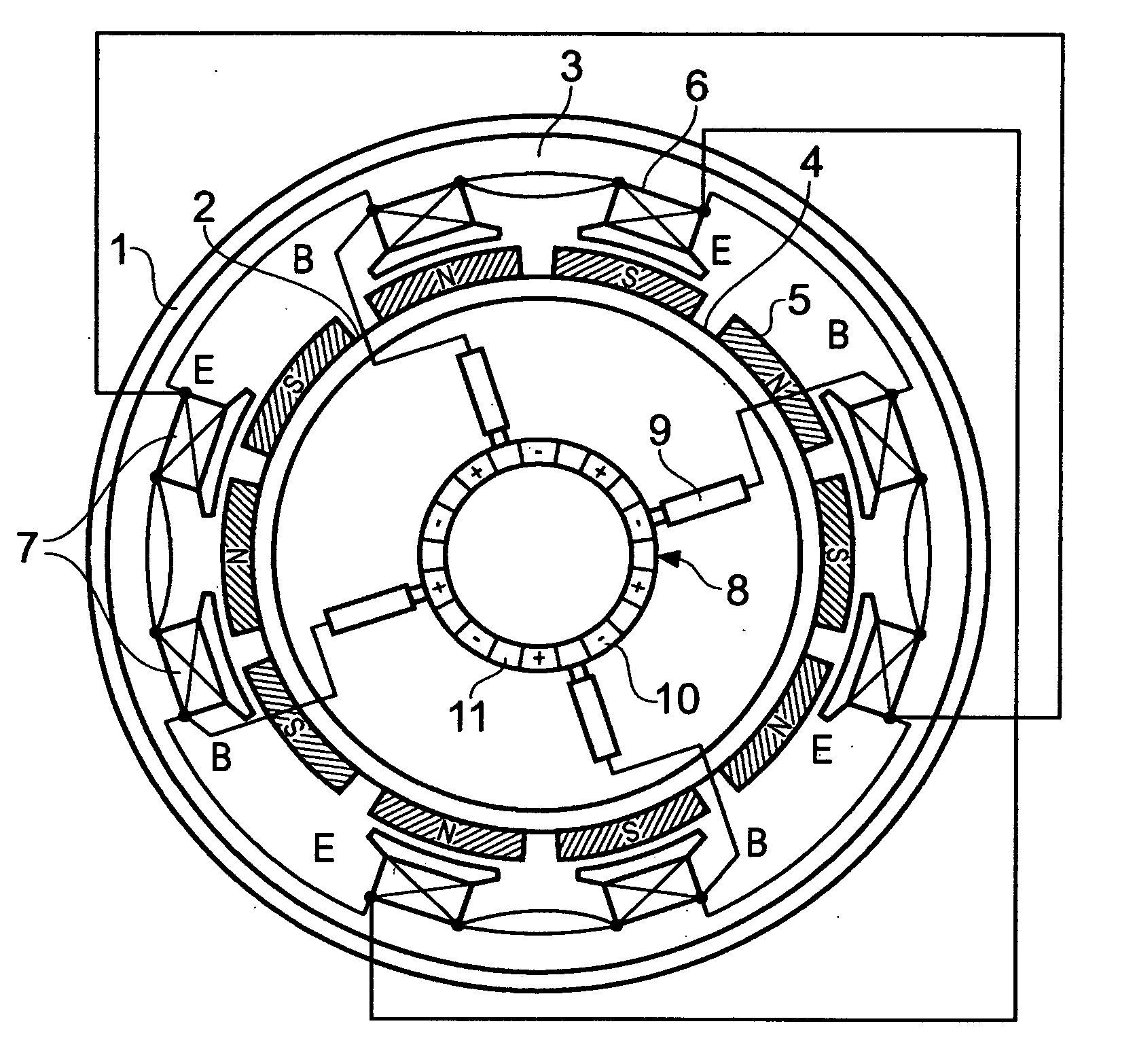

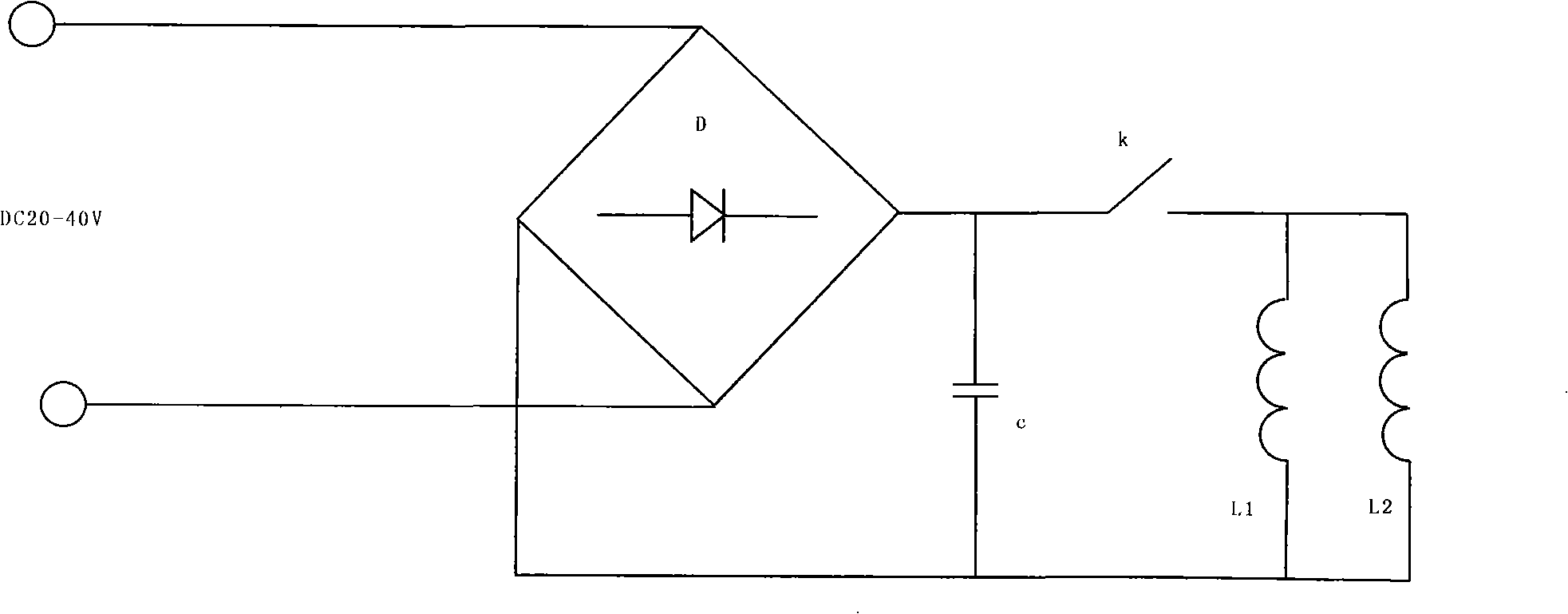

Pulsed-inertial electric motor

InactiveUS20060232154A1Improved performance characteristicsSimple designWindingsMagnetic circuitLow voltageDc current

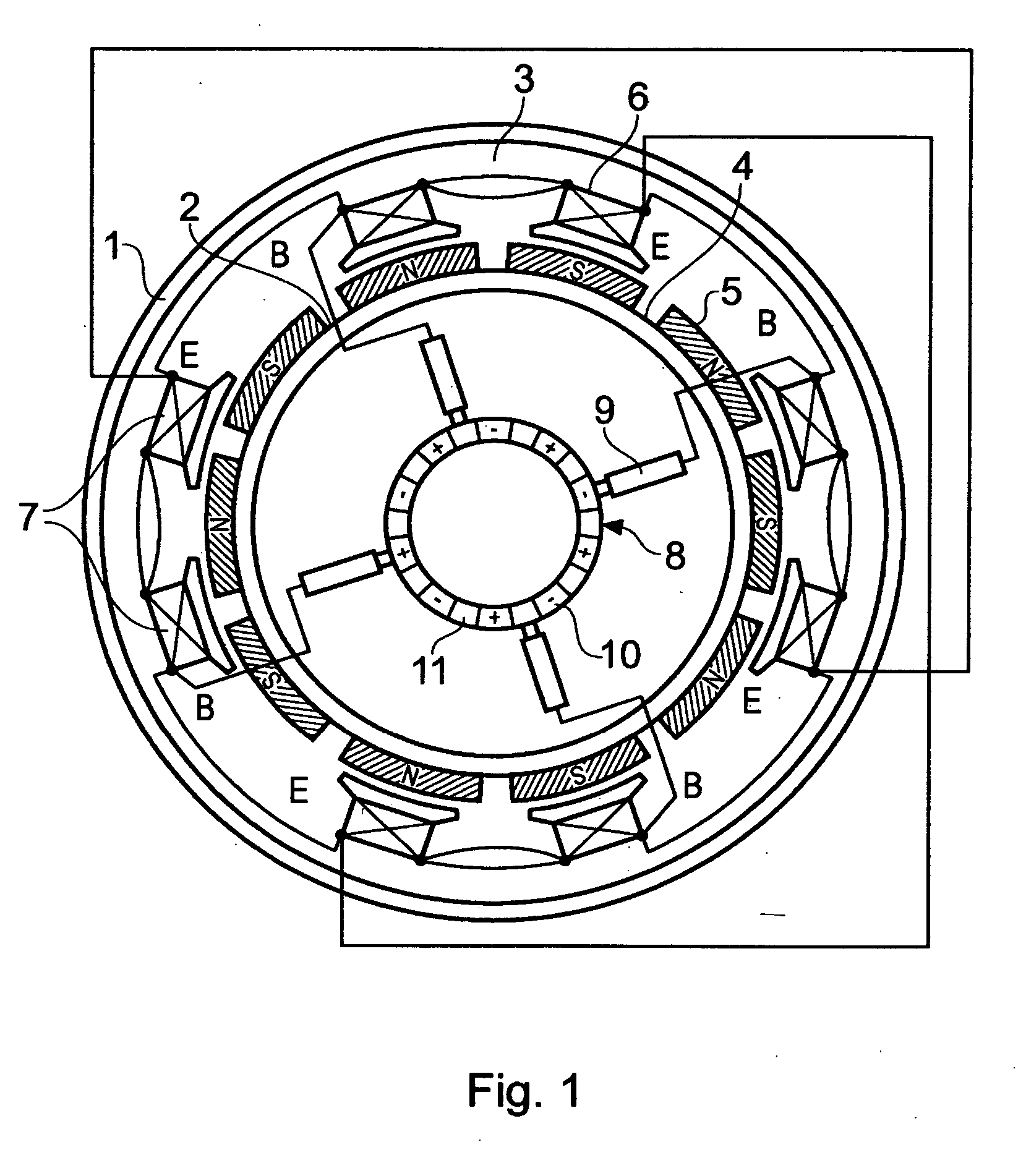

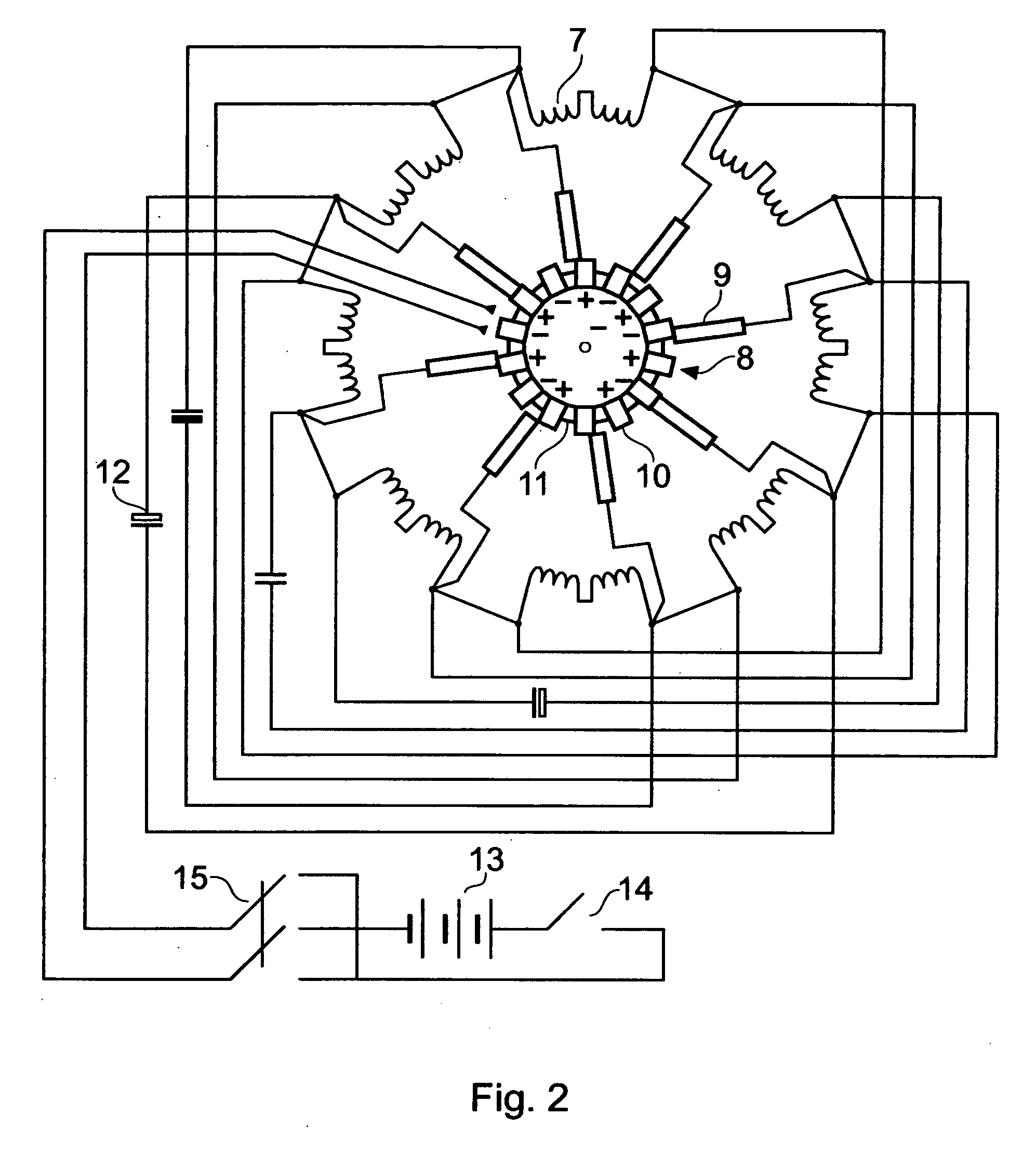

The invention relates to electric motors, particularly to low-voltage gearless commutator motors, and can be used as motor-wheels in transportation vehicles and in other technologies. The aim of the present invention is to provide an electric motor with increased performance characteristics, relatively simple design, and high reliability. A pulsed inertial electric motor according to the invention comprises: (i) a stator with circular magnetic conductor on which an even number of permanent magnets are uniformly arranged with a certain pitch; (ii) a rotor separated from the stator by air gap and bearing an even number of electromagnets, each electromagnet consisting of two coils with opposite winding directions connected in series, which are arranged over the circle in pairs one opposite to another; (iii) a collector distributor mounted on the stator body, containing circularly arranged current-conducting plates separated by insulating spacers and connected with alternating polarity to a dc current source, and (iv) current collectors-brushes mounted on the rotor and capable of contacting with plates of the collector distributor, whereby all brushes are connected to identical (beginning or end) terminals of the windings of said electromagnets and interconnected so that the coils in the opposite electromagnets are connected to each other via one identical terminal and to the opposite brushes via another identical terminal, with the number n of permanent magnets in the stator and the number m of electromagnets in the rotor selected so as to obey the relations n=10+4k, m=4+2l, where k is an arbitrary integer (k=0, 1, 2, . . . ) and l is any integer such that 0≦l≦k.

Owner:ULTRA MOTOR CO LTD

Sliding electrical contact material and electrical contact metal composite material

ActiveCN101677170AImprove wear resistanceImprove pollutionRotary current collectorElectricityTrace element

The invention discloses two Au-containing sliding electrical contact materials which respectively comprise the main components: Au, Ag, Cu and Y as well as Au, Ag, Cu, Pd and Y; and on that basis, thetwo materials are respectively added with one or more of the trace elements Zr, Cr, Ta and Ti, and the total content of the trace elements does not exceed 2%. The alloy has good wear resistance, arcresistant capability and organic pollution resistance, so as to be excellent sliding electrical contact material, thus being suitable for manufacturing a commutator of a DC motor.

Owner:CHONGQING CHUANYI AUTOMATION

Method and apparatus for controlling the position of an electric motor

InactiveUS20110169432A1InaccuracyAvoid problemsAir-treating devicesAC motor controlMotor speedEngineering

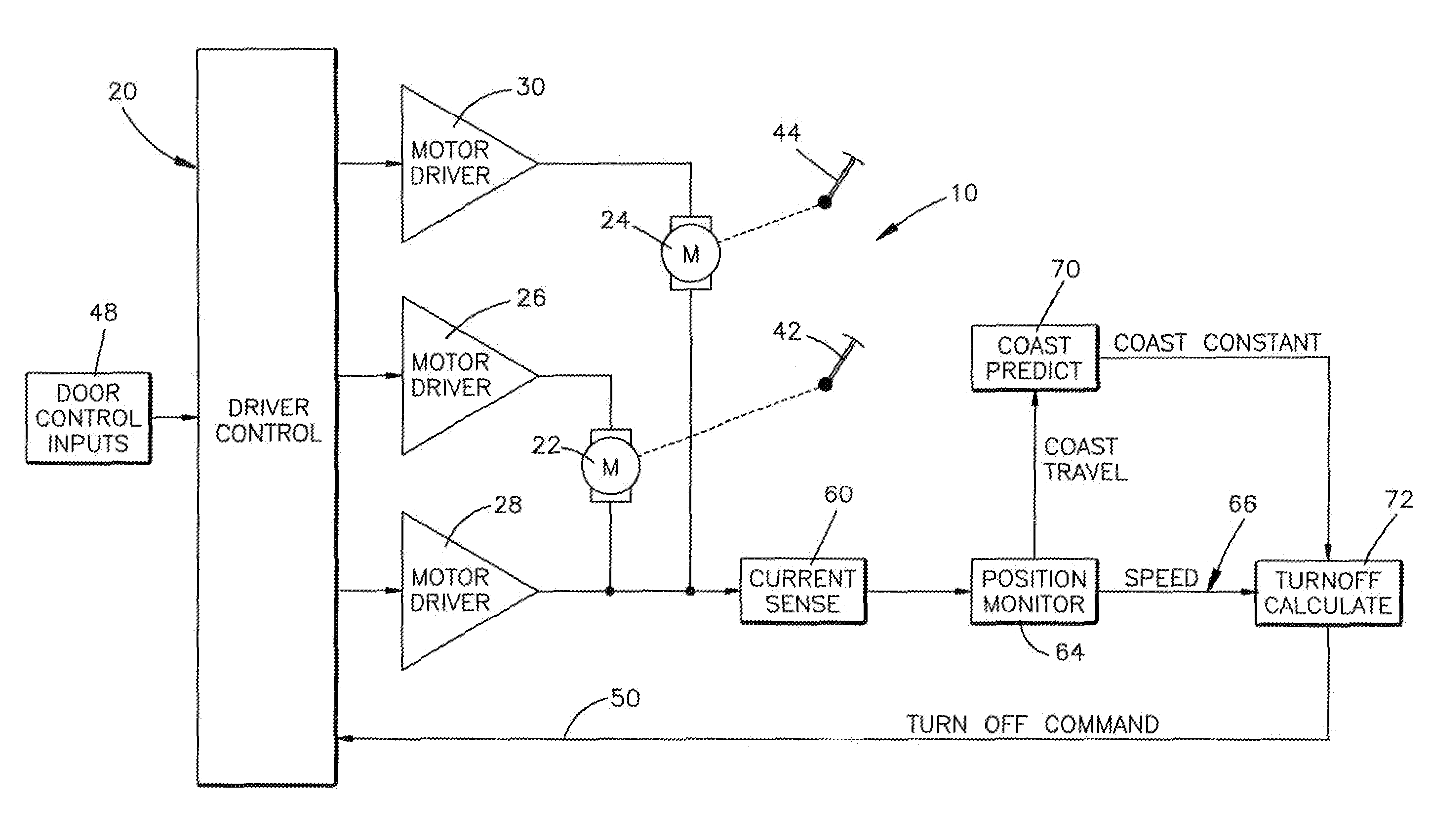

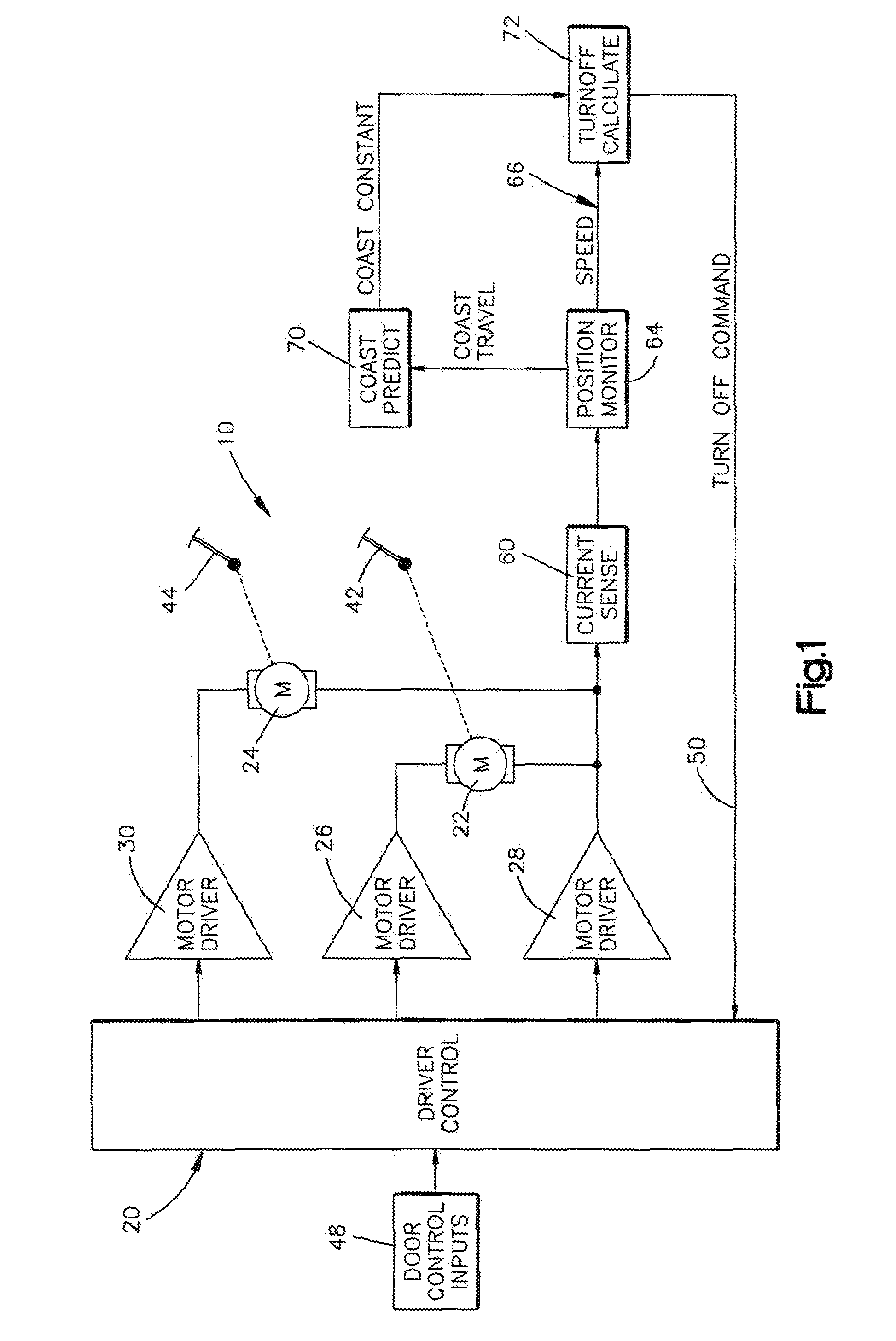

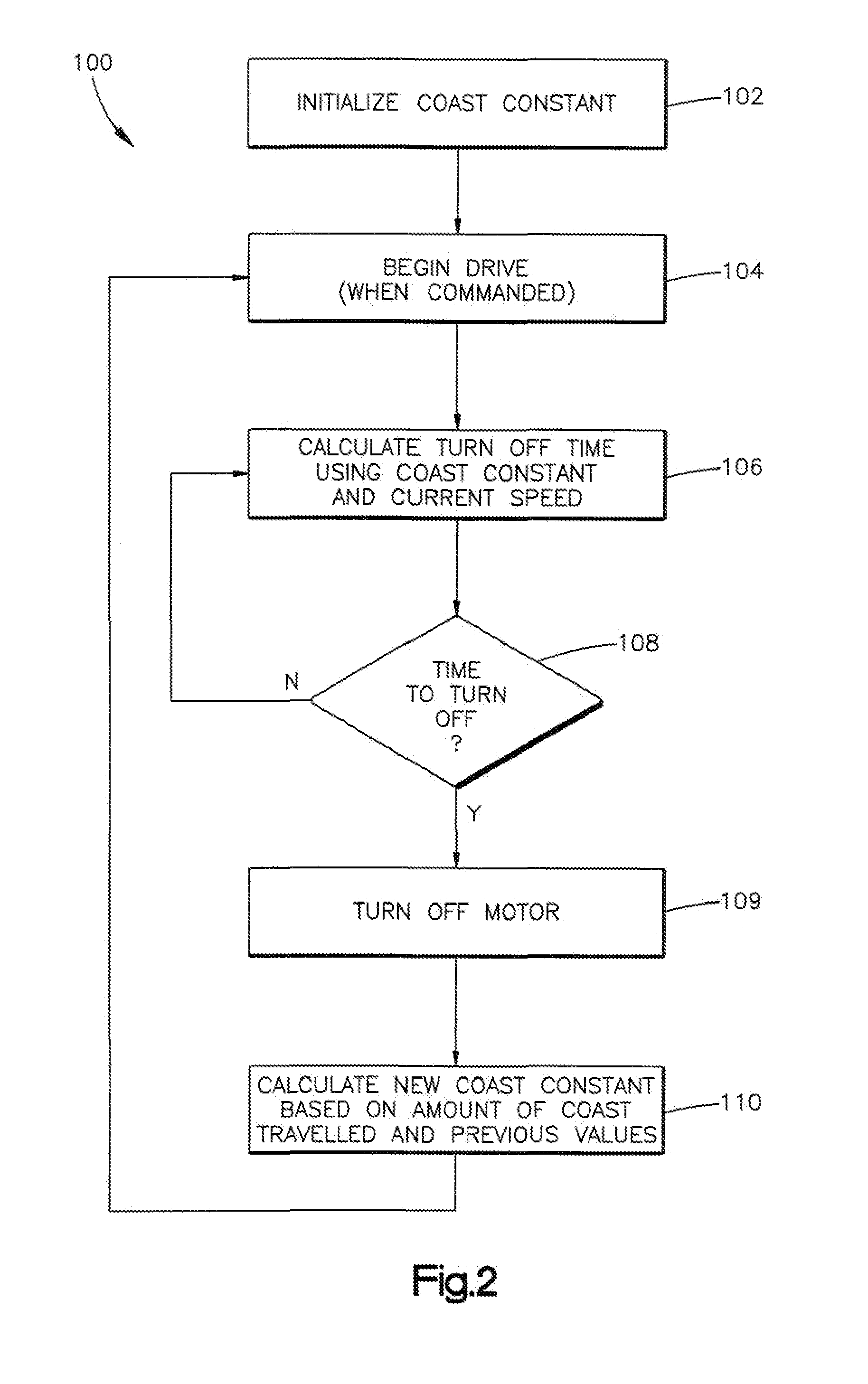

A method is provided for controlling a position of an electric dc brush motor (22, 24) including the steps of supplying drive current (104) to drive the electric motor and calculating (70, 108) a coast constant for the motor. Current through the motor is monitored (80) and motor speed (66) is determined in response to monitored motor current. Electrical current to the motor is interrupted (50) in response to the calculated coast constant (70, 106) and motor speed when it is desired to stop the electric motor so that a brush of the motor will come to rest at a location on a commutator segment of the motor (22, 24).

Owner:KELSEY HAYES CO

Built-in permanent magnet steel hub driving motor of electric vehicle

InactiveCN103887948AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorElectrical energy consumption

The invention provides a built-in permanent magnet steel hub driving motor of an electric vehicle and belongs to the technical field of automobile motor electric appliances. The built-in permanent magnet steel hub driving motor of the electric vehicle consists of a front end cover, a rear end cover, a hub casing, a rotor, a stator, a stator support and a shaft. Two pieces of completely-identical rectangular permanent magnet steel are respectively placed in two rectangular grooves forming a shape of a regular Chinese character 'ba' of a rotor iron core to form an N-pole, the other two pieces of completely-identical rectangular permanent magnet steel are respectively placed in a regular Chinese character 'ba' shaped groove formed by the other two adjacent rectangular grooves of the rotor iron core to form an S-pole, the rest can be done in the same manner to form the permanent magnet rotor with N-poles and S-poles arranged at intervals, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, and the failure rate is low.

Owner:SHANDONG UNIV OF TECH

Automobile air-conditioning evaporating fan with adjustable air volume, low noise and no interference

ActiveCN102900680AExtended service lifeAvoid electromagnetic interferenceMagnetic circuit rotating partsPump componentsLow noiseDC - Direct current

The invention relates to an automobile air-conditioning evaporating fan with adjustable air volume, low noise and no interference. The automobile air-conditioning evaporating fan comprises two hollow cylindrical centrifugal fans, two volutes, a resistance speed regulator and a permanent magnet direct current motor, wherein the two centrifugal fans are fixedly connected to two ends of a center rotating shaft of the direct current motor; the sealing volutes for allowing air to enter from the end part are arranged outside excircles and the end faces of the centrifugal fans; and the resistance speed regulator is connected between a direct current power supply and the direct current motor in series. According to the automobile air-conditioning evaporating fan disclosed by the invention, the resistance speed regulator can be used for adjusting the air volume; blades of the centrifugal fans are arrayed in a non-equidistant way, so that noises are reduced; the volutes accommodate the centrifugal fans, so that air leakage and pressure relief are avoided; an electric brush box is lengthened and the service life of an electric brush is prolonged; a flowing channel for generating electromagnetic waves is arranged on a line of an electric brush device and is combined with an electric spark-free commutator, so that the possible electromagnetic interference of the whole motor to vehicle-mounted television and telephone and the like is basically eliminated; and a clearance is reserved between a motor casing and an end cover and the temperature rise of the motor is reduced, so the automobile air-conditioning evaporating fan adapts to the operation at high temperature in summer.

Owner:JIANGSU YATAI MECHANICAL & ELECTRICAL

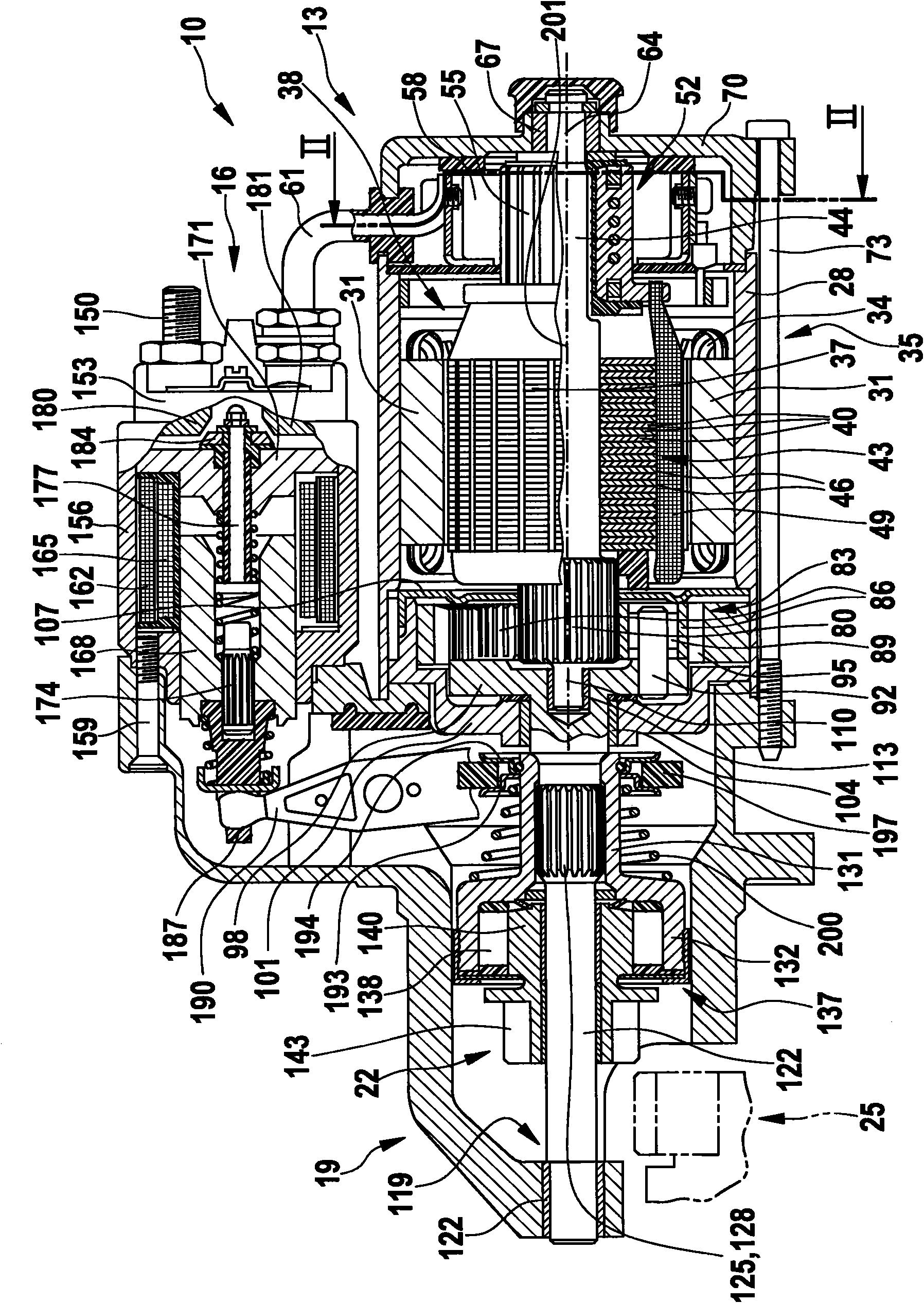

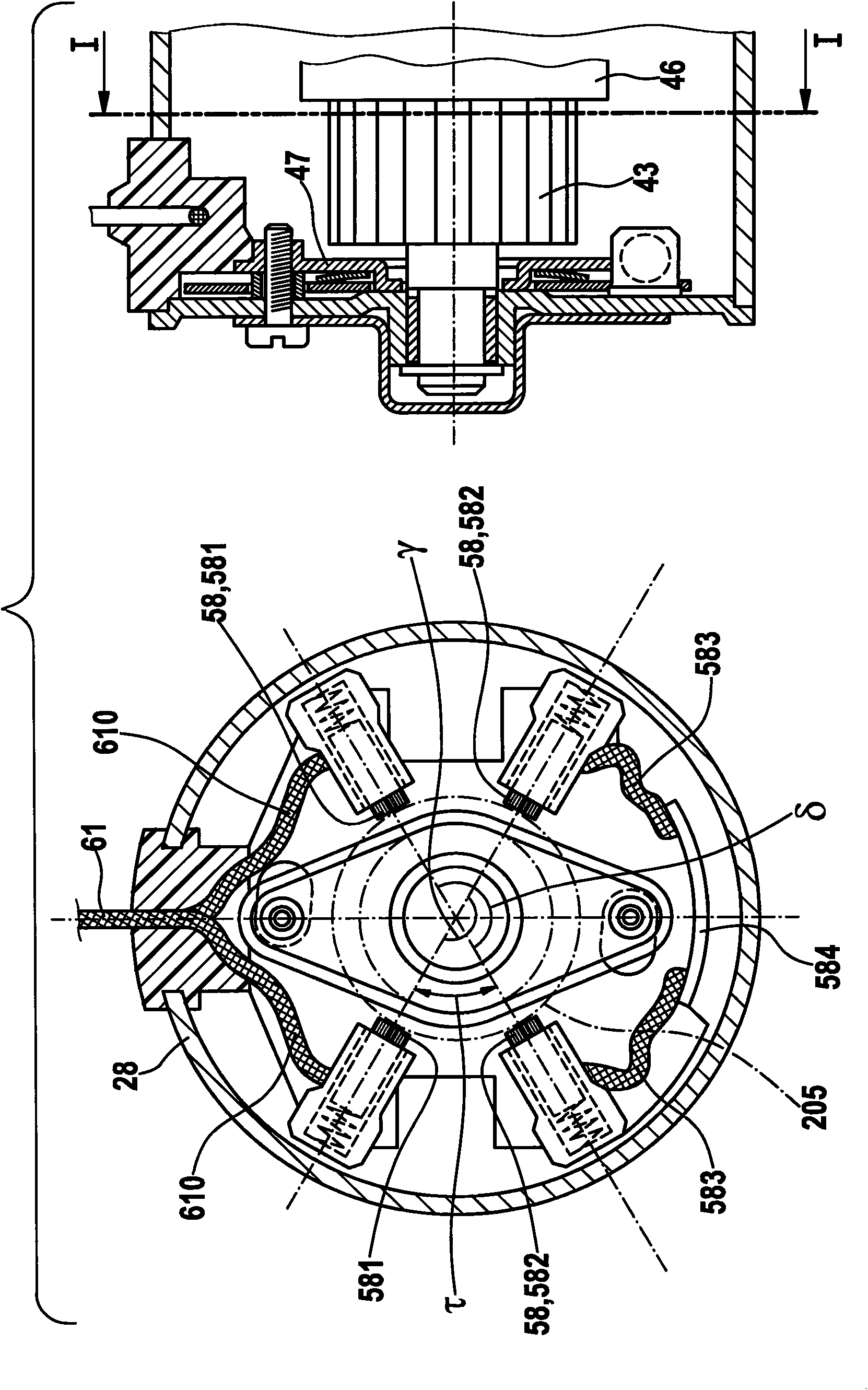

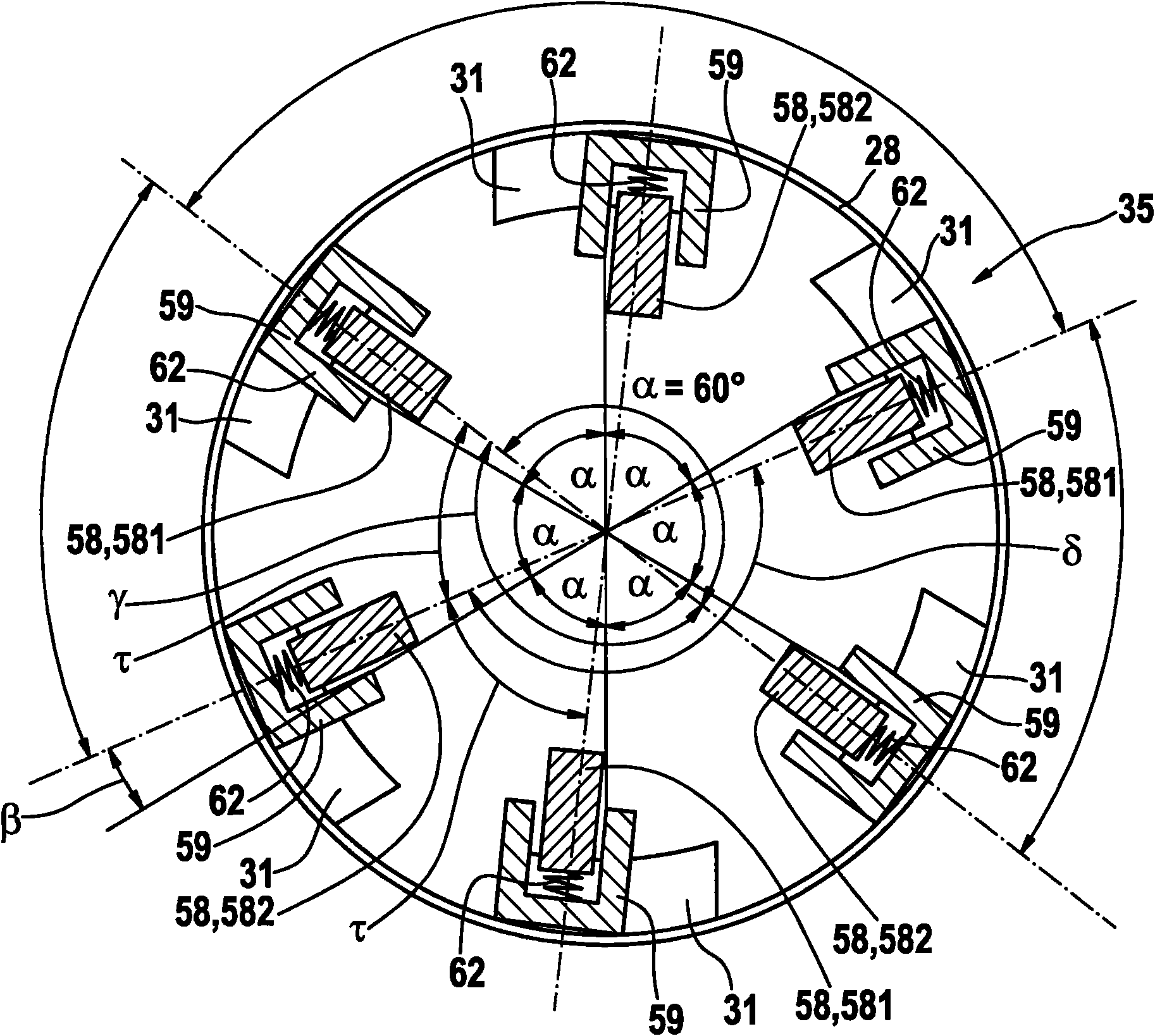

Electrical drive machine having stator and rotor

An electrical drive machine having a stator (35) and a rotor (38), wherein said rotor (38) carries a rotor winding (49) in grooves (46), which can be supplied with electrical current via a power supply system made of a commutator (52) and sliding contacts (58), wherein said sliding contacts (58), which press on a surface of said commutator (52), have at least two pairs made of one positive sliding contact (581) and one negative sliding contact (582) each, wherein said positive sliding contact (581) and said negative sliding contact (582) oppose one another at an angle which deviates by 180 DEG in at least a first pair of one positive sliding contact (581) and one negative sliding contact (582).

Owner:SEG AUTOMOTIVE GERMANY GMBH

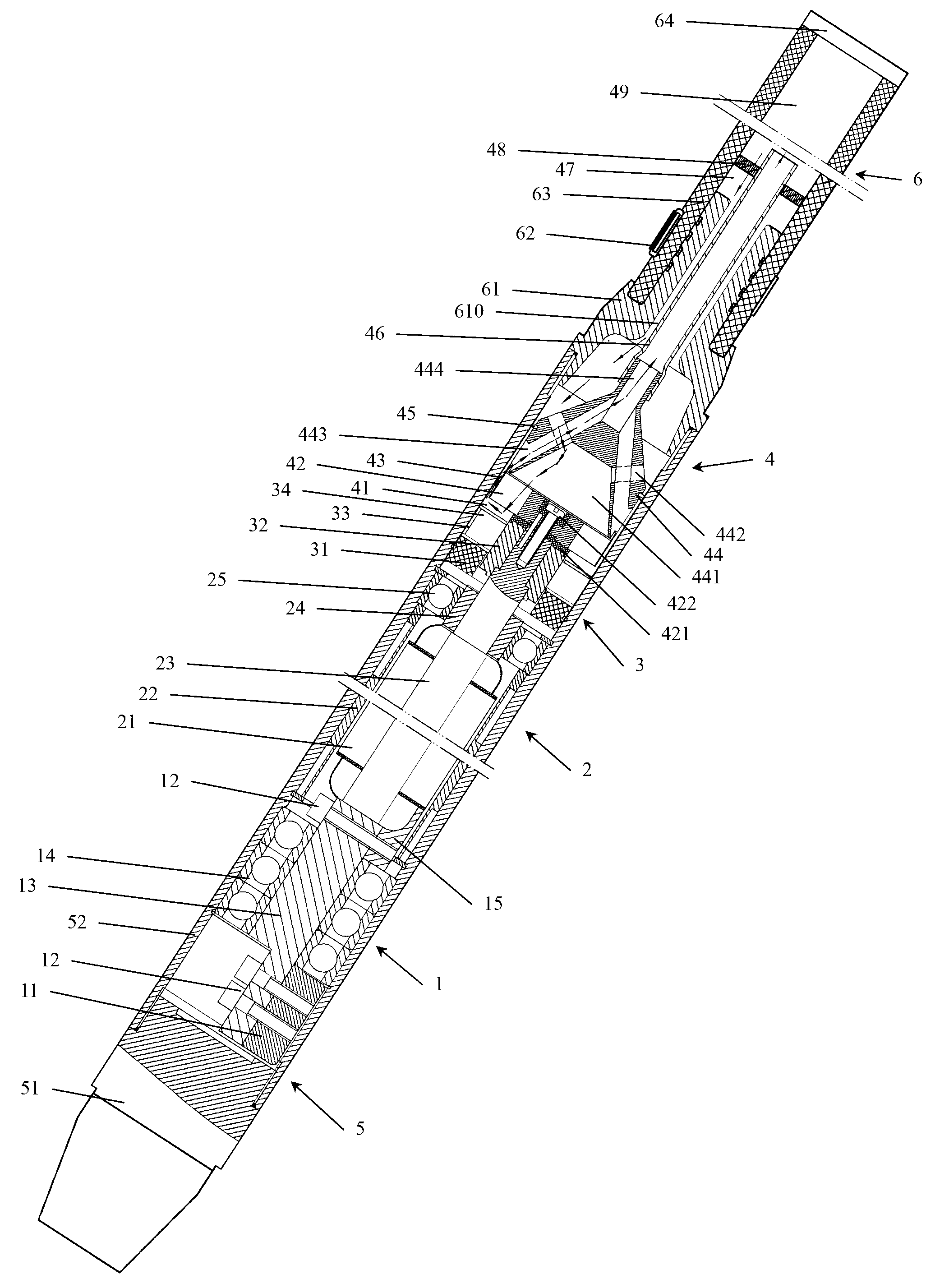

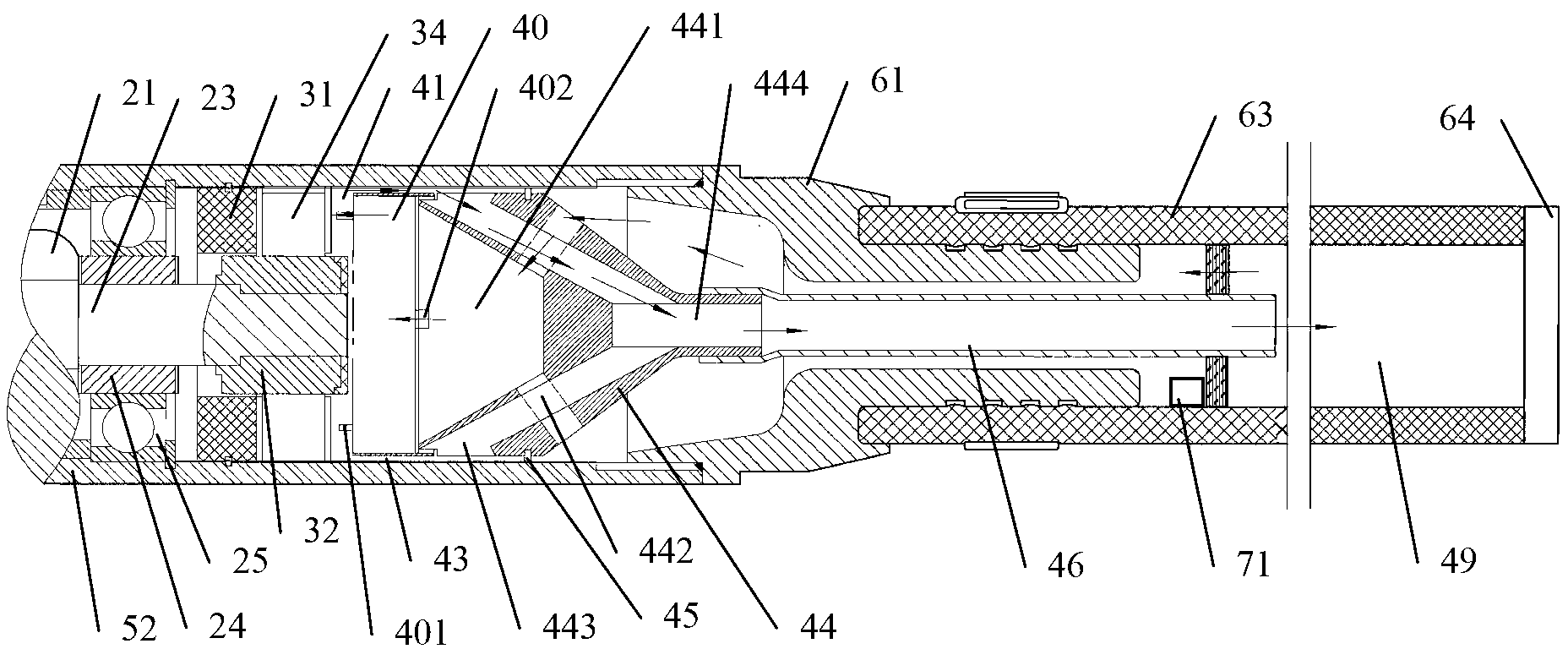

Motor and concrete vibrating rod using same

InactiveCN103166414AImprove work performanceReduce power consumptionDC commutatorBuilding material handlingStructural engineeringBrush

The invention discloses a motor and a concrete vibrating rod using the same. The brush motor comprises a stator, a rotating shaft and a rotor fixed on the rotating shaft, wherein the rotating shaft is supported by a bearing; a commutator assembly and a corresponding electric brush assembly are arranged on the rotating shaft; the rear end of the motor supports the first bearing of the rotating shaft between the rotor and the commutator assembly to partition the rotor, the commutator assembly and the electric brush assembly in two difference spaces, so that the commutator assembly and the electric brush assembly are positioned in a space outside the first bearing. The invention also discloses a method for improving the working performance of the brush motor and the concrete vibrating rod using the brush motor. The space outside the first bearing is communicated with a pipeline-type cavity in a tail pipe system. The related technical indexes of the vibrating rod can be effectively met without any external equipment.

Owner:冯玉加

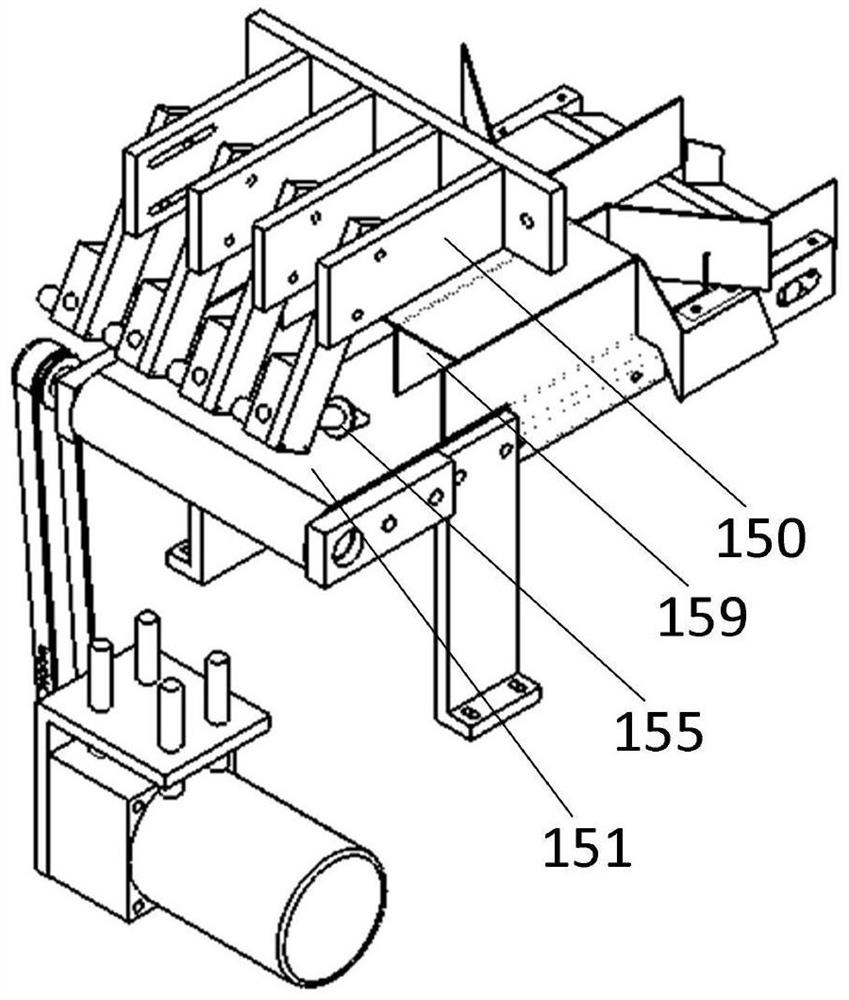

Commutator size and appearance defect detection equipment based on CCD vision

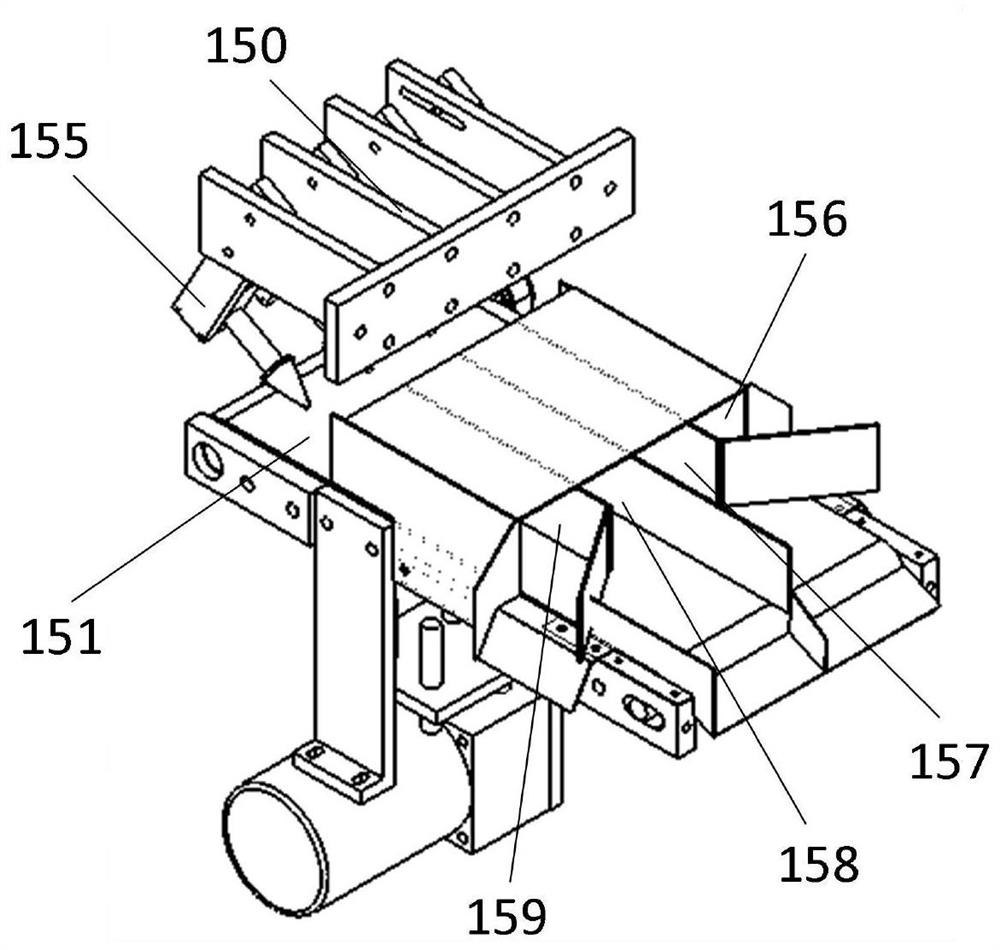

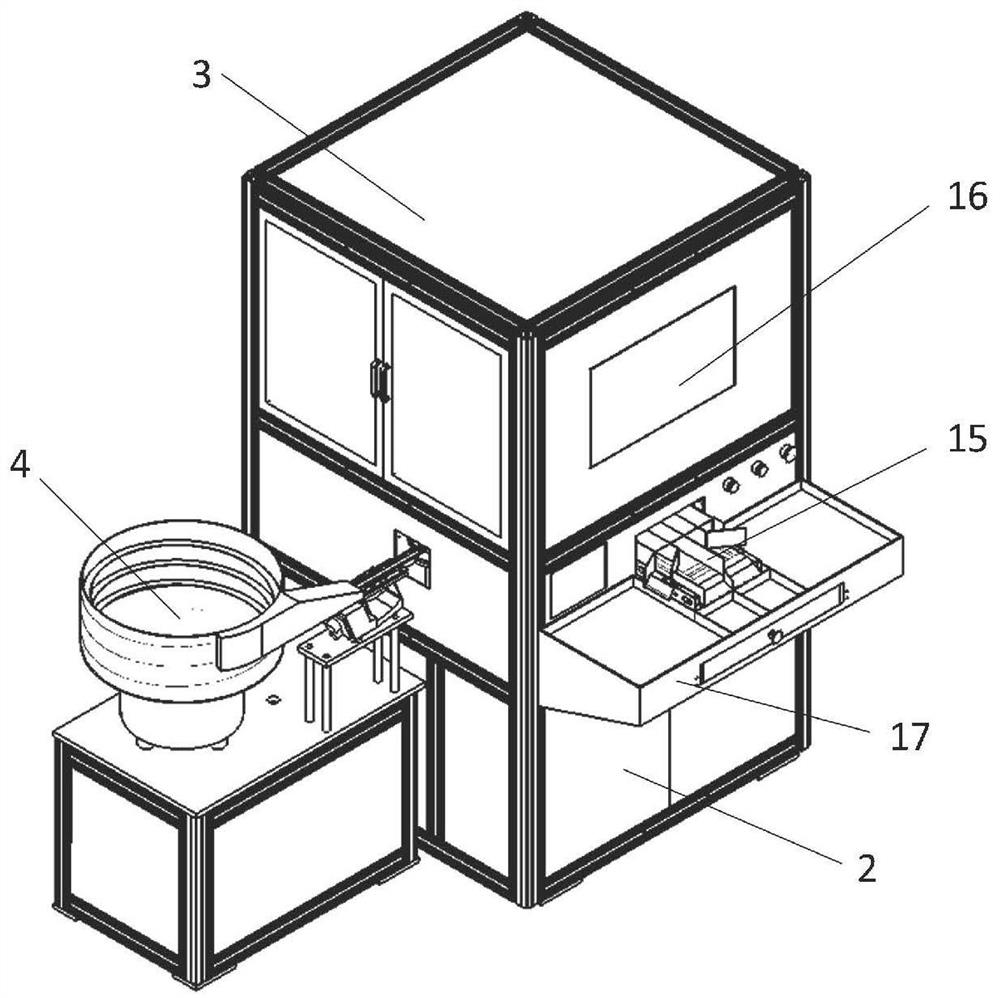

ActiveCN113714143ARealize automatic continuous feedingImprove work efficiencyMaterial analysis by optical meansUsing optical meansDisplay deviceCommutator (electric)

The invention discloses commutator size and appearance defect detection equipment based on CCD vision. The commutator size and appearance defect detection equipment comprises an electrical cabinet, a workbench and a hood, wherein a vibration feeding device is arranged on one side of the workbench, a rotary shifting mechanism connected with a discharging port of the vibration feeding device is arranged on one side of the top surface of the workbench, a glass rotating mechanism connected with a discharging port of the rotary shifting mechanism is arranged in the center of the top surface of the workbench, and a guide mechanism is arranged at the axis of the glass rotating mechanism; a first camera assembly, an optical fiber detection assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a discharging assembly which are located on the outer side of the glass rotating mechanism are sequentially arranged on the top surface of the workbench; and a display is arranged at the top of the outer side wall of the hood. According to the commutator size and appearance defect detection equipment, continuous automatic feeding, placement, positioning, all-dimensional detection and classified discharging of a commutator product to be detected can be realized, appearance detection is comprehensively covered, the detection result is accurate and reliable, and the detection efficiency is high.

Owner:安徽思普泰克智能制造科技有限公司

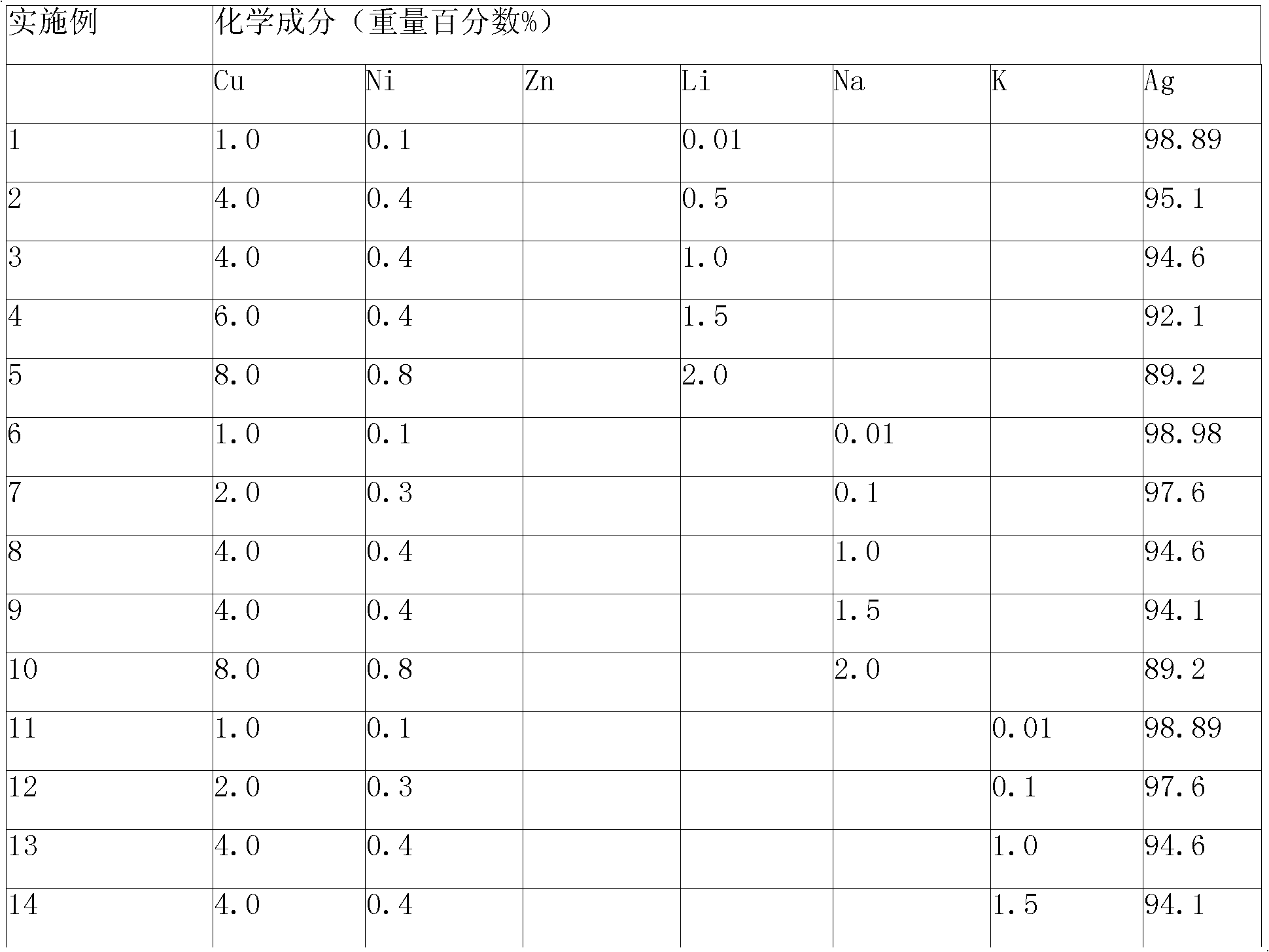

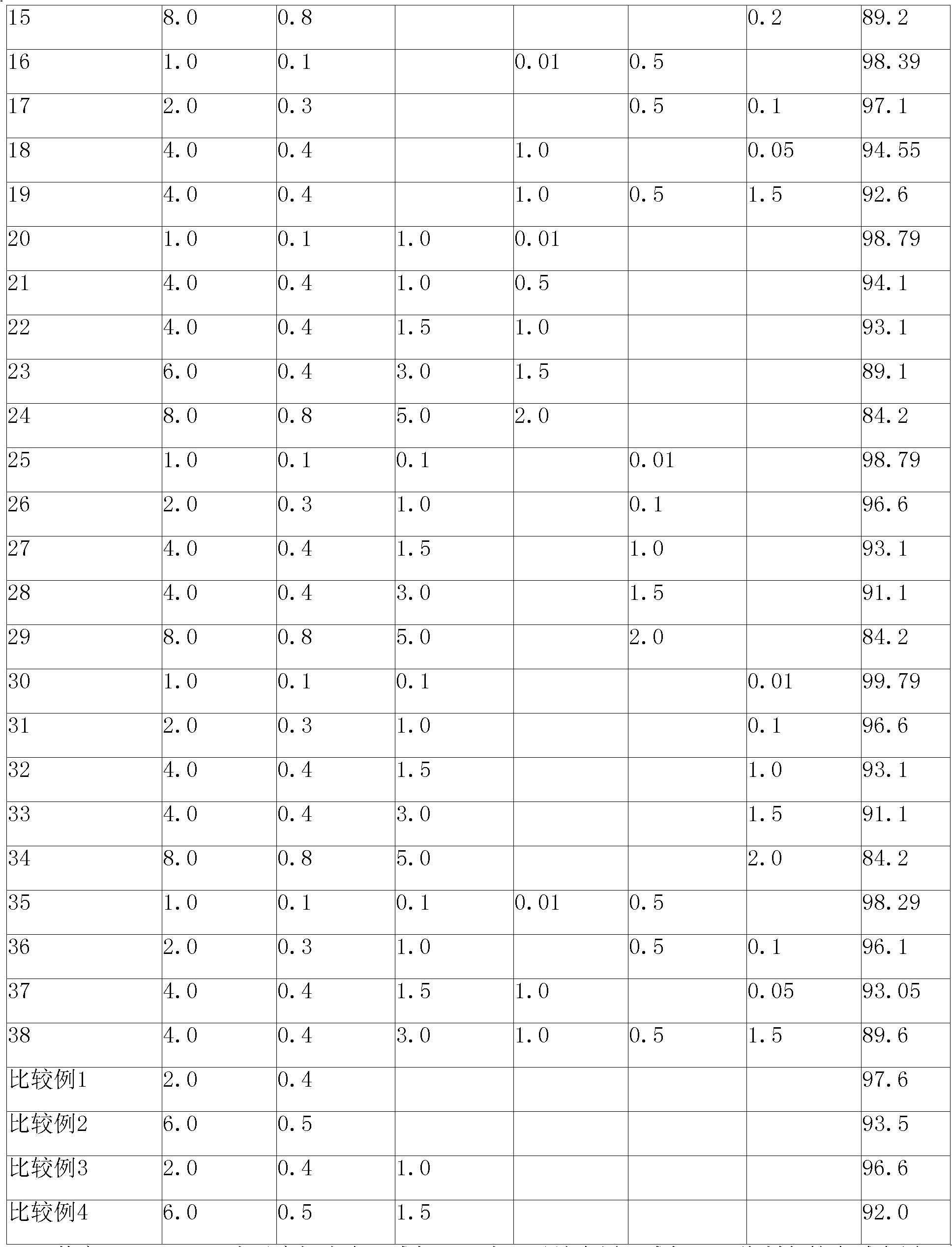

Alkali metal-containing silver-copper-nickel sliding electrical contact material

ActiveCN101924311AAvoid damageVolatileRotary current collectorMetal/alloy conductorsElectricitySilver copper

The invention discloses an alkali metal-containing silver-copper-nickel sliding electrical contact material which is prepared by adding a small amount of alkali metal elements to AgCuNi and AgCuZnNi, wherein the additive amount (in mass by percentage) of alkali metal Li, Na and K is 0.01%-3.0%, the elements can be respectively and independently added, and two or three elements are added in a matching way , but the total additive amount of the elements can not be more than 3.0%. The alkali metal-containing silver-copper-nickel sliding electrical contact material has favorable self-lubricating performance and arc-extinguishing performance, and can improve the service life and the contact stability and reliability of direct-current motor commutators when used for making the direct-current motor commutators.

Owner:CHONGQING CHUANYI AUTOMATION

Electric motor and carbon brush assembly used therefor

ActiveCN101540466AAvoid short circuitAct as a fixed springRotary current collectorDC commutatorElectric machineBrush

This invention relates to an electric motor and a carbon brush assembly used therefore. The carbon brush assembly comprises: a carbon brush having a first tail end and a second tail end, the first tail end being used for slidably contacting with a commutator of a motor; a carbon brush case for mounting the carbon brush and guiding the carbon brush to move; the carbon brush case comprising a first end part and a second end part; the first end part of the carbon brush being close to the first tail end of the carbon brush as well as the second end part being far away from the first tail end of the carbon brush; a constant-force spring having two curling parts and a connecting part for connecting two curling parts, the connecting part being resisted against the second tail end of the carbon brush; the tail end of the curling part forming a wound roll structure; two sides of the first end part of the carbon brush case being provided with a hanger, respectively; the wound roll structure being hanged on the corresponding hanger, respectively; the part of the curling part located between the tail end and the connecting part being straightened. The carbon brush assembly provided by this invention can avoid the short circuit due to the falling of the spring from the carbon brush case because the hanger on the carbon brush case can fix the spring when the carbon brush is assembled and the service life will finished.

Owner:JOHNSON ELECTRIC SHENZHEN

Magnetic powder dust core with entirely buried coil or magnet

ActiveUS10848016B2Improve efficiencyMagnetic circuit rotating partsMagnetic circuit stationary partsCurrent electricField element

A direct-current electric motor (an electrically powered machine) is a 3-pole brush-equipped direct-current electric motor which is provided with an armature (a rotor), a field element (a stator), a shaft, a commutator, a brush, a bracket, and an end plate. Of these, the armature (an armature) is provided with a dust core configured with a compressed powder compact formed of magnetic powder, and a coil buried in the dust core. On the other hand, the field element is provided with a field magnet which generates a magnetic flux, and a yoke housing which supports the field magnet and also functions as a housing.

Owner:SEIKO EPSON CORP

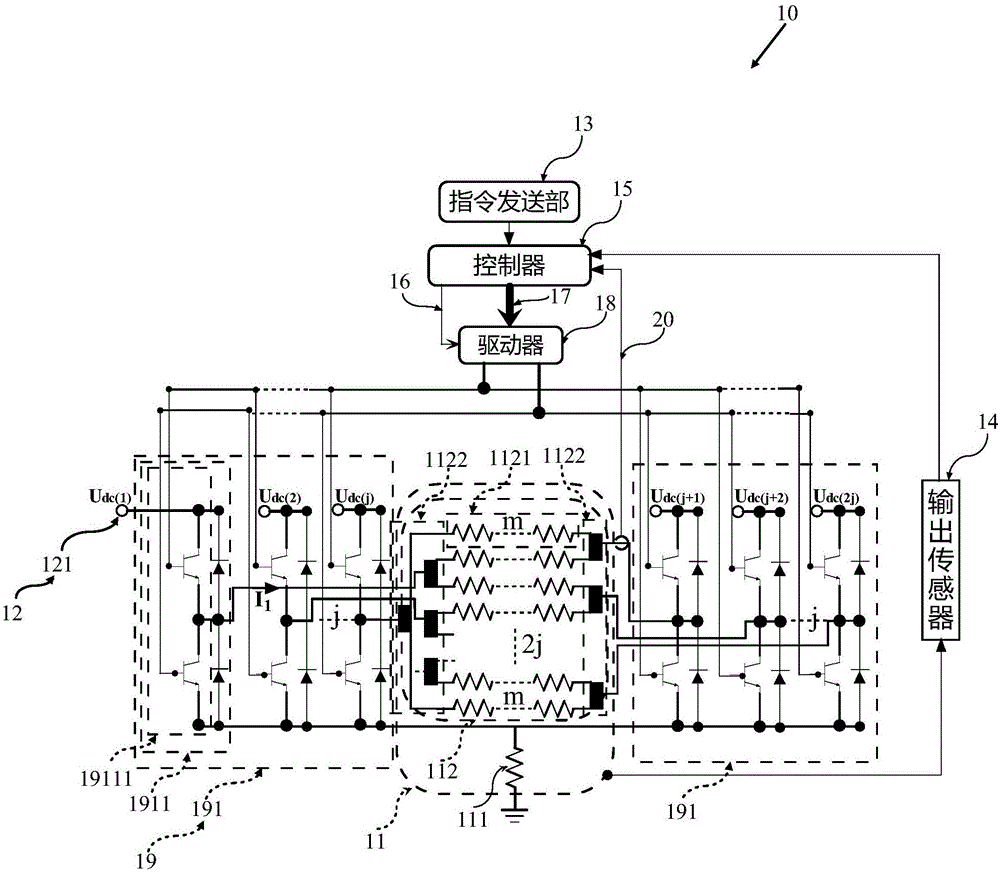

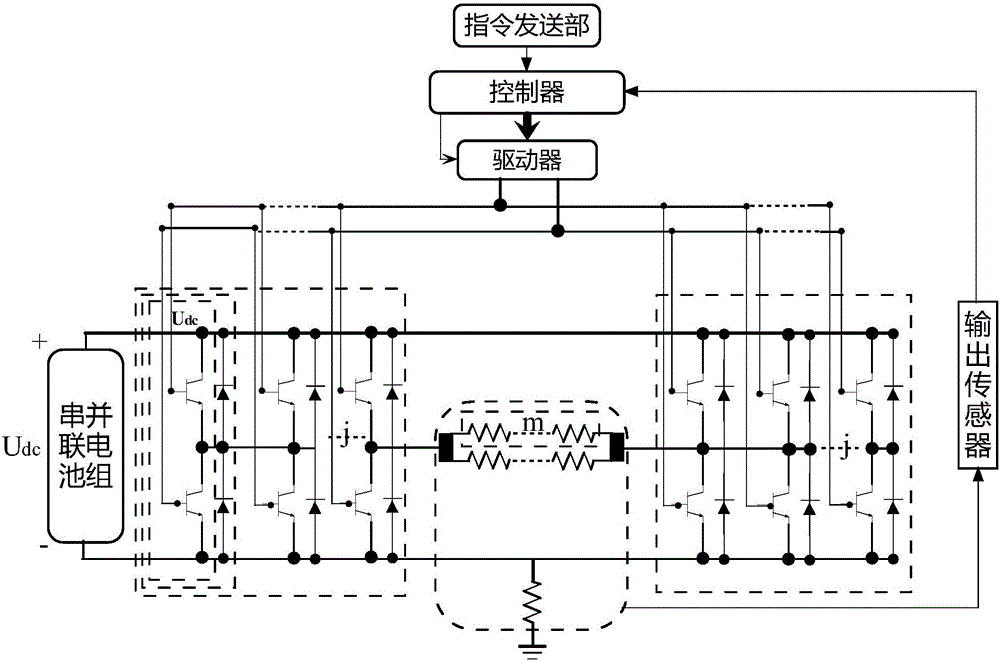

DC electric drive device and electric equipment

ActiveCN106849784AReduce contact resistanceReduced insulation requirementsDC motor speed/torque controlDC - Direct currentElectric drive

The invention provides a DC electric drive device and electric equipment. The DC electric drive device is arranged in the electric equipment and is used for driving the electric equipment. The DC electric drive device comprises a DC motor, a DC power supply, an instruction transmission part, an output sensor, a controller, a driver and a chopper. The DC electric drive device is characterized in that the DC motor is provided with 2j independent armature winding branches, 2j*m commutator bars connected with windings, and 2j independent electric brushes in contact with the commutator bars, wherein each armature winding branch is formed by m windings; the chopper is provided with 2j bridge arm units which correspond to the electric brushes one by one; the DC power supply comprises 2j independent power supply units; each power supply unit is connected with one bridge arm unit and one electric brush in a manner of one-to-one correspondence; the armature winding branches connected with the electric brushes are powered; and j and m are positive integers not smaller than 2.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Two speed electric motor with link wound dual-commutator and dual-armature winding

A permanent magnet D.C. electric motor includes a stator housing, permanent magnet structure, and an armature assembly. The armature assembly includes a shaft rotatably mounted in the stator housing, lamination structure, first and second coil windings associated with the lamination structure, a first commutator electrically connected with the first coil windings, and second commutator electrically connected with the second coil windings, each of the first and second commutators being generally cylindrical and having a plurality of commutator segments. Certain segments of the first commutator and certain segments of the second commutator are electrically connected. The motor also includes a brush card assembly including a high speed side having first brush structure associated with the first commutator, and a low speed side having a second brush structure associated with the second commutator, and switches for selectively connecting a D.C. voltage in such a way as to cause the armature assembly to rotate at a first speed and a second speed.

Owner:BROSE FAHRZEUGTEILE GMBH & CO KG HALLSTADT (DE)

Hybrid magnetic engine

InactiveCN101359846ASolve usabilityReduce energy consumptionMagnetic circuit rotating partsMagnetic circuit stationary partsElectricityMechanical energy

The invention discloses a mixed magnetic engine, which is provided with a mixed magnetic stator, a mixed magnetic rotor, a commutator, a controller and a casing; and the mixed magnetic rotor is arranged in the mixed magnetic stator, the mixed magnetic rotor is fixed on the casing (1) wrapping the mixed magnetic stator through two end caps, a rotor winding (6) disposed in the mixed magnetic rotor is connected with a stator winding (2) arranged in the mixed magnetic stator in parallel through the commutator and a carbon brush, and is electrically connected to the controller. The engine utilizes a permanent magnet composed of natural energy resources of natural magnetic ore, strong magnetic material, soft magnetic material and weak magnetic material with big potential, combines permanent magnetism and electromagnetism cleverly, and uses minimal electric energy to activate the mechanical energy for rotation, so the engine has advantages of simple structure, high efficiency, energy saving, safety and strong practicability, and can solve the environmental protection problem of the current power sources. The engine can be widely applied to various power devices in industrial, agricultural, traffic and national defense fields.

Owner:LUOYANG SHIHAO ENERGY POWER DESIGN RES INST

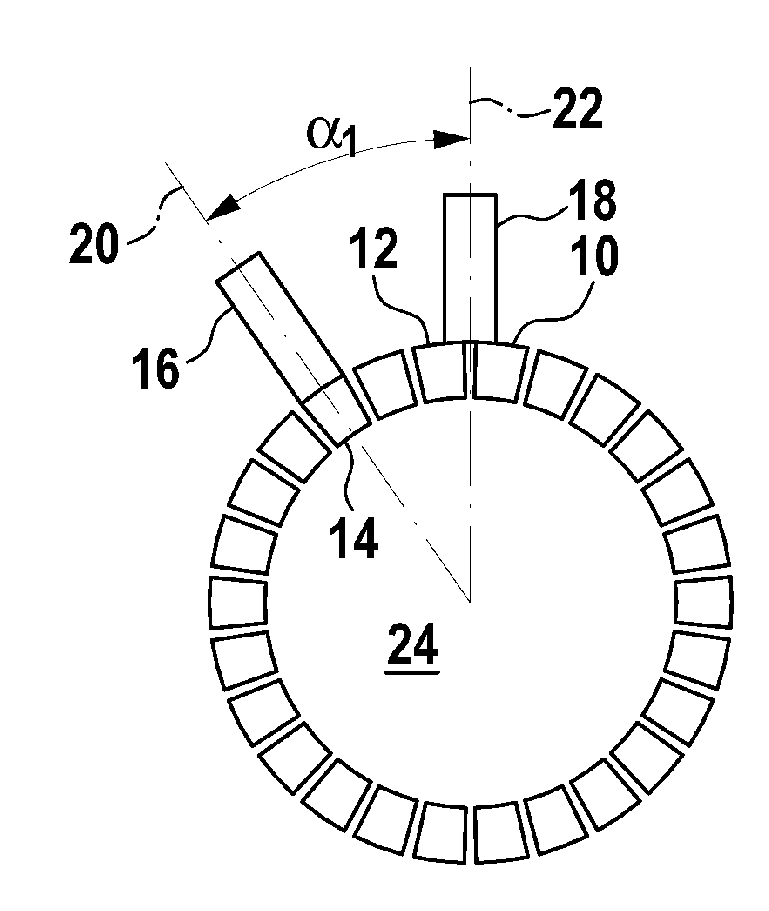

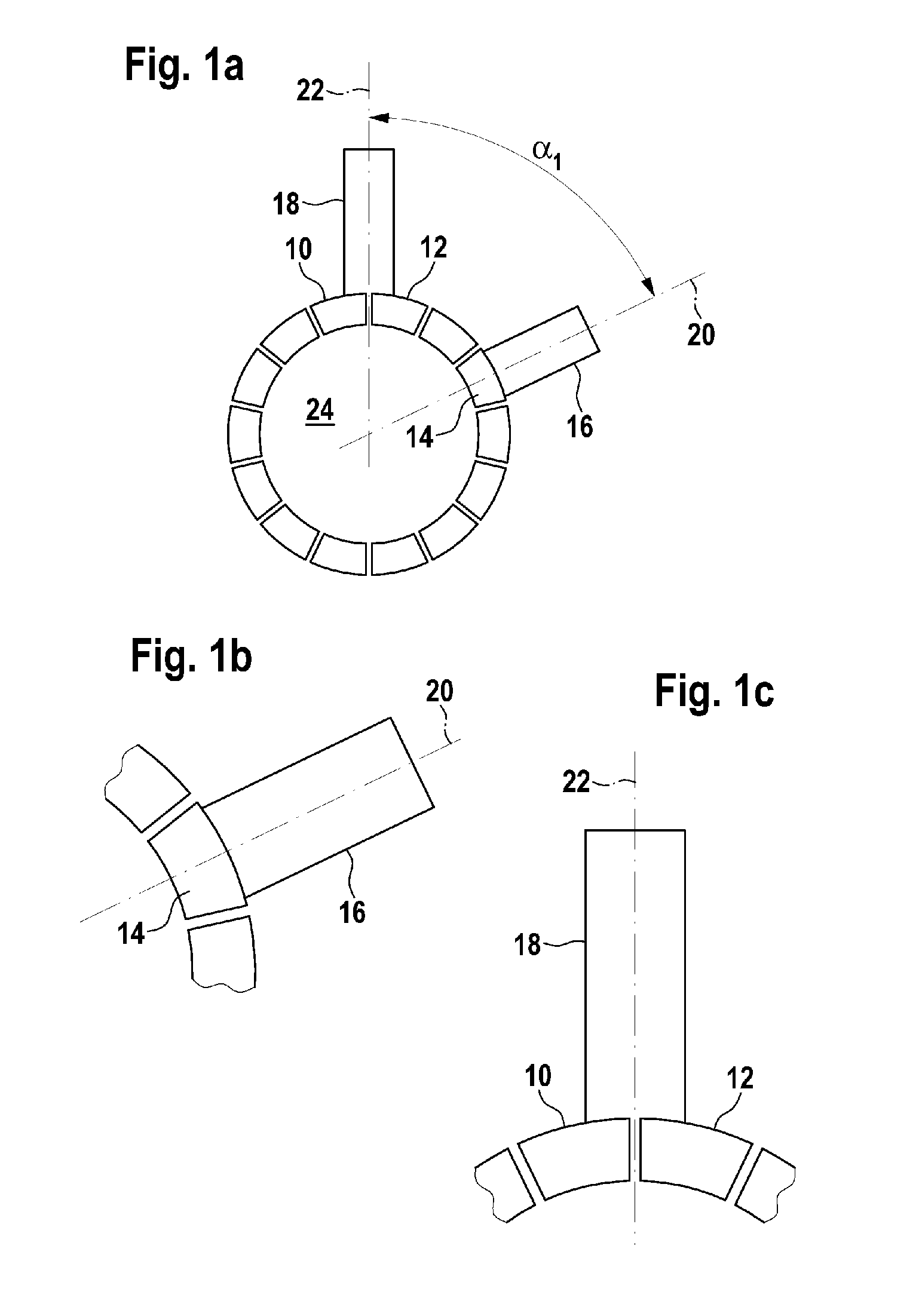

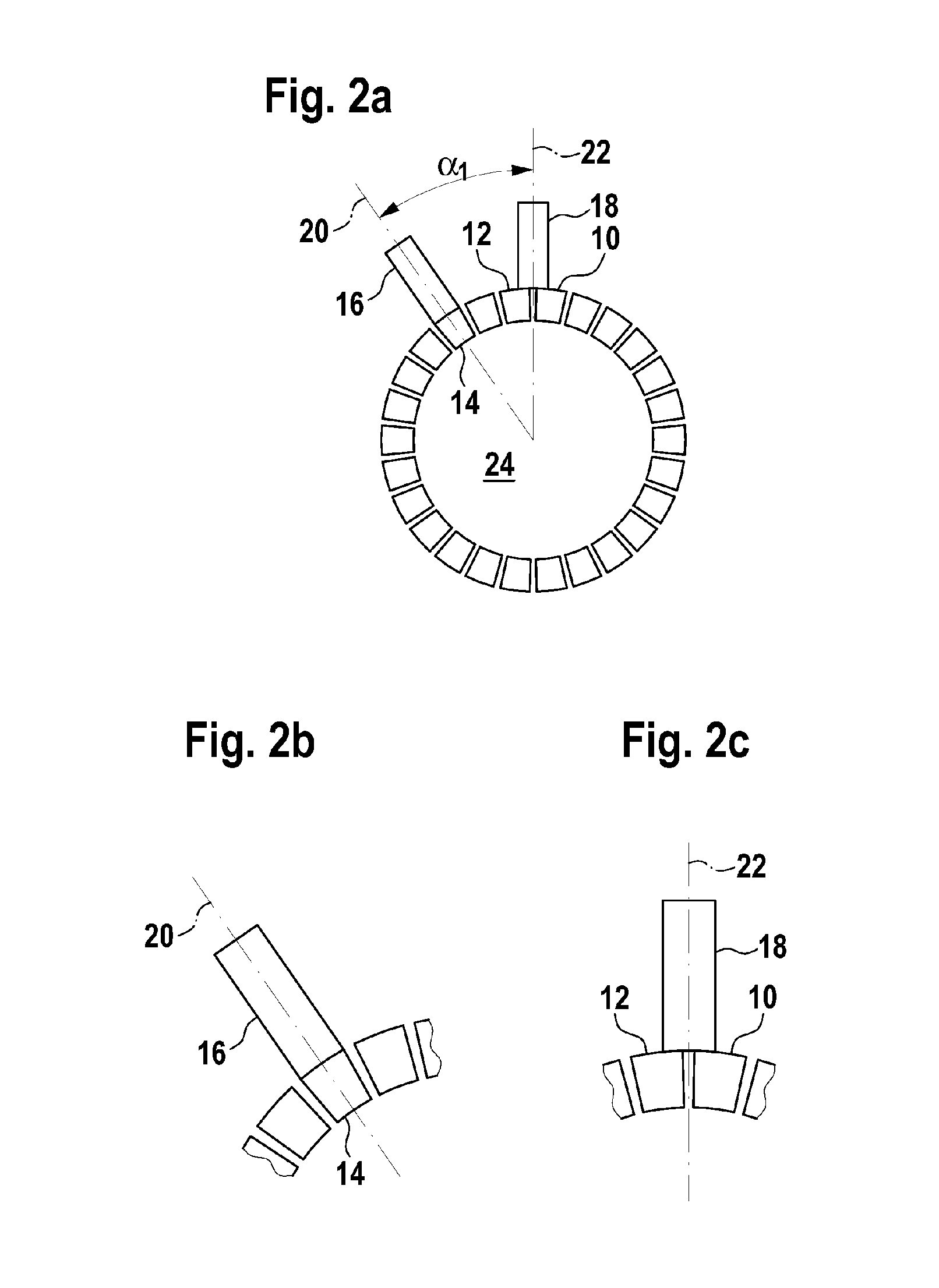

Brush arrangement for electrical machine

ActiveUS20120133240A1Reduce power lossRotary current collectorDC commutatorElectric machineClassical mechanics

An electrical machine, in particular an electric motor, has a first number (k) of commutator laminates (10, 12, 14) and brushes (16, 18), wherein the commutator laminates (10, 12, 14) are arranged distributed uniformly in the circumferential direction of a circumference of a laminate support (24). The brushes (16, 18) are arranged such that commutation times are distributed as uniformly as possible in order to reduce current ripple when using a wave winding and a number of brushes (16, 18) which is less than a number of poles (2p) in the electrical machine.

Owner:ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com