Brush holder device for dynamoelectric machine

A technology for electric motors and brush holders, which is applied in the direction of electromechanical devices, electric components, and control of mechanical energy, and can solve problems such as difficult cover and reliable insulation of terminal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

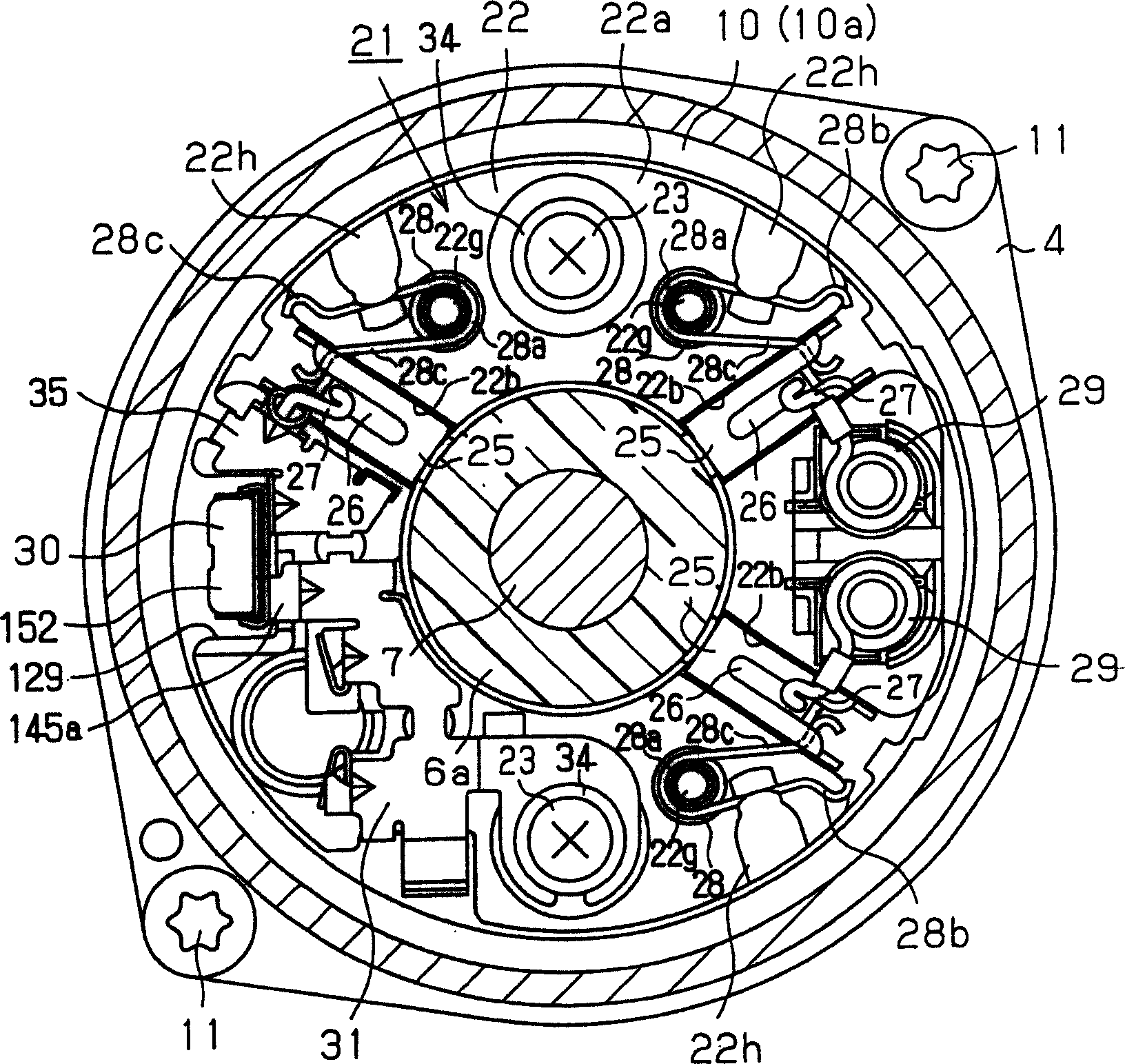

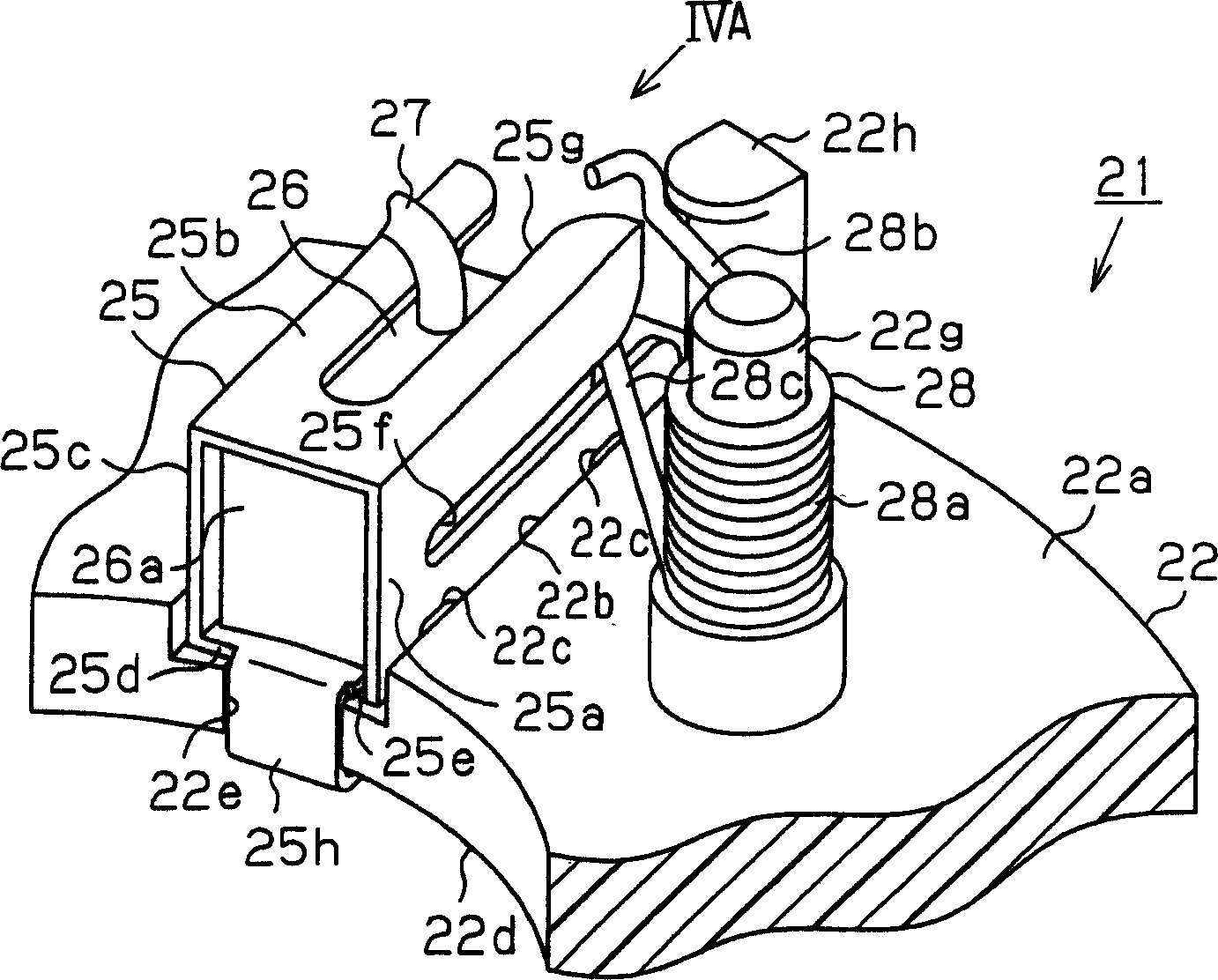

[0043] Embodiments of the present invention will be described below with reference to the drawings.

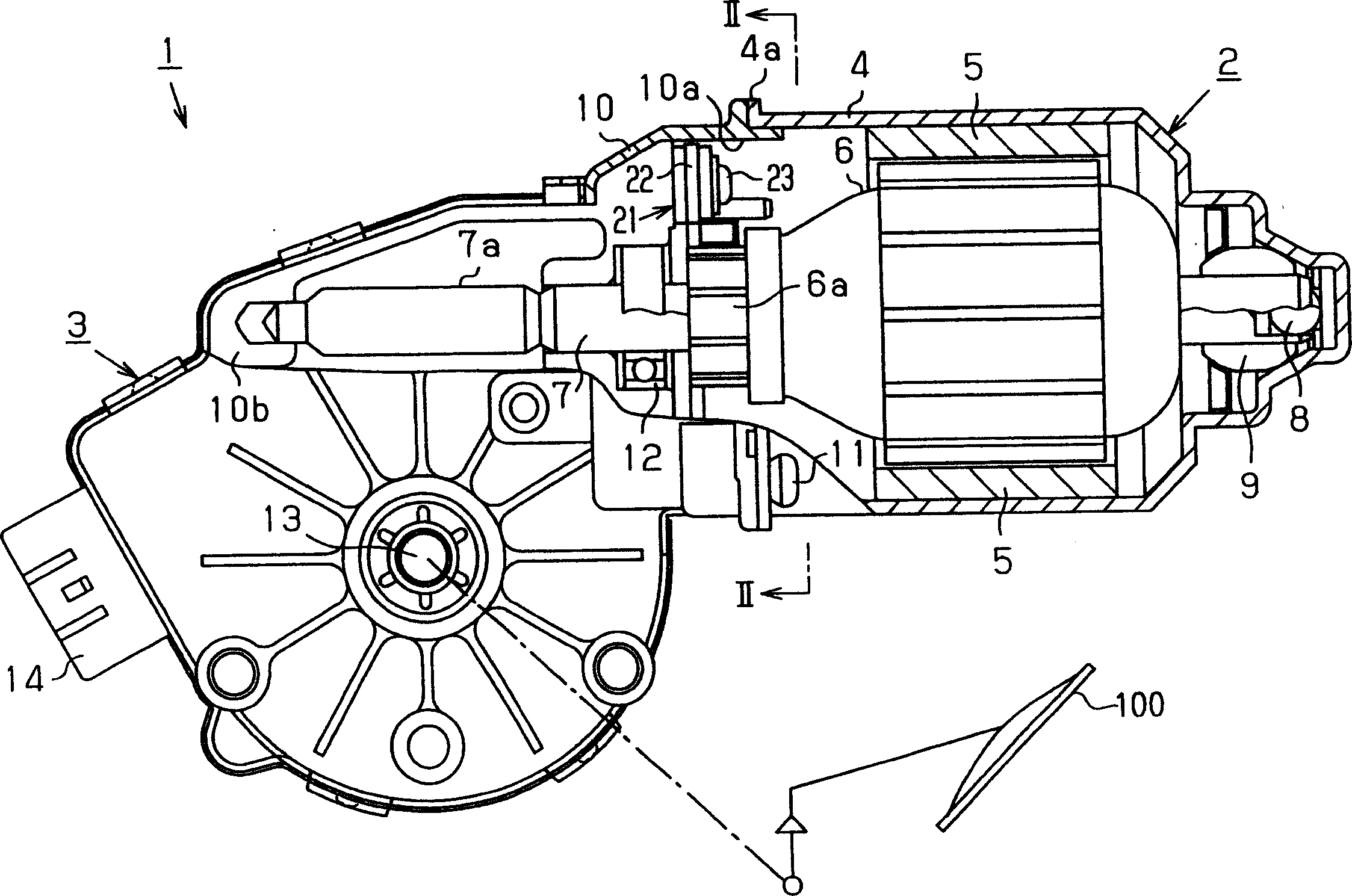

[0044] figure 1 The wiper motor (electric machine) 1 shown in is used as a drive source for the vehicle wiper system by using the wiper 100 (only in figure 1 One is shown in ) Wipe off the raindrops adhering to the windshield (front glass). The wiper motor 1 includes a motor unit 2 and a reduction unit 3 .

[0045] The yoke housing 4 of the motor unit 2 is made of a conductive metal material and formed into a cup shape. A plurality of magnets 5 are fixed to the inner peripheral surface of the yoke housing 4 . The armature 6 is rotatably accommodated in the yoke housing 4 at a corresponding position radially inward of the magnet 5 . A thrust bearing 8 and a radial bearing 9 are provided on the base of the yoke housing 4 , both of which rotatably support the base end of the rotatable shaft 7 of the armature 6 . The gear case 10 of the reduction unit 3 is assembled into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com