Patents

Literature

37results about How to "Guaranteed not to lose magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

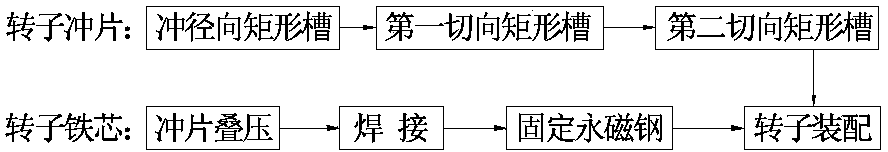

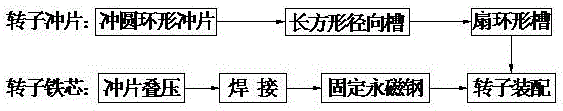

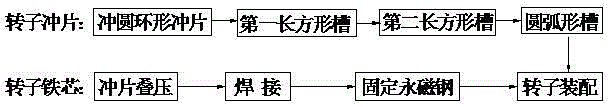

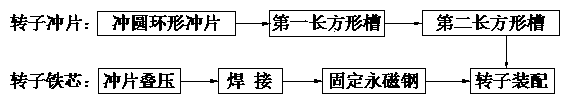

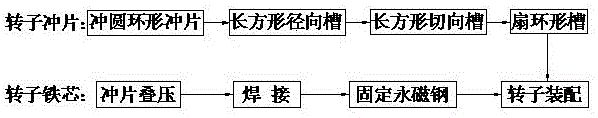

Production method for embedded permanent magnet rotor of tangential and radial resultant magnetic field driving motor

InactiveCN103762794AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

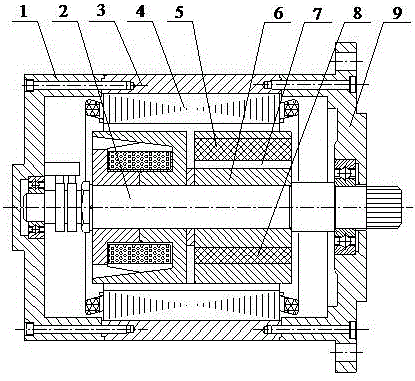

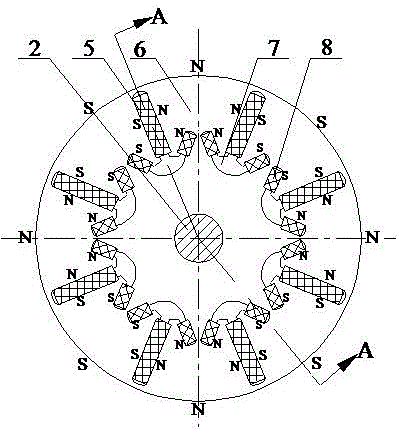

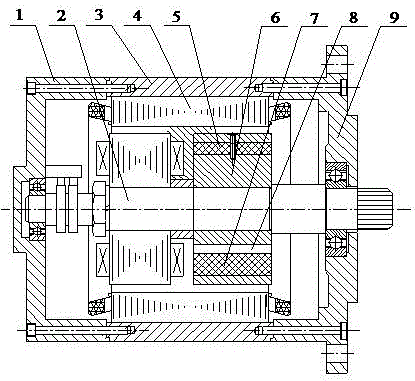

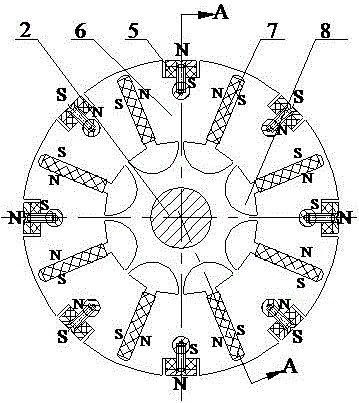

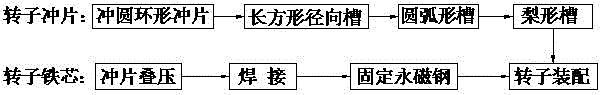

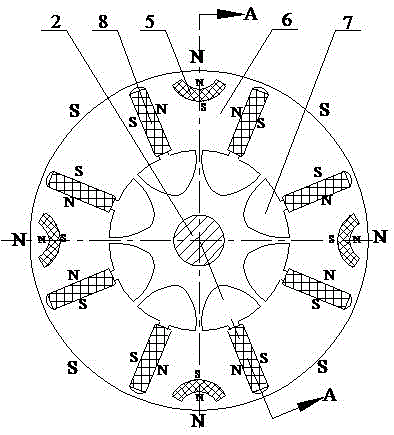

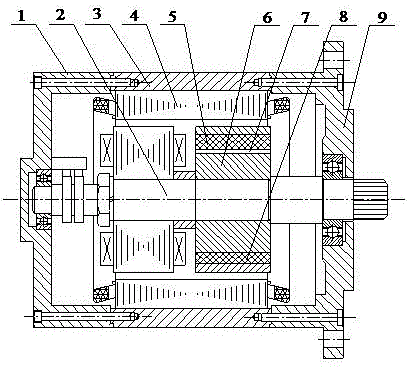

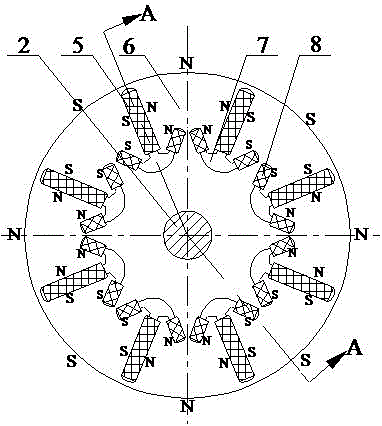

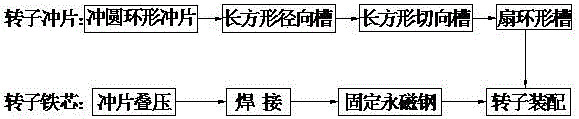

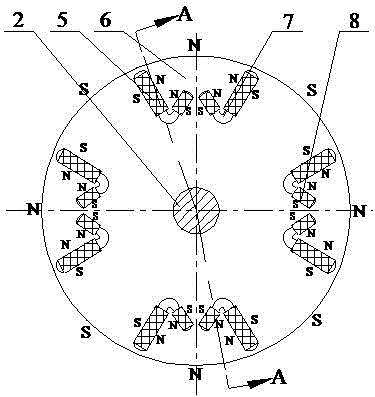

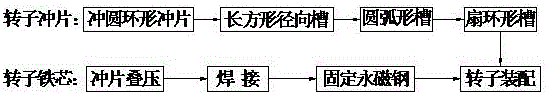

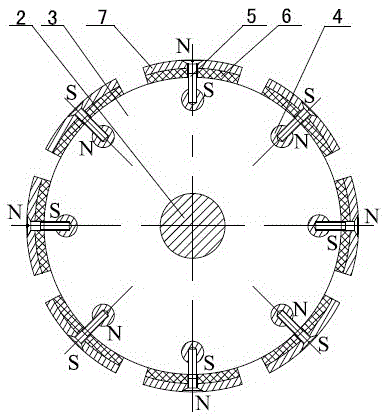

The invention provides a production method for an embedded permanent magnet rotor of a tangential and radial resultant magnetic field driving motor, and belongs to the technical field of automobile motor electric appliances. Pieces of rectangular permanent magnet steel are embedded into radial rectangular grooves and second tangential rectangular grooves of a rotor iron core respectively. Due to the fact that the tangential and radial resultant magnetic field driving motor is of a rotor magnetic bypass structure, the problem that irreversible demagnetization is generated when the permanent magnet steel bears the action of the armature reaction of an impact current can be effectively avoided, it is ensured that demagnetization does not happen on the permanent magnet steel, the magnetic field of the rotor of the driving motor is supplied by both the tangential magnetic field and the radial magnetic field, the magnetic field intensity is large, output power is high, and the embedded permanent magnet rotor has the advantages of being high in efficiency and power density, compact in structure, reliable in work and the like.

Owner:SHANDONG UNIV OF TECH

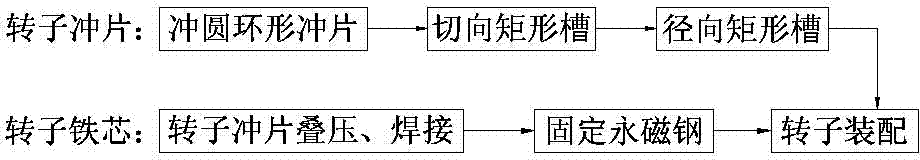

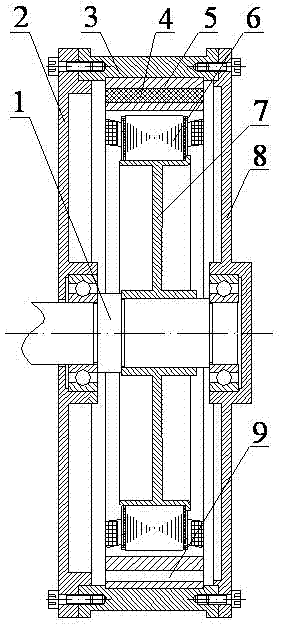

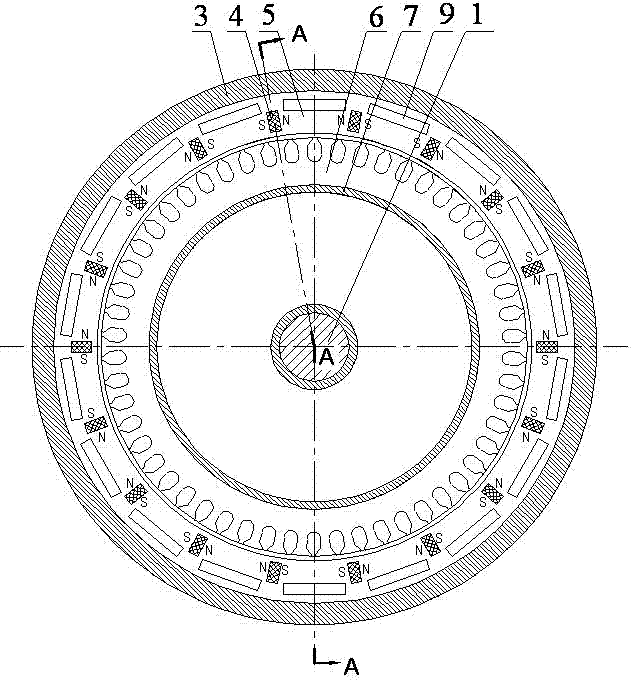

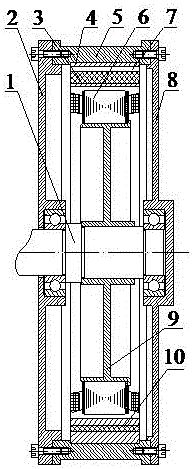

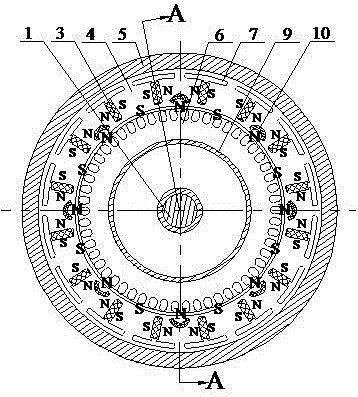

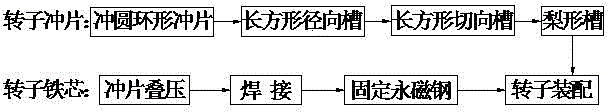

Production method for hub motor rotor with embedded radial permanent magnet steel and embedded tangential permanent magnet steel

InactiveCN103887936AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesPermanent magnet rotorPower flow

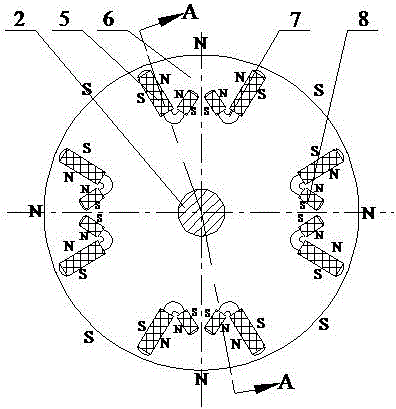

The invention provides a production method for a hub motor rotor with embedded radial permanent magnet steel and embedded tangential permanent magnet steel, and belongs to the technical field of automobile motors and electrical appliances. Rectangular permanent magnet steel is embedded in a radial rectangular groove and a second tangential rectangular groove of a rotor core respectively to form an embedded permanent magnet rotor. The structure is a rotor magnetic bypass structure, the problem that irreversible demagnetization happens to the permanent magnet steel under the action of armature reaction of impulse current can be effectively prevented, it is guaranteed that the permanent magnet steel does not lose magnetism, and meanwhile a hub drive motor rotor field is jointly provided by a radial magnetic field and a tangential magnetic field. Besides, the hub motor rotor with the embedded radial permanent magnet steel and the embedded tangential permanent magnet steel has the advantages that magnetic field intensity is high, output power is high, efficiency is high, power density is high, the structure is compact, and working is reliable.

Owner:SHANDONG UNIV OF TECH

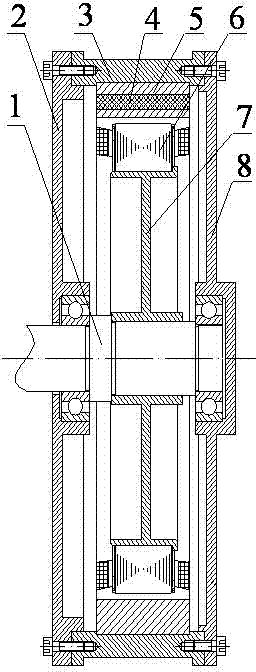

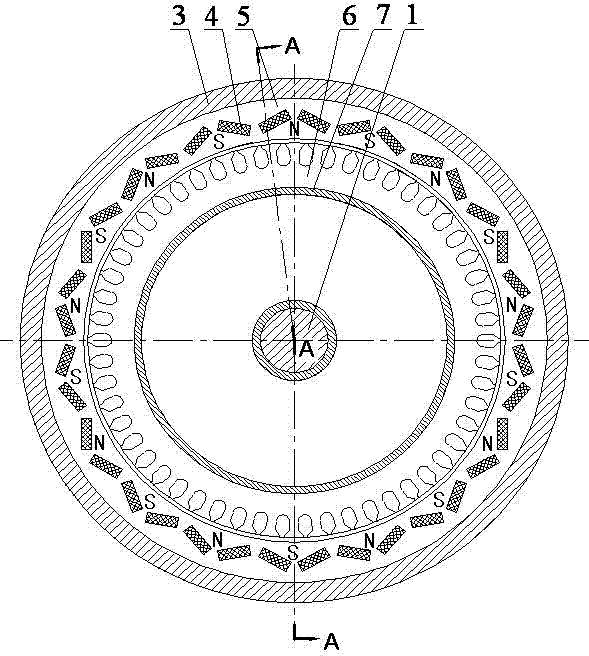

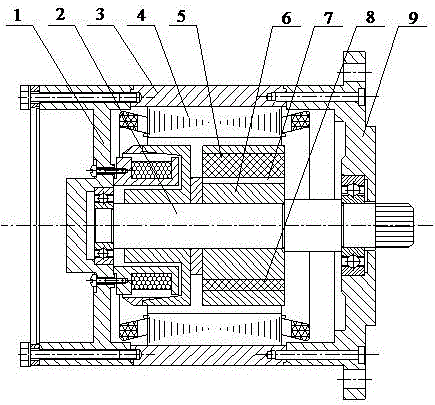

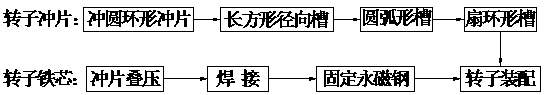

Built-in permanent magnet steel hub driving motor of electric vehicle

InactiveCN103887948AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorElectrical energy consumption

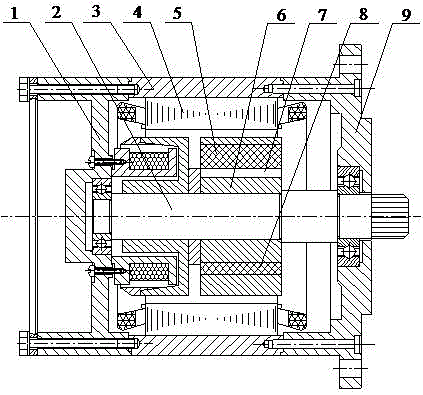

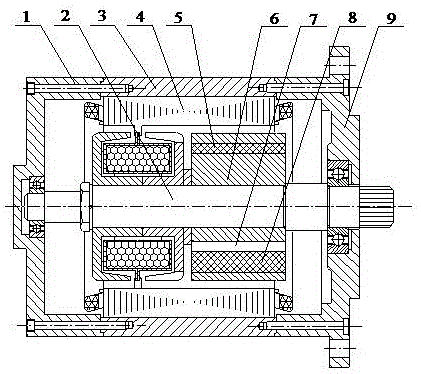

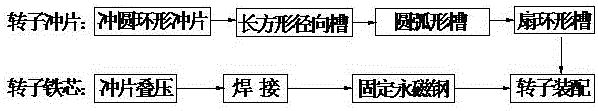

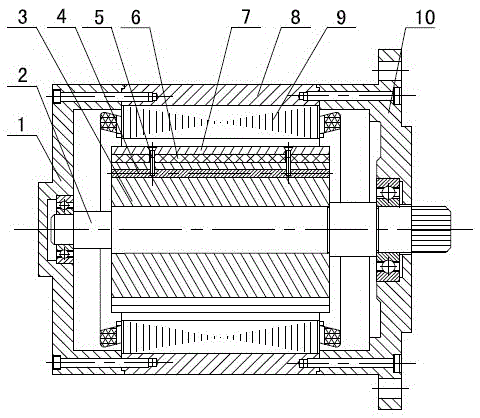

The invention provides a built-in permanent magnet steel hub driving motor of an electric vehicle and belongs to the technical field of automobile motor electric appliances. The built-in permanent magnet steel hub driving motor of the electric vehicle consists of a front end cover, a rear end cover, a hub casing, a rotor, a stator, a stator support and a shaft. Two pieces of completely-identical rectangular permanent magnet steel are respectively placed in two rectangular grooves forming a shape of a regular Chinese character 'ba' of a rotor iron core to form an N-pole, the other two pieces of completely-identical rectangular permanent magnet steel are respectively placed in a regular Chinese character 'ba' shaped groove formed by the other two adjacent rectangular grooves of the rotor iron core to form an S-pole, the rest can be done in the same manner to form the permanent magnet rotor with N-poles and S-poles arranged at intervals, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, and the failure rate is low.

Owner:SHANDONG UNIV OF TECH

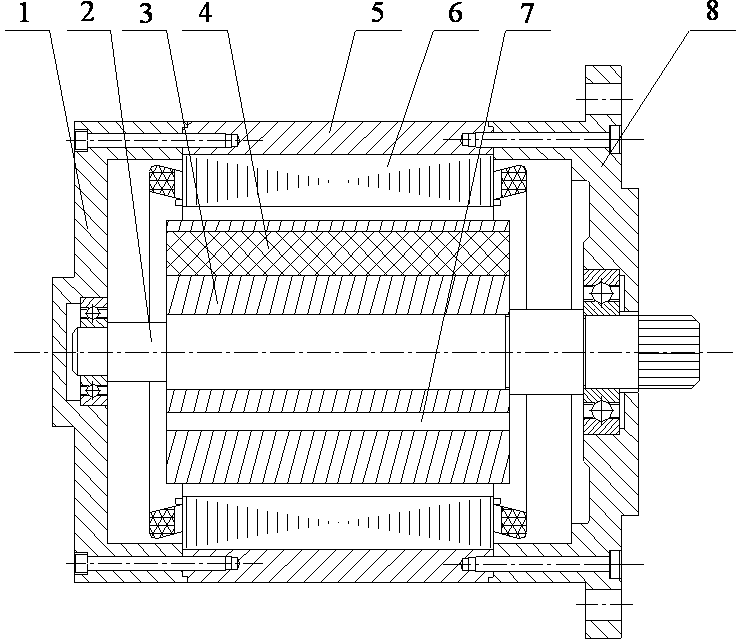

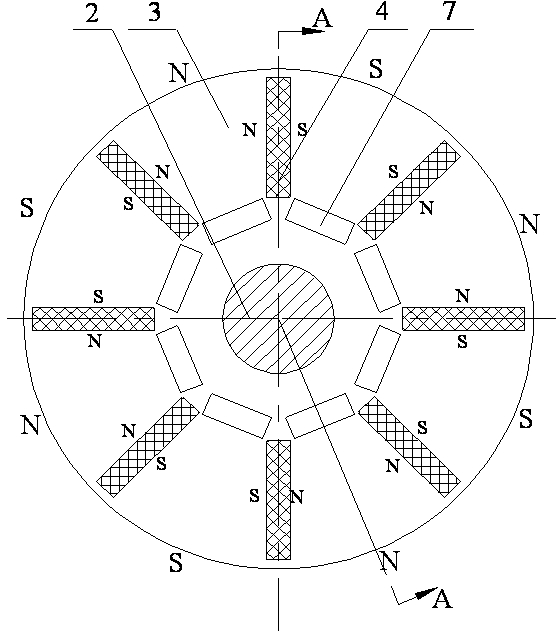

Built-in permanent magnet rotor driving motor of electric automobile

InactiveCN103746483AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectric machine

The invention provides a built-in permanent magnet rotor driving motor of an electric automobile, and belongs to the technical field of automobile motor appliances. The built-in permanent magnet rotor driving motor comprises a front end housing, a rear end housing, a shell, a rotor and a stator, wherein permanent magnet steel is embedded in a rotor core, and the structure is a rotor magnetic bypass structure which can effectively prevent an irreversible demagnetization problem of the permanent magnet due to ultrahigh temperature or an armature reaction of impulse current, ensure that the permanent magnet steel is free from loss of excitation. The rotor field of the driving motor is provided by the permanent magnet steel, so that the built-in permanent magnet rotor driving motor is free from electric exciting windings, carbon brush and a mechanical rectifier, low in power consumption and failure rate, high in efficiency and power density, obvious in magnetic flux gathering effect, and capable of providing large enough power for the electric automobile.

Owner:SHANDONG UNIV OF TECH

Built-in tangential permanent magnet steel hub driving motor of electric vehicle

InactiveCN103887947AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorDrive motor

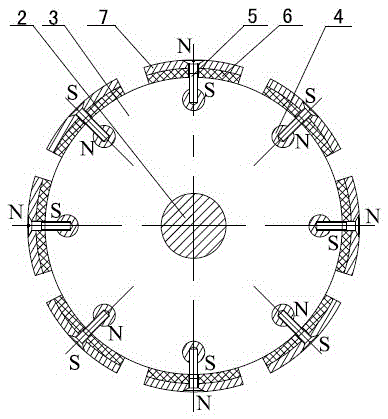

The invention provides a built-in tangential permanent magnet steel hub driving motor of an electric vehicle and belongs to the technical field of automobile motor electric appliances. The built-in tangential permanent magnet steel hub driving motor of the electric vehicle consists of a shaft, a front end cover, a rear end cover, a hub casing, a rotor, a stator and a stator support. A first piece of rectangular permanent magnet steel and the other piece of rectangular permanent magnet steel are sequentially installed in radial rectangular grooves of a rotor iron core in a mode that an N-pole of the first piece of rectangular permanent magnet steel is opposite to an N-pole of the other piece of rectangular permanent magnet steel, and an S-pole of the first piece of rectangular permanent magnet steel is opposite to an S-pole of the other piece of rectangular permanent magnet steel, a tangential permanent magnet rotor with N-poles and S-poles arranged at intervals is formed, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, the failure rate is low, and the built-in tangential permanent magnet steel hub driving motor has high-efficiency, high-power-density and remarkable magnetic focusing effect and can provided enough power for the electric vehicle.

Owner:SHANDONG UNIV OF TECH

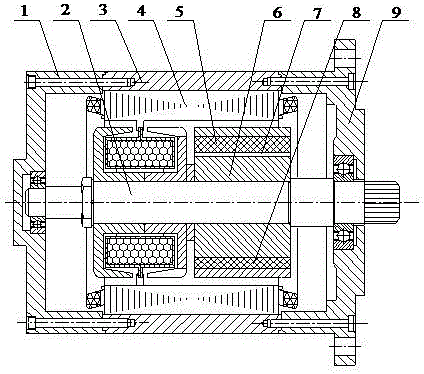

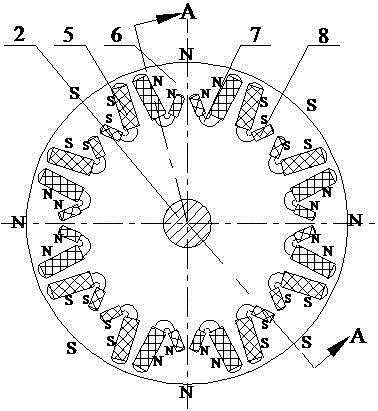

Electric automobile electromagnetic and built-in permanent magnet combined magnetic pole hybrid excitation driving motor

InactiveCN105846569AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machineMagnetic poles

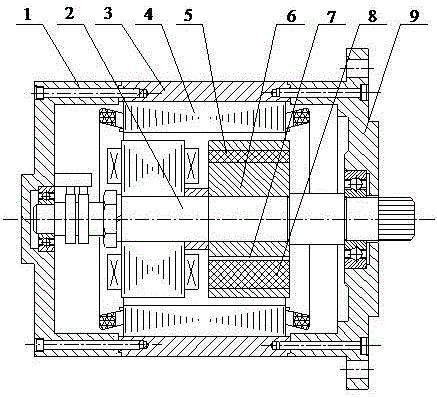

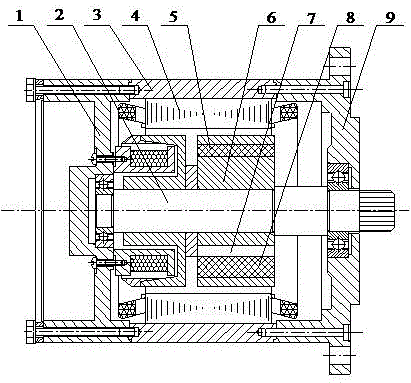

The invention provides an electric vehicle electromagnetic and built-in permanent magnet combined magnetic pole hybrid excitation drive motor, which belongs to the technical field of electric vehicle motors and appliances. It is composed of a front end cover, a rear end cover, a casing, a rotor, and a stator. The rectangular permanent magnet steel is respectively embedded in the first rectangular slot and the second rectangular slot, which can effectively prevent the permanent magnet steel from being affected by the armature reaction of the impact current. Irreversible demagnetization is generated to ensure that the permanent magnet steel does not lose its magnetism. The magnetic field in the air gap of the drive motor is provided by the permanent magnet steel and the electric excitation winding, with high magnetic field strength and high output power.

Owner:SHANDONG UNIV OF TECH

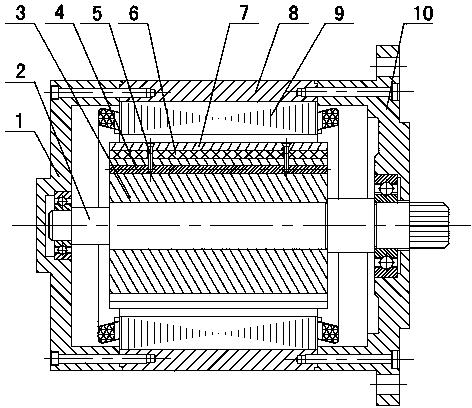

Salient electromagnetic and embedded permanent magnet hybrid excitation drive motor for electric automobiles

InactiveCN105958772AAvoid irreversible demagnetizationGuaranteed not to lose magnetismSynchronous machine detailsMagnetic circuit rotating partsDrive motorMagnet

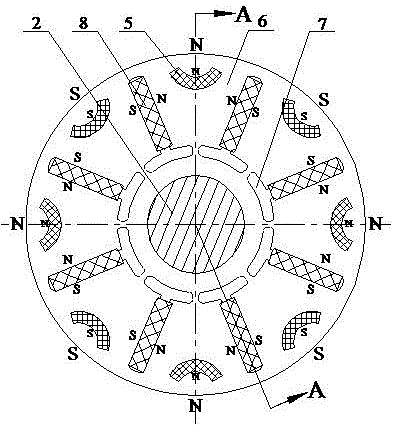

The invention provides a salient electromagnetic and embedded permanent magnet hybrid excitation drive motor for electric automobiles, and belongs to the technical field of electric automobile motors and appliances. The drive motor is composed of a front end cover, a rear end cover, a case, a rotor, and a stator. Rectangular permanent magnet steel pieces are embedded into radial rectangular slots, and tile-shaped permanent magnet steel pieces are embedded into circular arc slots. The permanent magnet steel pieces can be effectively prevented from generating irreversible demagnetization under the armature reaction effect of impact current, and that the permanent magnet steel pieces do not lose magnetism is ensured. The magnetic field in the air gap of the drive motor is provided jointly by the permanent magnet steel pieces and an electric excitation winding. The magnetic field is strong, and the output power is high.

Owner:SHANDONG UNIV OF TECH

Combined permanent magnetic and electromagnetic mixed excitation driving motor

InactiveCN105914995AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsSynchronous machine detailsPhysicsDrive motor

The invention provides a combined permanent magnetic and electromagnetic mixed excitation driving motor, belonging to the automobile motor electric appliance technical field, and comprises a front end cover, a rear end cover, a casing, a rotor and a stator. Rectangular permanent magnet steels are respectively installed in tangential and radial rectangular notches. The motor can effectively prevent permanent magnet steels from generating irreversible demagnetization under the surge current armature reaction effect, and avoid loss of excitation of the permanent magnet steels; a magnetic field in driving motor air gaps is provided by the permanent magnet steels and electro-magnetic coils, and has the characteristics of great magnetic field intensity and high output power.

Owner:张学义

Method for producing combined magnetic pole and invisible magnetic pole driven motor rotor

InactiveCN105896848AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsManufacturing stator/rotor bodiesRotor magnetsElectric machine

The invention provides a method for producing a combined magnetic pole and invisible magnetic pole driven motor rotor, and belongs to the technical field of motors and electric appliances of electric vehicles. A permanent magnet steel is separately embedded into an oblong radial slot and an arc slot of a rotor core; the structure is a rotor magnet bypass structure, and can effectively prevent the permanent magnet steels from producing irreversible demagnetization under the action of armature reaction of impulse current and guarantee the permanent magnet steels not demagnetized; meanwhile, the magnetic field for driving the motor rotor is provided by the permanent magnet steels, so that the magnetic field intensity and the output power are high; and the motor rotor has the characteristics of high efficiency, high power density, compact structure, reliable operation and the like.

Owner:张学义

Composite permanent-magnet invisible magnetic pole and brushless electromagnetic hybrid excitation driving motor

InactiveCN105811704AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsSynchronous machine detailsElectric machineMagnetic poles

The invention provides a composite permanent-magnet invisible magnetic pole and brushless electromagnetic hybrid excitation driving motor, and belongs to the technical field of a motor electrical device of an electric vehicle. The hybrid excitation driving motor comprises a front end cover, a rear end cover, an enclosure, a rotor and a stator, wherein rectangular permanent-magnet steel is separately embedded into a radial rectangular groove and an arc groove in a rotor iron core, the permanent-magnet steel can be effectively prevented from generating irreversible demagnetization under the effect of armature reaction of impact current and is enabled not to loss magnetism, a magnetic field in an air gap of a driving motor is jointly provided by the permanent-magnet and an electric excitation magnetic winding, the generated magnetic field directly faces the air gap, and less magnetic leakage is achieved.

Owner:SHANDONG UNIV OF TECH

Electromagnetic hybrid type excitation driving motor with permanent magnet invisible magnetic poles and salient poles

InactiveCN105811619AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsHybrid typeElectric machine

The invention provides an electromagnetic hybrid type excitation driving motor with permanent magnet invisible magnetic poles and salient poles, and belongs to the technical field of motors and electric appliances of electric automobiles. The electromagnetic hybrid type excitation driving motor comprises a front end cover, a back end cover, a machine case, a rotor and a stator, wherein rectangular permanent magnet steels are embedded in corresponding first rectangular grooves and second rectangular grooves embedded in the rotor iron core respectively. The irreversible demagnetizing of the permanent magnet steels generated under an armature reaction of the impact current can be effectively prevented so as to ensure that the permanent magnet steels are not demagnetized; and the magnetic field in the air gap of the driving motor is jointly supplied by the permanent magnet steels and the electric exciting winding; and meanwhile, the generated magnetic field directly faces to the air gap, so that the leakage flux is low in amount.

Owner:SHANDONG UNIV OF TECH

Radial-tangential permanent magnet and brushless electromagnetism hybrid excitation driving motor

InactiveCN105958782AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsSynchronous machine detailsPower flowConductor Coil

The invention provides a radial-tangential permanent magnet and brushless electromagnetism hybrid excitation driving motor, and belongs to the technical field of electric automobile motors and electrical appliances. The radial-tangential permanent magnet and brushless electromagnetism hybrid excitation driving motor is composed of a front end cover, a rear end cover, a casing, a rotor and a stator, and is characterized in that rectangular permanent magnet steel is respectively embedded in first rectangular grooves and second rectangular grooves, so that the permanent magnet steel can be effectively prevented from generating irreversible demagnetization under the action of an armature reaction of impulse current, and the permanent magnet steel is ensured not to be demagnetized. A magnetic field in an air gap of the driving motor is provided by the permanent magnet steel and an electrical excitation winding together, so that the magnet field intensity is great, and the output power is high.

Owner:张学义

Brushless electromagnetic and invisible magnetic pole composite excitation driving motor

InactiveCN105743312AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machinesPower flowMagnetic poles

The invention provides a brushless electromagnetic and invisible magnetic pole composite excitation driving motor, and belongs to the technical field of electric automobile motor and electric appliances. The brushless electromagnetic and invisible magnetic pole composite excitation driving motor is composed of a front end cover, a rear end cover, a housing, a rotor and a stator. Rectangular permanent magnet steel is embedded in radial rectangular slots, and tile permanent magnet steel is embedded in arc-shaped slots. The permanent magnet steel is effectively prevented against irreversible demagnetization under the effect of an armature reaction of an impact current, and the permanent magnet steel is prevented against excitation loss; a magnetic field in an air gap of the driving motor is provided by the permanent magnet steel and electric excitation windings together, the generated magnetic field directly faces the air gap, and the magnetic leakage is low.

Owner:SHANDONG UNIV OF TECH

Production method for rotor of hub driving motor with radial and built-in tangential permanent magnet steels

InactiveCN105811679AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesHigh magnetic field strengthElectric machine

The invention provides a production method for a rotor of a hub driving motor with radial and built-in tangential permanent magnet steels, and belongs to the technical field of motors and electric appliances of electric automobiles. Rectangular permanent magnet steels are mounted in corresponding rectangular radial grooves and rectangular tangential grooves of the rotor iron core respectively. The structure is a rotor magnetic bypass structure, so that the irreversible demagnetizing of the permanent magnet steels generated under an armature reaction of the impact current can be effectively prevented so as to ensure that the permanent magnet steels are not demagnetized; meanwhile, the magnetic field of the rotor of the driving motor is jointly supplied by the radial magnetic field and the tangential magnetic field, so that high magnetic field strength and high power density are realized; and in addition, the characteristics of high efficiency, high power density, compact structure, reliable operation and the like are achieved as well.

Owner:SHANDONG UNIV OF TECH

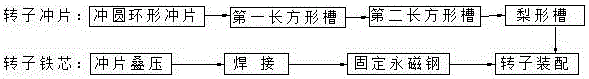

Production method of electric automobile embedded tangential magnetic field permanent magnet steel driving motor rotor

InactiveCN105743255AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machinesFailure rateElectric machine

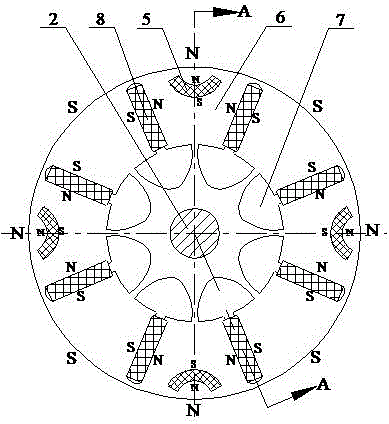

The invention provides a production method and an electric automobile embedded tangential magnetic field permanent magnet steel driving motor rotor and belongs to the technical field of electric automobile motor devices. Rectangular permanent magnet steel is embedded in rectangular radial slots of a rotor iron core. The magnetic field of each magnetic pole of a driving motor rotor is provided by the two pieces of permanent magnet steel together, the magnetic field intensity is large, and the power density is high; the structure is a rotor magnetic bypass structure, so that permanent magnet steel is effectively prevented against irreversible demagnetization under the effect of an armature reaction of an impact current, and the permanent magnet steel is prevented against excitation loss; in addition, electric exciting windings are not needed, less electric energy is consumed, no carbon brush slip ring structures are arranged, the failure rate is low, the structure is compact, and the working is reliable.

Owner:SHANDONG UNIV OF TECH

Production method for rotor of permanent magnet driving motor with built-in tangential and combined type radial magnetic fields

InactiveCN105811682AAvoid irreversible demagnetizationPrevent loss of magnetismManufacturing stator/rotor bodiesHigh magnetic field strengthElectric machine

The invention provides a production method for rotor of a permanent magnet driving motor with built-in tangential and combined type radial magnetic fields, and belongs to the technical field of motors and electric appliances of electric automobiles. Rectangular permanent magnet steels are embedded in corresponding first rectangular grooves and second rectangular grooves of the rotor iron core respectively; the magnetic field of each magnetic pole of the rotor of the driving motor is jointly supplied by four permanent magnet steels separately, so that high magnetic field strength and high power density are realized; the structure is a rotor magnetic bypass structure, so that the irreversible demagnetizing of the permanent magnet steels generated under an armature reaction of the impact current can be effectively prevented so as to ensure that the permanent magnet steels are not demagnetized; and in addition, the driving motor has the advantages of high efficiency and high reliability.

Owner:SHANDONG UNIV OF TECH

Production method of built-in permanent magnet rotor of electric vehicle hub driving motor

InactiveCN103887937AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesManufacturing stator/rotor bodiesDrive motorElectric vehicle

The invention provides a production method of a built-in permanent magnet rotor of an electric vehicle hub driving motor and belongs to the technical field of automobile motor electric appliances. Two pieces of completely-identical rectangular permanent magnet steel are respectively placed in two rectangular grooves forming a shape of a regular Chinese character 'ba' of a rotor iron core to form an N-pole, the other two pieces of completely-identical rectangular permanent magnet steel are respectively placed in a regular Chinese character 'ba' shaped groove formed by the other two adjacent rectangular grooves of the rotor iron core to form an S-pole, the rest can be done in the same manner to form the permanent magnet rotor with N-poles and S-poles arranged at intervals, the structure is a rotor magnetic bypass structure and can effectively prevent the permanent magnet steel from producing irreversible demagnetization under the armature reaction effect of impact current, and excitation loss of the permanent magnet steel is ensured. A rotor magnetic field of the hub driving motor is provided by the permanent magnet steel without electro-magnetic windings, electric energy consumption is low, carbon brushes and mechanical commutators are not adopted, and the failure rate is low.

Owner:SHANDONG UNIV OF TECH

Invisible composite magnetic pole and brushless electromagnetic drive motor

InactiveCN105958769AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsSynchronous machine detailsMagnetic polesDrive motor

The invention provides an invisible composite magnetic pole and brushless electromagnetic drive motor, and belongs to the technical field of electric automobile motors and appliances. The drive motor is composed of a front end cover, a rear end cover, a case, a rotor, and a stator. Rectangular permanent magnet steel pieces are respectively embedded into first rectangular slots and second rectangular slots. The permanent magnet steel pieces can be effectively prevented from generating irreversible demagnetization under the armature reaction effect of impact current, and that the permanent magnet steel pieces do not lose magnetism is ensured. The magnetic field in the air gap of the drive motor is provided jointly by the permanent magnet steel pieces and an electric excitation winding. The generated magnetic field directly faces the air gap, and there is less magnetic flux leakage.

Owner:SHANDONG UNIV OF TECH

Combined-type permanent magnet pole drive motor rotor production method

ActiveCN105790525AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsManufacturing stator/rotor bodiesHigh power densityDrive motor

The invention provides a combined-type permanent magnet pole drive motor rotor production method, and belongs to the technical field of electric car motor and electric appliances. Permanent magnet steels are respectively embedded into a rectangular radial groove and an arc-shaped groove of a rotor core. The structure is a rotor magnetic bypass structure, can effectively prevent the permanent magnet steels from causing irreversible demagnetization under the armature reaction of an impact current, and guarantees that the permanent magnet steels are not demagnetized. Meanwhile, the magnetic field of each magnetic pole of the drive motor rotor is provided by three permanent magnet steels, and is large in intensity. The method is high in output power, is high in efficiency, is high in power density, and is high in reliability.

Owner:SHANDONG UNIV OF TECH

Production method of electric car hub driving motor stealth magnetic pole rotor

InactiveCN105827073AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesManufacturing stator/rotor bodiesFailure rateElectric machine

The invention provides a production method of an electric car hub driving motor stealth magnetic pole rotor, and belongs to the technical field of an electric car motor electric appliance. The production method is characterized in that permanent magnet steel are respectively embedded in a rectangular radial slot and an arc-shaped slot of a rotor core; the structure is a rotor magnetic bypass structure, and can effectively prevent the permanent magnet steel from generating irreversible demagnetization under the armature reaction of the impulse current so as to guarantee no magnetic loss occurs in the permanent magnet steel; and at the same time, a hub driving motor rotor magnetic field is provided by the permanent magnet steel. The production method of an electric car hub driving motor stealth magnetic pole rotor has the advantages of having no demand for electrical excitation winding, consuming less electric energy, having non carbon brushes and mechanical commutators, being low in failure rate, being compact in structure, and being reliable in working.

Owner:张学义

A radial permanent magnet drive motor for an electric van transport vehicle

ActiveCN103746531BAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

The invention provides a power-driven compartment transport vehicle radial permanent magnet drive motor and belongs to the technical field of vehicle drive motors. The power-driven compartment transport vehicle radial permanent magnet drive motor comprises a front end cover (10), a rear end cover (1), a casing (8), a rotor and a stator (9), and is characterized in that the rotor is a radial permanent magnet rotor with a pole shoe; the radial permanent magnet rotor with the pole shoe comprises a shaft (2), a rotor core (3), a plurality of bolts (5), tile permanent magnet steels (6) and the pole shoe (7), the rotor core (3) is mounted on the shaft (2) in a pressed manner, an even number of the tile permanent magnet steels (6) are fixed on the excircle of the rotor core (3) in a way that the N poles and S poles are arranged on convex sides at intervals, and the pole shoe (7) is fixed on the outer rings of the tile permanent magnet steels (6) through the bolts (5). The magnetic field of the power-driven compartment transport vehicle radial permanent magnet drive motor is provided by the permanent magnet steels, electric field windings are not required, power consumption is less, a carbon brush or a mechanical commutator is not required, and the failure rate is low.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

Method for producing built-in biradial permanent magnet steel resultant magnetic field driving motor rotor

InactiveCN105763000AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsManufacturing stator/rotor bodiesHigh power densityDrive motor

The invention provides a method for producing a built-in biradial permanent magnet steel resultant magnetic field driving motor rotor and belongs to the technical field of electric automobile motors and electric equipment.Rectangular permanent magnet steel is embedded in a first rectangular groove and a second rectangular groove of a rotor core.A rotor magnetic bypass structure is adopted, irreversible demagnetization of permanent magnet steel caused under the armature reaction of impulse current can be effectively prevented, and loss of excitation of permanent magnet steel is avoided; meanwhile, the magnetic field of the driving motor rotor is provided by biradial permanent magnet steel, magnetic field intensity is high, output power is high, and the driving motor rotor has the advantages of being high in efficiency, high in power density, compact in structure, reliable in work and the like.

Owner:SHANDONG UNIV OF TECH

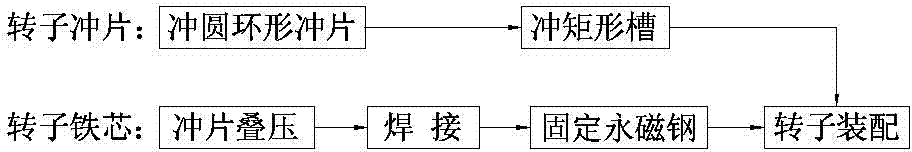

A kind of production method of radial permanent magnet rotor of drive motor of electric van transport vehicle

ActiveCN103762793BAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

The invention discloses a production method of a radial permanent-magnet rotor of a drive motor of a power-driven transport van, and belongs to the technical field of vehicle drive motors. The production method includes the following steps that center circular holes for installing a shaft (2) are drilled in the centers of a plurality of rotor sheets, and an even number of rivet circular holes are evenly formed in the circumferences of the rotor sheets, wherein the distance between the outer end of each rivet circular hole and the outer circle of the corresponding rotor sheet ranges from 1mm to 4mm; the rotor sheets are overlaid according to the uniform sequence of burrs and are riveted through iron rivets (4) to form a rotor iron core (3); tile permanent-magnet steel (6) is fixed to the outer circle of the rotor iron core (3) by screws (5) through pole shoes (7) in the form that N poles and S poles are alternatively arrayed on the protruding faces; the rotor iron core (3) is arranged on the shaft (2) in a pressing mode, and accordingly assembling of the radial permanent-magnet rotor of the drive motor of the power-driven transport van is completed. The rotor produced according to the production method can effectively avoid irreversible demagnetization generated by the permanent-magnet steel under the action of the armature reaction of impact current and protect the permanent-magnet steel against loss of excitation.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

Electric automobile invisible magnetic pole and tile permanent magnet steel wheel hub driving motor

InactiveCN105915006AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsElectric machinesFailure ratePower flow

The invention provides an electric automobile invisible magnetic pole and tile permanent magnet steel wheel hub driving motor, belonging to the automobile motor electric appliance technical field, and comprises a front end cover, a rear end cover, a wheel hub type casing, a rotor, a stator, a stator support and a shaft; a rectangular permanent magnet steel is embedded in a radial rectangular notch, and a tile permanent magnet steel is embedded in a circular arc notch; a wheel hub driving motor rotor magnetic field is provided by permanent magnet steels. The motor is a rotor magnetic bypass structure, and can effectively prevent permanent magnet steels from generating irreversible demagnetization under the surge current armature reaction effect, and avoid loss of excitation of the permanent magnet steels; in addition, the motor has no electro-magnetic coils, consumes less electric energy, has no carbon brushes and mechanical commutators, and possesses the characteristics of low failure rate, compact structure, and reliable operation.

Owner:张学义

Biradial permanent magnet and brushless electromagnetic hybrid excitation drive motor

InactiveCN105932843AIncrease the magnetic field strengthIncrease output powerMagnetic circuit rotating partsSynchronous machine detailsMagnetic field magnitudeDrive motor

The invention provides a biradial permanent magnet and brushless electromagnetic hybrid excitation drive motor, and belongs to the technical field of electric car motor appliances. The drive motor consists of a front end cover, a rear end cover, a motor case, a rotor, and a stator. Rectangular permanent magnet steels are respectively embedded into a first rectangular groove and a second rectangular groove. The drive motor can effectively prevent the permanent magnet steels from causing irreversible demagnetization under the action of armature reaction of an impact current, and guarantees that the permanent magnet steels are not demagnetized. A magnetic field in a gap of the drive motor is provided by the permanent magnet steels and an excitation winding, and is high in intensity. The output power is high.

Owner:SHANDONG UNIV OF TECH

Production method of double radial permanent magnet steel rotor embedded in hub drive motor

ActiveCN105790524BAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesElectric machineEngineering

Owner:SHANDONG UNIV OF TECH

Combined permanent magnet pole drive motor rotor production method

ActiveCN105790525BAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsManufacturing stator/rotor bodiesPower flowElectric machine

The invention provides a combined permanent magnet pole-driven motor rotor production method, which belongs to the technical field of electric vehicle motors and electrical appliances. The bypass structure can effectively prevent the irreversible demagnetization of the permanent magnet steel under the armature reaction of the impact current, and ensure that the permanent magnet steel does not lose its magnetism. At the same time, the magnetic field of each pole of the drive motor rotor is provided by three pieces of permanent magnet steel. High strength, high output power, high efficiency, high power density, and high reliability.

Owner:SHANDONG UNIV OF TECH

Power-driven compartment transport vehicle radial permanent magnet drive motor

ActiveCN103746531AAvoid irreversible demagnetizationGuaranteed not to lose magnetismMagnetic circuit rotating partsManufacturing stator/rotor bodiesFailure ratePermanent magnet rotor

The invention provides a power-driven compartment transport vehicle radial permanent magnet drive motor and belongs to the technical field of vehicle drive motors. The power-driven compartment transport vehicle radial permanent magnet drive motor comprises a front end cover (10), a rear end cover (1), a casing (8), a rotor and a stator (9), and is characterized in that the rotor is a radial permanent magnet rotor with a pole shoe; the radial permanent magnet rotor with the pole shoe comprises a shaft (2), a rotor core (3), a plurality of bolts (5), tile permanent magnet steels (6) and the pole shoe (7), the rotor core (3) is mounted on the shaft (2) in a pressed manner, an even number of the tile permanent magnet steels (6) are fixed on the excircle of the rotor core (3) in a way that the N poles and S poles are arranged on convex sides at intervals, and the pole shoe (7) is fixed on the outer rings of the tile permanent magnet steels (6) through the bolts (5). The magnetic field of the power-driven compartment transport vehicle radial permanent magnet drive motor is provided by the permanent magnet steels, electric field windings are not required, power consumption is less, a carbon brush or a mechanical commutator is not required, and the failure rate is low.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

Production method for rotor of hub driving motor with built-in tangential and radial permanent magnet steels

InactiveCN105811687AAvoid irreversible demagnetizationGuaranteed not to lose magnetismManufacturing stator/rotor bodiesHigh magnetic field strengthElectric machine

The invention provides a production method for a rotor of a hub driving motor with built-in tangential and radial permanent magnet steels, and belongs to the technical field of motors and electric appliances of electric automobiles. Rectangular permanent magnet steels are mounted in corresponding rectangular radial grooves and rectangular tangential grooves of the rotor iron core respectively. The structure is a rotor magnetic bypass structure, so that the irreversible demagnetizing of the permanent magnet steels generated under an armature reaction of the impact current can be effectively prevented so as to ensure that the permanent magnet steels are not demagnetized; meanwhile, the magnetic field of the rotor of the driving motor is jointly supplied by the radial magnetic field and the tangential magnetic field, so that high magnetic field strength and high power density are realized; and in addition, the characteristics of high efficiency, compact structure, reliable operation and the like are achieved as well.

Owner:张学义

Production method of drive motor rotor embedded with rare-earth permanent magnet steel for electric automobile

InactiveCN105811685AAvoid irreversible demagnetizationGuaranteed not to lose magnetismElectric machinesManufacturing stator/rotor bodiesRare earthDrive motor

The invention provides a production method of a drive motor rotor embedded with rare-earth permanent magnet steel for an electric automobile, and belongs to the technical field of electric automobile motors and electric appliances. Rectangular permanent magnet steel is embedded into rectangular radial slots and rectangular tangential slots of a rotor core respectively; a magnetic field of the drive motor rotor is provided by three pieces of permanent magnet steel; the magnetic field is high in strength; the power density is high; and the structure is a rotor flux bypass structure. The problem that the permanent magnet steel generates irreversible demagnetization under the effect of armature reaction of an impulse current can be effectively solved; the condition that the permanent magnet steel is not demagnetized is ensured; an electrical exciting winding is avoided; electric energy consumption is low; a carbon brush or a mechanical commutator is avoided; the fault rate is low; and the drive motor rotor has the characteristics of being compact in structure, reliable to work and the like.

Owner:张学义

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com