Production method of electric car hub driving motor stealth magnetic pole rotor

A hub-driven, invisible magnetic pole technology, used in electric vehicles, manufacturing motor-generators, motors, etc., can solve the problems of irreversible demagnetization, lowering and lowering of drive motor efficiency, and achieve compact structure, low power consumption, and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with accompanying drawing:

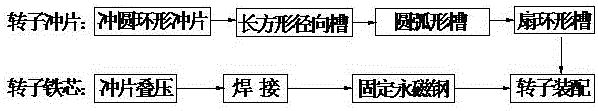

[0009] The production method of the invisible magnetic pole rotor of the electric vehicle hub drive motor is characterized in that: punching and cutting the circular rotor punching sheet, the rotor punching sheet is evenly distributed with an even number of rectangular radial grooves penetrating the thickness of the rotor punching sheet, and the inner side of the rectangular radial groove is Convex arc, the arch height of the convex arc is 1mm, there is a 1.5mm disconnected part between the bottom end of the rectangular radial groove and the inner circle of the rotor punch, and every two rectangular radial grooves are provided with a through-rotor punch. The inner arc of the sheet thickness faces the arc-shaped groove of the inner circle of the rotor punching sheet. The arc-shaped groove is not connected to the rectangular radial groove. In the disconnected part, the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com