Commutator size and appearance defect detection equipment based on CCD vision

A technology for appearance defects and detection equipment, applied in measuring devices, instruments, material analysis by optical means, etc., can solve problems such as failure to subdivide defect types of defective products, increase repair labor intensity and maintenance cost, and incomplete inspection, etc. Achieve accurate and comprehensive detection results, facilitate accurate repair work, and reduce unnecessary labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

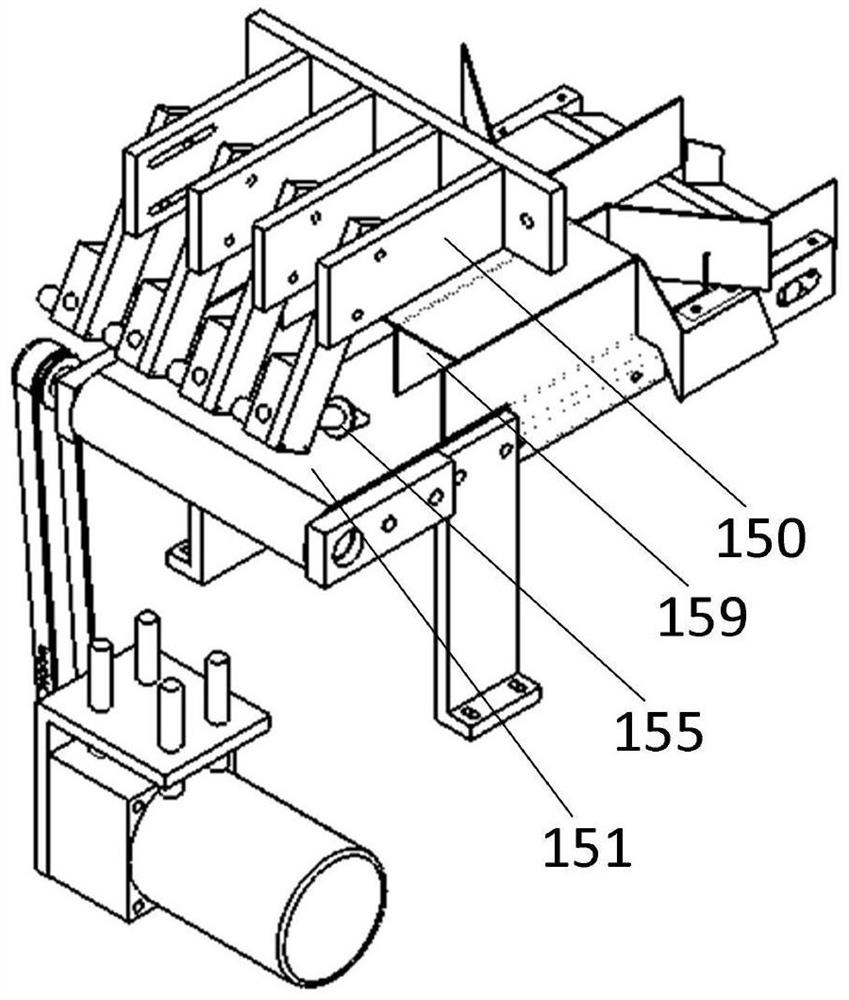

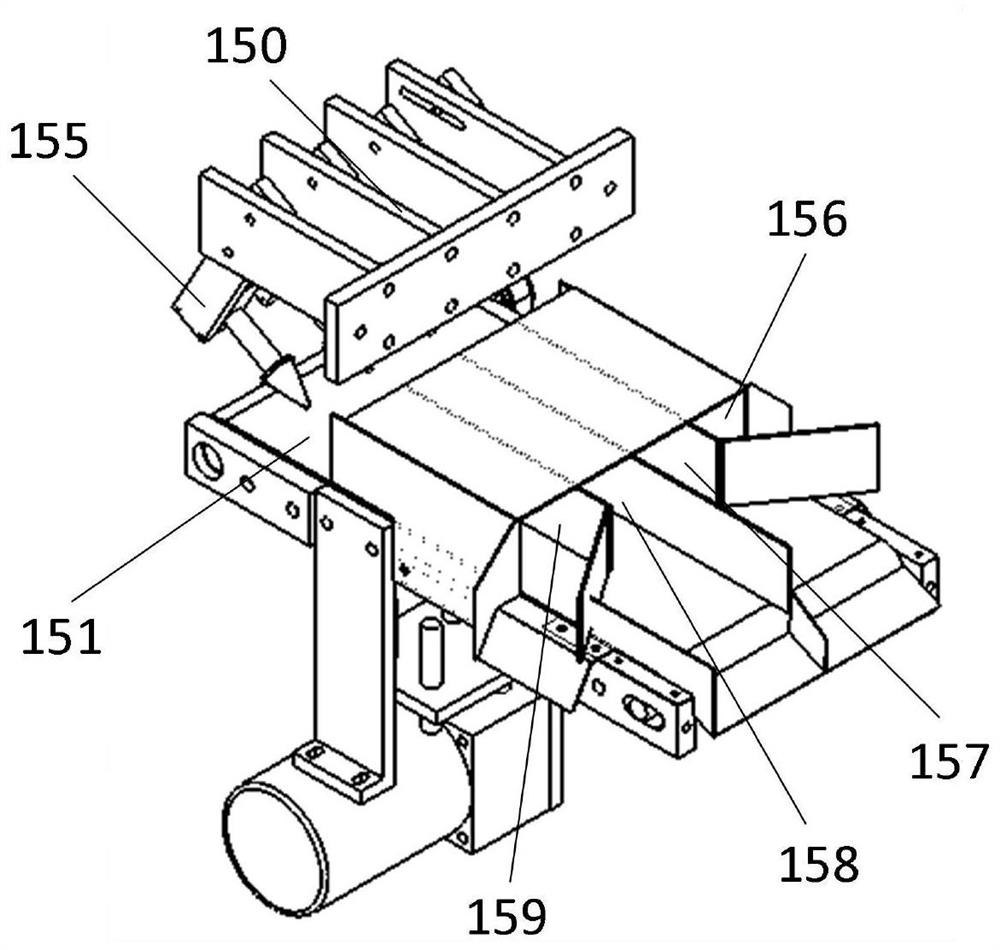

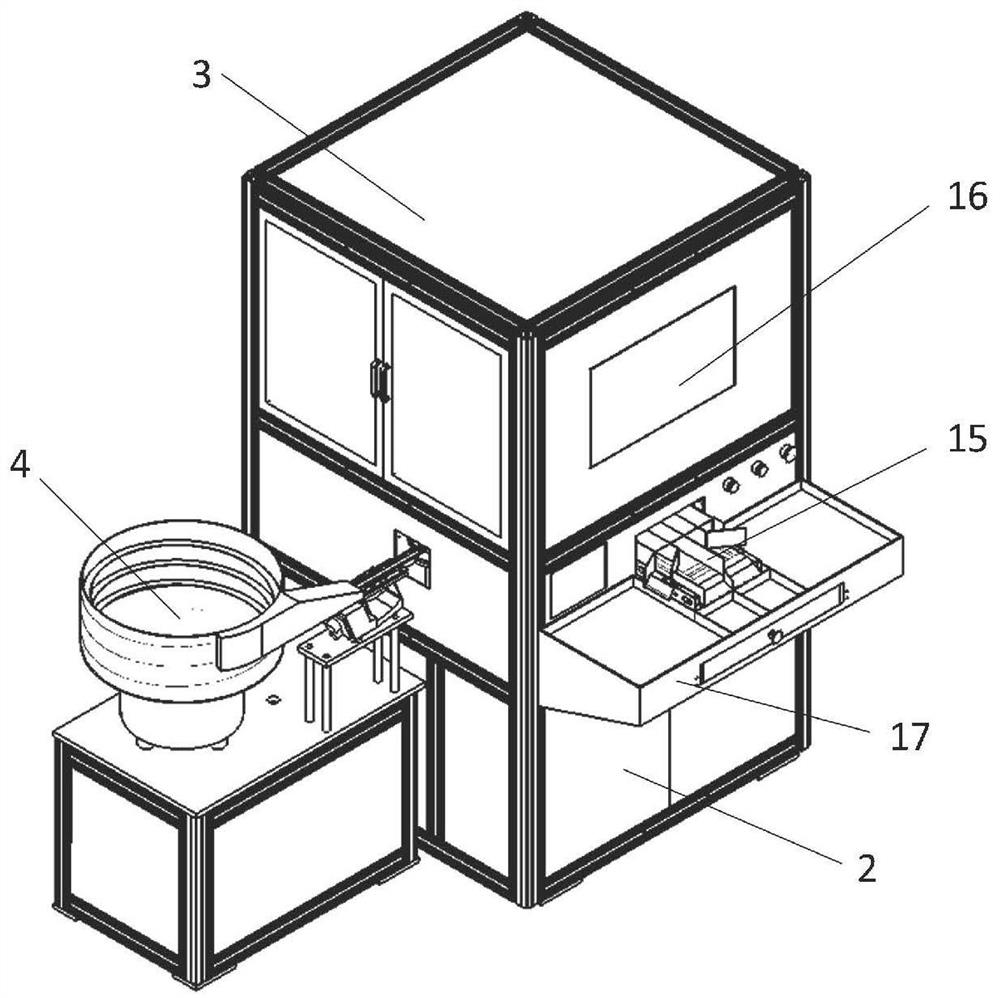

[0049] see Figure 1 to Figure 4 , a commutator size and appearance defect detection equipment based on CCD vision, comprising an electrical cabinet 2, a workbench 1 fixed on the top of the electrical cabinet 2, and a machine cover 3 fixedly arranged on the top of the workbench 1. Conventional control systems and power systems such as a computer host, air pressure supply equipment, and motor drivers are placed in the electrical cabinet 2 for the control of the entire equipment. The front side of the electric cabinet 2 is provided with a sheet metal side-by-side door, which is convenient for daily inspection and fault maintenance of each electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com