Patents

Literature

241results about How to "Realize all-round detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Remote obstacle detection method based on laser radar multi-frame point cloud fusion

ActiveCN110221603ASolve the problem of inability to effectively detect long-distance obstaclesPrecision FusionElectromagnetic wave reradiationPosition/course control in two dimensionsPoint cloudMultiple frame

The invention discloses a remote obstacle detection method based on laser radar multi-frame point cloud fusion. A local coordinate system and a world coordinate system are established, an extraction feature point of each laser point is calculated on an annular scanning line of the laser radar according to the original point cloud data under the local coordinate system, and the global pose of the current position relative to the initial position and the de-distortion point cloud in the world coordinate system are obtained through inter-frame feature point matching and map feature point matching; the de-distortion point clouds of the current frame and the previous frame are fused to obtain more compact de-distortion point cloud data, which is unified to the local coordinate system, then projection is performed on two-dimensional grids, and an obstacle is screened according to the height change features of each two-dimensional grid. According to the method in the invention, the problem that the detection rate of the remote barrier caused by sparse laser point clouds is low is solved, the remote barriers can be effectively detected, the error detection rate and the leak detection rateare low, and the system cost can be greatly reduced.

Owner:ZHEJIANG UNIV

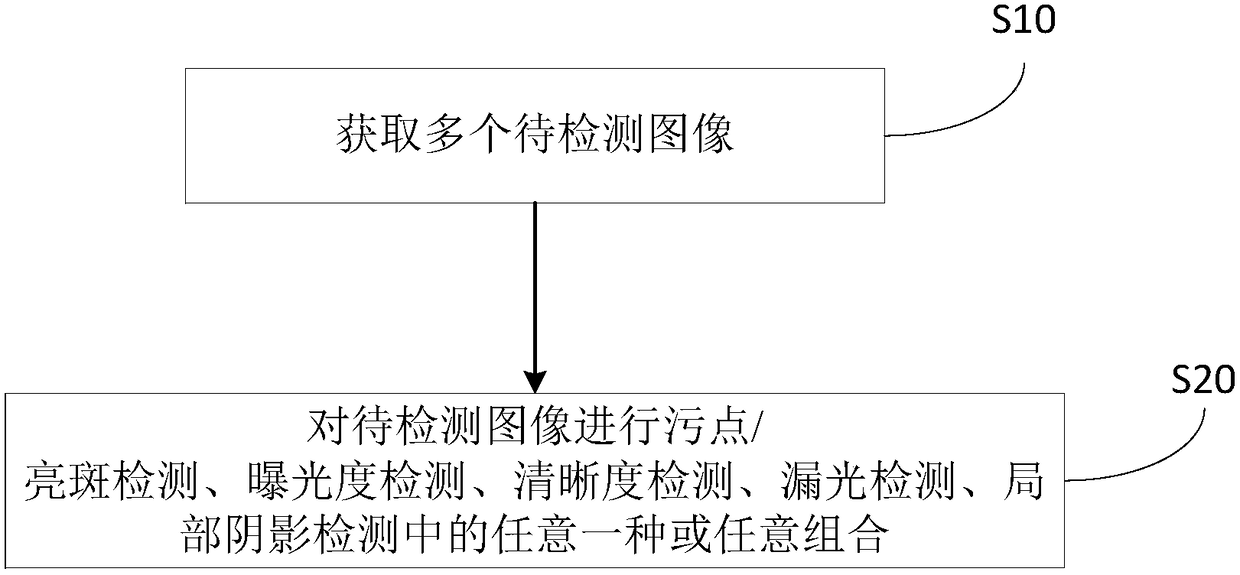

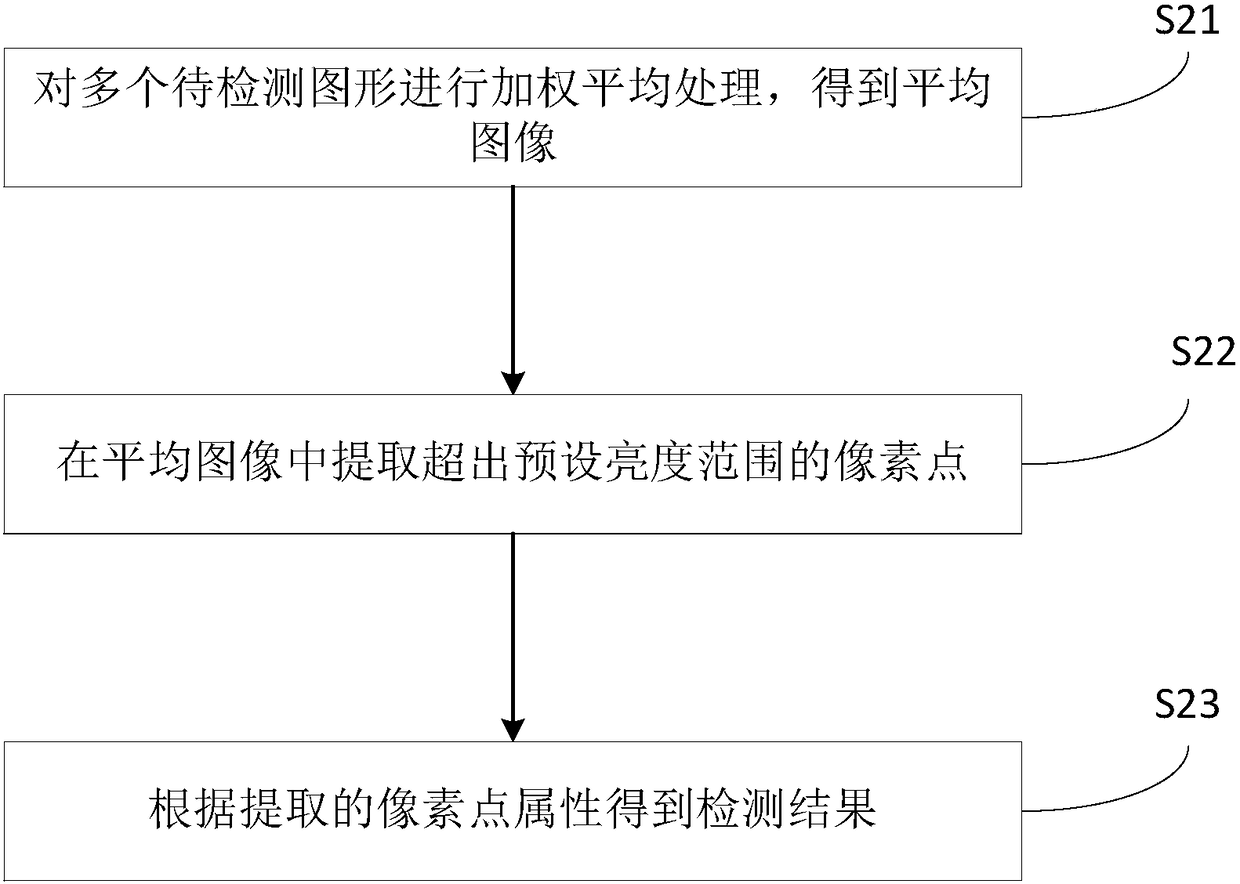

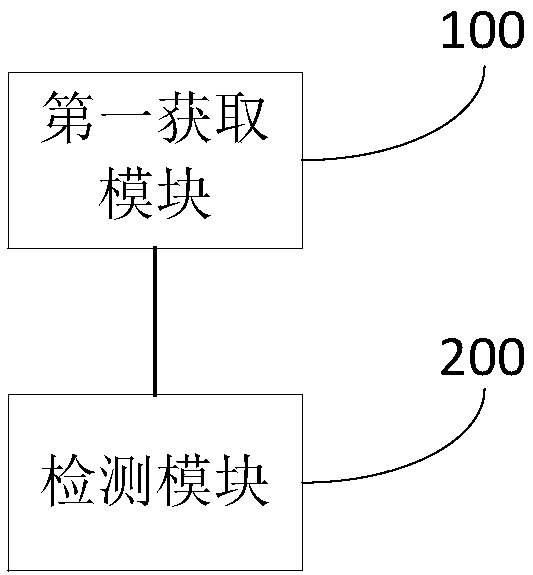

Image detection and processing method and device and terminal

ActiveCN108346149ARealize all-round detectionEfficient detectionImage enhancementImage analysisImage detectionComputer terminal

The invention discloses an image detection and processing method and device and a terminal. The image detection method comprises the steps that any one or any combination of stain / bright spot detection, exposure detection, definition detection, light leakage detection and local shadow detection is performed on multiple images after multiple images are acquired. The above mentioned detection can beperformed on the eye fundus image in turn, partial detection can also be performed according to the actual situation and omnidirectional detection of the image can also be realized so that the photographing quality of the image can be effectively detected.

Owner:BEIJING AIRDOC TECH CO LTD

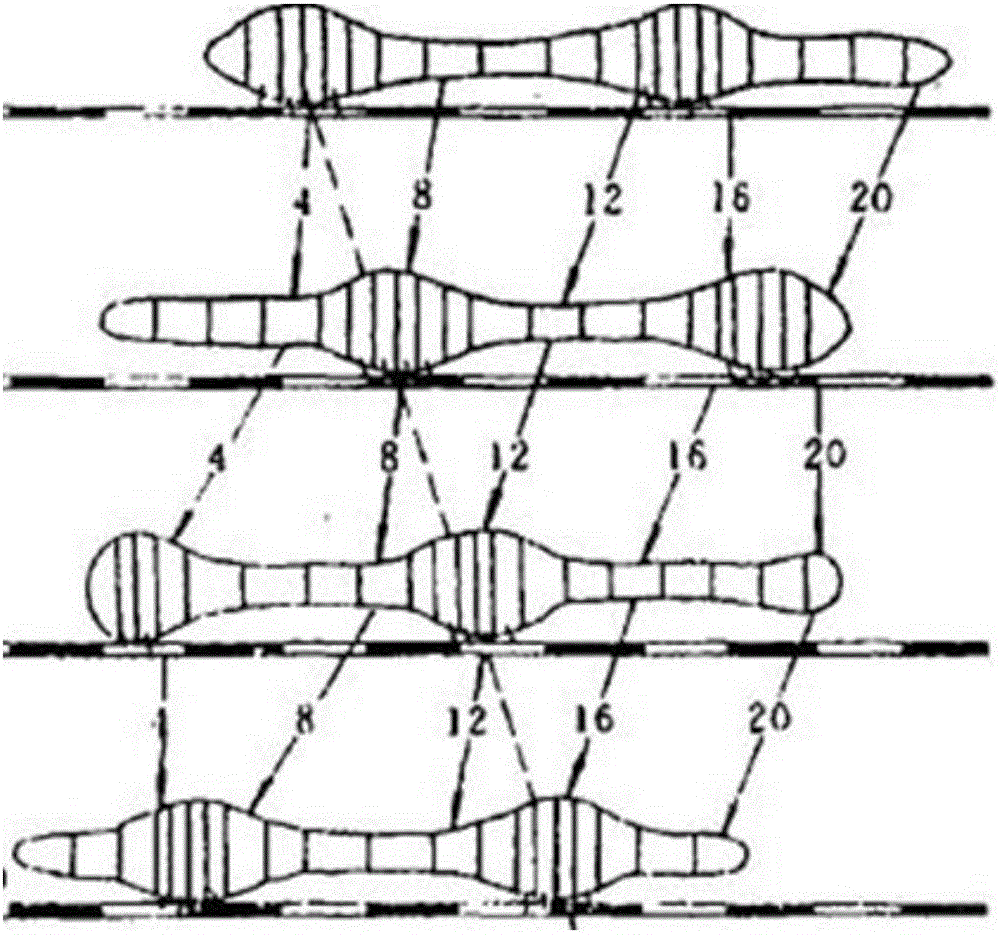

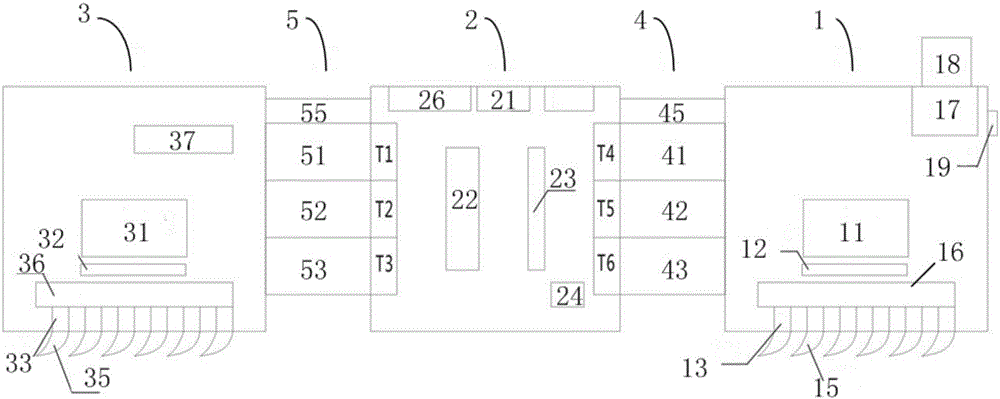

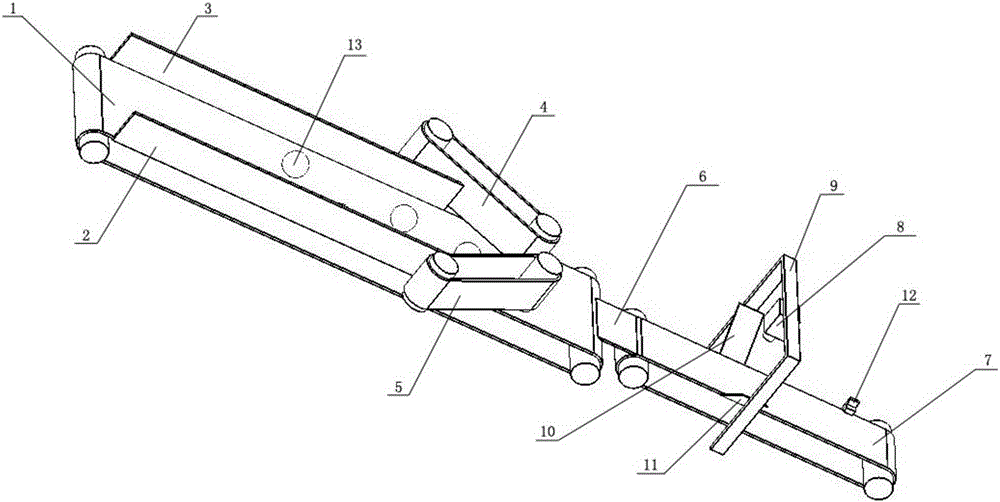

Pneumatic type soft motion robot based on earthworm motion principle

The invention provides a pneumatic type soft motion robot based on an earthworm motion principle. The robot comprises a first body part, a second body part and a third body part, wherein the first body part is connected with the second body part through a first telescopic part, the second body part is connected with the third body part through a second telescopic part, and the first body part and the second body part are controlled by a controller arranged on the second body part to stretch and retract; and mechanical steel bristles are arranged at the lower portion of the first body part and the lower portion of the third body part. By the adoption of the robot, a robot motion model is established according to the earthworm motion mechanism, and through the mechanical steel bristles, pneumatic control replacement and simulation of stretching and retracting of transverse muscles and longitudinal muscles of an earthworm, the robot can conduct complex actions of walking straightly, making a turn, crossing an obstacle and the like in a severe environment. Through intelligent control, the robot can be used in industrial pipeline exploration and disaster search and rescue.

Owner:SHANGHAI INST OF TECH

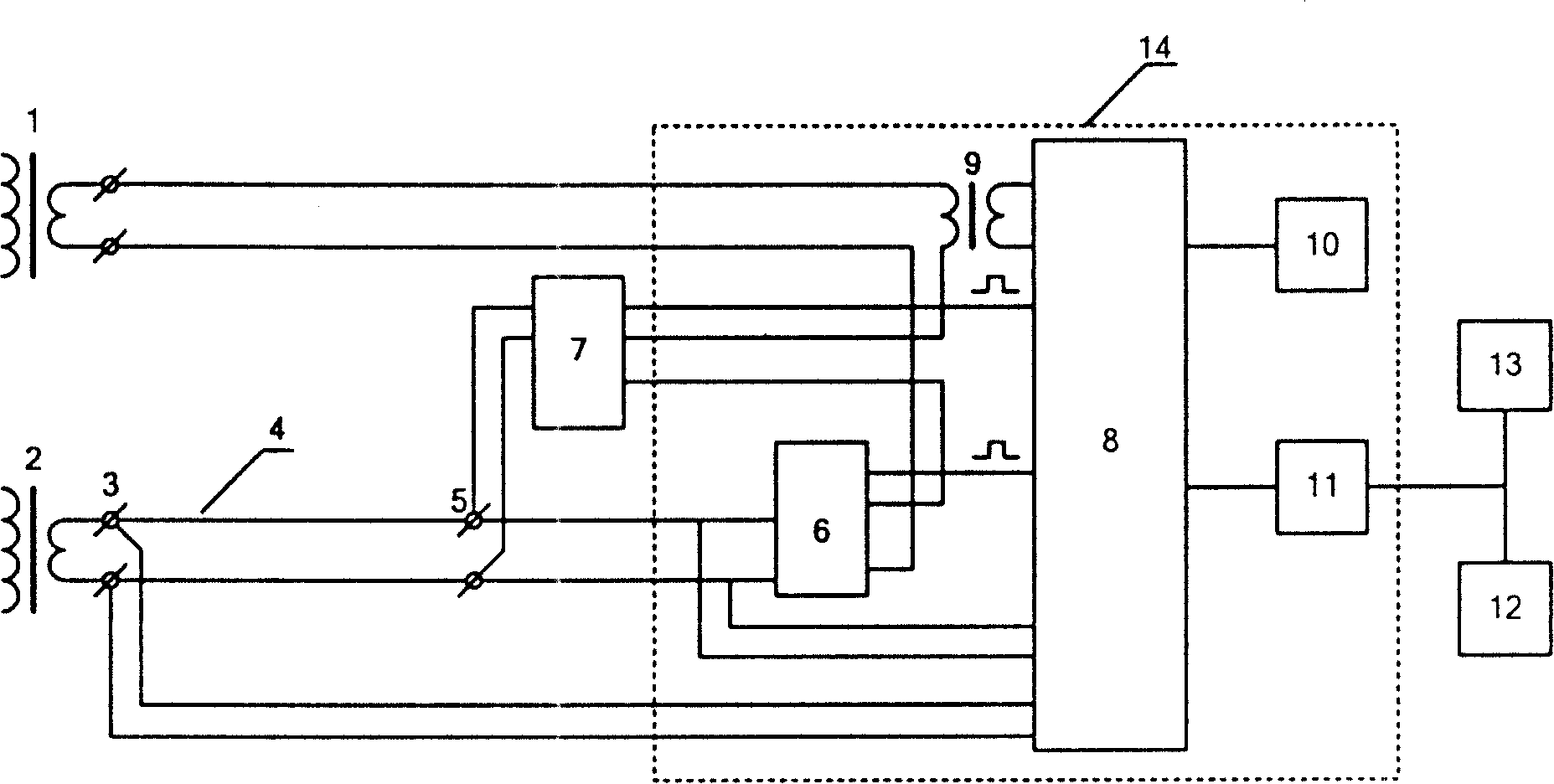

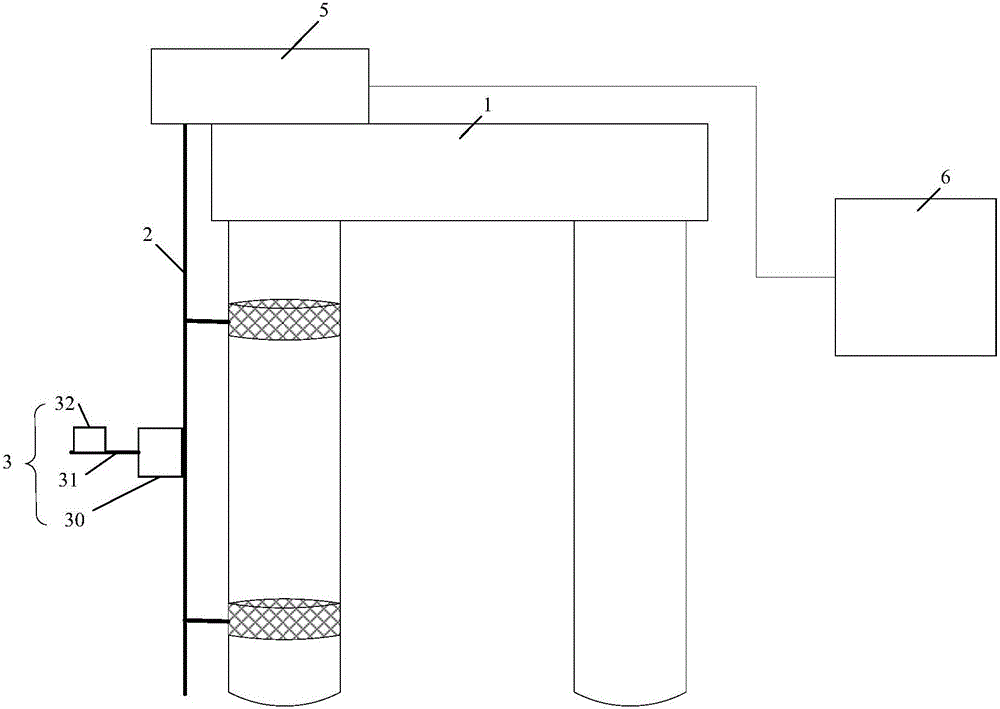

Watthour meter remote verify monitoring system

InactiveCN101162264ARealize real-time online detectionAvoid failureElectric signal transmission systemsElectrical measurementsMeasuring instrumentRemote computing

The invention provides a remote checking and monitoring system for electrical energy measuring instrument, the system is composed of a local unit, a local computer, a remote computer; a local display unit and a remote communication unit are connected with a microprocessor unit; the local computer and the remote computer are connected with the remote communication unit; the secondary voltage of a voltage transformer and the secondary current of a current transformer are connected with a checked ammeter and a standard ammeter in the local unit at a same time. The invention has the advantages that: firstly, an omni-bearing test for the whole electrical energy measuring system can be realized; secondly, a real-time on-line test for the electrical energy measuring system is realized; thirdly, the invention is provided with a remote communication function; fourthly, the invention can be interfaced with electrical energy measuring instruments of different types and from different factories; fifthly, the problems existing in the electrical energy measuring work of electrical customers can be accurately grasped.

Owner:红相电力(上海)有限公司

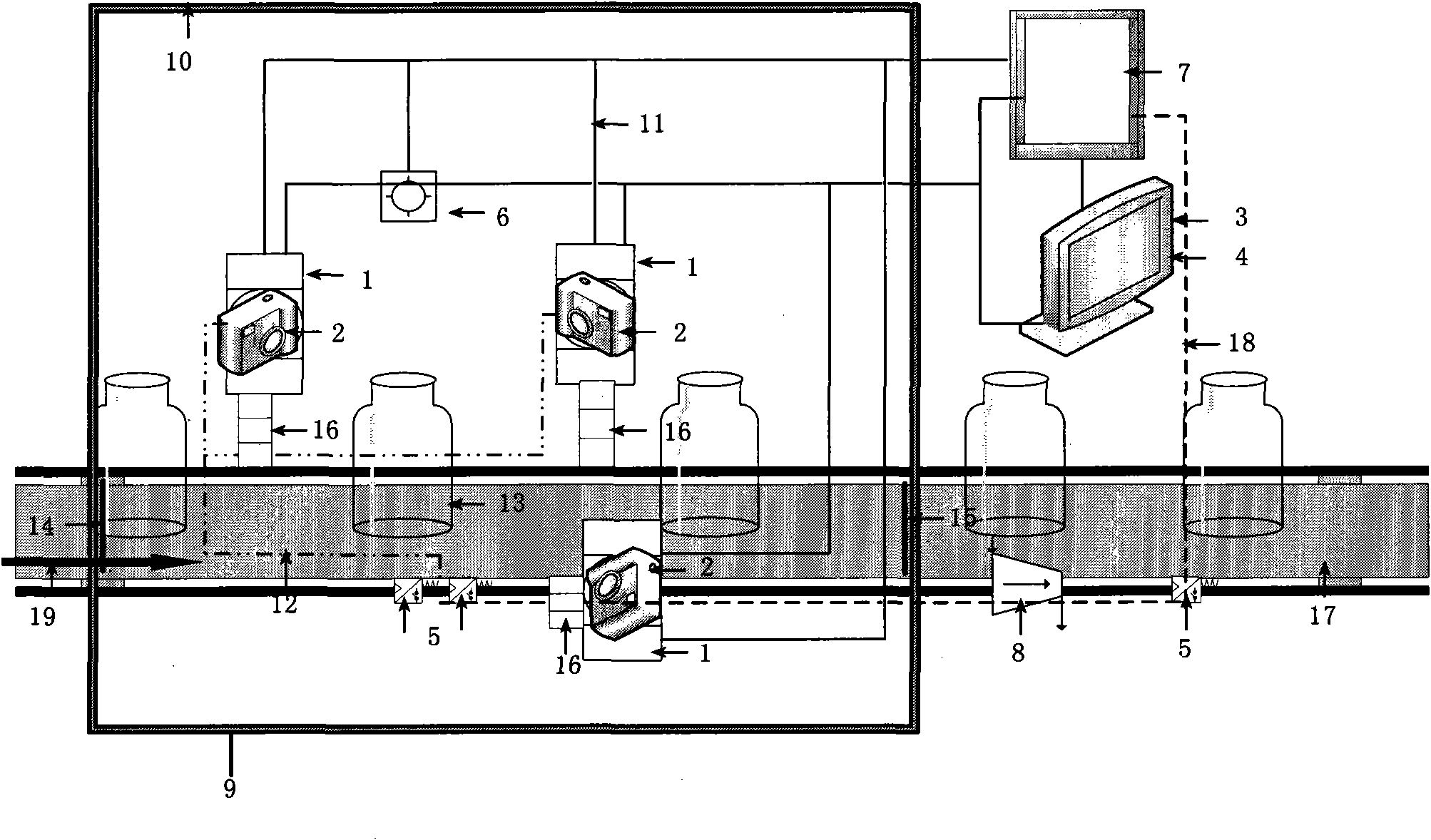

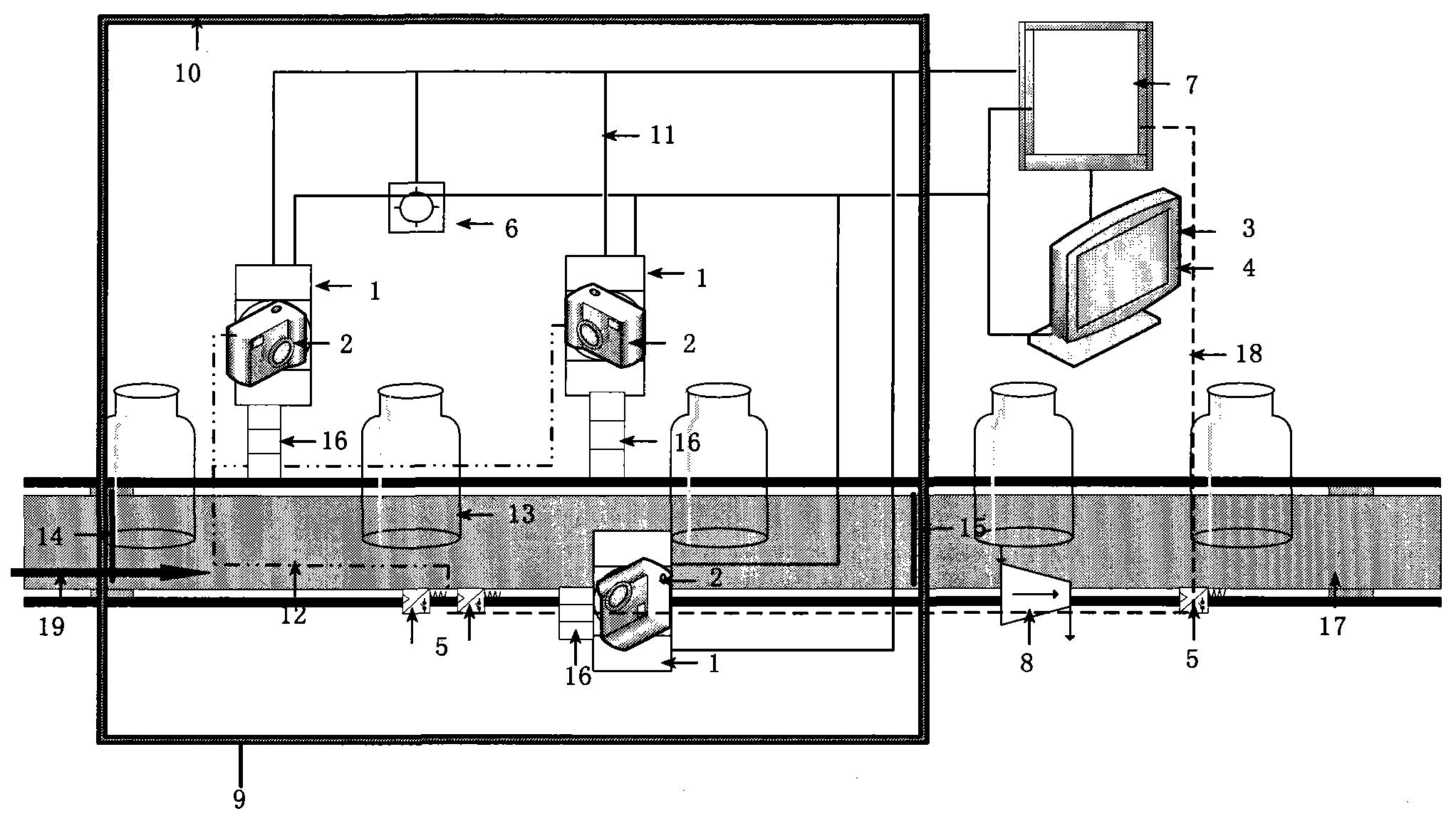

Vision detection device used for detecting defects on surface of plastic medicine bottle

InactiveCN102053091ARealize all-round detectionIncrease productivityMaterial analysis by optical meansPoint lightMedicine

The invention provides a vision detection device used for detecting defects on a surface of a plastic medicine bottle. The vision detection device consists of an annular light source (1), a camera (2), control software (3), a computer (4), a photoelectric sensor (5), a point light source (6), an electrical control cabinet (7), a removing device (8) and a shield (9). The annular light source (1) and the point light source (6) are respectively connected to the interior of the electrical control cabinet (7) by virtue of power lines (10); the annular light source (1) is arranged in front of the camera (2), the point light source (6) is arranged right above products (13) to be detected; and the computer (4) is respectively connected with the camera (2) and the electrical control cabinet (7). By utilizing the vision detection device provided by the invention, the detection accuracy can reach minimum 0.5mm of the diameter of a dark spot on the medicine bottle body, and omnidirectional detection on the bottle body is realized; and real-time, rapid, accurate and long-term continuous production detection can be realized, and the detectable rate of the defects on the surface of the plastic medicine bottle can be effectively controlled to be 99.99%, thus the vision detection device provided by the invention is beneficial to monitoring product quality and has higher application value in industrialized production.

Owner:王喆

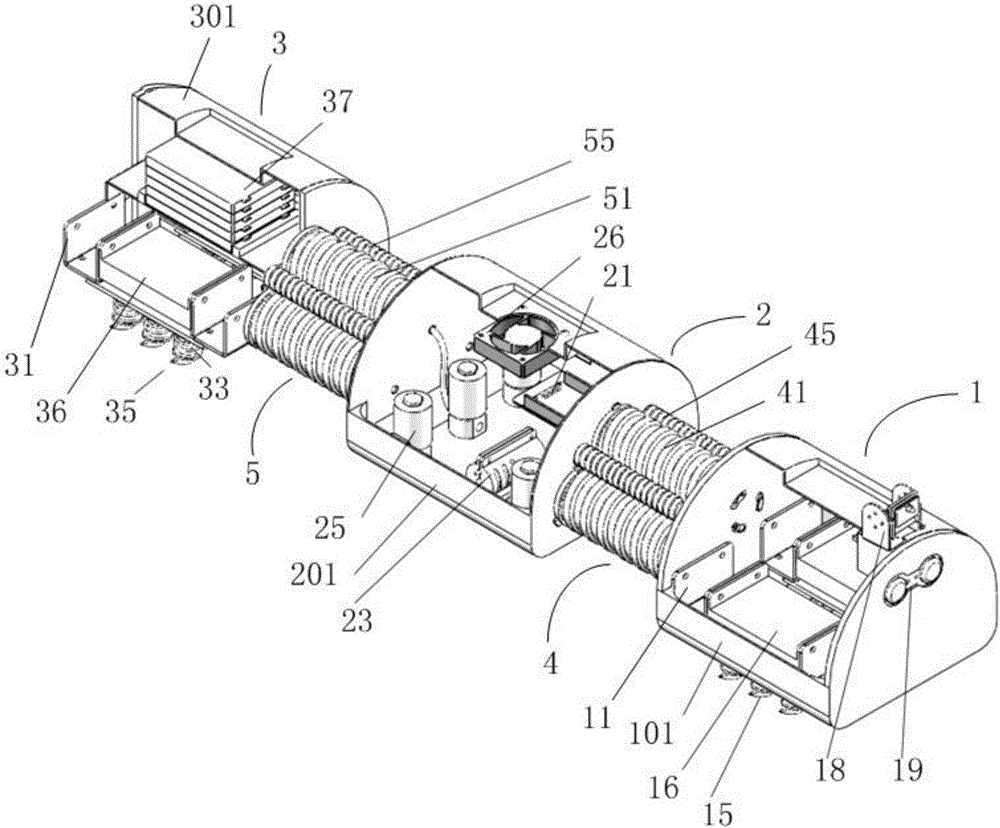

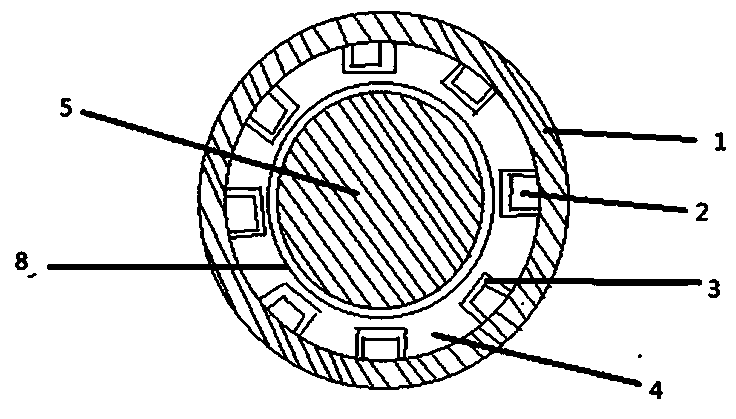

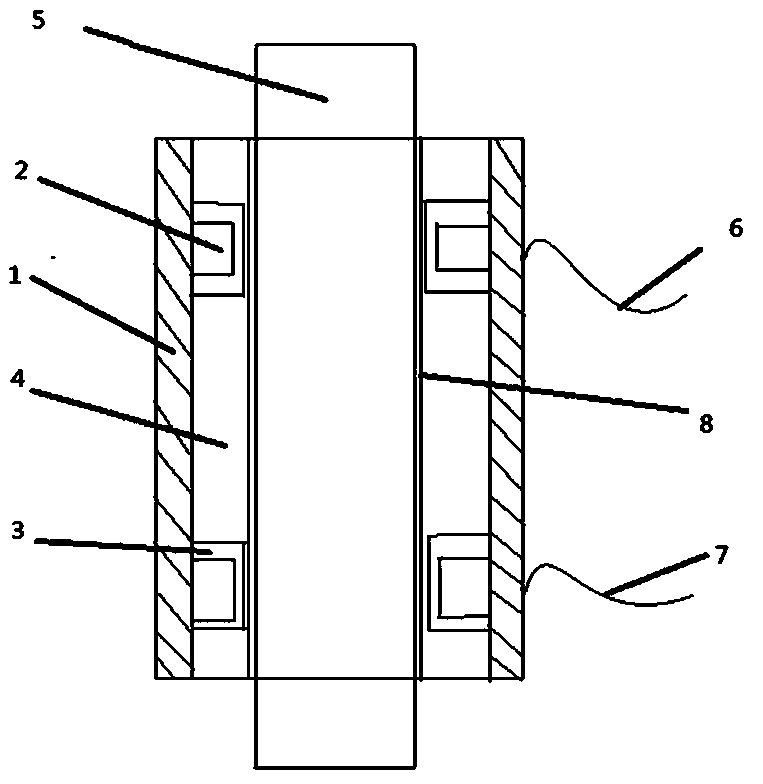

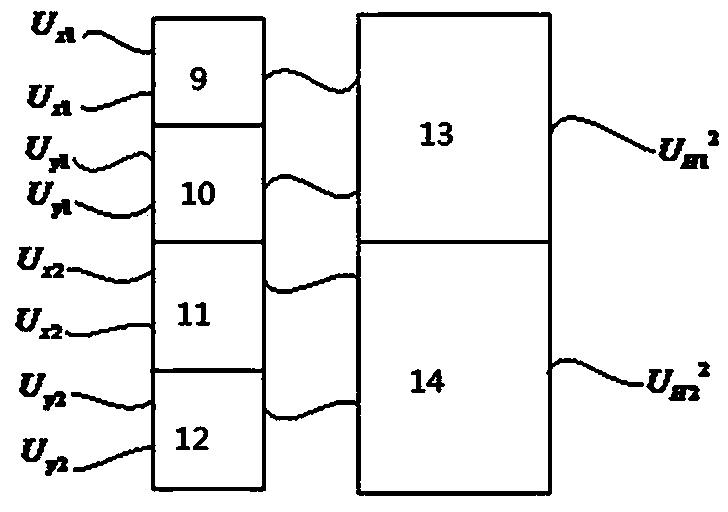

Steel wire rope magnetic memory on-line detection device

ActiveCN103995048AAvoid jitterImprove defect accuracyMaterial magnetic variablesNon destructiveMagnetic memory

The invention discloses a steel wire rope magnetic memory on-line detection device, and belongs to the technical field of non-destructive detection. The steel wire rope magnetic memory on-line detection device includes two groups of three-dimensional magnetoresistive sensors, adders, multipliers and subtracters, the two groups of three-dimensional magnetoresistive sensors are mounted on a steel wire rope and have the same mounting direction, and each group of three-dimensional magnetoresistive sensors comprises 8-12 three-dimensional magnetoresistive sensors uniformly distributed at a same circumference. An equilibrium and differential detection method is adopted to mainly aim to overcome steel wire rope shaking and outside interference, secondary output of signal characters is carried out, and the accuracy for judging metal member defects is improved; secondly, with adopting of a component signal single output method, whether a point is a steel wire rope defect is judged according to characteristic signals singly outputted by a normal component and a tangential component; and then, the two groups of annular uniformly-arranged three-dimensional magnetoresistive sensors HMC1053 are adopted to achieve all-dimensional inspection of the normal component and the tangential component of the steel wire rope, so as to eliminate the measured blind area problem.

Owner:TAIYUAN UNIV OF TECH

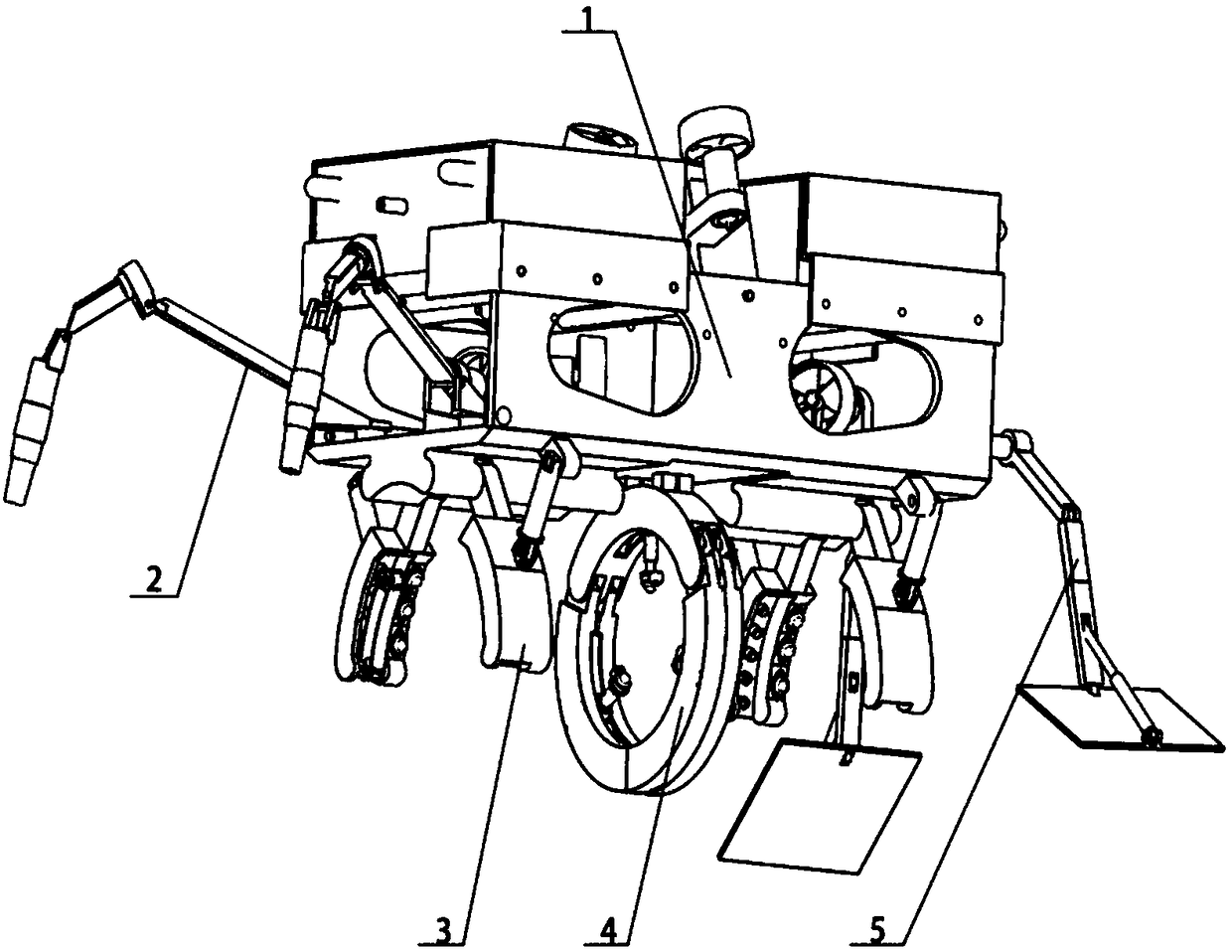

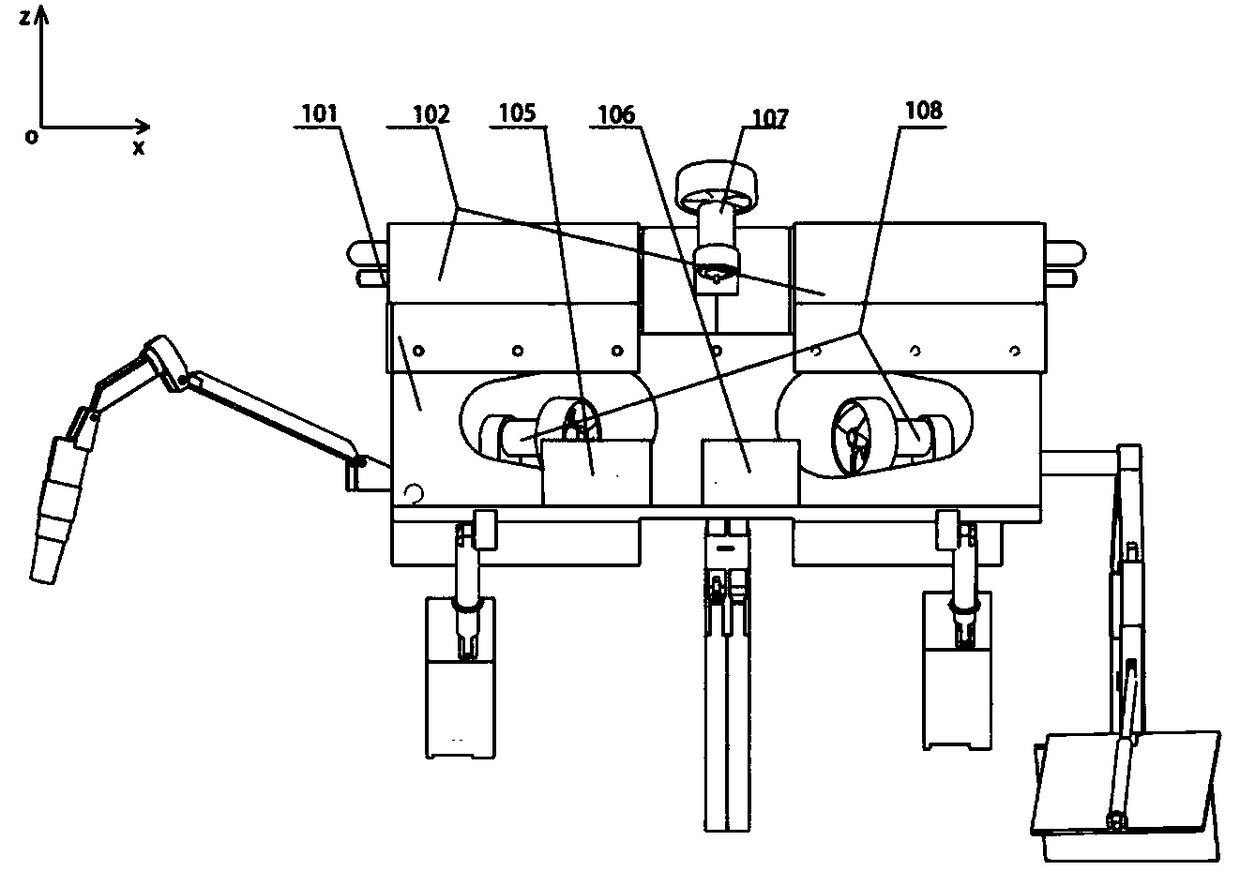

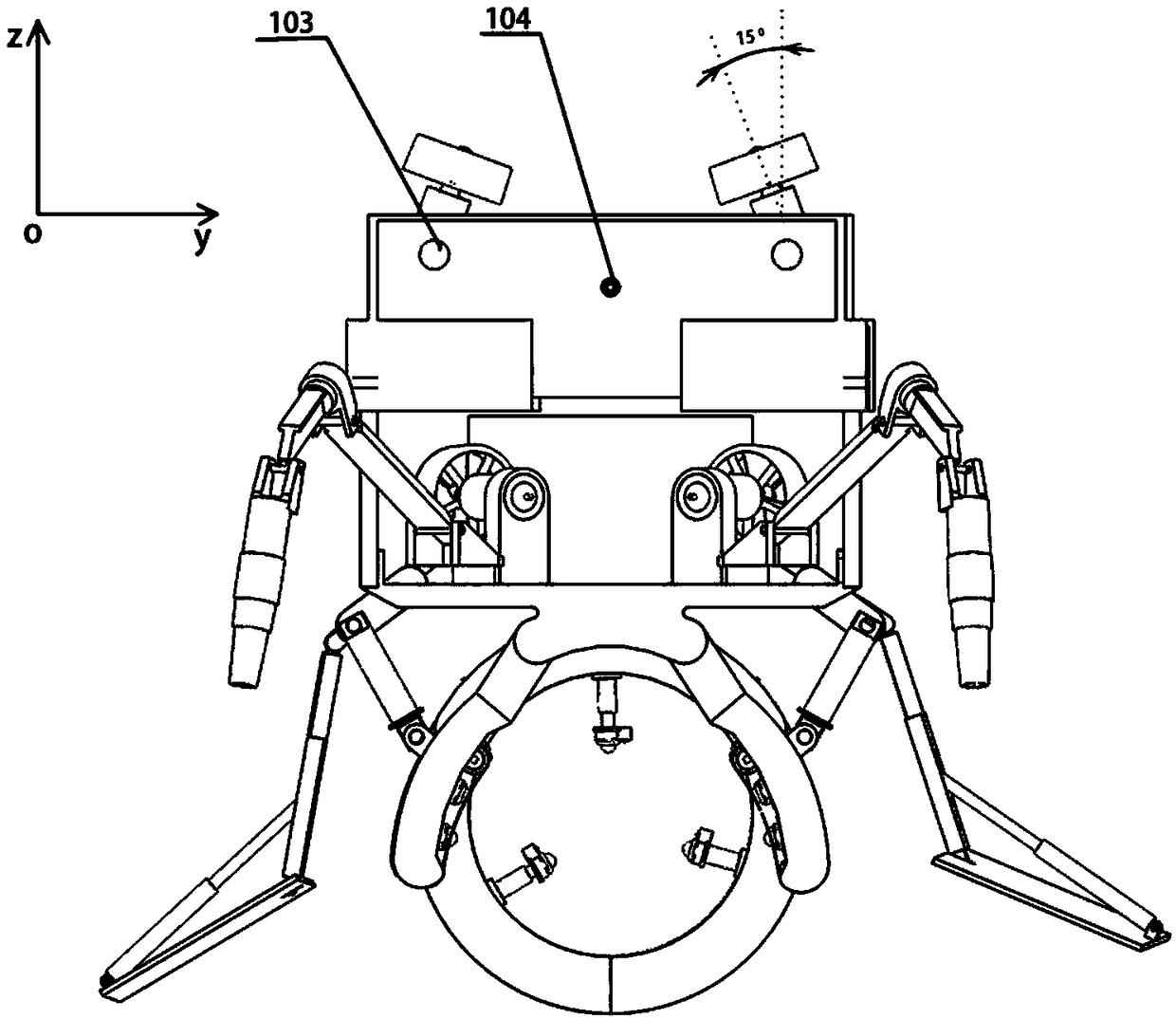

Underwater robot used for submarine pipeline magnetic memory detection

InactiveCN108468862AGuaranteed to rock back and forthWon't rock back and forthPipe laying and repairPipeline systemsOcean bottomLeveling mechanism

The invention provides an underwater robot used for submarine pipeline magnetic memory detection. The robot is mainly used for solving the problem that a conventional ROV cannot detect the bottom of the submarine pipeline particularly the bottom of the pipeline lying on the sea bed. The robot is characterized by comprising an ROV body, a spraying gun sand removal mechanism, a pipe attaching crawling clamping mechanism, a variable diameter sensor detection mechanism and a sediment leveling mechanism; the ROV body serves as a carrier to provide supporting and power for other devices, the spraying gun sand removal mechanism is used for cleaning sediment on a pipeline and the bottom, the pipe attaching crawling clamping mechanism is used for clamping pipelines with different diameters and achieving secondary cleaning, and it is ensured that universal rollers on a clamping jaw are tightly attached to the pipeline for crawling and cannot slip; the variable diameter sensor detection mechanismis used for achieving locking holding detection of a sensor for the pipelines of the different diameters. The robot can achieve full-cycle comprehensive non-dead-corner detection of submarine pipelines under the complex conditions of the deep water area, the sediment coverage and the like.

Owner:NORTHEAST GASOLINEEUM UNIV +1

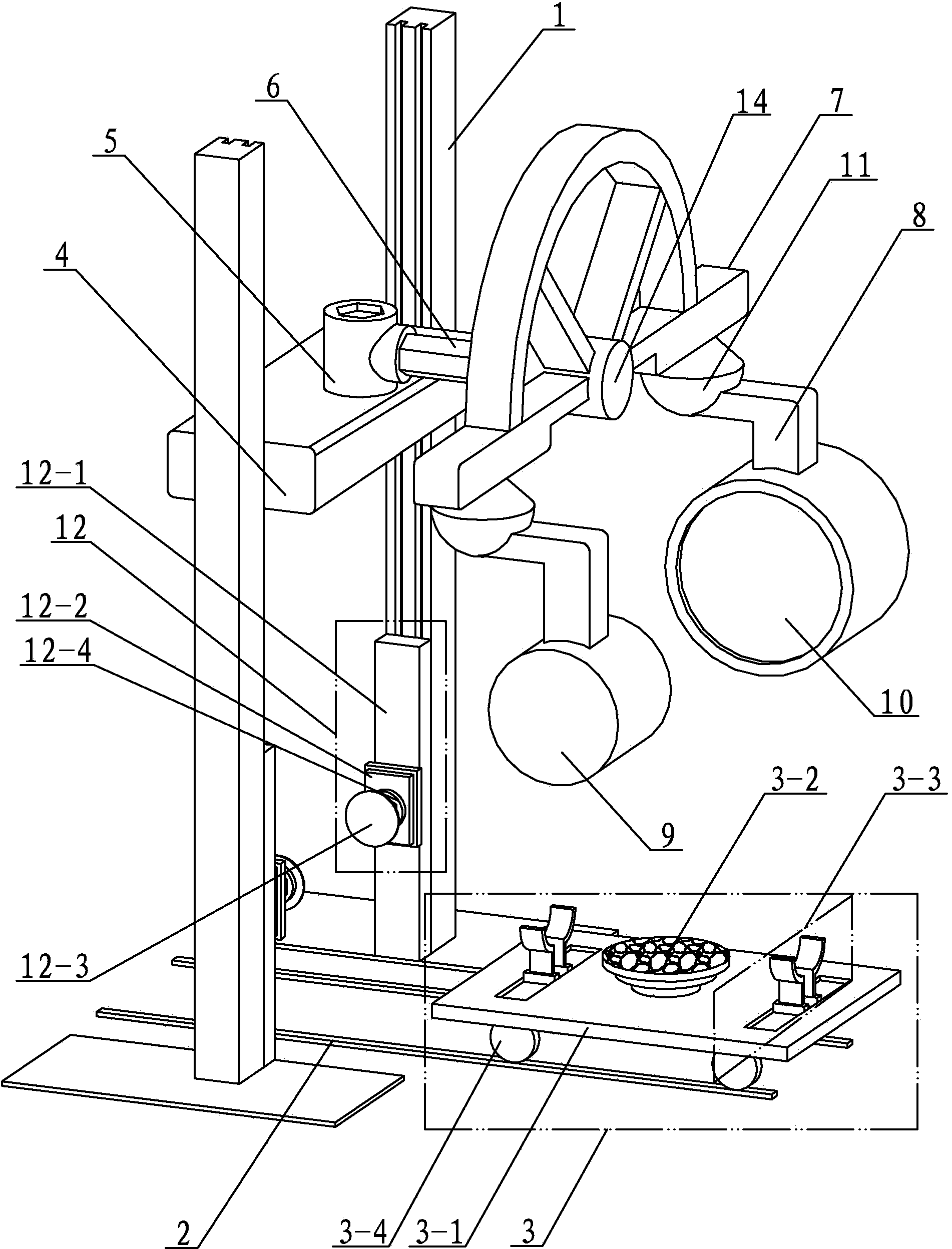

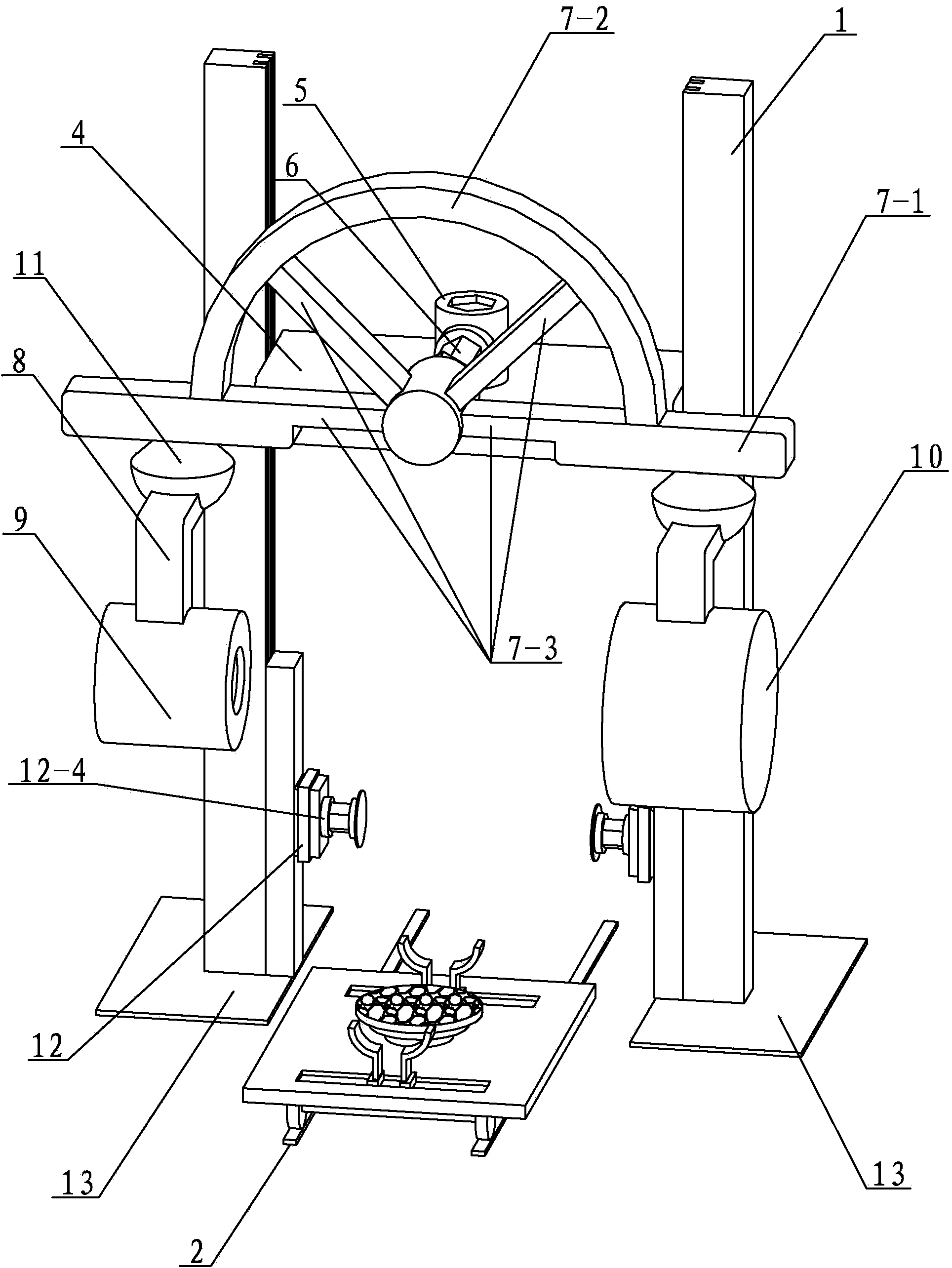

Wood nondestructive testing device capable of conducting imaging in real time at any angle

InactiveCN103792244AOvercome limitationsImprove clarityMaterial analysis by transmitting radiationSlide plateTest object

The invention discloses a wood nondestructive testing device capable of conducting imaging in real time at any angle to solve the problems that due to the fact that an existing testing device can not test a tested object at any angle and can usually test the object only in the two-dimensional plane, time for collecting images is long, definition is low, and the images can not be timely and coherently obtained, and relates to a wood testing device. According to the wood nondestructive testing device, two supports are vertically arranged in parallel, a slide rail is located between the two supports, a loading trolley is arranged on the slide rail in a slidable mode, radial moving sliding plates are arranged on the inner side walls of the two supports in a slidable mode, a swing adjusting motor is fixedly installed on the radial moving sliding plates, one end of an extension arm is connected with the swing adjusting motor, the other end of the extension arm is connected with a supporting arm through a rotating adjusting motor, the two ends of the supporting arm are respectively connected with a movable hinged joint, and a supporting rod is arranged on each hinged joint, and a ray transmitter and a receiver are fixedly arranged at the lower ends of the supporting rods respectively. The wood nondestructive testing device is used for testing wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

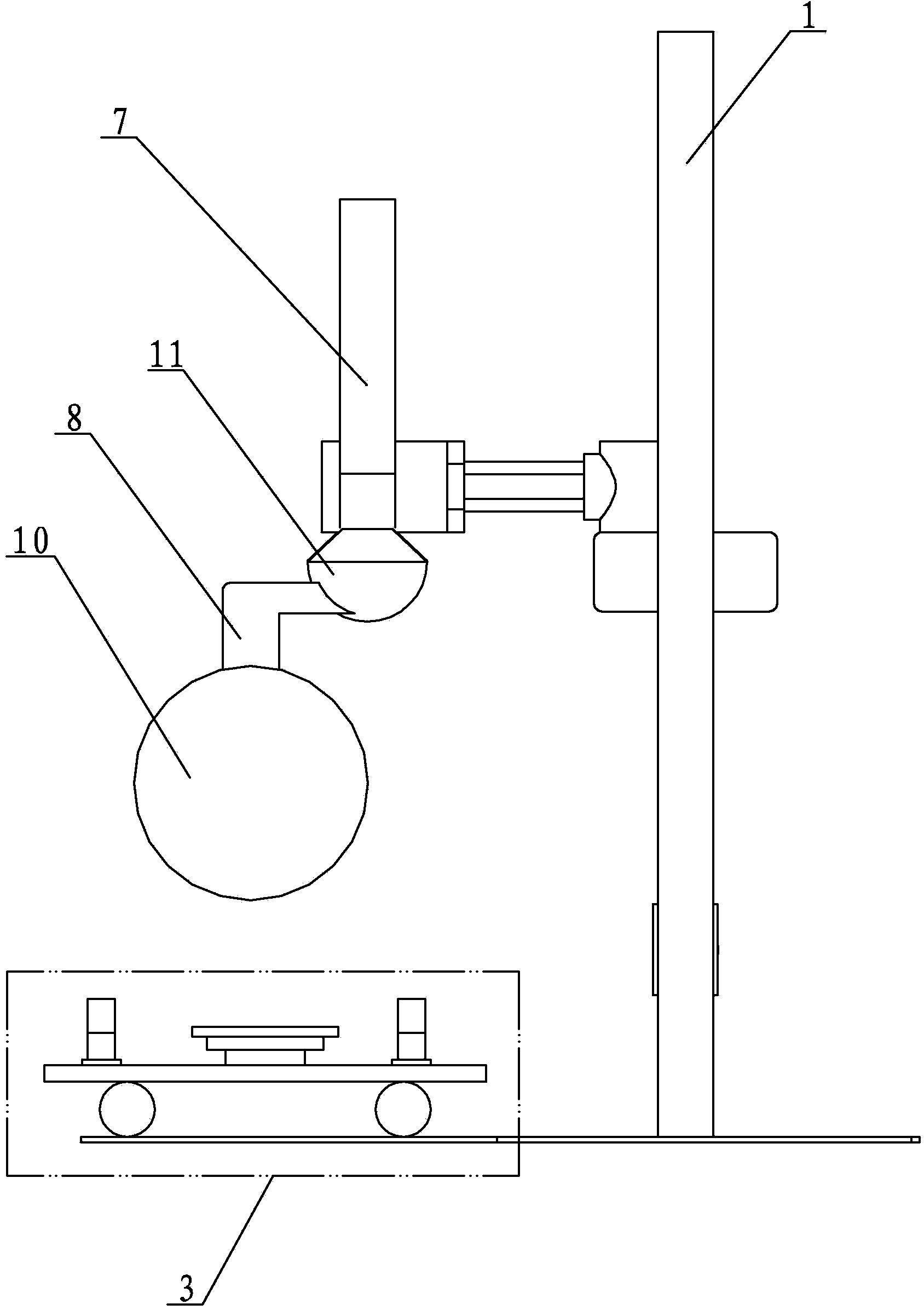

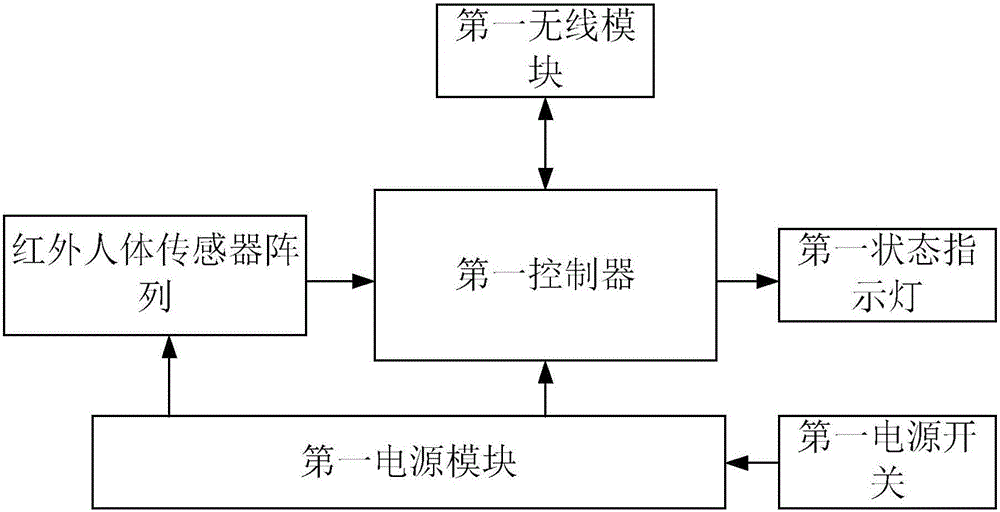

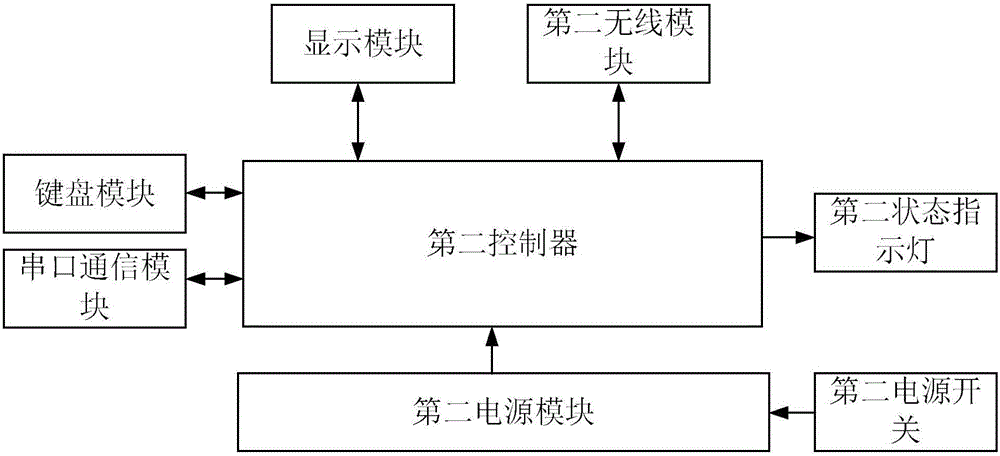

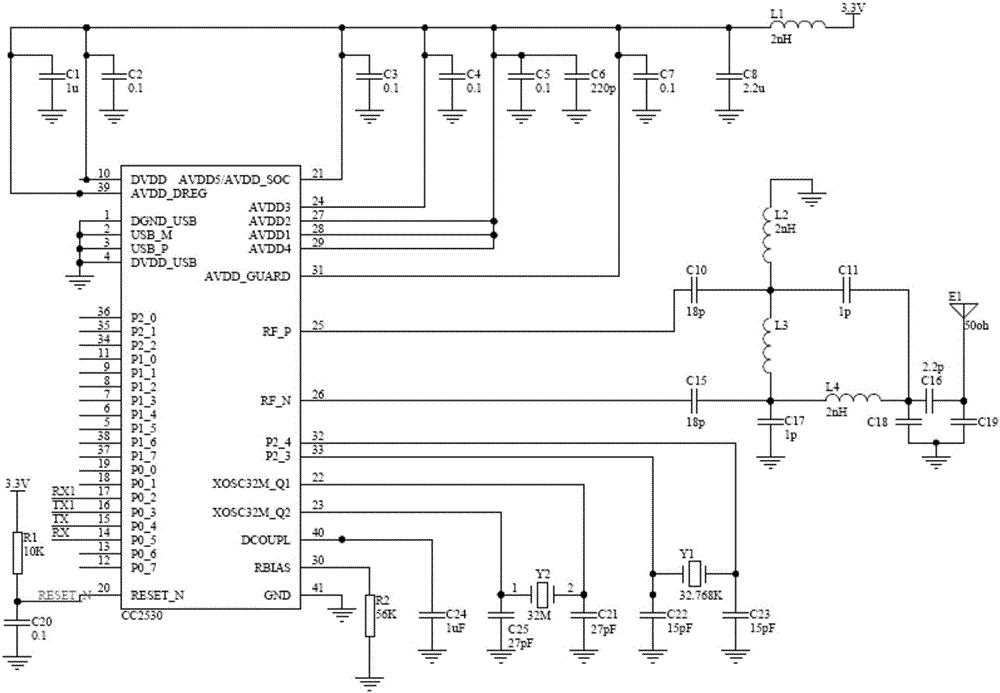

Indoor personnel positioning system and method based on infrared human body sensor array

InactiveCN104994576ARealize all-round detectionRealize the need for positioningPower managementNetwork topologiesSensor arraySignal source

The invention provides an indoor personnel positioning system and method based on an infrared human body sensor array. The system comprises a plurality of detecting nodes, a base station node, and a host computer. The detecting nodes are arranged at different positions indoors. The base station node is connected with the host computer through a serial port connecting line. The detecting nodes are wirelessly connected with the base station node. Each infrared human body sensor array comprises four infrared human body sensors. Each infrared human body sensor has a 90-degree detecting range such that each infrared human body sensor array may achieve 360-degree omnibearing detection. Each detecting node transmits a detected result to the base station node via a Zigbee network in order to compute personnel positions. Personnel to be positioned are not required to wear any tag or signal source and are completely passively positioned. The indoor personnel positioning system is high in positioning precision. Since each infrared human body sensor has an about 6-meter detecting radius, the information of more than 3 detecting node may achieve about 1-meter positioning precision which may completely satisfy an indoor personnel positioning requirement.

Owner:NORTHEASTERN UNIV

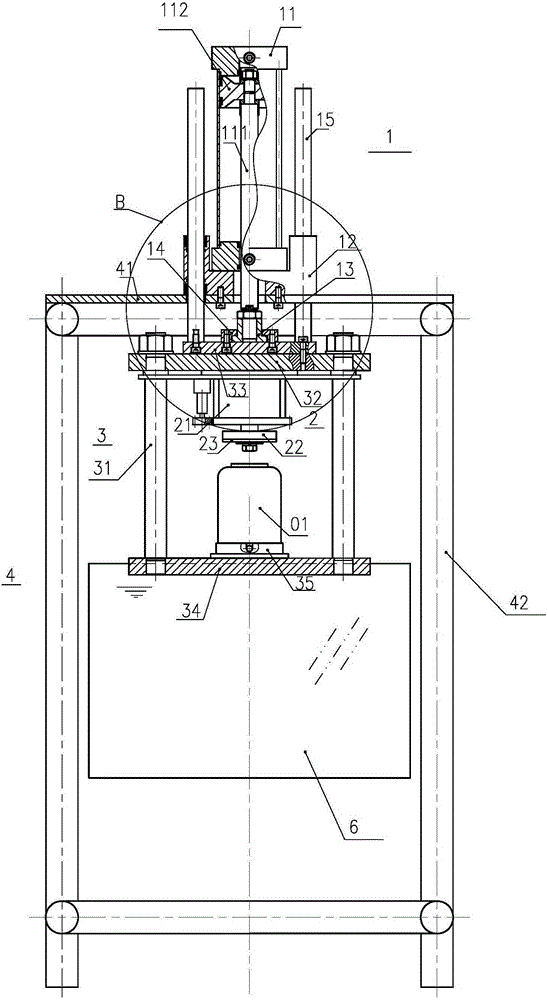

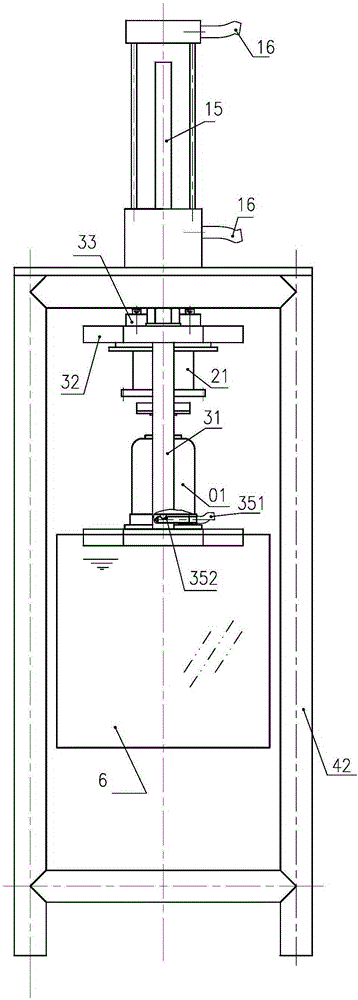

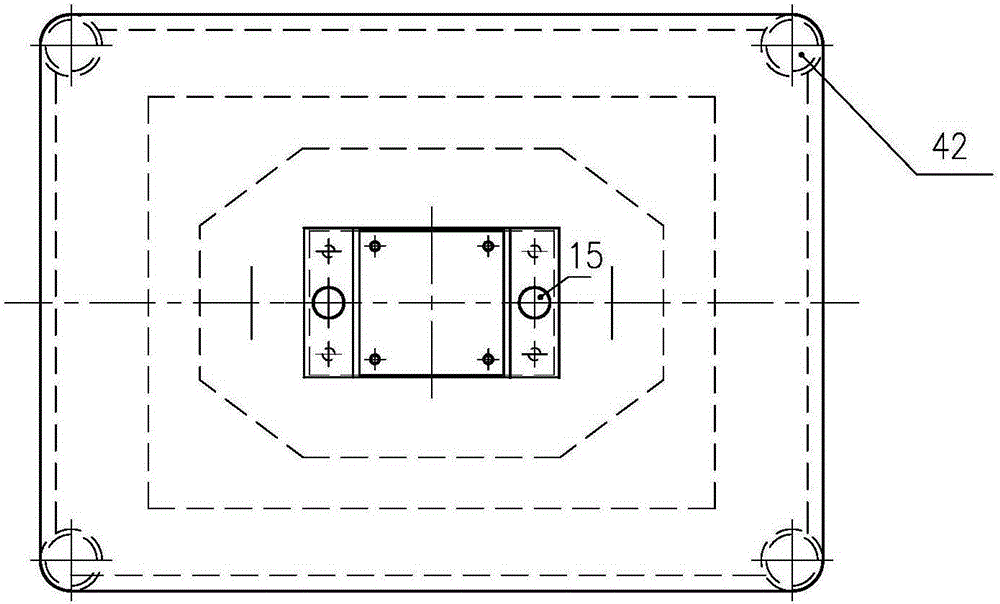

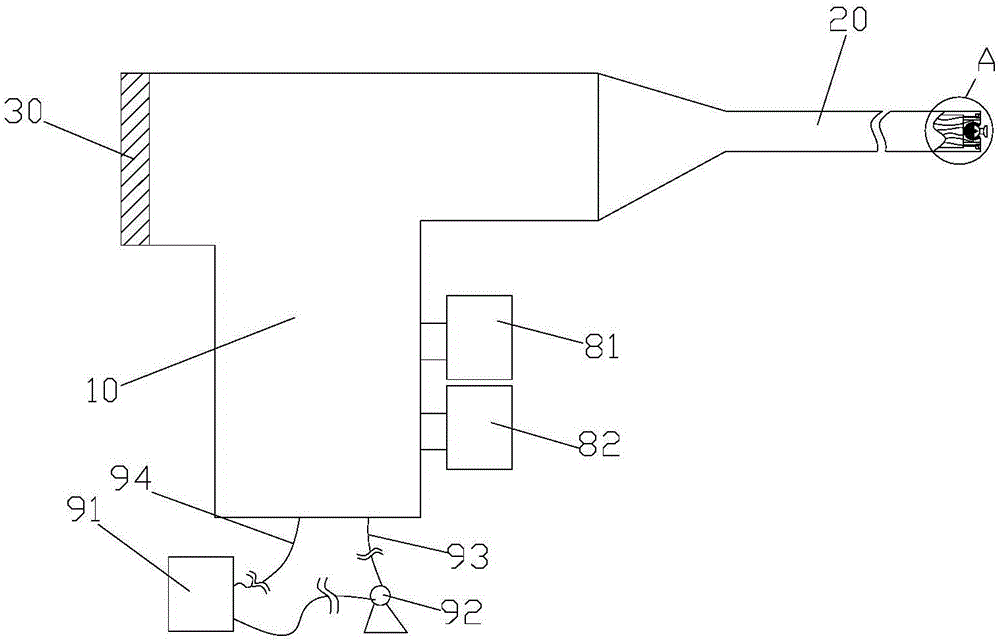

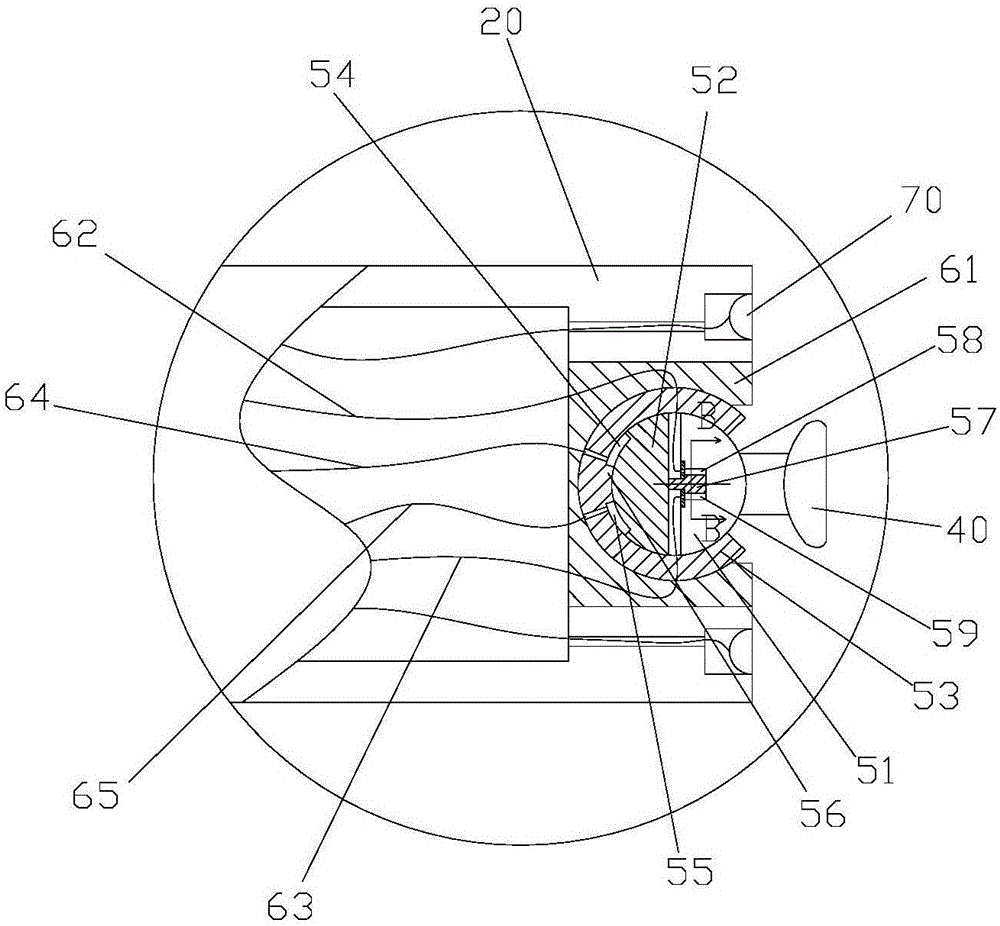

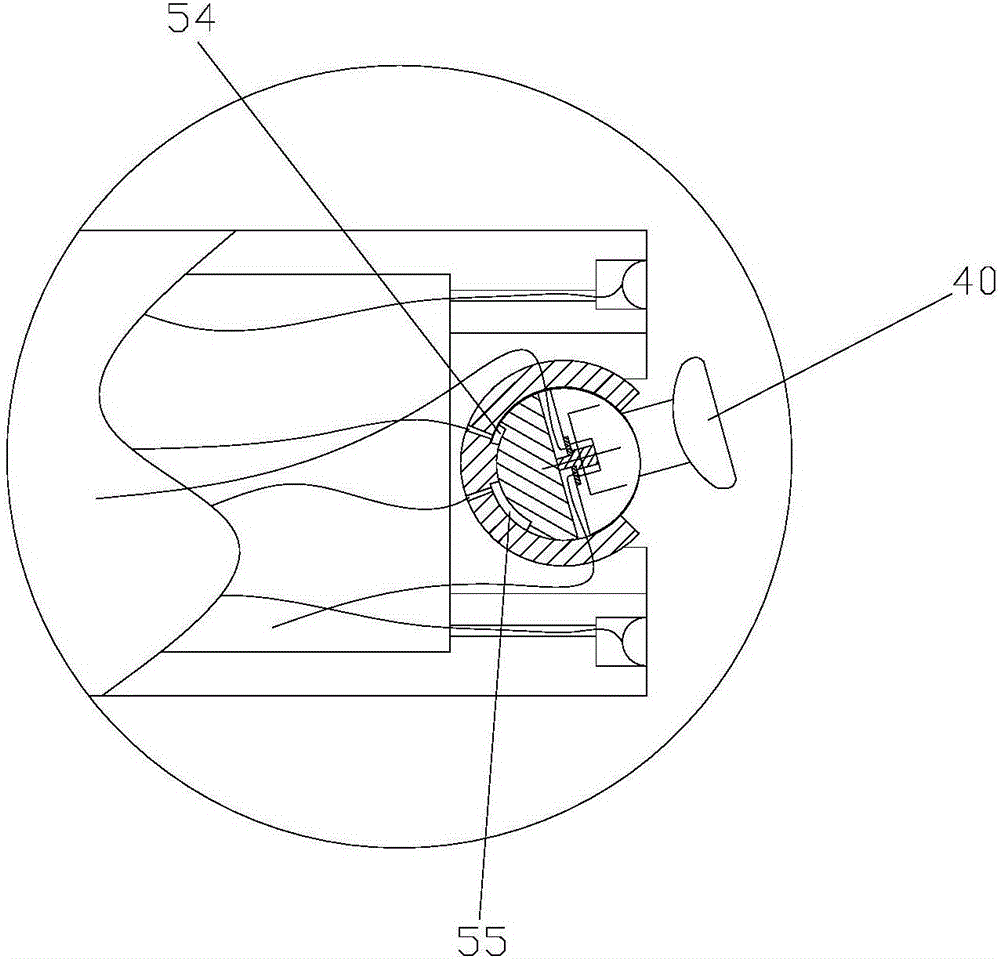

Welding tightness detection machine and method using detection machine to detect welding tightness

InactiveCN105181261ARealize all-round detectionSimple structureDetection of fluid at leakage pointFuel tankAir tightness

The invention relates to a welding tightness detection machine. The welding tightness detection machine comprises a work table, a liquid container which is arranged at the lower part of the work table, a workpiece placing tooling, a vertical movement device which is connected with the workpiece placing tooling and drives the workpiece placing tooling to vertically move to enable the workpiece placing tooling to lift together with a workpiece to come into or out of a container, a sealing positioning device which is arranged at the upper part of the workpiece placing tooling, a workpiece rotation device, a pressurizing mechanism which is arranged on the workpiece placing tooling, and a control device which is in communication connection with the vertical movement device, the sealing positioning device and the pressurizing mechanism. The invention further discloses a method using the detection machine to detect welding tightness. Through a first cylinder and a second cylinder, the welding tightness detection machine realizes the whole processes of workpiece clamping and positioning and tightness detection. The whole device has the advantages of simple structure, reliable work and simple process, and is particularly suitable for the tightness detection of a cylinder, a fuel tank, a welding pipe and the like.

Owner:NANTONG TONGRUN AUTO ACCESSORY

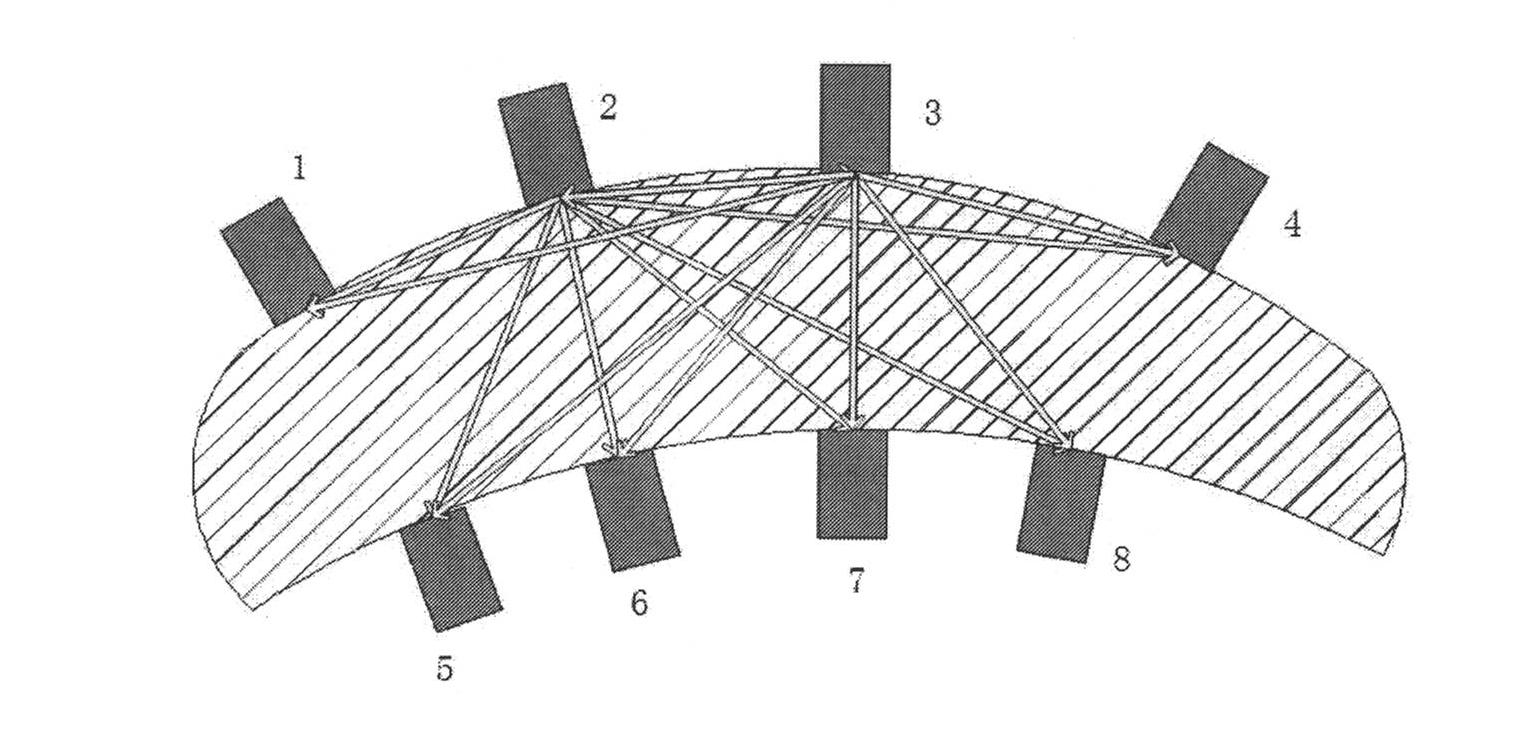

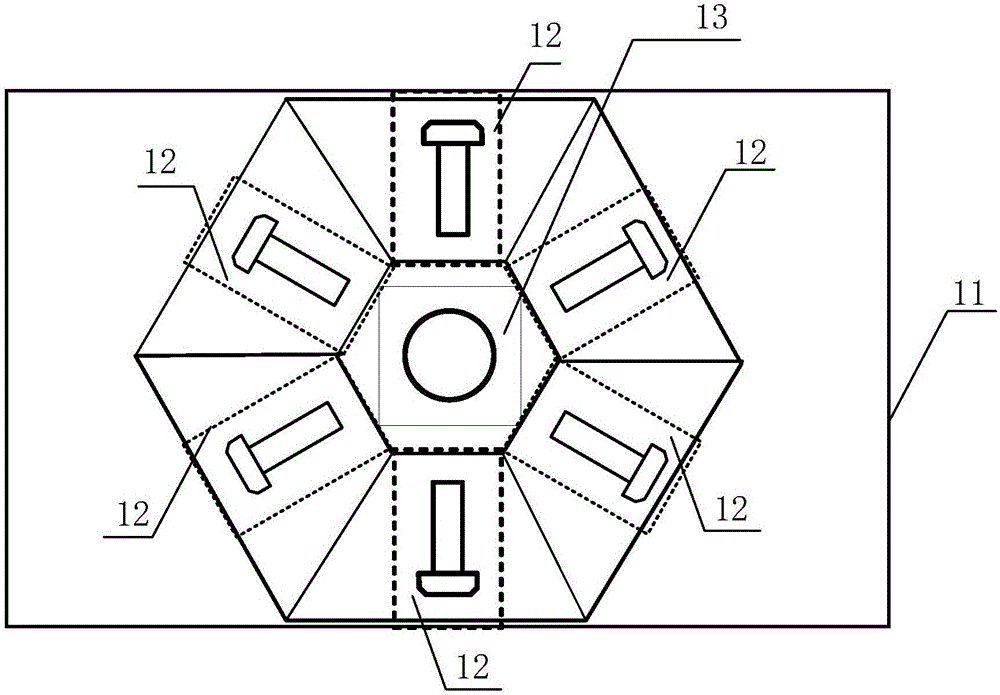

Array ultrasonic detection technology of complex surface microdefect

InactiveCN102426194ARealize all-round detectionImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSensor arrayAviation

The present invention relates to an array ultrasonic detection technology for rapidly detecting internal microdefects of a complex surface component. The technology can be applicable for the fields of aviation, aerospace, weapons, automobiles, medicine and the like. According to the present invention, transducers are concurrently arranged on the upper surface and the lower surface of the complex surface component, and the different amount of the transducers are arranged on the parts with different curvatures, such that the effective action range of the ultrasonic sensor covers all the positions of the component, wherein the positions of the component require detections. With the present invention, a computer technology is adopted to control the sensor array to rapidly extract the internal information of the complex surface component, such that the detection efficiency can be substantially improved, the disadvantages of low scanning detection efficiency and less collected information content of the traditional single probe can be overcome, and the detection accuracy of the internal defects of the complex surface component can be effectively improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Automatic selection device of citrus peeling equipment

The invention relates to an automatic selection device of citrus peeling equipment. The automatic selection device comprises a conveying separation device and a visual detection removal device. The conveying separation device comprises a large conveyor belt, a right baffle, a left baffle, a left rotary conveyor belt and a right rotary conveyor belt. The left rotary conveyor belt and the right rotary conveyor belt are arranged in a splayed manner. The visual detection removal device comprises a transition plate, a single fruit conveyor belt, a camera support, a camera, a left reflector, a right reflector and a removal device. The single fruit conveyor belt is located at one end of the large conveyor belt. The transition plate is placed between the large conveyor belt and the single fruit conveyor belt. The camera is fixed to the top of the camera support located in the middle of the single fruit conveyor belt. The left reflector and the right reflector are fixed to the middle of the camera support. The removal device is fixed to one side of the single fruit conveyor belt. After citrus fruits are peeled, peeled citrus fruits directly enter the removal device, so that labor is effectively saved, and labor intensity is effectively relieved; and the camera is adopted for detecting the peeled citrus fruits without mechanical contact, so that judgment accuracy is improved, and breakage is reduced.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

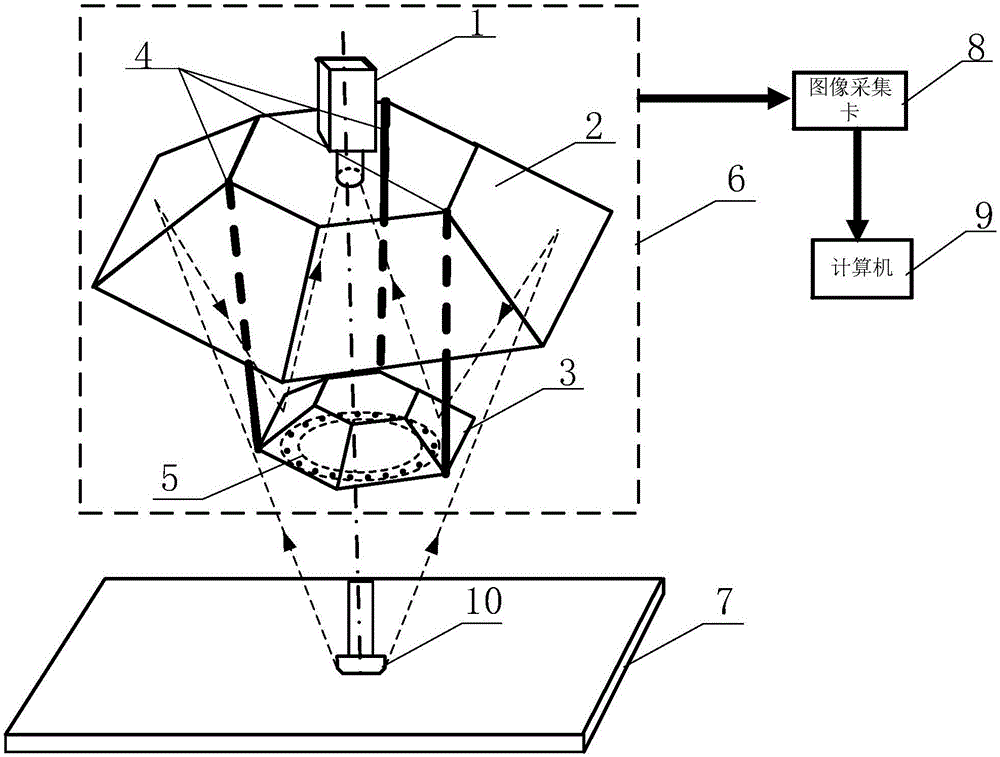

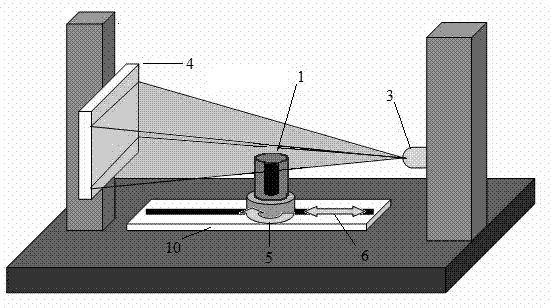

Single-camera wide-field-of-view visual thread detection device and detection method thereof

PendingCN106226316ASave spaceMiniaturizationOptically investigating flaws/contaminationWide fieldVision sensor

The invention belongs to the field of thread detection technology researching, and discloses a single-camera wide-field-of-view visual thread detection device and a detection method thereof. The single-camera wide-field-of-view visual thread detection device comprises a single-camera wide-field-of-view visual sensor, a carrying platform, an image acquiring card and a computer, wherein the single-camera wide-field-of-view visual sensor comprises a camera, an upper reflecting mirror group, a lower reflecting mirror group, a metal rod and an LED (Light-Emitting Diode) annular light source; a threaded fastener to be detected is vertically arranged under the single-camera wide-field-of-view visual sensor and at the central position of the carrying platform; the image acquiring card is arranged in the computer, and is connected with the camera in the single-camera wide-field-of-view visual sensor through a cable; the computer is used for analyzing images acquired by the image acquiring card to realize thread defect detection of the fastener.

Owner:JIANGSU UNIV

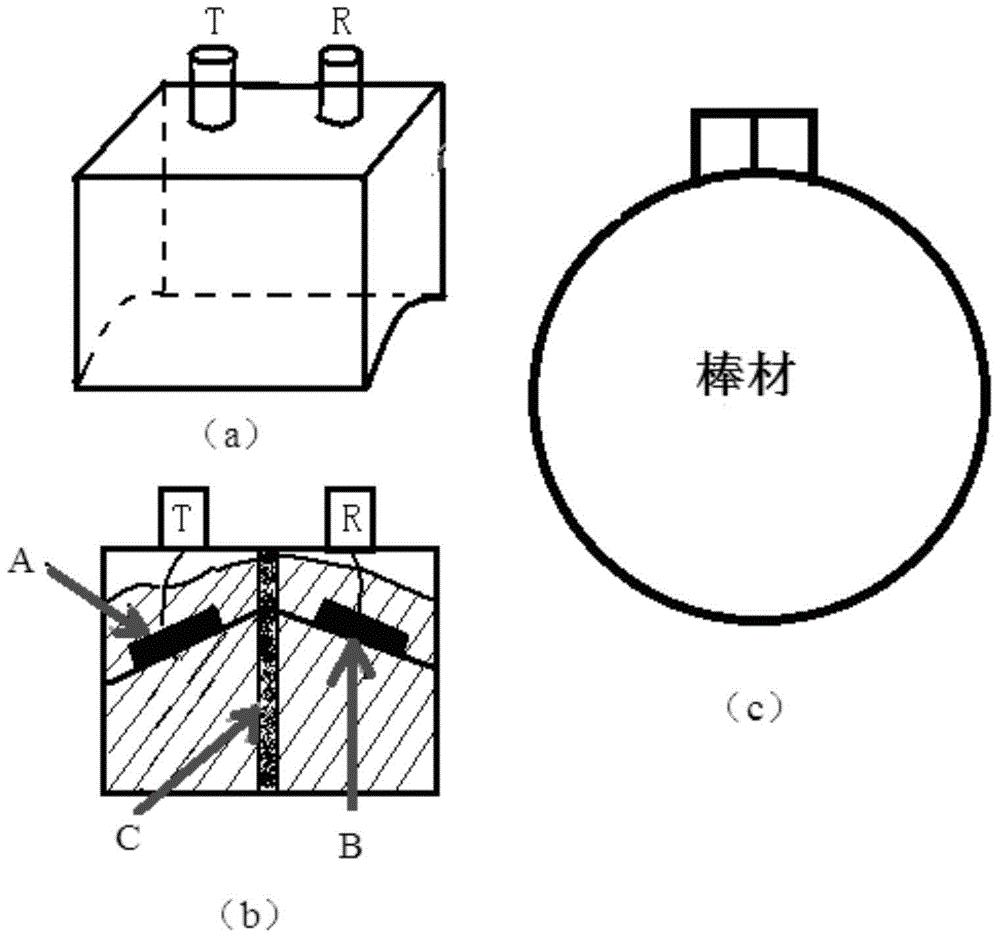

Nondestructive flaw detection method for aluminum alloy bar by adopting ultrasonic technology

InactiveCN104391041AImprove accuracyRealize all-round detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesLongitudinal waveUltrasonic technology

The invention relates to a nondestructive flaw detection method for an aluminum alloy bar by adopting an ultrasonic technology, which belongs to the field of metal flaw detection, and is used for solving the problems of low working efficiency and large error caused by adopting a contact flaw detection method. The method comprises the following steps: step 1, grinding the bottom of a longitudinal-wave twin-crystal probe to form an inner arc, wherein the inner arc is matched with an outer arc of the aluminum alloy bar to be detected; step 2, drawing a pi1.2mm flat-bottom hole distance-amplitude DAC curve and a pi0.8mmn flat-bottom hole distance-amplitude DAC curve by adopting a flat-bottom hole test block; debugging the flaw detection sensitivity, wherein the flaw detection sensitivity comprises benchmark sensitivity, detection sensitivity and scanning sensitivity; and step 3, placing the longitudinal wave twin-crystal probe on an outer circular surface of the aluminum alloy bar to be detected, and scanning the bar along the longitudinal direction; and labeling a rotation mark on the bar, wherein the bar is rotated for three times, and each rotation angle is 90+ / -2 degrees, so that the complete circumferential area of the aluminum alloy bar to be detected can be scanned.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Ultrasonic testing device of defect of wheel spoke of engine vehicle

ActiveCN101666781AEfficient detectionRealize all-round detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringUltrasonic testing

The invention relates to an ultrasonic testing device of a wheel spoke of an engine vehicle, wherein, an ultrasonic probe thereof comprises four pairs of single-emission and single-receiving probes and six probes integrated with emission and receiving. In the four pairs of probes, the emission angle or receiving angle of each probe is 15-33 degrees; the torsion angle is 5-35 degrees; and each pairof probes is arranged according to the set position. In the six probes integrated with emission and receiving, two normal probes are respectively arranged at two sides of a rolling circle; the axialdistance with the rolling circle is 1-8 mm; the emission angles of two angle probes are parallel to the rolling circle surface and the axial distance with the rolling circle is 1-8 mm; and two probeswith the emission angle of 1-10 degrees are respectively arranged at two sides beside the rolling circle and the axial distance with the rolling circle is 1-4 mm. The device can carry out all-around detection on the defects of each type of wheel spoke; the detection process is free of manual work participation with high detection rate; and the detection method is simple and the detection result isreliable.

Owner:CHENGDU LEAD SCI TECH CO LMT

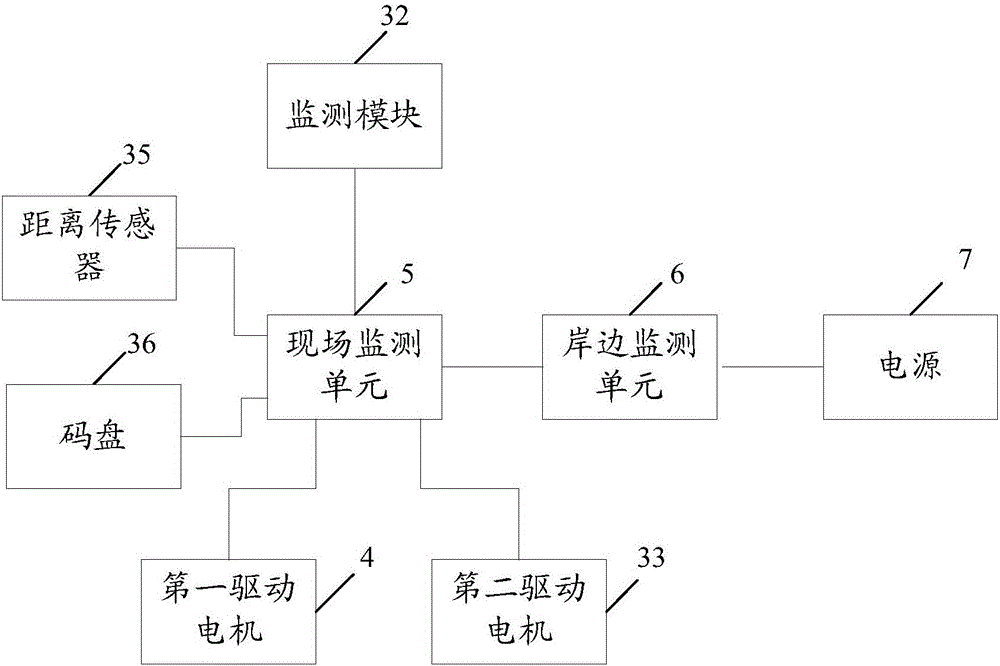

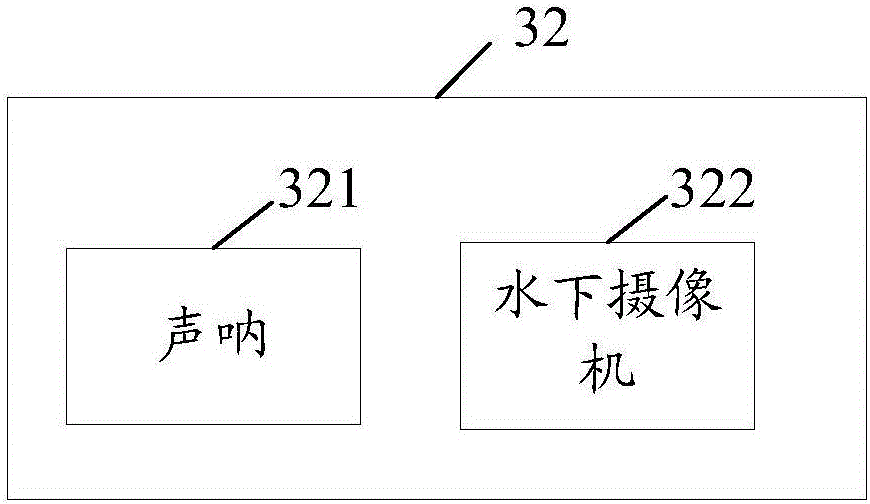

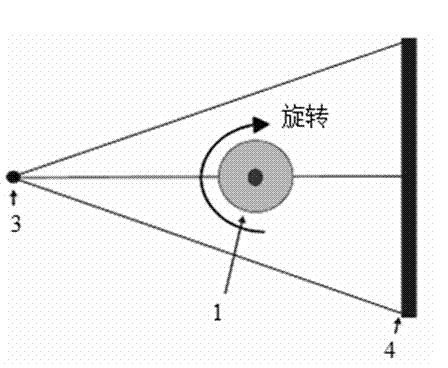

Underwater environment monitoring system for nuclear power station water intake

ActiveCN106226770AEasy to operateImprove operational reliabilityAcoustic wave reradiationMarine engineeringNuclear power

The invention discloses an underwater environment monitoring system for a nuclear power station water intake. The underwater environment monitoring system comprises an upright pole platform arranged in the monitoring area of the nuclear power station water intake, a guide rail arranged in the vertical direction and fixedly connected with an upright pole of the upright pole platform, a monitoring dolly arranged on the guide rail in a slidable manner, and a first driving motor used for driving the monitoring dolly to slide on the guide rail. The monitoring trolley comprises a monitoring dolly main body arranged on the guide rail in a slidable manner, a horizontal rotating platform arranged on the monitoring dolly main body, a monitoring module which is arranged on the horizontal revolving platform and can rotate along with the horizontal rotating platform, and a second driving motor used for driving the horizontal rotating platform to rotate horizontally. The underwater environment monitoring system for the nuclear power station water intake can carry out omnibearing detection to water areas on the water intake in different water depths and different directions, and is simple to operate, and high in operation reliability and practicality.

Owner:YANGJIANG NUCLEAR POWER +3

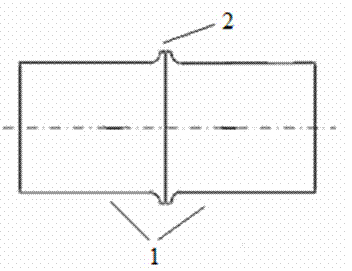

Microfocus three-dimensional CT imaging detection method for hot-melt welding quality of polyethylene pipelines

InactiveCN104198505AQuality assuranceImprove image qualityMaterial analysis by transmitting radiationEngineeringWelding defect

The invention discloses a microfocus three-dimensional CT imaging detection method for hot-melt welding quality of polyethylene pipelines, and relates to the field of pressure pipelines detection technology in petroleum industry. The method comprises the steps: a, arranging the microfocus three-dimensional CT imaging position; b, adjusting the position of a welding joint; c, adjusting an image; d, acquiring a sectioned image of the welding joint; e, performing image reconstruction; and f, comparing with an acquired image on a computer to observe a welding defect detection result displayed on an image, and performing defect grade evaluation. The detection method has the advantages of high detection precision, good reliability and the like, is especially capable of reproducing a three-dimensional object and visually obtaining the position, the shape, the size and other information of a defect, and helps to solve the problems about space positioning, depth quantification and integral determination on the nature for the defect.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

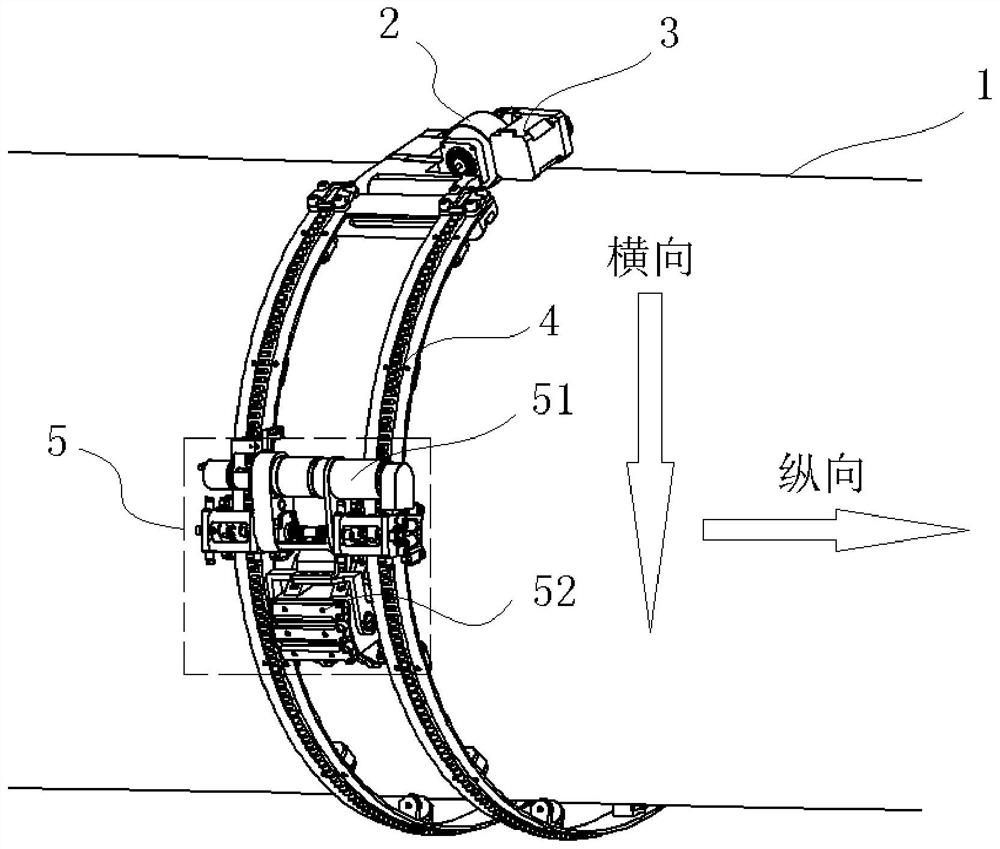

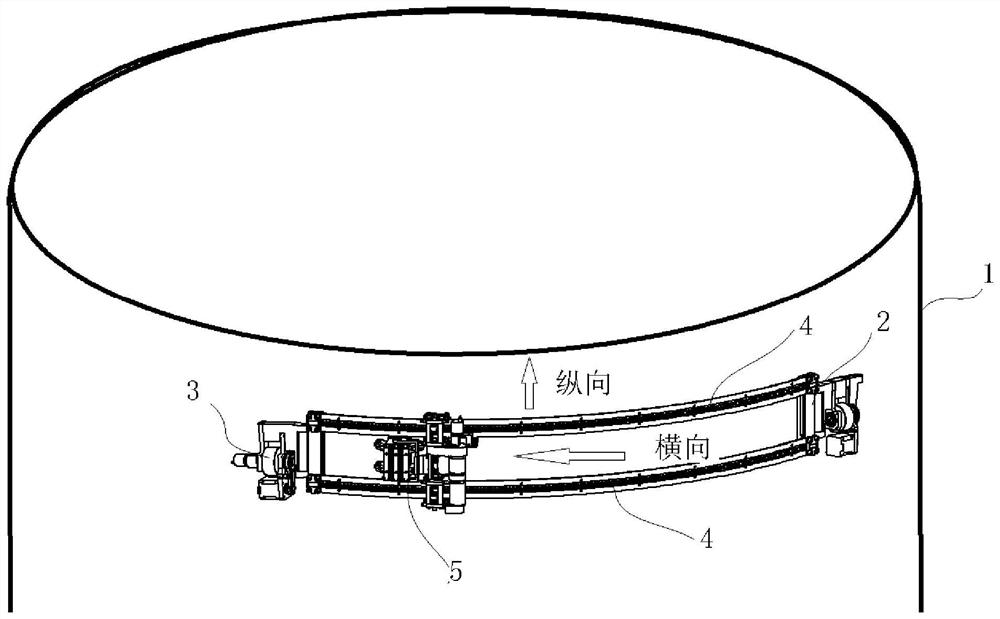

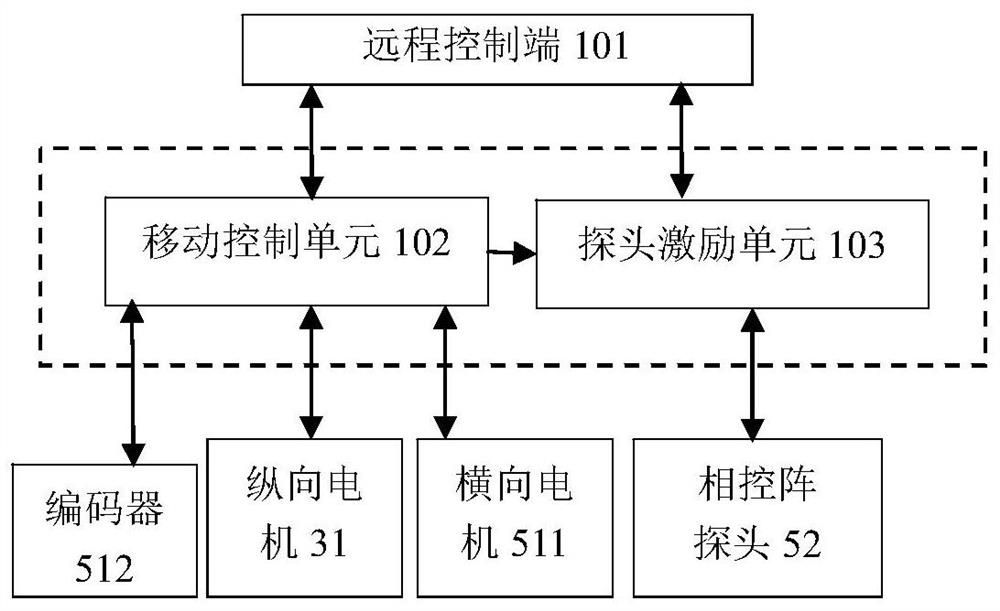

Ultrasonic detection device and detection method for in-service pipeline or pressure vessel

PendingCN112014465ARealize all-round detectionEasy to carryAnalysing solids using sonic/ultrasonic/infrasonic wavesPipeline systemsEngineeringMovement control

The invention provides an ultrasonic detection device and a detection method for an in-service pipeline or a pressure vessel. The device comprises a track assembly, a detection trolley, a longitudinaldriving assembly and a detection controller, wherein the track assembly comprises a flexible track and an auxiliary positioning part for positioning the flexible track on a to-be-detected wall surface; the detection trolley comprises a trolley main body, a transverse driving assembly and a phased array detection probe assembly, the phased array detection probe assembly is fixed with the trolley main body, and the trolley main body is arranged on the flexible track and is driven by the transverse driving assembly to move along the flexible track; the longitudinal driving assembly is connectedwith the flexible track and drives the flexible track to move along the to-be-detected wall surface; and the detection controller comprises a probe excitation unit connected with a phased array probein the phased array detection probe assembly, and a movement control unit connected with the longitudinal driving assembly and the transverse driving assembly. The device is suitable for detection ofvarious external diameters and various wall surfaces.

Owner:上海鼎声电子科技有限公司 +1

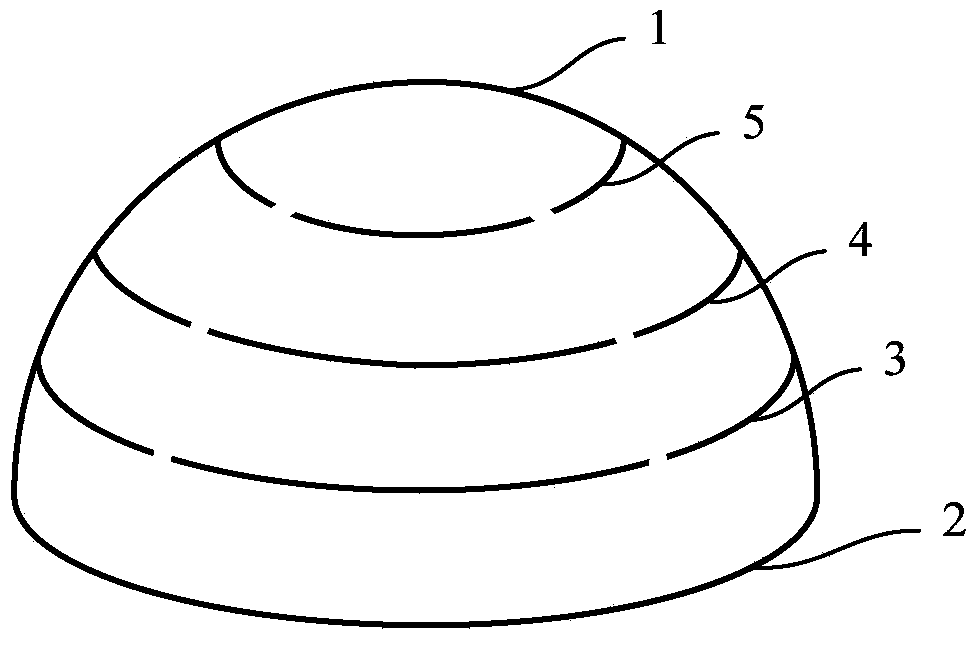

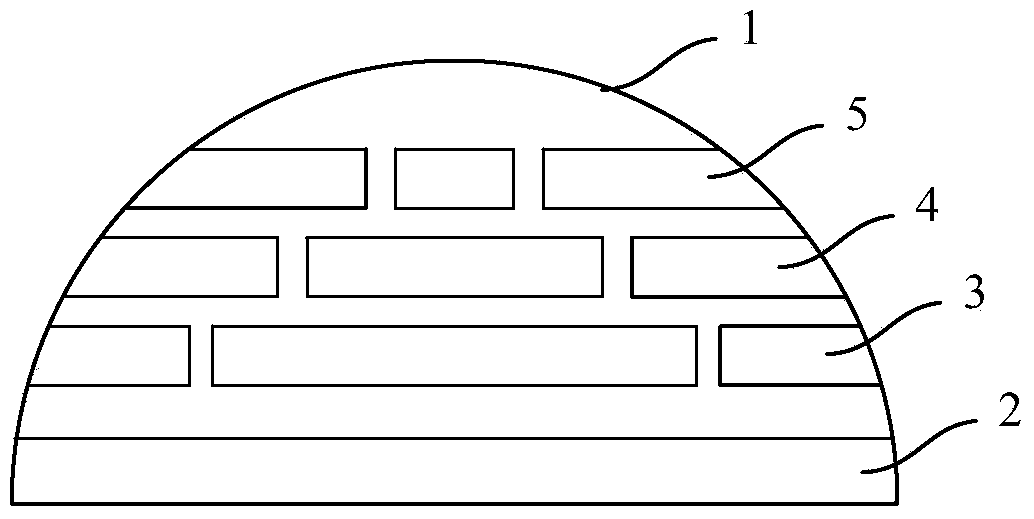

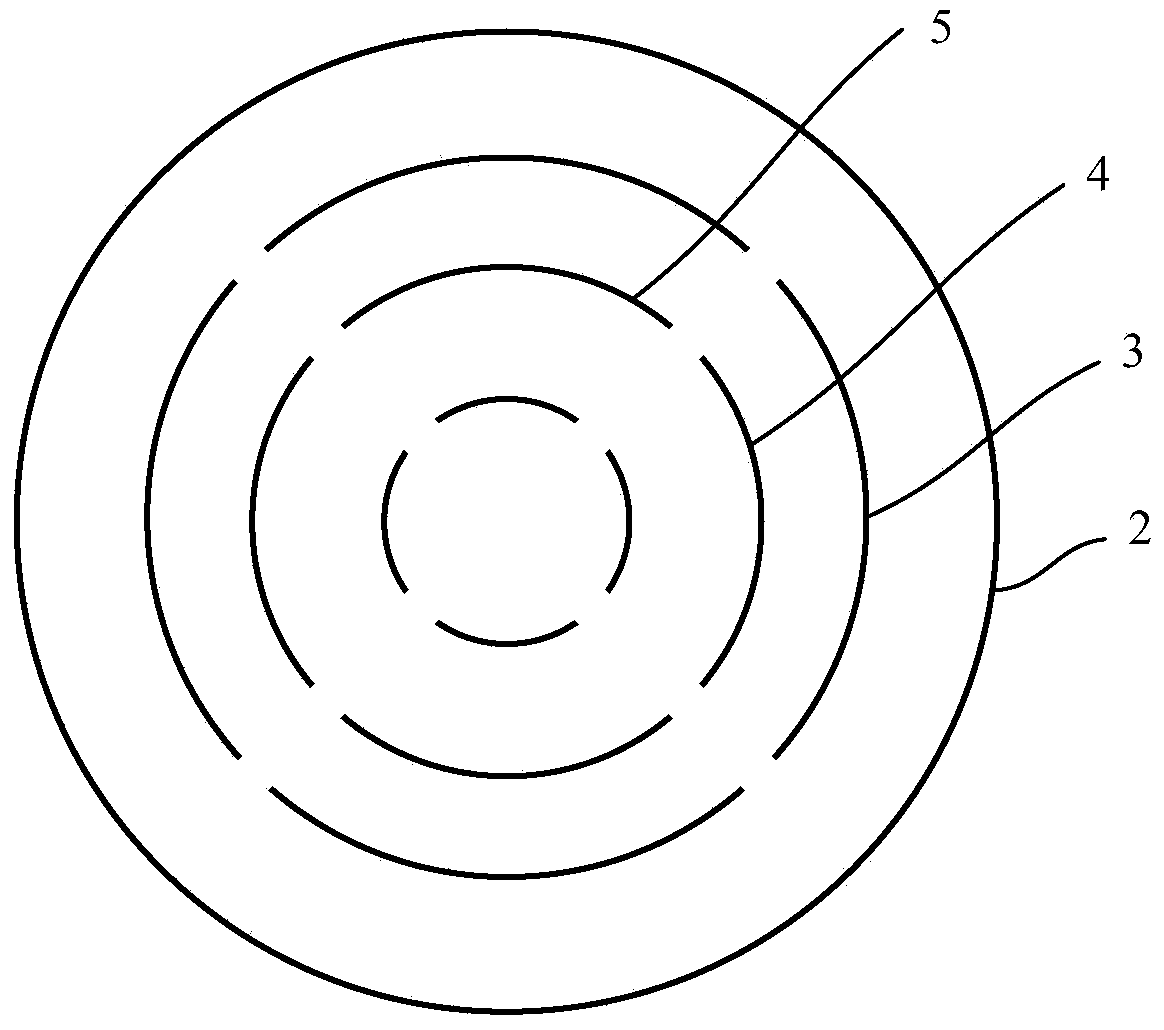

Electric field detection device

The invention provides an electric field detection device which at least comprises a bearing body, a reference electrode layer arranged on the bearing body and at least three induction electrode layers arranged on the bearing body and located above the reference electrode layer. Each induction electrode layer comprises at least four induction electrodes evenly distributed. An independent electric field measurement circuit is formed by each induction electrode and the reference electrode layer. According to the electric field detection device, the induction electrodes distributed on multiple layers are adopted, the induction electrodes and the reference electrodes are all of a strip shape, and the strip-shaped electrodes are small in size, thin, capable of being integrated inside a cap easily and good in concealment performance. Meanwhile, due to the adoption of the induction electrodes distributed on multiple layers, the intensity of an electric field can be detected, the electric field can further be detected at multiple angles in multiple directions, and the direction of the electric field can be judged.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

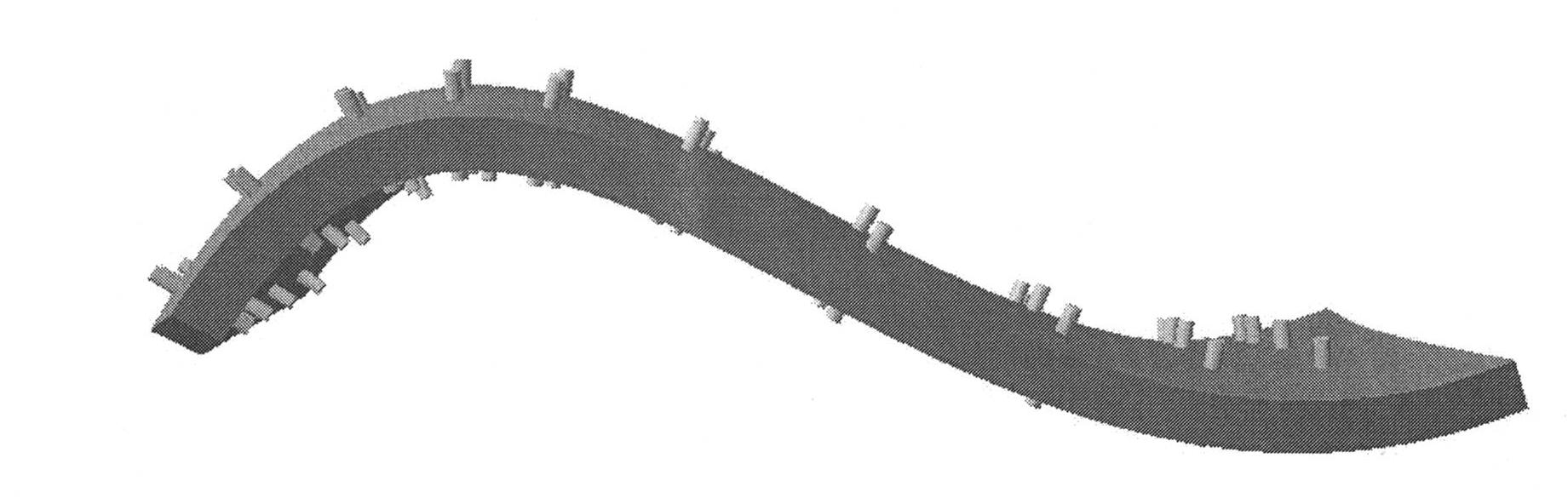

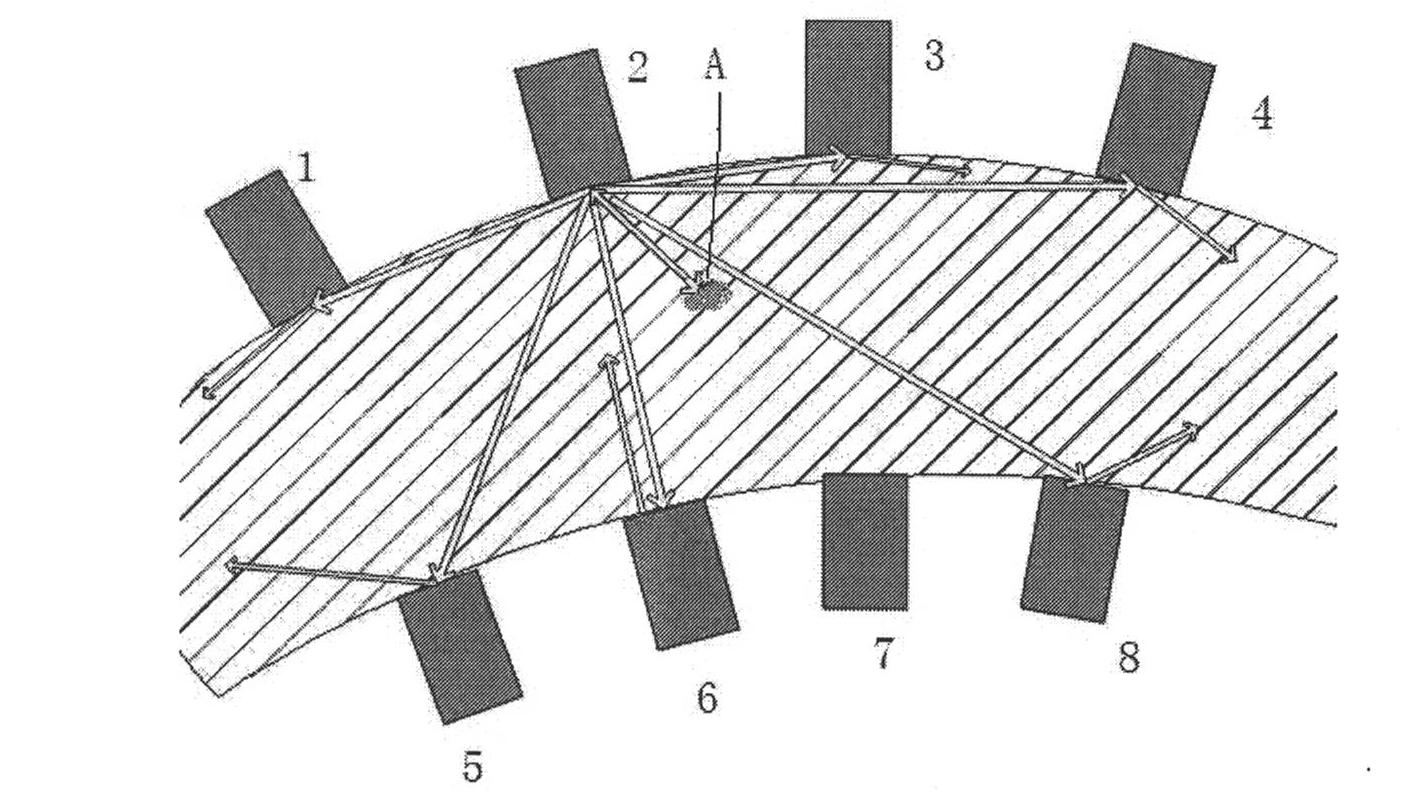

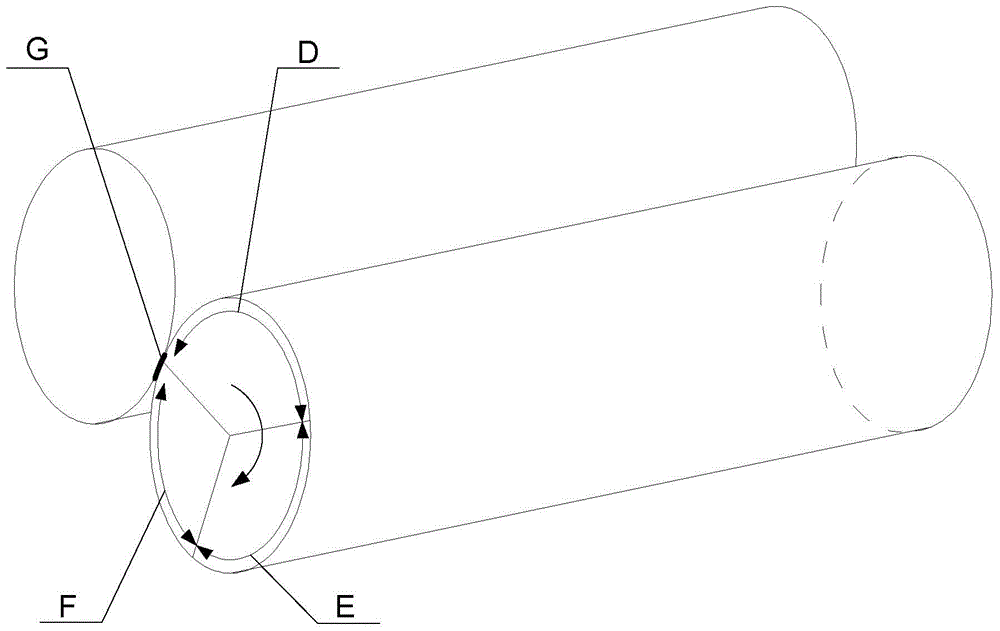

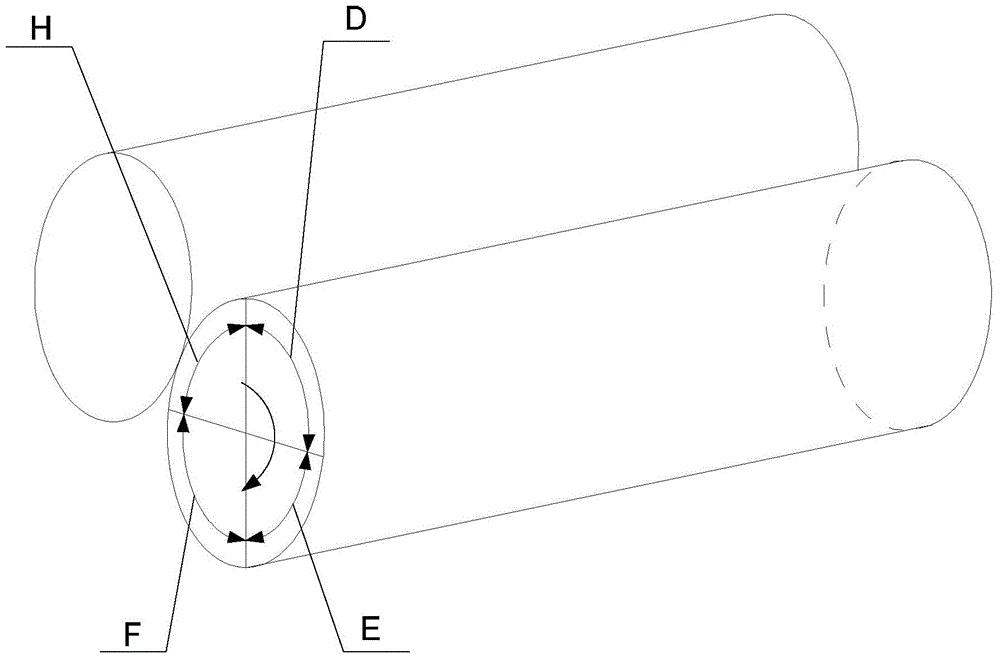

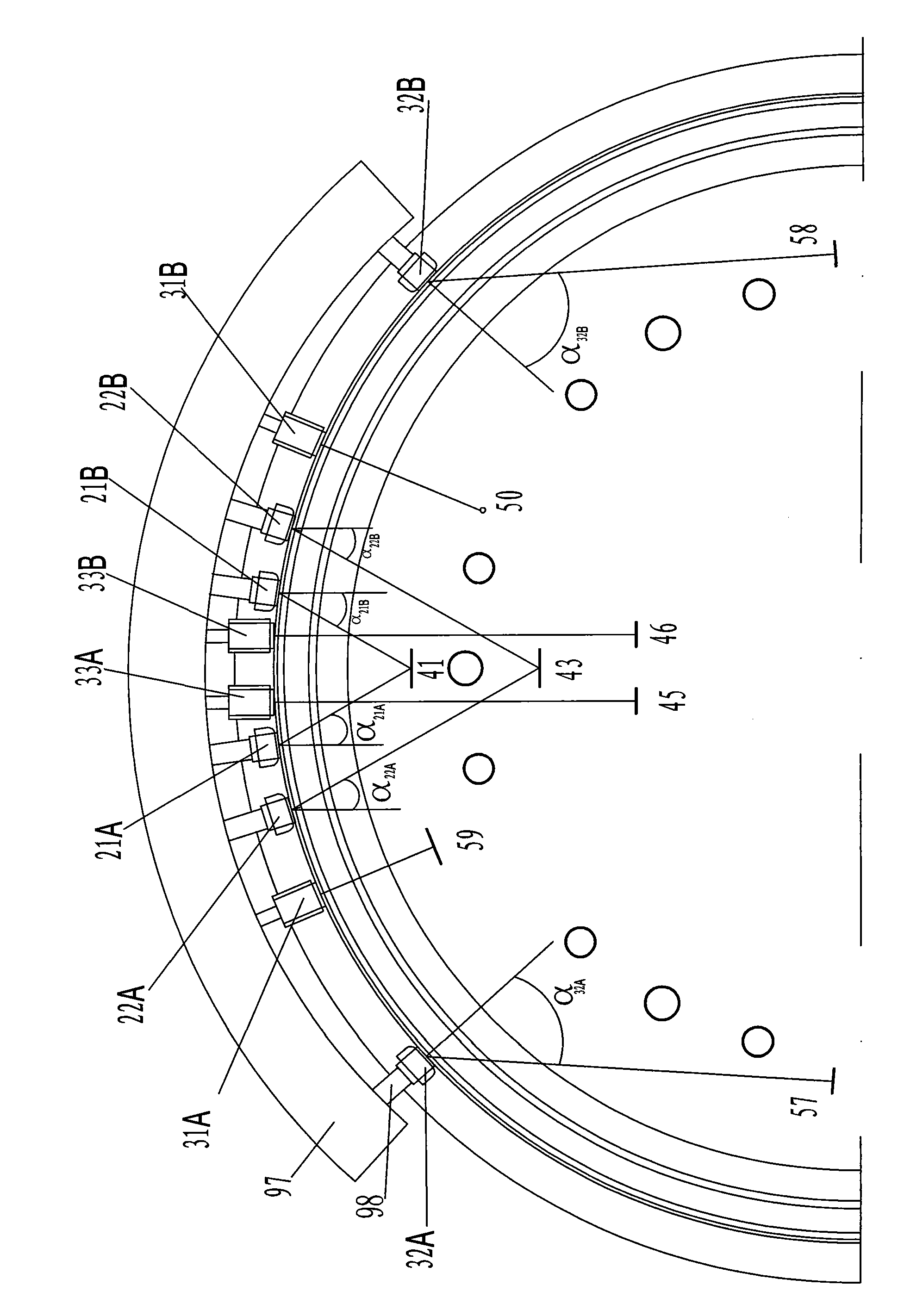

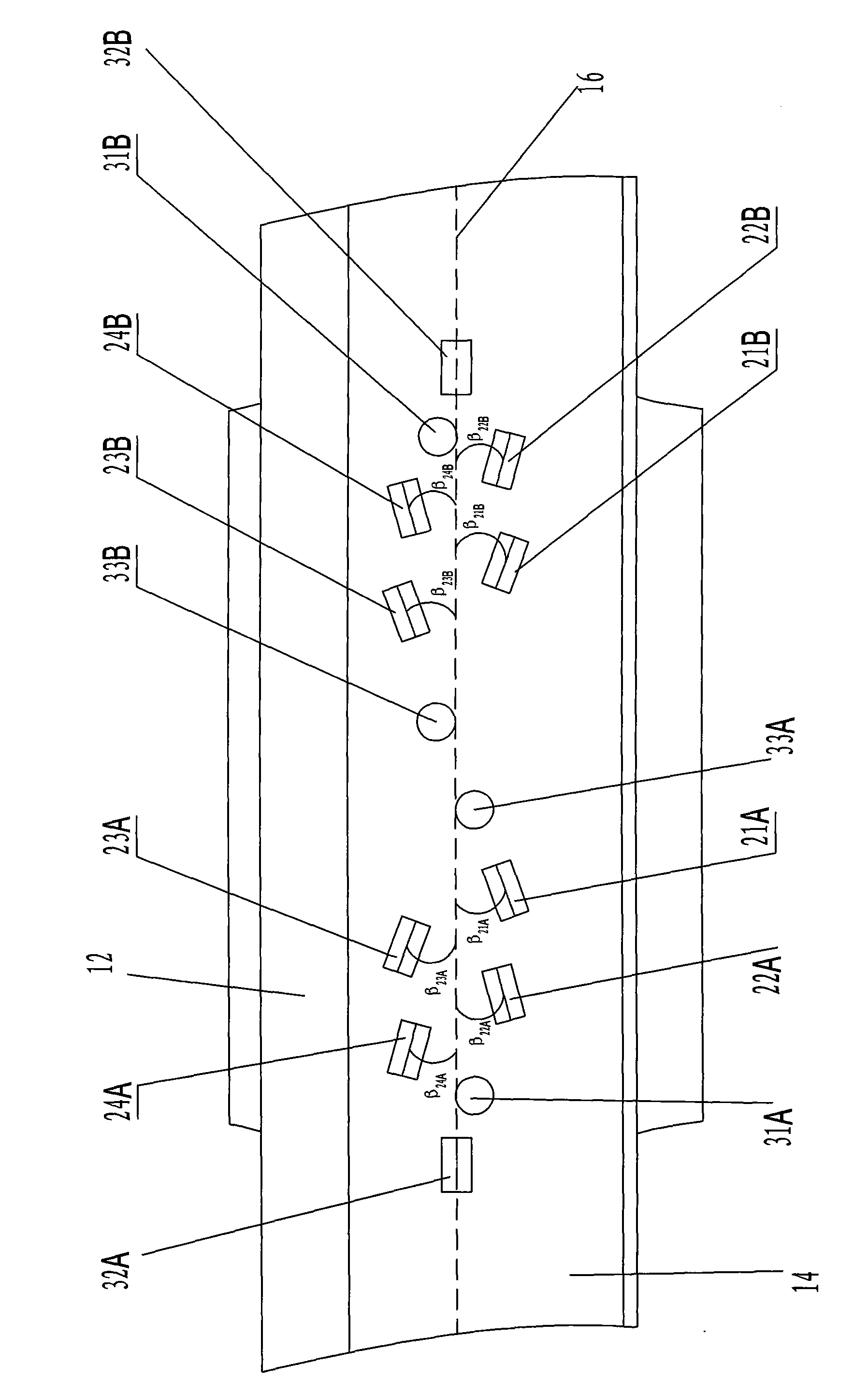

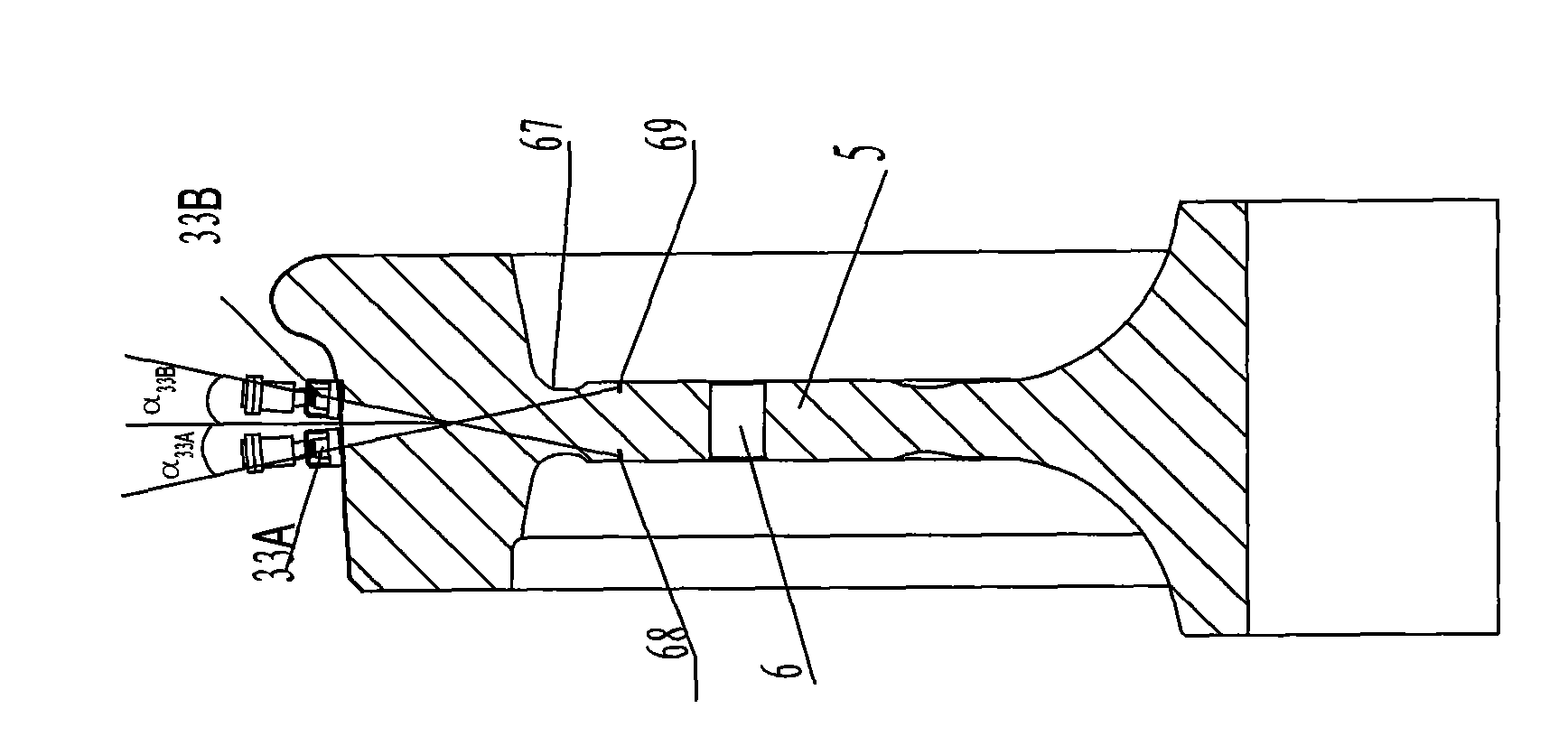

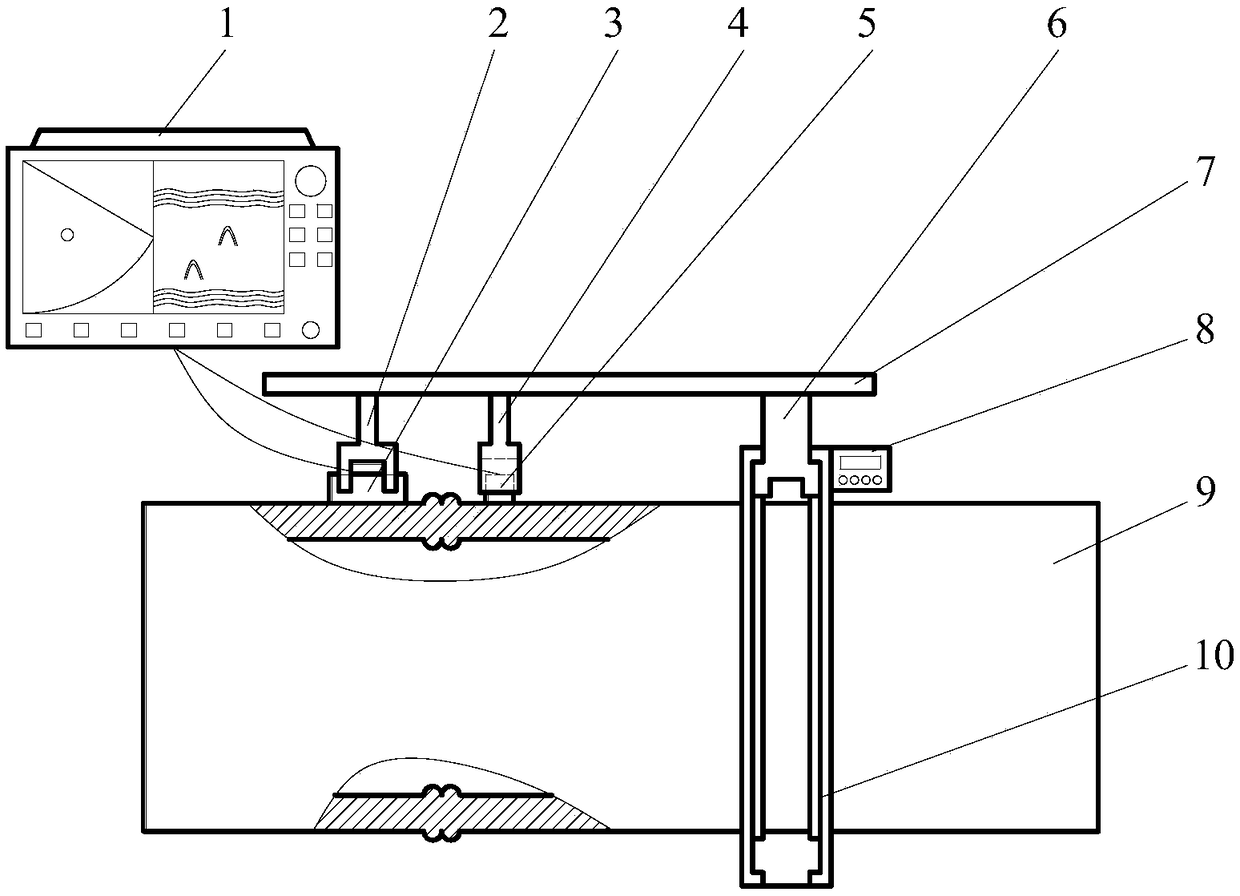

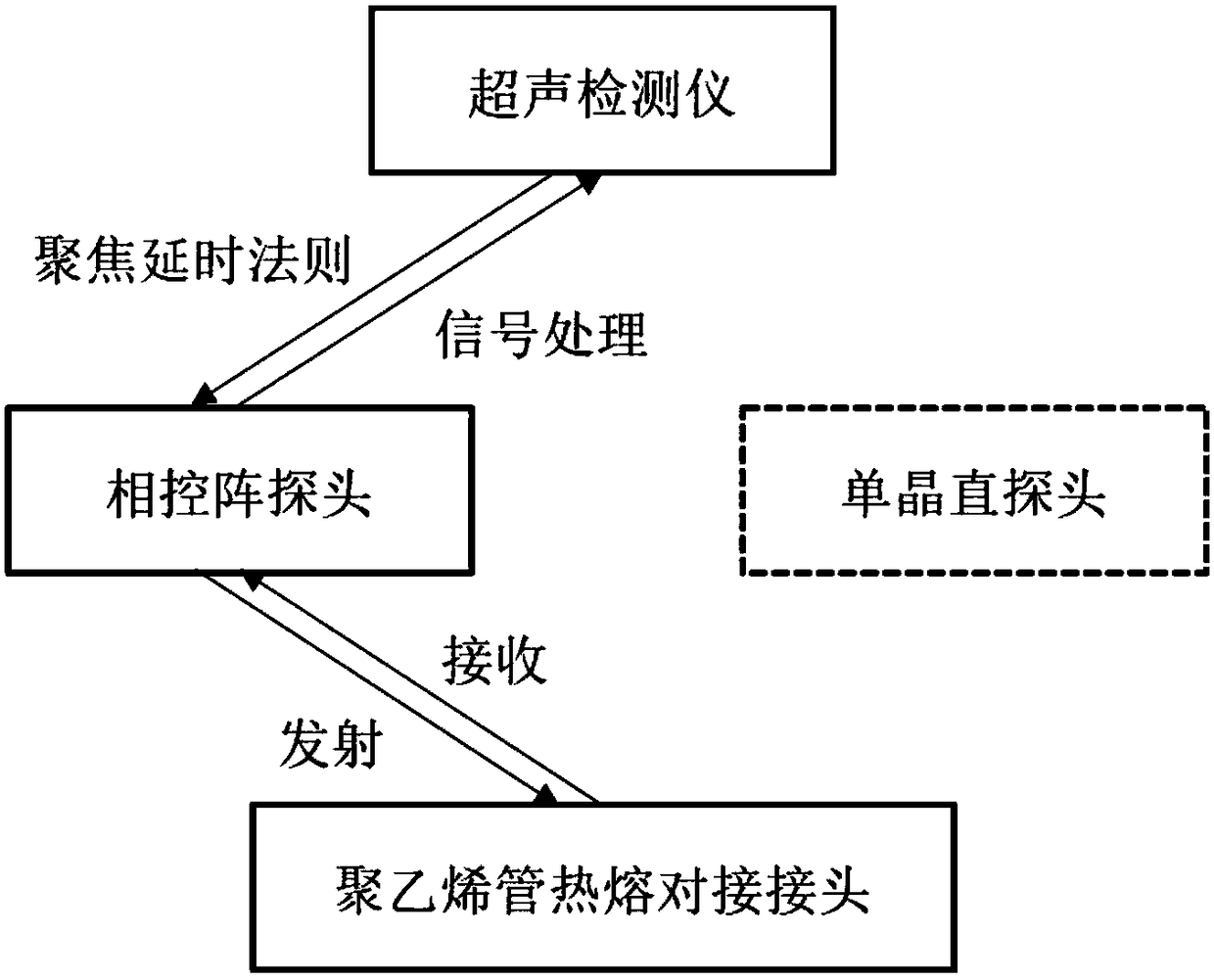

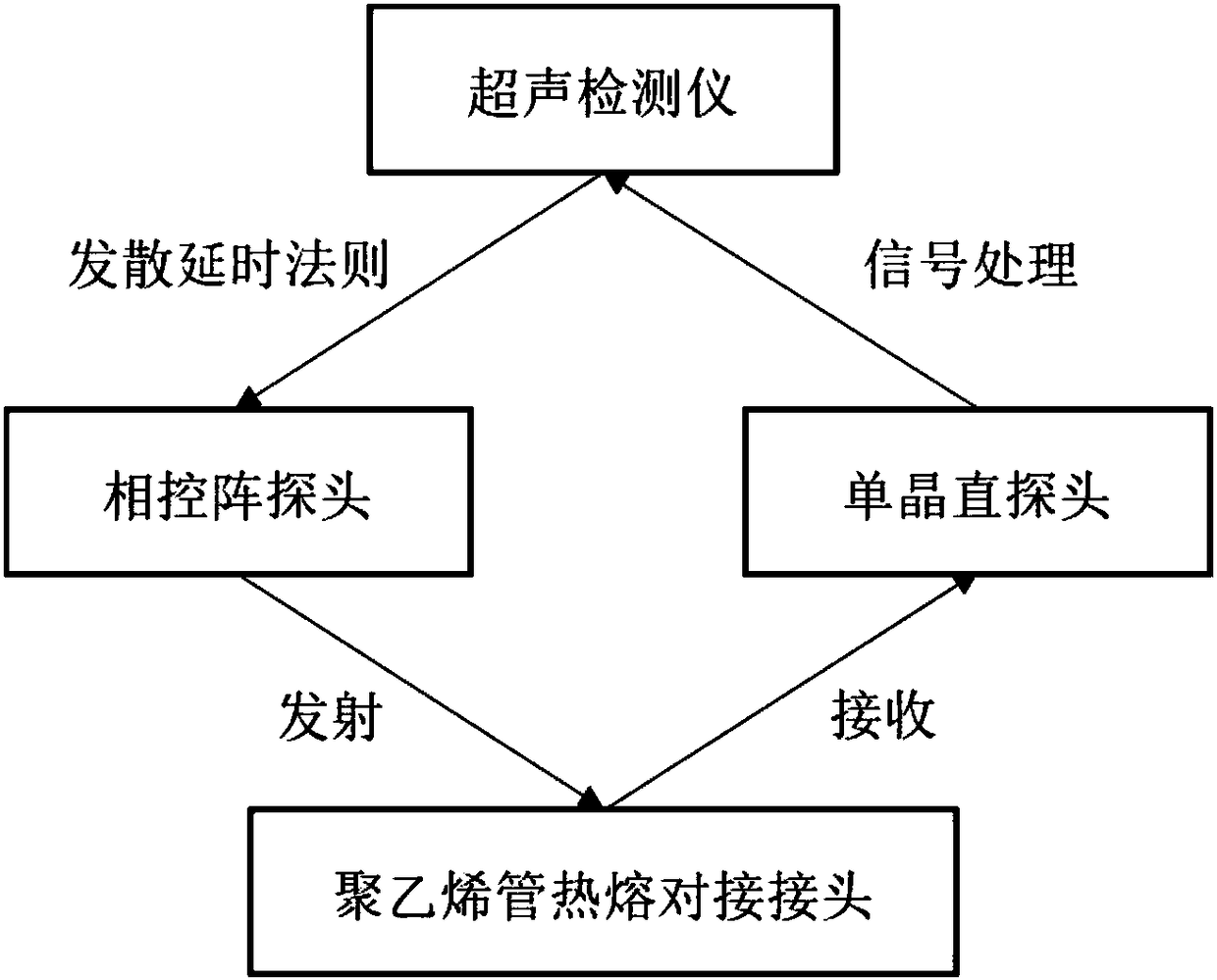

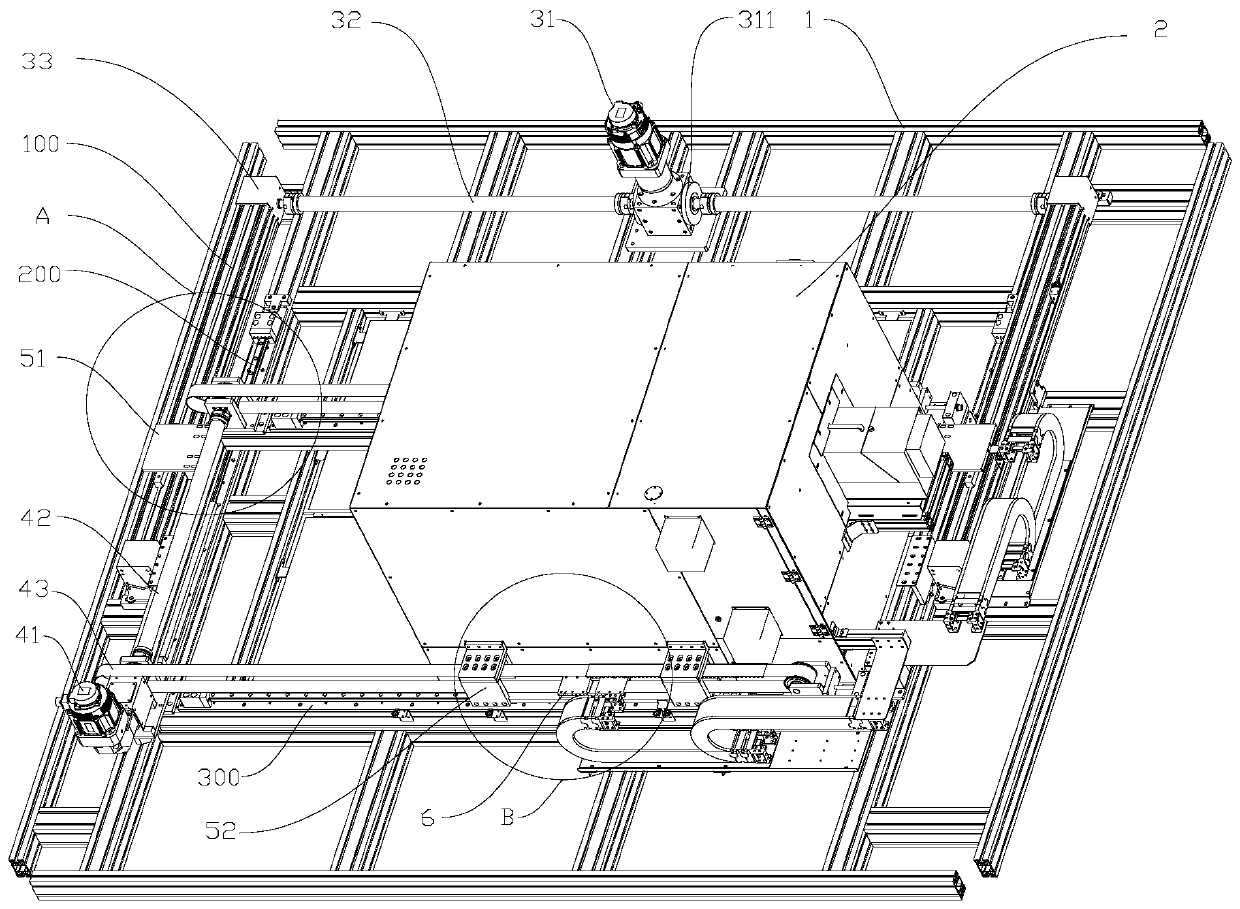

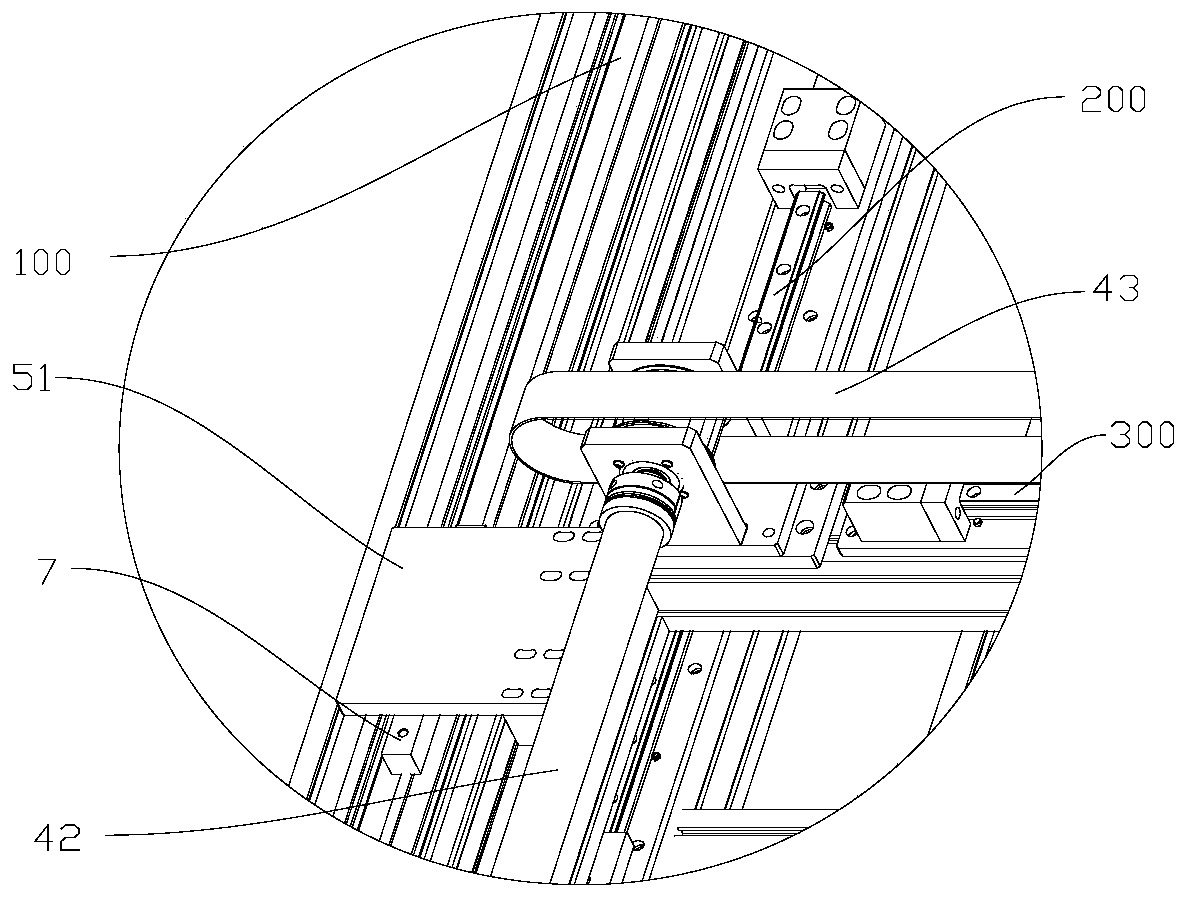

Ultrasonic detection device and method for PA-TOFD combined polyethylene pipeline hot-melt butt joint

ActiveCN108562647AOvercome the resultOvercoming data cannot be recordedAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveButt joint

The invention relates to a non-destructive testing technology of polyethylene pipeline hot-melt butt joint and aims to provide an ultrasonic detection device and method for PA-TOFD combined polyethylene pipeline hot-melt butt joint. The ultrasonic detection device comprises a circumferential scanning track which is arranged on a polyethylene pipeline; the circumferential scanning track is providedwith a circumferential scanning device; one end of the connecting rod is fixed on the top of the circumferential scanning device, and the other end of the connecting rod is respectively provided witha phased array probe and a single crystal straight probe through a probe holder; the two probes are positioned on two sides of the hot-melt butt joint of the polyethylene pipeline, and a gap is maintained between the end part of the probe and the polyethylene pipeline. The ultrasonic detector has two detection functions of ultrasonic phase control detection and TOFD detection, and the phased array probe is used as an acoustic wave transmitting probe for ultrasonic phased array detection and TOFD detection. And the two detection results are synchronously displayed in real time. The method overcomes the defects that the traditional pulse-type ultrasonic detection technology is not intuitive, the data cannot be recorded and stored, and the defects of precise positioning and quantification are difficult to be made.

Owner:ZHEJIANG UNIV

Glass substrate detection device

InactiveCN109724999ARealize all-round detectionQuality improvementOptically investigating flaws/contaminationBlind zoneEffect light

The invention relates to a glass substrate detection device comprising a mounting rack (1) used for being arranged above the glass substrate; a sliding table movably arranged on the mounting rack (1)in a first direction; and a lighting unit (2) for irradiating detection light onto the glass substrate. The lighting unit (2) is movably arranged on the sliding table in a second direction. Accordingto the glass substrate detection device, the lighting unit can be movable in the first direction and the second direction, that is to say, the lighting unit can be moved to any position within a plane, so that the detection light can be irradiated to any position of the glass substrate; omnidirectional detection of the glass substrate is achieved; the observation blind zone is eliminated; the quality of finished products can be improved.

Owner:JIANGSU HONGXIN YITAI INTELLIGENT EQUIP CO LTD +1

Detector for objects inside box

InactiveCN103472496ARealize all-round detection without dead angleIncreased sensitivityOptical detectionEngineering

The invention provides a detector for objects inside a box. The detector comprises a camera, an image comparison device, a controller, an alertor, a base plate and an object detecting device. The camera is arranged above a box opening, and the camera, the image caparison device and the alertor are respectively connected with the controller electrically. The base plate is arranged on the bottom of the box in an inclined mode in the diagonal direction of a box body, the object detecting device is arranged at the lowest position of the base plate, and the object detecting device is electrically connected with the controller. Every time a box door is opened, the camera can be triggered to conduct photographing once on a scene inside the box, photos which are taken are transmitted to the image comparison device through the controller, the image comparison device conducts comparison analysis on two adjacent photos before and after, and if the comparison result is that the two photos before and after are different, the alertor is triggered through the controller to warn and indicate that an object is placed into the box. According to the technical scheme, the detector for the objects inside the box is improved, and the non-dead-angle detector for objects inside the box is provided.

Owner:马晓璐

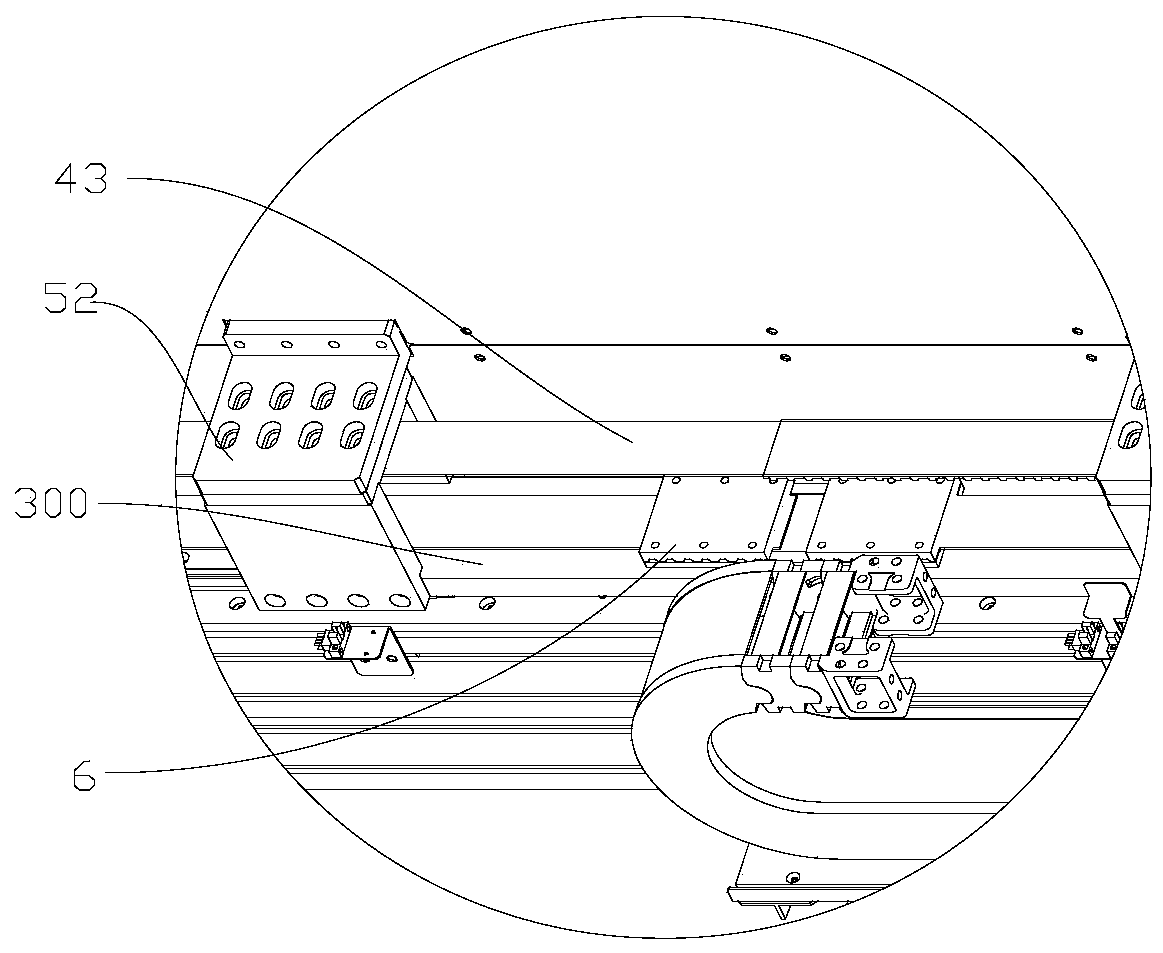

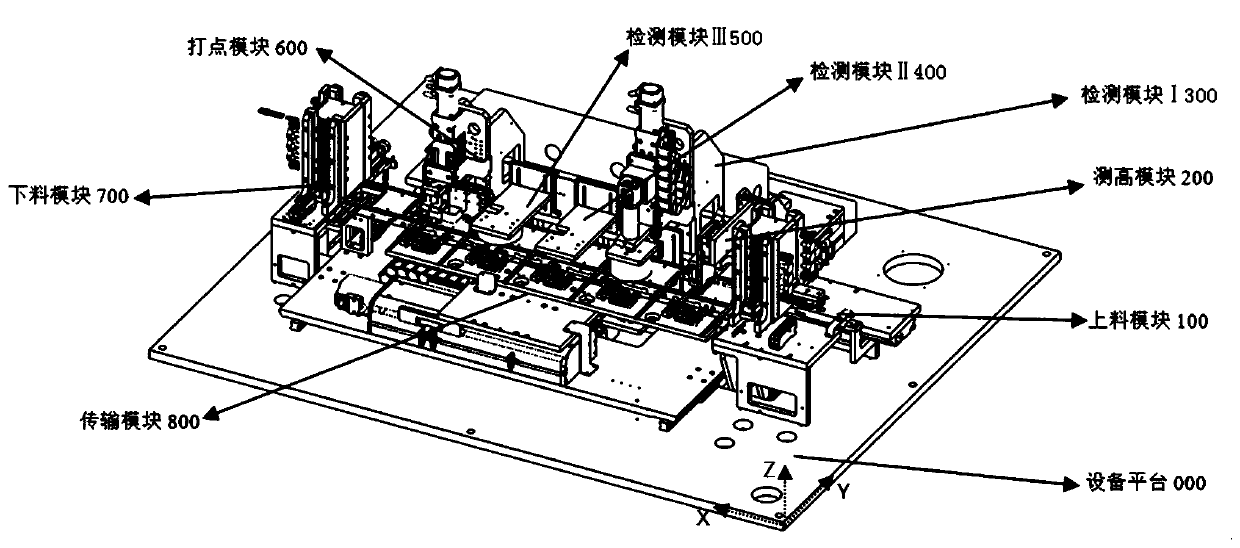

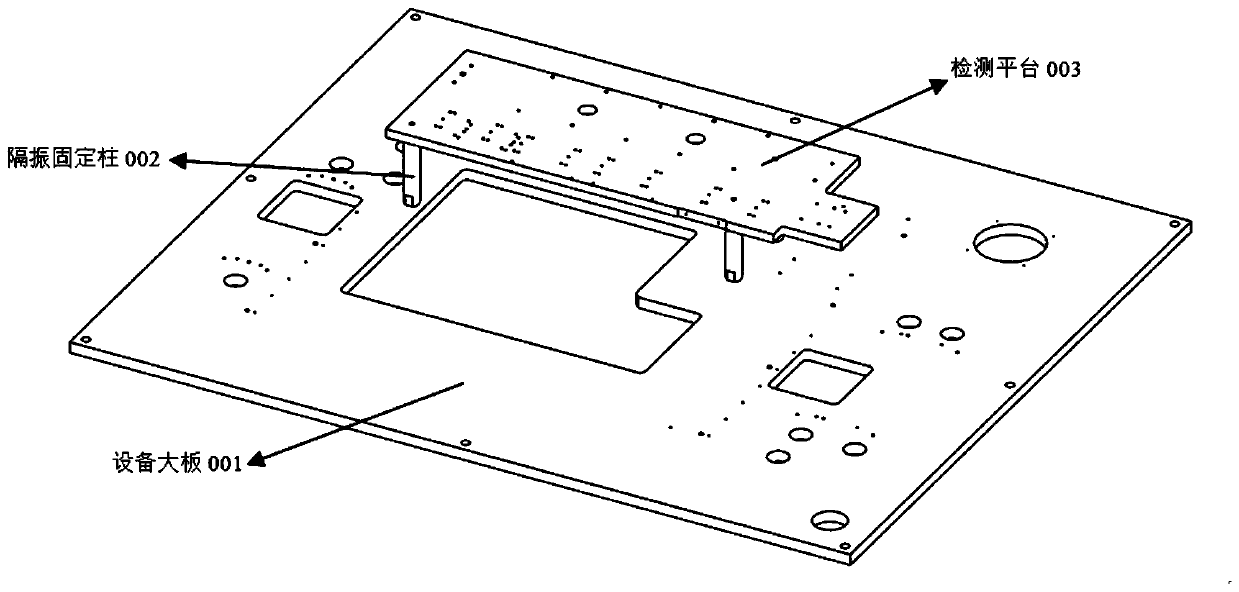

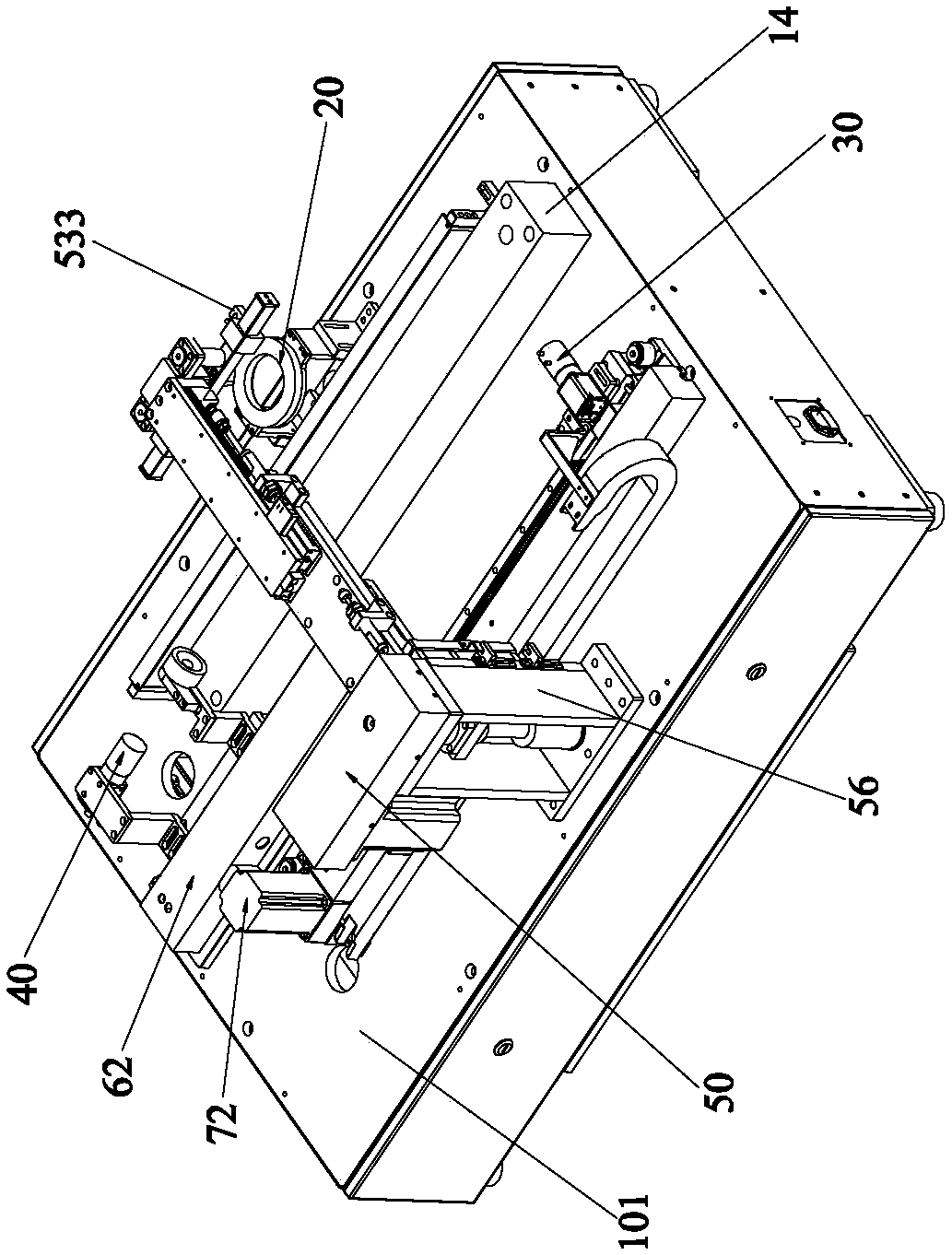

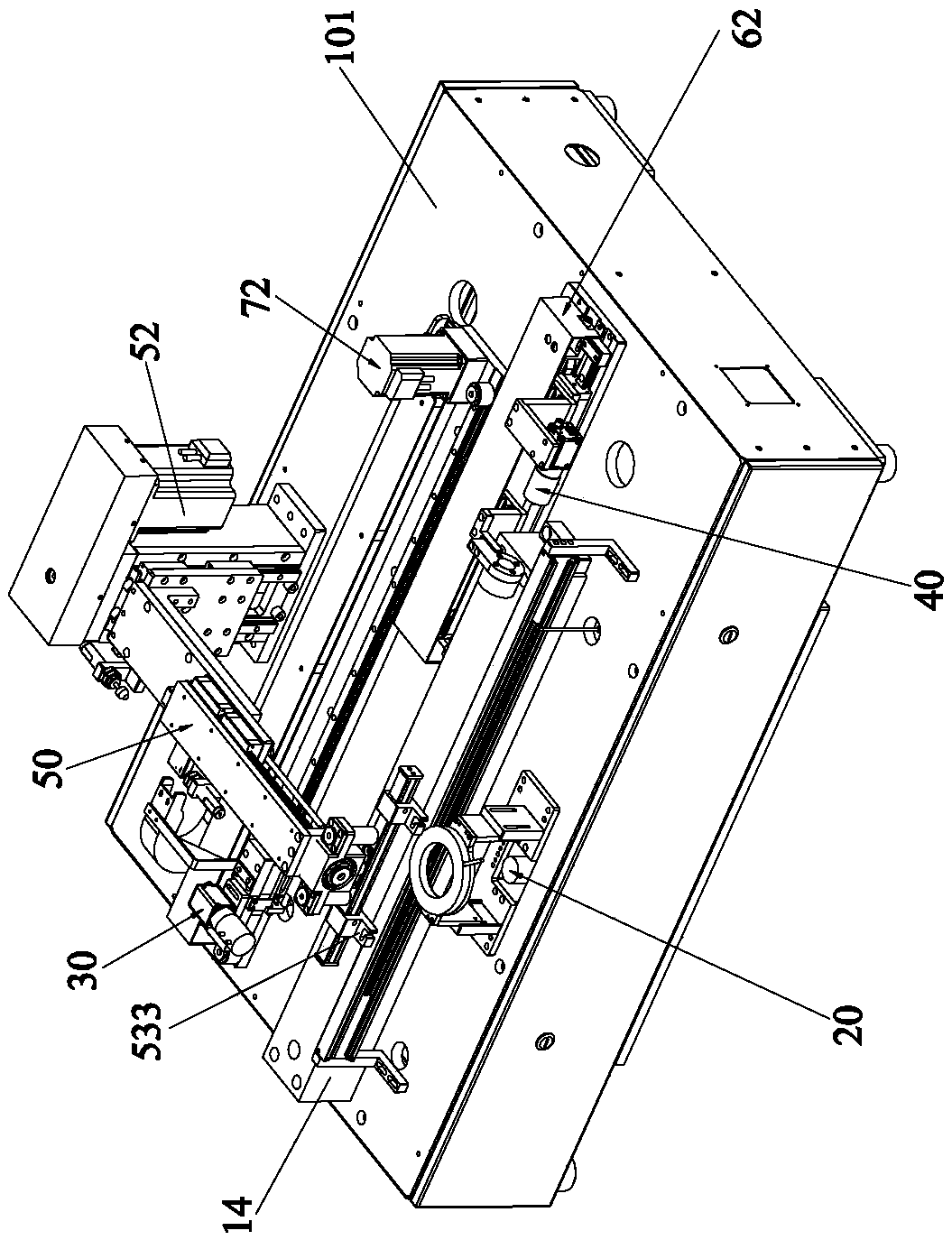

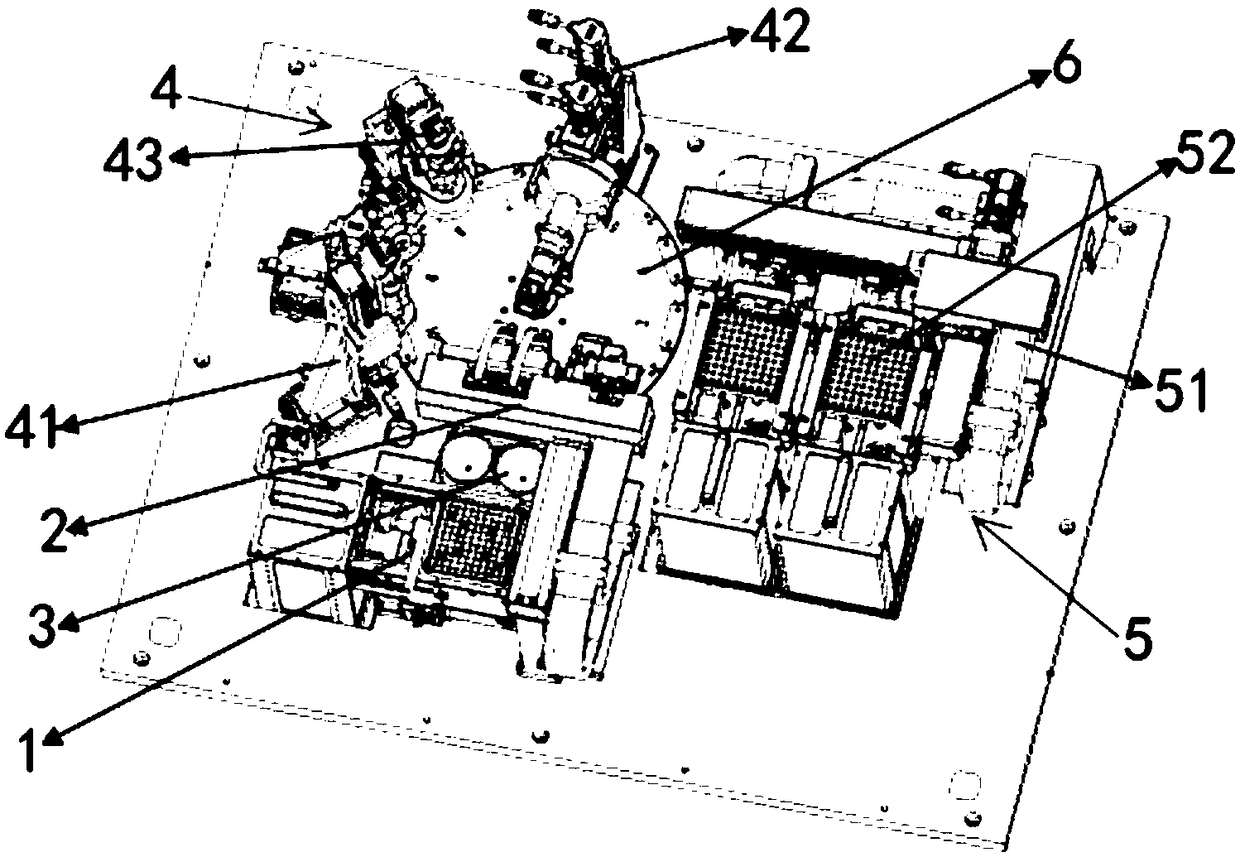

Automatic detecting equipment for appearance defects of mobile phone lens

The invention discloses automatic detecting equipment for appearance defects of a mobile phone lens. The automatic detecting equipment comprises equipment platform, a loading module, a height measuring module, at least one detecting module, a dotting module, a discharging module, a conveying module and an upper computer, wherein the equipment platform comprises a big equipment plate, a vibration isolation fixed column and a detecting platform; the big equipment plate is rectangular on the whole and is used as an installation substrate; a circulation system for the lens product to be detected is formed by the loading module, the discharging module and the conveying module; the whole circulation system is fixed to the big equipment plate; a detecting system for the lens product to be detected is formed by the height measuring module, the at least one detecting module and the dotting module; and the whole detecting system is fixed to the detecting platform, so that the circulation systemand the detecting system are mechanically or electrically isolated from each other. The automatic detecting equipment can be used for detecting the defects of the mobile phone lens accurately and quickly.

Owner:汪成林

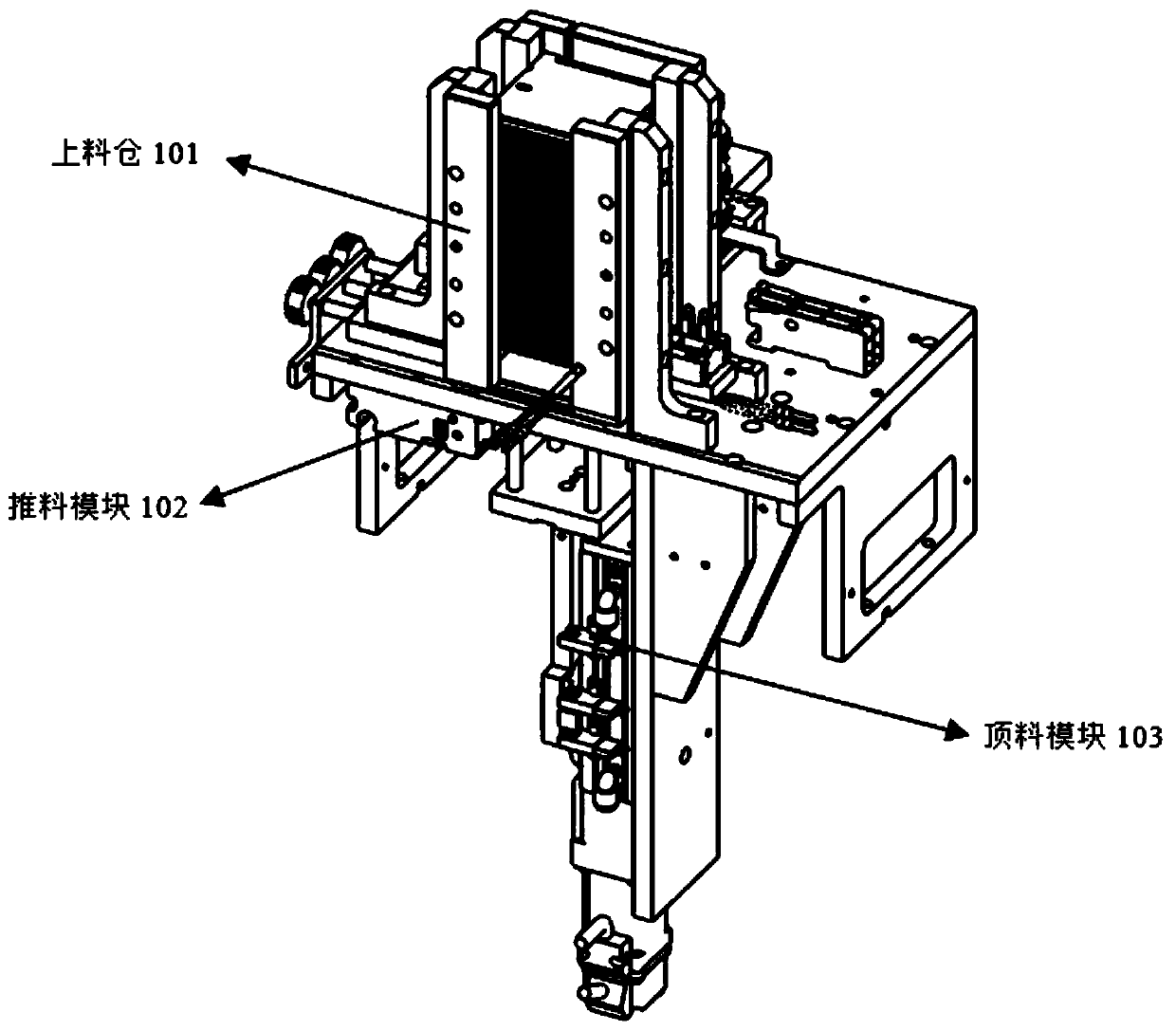

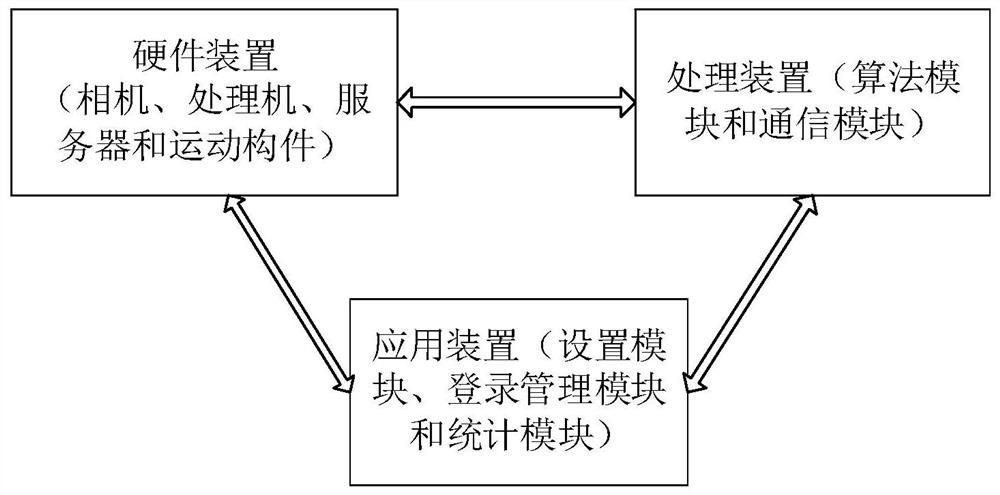

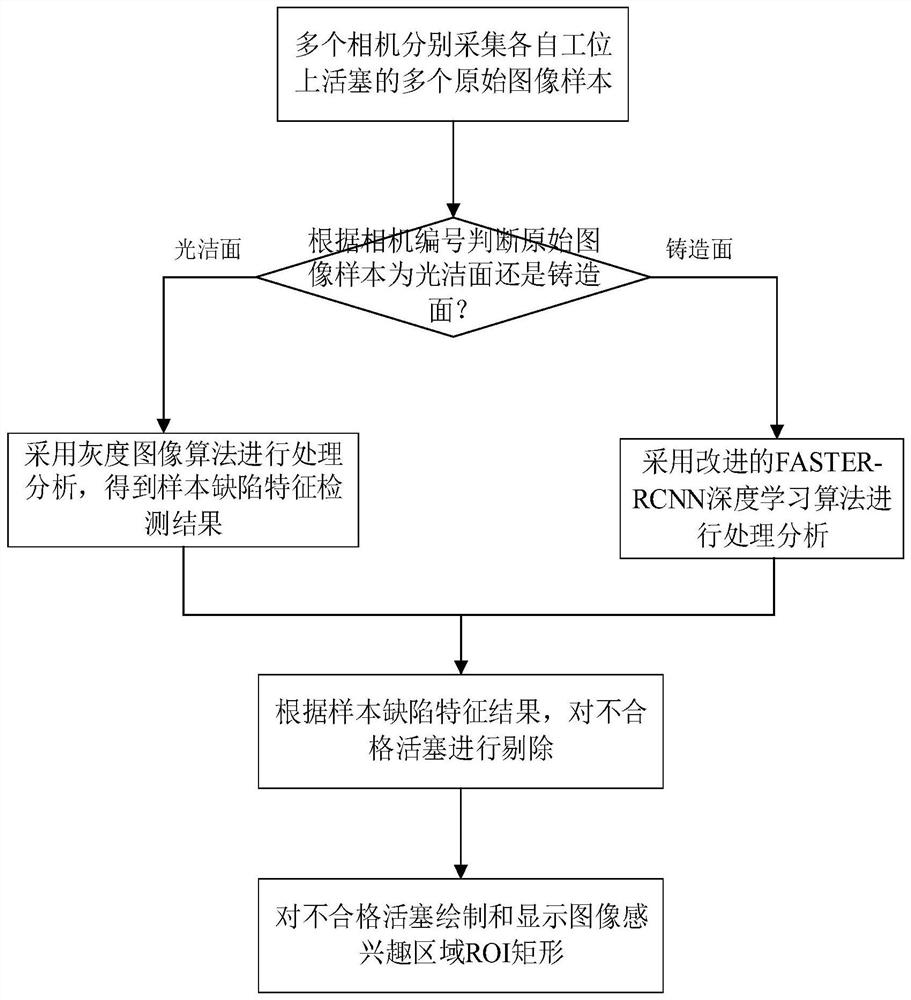

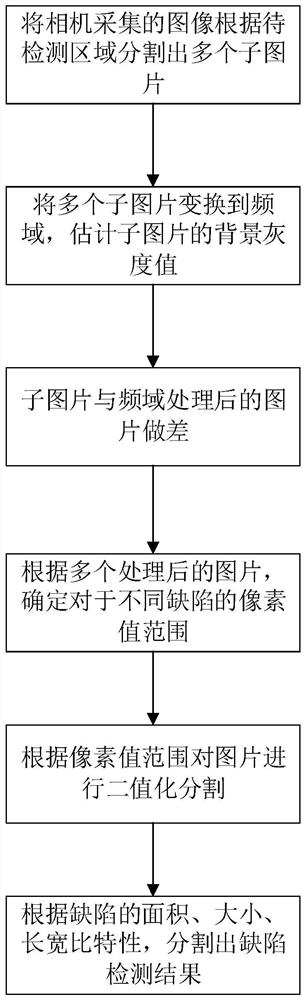

Piston surface defect detection method and system based on deep learning

PendingCN112184648ARealize detectionImprove detection accuracyImage analysisCharacter and pattern recognitionPattern recognitionImaging processing

The invention provides a piston surface defect detection method and system based on deep learning, and belongs to the technical field of piston detection. According to the detection method, machine vision and a deep learning neural network are combined for piston surface defect detection, a gray image processing algorithm is adopted for defect detection on a smooth surface, and an improved FASTER-RCNN deep learning neural network is adopted for defect detection on a cast surface; meanwhile, a plurality of cameras and end light sources with different angles and wavebands are adopted to performimage acquisition at different image acquisition stations, so that the optimal image acquisition effect is achieved; and segmentation processing is carried out on the high-resolution picture, so thatthe accuracy of picture detail identification is improved. According to the invention, efficient and accurate automatic detection of various defects is realized.

Owner:SUZHOU CASIA ALL PHASE INTELLIGENCE TECH CO LTD

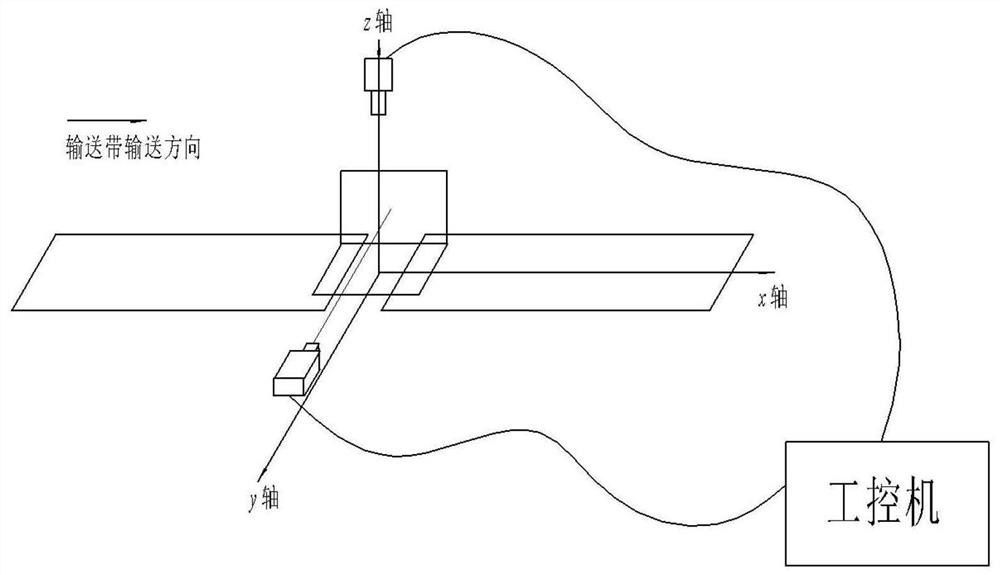

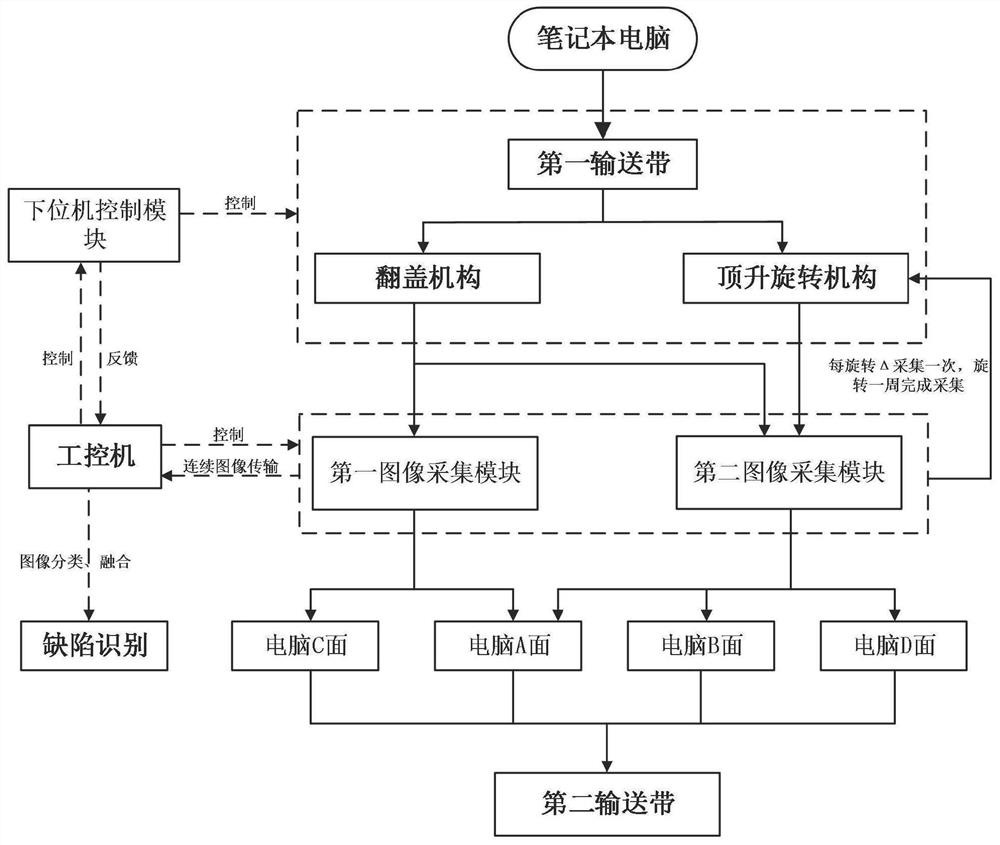

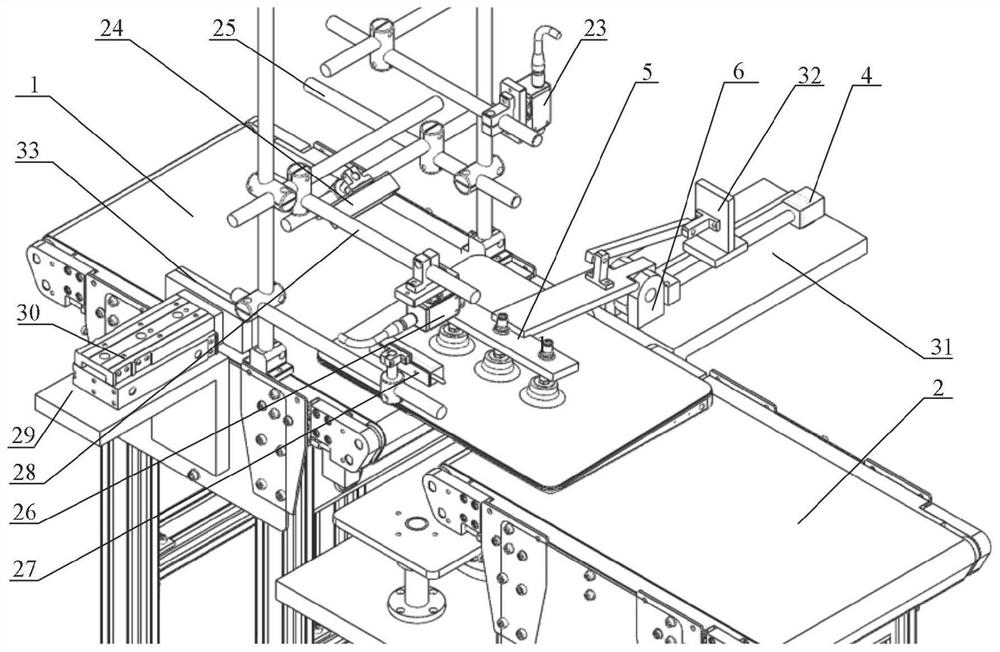

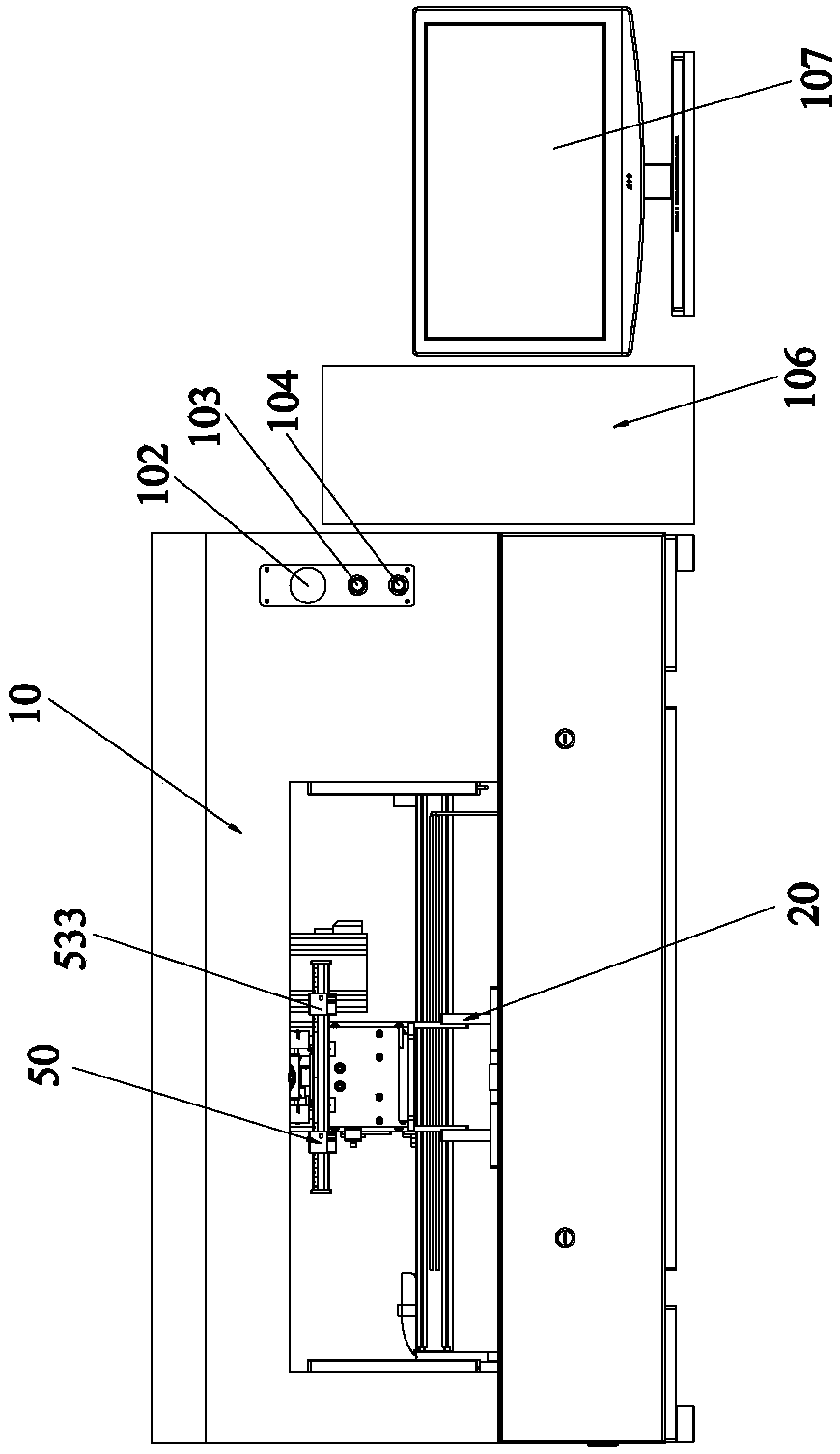

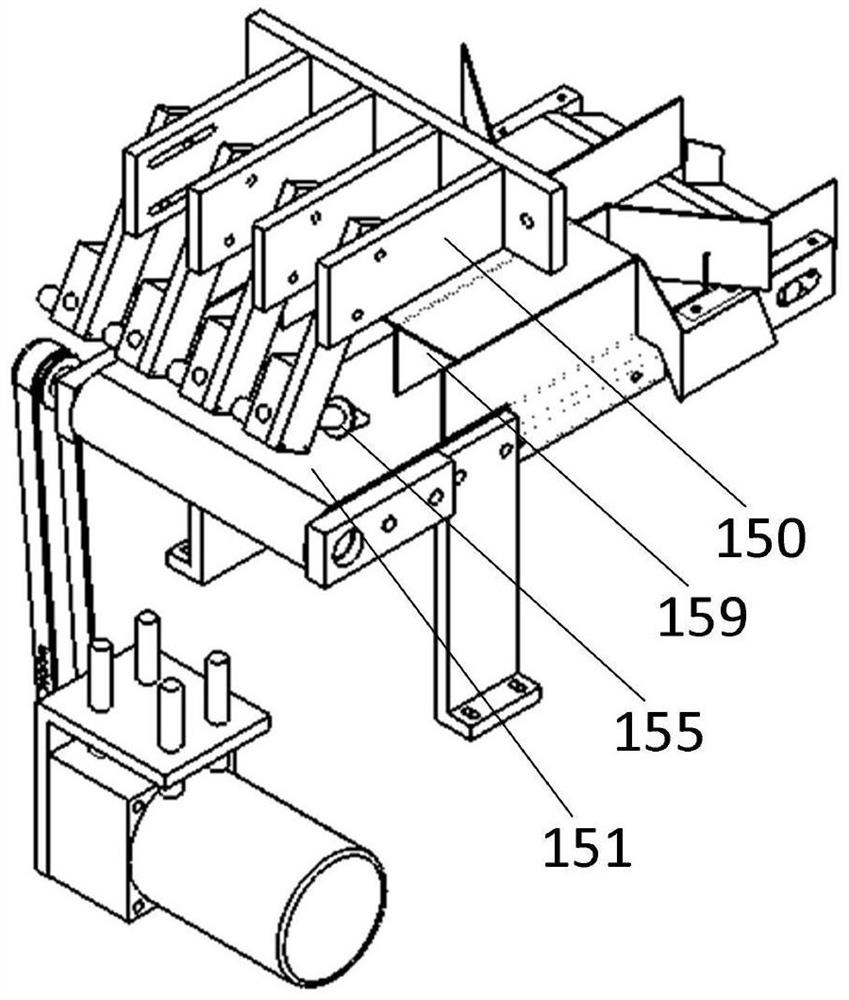

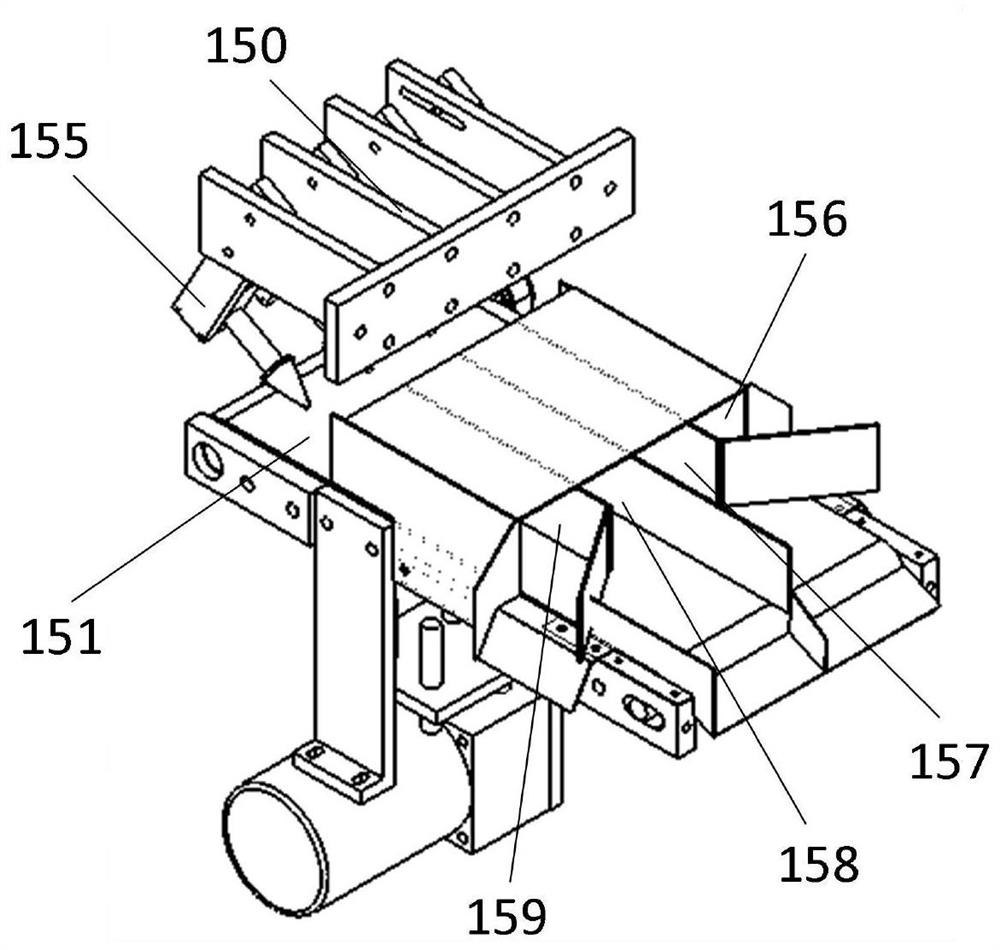

Omnibearing high-precision detection device and method for defects of notebook computer shell

ActiveCN113670923ARealize all-round detectionIncrease size diversityImage enhancementImage analysisSoftware engineeringPersonal computer

The invention discloses an omnibearing high-precision detection device and method for defects of a notebook computer shell . The detection device is composed of an industrial personal computer, an image acquisition module, a lower computer control module, a conveying belt, a cover turning mechanism and a jacking rotating mechanism. The industrial personal computer and the lower computer control module control the notebook computer to stop when the notebook computer arrives at a specified detection station, and the cover turning mechanism and the jacking rotating mechanism are controlled by the servo motor to cooperatively act to adjust the angle of each surface of the notebook computer, so that the image of each surface of the notebook computer is acquired by the image acquisition module and provided for the industrial personal computer; after classification and fusion of multiple acquired images of various surfaces, image feature-defect form classification and identification are carried out. According to the invention, all-directional high-precision detection of the defects of the notebook computer shell can be realized.

Owner:HEFEI UNIV OF TECH

Scraper detection device for omnidirectional detection

PendingCN108692695ARealize all-round detectionRepair in timeOptically investigating flaws/contaminationEngineering

Owner:东莞市南部佳永电子有限公司

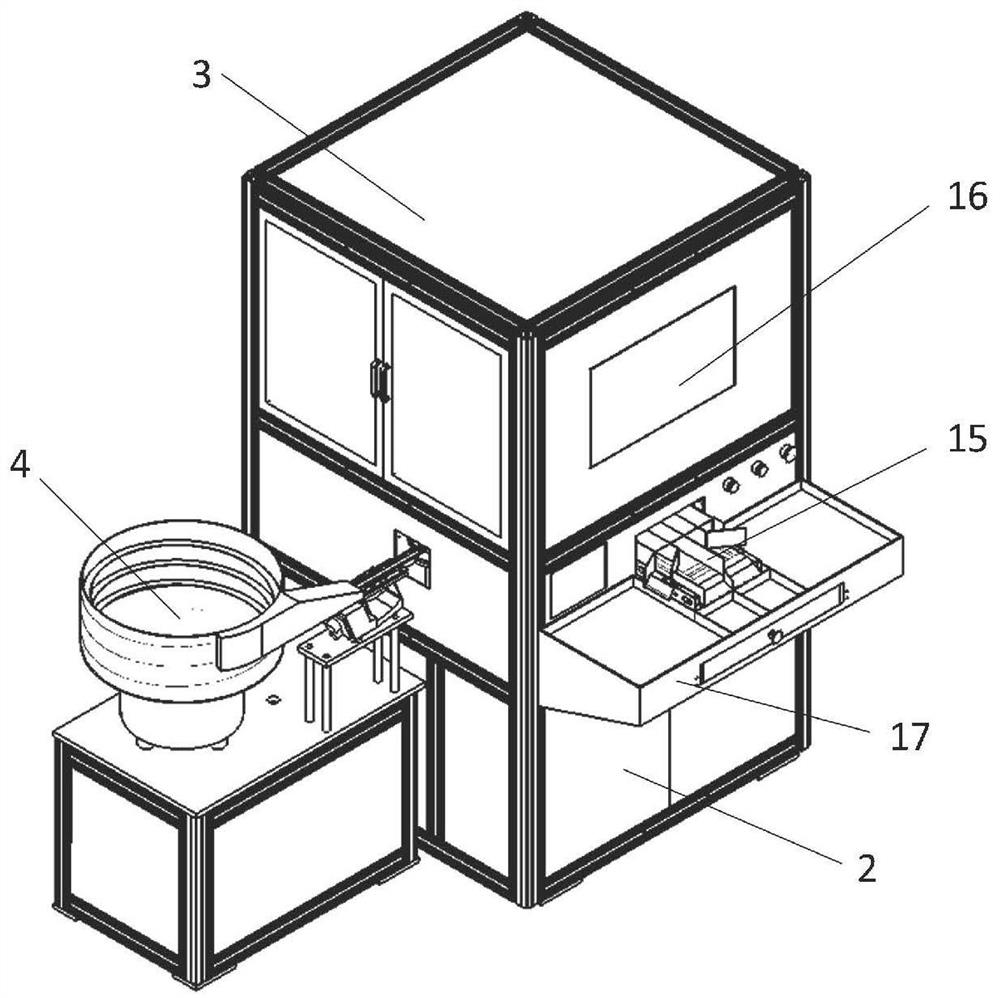

Commutator size and appearance defect detection equipment based on CCD vision

ActiveCN113714143ARealize automatic continuous feedingImprove work efficiencyMaterial analysis by optical meansUsing optical meansDisplay deviceCommutator (electric)

The invention discloses commutator size and appearance defect detection equipment based on CCD vision. The commutator size and appearance defect detection equipment comprises an electrical cabinet, a workbench and a hood, wherein a vibration feeding device is arranged on one side of the workbench, a rotary shifting mechanism connected with a discharging port of the vibration feeding device is arranged on one side of the top surface of the workbench, a glass rotating mechanism connected with a discharging port of the rotary shifting mechanism is arranged in the center of the top surface of the workbench, and a guide mechanism is arranged at the axis of the glass rotating mechanism; a first camera assembly, an optical fiber detection assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a discharging assembly which are located on the outer side of the glass rotating mechanism are sequentially arranged on the top surface of the workbench; and a display is arranged at the top of the outer side wall of the hood. According to the commutator size and appearance defect detection equipment, continuous automatic feeding, placement, positioning, all-dimensional detection and classified discharging of a commutator product to be detected can be realized, appearance detection is comprehensively covered, the detection result is accurate and reliable, and the detection efficiency is high.

Owner:安徽思普泰克智能制造科技有限公司

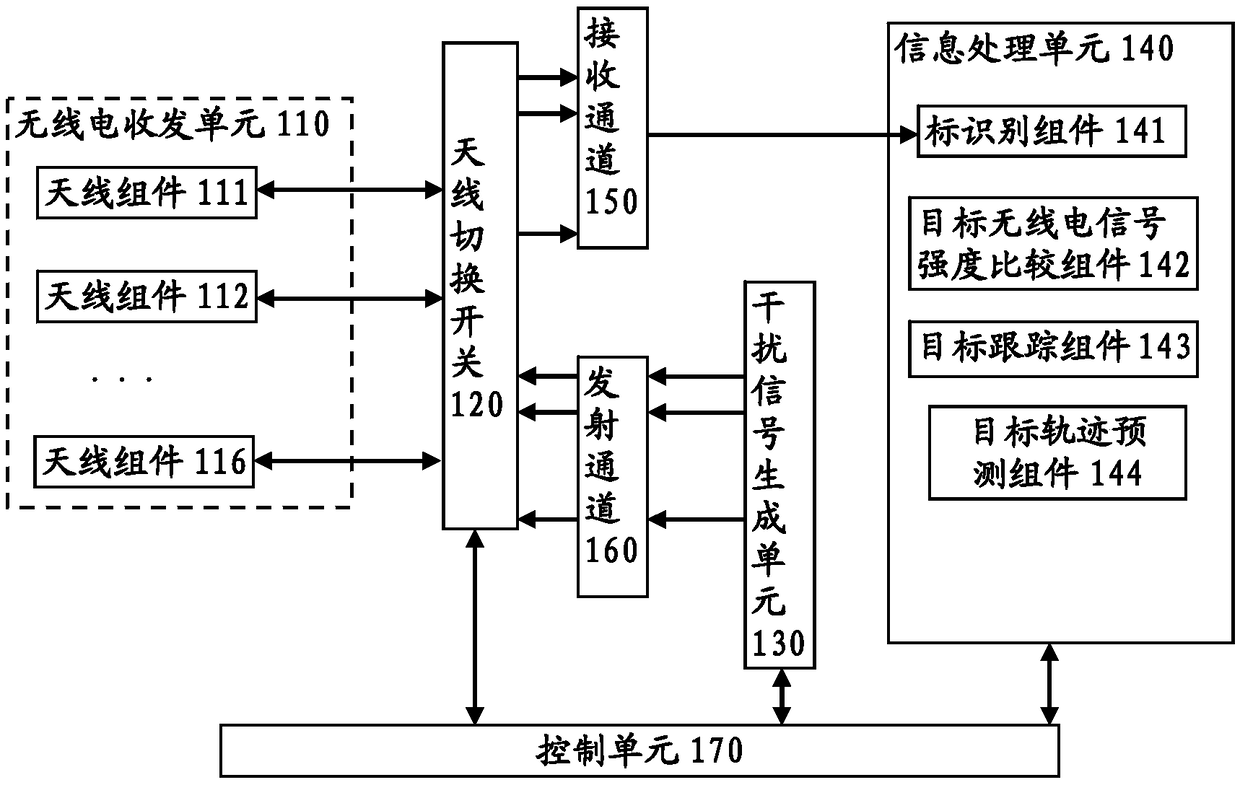

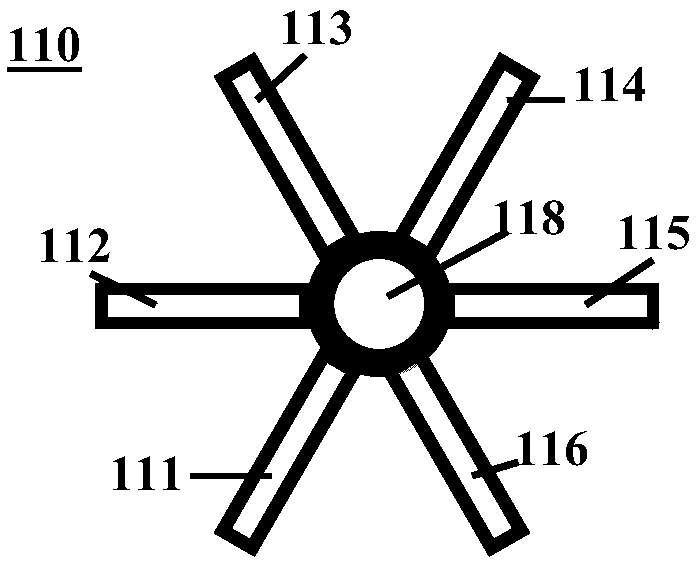

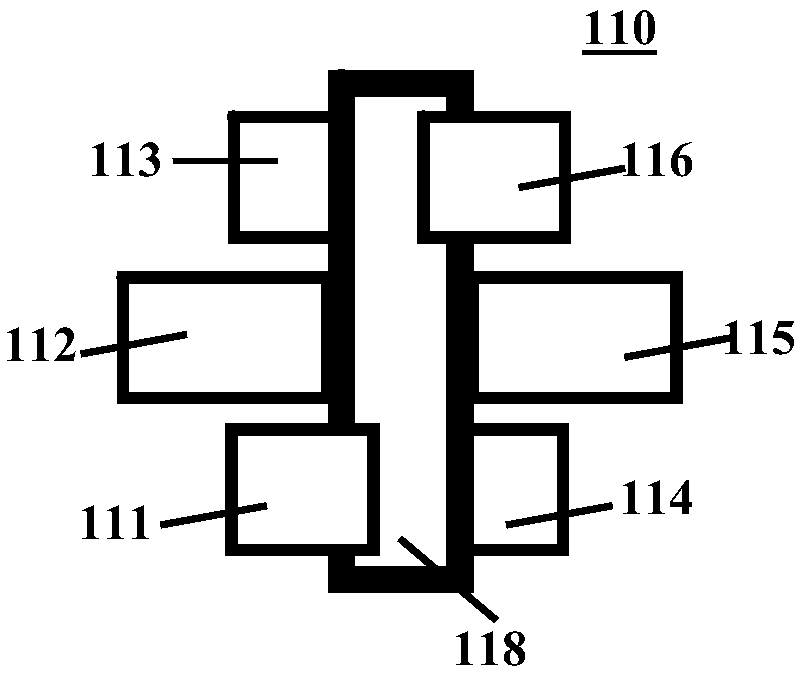

Flying target detection interference system and method

PendingCN109347596ARealize all-round detectionAchieve interferenceCommunication jammingTransceiverEngineering

The invention relates to a flying target detection interference system and method. The system comprises a radio transceiver unit, a signal processing unit, an interference signal generation unit and acontrol unit. The radio transceiver unit is used for receiving a target radio signal transmitted by a flying target or transmitting a radio interference signal to the flying target in a specific airspace. The signal processing unit is used to receive and process the target radio signal from one of radio antenna assemblies, and determine a serial number of the radio antenna assembly closest to theflying target. The interference signal generation unit generates a radio interference signal and transmits the radio interference signal to one of the radio antenna assemblies for performing transmission. The control unit controls the radio antenna assembly corresponding to the serial number to receive the radio interference signal generated by the interference signal generation unit and transmitthe radio interference signal to the flying target.

Owner:BEIJING SHIAN LITIAN TECH DEV CO LTD

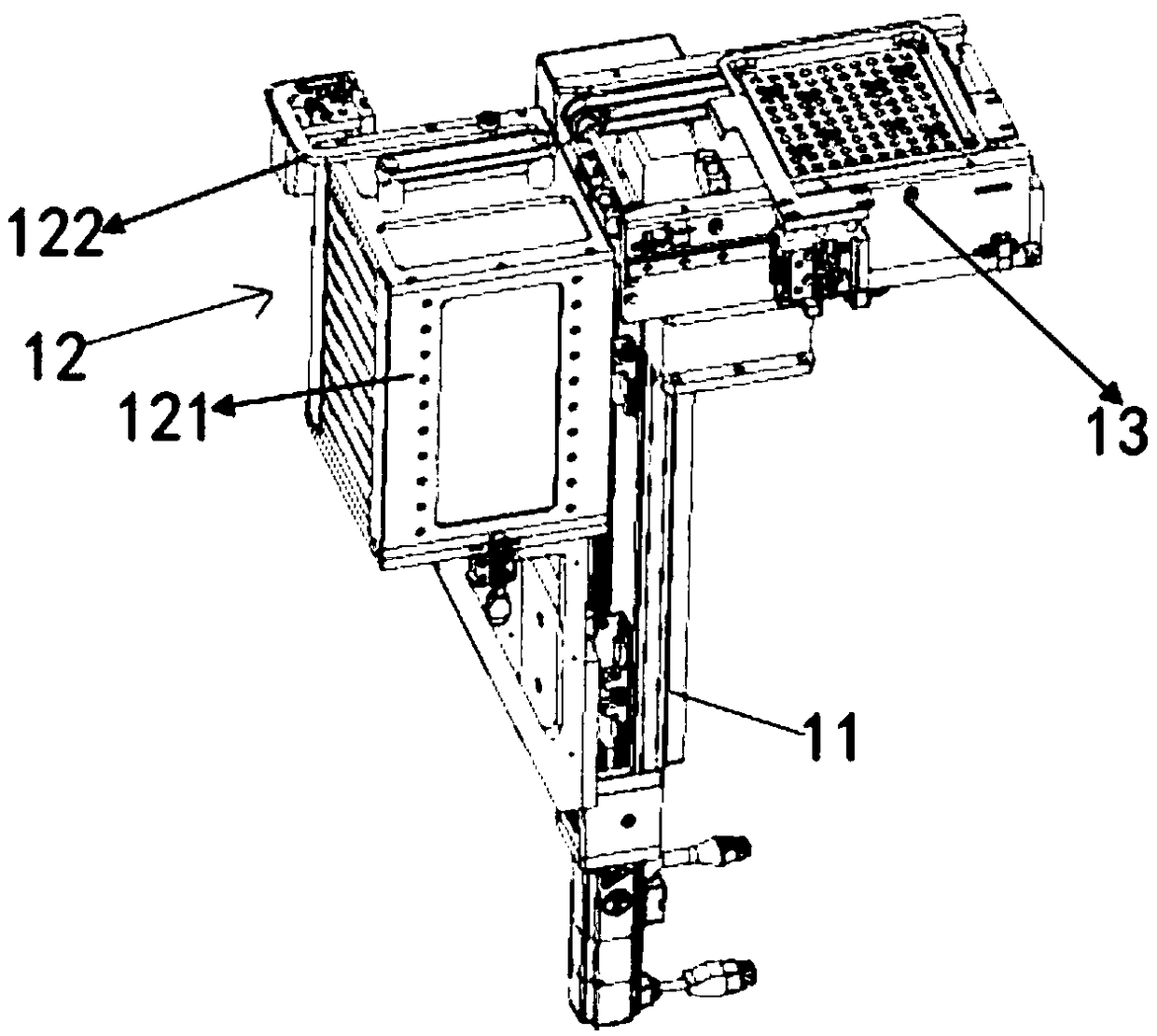

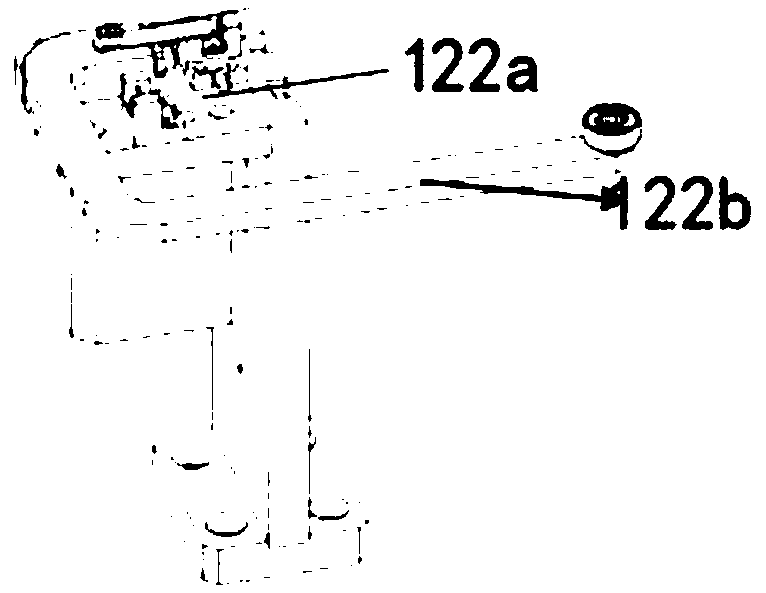

Examination device for otorhinolaryngological department

ActiveCN106214114ARealize all-round detectionBronchoscopesLaryngoscopesRotational freedomHydraulic pump

The invention discloses an examination device for the otorhinolaryngological department, which is used in the position for detecting the focus in the auditory meatus. The device comprises a main body, an intubation tube arranged at the front end of the main body, an LED lamp arranged on the wall of the front end of the intubation tube, a ball fixed in the hole in the front end of the intubation tube, a bulb which is arranged in the ball and can rotate in the ball, a camera fixed on the bulb, a display screen which is arranged at the rear end of the main body and is used for displaying video images shot by the camera and a hydraulic drive mechanism which is used for driving the bulb to rotate, wherein the hydraulic drive mechanism is used for selectively introducing hydraulic medium to four cavities, so that the angle of the camera is adjusted under two degrees of rotational freedom, and the auditory meatus can be overall detected.

Owner:融创达科技成果转化(江苏)有限公司

Automatic detection equipment for lens defects

PendingCN109158337ARealize automated detectionImprove detection efficiencySortingCamera lensAutomatic test equipment

Owner:NINGBO SUNNY INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com