Welding tightness detection machine and method using detection machine to detect welding tightness

An air tightness and testing machine technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of low production efficiency, complex structure, low working reliability, etc. problems, to achieve the effect of reliable work, simple device structure and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

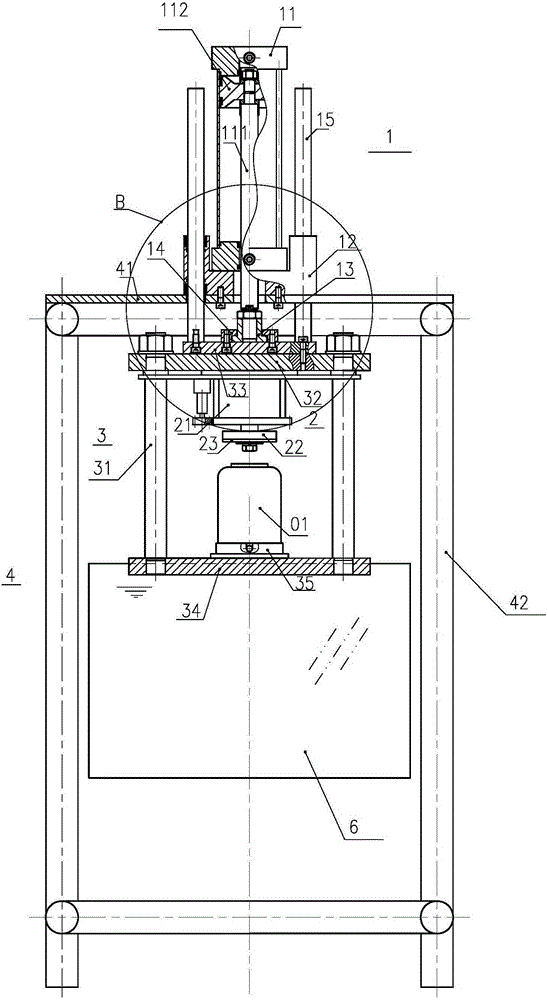

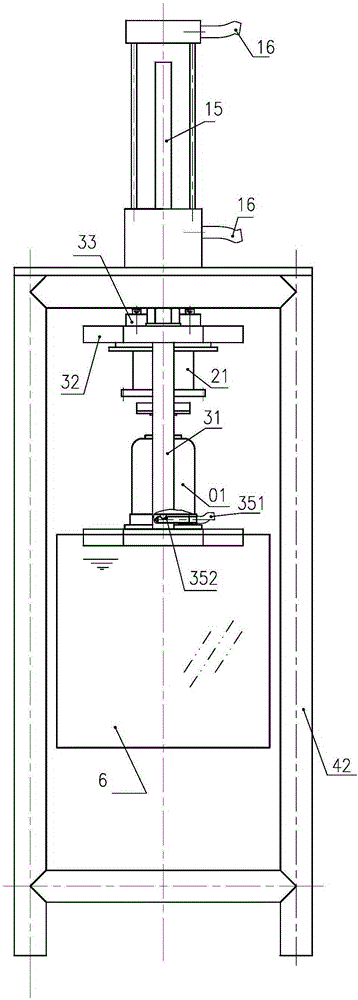

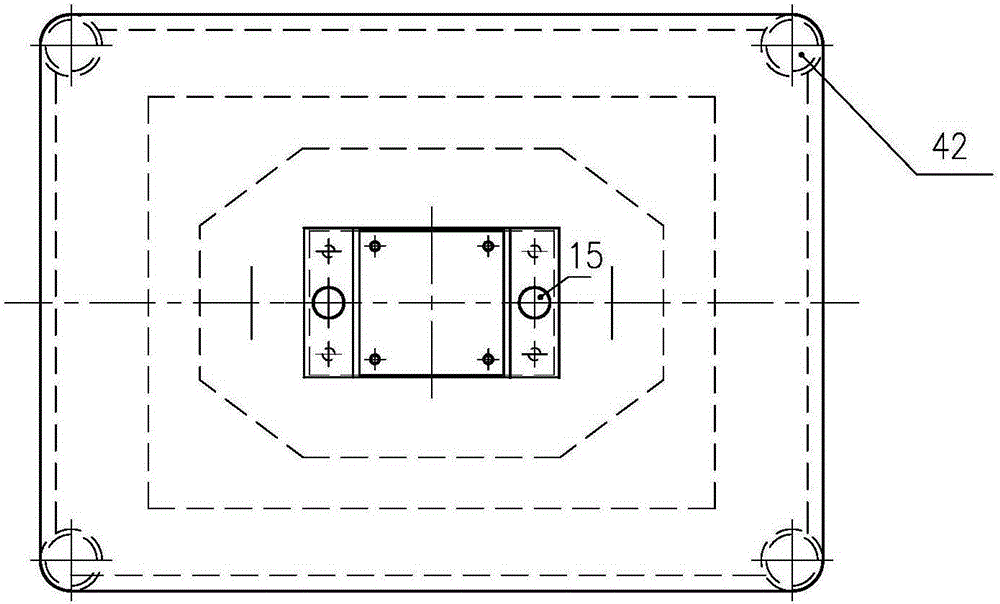

[0034] Such as figure 1 , 2 , 3, and 5, the welding air tightness testing machine includes a workbench 4, a liquid container 6 arranged at the bottom of the workbench 4, a workpiece placement tool 3, and also includes: a vertical motion device 1, which is connected to the workpiece The placement tool 3 is connected, drives the workpiece placement tool 3 to move vertically, and makes the workpiece placement tool 3 rise and fall together with the workpiece to enter or leave the container 6; the sealing positioning device 2 arranged on the upper part of the workpiece placement tool 3 is used to seal and position the workpiece in the The workpiece is placed on the tooling 3; the workpiece rotating device is used to rotate the workpiece 01 placed in the liquid container 6, so that people can observe the airtightness of the workpiece at a fixed position; the pressurizing mechanism is arranged at the 3 places of the workpiece placing tool, Used to charge compressed gas to sealed wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com